Effect of the Martensitic Transformation on the Stamping Force and Cycle Time of Hot Stamping Parts

Abstract

:1. Introduction

2. Materials and Methods

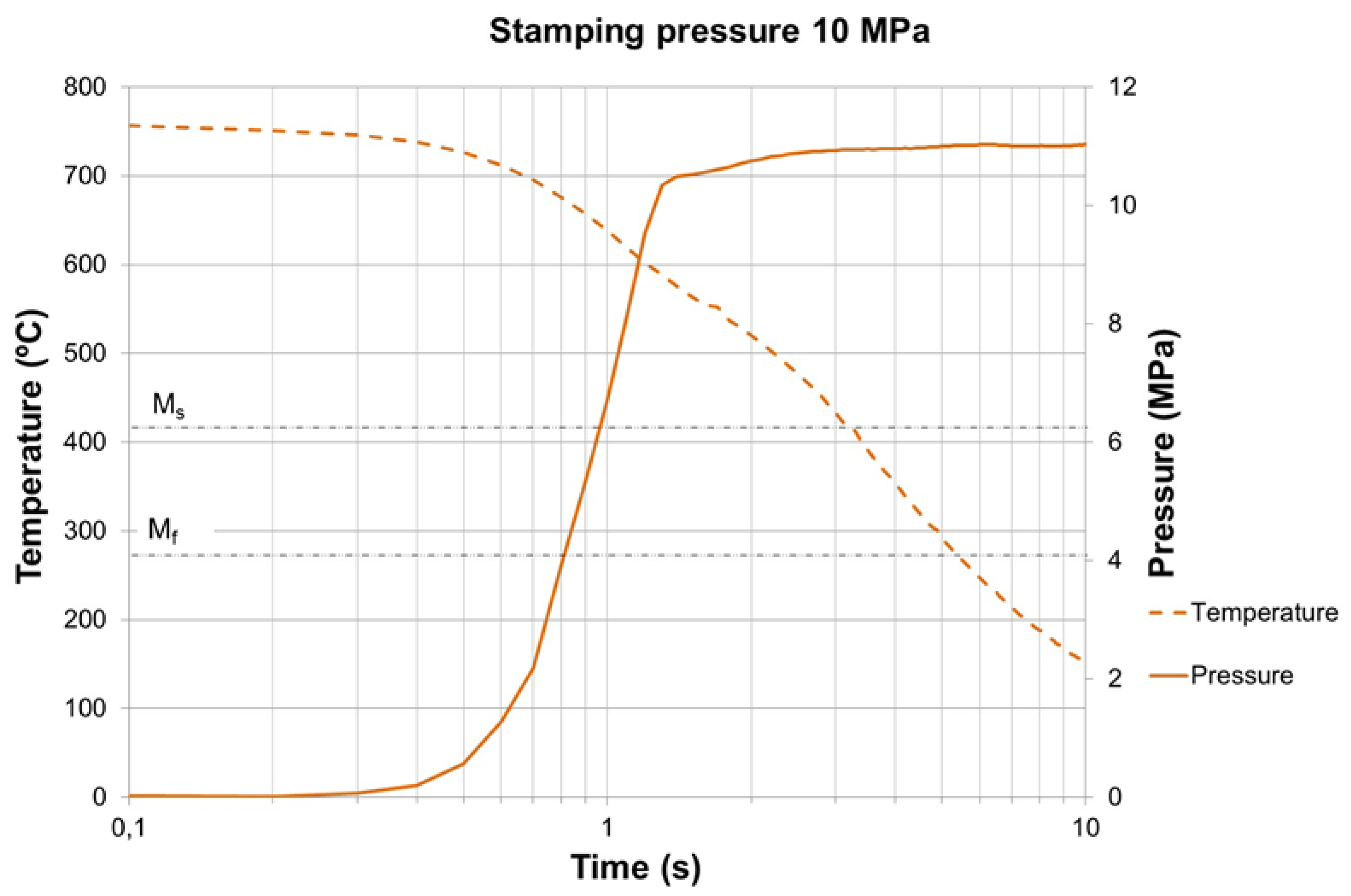

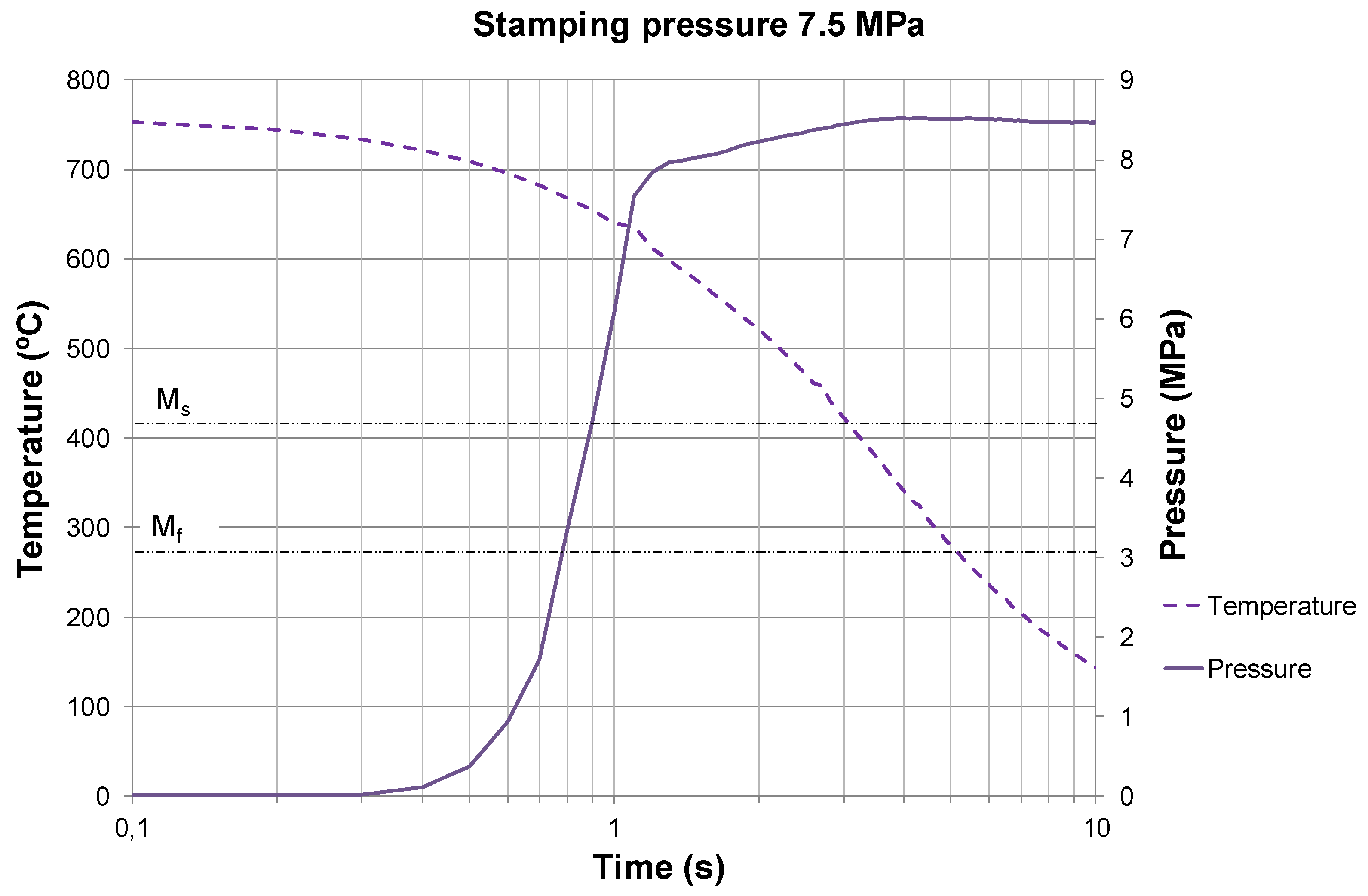

3. Results

4. Discussion

- Force monitoring must exist on the lowest quenching pressure site of the stamped part.

- The press force set-point must be achieved before quenching starts.

- The site of the stamped part must have a flat sheet-to-tool contact surface.

- It must be possible to program the press stroke so that it maintains its BDC during quenching.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Karbasian, H.; Tekkaya, A.E. A review on hot stamping. J. Mater. Process. Technol. 2010, 210, 2103–2118. [Google Scholar] [CrossRef]

- Neugebauer, R.; Schieck, F.; Polster, S.; Mosel, A.; Rautenstrauch, A.; Schönherr, J.; Pierschel, N. Press hardening—An innovative and challenging technology. Arch. Civil Mech. Eng. 2012, 12, 113–118. [Google Scholar] [CrossRef]

- Mori, K.; Bariani, P.F.; Behrens, B.-A.; Brosius, A.; Bruschi, S.; Maeno, T.; Merklein, M.; Yanagimoto, J. Hot stamping of ultra-high strength steel parts. CIRP Ann. Manuf. Technol. 2017, 66, 755–777. [Google Scholar] [CrossRef]

- Palm, C.; Vollmer, R.; Aspacher, J.; Gharbi, M. Increasing performance of hot stamping systems. Procedia Eng. 2017, 207, 765–770. [Google Scholar] [CrossRef]

- Ghiotti, A.; Bruschi, S.; Medea, F.; Hamasaiid, A. Tribological behavior of high thermal conductivity steels for hot stamping tools. Tribol. Int. 2016, 97, 412–422. [Google Scholar] [CrossRef]

- He, B.; Ying, L.; Li, X.; Hu, P. Optimal design of longitudinal conformal cooling channels in hot stamping tools. Appl. Therm. Eng. 2016, 106, 1176–1189. [Google Scholar] [CrossRef]

- Caron, E.J.F.R.; Daun, K.J.; Wells, M.A. Experimental heat transfer coefficient measurements during hot forming die quenching of boron steel at high temperatures. Int. J. Heat Mass Transf. 2014, 71, 396–404. [Google Scholar] [CrossRef]

- Abdulhay, B.; Bourouga, B.; Dessain, C. Thermal contact resistance estimation: Influence of the pressure contact and the coating layer during a hot forming process. Int. J. Mater. Form. 2012, 5, 183–197. [Google Scholar] [CrossRef]

- Mendiguren, J.; Ortubay, R.; Saenz de Argandoña, E.; Galdos, L. Experimental characterization of the heat transfer coefficient under different close loop controlled pressures and die temperatures. Appl. Therm. Eng. 2016, 99, 813–824. [Google Scholar] [CrossRef]

- Salomonsson, P.; Oldenburg, M.; Akerström, P.; Bergman, G. Experimental and numerical evaluation of the heat transfer coefficient in press hardening. Steel Res. Int. 2009, 80, 841–845. [Google Scholar] [CrossRef]

- Gorriño, A.; Angulo, C.; Muro, M.; Izaga, J. Investigation of thermal and mechanical properties of quenchable high-strength steels in hot stamping. Metall. Mater. Trans. B 2016, 47, 1527–1531. [Google Scholar] [CrossRef]

- Naderi, M.; Saeed-Akbari, A.; Bleck, W. The effects of non-isothermal deformation on martensitic transformation in 22MnB5 steel. Mater. Sci. Eng. A 2008, 487, 445–455. [Google Scholar] [CrossRef]

- Chang, Y.; Tang, X.; Zhao, K.; Hu, P.; Wu, Y. Investigation of the factors influencing the interfacial heat transfer coefficient in hot stamping. J. Mater. Process. Technol. 2016, 228, 25–33. [Google Scholar] [CrossRef]

- Ancona, F.; Palumbo, D.; De Finis, R.; Demelio, G.P.; Galietti, U. Automatic procedure for evaluating the Paris Law of martensitic and austenitic stainless steels by means of thermal methods. Eng. Fract. Mech. 2016, 163, 206–219. [Google Scholar] [CrossRef]

- Wang, L.; Zhu, B.; Wang, Y.; An, X.; Wang, Q.; Zhang, Y. An online dwell time optimization method based on parts performance for hot stamping. Procedia Eng. 2017, 207, 759–764. [Google Scholar] [CrossRef]

- Muvunzi, R.; Dimitrov, D.M.; Matope, S.; Harms, T.M. Development of a model for predicting cycle time in hot stamping. Procedia Manuf. 2018, 21, 84–91. [Google Scholar] [CrossRef]

- Gu, Z.; Lu, M.; Lu, G.; Li, X.; Xu, H. Effect of contact pressure during quenching on microstructure and mechanical properties of hot-stamping parts. J. Iron. Steel Res. Int. 2015, 22, 1138–1143. [Google Scholar] [CrossRef]

- Rider, C. Pressure Distribution Image Analysis Process. U.S. Patent 2002/0129658 A1, 19 September 2002. [Google Scholar]

| C | Si | Mn | P | S | Al | B | N2 | Ti | Cr | Ni |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.22 | 0.27 | 1.23 | 0.014 | 0.003 | 0.041 | 0.003 | 0.006 | 0.036 | 0.21 | 0.05 |

| Pressure Set-Point (MPa) | HV10 Hardness |

|---|---|

| 12.5 | 487 ± 7 |

| 10.0 | 477 ± 18 |

| 7.5 | 478 ± 9 |

| 5.0 | 488 ± 10 |

| 2.5 | 481 ± 10 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muro, M.; Artola, G.; Gorriño, A.; Angulo, C. Effect of the Martensitic Transformation on the Stamping Force and Cycle Time of Hot Stamping Parts. Metals 2018, 8, 385. https://doi.org/10.3390/met8060385

Muro M, Artola G, Gorriño A, Angulo C. Effect of the Martensitic Transformation on the Stamping Force and Cycle Time of Hot Stamping Parts. Metals. 2018; 8(6):385. https://doi.org/10.3390/met8060385

Chicago/Turabian StyleMuro, Maider, Garikoitz Artola, Anton Gorriño, and Carlos Angulo. 2018. "Effect of the Martensitic Transformation on the Stamping Force and Cycle Time of Hot Stamping Parts" Metals 8, no. 6: 385. https://doi.org/10.3390/met8060385

APA StyleMuro, M., Artola, G., Gorriño, A., & Angulo, C. (2018). Effect of the Martensitic Transformation on the Stamping Force and Cycle Time of Hot Stamping Parts. Metals, 8(6), 385. https://doi.org/10.3390/met8060385