Machinability of Drilling on Metallic Glass for Micro-Hole with Renewable Dielectric in an Electric Discharge Machining Process

Abstract

1. Introduction

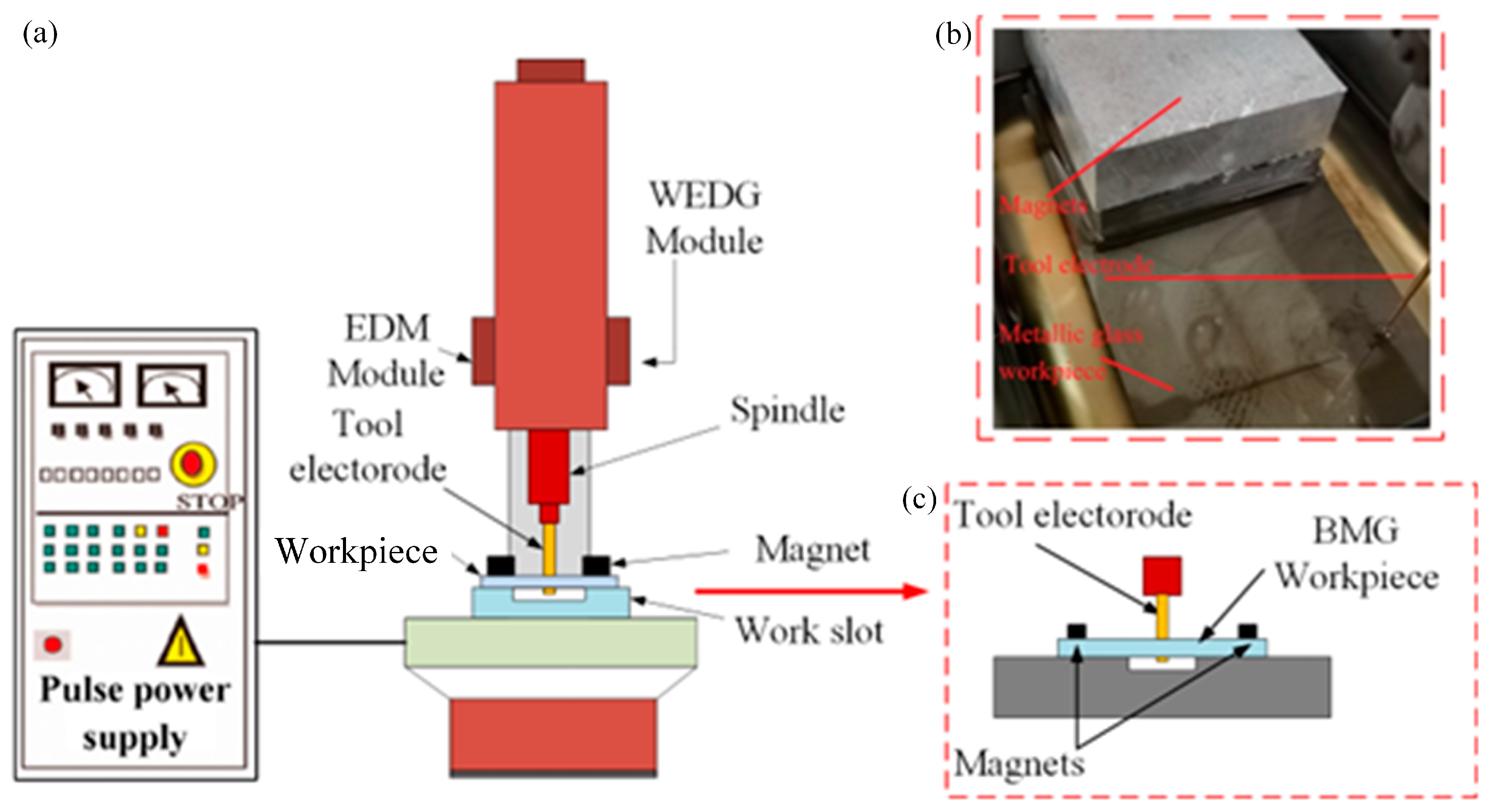

2. Experimental Design and Procedure

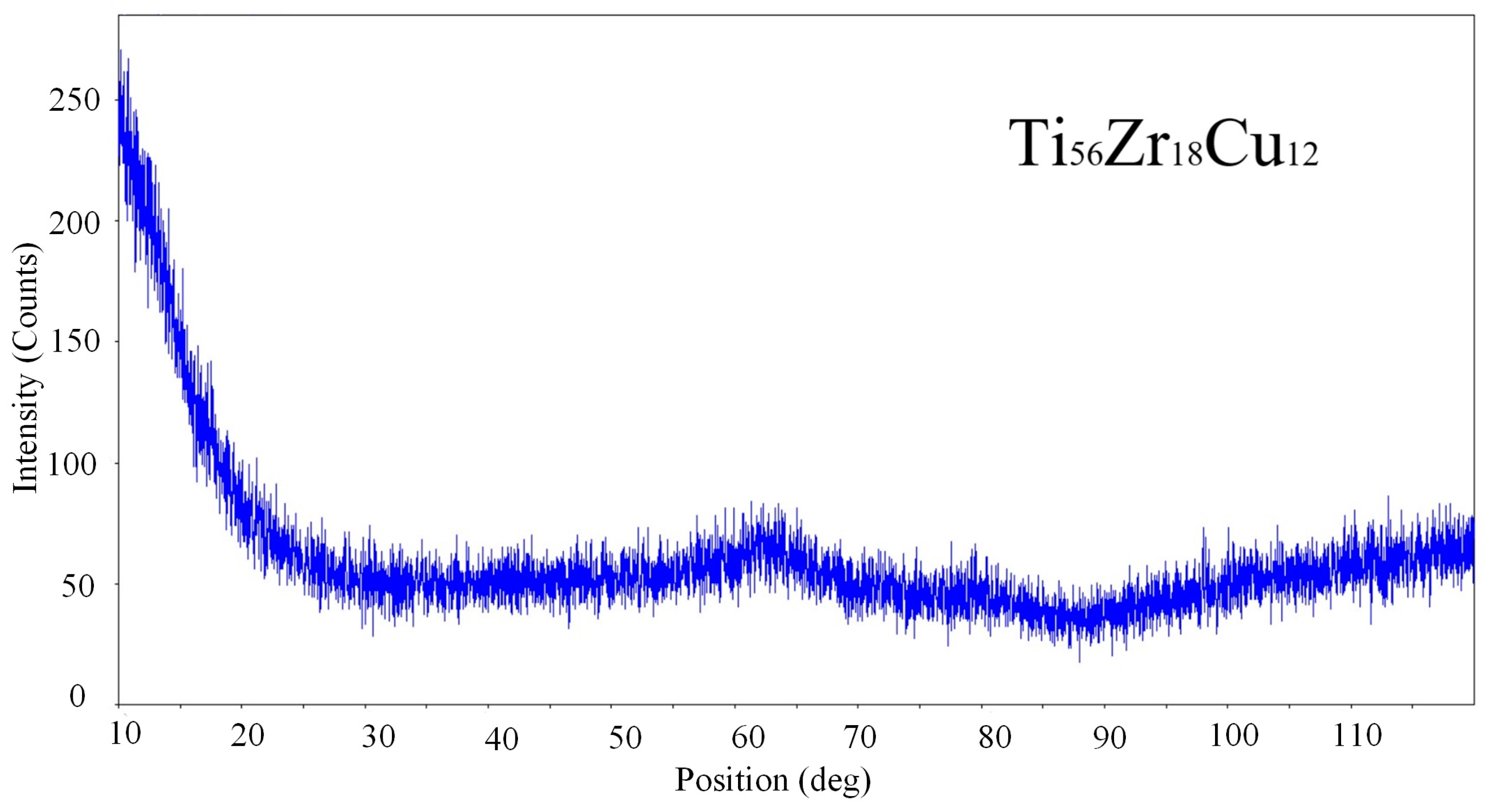

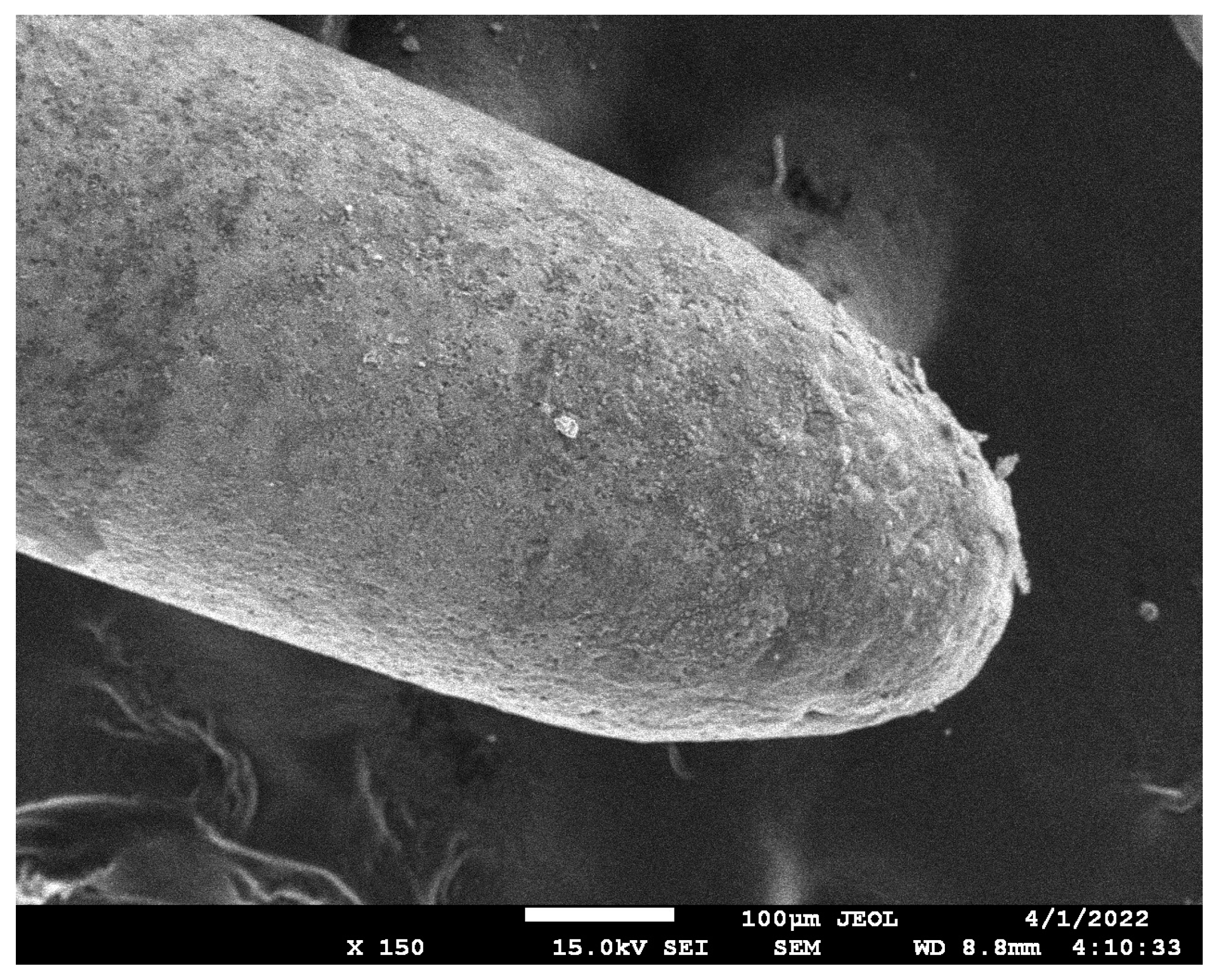

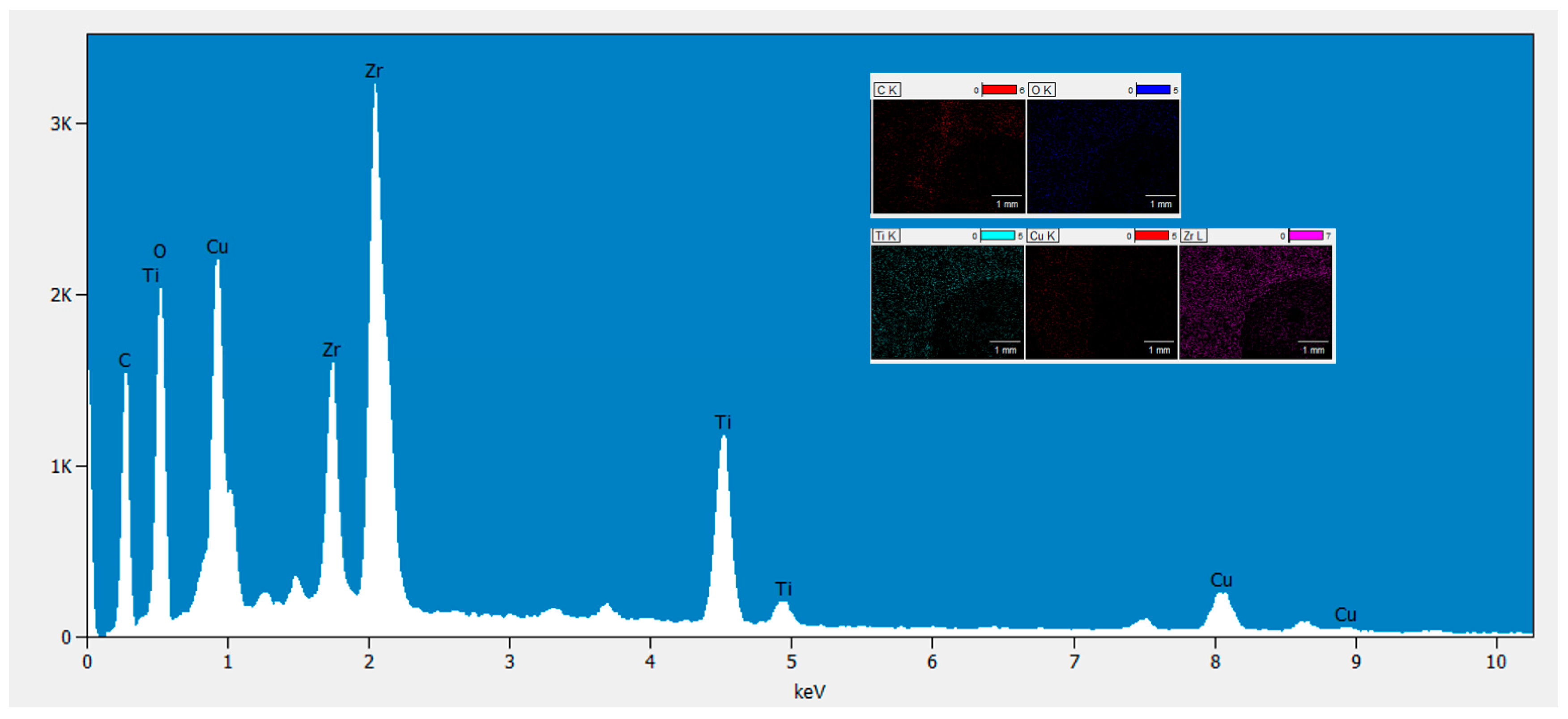

2.1. Materials and Dielectric

2.2. Machining Indicators

3. Results and Analysis

3.1. Analysis of Machinability Responses

3.1.1. MRR

3.1.2. Overcut

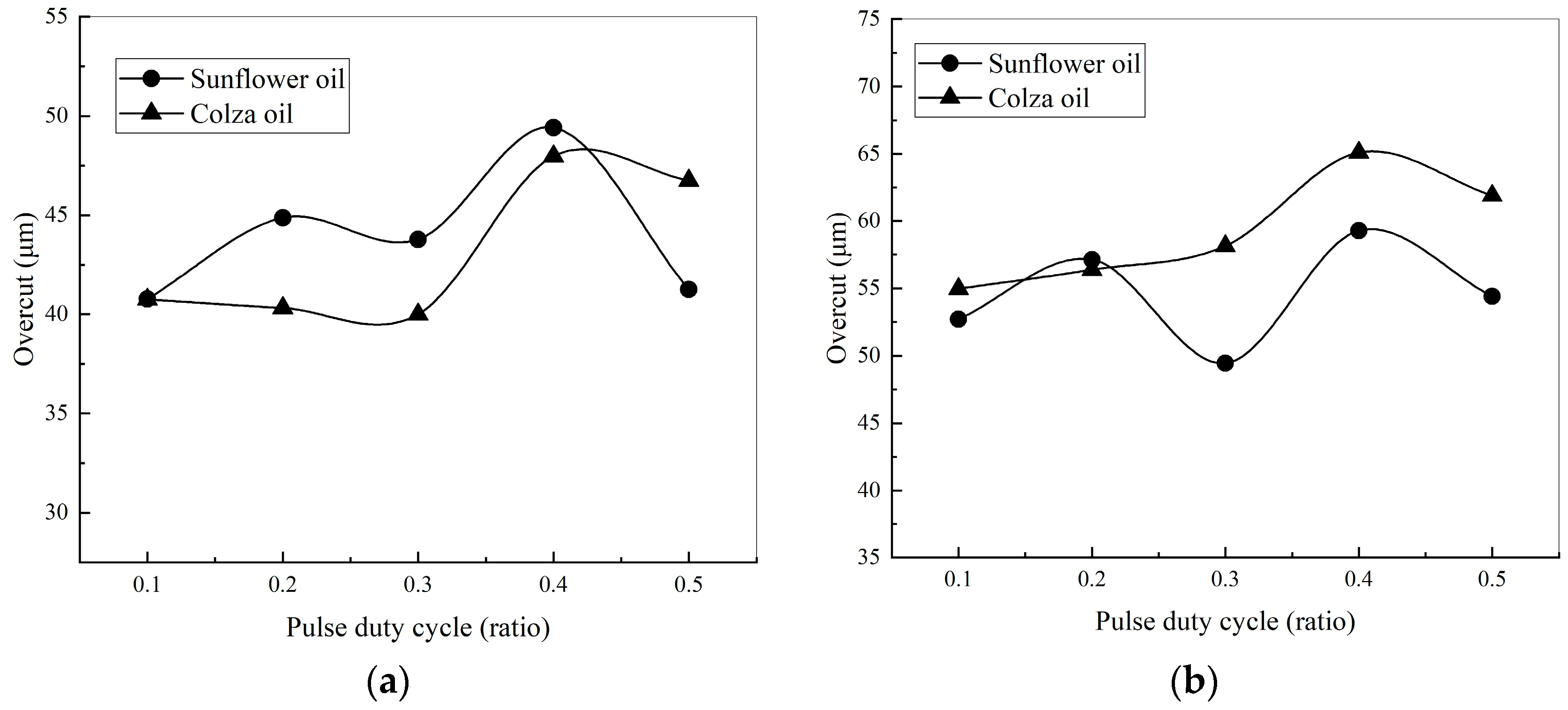

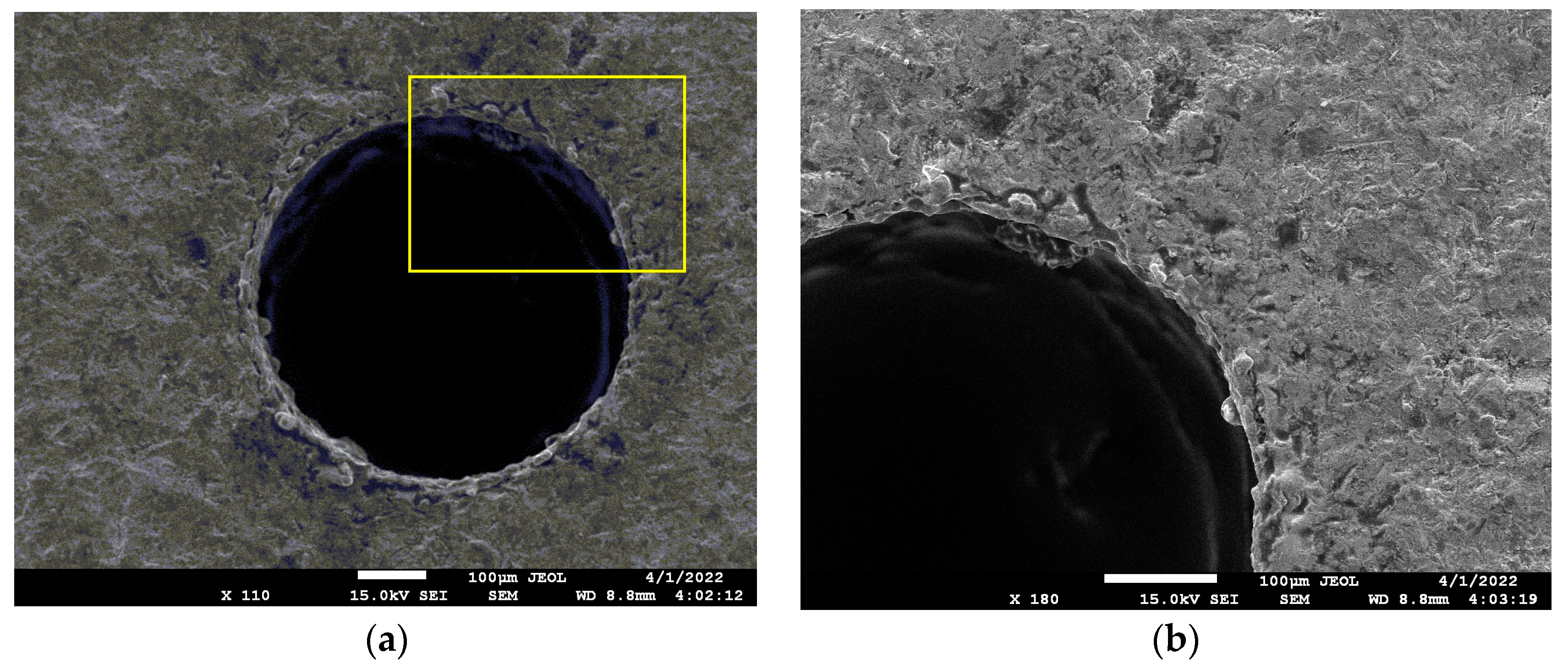

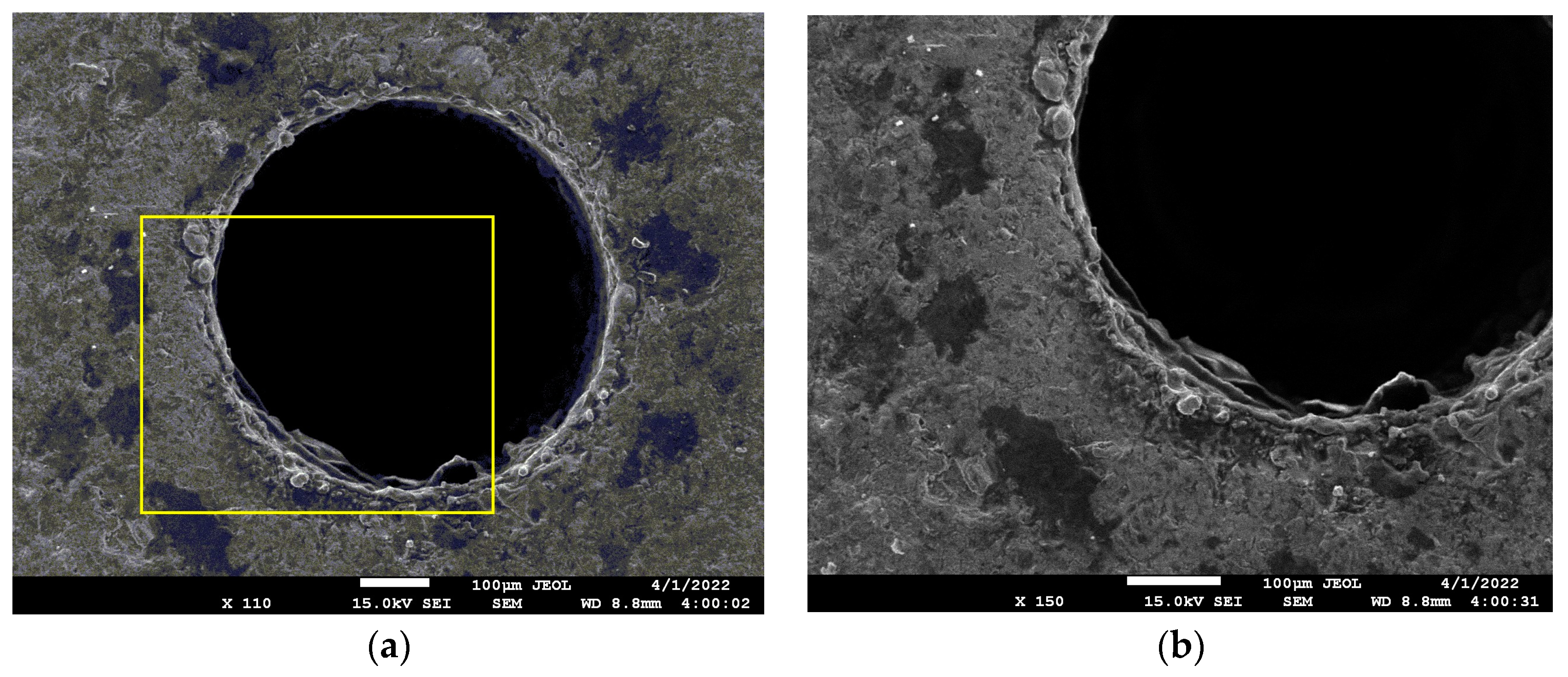

3.1.3. Edge Deviation

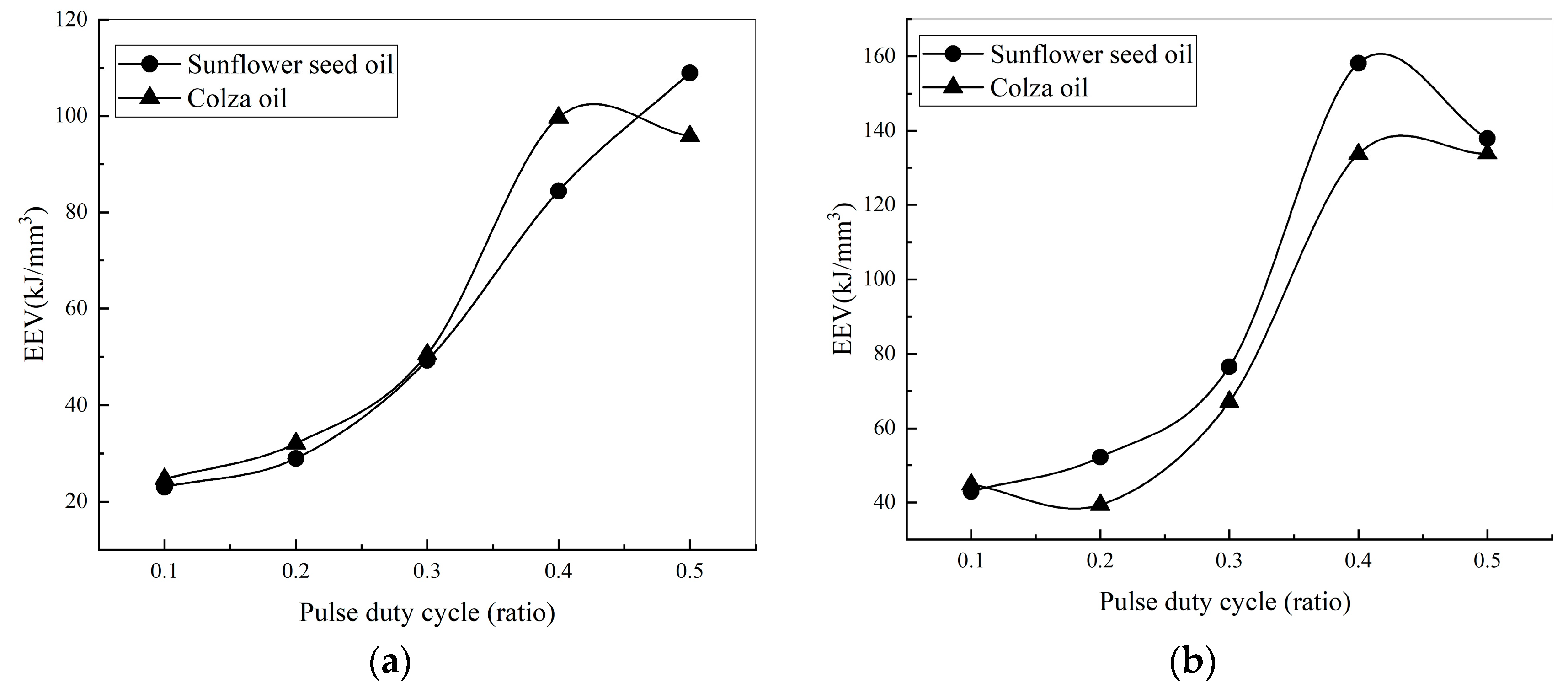

3.1.4. EEV

3.1.5. TWR

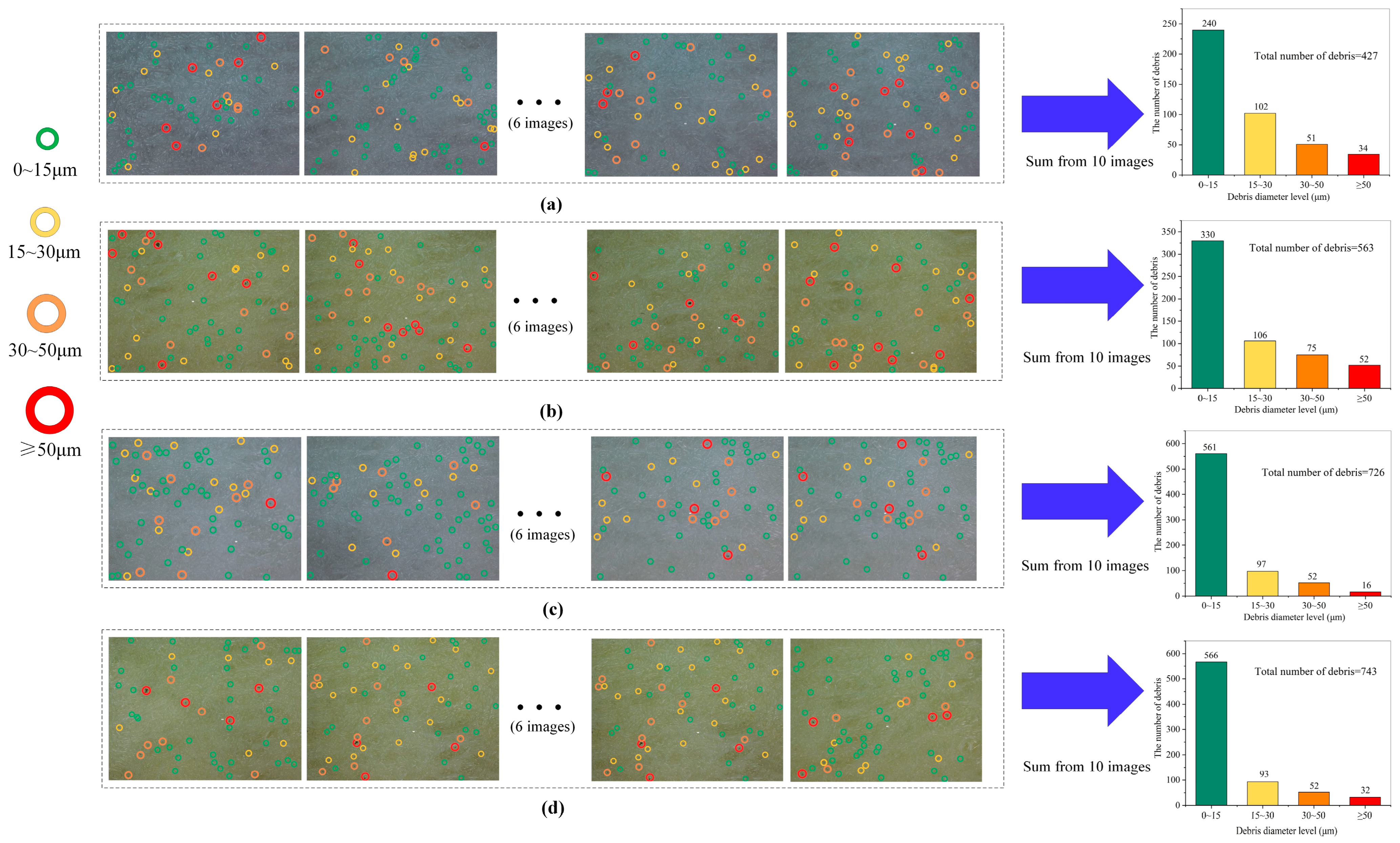

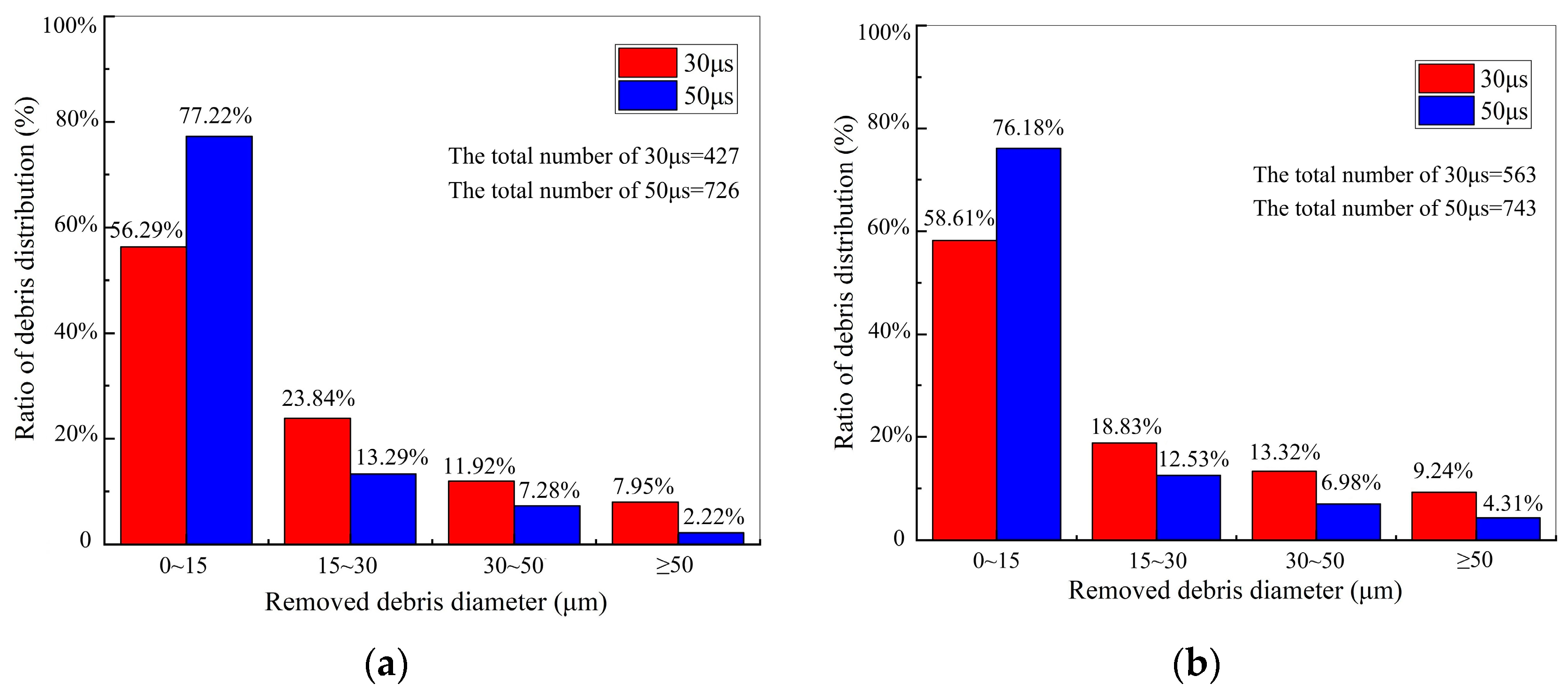

3.1.6. RDD

3.2. Optimization

3.2.1. MOORA Method

3.2.2. MOORA for Optimum Conditions

4. Discussion

4.1. Feasibility of Machining BMG with Renewable Dielectrics

4.2. Multi-Objective Optimization Under Green Manufacturing

4.3. Impact of Sustainable EDM

5. Conclusions and Outlooks

- EDM can be utilized to drill micro-holes on Ti56Zr18Cu12 with renewable dielectrics. Moreover, utilizing renewable dielectric, the minimum overcut and edge deviation of micro-hole drilling in Ti56Zr18Cu12 are 39.99 and 9.41 μm, respectively. This indicates that renewable dielectrics like sunflower and colza oil have the potential to take the place of traditional kerosene dielectrics.

- The maximum value of MRR of 0.0103 mm3/min is achieved when the pulse-on time of 30 μs and sunflower oil renewable dielectric are selected. When sunflower oil or colza oil is used as a renewable dielectric, the optimal value of MRR is obtained under a middle pulse duty cycle of 0.2. In addition, the type of renewable dielectrics and the density of discharge energy have obvious effects on MRR.

- While drilling micro-holes in metallic glass, it is found that the TWR is very low (near close to zero). In MOORA, the criteria to be minimized are overcut, edge deviation, and EEV, whereas the criterion to be maximized is MRR. According to the analysis, the pulse duty cycle is the most important parameter affecting the micro-hole quality, and near the middle pulse duty cycle of 0.2–0.3 is optimal.

- The demand for environmentally friendly manufacturing techniques is on the rise right now, particularly in the mechanical manufacturing industry. Through the use of renewable dielectrics such as sunflower oil and colza oil, the new method of EDM BMG materials using renewable dielectrics is expected to be a sustainable manufacturing process.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ridgway, M.C.; Glover, C.J.; Foran, G.J.; Yu, K.M. Characterization of the local structure of amorphous GaAs produced by ion implantation. J. Appl. Phys. 1998, 83, 4610–4614. [Google Scholar] [CrossRef]

- Li, Z.; Huang, Z.; Sun, F.; Li, X.; Ma, J. Forming of Metallic Glasses: Mechanisms and Processes. Mater. Today Adv. 2020, 7, 100077. [Google Scholar] [CrossRef]

- Ming, W.Y.; Zhao, Y.J.; Cao, C.; Ma, J.; Zhang, G.J.; Du, J.G.; Li, X.K.; Li, L.W. Numerical and Experimental Study on EDM Drilling of Ti-Cu-Zr Metallic Glass Considering Energy Efficiency. Int. J. Adv. Manuf. Technol. 2023, 128, 3949–3968. [Google Scholar] [CrossRef]

- Williams, E.; Lavery, N. Laser processing of bulk metallic glass: A review. J. Mater. Process. Technol. 2017, 247, 73–91. [Google Scholar] [CrossRef]

- Kim, S.T.; Demetriou, M.D.; Johnson, W.L. Tough Iron-Based Metallic Glass Alloys. EP2622109 A2, 28 March 2012. [Google Scholar]

- Morrison, M.L.; Buchanan, R.A.; Peker, A.; Liaw, P.K.; Horton, J.A. Electrochemical behavior of a Ti-based bulk metallic glass. J. Non-Cryst. Solids 2007, 353, 2115–2124. [Google Scholar] [CrossRef]

- Stoica, M.; Eckert, J.; Roth, S.; Zhang, Z.F.; Schultz, L.; Wang, W.H. Mechanical behavior of Fe65.5Cr4Mo4Ga4P12C5B5.5 bulk metallic glass. Intermetallics 2005, 13, 764–769. [Google Scholar] [CrossRef]

- Chen, X.H.; Zhang, X.C.; Zhang, Y.; Chen, G.L. Fabrication and characterization of metallic glasses with a specific microstructure for micro-electro-mechanical system applications. J. Non-Cryst. Solids 2008, 354, 3308–3316. [Google Scholar] [CrossRef]

- Ming, W.Y.; Sun, P.Y.; Zhang, Z.; Qiu, W.Z.; Du, J.G.; Li, X.K.; Zhang, Y.M.; Zhang, G.J.; Liu, K.; Wang, Y.; et al. A systematic review of machine learning methods applied to fuel cells in performance evaluation, durability prediction, and application monitoring. Int. J. Hydrogen Energy 2023, 48, 5197–5228. [Google Scholar] [CrossRef]

- Ismagilov, F.R.; Papini, L.; Vavilov, V.E.; Guaskov, D.V. Design and Performance of a High-Speed Permanent Magnet Generator with Amorphous Alloy Magnetic Core for Aerospace Applications. IEEE Trans. Ind. Electron. 2020, 67, 1750–1758. [Google Scholar] [CrossRef]

- Chu, J.P.; Liu, T.Y.; Li, C.L.; Wang, C.H.; Jang, J.S.C.; Chen, M.J.; Chang, S.H.; Huang, W.C. Fabrication and characterizations of thin film metallic glasses: Antibacterial property and durability study for medical application. Thin Solid Films 2014, 561, 102–107. [Google Scholar] [CrossRef]

- Schroers, J.; Nguyen, T.; O’Keeffe, S.; Desai, A. Thermoplastic forming of bulk metallic glass—Applications for MEMS and microstructure fabrication. Mater. Sci. Eng. A 2007, 449, 240–247. [Google Scholar] [CrossRef]

- Schroers, J. Processing of Bulk Metallic Glass. Adv. Mater. 2010, 22, 1566–1597. [Google Scholar] [CrossRef]

- Plummer, J. Is metallic glass poised to come of age? Nat. Mater. 2015, 14, 553–555. [Google Scholar] [CrossRef]

- Aliyeva, N.; Sas, H.S.; Saner Okan, B. Recent Developments on the Overmolding Process for the Fabrication of Thermoset and Thermoplastic Composites by the Integration of Nano/Micron-Scale Reinforcements. Compos. Part A Appl. Sci. Manuf. 2021, 149, 106525. [Google Scholar] [CrossRef]

- Bakkal, M.; Shih, A.J.; Scattergood, R.O. Chip formation, cutting forces, and tool wear in turning of Zr-based bulk metallic glass. Int. J. Mach. Tools Manuf. 2004, 44, 915–925. [Google Scholar] [CrossRef]

- Bakkal, M.; Shih, A.J.; Scattergood, R.O.; Liu, C.T. Machining of a Zr-Ti-Al-Cu-Ni metallic glass. Scr. Mater. 2004, 50, 583–588. [Google Scholar] [CrossRef]

- Zhu, J.; Kim, H.J.; Kapoor, S.G. Microscale drilling of bulk metallic glass. J. Micro Nano-Manuf. 2013, 1, 041004. [Google Scholar] [CrossRef]

- Li, L.W.; Sun, S.; Xing, W.B.; Zhang, Y.Y.; Wu, Y.L.; Xu, Y.J.; Wang, H.Y.; Zhang, G.J.; Luo, G.F. Progress in Simulation Modeling Based on the Finite Element Method for Electrical Discharge Machining. Metals 2024, 14, 14. [Google Scholar] [CrossRef]

- Ma, F.X.; Yang, J.J.; Zhu, X.N.; Liang, C.Y.; Wang, H.S. Femtosecond laser-induced concentric ring microstructures on Zr-based metallic glass. Appl. Surf. Sci. 2010, 256, 3653–3660. [Google Scholar] [CrossRef]

- Quintana, I.; Dobrev, T.; Aranzabe, A.; Lalev, G. Laser micromachining of metallic glasses: Investigation of the material response to machining with micro-second and pico-second lasers. In Proceedings of the Laser Applications in Microelectronic and Optoelectronic Manufacturing XV, San Francisco, CA, USA, 23–28 January 2010; Volume 7584, p. 75840Y. [Google Scholar] [CrossRef]

- Kuriakose, S.; Patowari, P.K.; Bhatt, J. Machinability study of Zr-Cu-Ti metallic glass by micro hole drilling using micro-USM. J. Mater. Process. Technol. 2017, 240, 42–51. [Google Scholar] [CrossRef]

- Shi, B.L.; Dai, Y.F.; Xie, X.H.; Li, S.Y.; Zhou, L. Arc-enhanced plasma machining technology for high efficiency machining of silicon carbide. Plasma Chem. Plasma Process. 2016, 36, 891–900. [Google Scholar] [CrossRef]

- Wang, P.; Zhang, Z.; Wei, S.C.; Hao, B.; Chang, H.Z.; Huang, Y.; Zhang, G.J. Study on plasma behaviour, ablation mechanism, and surface morphology of CFRP by underwater laser-induced plasma micro-machining. J. Mater. Process. Technol. 2025, 338, 118757. [Google Scholar] [CrossRef]

- Yuan, Z.S.; Lei, X.; Wang, C.Y. Controllable Fabrication of Solid State Nanopores Array by Electron Beam Shrinking. Int. J. Mach. Tools Manuf. 2020, 159, 103623. [Google Scholar] [CrossRef]

- Kim, H.M.; Cho, S.Y.; Kim, K.B. Nanopore formation in tin membranes by the focused electron beam of a transmission electron microscope. J. Vac. Sci. Technol. B 2015, 33, 06F502. [Google Scholar] [CrossRef]

- Guerrini, G.; Fortunato, A.; Melkote, S.N.; Ascari, A.; Lutey, A.H.A. Hybrid Laser Assisted Machining: A New Manufacturing Technology for Ceramic Components. Procedia CIRP 2018, 74, 761–764. [Google Scholar] [CrossRef]

- Yeo, S.H.; Tan, P.C.; Aligiri, E.; Tor, S.B.; Loh, N.H. Processing of Zirconium-Based Bulk Metallic Glass (BMG) Using Micro Electrical Discharge Machining (Micro-EDM). Mater. Manuf. Process. 2009, 24, 1242–1248. [Google Scholar] [CrossRef]

- Huang, H.; Yan, J.W. On the surface characteristics of a Zr-based bulk metallic glass processed by microelectrical discharge machining. Appl. Surf. Sci. 2015, 355, 1306–1315. [Google Scholar] [CrossRef]

- Zhang, L.; Huang, H. Micro Machining of Bulk Metallic Glasses: A Review. Int. J. Adv. Manuf. Technol. 2019, 100, 637–661. [Google Scholar] [CrossRef]

- Chaudhury, P.; Samantaray, S. A Comparative Study of Different Dielectric Medium for Sustainable EDM of Non-Conductive Material by Electro-Thermal Modelling. Mater. Today Proc. 2021, 41, 437–444. [Google Scholar] [CrossRef]

- Dong, H.; Liu, Y.; Li, M.; Zhou, Y.; Liu, T.; Li, D.G.; Sun, Q.; Zhang, Y.Z.; Ji, R.J. Sustainable electrical discharge machining using water in oil nanoemulsion. J. Manuf. Process. 2019, 46, 118–128. [Google Scholar] [CrossRef]

- Valaki, J.B.; Rathod, P.P.; Sankhavara, C.D. Investigations on technical feasibility of Jatropha curcas oil based bio dielectric fluid for sustainable electric discharge machining (EDM). J. Manuf. Process. 2016, 22, 151–160. [Google Scholar] [CrossRef]

- Ng, P.S.; Kong, S.A.; Yeo, S.H. Investigation of biodiesel dielectric in sustainable electrical discharge machining. Int. J. Adv. Manuf. Technol. 2017, 90, 2549–2556. [Google Scholar] [CrossRef]

- Ming, W.Y.; Xie, Z.B.; Ma, J.; Du, J.G.; Zhang, G.J.; Cao, C.; Zhang, Y. Critical review on sustainable techniques in electrical discharge machining. J. Manuf. Process. 2021, 72, 375–399. [Google Scholar] [CrossRef]

- Zahiruddin, M.; Kunieda, M. Comparison of energy and removal efficiencies between micro and macro EDM. CIRP Ann. 2012, 61, 187–190. [Google Scholar] [CrossRef]

- Marashi, H.; Jafarlou, D.M.; Sarhan, A.A.D.; Hamdi, M. State of the art in powder mixed dielectric for EDM applications. Precis. Eng. 2016, 46, 11–33. [Google Scholar] [CrossRef]

- Radu, M.C.; Tampu, R.; Nedeff, V.; Patriciu, O.I.; Schnakovszky, C.; Herghelegiu, E. Experimental investigation of stability of vegetable oils used as dielectric fluids for electrical discharge machining. Processes 2020, 8, 1187. [Google Scholar] [CrossRef]

- Mathew, J.; Sivapirakasam, S.P.; Surianarayanan, M. Evaluation of Occupational Exposure to Aerosol Emitted from Die Sinking Electrical Discharge Machining Process. Int. J. Environ. Health 2010, 4, 1–17. [Google Scholar] [CrossRef]

- Yadav, A.; Singh, Y.; Singh, S.; Negi, P. Sustainability of vegetable oil based bio-diesel as dielectric fluid during EDM process—A review. Mater. Today 2021, 46, 11155–11158. [Google Scholar] [CrossRef]

- Yadav, L.; Lal, S.; Singh, N.K. Experimental investigation of non-edible dielectric fluid (bio-dielectric) in electrical discharge machining process. Mater. Today 2021, 46, 10125–10137. [Google Scholar] [CrossRef]

- Jiang, K.; Wu, X.Y.; Lei, J.G.; Hu, Z.H.; Gao, G.L.; Tang, Y.; Diao, D.F. Investigation on the geometric evolution of microstructures in EDM with a composite laminated electrode. J. Clean. Prod. 2021, 298, 126765. [Google Scholar] [CrossRef]

- Ming, W.Y.; Shen, F.; Zhang, G.J.; Liu, G.D.; Du, J.G.; Chen, Z.J. Green machining: A framework for optimization of cutting parameters to minimize energy consumption and exhaust emissions during electrical discharge machining of Al 6061 and SKD 11. J. Clean. Prod. 2020, 285, 124889. [Google Scholar] [CrossRef]

- Zhang, Y.; Xie, B.C. Investigation on hole diameter non-uniformity of hole arrays by ultrasonic vibration-assisted EDM. Int. J. Adv. Manuf. Technol. 2021, 112, 3083–3091. [Google Scholar] [CrossRef]

- Jilani, S.T.; Pandey, P.C. Experimental investigations into the performance of water as dielectric in EDM. Int. J. Mach. Tool Des. Res. 1984, 24, 31–43. [Google Scholar] [CrossRef]

- Brauers, W.K.M.; Zavadskas, E.K. The MOORA method and its application to privatization in a transition economy. Control Cybern. 2006, 35, 445–469. [Google Scholar]

- Karande, P.; Chakraborty, S. Application of multi-objective optimization on the basis of ratio analysis (MOORA) method for materials selection. Mater. Des. 2012, 37, 317–324. [Google Scholar] [CrossRef]

- Deng, X.; Chen, J.X.; Wang, X.; Geng, F.T. Non-Dominated Sorting Genetic Algorithm-II for Possibilistic Mean-Semiabsolute Deviation-Yager Entropy Portfolio Model with Complex Real-World Constraints. Math. Comput. Simul. 2022, 202, 59–78. [Google Scholar] [CrossRef]

- Han, Z.H.; Xu, C.Z.; Zhang, L.; Zhang, Y.; Zhang, K.; Song, W.P. Efficient Aerodynamic Shape Optimization Using Variable-Fidelity Surrogate Models and Multilevel Computational Grids. Chin. J. Aeronaut. 2020, 33, 31–47. [Google Scholar] [CrossRef]

- Nayakappa, P.A.; Walke, G.A.; Mahesh, G. Grey Relation Analysis Methodology and Its Application. Res. Rev. Int. J. Multidiscip. 2019, 4, 409–411. [Google Scholar] [CrossRef]

- Atroshenko, S.A.; Morozov, N.F.; Zheng, W.; Huang, Y.J.; Sudenkov, Y.V.; Naumova, N.S.; Shen, J. Deformation behaviors of a TiZrNiCuBe bulk metallic glass under shock loading. J. Alloys Compd. 2010, 505, 501–504. [Google Scholar] [CrossRef]

- Zhao, Y.Y.; Zhang, G.L.; Estévez, D.A.; Chang, C.T.; Wang, X.M.; Li, R.W. Evolution of shear bands into cracks in metallic glasses. J. Alloys Compd. 2015, 621, 238–243. [Google Scholar] [CrossRef]

- Kuriakose, S.; Patowari, P.K.; Bhatt, J. Effect of micro-EDM machining parameters on the accuracy of micro hole drilling in Zr-based metallic glass. Eng. Res. Express 2019, 2, 015001. [Google Scholar] [CrossRef]

- Sadiq, M.; Nawaz, M.A.; Sharif, A.; Hanif, S. Bridging Green Supply Chain Practices and Environmental Performance in Chinese Semiconductor Sector: With the Role of Energy Efficiency and Green HRM. Int. J. Prod. Econ. 2024, 277, 109381. [Google Scholar] [CrossRef]

- Liu, C.; Duong, N.; Jahan, M.P.; Ma, J.F.; Kirwin, R. Experimental investigation and numerical simulation of micro-EDM of bulk metallic glass with focus on crater sizes. Procedia Manuf. 2019, 34, 275–286. [Google Scholar] [CrossRef]

- Jung, J.H.; Kwon, W.T. Optimization of EDM process for multiple performance characteristics using Taguchi method and Grey relational analysis. J. Mech. Sci. Technol. 2010, 24, 1083–1090. [Google Scholar] [CrossRef]

- Garg, A.; Lam, J.S.L. Modeling multiple-response environmental and manufacturing characteristics of EDM process. J. Clean. Prod. 2016, 137, 1588–1601. [Google Scholar] [CrossRef]

- Ming, W.Y.; Ma, J.; Zhang, Z.; Huang, H.; Shen, D.L.; Zhang, G.J.; Huang, Y. Soft computing models and intelligent optimization system in electro-discharge machining of SiC/Al composites. Int. J. Adv. Manuf. Technol. 2016, 87, 201–217. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Zhang, G.J.; Zhang, Z.; Zhang, Y.; Huang, Y. Effect of assisted transverse magnetic field on distortion behavior of thin-walled components in WEDM process. Chin. J. Aeronaut. 2022, 35, 291–307. [Google Scholar] [CrossRef]

- Ming, W.Y.; Zhang, S.F.; Zhang, G.J.; Du, J.G.; Ma, J.; He, W.B.; Cao, C.; Liu, K. Progress in modeling of electrical discharge machining process. Int. J. Heat Mass Transf. 2022, 187, 122563. [Google Scholar] [CrossRef]

| Properties | Kerosene | Sunflower Oil | Colza Oil |

|---|---|---|---|

| Flash point (°C) | 52 | 439 | 453 |

| Viscosity (27 °C) (cSt) | 1.22 | 4.9 | 5.83 |

| Dielectric constant (27 °C) | 2.11 | 3 | 3.2 |

| Thermal conductivity (W/mK) | 0.128 | 0.159 | 0.176 |

| Parameters | Levels | Values |

|---|---|---|

| Pulse-on time (POT) | 2 | 30 μs, 50 μs |

| Pulse duty cycle (PDC) | 5 | 0.1 ratio, 0.2 ratio, 0.3 ratio, 0.4 ratio, 0.5 ratio |

| Dielectric | 2 | Sunflower oil, colza oil |

| Exp. No. | Input Process Parameters | Machining Performance | |||||

|---|---|---|---|---|---|---|---|

| Pulse-On Time (μs) | Pulse Duty Cycle (Ratio) | Dielectric | MRR (mm3/min) | Overcut (μm) | Edge Deviation (μm) | EEV (kJ/mm3) | |

| 1 | 30 | 0.1 | Sunflower oil | 0.0065 | 40.76 | 18.2 | 23.01 |

| 2 | 30 | 0.2 | Sunflower oil | 0.0103 | 44.88 | 11.53 | 28.96 |

| 3 | 30 | 0.3 | Sunflower oil | 0.0091 | 43.79 | 23.33 | 49.21 |

| 4 | 30 | 0.4 | Sunflower oil | 0.0071 | 49.41 | 21.78 | 84.38 |

| 5 | 30 | 0.5 | Sunflower oil | 0.0068 | 41.25 | 11.78 | 108.95 |

| 6 | 50 | 0.1 | Sunflower oil | 0.0034 | 52.70 | 19.77 | 42.97 |

| 7 | 50 | 0.2 | Sunflower oil | 0.0057 | 57.13 | 15.11 | 52.15 |

| 8 | 50 | 0.3 | Sunflower oil | 0.0058 | 49.44 | 18.14 | 76.54 |

| 9 | 50 | 0.4 | Sunflower oil | 0.0037 | 59.27 | 21.64 | 158.12 |

| 10 | 50 | 0.5 | Sunflower oil | 0.0054 | 54.41 | 17.58 | 137.91 |

| 11 | 30 | 0.1 | Colza oil | 0.006 | 40.74 | 29.26 | 24.70 |

| 12 | 30 | 0.2 | Colza oil | 0.0093 | 40.31 | 25.15 | 32.07 |

| 13 | 30 | 0.3 | Colza oil | 0.0089 | 39.99 | 23.6 | 50.51 |

| 14 | 30 | 0.4 | Colza oil | 0.006 | 47.97 | 31.92 | 99.67 |

| 15 | 30 | 0.5 | Colza oil | 0.0078 | 46.75 | 9.94 | 95.82 |

| 16 | 50 | 0.1 | Colza oil | 0.0033 | 54.97 | 19.22 | 44.76 |

| 17 | 50 | 0.2 | Colza oil | 0.0076 | 56.37 | 13.51 | 39.36 |

| 18 | 50 | 0.3 | Colza oil | 0.0067 | 58.14 | 9.41 | 67.15 |

| 19 | 50 | 0.4 | Colza oil | 0.0044 | 65.10 | 22.47 | 133.71 |

| 20 | 50 | 0.5 | Colza oil | 0.0056 | 61.90 | 18.31 | 133.85 |

| Exp. No | MRR | Overcut | Edge Deviation | EEV | Assessment Value |

|---|---|---|---|---|---|

| 1 | 0.050 | 0.041 | 0.048 | 0.016 | −0.054 |

| 2 | 0.080 | 0.045 | 0.030 | 0.020 | −0.015 |

| 3 | 0.070 | 0.044 | 0.061 | 0.033 | −0.068 |

| 4 | 0.055 | 0.049 | 0.057 | 0.057 | −0.108 |

| 5 | 0.053 | 0.041 | 0.031 | 0.073 | −0.093 |

| 6 | 0.026 | 0.052 | 0.052 | 0.029 | −0.107 |

| 7 | 0.044 | 0.057 | 0.040 | 0.035 | −0.088 |

| 8 | 0.045 | 0.049 | 0.048 | 0.052 | −0.103 |

| 9 | 0.029 | 0.059 | 0.057 | 0.107 | −0.194 |

| 10 | 0.042 | 0.054 | 0.046 | 0.093 | −0.151 |

| 11 | 0.046 | 0.041 | 0.077 | 0.017 | −0.087 |

| 12 | 0.072 | 0.040 | 0.066 | 0.022 | −0.056 |

| 13 | 0.069 | 0.040 | 0.062 | 0.034 | −0.067 |

| 14 | 0.046 | 0.048 | 0.084 | 0.067 | −0.152 |

| 15 | 0.060 | 0.047 | 0.026 | 0.065 | −0.077 |

| 16 | 0.026 | 0.055 | 0.050 | 0.030 | −0.110 |

| 17 | 0.059 | 0.056 | 0.035 | 0.027 | −0.059 |

| 18 | 0.052 | 0.058 | 0.025 | 0.045 | −0.076 |

| 19 | 0.034 | 0.065 | 0.059 | 0.090 | −0.180 |

| 20 | 0.043 | 0.062 | 0.048 | 0.090 | −0.156 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Cao, C.; Zhao, Y.; Sun, S.; Du, J.; Ming, W. Machinability of Drilling on Metallic Glass for Micro-Hole with Renewable Dielectric in an Electric Discharge Machining Process. Metals 2025, 15, 415. https://doi.org/10.3390/met15040415

Li L, Cao C, Zhao Y, Sun S, Du J, Ming W. Machinability of Drilling on Metallic Glass for Micro-Hole with Renewable Dielectric in an Electric Discharge Machining Process. Metals. 2025; 15(4):415. https://doi.org/10.3390/met15040415

Chicago/Turabian StyleLi, Liwei, Chen Cao, Yangjing Zhao, Shuo Sun, Jinguang Du, and Wuyi Ming. 2025. "Machinability of Drilling on Metallic Glass for Micro-Hole with Renewable Dielectric in an Electric Discharge Machining Process" Metals 15, no. 4: 415. https://doi.org/10.3390/met15040415

APA StyleLi, L., Cao, C., Zhao, Y., Sun, S., Du, J., & Ming, W. (2025). Machinability of Drilling on Metallic Glass for Micro-Hole with Renewable Dielectric in an Electric Discharge Machining Process. Metals, 15(4), 415. https://doi.org/10.3390/met15040415