Effects of Platform Pre-Heating and Thermal-Treatment Strategies on Properties of AlSi10Mg Alloy Processed by Selective Laser Melting

Abstract

:1. Introduction

2. Materials and Methods

3. Results

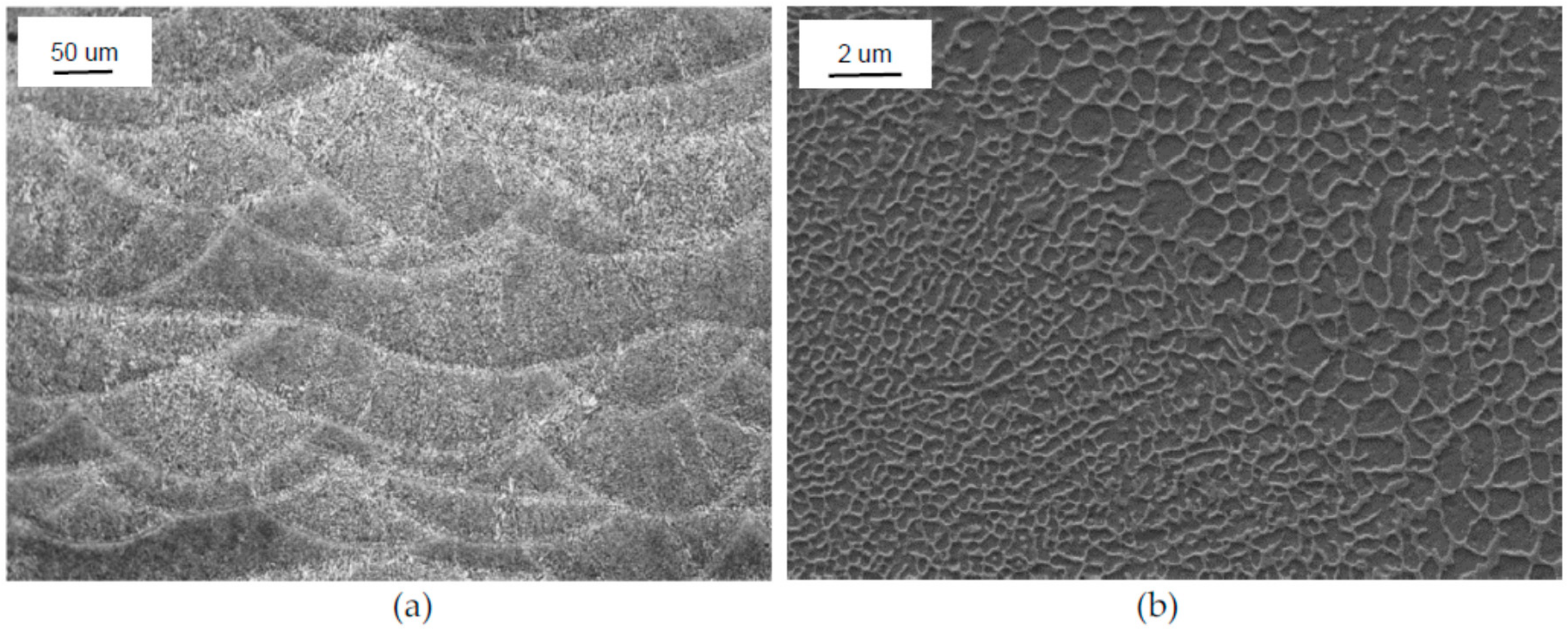

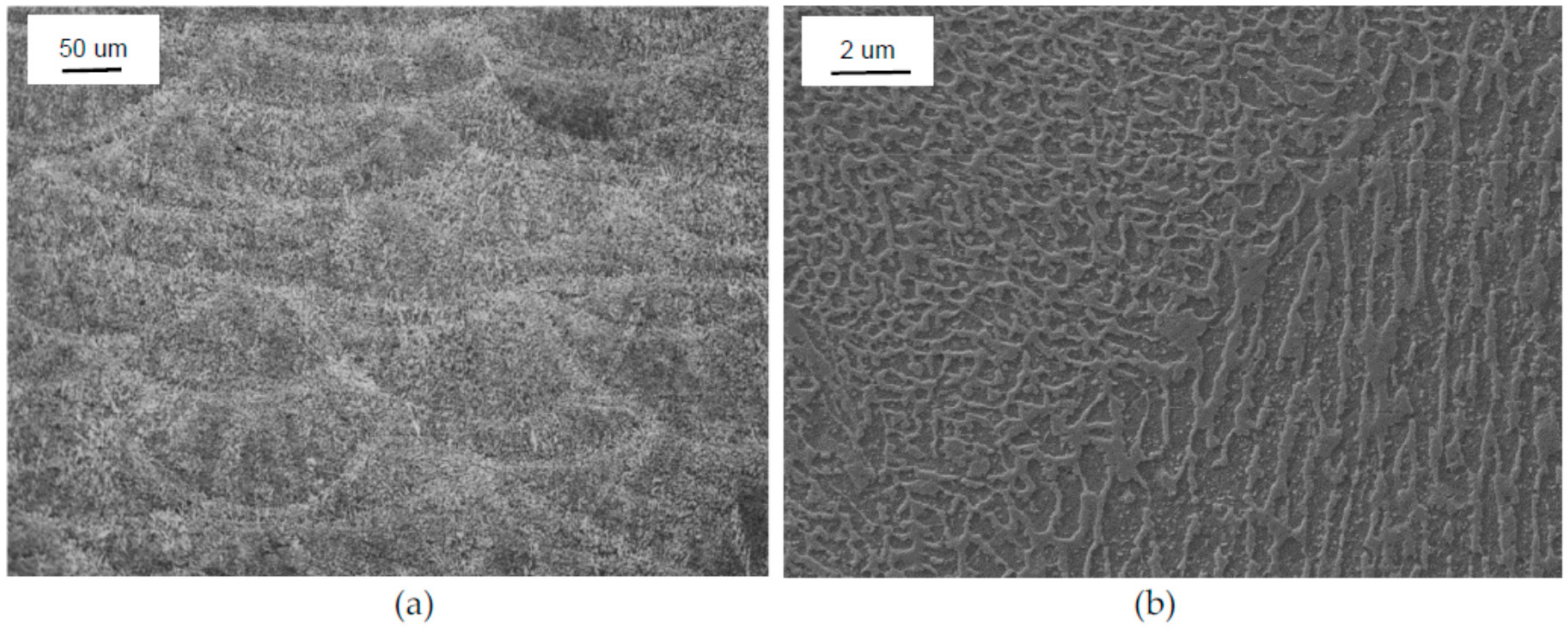

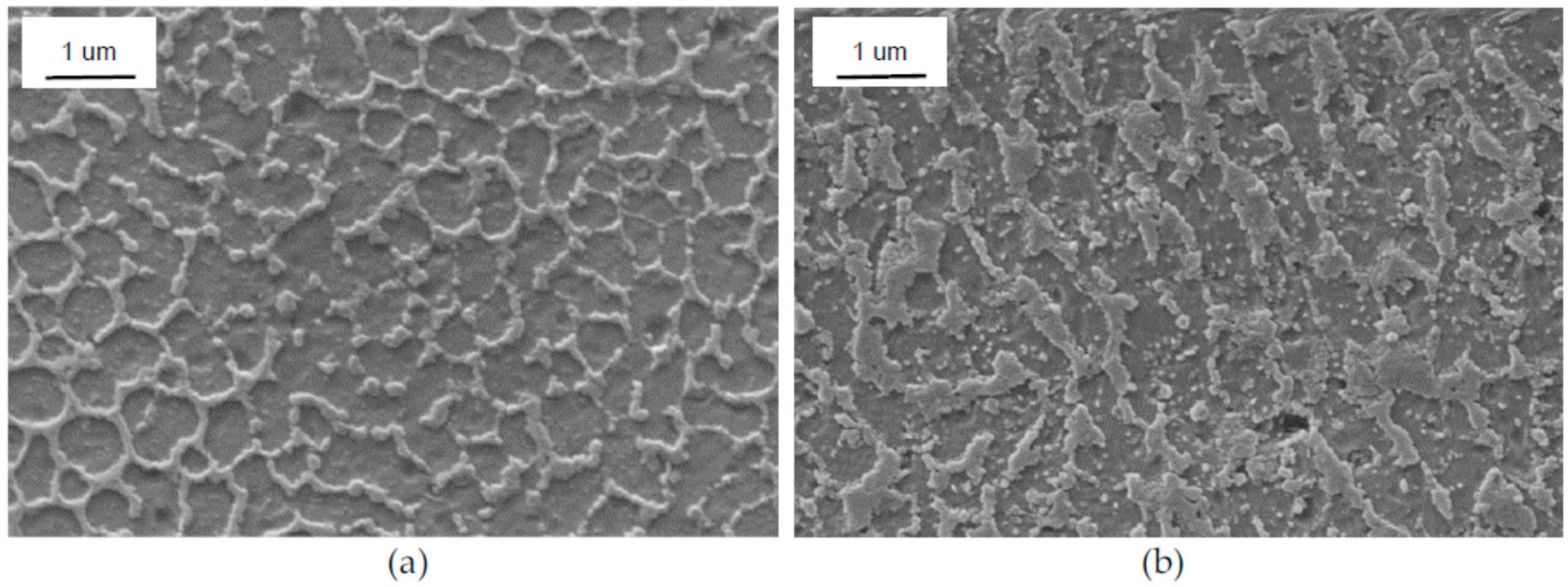

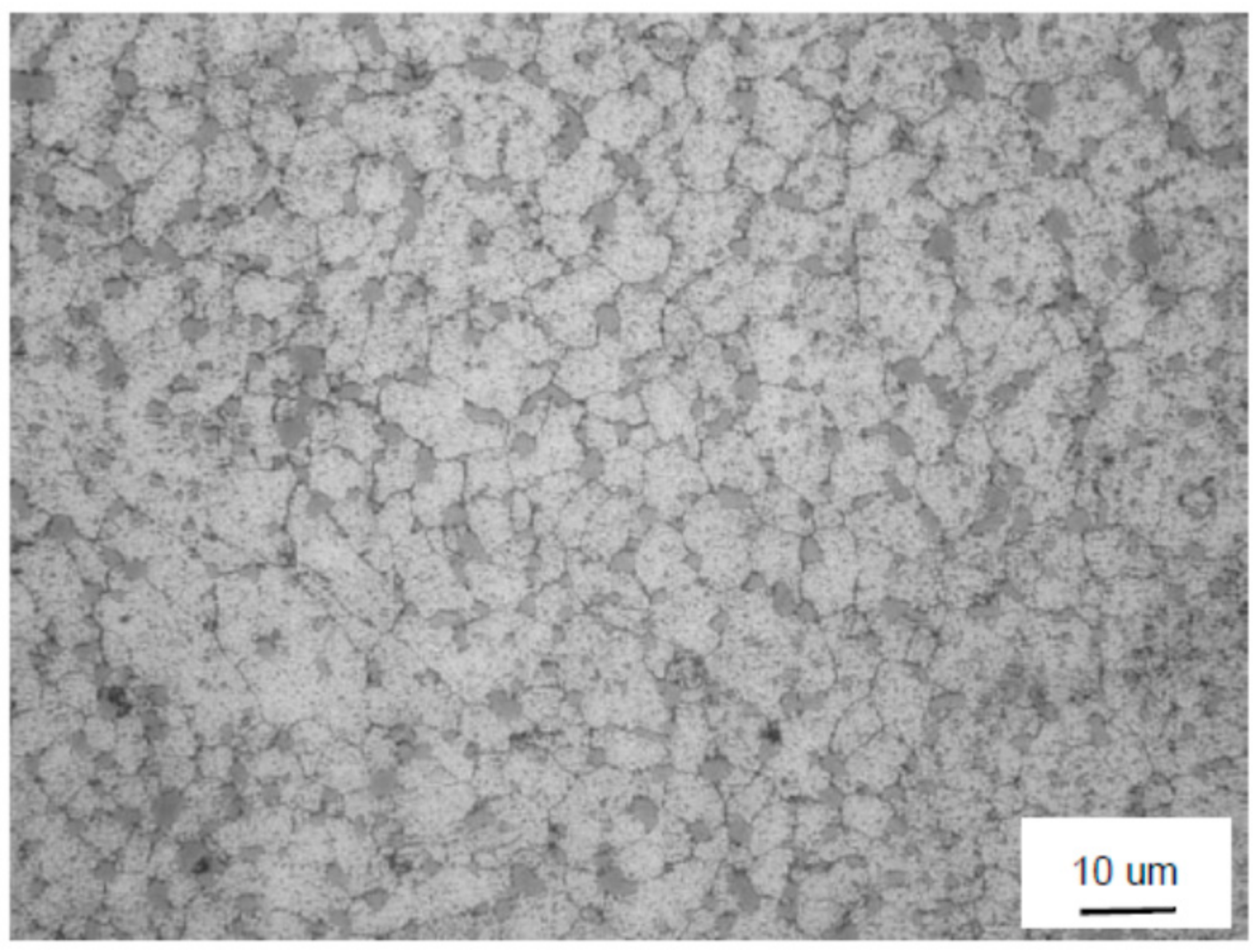

3.1. Microstructure

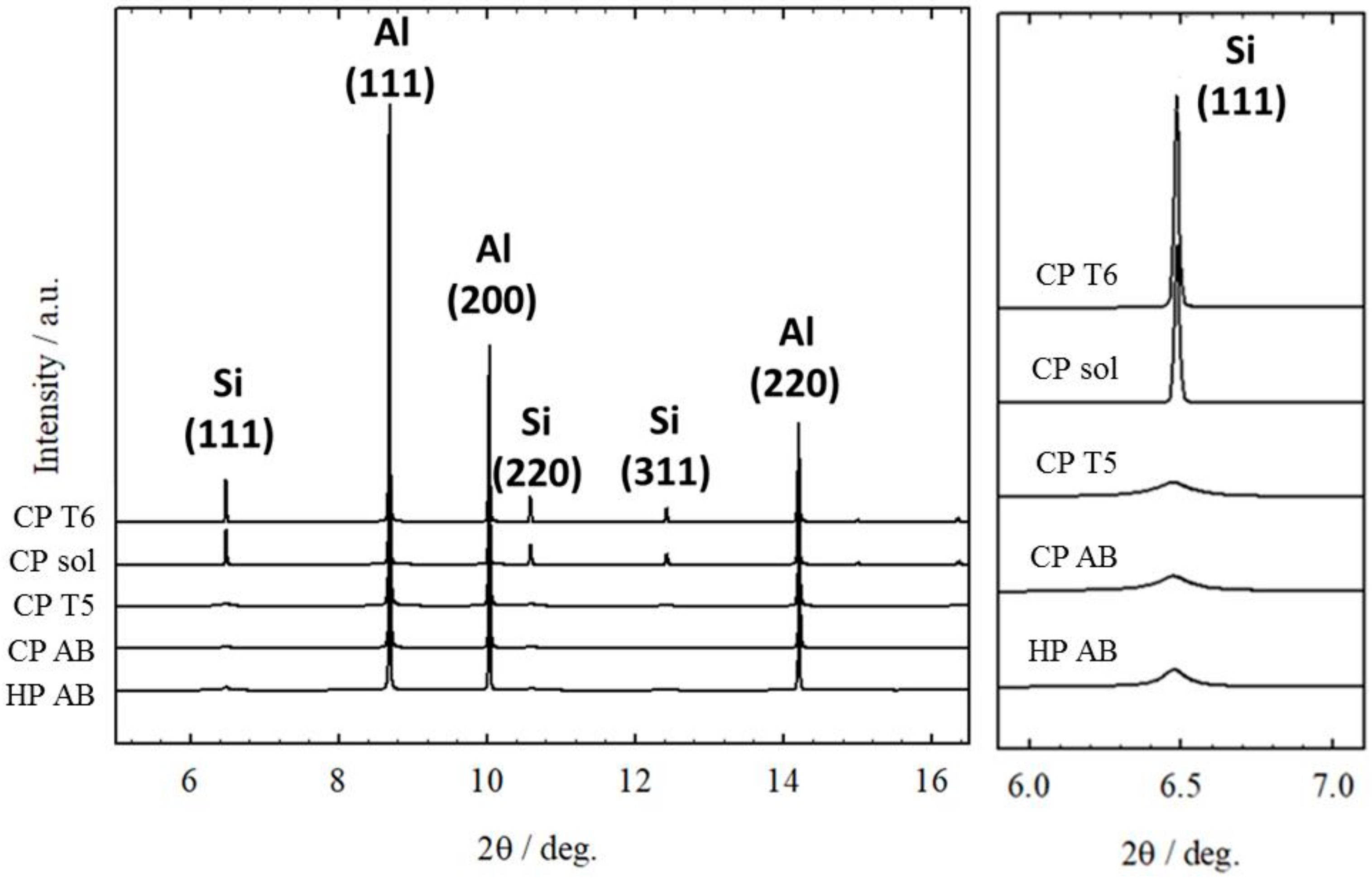

3.2. X-ray Diffraction

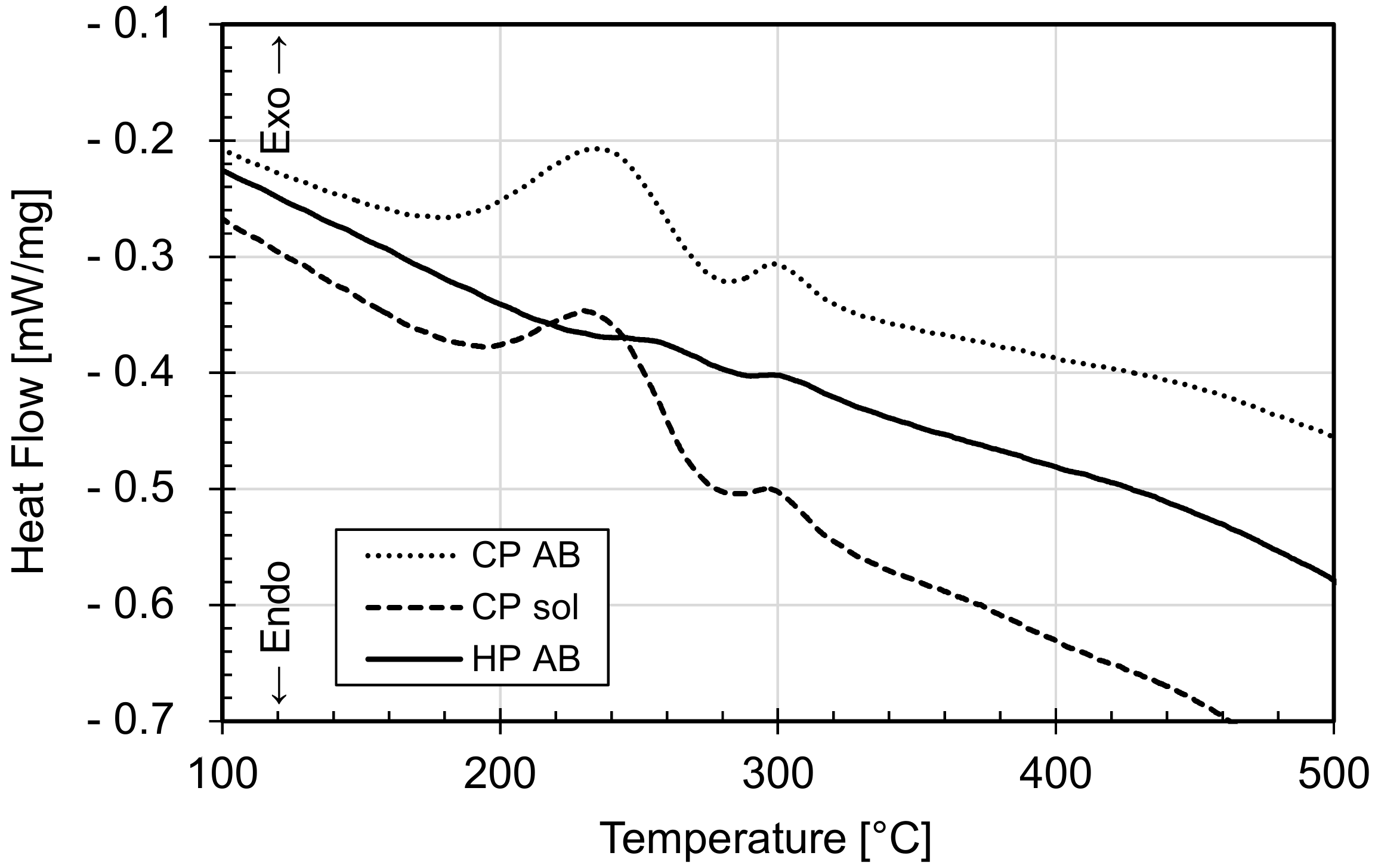

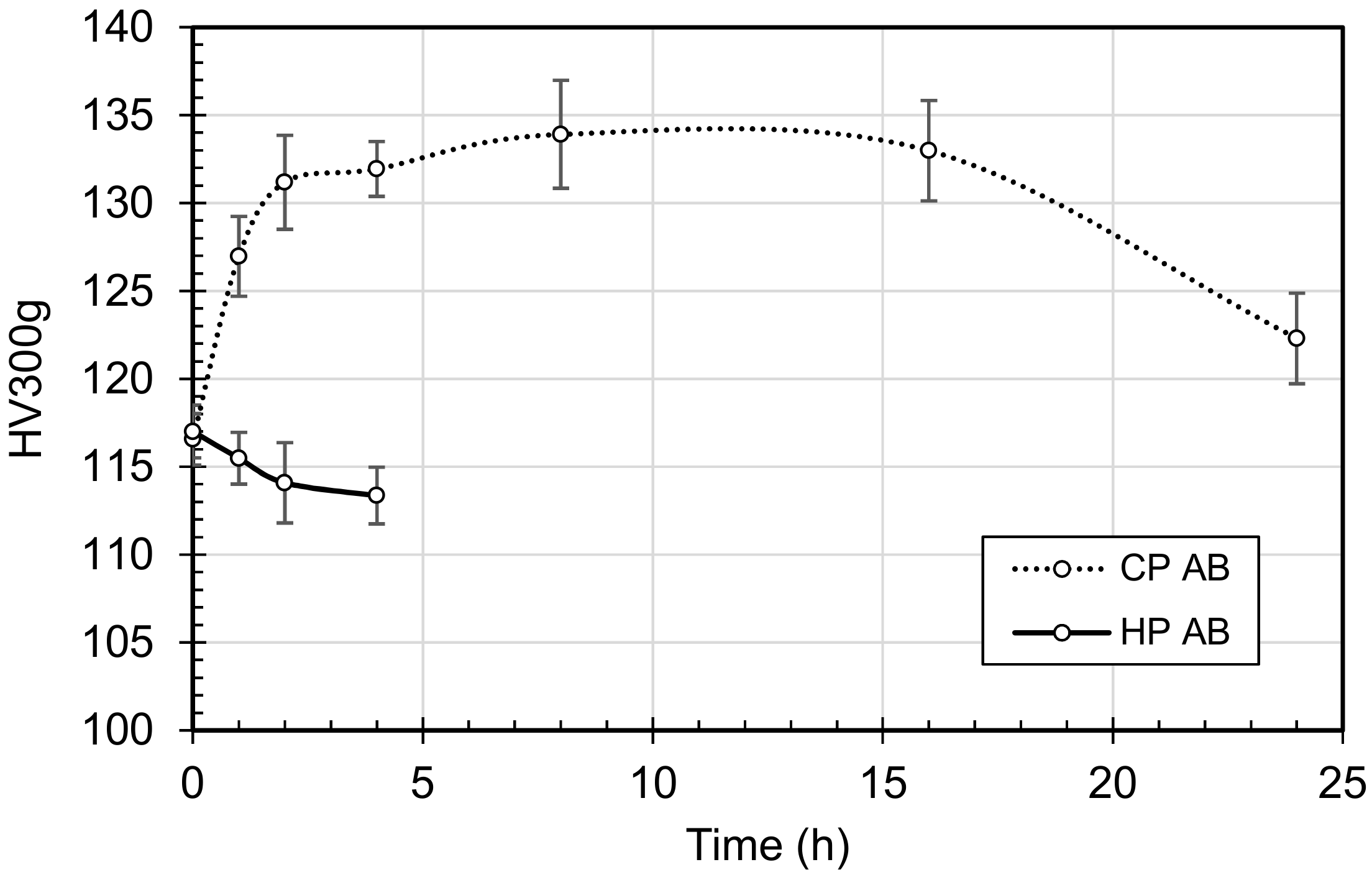

3.3. Thermal Analysis and Aging Curves

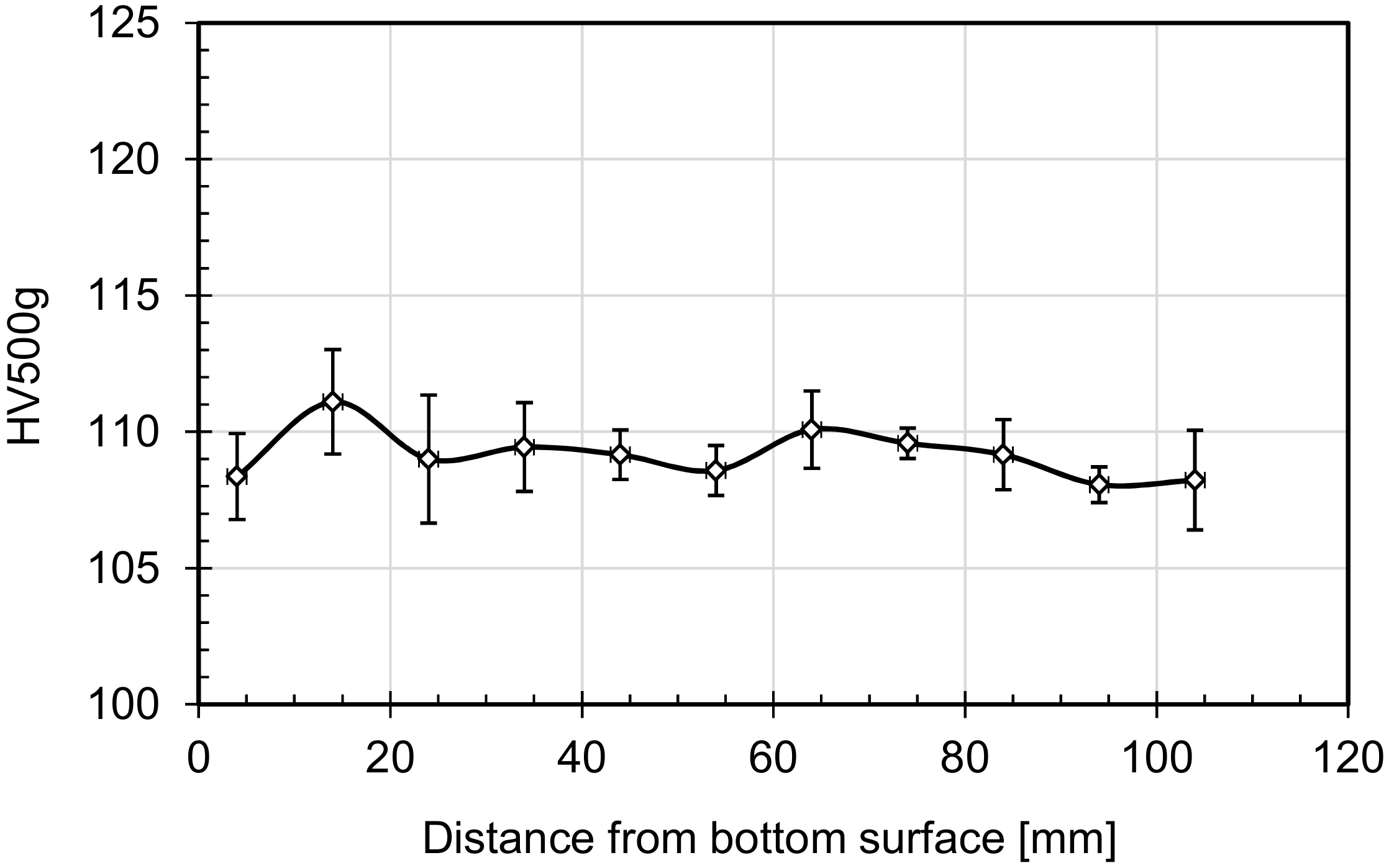

3.4. Mechanical Properties

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2018, 61, 1–46. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuiback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Bradl, E.; Heckenberger, U.; Holzinger, V.; Buchbinder, D. Additive manufactured AlSi10Mg samples using selective laser melting: Microstructure, high cycle fatigue, and fracture behavior. Mater. Des. 2012, 34, 159–169. [Google Scholar] [CrossRef]

- Thijs, L.; Kempen, K.; Kruth, J.-P.; Van Humbeeck, J. Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powder. Acta Mater. 2013, 61, 1800–1819. [Google Scholar] [CrossRef] [Green Version]

- Kimura, T.; Nakamoto, T. Microstructures and mechanical properties of A357 (AlSi7Mg0,3) aluminium alloy fabricated by selective laser melting. Mater. Des. 2016, 89, 1294–1301. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, H.; Qi, T.; Hu, Z.; Zeng, X. Selective laser melting of high strength Al-Cu-Mg alloys: Processing microstructure and mechanical properties. Mater. Sci. Eng. A 2016, 656, 47–54. [Google Scholar] [CrossRef]

- Montero Sistiaga, M.L.; Mertens, R.; Vrancken, B.; Wang, X.; Van Hooreweder, B.; Kruth, J.P.; Van Humbeeck, J. Changing the alloy composition of Al7075 for better processability by selective laser melting. J. Mater. Proc. Technol. 2016, 238, 437–445. [Google Scholar] [CrossRef]

- Rosenthal, I.; Stern, A.; Frage, N. Strain rate sensitivity and fracture mechanism of AlSi10Mg parts produced by selective laser melting. Mater. Sci. Eng. A 2017, 682, 509–517. [Google Scholar] [CrossRef]

- Fousová, M.; Dvorsky, D.; Michalková, A.; Vojtěch, D. Changes in microstructure and mechanical properties of additively manufactured AlSi10Mg alloy after exposure to elevated temperatures. Mater. Charact. 2018, 137, 119–126. [Google Scholar] [CrossRef]

- Rosenthal, I.; Schneck, R.; Stern, A. Heat treatment effect on the mechanical properties and fracture mechanism in AlSi10Mg fabricated by additive manufacturing selective laser melting. Mater. Sci. Eng. A 2018, 729, 310–322. [Google Scholar] [CrossRef]

- Zang, C.; Zhu, H.; Liao, H.; Cheng, Y.; Hu, Z.; Zeng, X. Effect of heat treatment on fatigue property of selective laser melting AlSi10Mg. Int. J. Fatigue 2018, 116, 513–522. [Google Scholar] [CrossRef]

- Fiocchi, J.; Tuissi, A.; Bassani, P.; Biffi, C.A. Low temperature annealing dedicated to AlSI10Mg selective laser melting products. J. Alloys Compd. 2017, 695, 3402–3409. [Google Scholar] [CrossRef]

- Li, W.; Li, S.; Liu, J.; Zhang, A.; Zhou, Y.; Wei, Q.; Yan, C.; Shi, Y. Effect of heat treatment on AlSi10Mg alloy fabricated by selective laser melting: Microstructure evolution, mechanical properties and fracture behaviour. Mater. Sci. Eng. A 2016, 663, 116–125. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Tuck, C.; Ashcroft, I.; Everitt, N.M. On the precipitation hardening of selective laser melted AlSi10Mg. Metall. Mater. Trans. 2015, 46A, 3337–3341. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Maskery, I.; Tuck, C.; Ashcroft, I.; Everitt, N.M. The microstructure and mechanical properties of selectively laser melted AlSi10Mg: The effect of a conventional T6-like heat treatment. Mater. Sci. Eng. A 2016, 667, 139–146. [Google Scholar] [CrossRef] [Green Version]

- Tradowski, U.; White, J.; Ward, R.M.; Reimers, W.; Attallah, M.M. Selective laser melting of AlSi10Mg: Influence of post-processing on the microstructural and tensile properties development. Mater. Des. 2016, 105, 217–222. [Google Scholar] [CrossRef]

- Wang, L.F.; Sun, J.; Yu, X.L.; Shi, Y.; Zhu, X.G.; Cheng, L.Y.; Liang, H.H.; Yan, B.; Guo, L.J. Enhancement in mechanical properties of selectively laser melted AlSi10Mg aluminium alloys by T6-like heat treatment. Mater. Sci. Eng. A 2018, 734, 299–310. [Google Scholar] [CrossRef]

- Casati, R.; Vedani, M. Aging response of an A357 Al alloy processed by selective laser melting. Adv. Eng. Mater. 2018, 1–7. [Google Scholar] [CrossRef]

- Yang, K.V.; Rometsch, P.; Davies, C.H.J.; Huang, A.; Wu, X. Effect of heat treatment on the microstructure and anisotropy in mechanical properties of A357 alloy produced by selective laser melting. Mater. Des. 2018, 154, 275–290. [Google Scholar] [CrossRef]

- Tang, M.; Pistorius, P.C. Oxides, porosity and fatigue performance of AlSi10Mg parts produced by selective laser melting. Int. J. Fatigue 2017, 94, 192–201. [Google Scholar] [CrossRef]

- Maamoun, A.H.; Elbestawl, M.; Dosbaeva, G.K.; Veldhuis, S.C. Thermal post-processing of AlSi10Mg parts produced by selective laser melting using recycled powder. Addit. Manuf. 2018, 21, 234–247. [Google Scholar] [CrossRef]

- Chen, W.C.; Lee, S.L.; Tan, A.H. Effect of Pre-Ageing on the precipitation behaviors and mechanical properties of Al-7Si-Mg Alloys. J. Mater. Sci. Chem. Eng. 2018, 6, 55–67. [Google Scholar] [CrossRef]

- Edward, G.A.; Stiller, K.; Dunlop, G.L.; Couper, M.J. The precipitation sequence in Al-Mg-Si alloys. Acta Mater. 1998, 46, 3893–3904. [Google Scholar] [CrossRef]

- Tadeka, M.; Ohkubo, F.; Shirai, T.; Fukui, K. Stability of metastable phases and microstructures in the ageing process of Al-Mg-Si ternary alloys. J. Mater. Sci. 1998, 33, 2385–2390. [Google Scholar]

- Marola, S.; Manfredi, D.; Fiore, G.; Poletti, M.G.; Lombardi, M.; Fino, P.; Battezzati, L. A comparison of Selective Laser Melting with bulk rapid solidification of AlSi10Mg alloy. J. Alloys Compd. 2018, 742, 271–279. [Google Scholar] [CrossRef]

- Brandão, A.D.; Gumpinger, J.; Gschweitl, M.; Seyfert, C.; Hofbauer, P.; Ghidini, T. Fatigue properties of additively manufactured AlSi10Mg—Surface treatment effects. Proc. Struct. Int. 2017, 7, 58–66. [Google Scholar] [CrossRef]

- Shi, Y.; Yang, K.V.; Kairy, S.K.; Palm, F.; Wu, X.; Rometsch, P.A. Effect of platform temperature on the porosity, microstructure and mechanical properties of an Al-Mg-Sc-Zr alloy fabricated by selective laser Melting. Mater. Sci. Eng. A 2018, 732, 41–52. [Google Scholar] [CrossRef]

- Yang, K.V.; Shi, Y.; Palm, F.; Wu, X.; Rometsch, P. Columnar to equiaxed transition in Al-Mg(-Sc)-Zr alloys produced by selective laser melting. Scripta Mater. 2018, 145, 113–117. [Google Scholar] [CrossRef]

- Williamson, G.K.; Hall, W.H. X-ray line broadening from filed aluminium and wolfram. Acta Metall. 1953, 1, 22–31. [Google Scholar] [CrossRef]

- Jägle, E.A.; Sheng, Z.; Wu, L.; Lu, L.; Kisse, J.; Weisheit, A.; Raabe, D. Precipitation reactions in age-hardenable alloys during laser additive manufacturing. JOM 2016, 68, 943–949. [Google Scholar] [CrossRef]

- Casati, R.; Lemke, J.N.; Zanatta Alarcon, A.; Vedani, M. Aging behavior of high-strength Al Alloy 2618 produced by selective laser melting. Metall. Mater. Trans. A 2017, 48A, 575–579. [Google Scholar] [CrossRef]

- Casati, R.; Lemke, J.N.; Tuissi, A.; Vedani, M. Aging behaviour and mechanical performance of 18-Ni 300 steel processed by selective laser melting. Metals 2016, 6, 218. [Google Scholar] [CrossRef] [Green Version]

- Li, C.; Liu, Z.Y.; Fang, X.Y.; Guo, Y.B. Residual stresses in metal additive manufacturing. Procedia CIRP. 2018, 71, 348–353. [Google Scholar] [CrossRef]

- Mukherjee, T.; Zhang, W.; DebRoy, T. An improved prediction of residual stresses and distortion in additive manufacturing. Comput. Mater. Sci. 2017, 126, 360–372. [Google Scholar] [CrossRef]

- Bartlett, J.L.; Croom, B.P.; Burdick, J.; Henkel, D.; Li, X. Revealing mechanisms of residual stress development in additive manufacturing via digital image correlation. Addit. Manuf. 2018, 22, 1–12. [Google Scholar] [CrossRef]

| Sample Code | Power (W) | Hatch Distance (mm) | Scan Rate (mm/s) | Layer Thickness (mm) | Platform Temperature (°C) |

|---|---|---|---|---|---|

| CP | 340 | 0.2 | 1300 | 0.03 | RT |

| HP | 160 |

| Sample Code | Platform Temperature | Solution Treatment | Aging |

|---|---|---|---|

| CP AB | RT | None | None |

| CP T5 | RT | None | 160 °C 4 h |

| CP sol | RT | 540 °C 1 h, w.q. | None |

| CP T6 | RT | 540 °C 1 h, w.q. | 160 °C 4 h |

| HP AB | 160 °C | None | None |

| Sample Code | Lattice Parameters (nm) | Si Phase (wt %) | Size Range of Si Crystallites | |

|---|---|---|---|---|

| α-Al | Si | |||

| CP AB | 0.404833 | 0.54361 | 8.77 (0.05) | 8 nm |

| CP T5 | 0.405011 | 0.54386 | 10.03 (0.05) | 8 nm |

| CP sol | 0.405182 | 0.54276 | 10.16 (0.03) | micrometric |

| CP T6 | 0.405155 | 0.54286 | 10.23 (0.03) | micrometric |

| HP AB | 0.405079 | 0.54333 | 10.21 (0.05) | 15 nm |

| Sample Code | Sample Orientation | UTS (N/mm2) | 0.2 YS (N/mm2) | Strain at Fracture (%) |

|---|---|---|---|---|

| CP T5 | horizontal | 471 (0.8) | 321 (1.8) | 8.6 (0.5) |

| vertical | 493 (0.6) | 292 (0.6) | 6.0 (0.6) | |

| CP T6 | horizontal | 323 (0.0) | 243 (0.0) | 15.3 (2.4) |

| vertical | 302 (1.4) | 223 (2.8) | 16.0 (2.5) | |

| HP AB | horizontal | 386 (2.6) | 248 (1.7) | 8.6 (1.4) |

| vertical | 412 (5.5) | 228 (4.1) | 7.0 (0.1) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Casati, R.; Hamidi Nasab, M.; Coduri, M.; Tirelli, V.; Vedani, M. Effects of Platform Pre-Heating and Thermal-Treatment Strategies on Properties of AlSi10Mg Alloy Processed by Selective Laser Melting. Metals 2018, 8, 954. https://doi.org/10.3390/met8110954

Casati R, Hamidi Nasab M, Coduri M, Tirelli V, Vedani M. Effects of Platform Pre-Heating and Thermal-Treatment Strategies on Properties of AlSi10Mg Alloy Processed by Selective Laser Melting. Metals. 2018; 8(11):954. https://doi.org/10.3390/met8110954

Chicago/Turabian StyleCasati, Riccardo, Milad Hamidi Nasab, Mauro Coduri, Valeria Tirelli, and Maurizio Vedani. 2018. "Effects of Platform Pre-Heating and Thermal-Treatment Strategies on Properties of AlSi10Mg Alloy Processed by Selective Laser Melting" Metals 8, no. 11: 954. https://doi.org/10.3390/met8110954

APA StyleCasati, R., Hamidi Nasab, M., Coduri, M., Tirelli, V., & Vedani, M. (2018). Effects of Platform Pre-Heating and Thermal-Treatment Strategies on Properties of AlSi10Mg Alloy Processed by Selective Laser Melting. Metals, 8(11), 954. https://doi.org/10.3390/met8110954