The Annealing Effect on Microstructure and Texture Evolution of Spun Al-Mg Alloy Tubes with Cross Inner Ribs

Abstract

:1. Introduction

2. Experimental Materials and Methods

3. Results and Discussion

4. Conclusions

- (1)

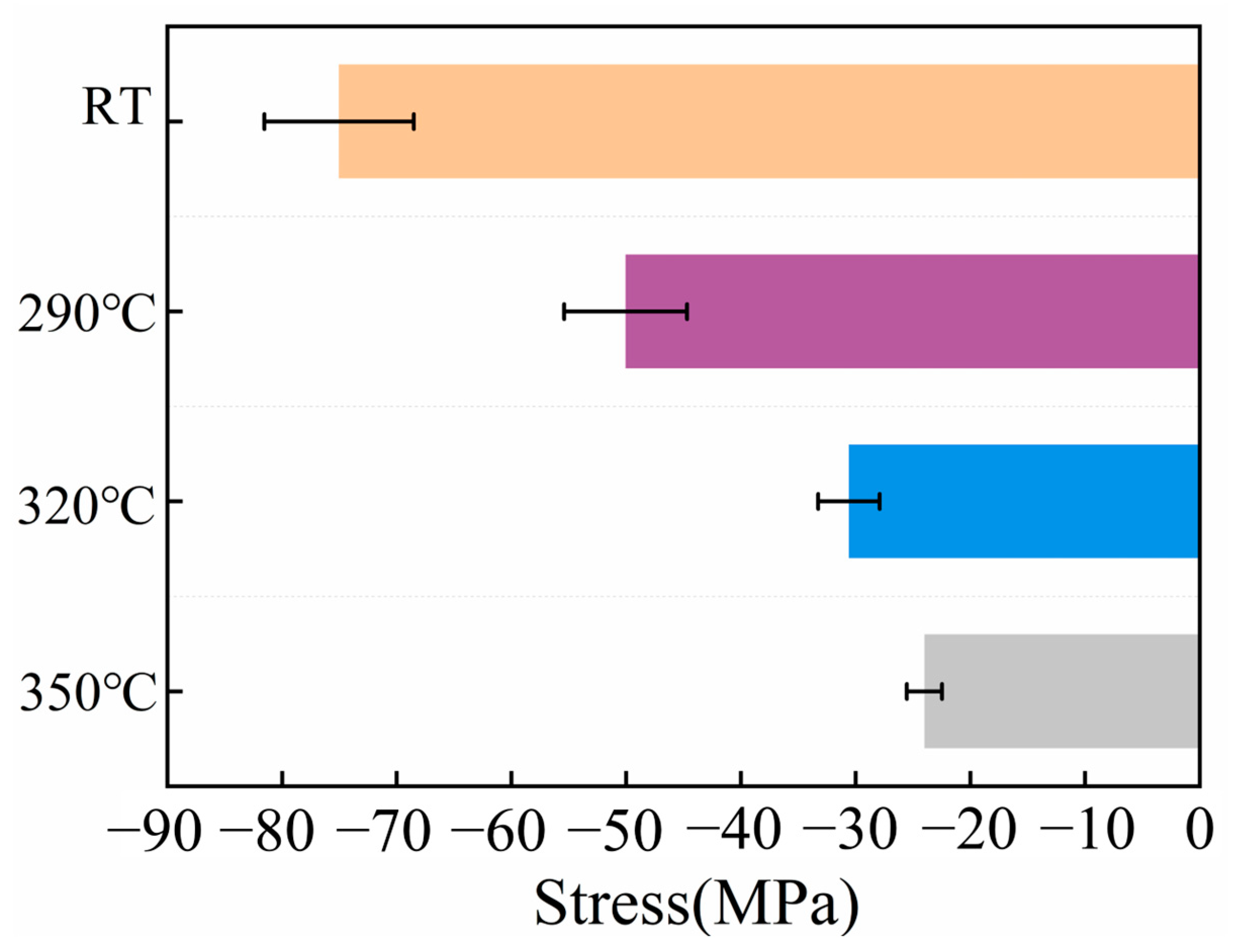

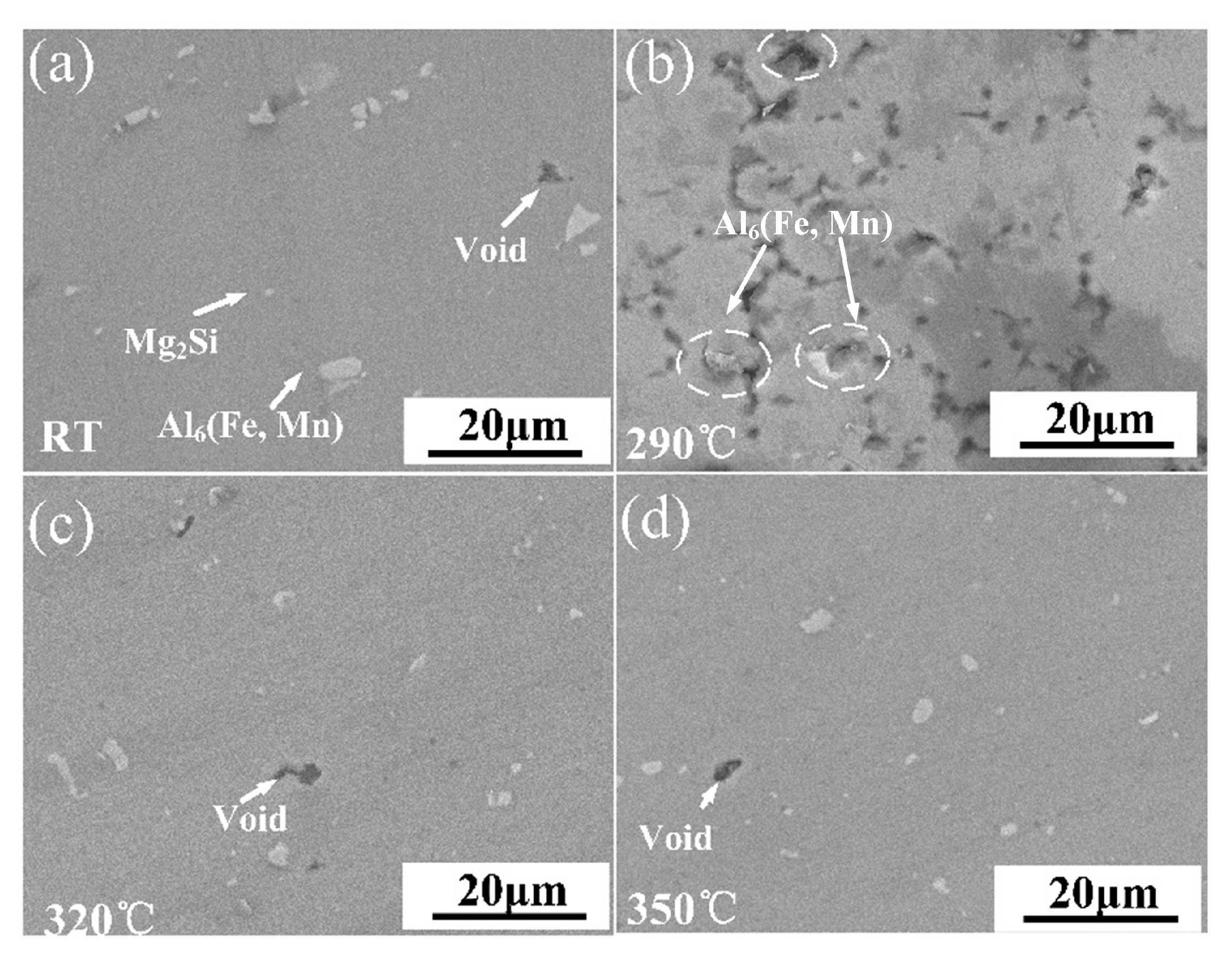

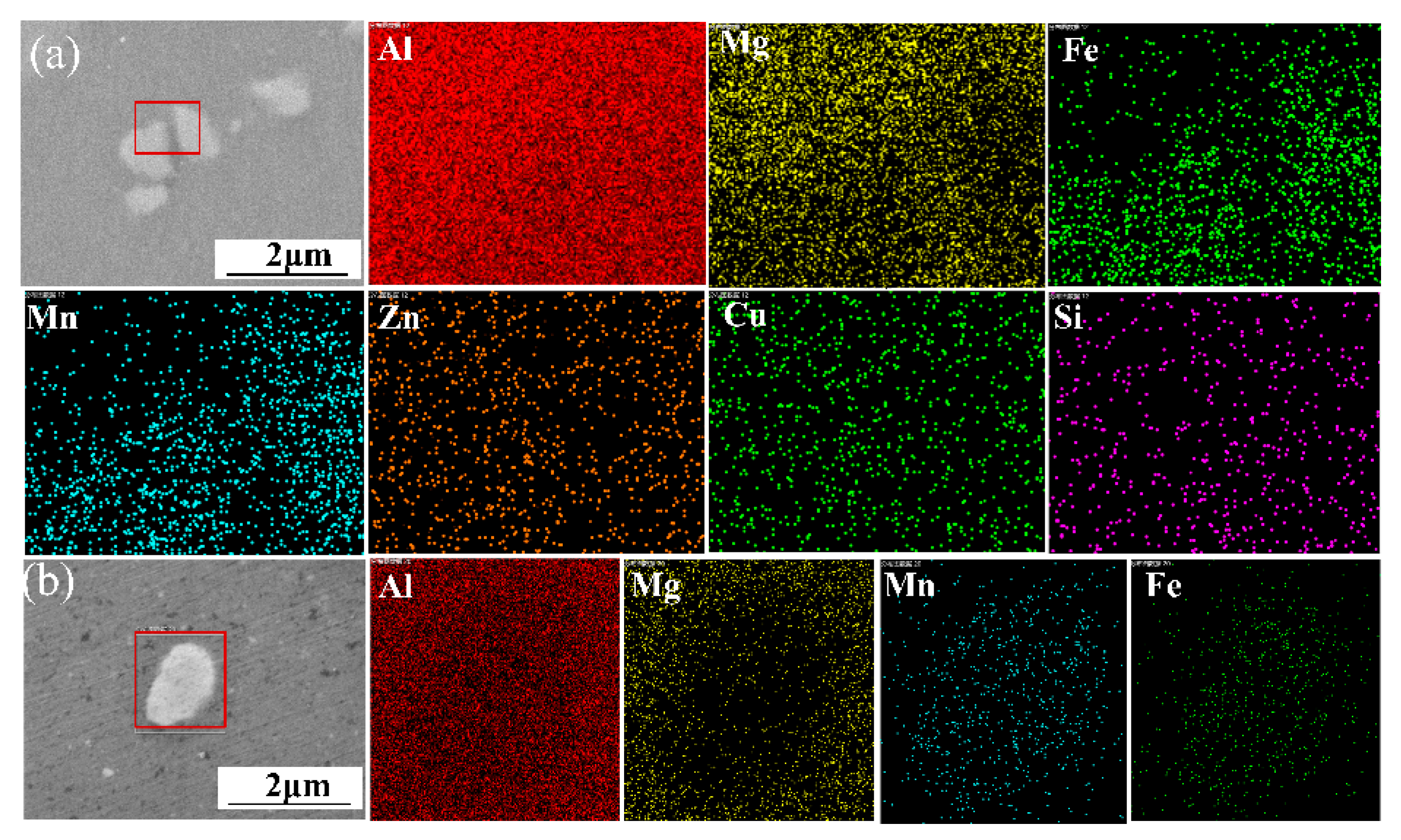

- After annealing, the residual stress in the TIR decreased from 70.5 MPa to 24.01 MPa. After annealing, the fragmented second-phase particles disappeared. Precipitation appeared at the triple grain boundaries and was accompanied by the formation of fine precipitates.

- (2)

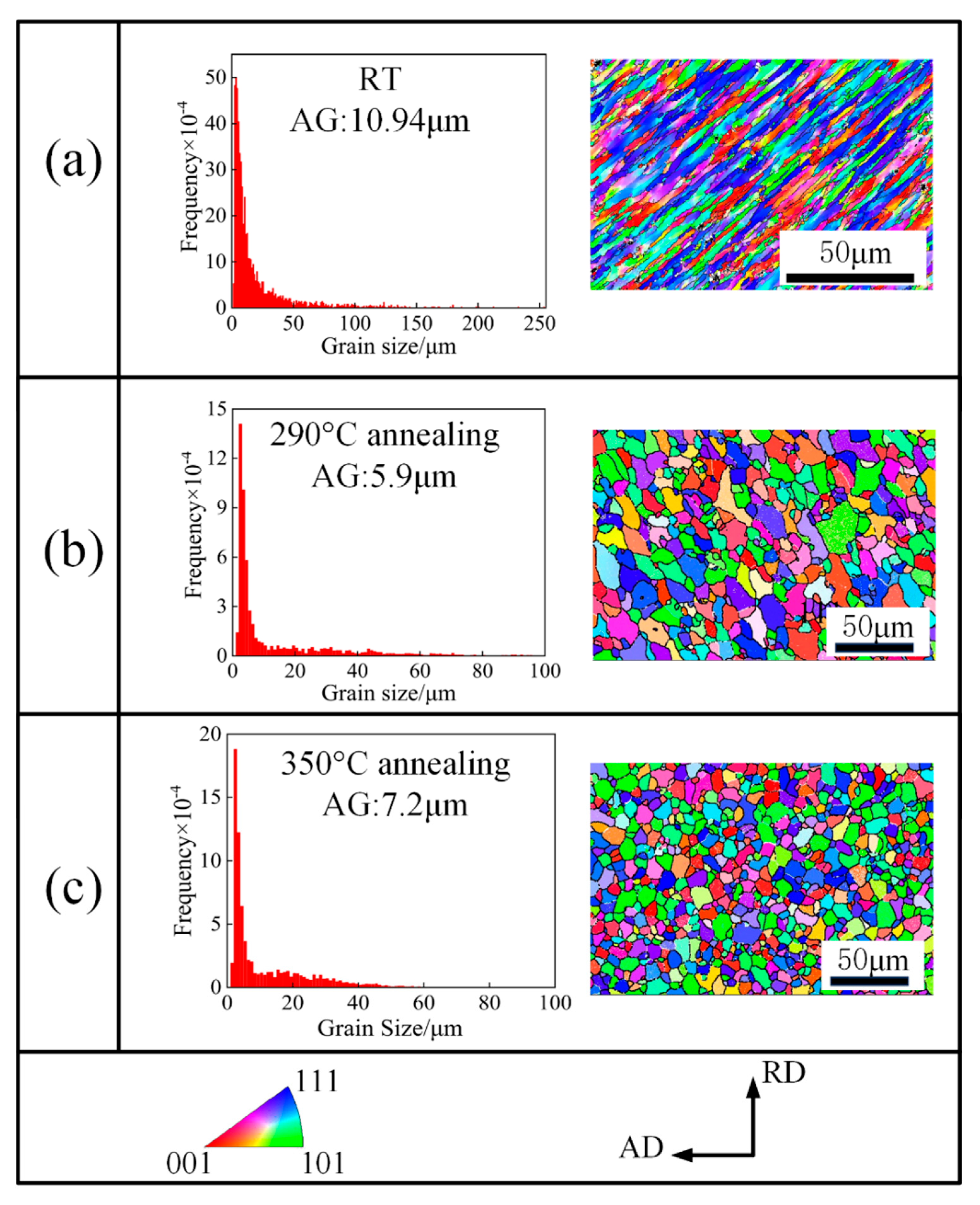

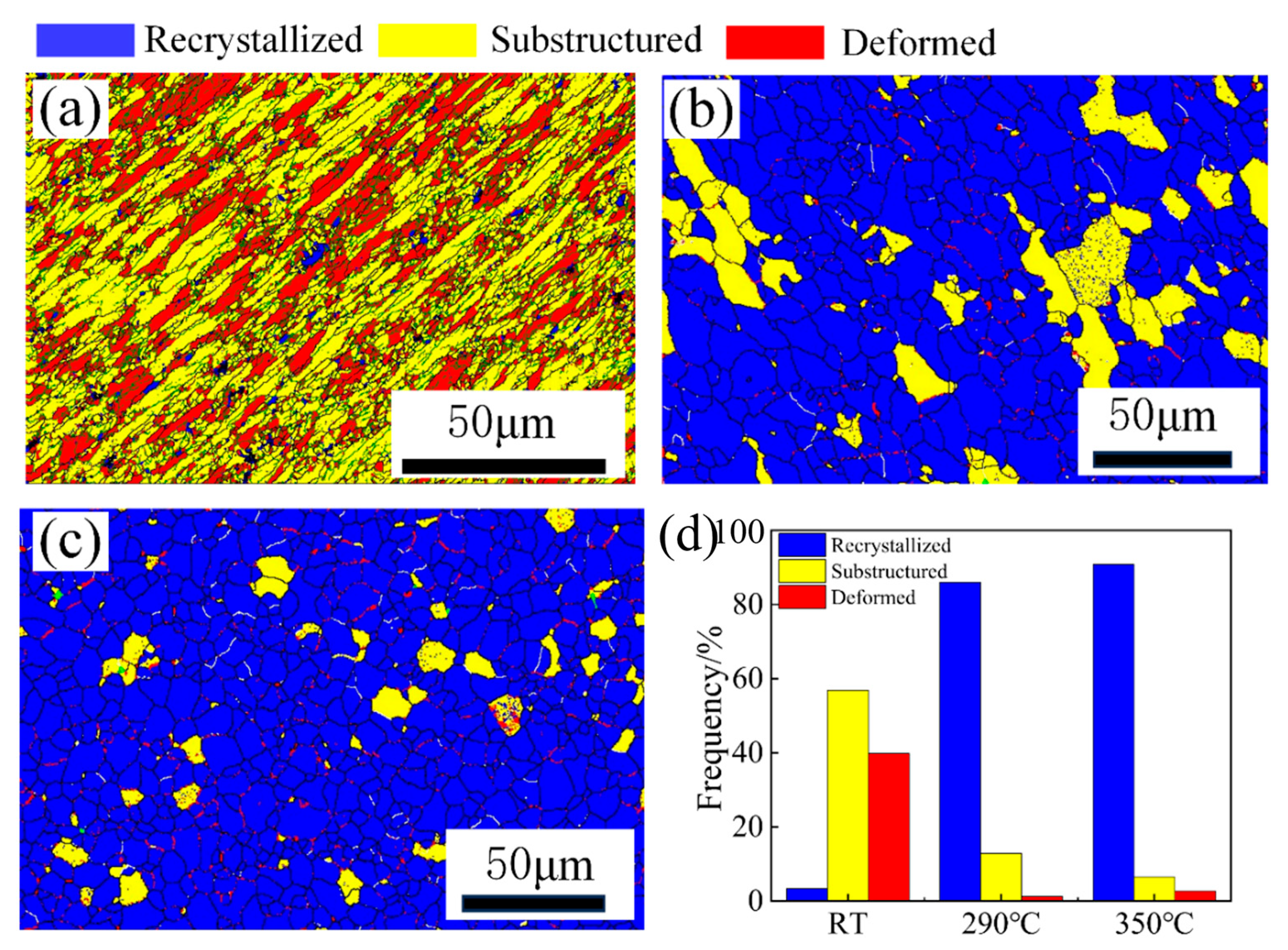

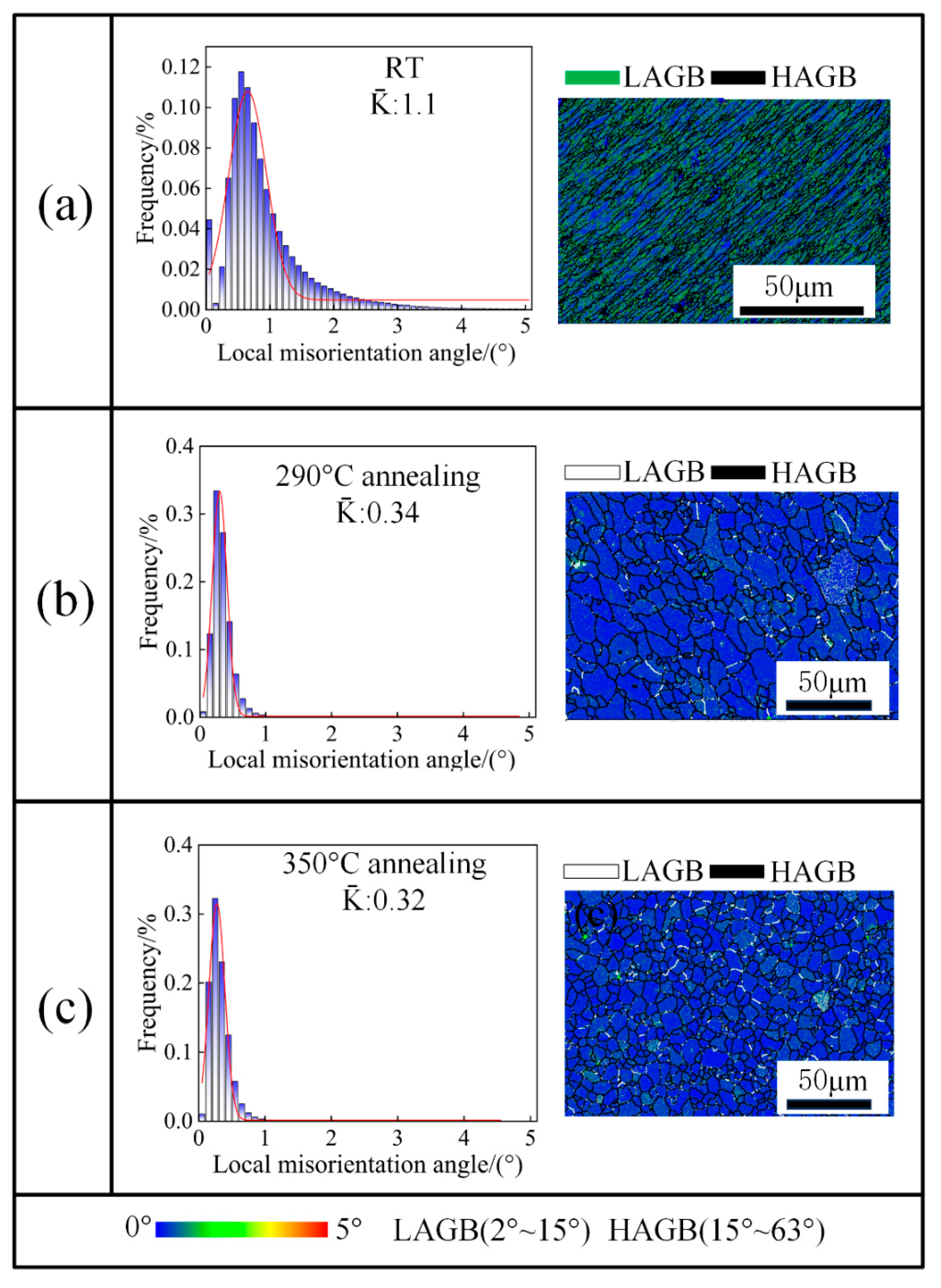

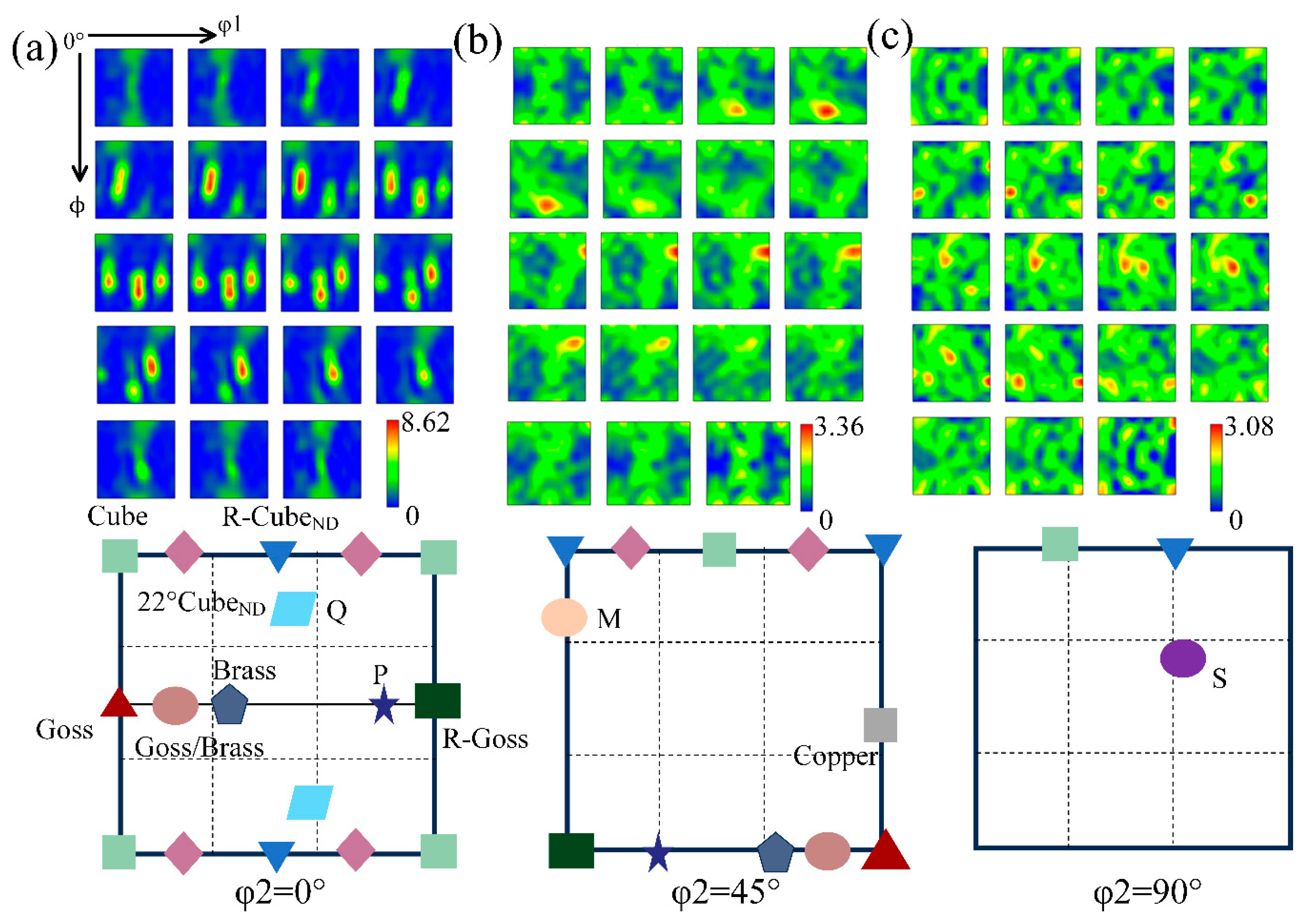

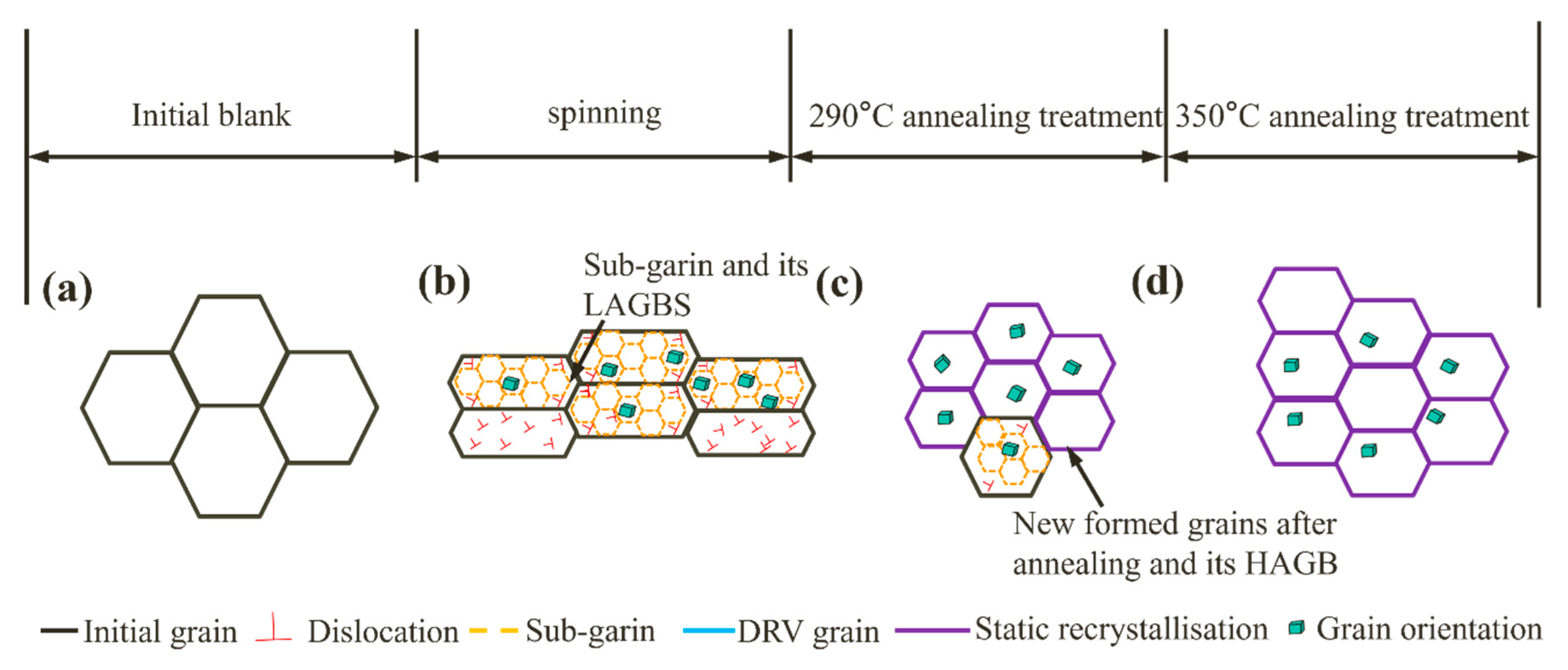

- After annealing, 5A06 aluminum alloy is transformed from stronger {221}<1-22> and {111}<3-41> textures to recrystallized texture (Cube{001}<100> and R-CubeND{001}<110>). The annealing process promotes grain recrystallization, weakening the texture strengthening effect induced by plastic deformation and decreasing dislocation density. The percentage of recrystallized grains at 350 °C was 90.8%.

- (3)

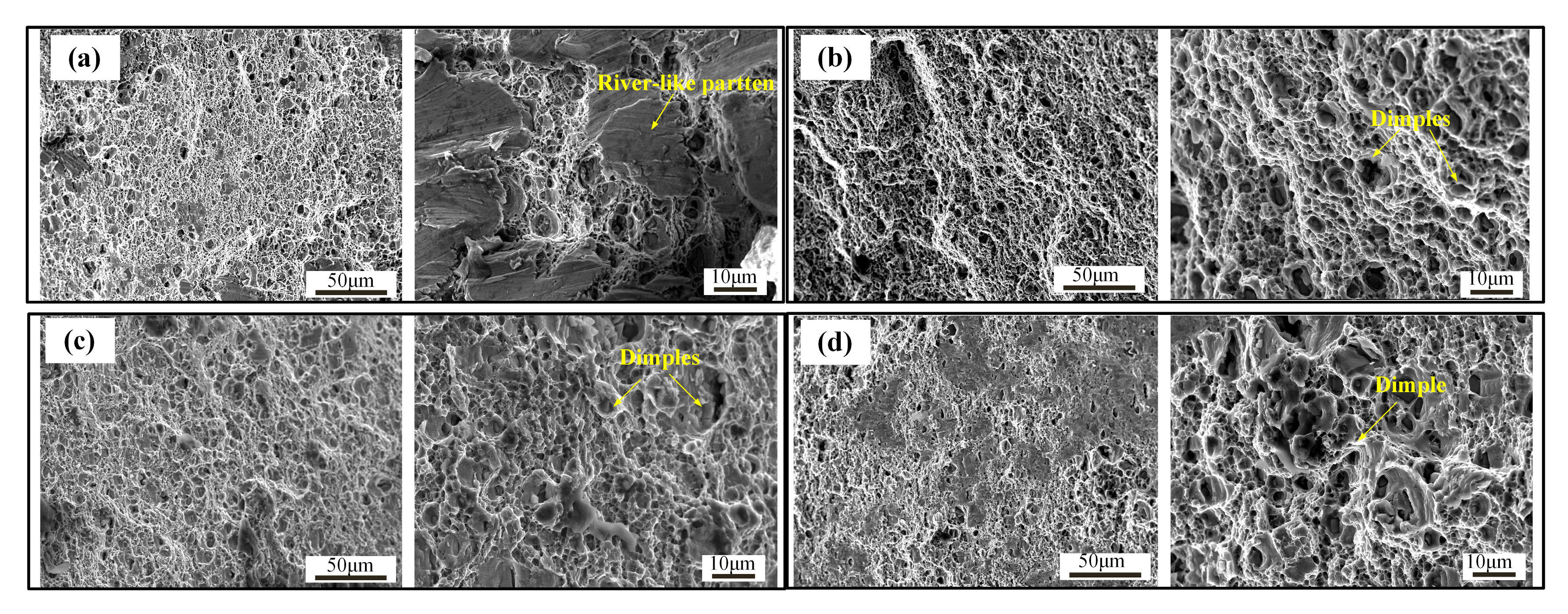

- The EL is the first to increase and then decrease with the increase in the annealing temperature. The mechanical properties of the specimen at 290 °C annealing temperature are the best, with a yield strength and ultimate tensile strength of 106.22 MPa and 378.55 MPa, respectively, and the EL is 42.43%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, Y.-Y.; Chen, H.-S.; Zhou, J.; Nie, H.-H.; Xu, X.; Xi, S.-X.; Chang, Y.-L. Study on interface behavior and mechanical properties of Al/Cu laminated tubes fabricated by strong staggered spinning at room temperature. J. Mater. Res. Technol. 2023, 25, 7307–7324. [Google Scholar] [CrossRef]

- Zhang, R.; Li, J.; Li, Q.; Qi, Y.; Zeng, Z.; Qiu, Y.; Chen, X.; Kairy, S.K.; Thomas, S.; Birbilis, N. Analysing the degree of sensitisation in 5xxx series aluminium alloys using artificial neural networks: A tool for alloy design. Corros. Sci. 2019, 150, 268–278. [Google Scholar] [CrossRef]

- Zheng, Z.; Ma, P.; Chen, L.; Liu, C. Microstructural Modification by Large Pre-Deformation and Post-Aging to Improve Properties in Al-Mg-Li Alloy. Metals 2025, 15, 290. [Google Scholar] [CrossRef]

- Gao, P.; Gong, Y.; Ren, Z.; Zhan, M. A new spinning-extrusion forming technology for the inner-ribbed component. Int. J. Mech. Sci. 2024, 279, 109494. [Google Scholar] [CrossRef]

- Chen, X.; Yu, Z.; Chen, W.; Wang, F.; Zhao, Y.; Lin, Z. Study on generating rolling method for manufacturing cylindrical parts with external cross ribs. J. Manuf. Process. 2024, 111, 1–20. [Google Scholar] [CrossRef]

- Wong, C.C.; Dean, T.A.; Lin, J. A review of spinning, shear forming and flow forming processes. Int. J. Mach. Tools Manuf. 2003, 43, 1419–1435. [Google Scholar] [CrossRef]

- Xia, Q.; Xiao, G.; Long, H.; Cheng, X.; Sheng, X. A review of process advancement of novel metal spinning. Int. J. Mach. Tools Manuf. 2014, 85, 100–121. [Google Scholar] [CrossRef]

- Zeng, X.; Fan, X.; Li, H.; Li, S. Flow forming process of thin-walled tubular parts with cross inner ribs. Procedia Manuf. 2018, 15, 1239–1246. [Google Scholar] [CrossRef]

- Wong, C.C.; Dean, T.A.; Lin, J. Incremental forming of solid cylindrical components using flow forming principles. J. Mater. Process. Technol. 2004, 153–154, 60–66. [Google Scholar] [CrossRef]

- Xia, Q.; Xiao, G.; Long, H.; Cheng, X.; Yang, B. A study of manufacturing tubes with nano/ultrafine grain structure by stagger spinning. Mater. Des. 2014, 59, 516–523. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, F.; Dong, J.; Jin, L.; Liu, C.; Ding, W. Grain refinement and orientation of AZ31B magnesium alloy in hot flow forming under different thickness reductions. J. Mater. Sci. Technol. 2018, 34, 1091–1102. [Google Scholar] [CrossRef]

- RadoviĆ, L.; NikaČEviĆ, M.; JordoviĆ, B. Deformation behaviour and microstructure evolution of AlMg6Mn alloy during shear spinning. Trans. Nonferrous Met. Soc. China 2012, 22, 991–1000. [Google Scholar] [CrossRef]

- Wang, X.X.; Zhan, M.; Gao, P.F.; Zhang, H.R. Micromechanical behaviour of TA15 alloy cylindrical parts processed by multi-pass flow forming. Mater. Sci. Eng. A 2018, 737, 328–335. [Google Scholar] [CrossRef]

- Zeng, X.; Fan, X.G.; Li, H.W.; Zhan, M.; Li, S.H.; Wu, K.Q.; Ren, T.W. Heterogeneous microstructure and mechanical property of thin-walled tubular part with cross inner ribs produced by flow forming. Mater. Sci. Eng. A 2020, 790, 139702. [Google Scholar] [CrossRef]

- Dahms, F.; Homberg, W. Manufacture of Defined Residual Stress Distributions in the Friction-Spinning Process: Investigations and Run-to-Run Predictive Control. Metals 2022, 12, 158. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, Y.; Wang, M.; Li, W.; Zhang, C.; Luo, J. Relationship Between Fracture Fractal and Mechanical Properties of 5083 Aluminum Alloy Sheet Prepared by Alternate Ring-Groove Pressing and Torsion. Metals 2024, 14, 1382. [Google Scholar] [CrossRef]

- Yuan, T.; Wang, Y.; Du, W.; Zeng, C.; Sun, Z.; Peng, W.; Liu, Y.; Hu, H.; Zeng, Z. Influence of annealing on the interfacial structure, recrystallization behaviour, and texture evolution of hot extruded Mg/Al laminated composites. Mater. Today Commun. 2024, 40, 110132. [Google Scholar] [CrossRef]

- Peng, J.; Zhang, J.; Li, Z.; Chen, X.; Cui, L. Grain structure evolution, textures, and mechanical properties of cryogenic-rolled AA6061 under high-temperature short-term annealing. Mater. Today Commun. 2024, 40, 109682. [Google Scholar] [CrossRef]

- Du, P.; Li, C.; Gao, P.; Liu, L.; Chen, B.; Li, M.; Wang, Z. Effect of rolling method on the recrystallization behavior and recrystallization texture of Al-Mn alloy. Mater. Today Commun. 2024, 38, 108001. [Google Scholar] [CrossRef]

- Wang, X.X.; Liu, T.; Zhang, R.X.; Jin, H.J.; Zhao, X.N.; Wu, W.H.; Cheng, J. Texture evolution related to static recrystallization during annealing of TA15 alloy tube formed by flow forming. J. Mater. Res. Technol. 2023, 24, 5769–5781. [Google Scholar] [CrossRef]

- Xu, W.; Zhao, X.; Ma, H.; Shan, D.; Lin, H. Influence of roller distribution modes on spinning force during tube spinning. Int. J. Mech. Sci. 2016, 113, 10–25. [Google Scholar] [CrossRef]

- Zeng, X.; Fan, X.G.; Li, H.W.; Zhan, M.; Zhang, H.R.; Wu, K.Q.; Ren, T.W.; Li, S.H. Die filling mechanism in flow forming of thin-walled tubular parts with cross inner ribs. J. Manuf. Process. 2020, 58, 832–844. [Google Scholar] [CrossRef]

- Wang, J.; Xiao, G.; Zhang, J. A new constitutive model and hot processing map of 5A06 aluminum alloy based on high-temperature rheological behavior and higher-order gradients. Mater. Today Commun. 2023, 36, 106502. [Google Scholar] [CrossRef]

- Rossini, N.S.; Dassisti, M.; Benyounis, K.Y.; Olabi, A.G. Methods of measuring residual stresses in components. Mater. Des. 2012, 35, 572–588. [Google Scholar] [CrossRef]

- Zhang, W.; Jin, T.; Lou, W.; Li, W.; Dai, W. Mechanical Properties and Corrosion Behavior of 5A06 Alloy in Seawater. IEEE Access 2018, 6, 24952–24961. [Google Scholar] [CrossRef]

- Zhang, H.; Guo, C.; Li, S.; Li, B.; Nagaumi, H. Influence of cold pre-deformation on the microstructure, mechanical properties and corrosion resistance of Zn-bearing 5xxx aluminum alloy. J. Mater. Res. Technol. 2022, 16, 1202–1212. [Google Scholar] [CrossRef]

- Yan, S.; Yang, H.; Li, H.; Yao, X. Microstructure Evolution and Flow Localization Characteristics of 5A06 Alloy in High Strain Rate Forming Process. Procedia Eng. 2014, 81, 1198–1203. [Google Scholar] [CrossRef]

- Yan, S.L.; Yang, H.; Li, H.W.; Ren, G.Y. Experimental study of macro–micro dynamic behaviors of 5A0X aluminum alloys in high velocity deformation. Mater. Sci. Eng. A 2014, 598, 197–206. [Google Scholar] [CrossRef]

- Zuo, J.; Hou, L.; Shi, J.; Cui, H.; Zhuang, L.; Zhang, J. The mechanism of grain refinement and plasticity enhancement by an improved thermomechanical treatment of 7055 Al alloy. Mater. Sci. Eng. A 2017, 702, 42–52. [Google Scholar] [CrossRef]

- Ding, Y.; Gao, K.; Huang, H.; Wen, S.; Wu, X.; Nie, Z.; Guo, S.; Shao, R.; Huang, C.; Zhou, D. Nucleation and evolution of β phase and corresponding intergranular corrosion transition at 100–230 °C in 5083 alloy containing Er and Zr. Mater. Des. 2019, 174, 107778. [Google Scholar] [CrossRef]

- Ma, B.X.; Wang, G.J.; Guo, E.J. Effect of annealing temperature on microstructure and tensile properties of Al–Mg alloy 5A06 sheet. Mater. Sci. Technol. 2013, 29, 1044–1047. [Google Scholar] [CrossRef]

- Wang, X.; Guo, M.; Zhang, Y.; Xing, H.; Li, Y.; Luo, J.; Zhang, J.; Zhuang, L. The dependence of microstructure, texture evolution and mechanical properties of Al–Mg–Si–Cu alloy sheet on final cold rolling deformation. J. Alloys Compd. 2016, 657, 906–916. [Google Scholar] [CrossRef]

- Robson, J.D.; Henry, D.T.; Davis, B. Particle effects on recrystallization in magnesium–manganese alloys: Particle pinning. Mater. Sci. Eng. A 2011, 528, 4239–4247. [Google Scholar] [CrossRef]

- Engler, O.; Kong, X.W.; Yang, P. Influence of particle stimulated nucleation on the recrystallization textures in cold deformed Al-alloys Part I—Experimental observations. Scr. Mater. 1997, 37, 1665–1674. [Google Scholar] [CrossRef]

- Srinivas, B.; Dhal, A.; Panigrahi, S.K. A mathematical prediction model to establish the role of stacking fault energy on the cryo-deformation behavior of FCC materials at different strain levels. Int. J. Plast. 2017, 97, 159–177. [Google Scholar] [CrossRef]

- Li, M.H.; Ma, M.; Liu, W.C.; Yang, F.Q. Recrystallization behavior of cold-rolled Zr 702. J. Nucl. Mater. 2013, 433, 6–9. [Google Scholar] [CrossRef]

- Homer, E.R.; Holm, E.A.; Foiles, S.M.; Olmsted, D.L. Trends in Grain Boundary Mobility: Survey of Motion Mechanisms. JOM 2013, 66, 114–120. [Google Scholar] [CrossRef]

- Wright, S.I.; Nowell, M.M.; Field, D.P. A review of strain analysis using electron backscatter diffraction. Microsc. Microanal. 2011, 17, 316–329. [Google Scholar] [CrossRef]

- Lu, X.; Dunne, F.P.E.; Xu, Y. A crystal plasticity investigation of slip system interaction, GND density and stored energy in non-proportional fatigue in Nickel-based superalloy. Int. J. Fatigue 2020, 139, 105782. [Google Scholar] [CrossRef]

- Wu, C.; Ma, K.; Zhang, D.; Wu, J.; Xiong, S.; Luo, G.; Zhang, J.; Chen, F.; Shen, Q.; Zhang, L.; et al. Precipitation phenomena in Al-Zn-Mg alloy matrix composites reinforced with B4C particles. Sci. Rep. 2017, 7, 9589. [Google Scholar] [CrossRef]

- Hielscher, R. Kernel density estimation on the rotation group and its application to crystallographic texture analysis. J. Multivar. Anal. 2013, 119, 119–143. [Google Scholar] [CrossRef]

- Zhou, Y.L.; Yang, Y.; Tan, Y.B.; Xiang, S.; Ma, M.; Zhao, F.; Yang, M. Recrystallization behavior and texture evolution during annealing of cryogenic-rolled 3003 aluminum alloy. J. Alloys Compd. 2024, 997, 174818. [Google Scholar] [CrossRef]

- Chen, Y.D.; Dan, C.Y.; Chen, C.; Chen, C.X.; Jin, L.; Wang, H.W.; Chen, Z. Quasi in situ investigation on the influence of particle stimulate nucleation on recrystallization textures in TiB2 particles reinforced Al-3wt%Mg composites. J. Mater. Sci. 2023, 58, 9337–9348. [Google Scholar] [CrossRef]

- Fu, Y.-B.; Lu, Y.-P.; Wang, Z.-J.; Cao, Z.-Q.; Xu, A.-J. Microstructural refinement and performance improvement of Cu–36 wt% Zn alloy by Al2O3 nanoparticles coupling electromagnetic stirring. Rare Met. 2016, 41, 3560–3565. [Google Scholar] [CrossRef]

- Du, Y.J.; Xu, S.M.; Wang, F.; Li, J.L.; Wen, G.D.; Xiong, J.T.; Guo, W. Simultaneously enhancing strength–ductility synergy in refractory high entropy alloys by a heterogeneous structure design. J. Alloys Compd. 2024, 993, 174550. [Google Scholar] [CrossRef]

- Liu, D.H.; Yu, H.P.; Li, C.F. Comparative study of the microstructure of 5052 aluminum alloy sheets under quasi-static and high-velocity tension. Mater. Sci. Eng. A 2012, 551, 280–287. [Google Scholar] [CrossRef]

- Li, C.; Liu, D.; Yu, H.; Ji, Z. Research on formability of 5052 aluminum alloy sheet in a quasi-static–dynamic tensile process. Int. J. Mach. Tools Manuf. 2009, 49, 117–124. [Google Scholar] [CrossRef]

| Material | Chemical Composition (wt%) | ||||||

|---|---|---|---|---|---|---|---|

| 5A06 alloy | Si | Fe | Cu | Mn | Mg | Ti | Al |

| 0.02 | 0.14 | 0.01 | 0.61 | 6.3 | 0.04 | Bal. | |

| Forming Parameters | Values |

|---|---|

| Roller disk misalignment (mm) | 4 |

| Diameter of the roller (mm) | 200 |

| Radius of roller rounding (mm) | 5 |

| Mandrel rotation speed/(r/mm) | 300 |

| Feed speed/(mm/min) | 100 |

| Reduction rate (%) | 50 |

| Exit angle of the roller (°) | 25 |

| Component | Euler Angles (φ1, φ, φ2) | Miller Indices |

|---|---|---|

| Brass | (35, 45, 0) | {110}<112> |

| Goss | (0, 45, 0) | {110}<001> |

| Brass/Goss | (74, 90, 45) | {110}<115> |

| R-Goss | (90, 45, 0) | {110}<110> |

| Cube | (0, 0, 0) | {001}<100> |

| 22.5 °CubeND | (22.5, 0, 0) | {001}<210> |

| R-CubeND | (45, 0, 0) | {001}<110> |

| Q | (58, 18, 0) | {013}<231> |

| P | (65, 45, 0) | {011}<566> |

| M | (0, 25, 45) | {113}<110> |

| Copper | (90, 35, 45) | {112}<111> |

| S | (59, 37, 63) | {123}<634> |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, K.; Chen, H.; Chai, F.; Wang, Z. The Annealing Effect on Microstructure and Texture Evolution of Spun Al-Mg Alloy Tubes with Cross Inner Ribs. Metals 2025, 15, 441. https://doi.org/10.3390/met15040441

Yuan K, Chen H, Chai F, Wang Z. The Annealing Effect on Microstructure and Texture Evolution of Spun Al-Mg Alloy Tubes with Cross Inner Ribs. Metals. 2025; 15(4):441. https://doi.org/10.3390/met15040441

Chicago/Turabian StyleYuan, Ke, Hongsheng Chen, Fei Chai, and Zhuoran Wang. 2025. "The Annealing Effect on Microstructure and Texture Evolution of Spun Al-Mg Alloy Tubes with Cross Inner Ribs" Metals 15, no. 4: 441. https://doi.org/10.3390/met15040441

APA StyleYuan, K., Chen, H., Chai, F., & Wang, Z. (2025). The Annealing Effect on Microstructure and Texture Evolution of Spun Al-Mg Alloy Tubes with Cross Inner Ribs. Metals, 15(4), 441. https://doi.org/10.3390/met15040441