Effect of Al 6061 Alloy Compositions on Mechanical Properties of the Automotive Steering Knuckle Made by Novel Casting Process

Abstract

:1. Introduction

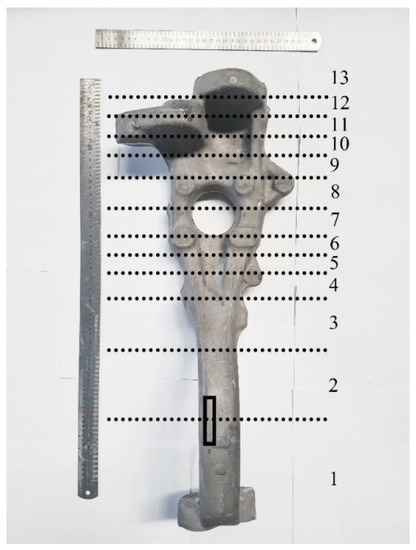

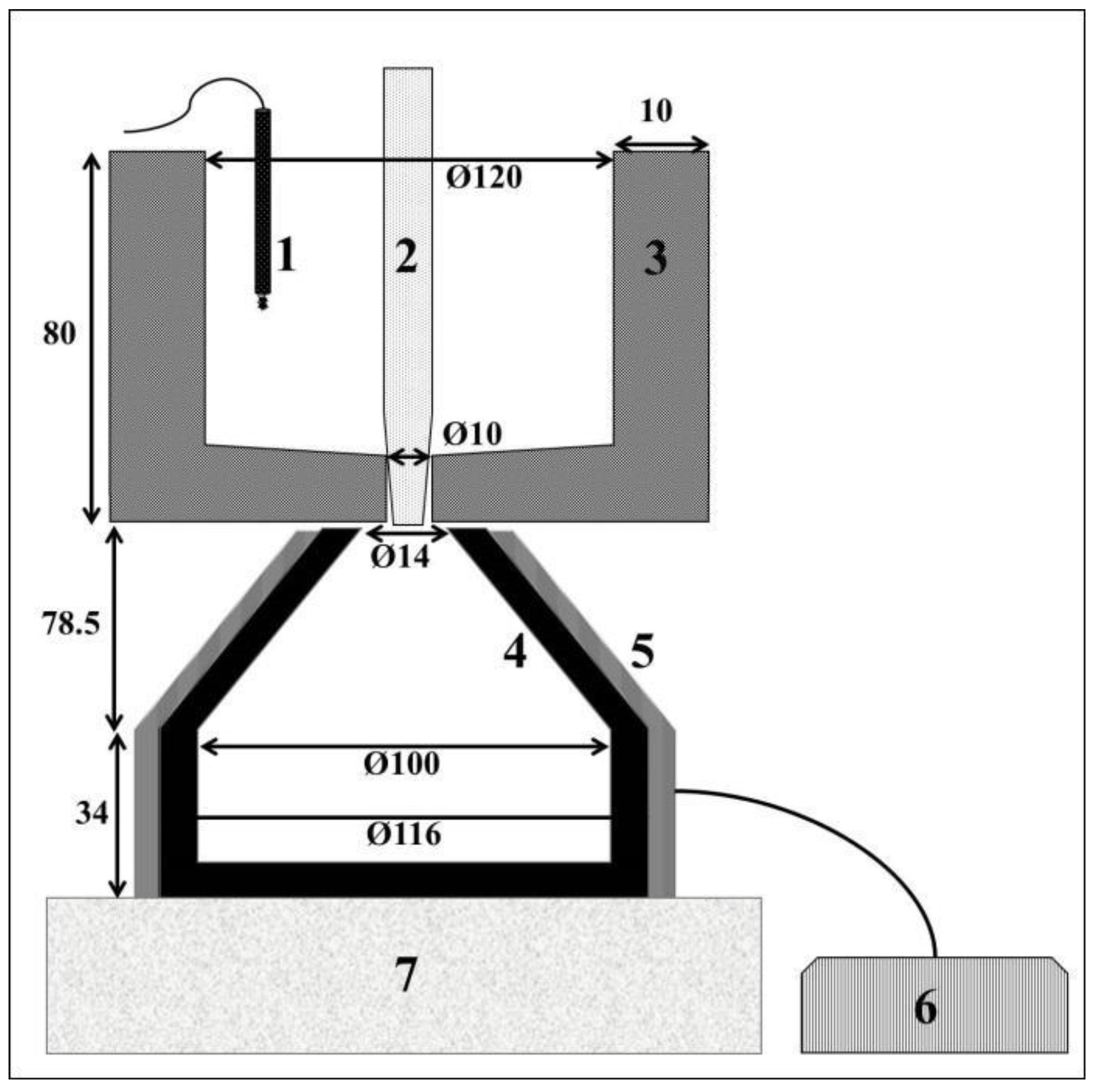

2. Material and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Campbell, J. Castings, 2nd ed.; Elsevier Butterworth-Heinemann: Burlington, MA, USA, 2003; p. 1. [Google Scholar]

- Skallerud, B.; Iveland, T.; Härkegård, G. Fatigue life assessment of aluminum alloys with casting defects. Eng. Fract. Mech. 1993, 44, 857–874. [Google Scholar] [CrossRef]

- Suyitno; Kool, W.H.; Katgerman, L. Micro-mechanical model of hot tearing at triple junctions in dc casting. 2002, 396–402, 179–184. [Google Scholar]

- Liu, Y.; Jie, W.; Gao, Z.; Zheng, Y. Investigation on the formation of microporosity in aluminum alloys. J. Alloys Compd. 2015, 629, 221–229. [Google Scholar] [CrossRef]

- Seo, K.H.; Jeon, J.B.; Youn, J.W.; Kim, S.J.; Kim, K.Y. Recycling of al-si die casting scraps for solar si feedstock. J. Cryst. Growth 2016, 442, 1–7. [Google Scholar] [CrossRef]

- Hanko, G.; Antrekowitsch, H.; Ebner, P. Recycling automotive magnesium scrap. JOM 2002, 54, 51–54. [Google Scholar] [CrossRef]

- Arafune, K.; Ohishi, E.; Sai, H.; Ohshita, Y.; Yamaguchi, M. Directional solidification of polycrystalline silicon ingots by successive relaxation of supercooling method. J. Cryst. Growth 2007, 308, 5–9. [Google Scholar] [CrossRef]

- Vijayarangan, S.; Rajamanickam, N.; Sivananth, V. Evaluation of metal matrix composite to replace spheroidal graphite iron for a critical component, steering knuckle. Mater. Des. 2013, 43, 532–541. [Google Scholar] [CrossRef]

- Sharma, M.M.; Ziemian, C.W.; Eden, T.J. Fatigue behavior of sic particulate reinforced spray-formed 7xxx series al-alloys. Mater. Des. 2011, 32, 4304–4309. [Google Scholar] [CrossRef]

- Sivananth, V.; Vijayarangan, S.; Rajamanickam, N. Evaluation of fatigue and impact behavior of titanium carbide reinforced metal matrix composites. Mater. Sci. Eng. A 2014, 597, 304–313. [Google Scholar] [CrossRef]

- Morri, A.; Ceschini, L.; Messieri, S.; Cerri, E.; Toschi, S. Mo addition to the a354 (al–si–cu–mg) casting alloy: Effects on microstructure and mechanical properties at room and high temperature. Metals 2018, 8. [Google Scholar] [CrossRef]

- Kernebeck, S.; Weber, S. Influence of short-term heat treatment on the mechanical properties of al–mg–si profiles. Metals 2018, 8. [Google Scholar] [CrossRef]

- Liu, K.; Mirza, F.A.; Chen, X.G. Effect of overaging on the cyclic deformation behavior of an aa6061 aluminum alloy. Metals 2018, 8. [Google Scholar] [CrossRef]

- Stangeland, A.; MO, A.; Nielsen, Ø.; M’Hamdi, M.; Eskin, D. Development of thermal strain in the coherent mushy zone during solidification of aluminum alloys. Metall. Mater. Trans. A 2004, 35, 2903–2915. [Google Scholar] [CrossRef]

- Rappaz, M.; Drezet, J.M.; Gremaud, M. A new hot-tearing criterion. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 1999, 30, 449–455. [Google Scholar] [CrossRef] [Green Version]

- Liu, B.C.; Kang, J.W.; Xiong, S.M. A study on the numerical simulation of thermal stress during the solidification of shaped castings. Sci. Technol. Adv. Mater. 2001, 2, 157–164. [Google Scholar] [CrossRef] [Green Version]

- Eskin, D.G.; Suyitno; Katgerman, L. Mechanical properties in the semi-solid state and hot tearing of aluminium alloys. Prog. Mater. Sci. 2004, 49, 629–711. [Google Scholar] [CrossRef]

- Dahle, A.K.; Arnberg, L. Development of strength in solidifying aluminium alloys. Acta Mater. 1997, 45, 547–559. [Google Scholar] [CrossRef]

- Metz, S.A.; Flemings, M.C. Fundamental study of hot tearing. AFS Trans. 1970, 78, 453–460. [Google Scholar]

- Kamguo Kamga, H.; Larouche, D.; Bournane, M.; Rahem, A. Hot tearing of aluminum-copper b206 alloys with iron and silicon additions. Mater. Sci. Eng. A 2010, 527, 7413–7423. [Google Scholar] [CrossRef]

- Li, X.M.; Starink, M.J. Effect of compositional variations on characteristics of coarse intermetallic particles in overaged 7000 aluminium alloys. Mater. Sci. Technol. 2001, 17, 1324–1328. [Google Scholar] [Green Version]

- Li, X.M.; Starink, M.J. Identification and analysis of intermetallic phases in overaged zr-containing and cr-containing al-zn-mg-cu alloys. J. Alloys Compd. 2011, 509, 471–476. [Google Scholar] [CrossRef]

- Senkov, O.N.; Shagiev, M.R.; Senkova, S.V.; Miracle, D.B. Precipitation of al3(sc,zr) particles in an al-zn-mg-cu-sc-zr alloy during conventional solution heat treatment and its effect on tensile properties. Acta Mater. 2008, 56, 3723–3738. [Google Scholar] [CrossRef]

- Morimoto, K.; Takamiya, H.; Awano, Y.; Nakamura, M. Effects of si content and gas dissolution on shrinkage morphology of hypoeutectic al-si alloys. J. Jpn. Inst. Light Met. 1988, 38, 216–221. [Google Scholar] [CrossRef]

- Wang, X.; Guo, M.; Luo, J.; Zhu, J.; Zhang, J.; Zhuang, L. Effect of zn on microstructure, texture and mechanical properties of al-mg-si-cu alloys with a medium number of fe-rich phase particles. Mater. Charact. 2017, 134, 123–133. [Google Scholar] [CrossRef]

- Anyalebechi, P.N. Effect of process route on the structure, tensile, and fatigue properties of aluminium alloy automotive steering knuckles. Foundry Trade J. Int. 2012, 186, 189–196. [Google Scholar]

- Ruff, G.; Prucha, T.E.; Barry, J.; Patterson, D. Pressure counter pressure casting (pcpc) for automotive aluminum structural components. SAE Tech. Pap. 2001. [Google Scholar] [CrossRef]

| Samples | Al | Si | Mg | Cu | Cr | Mn | Fe | Zn | Ti | Zr | SST (K) | ET (K) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 300 K | 673 K | ||||||||||||

| A | Bal. | 0.975 | 0.678 | 0.308 | 0.136 | 0.0958 | 0.0831 | 0.001 | 0.139 | 0 | 591.74 ± 8.47 | 615.28 ± 8.47 | 580.0 |

| B | Bal. | 0.975 | 0.678 | 0.308 | 0.136 | 0.0958 | 0.0831 | 0.001 | 0.139 | 0.01 | 602.73 ± 6.46 | 624.12 ± 2.87 | 576.5 |

| C | Bal. | 0.975 | 0.678 | 0.308 | 0.136 | 0.0958 | 0.0831 | 0.001 | 0.139 | 0.02 | 610.09 ± 8.39 | 623.82 ± 8.70 | 576.5 |

| D | Bal. | 0.975 | 0.678 | 0.308 | 0.136 | 0.0958 | 0.0831 | 0.700 | 0.139 | 0 | 613.29 ± 10.73 | 630.33 ± 6.73 | 576.2 |

| E | Bal. | 0.975 | 0.678 | 0.500 | 0.136 | 0.0958 | 0.0831 | 1.500 | 0.139 | 0 | 600.94 ± 11.44 | 630.17 ± 2.91 | 573.7 |

| Samples | Strain Rate (×10−3, s−1) | Grain Boundary Angle (θ) | Value of δ | |||

|---|---|---|---|---|---|---|

| 300 K | 673 K | 300 K | 673 K | 300 K | 673 K | |

| A | 1.48 | 0.99 | 108.85 ± 12.25 | 104.57 ± 14.50 | 0.88 ± 0.14 | 0.84 ± 0.14 |

| B | 1.03 | 0.76 | 109.63 ± 13.71 | 101.83 ± 14.85 | 0.89 ± 0.14 | 0.81 ± 0.13 |

| C | 2.12 | 0.27 | 108.17 ± 15.82 | 98.64 ± 15.61 | 0.89 ± 0.18 | 0.79 ± 0.15 |

| D | 0.76 | 0.45 | 102.06 ± 11.68 | 93.91 ± 16.85 | 0.81 ± 0.11 | 0.75 ± 0.11 |

| E | 0.57 | 0.30 | 104.21 ± 13.11 | 87.83 ± 15.32 | 0.84 ± 0.15 | 0.71 ± 0.03 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeon, G.T.; Kim, K.Y.; Moon, J.-H.; Lee, C.; Kim, W.-J.; Kim, S.J. Effect of Al 6061 Alloy Compositions on Mechanical Properties of the Automotive Steering Knuckle Made by Novel Casting Process. Metals 2018, 8, 857. https://doi.org/10.3390/met8100857

Jeon GT, Kim KY, Moon J-H, Lee C, Kim W-J, Kim SJ. Effect of Al 6061 Alloy Compositions on Mechanical Properties of the Automotive Steering Knuckle Made by Novel Casting Process. Metals. 2018; 8(10):857. https://doi.org/10.3390/met8100857

Chicago/Turabian StyleJeon, Gyu Tae, Ki Young Kim, Jung-Hwa Moon, Chul Lee, Whi-Jun Kim, and Suk Jun Kim. 2018. "Effect of Al 6061 Alloy Compositions on Mechanical Properties of the Automotive Steering Knuckle Made by Novel Casting Process" Metals 8, no. 10: 857. https://doi.org/10.3390/met8100857

APA StyleJeon, G. T., Kim, K. Y., Moon, J.-H., Lee, C., Kim, W.-J., & Kim, S. J. (2018). Effect of Al 6061 Alloy Compositions on Mechanical Properties of the Automotive Steering Knuckle Made by Novel Casting Process. Metals, 8(10), 857. https://doi.org/10.3390/met8100857