Springback Estimation in the Hydroforming Process of UNS A92024-T3 Aluminum Alloy by FEM Simulations

Abstract

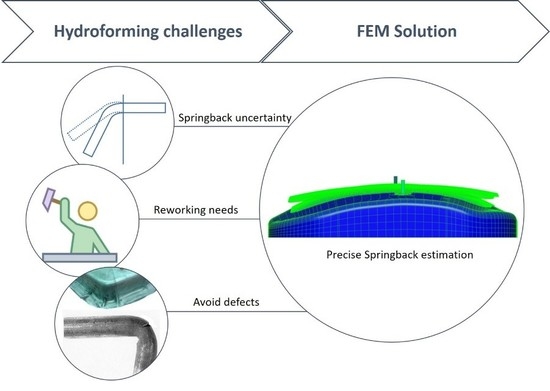

:1. Introduction

1.1. Anisotropic Plasticity Criteria

1.2. Hardening Law

1.3. Objective

2. Materials and Methods

2.1. Material Properties and Experimental Characterization Tests

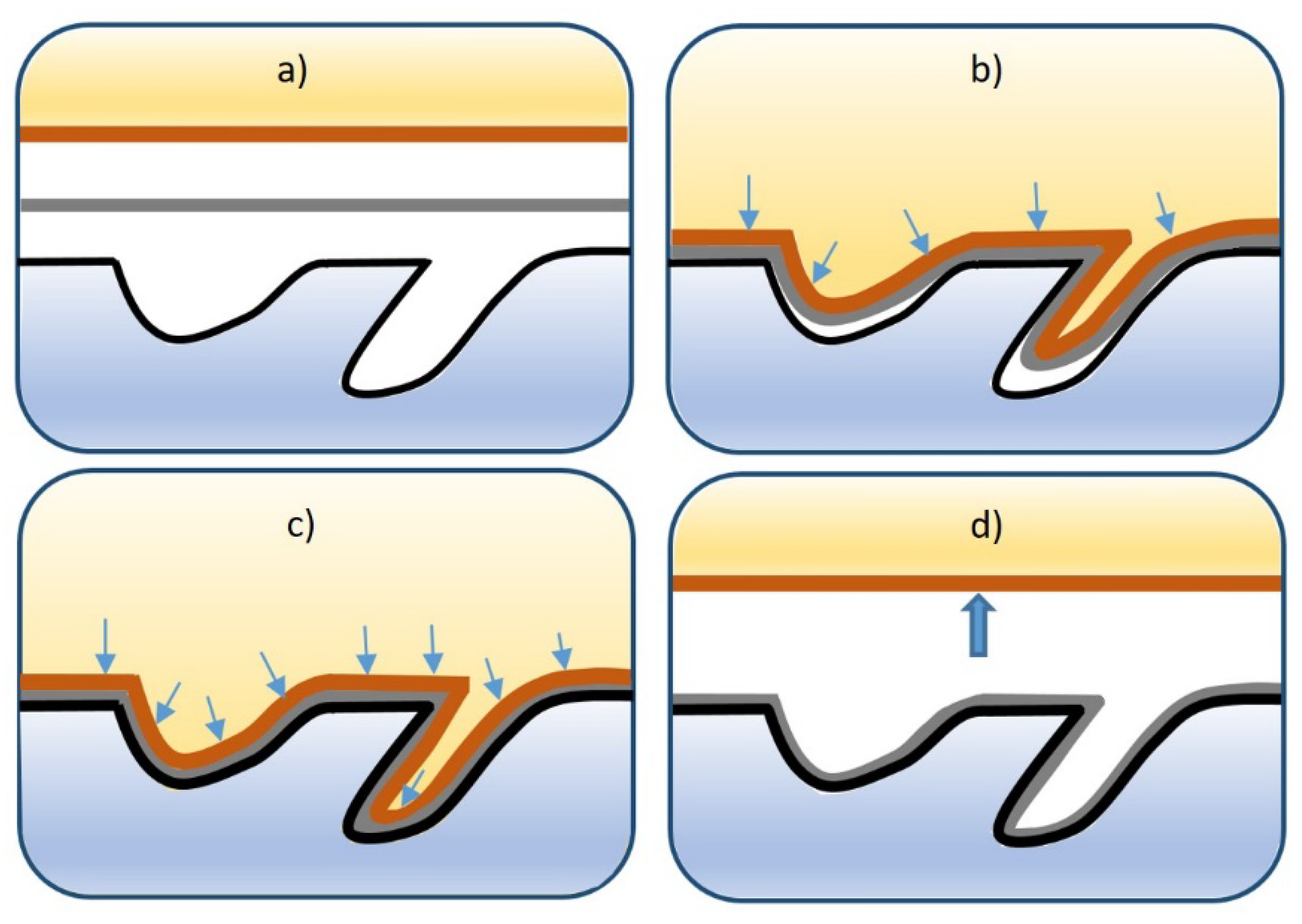

2.2. Experimental Hydroforming and Geometry Measurement

2.3. Simulation

3. Results and Discussion

3.1. Influence of Material Properties

3.2. Influence of the Rolling Direction

3.3. Influence of the Hardening Model

3.4. Validation of the Model

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Sala, G. A numerical and experimental approach to optimise sheet stamping technologies: Part II—Aluminium alloys rubber-forming. Mater. Des. 2000, 22, 299–315. [Google Scholar] [CrossRef]

- Chen, L.; Chen, H.; Guo, W.; Chen, G.; Wang, Q. Experimental and simulation studies of springback in rubber forming using aluminium sheet straight flanging process. Mater. Des. 2014, 54, 354–360. [Google Scholar] [CrossRef]

- Sinke, J. Spring back of Curved Flanges of Rubber Formed Aluminium parts. Key Eng. Mater. 2013, 554–557, 1851–1855. [Google Scholar] [CrossRef]

- Asnafi, N. On stretch and shrink flanging of sheet aluminium by fluid forming. Mater. Process. Technol. 1999, 96, 198–214. [Google Scholar] [CrossRef]

- Chen, L.; Chen, H.; Wang, Q.; Li, Z. Studies on wrinkling and control method in rubber forming using aluminium sheet shrink flanging process. Mater. Des. 2015, 65, 505–510. [Google Scholar] [CrossRef]

- Paunoiu, V.; Teodor, V.; Susac, F. Researches regarding the hydroforming process of aluminum components. Mod. Technol. Ind. Eng. 2015, 95, 1–6. [Google Scholar] [CrossRef]

- Belhassen, L.; Koubaa, S.; Wali, M.; Dammak, F. Numerical prediction of springback and ductile damage in rubber-pad forming process of aluminum sheet metal. Int. J. Mech. Sci. 2016, 117, 218–226. [Google Scholar] [CrossRef]

- Gomes, T.; Silva, F.J.G.; Campilho, R.D.G.S. Reducing the simulation cost on dual-phase steel stamping process. Procedia Manuf. 2017, 11, 474–481. [Google Scholar] [CrossRef]

- Neto, D.M.; Coër, J.; Oliveira, M.C.; Alves, J.L.; Manach, P.Y.; Menezes, L.F. Numerical analysis on the elastic deformation of the tools in sheet metal forming processes. Int. J. Solids Struct. 2016, 100–101, 270–285. [Google Scholar] [CrossRef]

- Firat, M. Computer aided analysis and design of sheet metal forming processes: Part III: Stamping die-face design. Mater. Des. 2007, 28, 1311–1320. [Google Scholar] [CrossRef]

- Kim, M.; Bang, S.; Lee, H.; Kim, N.; Kim, D. Enhancement of dimple formability in sheet metals by 2-step forming. Mater. Des. 2014, 54, 121–129. [Google Scholar] [CrossRef]

- Banabic, D. Phenomenological Constitutive Models Parameters Optimization. In Advanced Methods in Material Forming; Springer: Berlin/Heidelberg, Germany, 2007; p. 39. [Google Scholar]

- Hill, R. A theory of the yielding and plastic flow of anisotropic metals. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1948, A193, 281–297. [Google Scholar] [CrossRef]

- Seo, K.-Y.; Kim, J.-H.; Lee, H.-S.; Kimm, J.H.; Kim, B.-M. Effect of Constitutive Equations on Springback Prediction Accuracy in the TRIP1180 Cold Stamping. Metals 2017, 8, 18. [Google Scholar] [CrossRef]

- Atluri, S.N.; Yagawa, G.; Cruse, T.A. Computational Mechanics ’95: Vol. 1 and Vol. 2. Theory and Applications. In Proceedings of the International Conference on Computational Engineering Science, Atlanta, GA, USA, 10–14 April 1988; Springer: Berlin/Heidelberg, Germany, 1995; p. 1326, ISBN 978-3-642-79656-2. [Google Scholar]

- Abe, T.; Tsuta, T. Pergamon, Amsterdam-Oxford-New York-Tokyo. In Proceedings of the Asi-PAcific Symposium on Advances in Engineering Plasticity and Its Applications (AEPA’96), Hiroshima, Japan, 21–24 August 1996; p. 686. [Google Scholar]

- Zhao, B.; Zhang, S.; Lu, X.; Dong, Q. Cyclic tangential loading of a power-law hardening elastic–plastic spherical contact in pre-sliding stage. Int. J. Mech. Sci. 2017, 128–129, 652–658. [Google Scholar] [CrossRef]

- Elgindi, M.B.; Wei, D.; Liu, Y.; Kamran, K.; Xu, H. Buckling and deformation of Hollomon’s power-law tubes. Thin-Walled Struct. 2014, 74, 213–221. [Google Scholar] [CrossRef]

- AMS. Aluminium Alloy 2024, Plate and Sheet: SAE-AMS-QQ-A-250/4B (2015); Aerospace Material Specification, SAE International; AMS: Warrendale, PA, USA, 2015. [Google Scholar]

- AMS. Aluminum Alloy 2024, Bar, Rod, Shapes, Tube, and Wire, Extruded: SAE-AMS-QQ-A-200-3 (2007); Aerospace Material Specification, SAE International; AMS: Warrendale, PA, USA, 2015. [Google Scholar]

- ISO. Metallic Materials. Tensile Testing. Part 1: Method of Test at Room Temperature; International Standard ISO-6892-1:2016; International Organization for Standard: Geneva, Switzerland, 2016. [Google Scholar]

- Asnafi, N. On springback of double-curved autobody panels. Int. J. Mech. Sci. 2001, 43, 5–37. [Google Scholar] [CrossRef]

- Bruni, C.; Celeghini, M.; Geiger, M.; Gabrielli, F. A study of techniques in the evaluation of springback and residual stress in hydroforming. Int. J. Adv. Manuf. Technol. 2007, 33, 929–939. [Google Scholar] [CrossRef]

| Material | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other | Al | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Each | Total | ||||||||||

| UNS A92024-T3 | 0.038 | 0.091 | 4.46 | 0.62 | 1.41 | 0.005 | 0.083 | 0.031 | <0.05 | <0.15 | Bal. |

| Material Properties | Source | Description of Material Properties (MPs) |

|---|---|---|

| MP1 | Experimental tests | Tensile tests performed on UNS A92024-T3511 with the same thickness as the hydroformed sheet (2.5 mm) |

| MP2 | Experimental tests | 15 tensile tests performed on UNS A92024-T3 samples extracted from the same material batch used in the hydroforming process (2.5 mm) |

| MP3 | Standards data | Minimum MPs values requested by the aerospace standard SAE-AMS-QQ-A-250/5 [19] |

| MP4 | Standards data | Minimum MPs values requested by the aerospace standard SAE-AMS-QQ-A-200/3 [20] |

| MP5 | Standards data | MPs based on SAE-AMS-QQ-A-200/3 [21], with higher elongation value (20%) |

| MP6 | Standards data | MPs based on SAE-AMS-QQ-A-200/3 [21], with higher elongation value (30%) |

| Test Direction | Young’s Modulus (MPa) | Yield Strength (MPa) | Ultimate Tensile Stress (MPa) | Elongation (%) | R-Value |

|---|---|---|---|---|---|

| Rolling direction (0°) | 72,809 | 332 | 491 | 19.98 | 0.49 |

| Diagonal direction (45°) | 74,711 | 294 | 458 | 25.25 | 0.59 |

| Transverse direction (90°) | 71,803 | 337 | 481 | 20.86 | 0.50 |

| Summary of Mechanical Properties and FEM Results | MP1 | MP2 | MP3 | MP4 | MP5 | MP6 |

|---|---|---|---|---|---|---|

| Ultimate Tensile Strength, UTS (MPa) | 535 | 477 | 421 | 393 | 393 | 393 |

| Yield Strength, YS (MPa) | 396 | 321 | 276 | 290 | 290 | 290 |

| Elongation (%) | 11 | 22 | 15 | 12 | 20 | 30 |

| Maximum distance between simulated and real Part (mm) | 3.5 | 2.0 | 2.8 | 2.6 | 3.3 | 3.6 |

| Surface with distance between simulated and real Part < 0.5 mm (%) | 24.4 | 92.5 | 50.6 | 45.4 | 25.8 | 20.7 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Churiaque, C.; Sánchez-Amaya, J.M.; Caamaño, F.; Vazquez-Martinez, J.M.; Botana, J. Springback Estimation in the Hydroforming Process of UNS A92024-T3 Aluminum Alloy by FEM Simulations. Metals 2018, 8, 404. https://doi.org/10.3390/met8060404

Churiaque C, Sánchez-Amaya JM, Caamaño F, Vazquez-Martinez JM, Botana J. Springback Estimation in the Hydroforming Process of UNS A92024-T3 Aluminum Alloy by FEM Simulations. Metals. 2018; 8(6):404. https://doi.org/10.3390/met8060404

Chicago/Turabian StyleChuriaque, Cristina, Jose Maria Sánchez-Amaya, Francisco Caamaño, Juan Manuel Vazquez-Martinez, and Javier Botana. 2018. "Springback Estimation in the Hydroforming Process of UNS A92024-T3 Aluminum Alloy by FEM Simulations" Metals 8, no. 6: 404. https://doi.org/10.3390/met8060404

APA StyleChuriaque, C., Sánchez-Amaya, J. M., Caamaño, F., Vazquez-Martinez, J. M., & Botana, J. (2018). Springback Estimation in the Hydroforming Process of UNS A92024-T3 Aluminum Alloy by FEM Simulations. Metals, 8(6), 404. https://doi.org/10.3390/met8060404