AA7050 Al Alloy Hot-Forging Process for Improved Fracture Toughness Properties

Abstract

1. Introduction

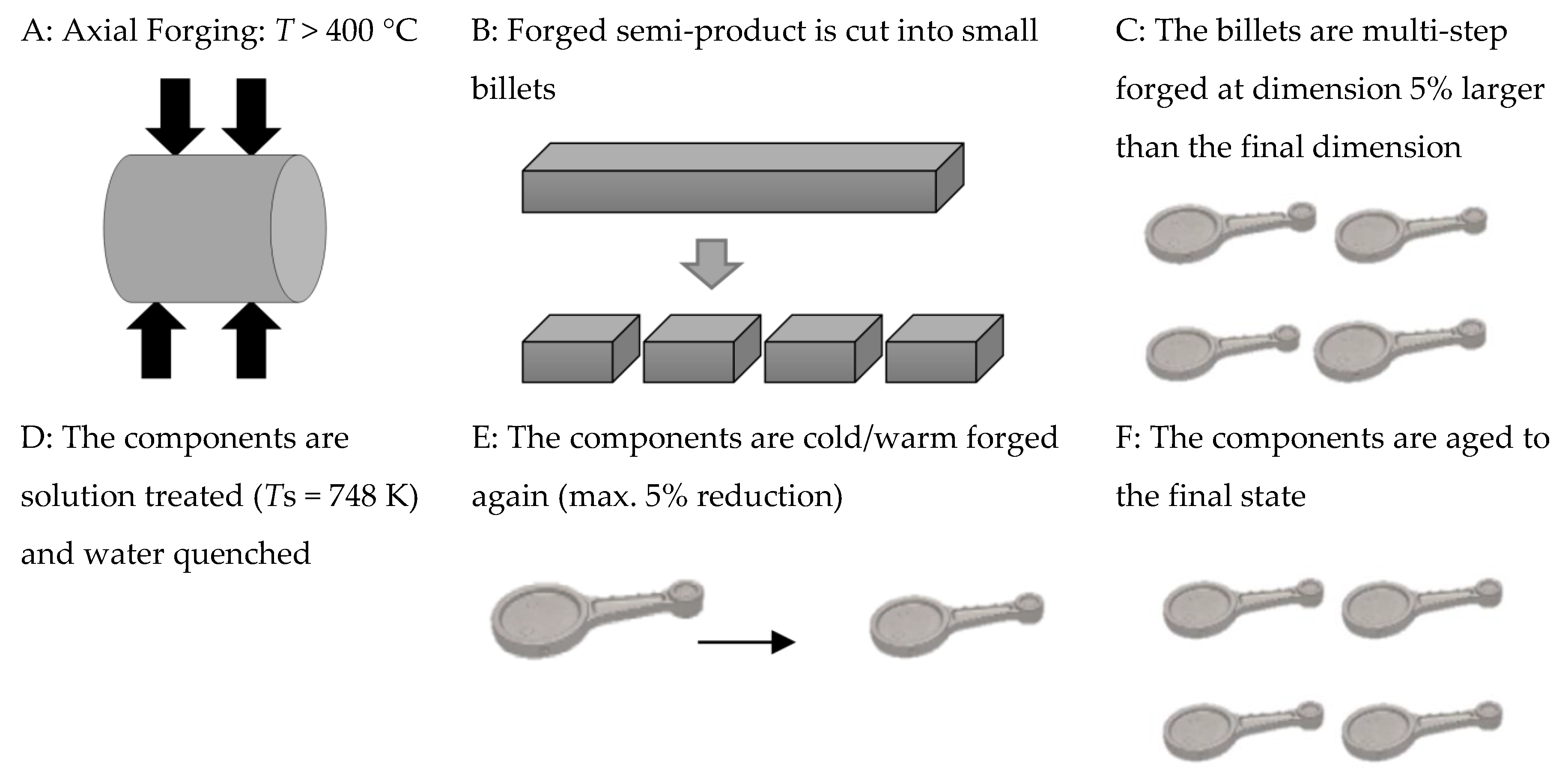

2. Materials and Methods

3. Results and Discussion

- the warm deformation temperature of 473 K resulted in the highest density of large particles with respect to the other two experimental conditions (increased density of large size precipitates in the matrix with a Feret-diameter between 10 and 50 nm, and large size precipitates at the sub-grain boundaries), suggesting a possible over-aging of the alloy during the final heat treatment (394 K for 5 h + 450 K for 8 h, fulfilling AMS2770N);

- the toughness KIC values increased, with a narrower dispersion range value with respect to the standard cycle value dispersion, see Figure 2. The more homogeneous and finer-grained structure obtained after warm deformation contributed to the increased fracture toughness.

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- American Society of Materials. ASM Handbook, Volume 2, Properties and Selection: Nonferrous Alloys and Special Purpose Materials; ASM International: Materials Park, OH, USA, 2005. [Google Scholar]

- Sauvage, X.; Lee, S.; Matsuda, K.; Horita, Z. Origin of the influence of Cu or Ag micro-additions on the age hardening behavior of ultrafine-grained Al-Mg-Si alloys. J. Alloy. Compd. 2017, 710, 199–202. [Google Scholar] [CrossRef]

- Mondolfo, L.F. Aluminum Alloys: Structure and Properties; Butterworth: London, UK, 1976; pp. 497–499. [Google Scholar]

- Wang, H.; Yi, Y.; Huang, S. Microstructure Evolution and Mechanical Properties of 2219 Al Alloy during Aging Treatment. J. Mater. Eng. Perform. 2017, 26, 1475–1482. [Google Scholar] [CrossRef]

- Alunni, A.; Cianetti, F.; Di Schino, A.; Nobili, F.; Richetta, M.; Testani, C. EFfect of microstructural parameters on the fatigue behavior for AA2014-T6 alloy. La Metall. Ital. 2017, 5, 25–31. [Google Scholar]

- Scott MacKenzie, D. Heat treating aluminum for aerospace applications. Heat Treat. Prog. 2005, 5, 37–43. [Google Scholar]

- Mott, N.F.; Nabarro, F.R.N. An attempt to estimate the degree of precipitation hardening, with a simple model. Proc. Phys. Soc. 1940, 52, 86–89. [Google Scholar] [CrossRef]

- Testani, C.; Ielpo, F.M.; Alunni, E. AA2618 and AA7075 alloys superplastic transition in isothermal hot-deformation tests. Mater. Des. 2001, 21, 305–310. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Liao, X.Z.; Jin, Z.; Valiev, R.Z.; Zhu, Y.T. Microstructures and mechanical properties of ultrafine grained 7075 Al alloy processed by ECAP and their evolutions during annealing. Acta Mater. 2004, 52, 4589–4599. [Google Scholar] [CrossRef]

- Garay–Reyes, C.G.; Gonzalez, L.; Cuadros-Lugo, E. Correlation between tool flank wear, force signals and surface integrity when turning bars of Inconel 718 in finishing conditions. Int. J. Adv. Manuf. Technol. 2017, 90, 3045–3053. [Google Scholar]

- Pan, L.; Liu, K.; Breton, F.; Chen, X. Effects of minor Cu and Mg additions on microstructure and material properties of 8xxx aluminum conductor alloys. J. Mater. Res. 2017, 32, 1094–1104. [Google Scholar] [CrossRef]

- Aerospace Structural Materials Handbook; DoD, Wright-Patterson Air Force Base: Dayton, OH, USA, 2001.

- Lu, F.; Zhao, F.; Zhang, J. Heat Treatment of metals. J. Iron Steel Res. 2017, 42, 144–149. [Google Scholar]

- Zhao, F.; Lu, F.; Guo, F. Comparative Analysis of Microstructures and Properties of Two Kinds of Thick Plates of 7050-T7451 Aluminum Alloy. J. Aeronaut. Mater. 2015, 35, 64–71. [Google Scholar]

- Kaibyshev, R.; Sitdikov, O.; Goloborodko, A. Grain refinement in as-cast 7475 aluminum alloy under hot deformation. Mater. Sci. Eng. A 2003, 344, 348–356. [Google Scholar] [CrossRef]

- Rokni, M.R.; Zarei-HAnzaki, A.; Roostaei, A.; Abedi, H.R. An investigation into the hot deformation characteristics of 7075 aluminum alloy. Mater. Des. 2011, 32, 2339–2344. [Google Scholar] [CrossRef]

- Li, D.; Zhang, D.; Liu, S.; Shan, Z.; Zhang, X.; Wang, Q.; Han, S. Dynamic recrystallization behavior of 7085 aluminum alloy during hot deformation. Trans. Nonferr. Met. Soc. China 2016, 26, 1491–1497. [Google Scholar] [CrossRef]

- Sanchez, J.M.; Rubio, E.; Alvarez, M.; Sebastian, M.A.; Marcos, M. Microstructural characterization of material adhered over cutting tool in the dry machining of aerospace aluminium alloys. J. Mater. Process. Technol. 2005, 164–165, 911–918. [Google Scholar] [CrossRef]

- Prasad, N.E.; Wanhill, R.J. Aerospace Materials and Material Technologies, Volume 1: Aerospace Materials; Springer: Singapore, 2017; pp. 29–52. [Google Scholar]

- Adam, K.F.; Long, Z.; Field, D.P. Analysis of Particle-Stimulated Nucleation (PSN)-Dominated Recrystallization for Hot-Rolled 7050 Aluminum Alloy. Metall. Mater. Trans. A 2017, 48, 2062–2076. [Google Scholar] [CrossRef]

- Maizza, G.; Pero, R.; Richetta, M.; Montanari, R. Continuous dynamic recrystallization (CDRX) model for aluminum alloys. J. Mater. Sci. 2018, 53, 4563–4573. [Google Scholar] [CrossRef]

- Parker, C.G.; Field, D.P. Observation of Structure Evolution during Annealing of 7xxx Series Al Deformed at High Temperature. In Light Metals 2012; Springer: Cham, Switzerland, 2012; pp. 383–386. [Google Scholar]

- Wang, S.; Luo, J.; Hou, L.; Zhang, J.; Zhuang, L. Physically based constitutive analysis and microstructural evolution of AA7050 aluminum alloy during hot compression. Mater. Des. 2016, 107, 277–289. [Google Scholar] [CrossRef]

- Angella, G.; Bassani, P.; Tuissi, A.; Vedani, M. Intermetallic particle evolution during ECAP processing of a 6082 alloy. Mater. Trans. 2004, 45, 2182–2186. [Google Scholar] [CrossRef]

- Angella, G.; Bassani, P.; Tuissi, A.; Ripamonti, D.; Vedani, M. Microstructure evolution and aging kinetics of Al-Mg-Si and Al-Mg-Si-Sc alloys processed by ECAP. Mater. Sci. Forum 2006, 503–504, 493–498. [Google Scholar] [CrossRef]

- Sabrof, A.M.; Boulger, F.W.; Henning, H.J.; Spretnak, F.W. A Manual on Fundamentals of Forging Practice; Battelle Memorial Institute: Columbus, OH, USA, 1971. [Google Scholar]

- Gourdet, S.; Montheillet, F. Effects of dynamic grain boundary migration during the hot compression of high stacking fault energy metals. Acta Mater. 2002, 50, 2801–2812. [Google Scholar] [CrossRef]

- McQueen, H.J. Development of dynamic recrystallization theory. Mater. Sci. Eng. A 2004, 387–389, 203–208. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Wyss, R.K. Method for Increasing the Strength of Aluminium Alloy Products through Warm Working. U.S. Patent US005194102A, 16 March 1993. [Google Scholar]

- Jarzebska, A.; Bogucki, R.; Bieda, M. Influence of degree of deformation and aging time on mechanical properties and microstructure of aluminium alloy with zinc. Arch. Metall. Mater. 2015, 60, 215–221. [Google Scholar] [CrossRef]

- De Hass, M.; De Hosson, J.T.M. Grain Boundary segregation and precipitation in aluminium alloys. Scr. Mater. 2001, 44, 281–286. [Google Scholar] [CrossRef]

- Ber, L.B. Accelerated artificial regimes of commercial aluminium alloys II: Al-Cu, Al-Zn-Mg-(Cu), Al-Mg-Si-(CU) alloys. Mater. Sci. Eng. A 2000, 280, 91–96. [Google Scholar] [CrossRef]

- Lang, Y.; Cui, H.; Cai, Y.; Zhang, J. Evolution of nanometer precipitates in AA7050 alloy subjected to overaging treatment and warm deformation. In Proceedings of the 13th International Conference on Aluminum Alloys (ICAA13), Pittsburgh, PA, USA, 3–7 June 2012; Weiland, H., Rollett, A.D., Cassada, W.A., Eds.; Springer: Cham, Switzerland, 2012; pp. 1223–1226. [Google Scholar]

- Zuo, J.; Hou, L.; Shi, J.; Cui, H.; Zhuang, L.; Zhang, J. Effect of deformation induced precipitation on grain refinement and improvement of mechanical properties AA 7055 aluminium alloy. Mater. Charact. 2017, 130, 123–134. [Google Scholar] [CrossRef]

- Standard AMS 2770N “Heat Treatment of Wrought Aluminium Alloy Parts”; SAE Aerospace: Warrendale, PA, USA, 2015.

- Voncina, M.; Medved, J.; Mrvar, P. Energy of precipitation of Al2Cu and a-AlFeSi phase from the AlCu3 alloy and the shape of precipitates. Metalurgija 2009, 48, 9–13. [Google Scholar]

- Mandal, P.K. Study on hardening mechanisms in aluminium alloys. Int. J. Eng. Res. Appl. 2016, 6, 91–97. [Google Scholar]

- Paton, N.E.; Sommer, A.W. Proceedings of 3rd International Conference on Strength of Metals and Alloys; Metals Society: London, UK, 1973; Volume 1. [Google Scholar]

- Polmear, I.J. Light Alloys, 3rd ed.; Arnold Ed: London, UK, 1995. [Google Scholar]

- Dumont, D.; Deschamps, A.; Brechet, Y. On the relationship between microstructure, strength and toughness in AA7050 aluminium alloy. Mater. Sci. Eng. A 2003, 356, 326–336. [Google Scholar] [CrossRef]

- Astarita, A.; Testani, C.; Scherillo, F.; Squillace, A.; Carrino, L. Beta Forging of a Ti6Al4V Component for Aeronautic Applications: Microstructure Evolution. Metallogr. Microstruct. Anal. 2014, 3, 460–467. [Google Scholar] [CrossRef]

| Elements | Al | Zr | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti |

|---|---|---|---|---|---|---|---|---|---|---|

| wt (%) | Bal. | 0.12 | <0.12 | <0.15 | 2.30 | <0.10 | 2.20 | <0.04 | 6.25 | <0.05 |

| Standard Industrial Hot-Forging Cycle (According to AMS2770N) | Modified Industrial Hot Forging Cycle |

|---|---|

| Total section area reduction: 75% | Total section area reduction: 75% |

| Solution treatment (Ts = 748 K) Soaking time: 5 h | Solution treatment (Ts = 748 K) Soaking time: 5 h (fulfills AMS2770N) |

| Water quenching | Water quenching (fulfills AMS2770N) |

| Room temperature up-setting: 5% max | 423 K and 473 K up-setting: 5% max each T (does not fulfill AMS2770N) |

| Ageing in two steps: 394 K for 5 h + 450 K for 8 h | Ageing in two steps: 394 K for 5 h + 450 K for 8 h, (fulfills AMS2770N) |

| Grain Boundary Misorientation Angle (°) | Map A1 | Map A2 | Map A3 | |||

|---|---|---|---|---|---|---|

| dwa (μm) | st. dev. | dwa (μm) | st. dev. | dwa (μm) | st. dev. | |

| 1 | 7.2 | 0.8 | 4.9 | 0.5 | 4.2 | 0.4 |

| 3 | 8.4 | 0.5 | 7.7 | 0.4 | 6.8 | 0.5 |

| 5 | 9.4 | 0.6 | 9.7 | 0.3 | 7.1 | 0.7 |

| Sample | PR50 | PR200 |

|---|---|---|

| Sample A1 (T = 293 K) | 1.00 | 1.00 |

| Sample A2 (T = 423 K) | 1.59 | 3.67 |

| Sample A3 (T = 473 K) | 2.06 | 4.96 |

| Spectrum Label | Al | Mg | Cu | Zn | O | Fe | Ni |

|---|---|---|---|---|---|---|---|

| 7 | 28.3 | 21.4 | 43.5 | 2.7 | 4.2 | - | - |

| 8 | 50.2 | - | 33.4 | 1.4 | - | 13.4 | 1.5 |

| 9 | 62.8 | 12.1 | 18.9 | 3.1 | 2.7 | - | - |

| 10 | 61.2 | 16.0 | 19.6 | 3.3 | - | - | - |

| 11 | 86.9 | 4.2 | 2.1 | 6.9 | - | - | - |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Angella, G.; Di Schino, A.; Donnini, R.; Richetta, M.; Testani, C.; Varone, A. AA7050 Al Alloy Hot-Forging Process for Improved Fracture Toughness Properties. Metals 2019, 9, 64. https://doi.org/10.3390/met9010064

Angella G, Di Schino A, Donnini R, Richetta M, Testani C, Varone A. AA7050 Al Alloy Hot-Forging Process for Improved Fracture Toughness Properties. Metals. 2019; 9(1):64. https://doi.org/10.3390/met9010064

Chicago/Turabian StyleAngella, Giuliano, Andrea Di Schino, Riccardo Donnini, Maria Richetta, Claudio Testani, and Alessandra Varone. 2019. "AA7050 Al Alloy Hot-Forging Process for Improved Fracture Toughness Properties" Metals 9, no. 1: 64. https://doi.org/10.3390/met9010064

APA StyleAngella, G., Di Schino, A., Donnini, R., Richetta, M., Testani, C., & Varone, A. (2019). AA7050 Al Alloy Hot-Forging Process for Improved Fracture Toughness Properties. Metals, 9(1), 64. https://doi.org/10.3390/met9010064