Effects of Deep Cryogenic Treatment on Wear Resistance and Structure of GB 35CrMoV Steel

Abstract

:1. Introduction

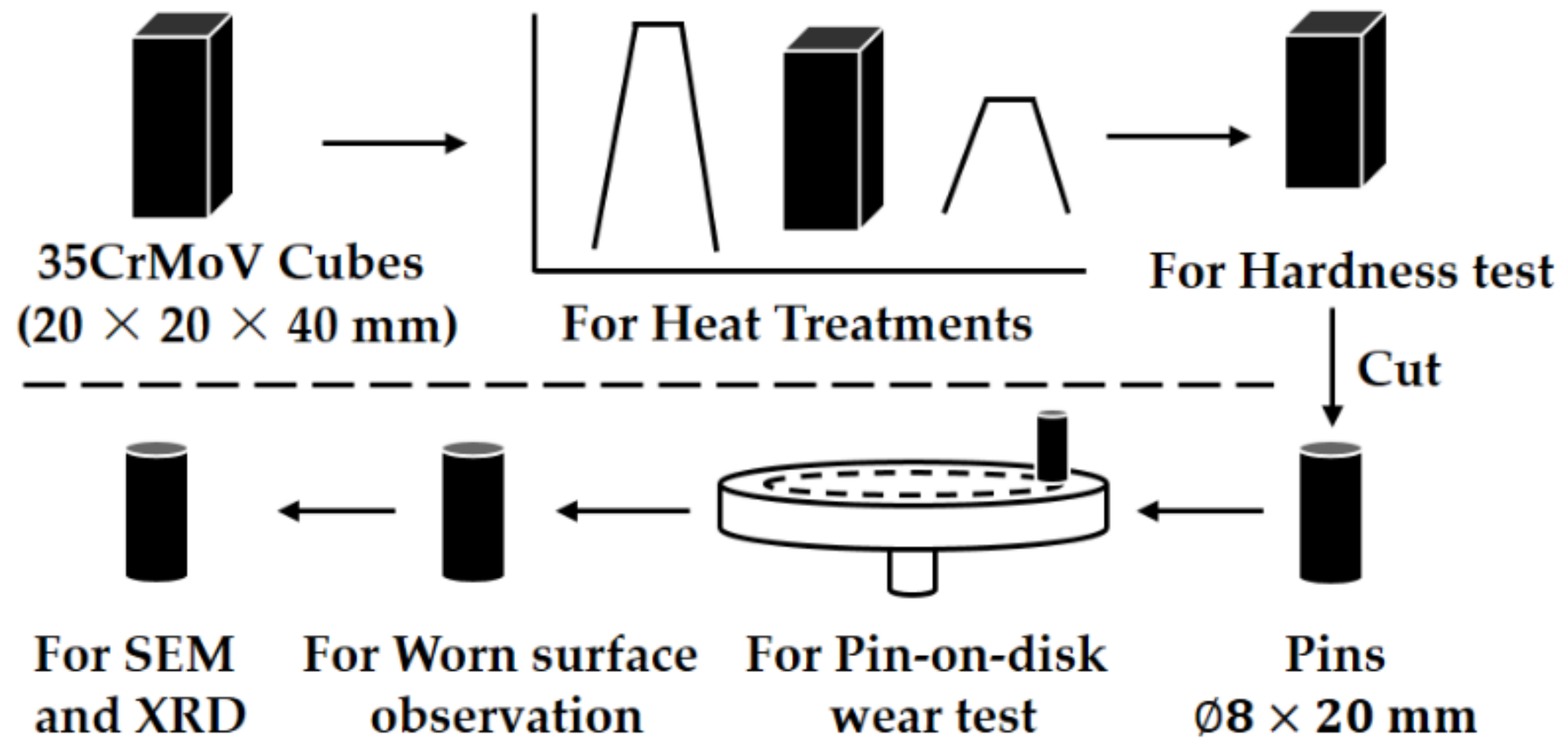

2. Materials and Methods

2.1. Materials

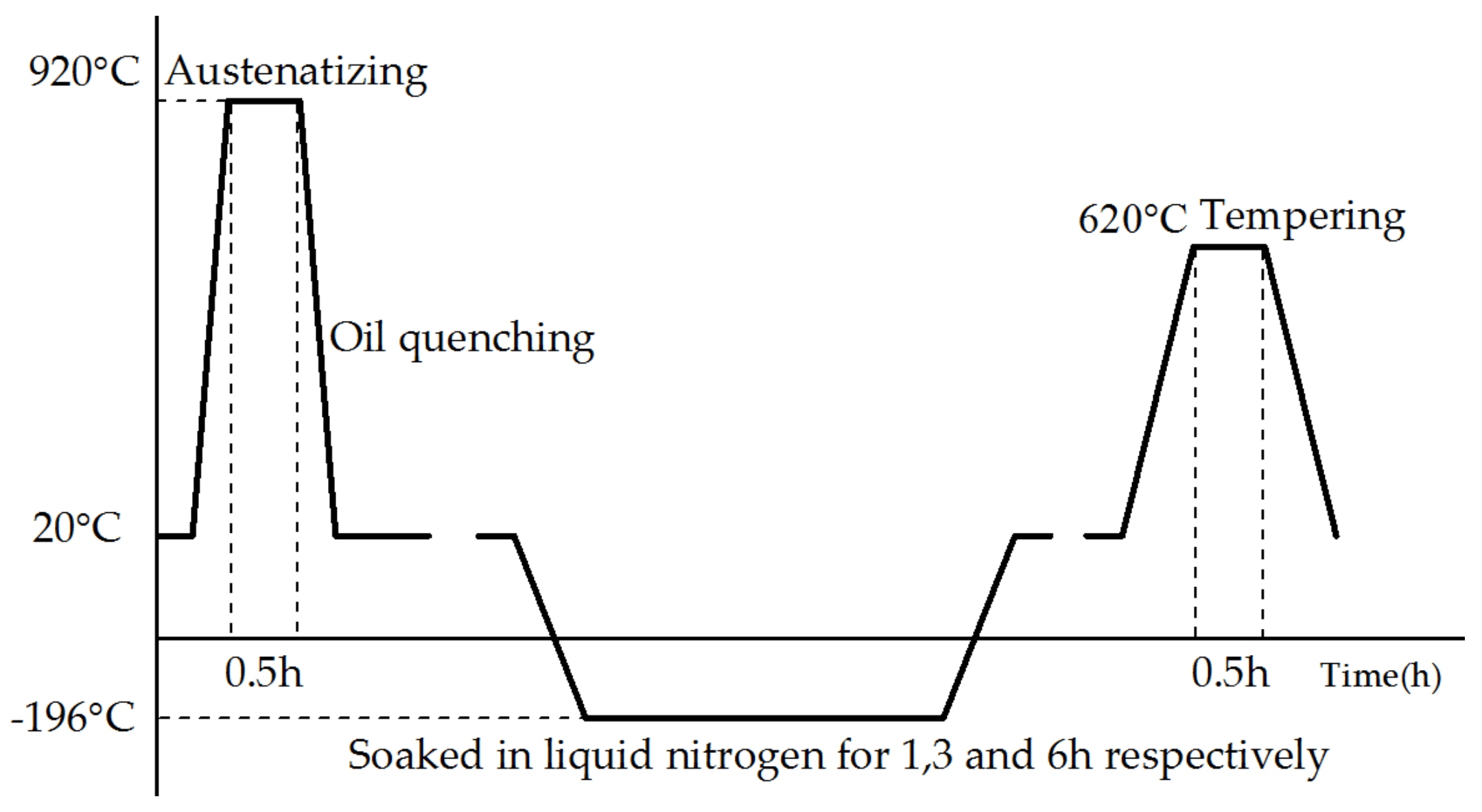

2.2. Heat Treatments

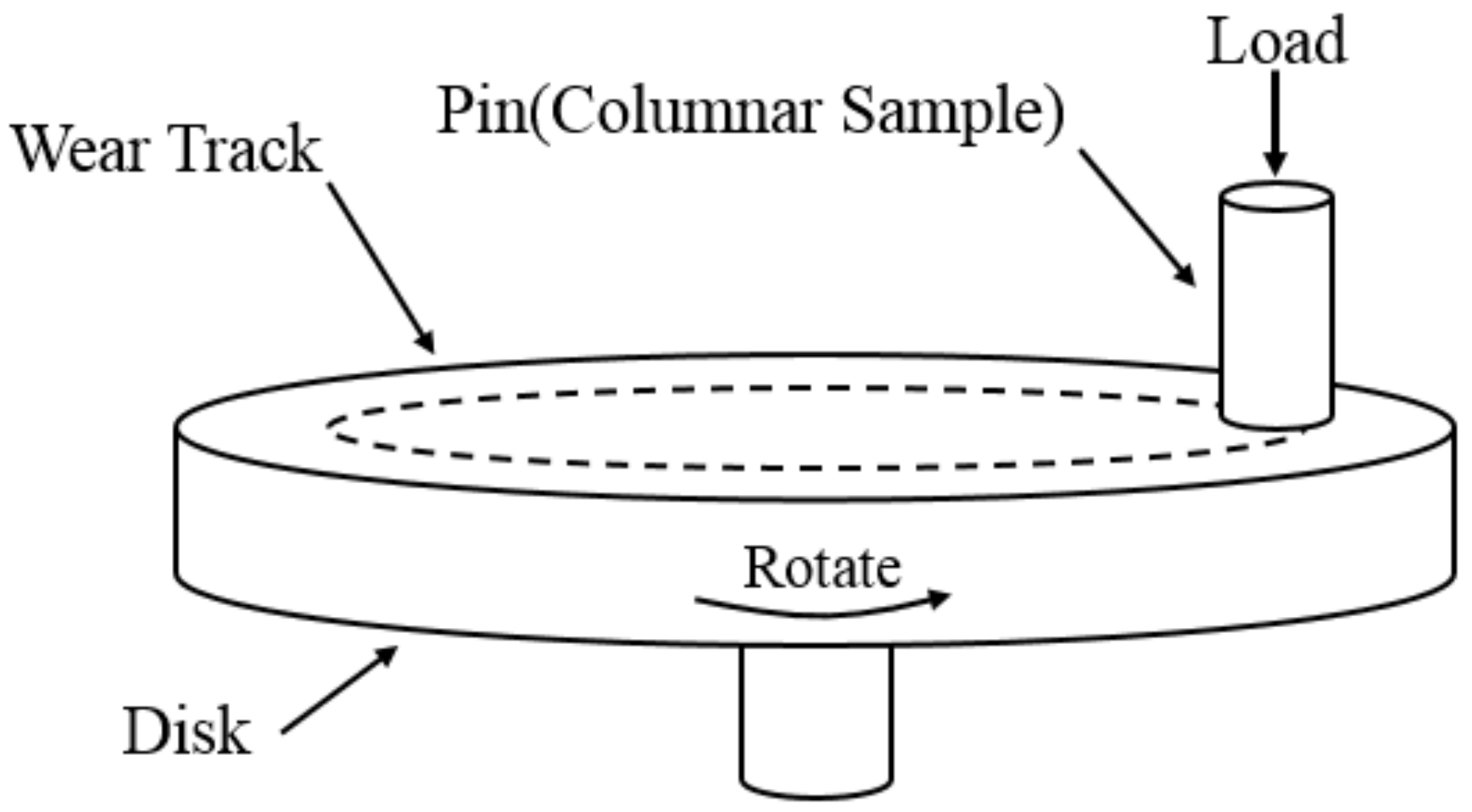

2.3. Hardness Test and Wear Test

2.4. Microstructural Examinations

3. Results and Discussion

3.1. Hardness

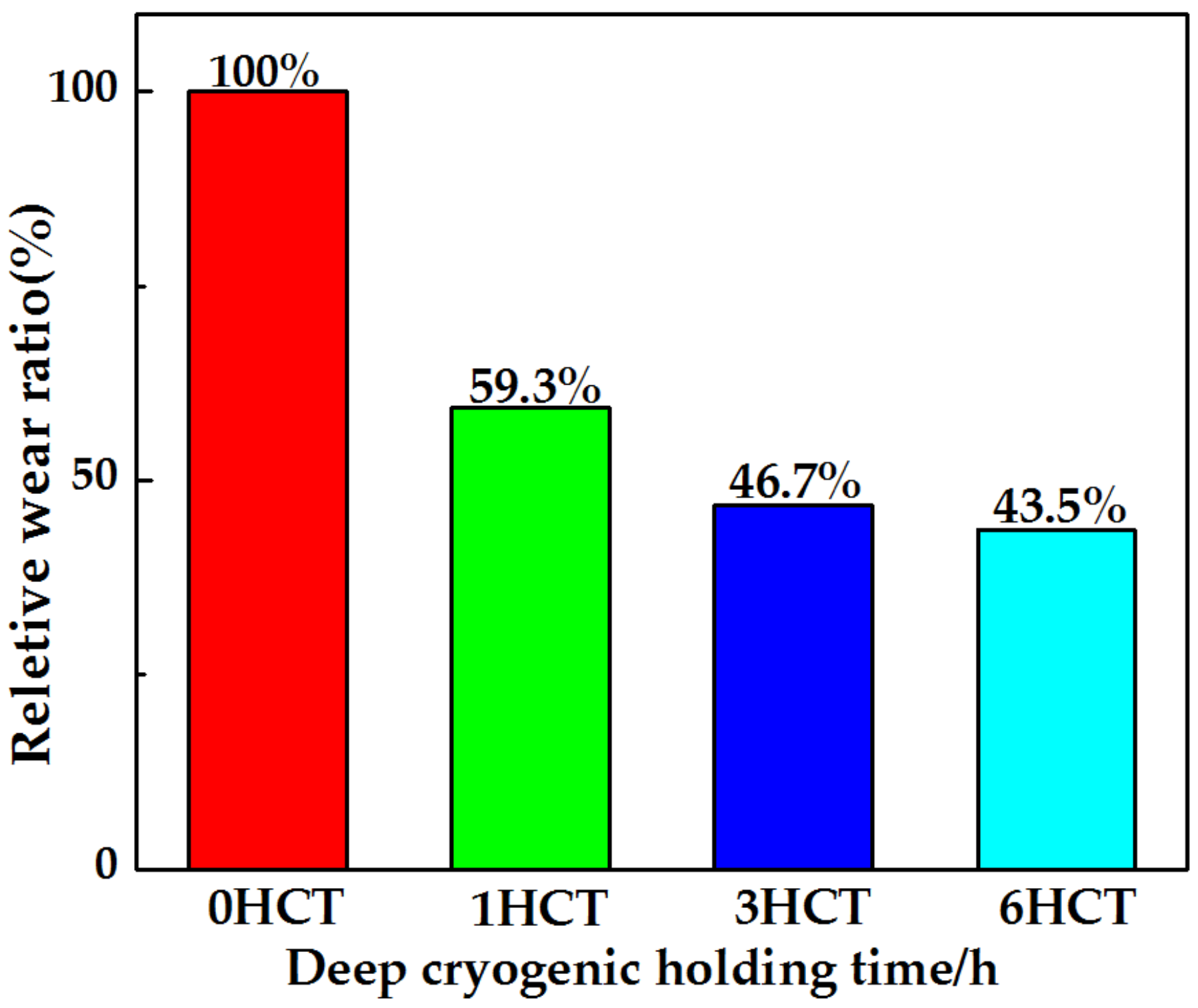

3.2. Wear Resistance

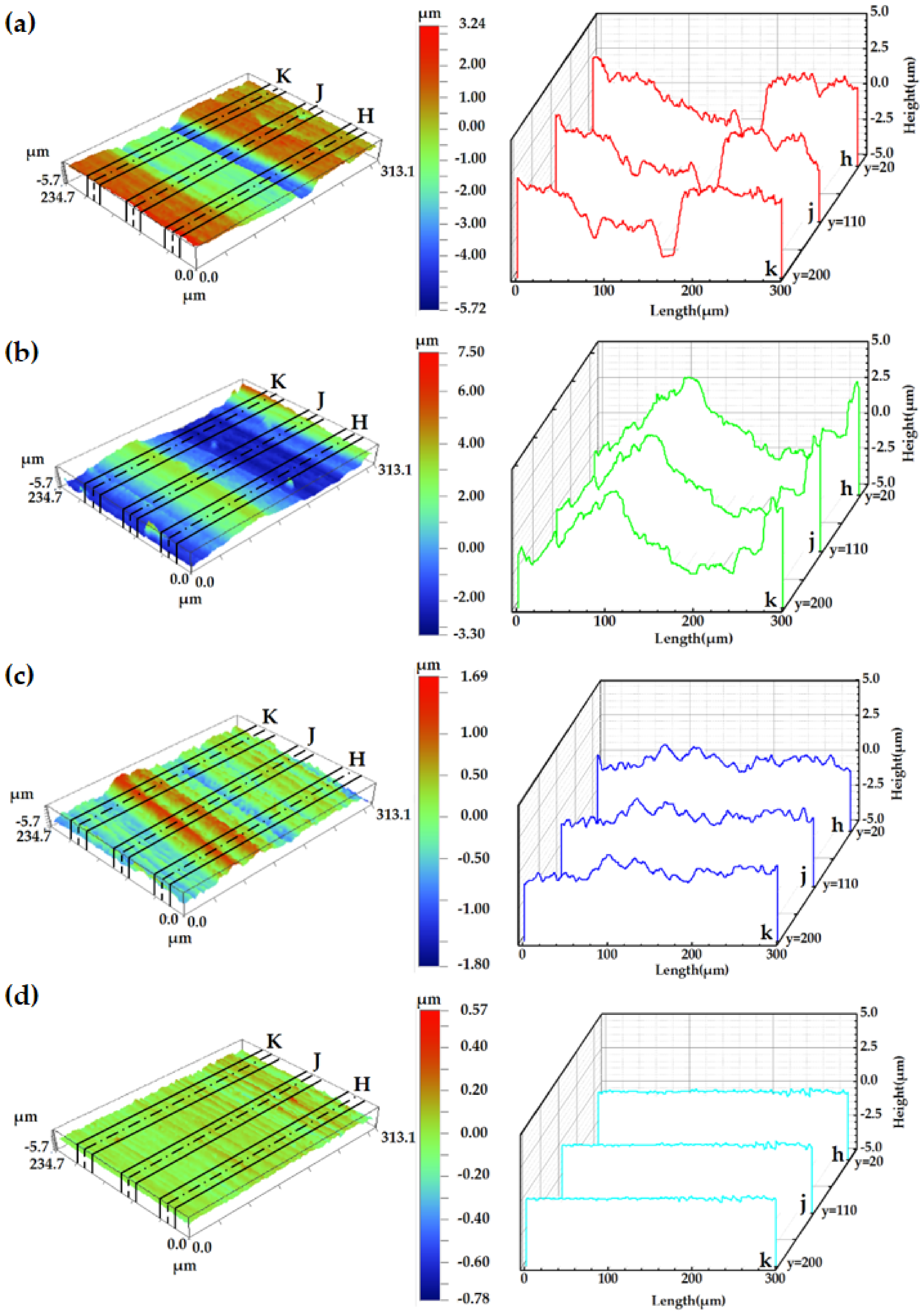

3.3. Worn Surface Observation

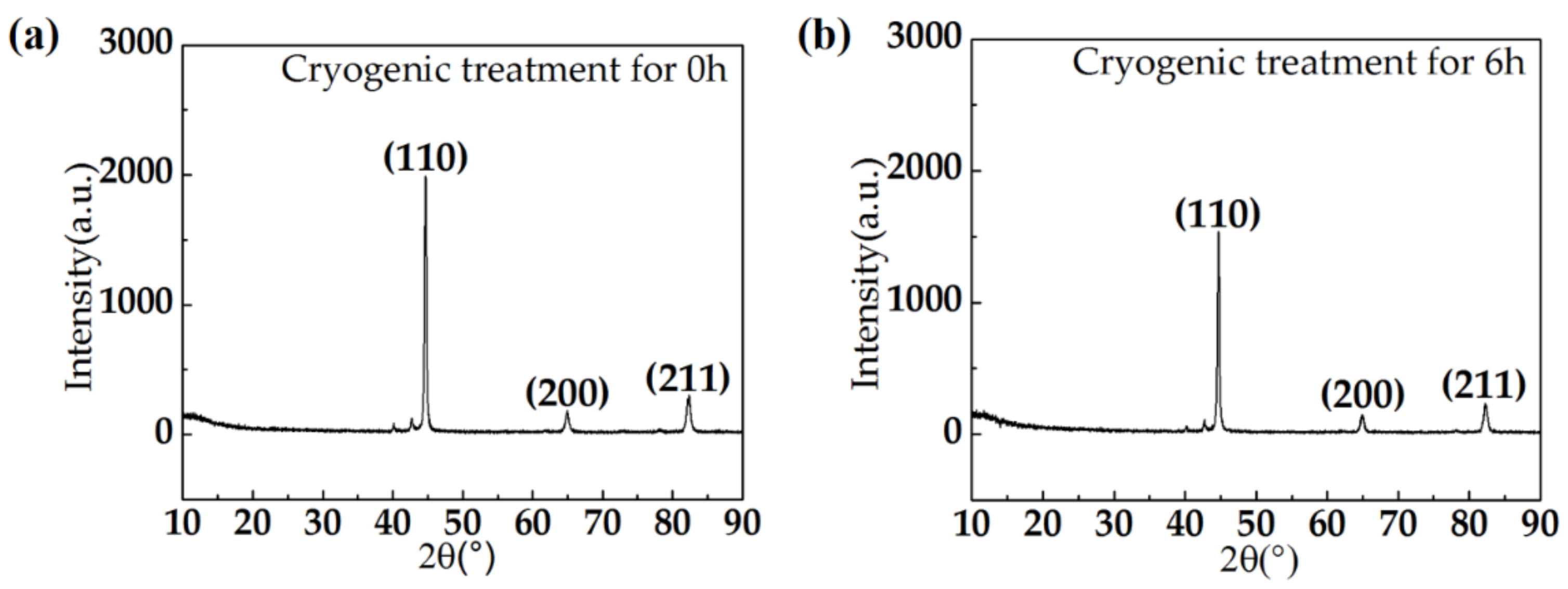

3.4. Mechanisms Analysis and Discussion

4. Conclusions

- (1)

- Deep cryogenic treatment could effectively enhance the hardness and wear resistance of GB 35CrMoV steel. The hardness (HV0.3) was increased by 3.7%, 6.1% and 10.5% for 1HCT, 3HCT and 6HCT, respectively, with respect to the hardness with no cryogenic treatment. For the wear ratio, decreases of 40.7%, 53.3% and 56.5% were observed for 1HCT, 3HCT and 6HCT, respectively.

- (2)

- Worn surface of deep cryogenic treated samples after the pin-on-disk wear test was obviously different from the conventional heat-treated sample, which showed scars suffering from typical microplowing and microcutting. Such scars were much less and lighter on the worn surfaces of samples that experienced the longer-time cryogenic treatment, especially the sample experiencing 6 h cryogenic treatment. The RMS parameter (Sq) indicated that the degree of smoothness of worn surface was improved with the prolonged deep cryogenic treatment time.

- (3)

- Improvements in hardness and wear resistance of 35CrMoV were ascribed to the precipitated carbides. Deep cryogenic treatment between the quenching and the tempering process promoted the precipitation of carbides. The mechanism could be interpreted not only as the promoted effect of deep cryogenic treatment in the decomposition kinetics of martensite, but also as the acceleration on the Ostwald ripening process by the prior precipitated nanoclusters of carbon atoms during deep cryogenic treatment. Precipitated carbides could effectively enhance the strength and hardness of matrix and resist the crack initiation and propagation.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yang, K.; Gao, Y.; Yang, K.; Bao, Y.; Jiang, Y. Microstructure and wear resistance of Fe-Cr13-C-Nb hardfacing alloy with Ti addition. Wear 2017, 376, 1091–1096. [Google Scholar] [CrossRef]

- Ahmed, M.P.; Jailani, H.S.; Mohideen, S.R.; Rajadurai, A. Effect of Cryogenic Treatment on Microstructure and Properties of CuBe2. Metallogr. Microstruct. Anal. 2016, 5, 528–535. [Google Scholar] [CrossRef]

- Thornton, R.; Slatter, T.; Ghadbeigi, H. Effects of deep cryogenic treatment on the dry sliding wear performance of ferrous alloys. Wear 2013, 305, 177–191. [Google Scholar] [CrossRef]

- Yang, H.; Jun, W.; Bao-Luo, S.; Hao-Huai, L.; Sheng-Ji, G.; Si-Jiu, H. Effect of cryogenic treatment on the matrix structure and abrasion resistance of white cast iron subjected to destabilization treatment. Wear 2006, 261, 1150–1154. [Google Scholar] [CrossRef]

- Silva, F.; Franco, S.D.; Machado, Á.R.; Ezugwu, E.O.; Souza, A.M., Jr. Performance of cryogenically treated HSS tools. Wear 2006, 261, 674–685. [Google Scholar] [CrossRef]

- Leskovšek, V.; Kalin, M.; Vižintin, J. Influence of deep-cryogenic treatment on wear resistance of vacuum heat-treated HSS. Vacuum 2006, 80, 507–518. [Google Scholar] [CrossRef]

- Firouzdor, V.; Nejati, E.; Khomamizadeh, F. Effect of deep cryogenic treatment on wear resistance and tool life of M2 HSS drill. J. Mater. Process. Technol. 2008, 206, 467–472. [Google Scholar] [CrossRef]

- Khun, N.W.; Liu, E.; Tan, A.; Senthilkumar, D.; Albert, B. Effects of deep cryogenic treatment on mechanical and tribological properties of AISI D3 tool steel. Friction 2015, 3, 234–242. [Google Scholar] [CrossRef] [Green Version]

- Amini, K.; Nategh, S.; Shafyei, A.; Rezaeian, A. Effect of deep cryogenic treatment on the properties of 80CrMo12 5 tool steel. Int. J. Miner. Metall. Mater. 2012, 19, 30–37. [Google Scholar] [CrossRef]

- Gavriljuk, V.G.; Theisen, W.; Sirosh, V.V.; Polshin, E.V.; Kortmann, A.; Mogilny, G.S.; Petrov, Y.N.; Tarusin, Y.V. Low-temperature martensitic transformation in tool steels in relation to their deep cryogenic treatment. Acta Mater. 2013, 61, 1705–1715. [Google Scholar] [CrossRef]

- Leskovšek, V.; Šuštaršič, B.; Jutriša, G. The influence of austenitizing and tempering temperature on the hardness and fracture toughness of hot-worked H11 tool steel. J. Mater. Process. Technol. 2006, 178, 328–334. [Google Scholar] [CrossRef]

- Podgornik, B.; Majdic, F.; Leskovsek, V.; Vizintin, J. Improving tribological properties of tool steels through combination of deep-cryogenic treatment and plasma nitriding. Wear 2012, 288, 88–93. [Google Scholar] [CrossRef]

- Jurči, P.; Dománková, M.; Hudáková, M.; Ptačinová, J.; Pašák, M.; Palček, P. Characterization of microstructure and tempering response of conventionally quenched, short- and long-time sub-zero treated PM Vanadis 6 ledeburitic tool steel. Mater. Charact. 2017, 134, 398–415. [Google Scholar] [CrossRef]

- Das, D.; Ray, K.K.; Dutta, A.K. Influence of temperature of sub-zero treatments on the wear behaviour of die steel. Wear 2009, 267, 1361–1370. [Google Scholar] [CrossRef]

- Podgornik, B.; Paulin, I.; Zajec, B.; Jacobson, S.; Leskovšek, V. Deep cryogenic treatment of tool steels. J. Mater. Process. Technol. 2016, 229, 398–406. [Google Scholar] [CrossRef]

- Das, D.; Dutta, A.K.; Ray, K.K. Correlation of microstructure with wear behaviour of deep cryogenically treated AISI D2 steel. Wear 2009, 267, 1371–1380. [Google Scholar] [CrossRef]

- Yan, X.G.; Li, D.Y. Effects of the sub-zero treatment condition on microstructure, mechanical behavior and wear resistance of W9Mo3Cr4V high speed steel. Wear 2013, 302, 854–862. [Google Scholar] [CrossRef]

- Li, J.; Yan, X.; Liang, X.; Hong, G.; Li, D.Y. Influence of different cryogenic treatments on high-temperature wear behavior of M2 steel. Wear 2017, 376, 1112–1121. [Google Scholar] [CrossRef]

- Era, P.K.; Mazancová, E. Mechanical and structural response of AISI 4135 steel after controlled cooling process. Metalurgija 2016, 55, 165–168. [Google Scholar]

- Nűrnberger, F.; Grydin, O.; Yu, Z.; Schaper, M. Microstructural Behaviour of Tempering Steels during Precision Forging and Quenching from Hot-forming Temperatures. Metall. Min. Ind. 2011, 7, 79–85. [Google Scholar]

- Jiang, X.; Zhou, Y.; Shi, C.; Mao, D. Effects of Ultrasonic-Aided Quenching on the Corrosion Resistance of GB 35CrMoV Steel in Seawater Environment. Metals 2018, 8, 104. [Google Scholar] [CrossRef]

- Wang, Q.B.; Li, X.Y. Effects of Nb, V, and W on Microstructure and Abrasion Resistance of Fe-Cr-C Hardfacing Alloys. Weld. J. 2010, 89, 133–139. [Google Scholar]

- Shivanna, D.M.; Kiran, M.B.; Kavitha, S.D. Evaluation of 3D Surface Roughness Parameters of EDM Components Using Vision System. Procedia Mater. Sci. 2014, 5, 2132–2141. [Google Scholar] [CrossRef]

- Do Vale, J.L.; Beltrão, V.D.C.; Silva, C.H.D.; Pintaúde, G. Evaluation of the error of the light beam incidence on concave surfaces in 3D roughness parameters using optical interferometry. Measurement 2018, 120, 182–192. [Google Scholar] [CrossRef]

- Al-Kindi, G.A.; Shirinzadeh, B. An evaluation of surface roughness parameters measurement using vision-based data. Int. J. Mach. Tools Manuf. 2007, 47, 697–708. [Google Scholar] [CrossRef]

- Das, D.; Dutta, A.K.; Ray, K.K. Sub-zero treatments of AISI D2 steel: Part I. Microstructure and hardness. Mater. Sci. Eng. A 2010, 527, 2182–2193. [Google Scholar] [CrossRef]

- Zhao, M.; Hanamura, T.; Qiu, H.; Nagai, K.; Yang, K. Grain growth and Hall–Petch relation in dual-sized ferrite/cementite steel with nano-sized cementite particles in a heterogeneous and dense distribution. Scr. Mater. 2006, 54, 1193–1197. [Google Scholar] [CrossRef]

- Miyamoto, G.; Oh, J.; Hono, K.; Furuhara, T.; Maki, T. Effect of partitioning of Mn and Si on the growth kinetics of cementite in tempered Fe–0.6 mass% C martensite. Acta Mater. 2007, 55, 5027–5038. [Google Scholar] [CrossRef]

- Luzginova, N.V.; Zhao, L.; Sietsma, J. The Cementite Spheroidization Process in High-Carbon Steels with Different Chromium Contents. Metall. Mater. Trans. A 2008, 39, 513–521. [Google Scholar] [CrossRef] [Green Version]

- Lescoat, M.L.; Ribis, J.; Chen, Y.; Marquis, E.A.; Bordas, E. Radiation-induced Ostwald ripening in oxide dispersion strengthened ferritic steels irradiated at high ion dose. Acta Mater. 2014, 78, 328–340. [Google Scholar] [CrossRef]

- Sun, Y.; Chen, J.; Liu, J. Effect of hydrogen on ductility of high strength quenched and tempered (QT) Cr–Ni–Mo steels. Mater. Sci. Eng. A 2015, 625, 89–97. [Google Scholar] [CrossRef]

- Guo, J.; Ai, L.; Wang, T.; Feng, Y.; Wan, D.; Yang, Q. Microstructure evolution and micro-mechanical behavior of secondary carbides at grain boundary in a Fe–Cr–W–Mo–V–C alloy. Mater. Sci. Eng. A 2018, 715, 359–369. [Google Scholar] [CrossRef]

| Chemical Composition | C | Si | Mn | P | S | Cr | Mo | V | Fe |

|---|---|---|---|---|---|---|---|---|---|

| Measured | 0.35 | 0.24 | 0.27 | 0.03 | 0.035 | 1.18 | 0.25 | 0.15 | Bal. |

| Samples | Weight before Wear Test (g) | Weight after Wear Test (g) | Weight Loss (g) |

|---|---|---|---|

| 0HCT | 7.7866 | 7.7606 | 0.0260 |

| 1HCT | 6.3707 | 6.3554 | 0.0153 |

| 3HCT | 7.9140 | 7.9019 | 0.0121 |

| 6HCT | 7.9479 | 7.9366 | 0.0113 |

| Samples | 0HCT | 1HCT | 3HCT | 6HCT |

| Sq (μm) | 0.268 | 0.201 | 0.150 | 0.051 |

| Samples | Counts | Average Size (μm) | Area Fraction (%) |

|---|---|---|---|

| 0HCT | 325 | 0.157 | 0.333 |

| 1HCT | 209 | 0.346 | 0.560 |

| 3HCT | 185 | 0.402 | 0.487 |

| 6HCT | 141 | 0.838 | 0.773 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, Y.; Zhou, Y. Effects of Deep Cryogenic Treatment on Wear Resistance and Structure of GB 35CrMoV Steel. Metals 2018, 8, 502. https://doi.org/10.3390/met8070502

Yao Y, Zhou Y. Effects of Deep Cryogenic Treatment on Wear Resistance and Structure of GB 35CrMoV Steel. Metals. 2018; 8(7):502. https://doi.org/10.3390/met8070502

Chicago/Turabian StyleYao, Yifeng, and Yajun Zhou. 2018. "Effects of Deep Cryogenic Treatment on Wear Resistance and Structure of GB 35CrMoV Steel" Metals 8, no. 7: 502. https://doi.org/10.3390/met8070502