Study of Solidification Cracking Susceptibility during Laser Welding in an Advanced High Strength Automotive Steel

Abstract

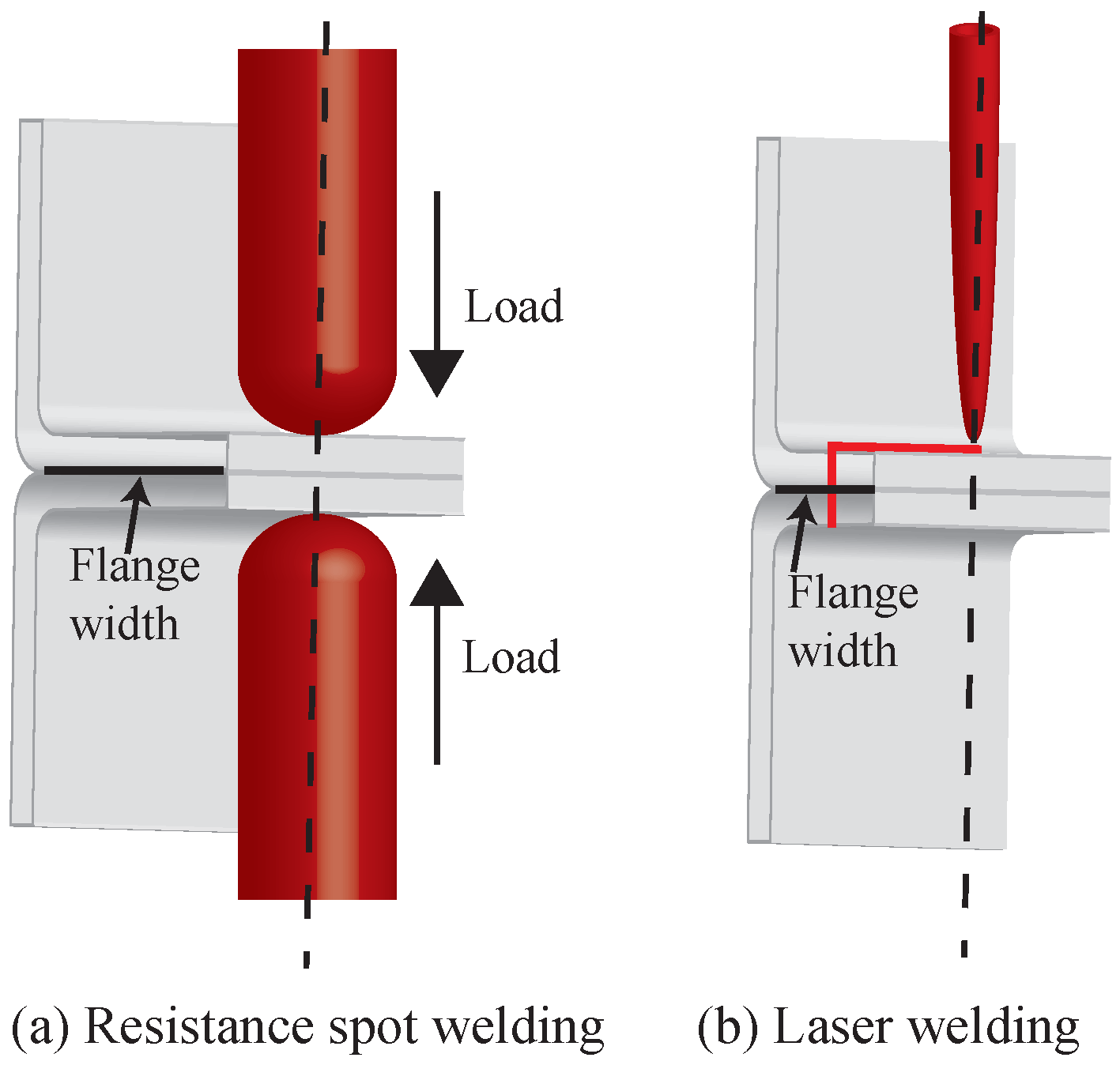

1. Introduction

- to maintain a constant restraint with respect to distance from the free edge during welding,

- to understand the effect of self-restraint on susceptibility to cracking,

- to identify the critical condition as a function of welding distance from the free edge in which no crack occurs,

- to develop an FE-based model to understand the process and delineate the critical factor(s) that may be responsible for the cracking behavior.

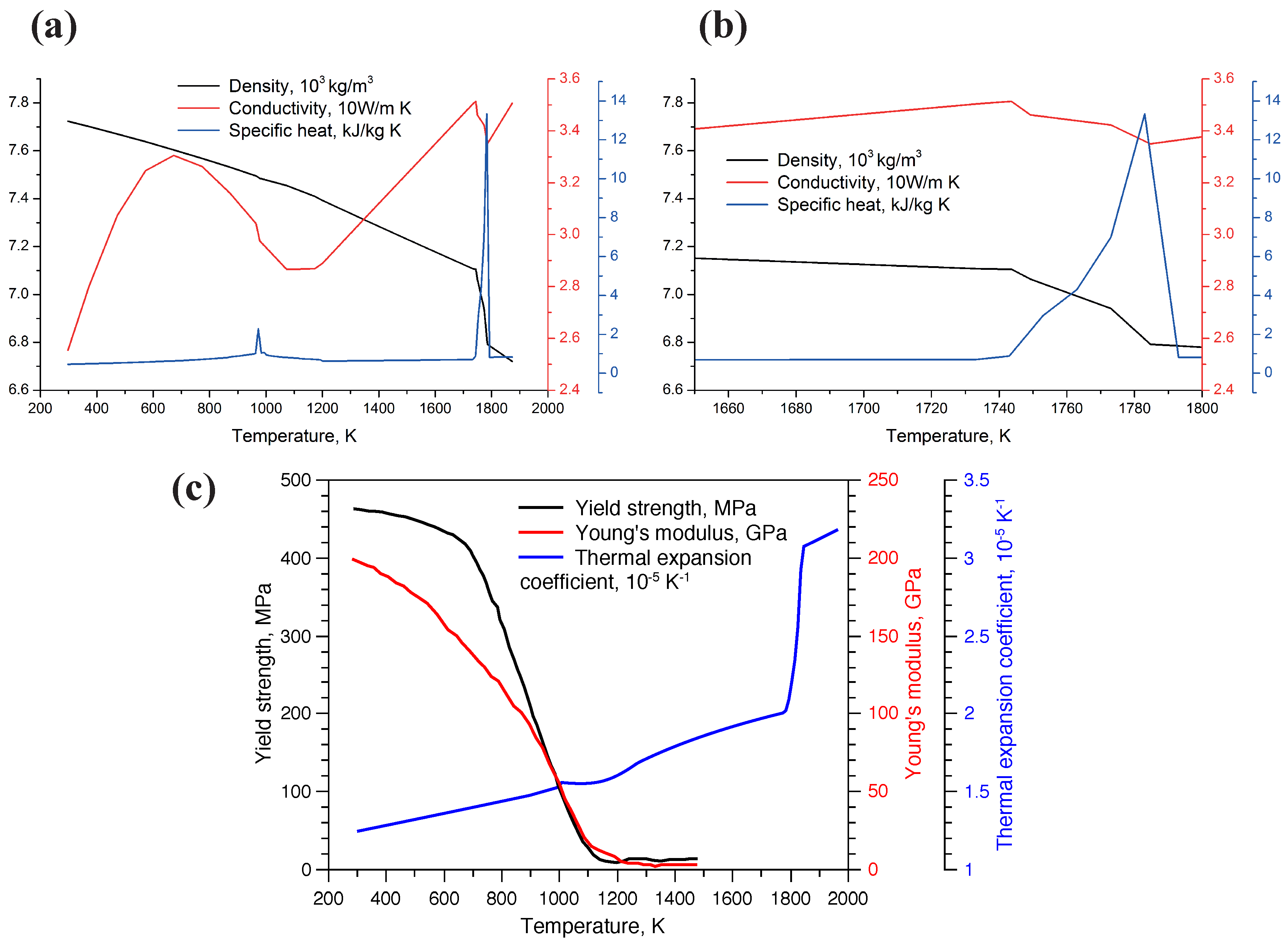

2. Materials and Methods

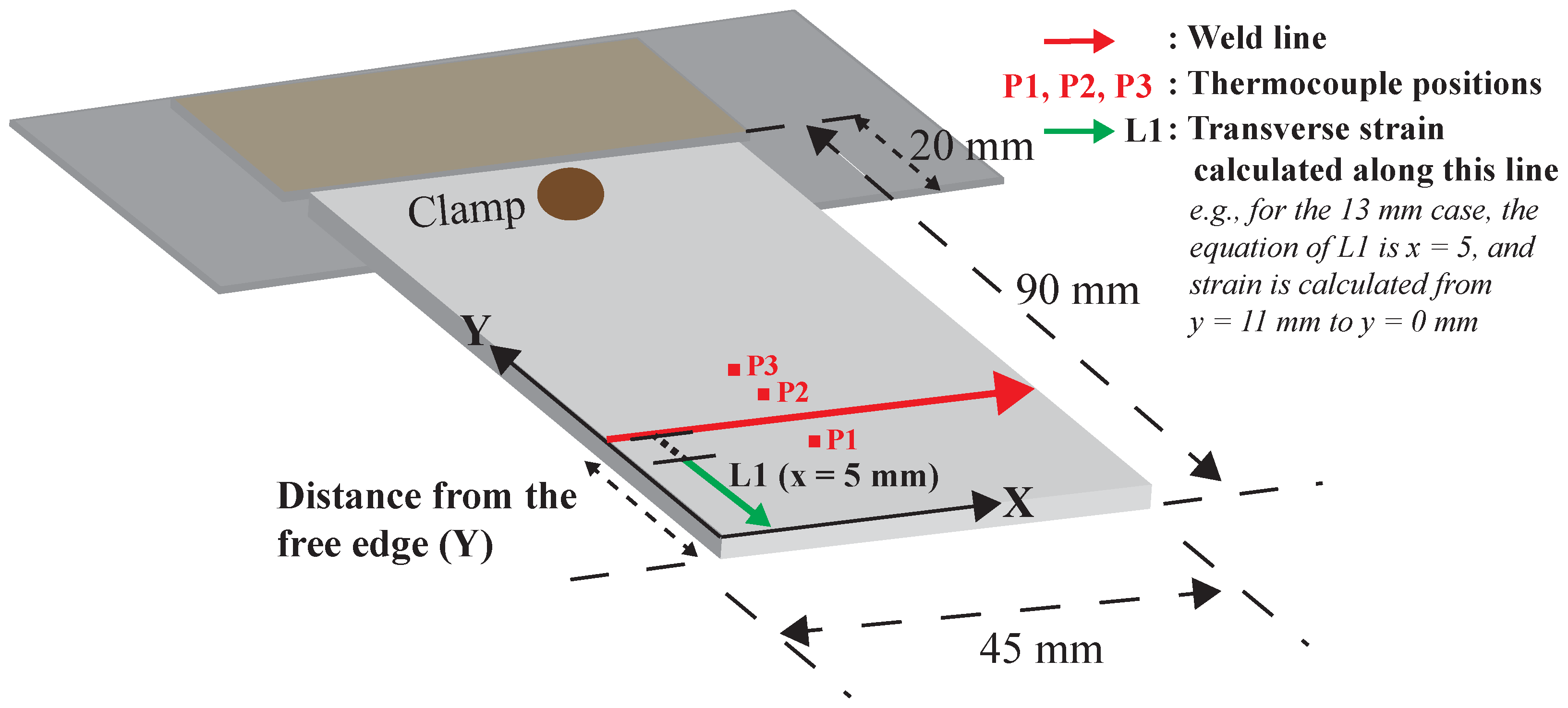

2.1. Experimental Section

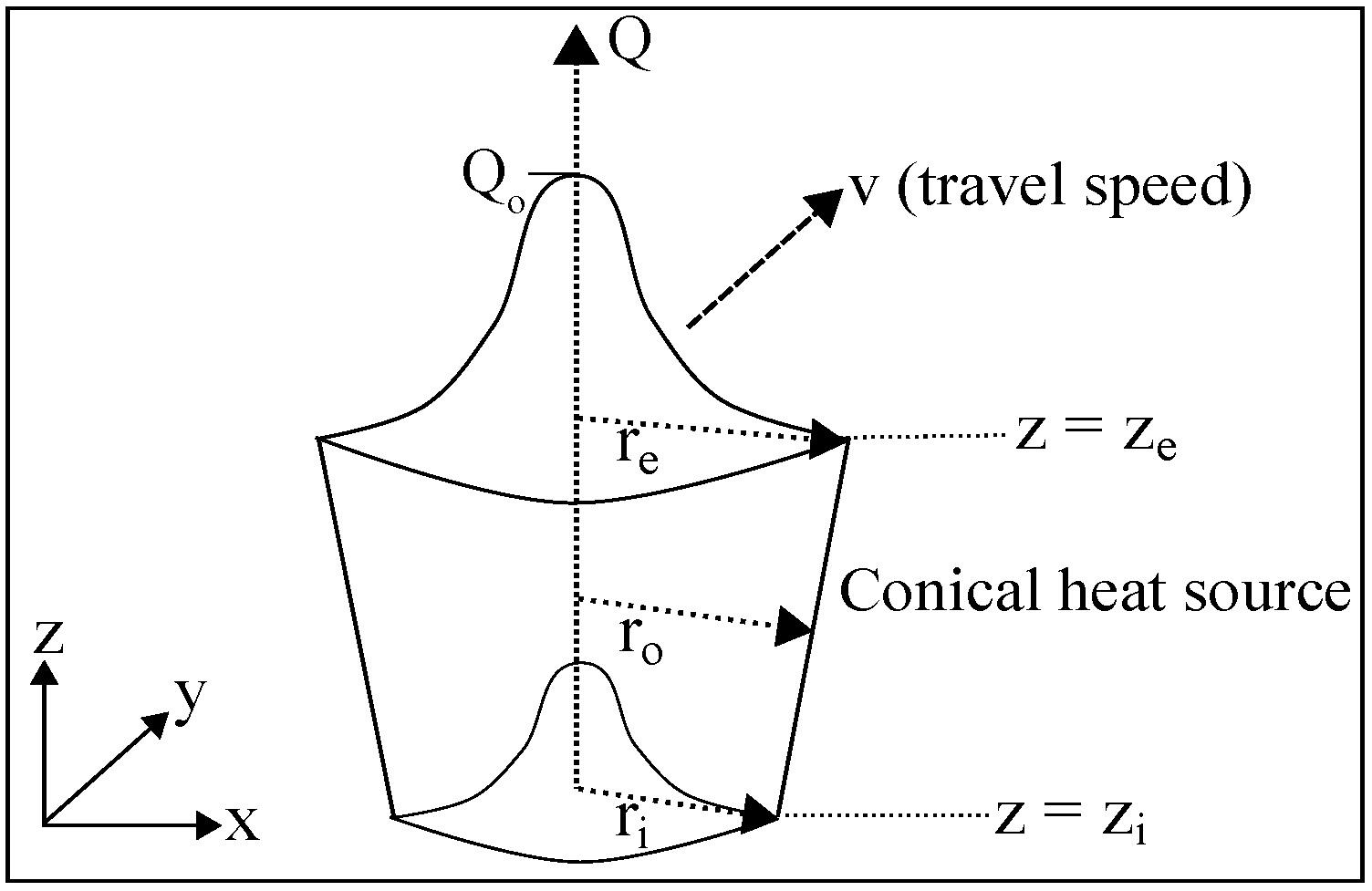

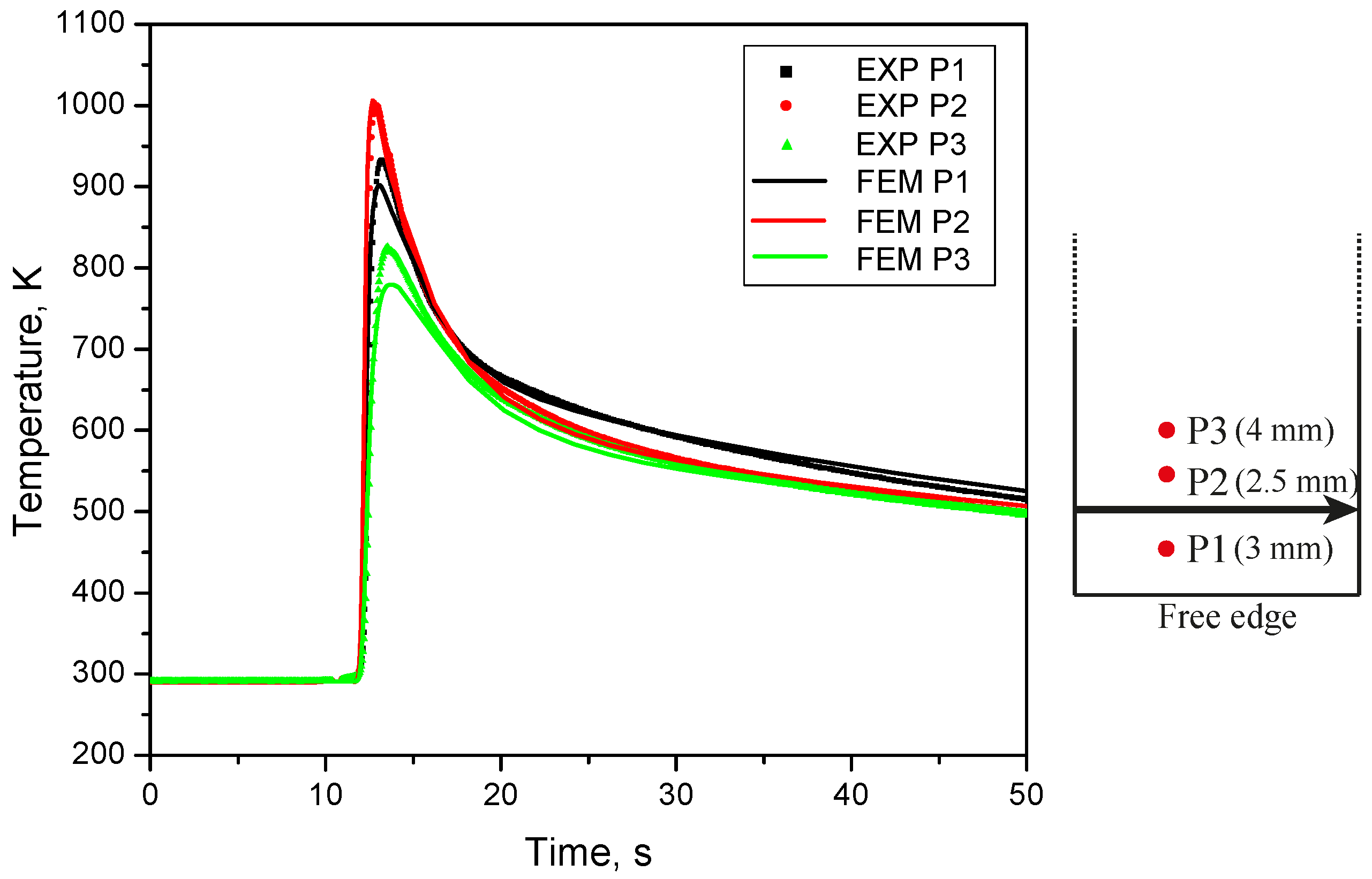

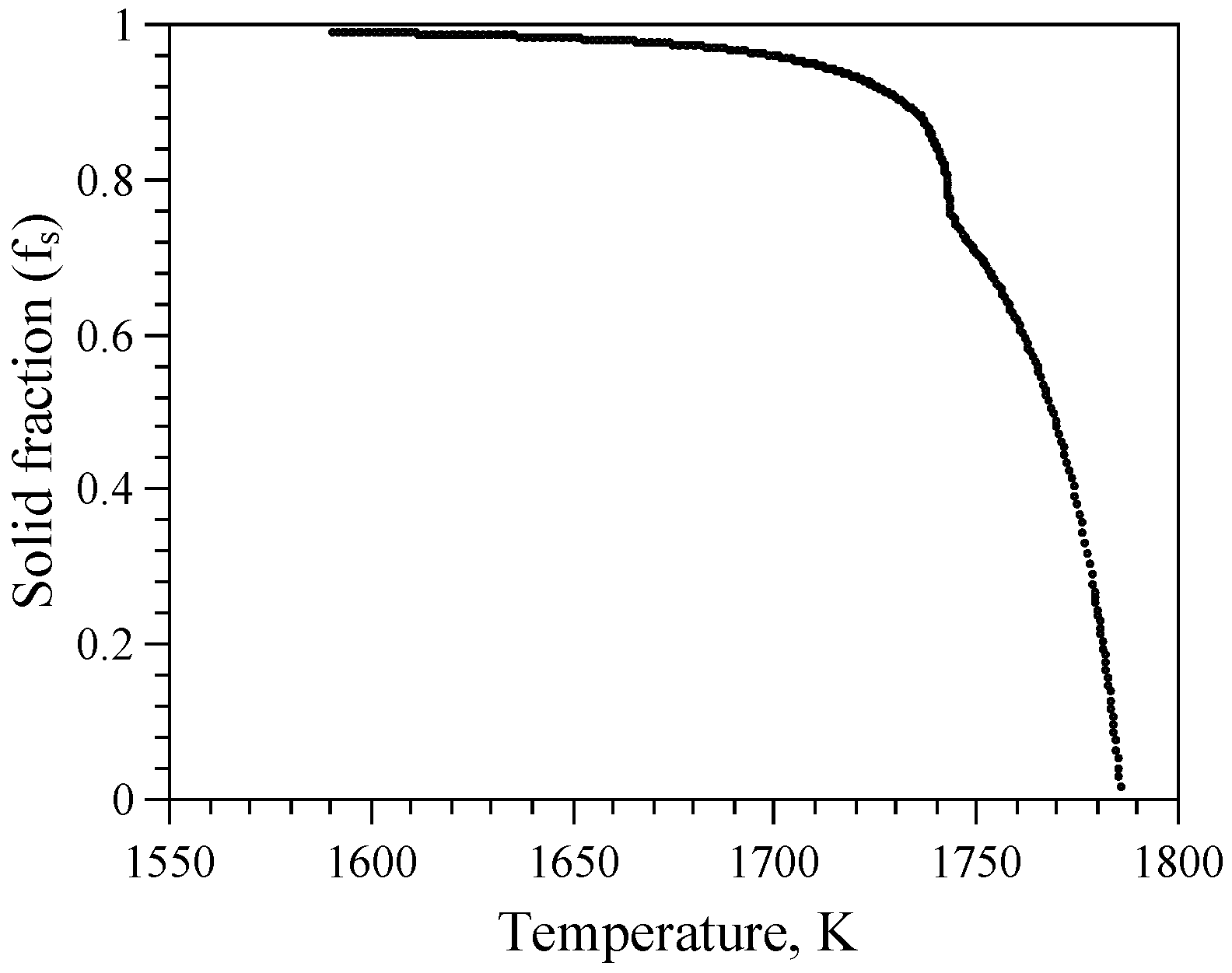

2.2. Modeling Approach

3. Results

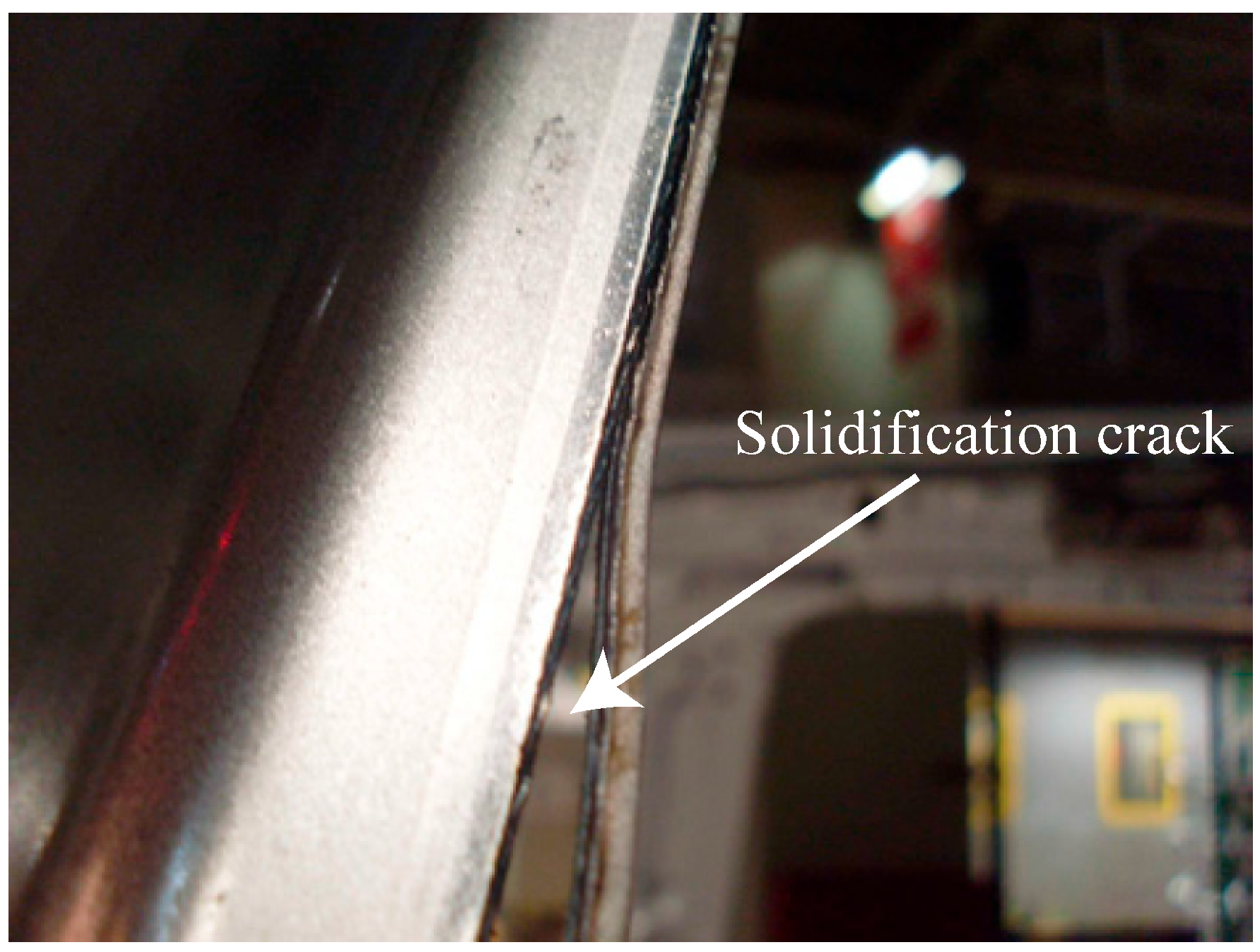

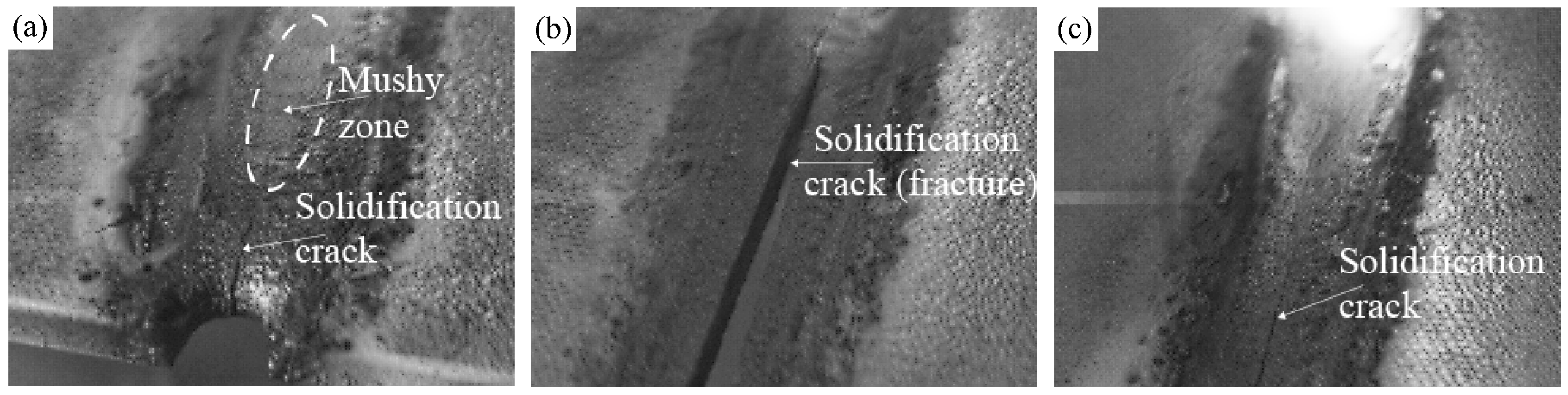

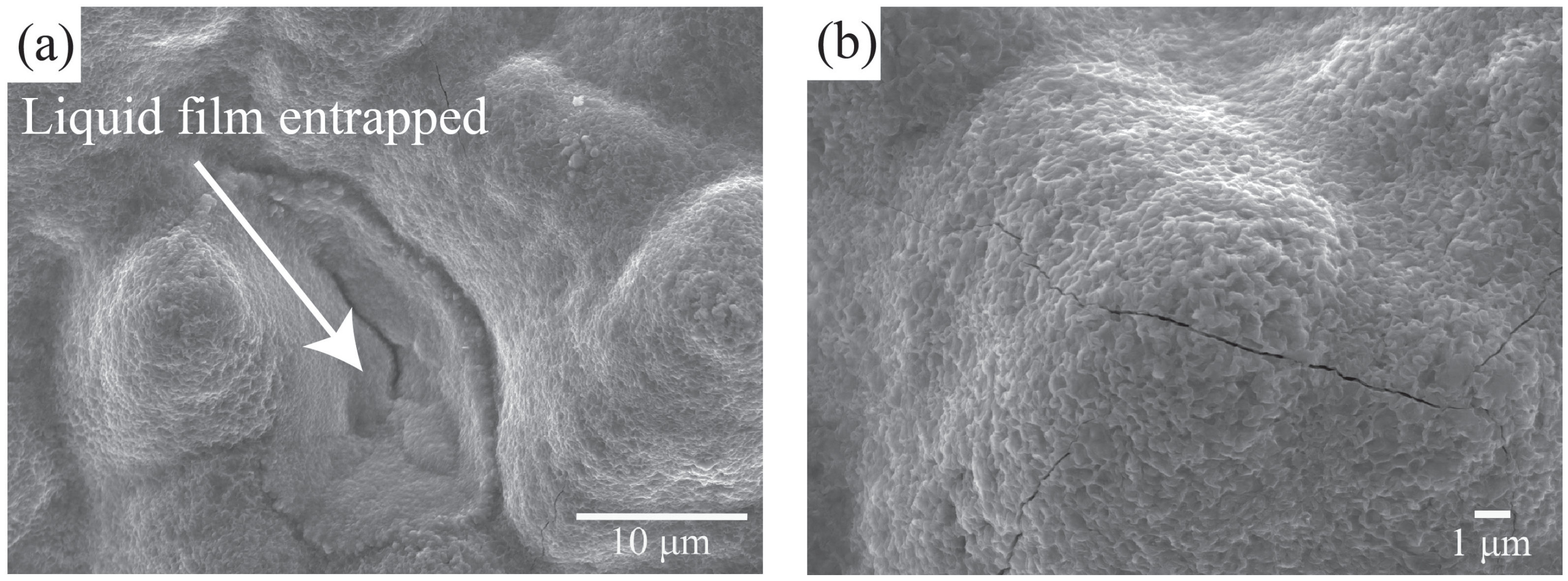

3.1. Observation of Solidification Cracking

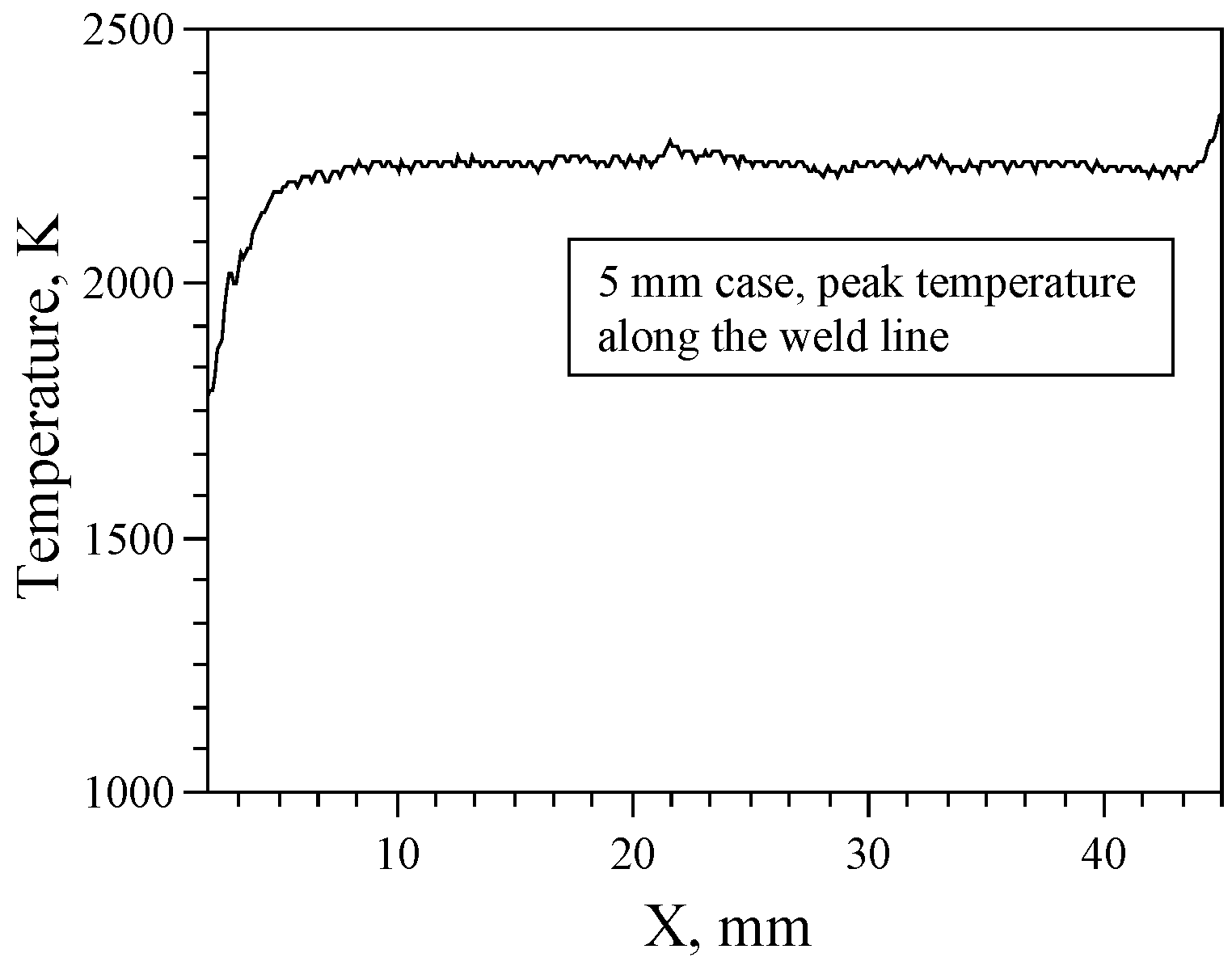

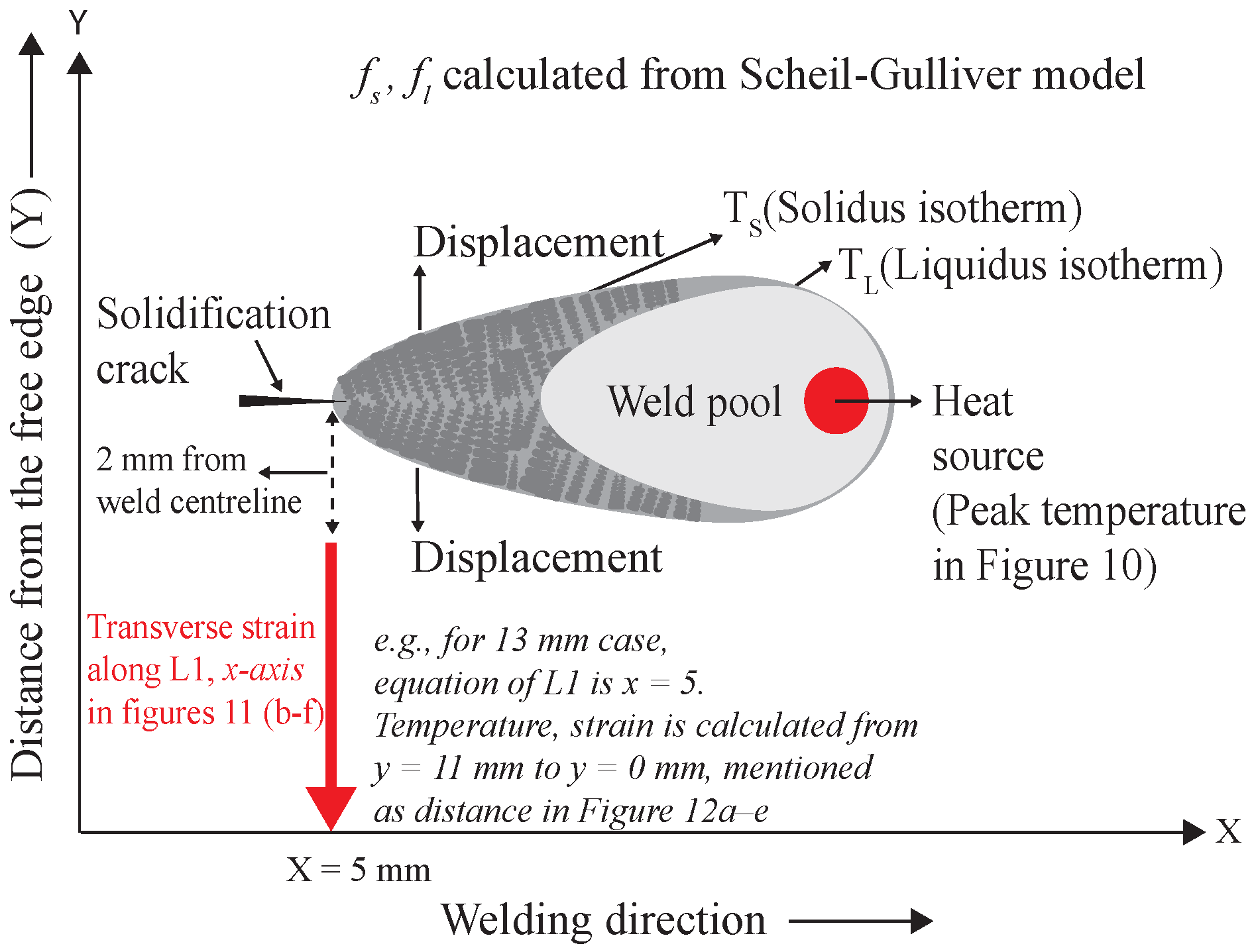

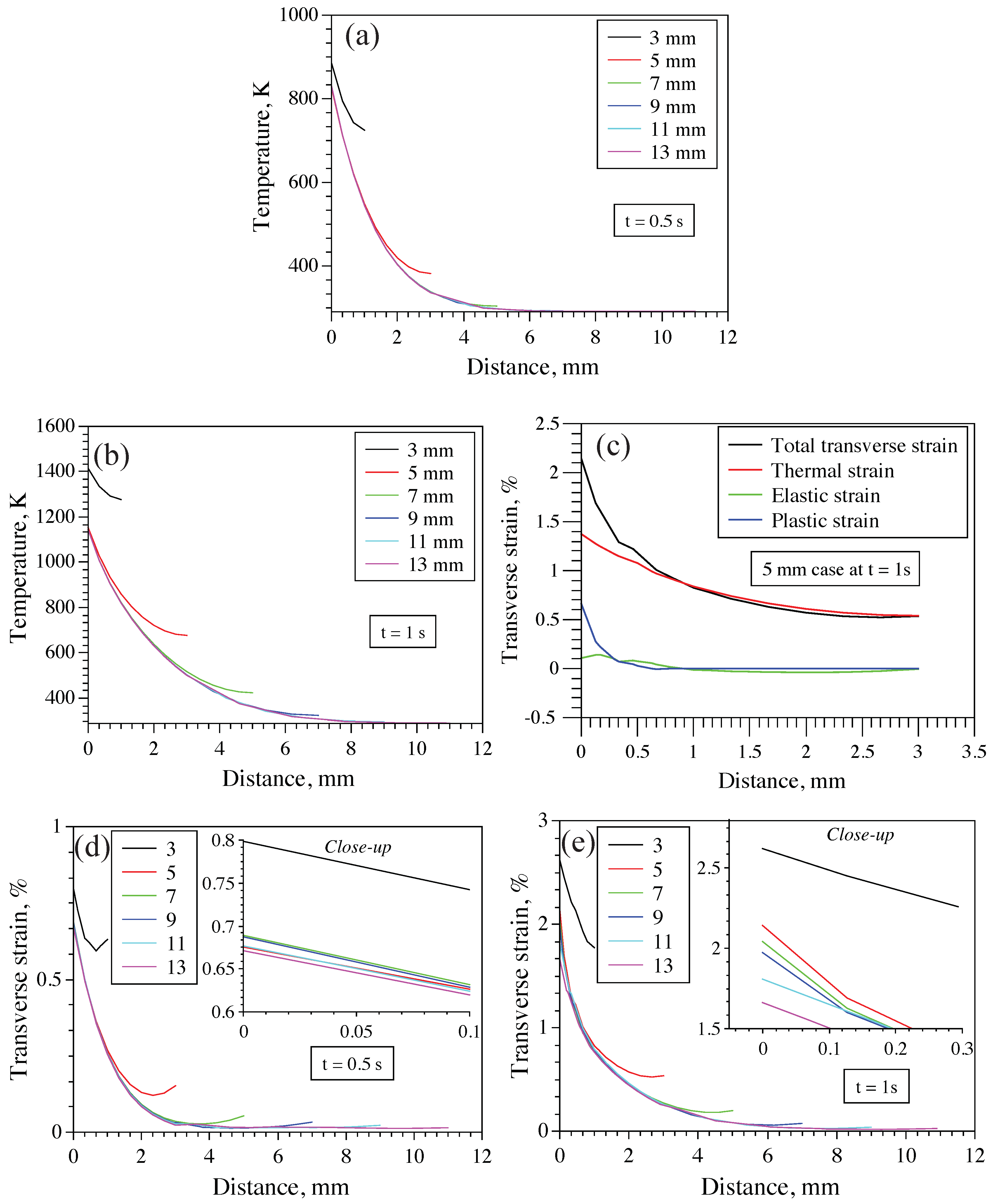

3.2. Thermomechanical Analysis of the Process

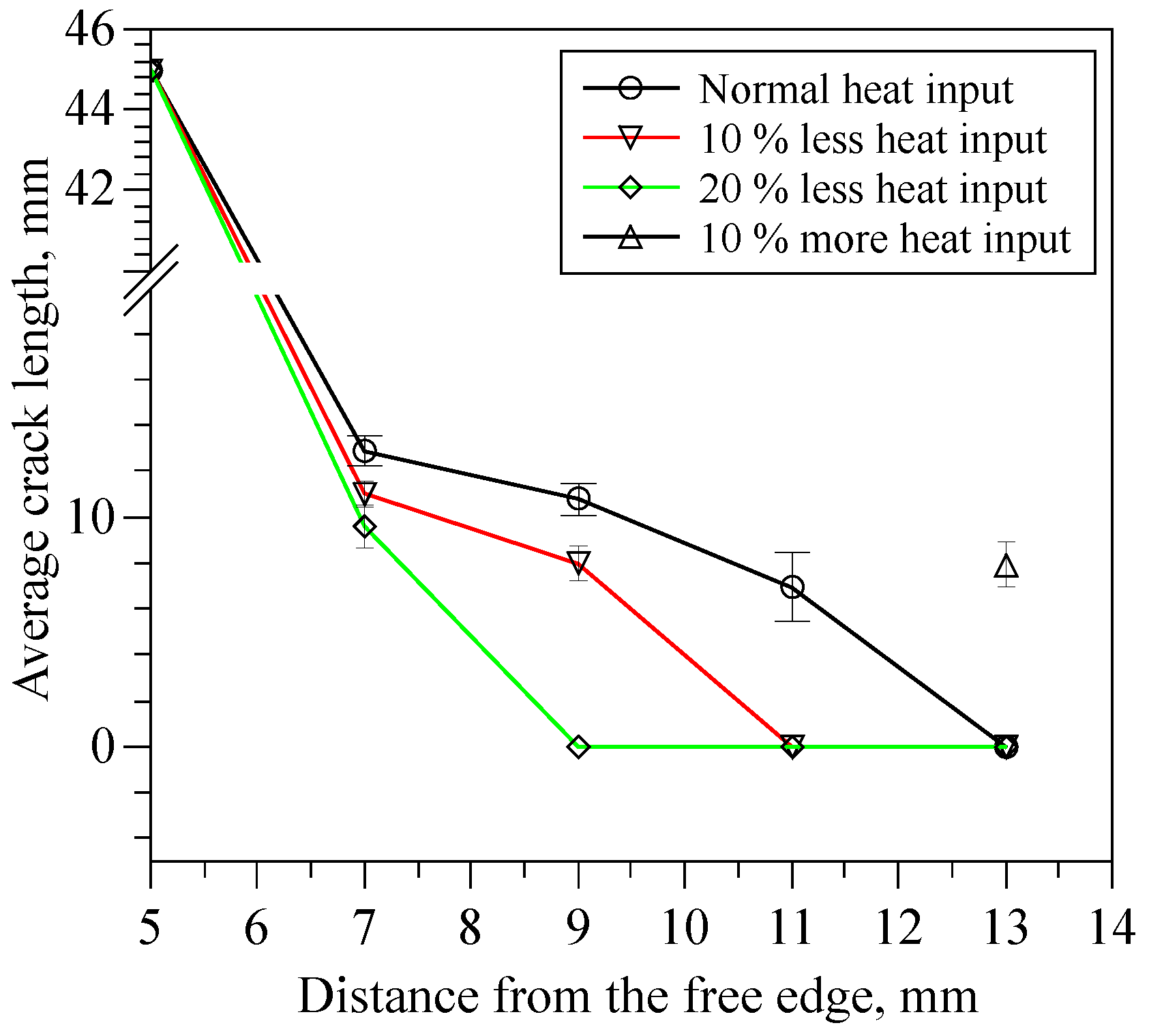

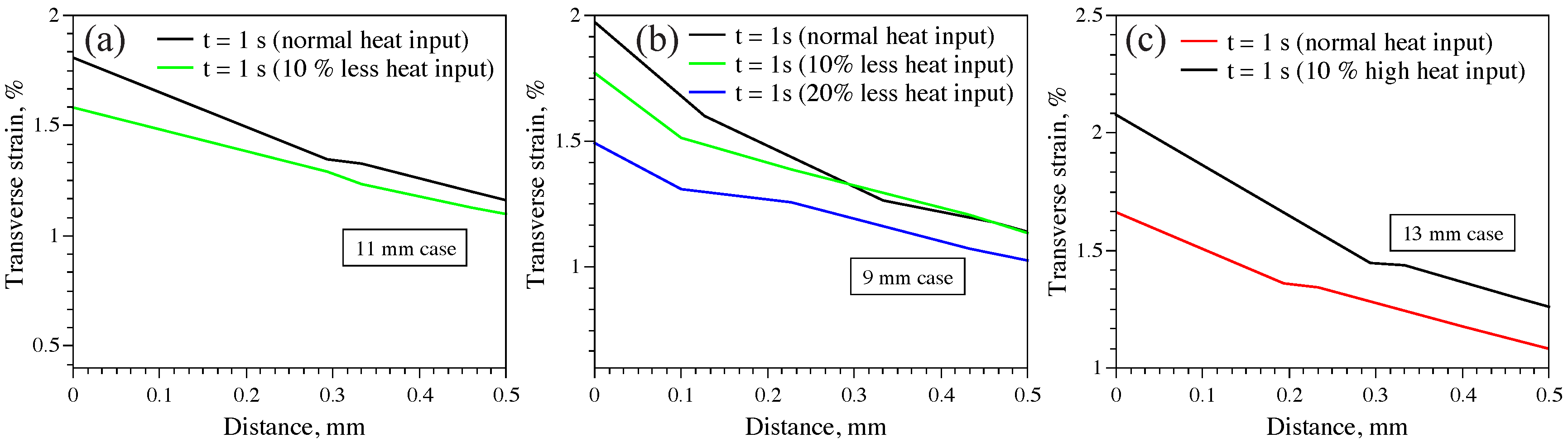

3.3. Effect of Heat Input on Transverse Strain and Crack Susceptibility

4. Discussion

5. Conclusions

- With the use of the presented hot cracking test, in general, any given material is most susceptible to solidification cracking when welding is carried out close to the free edge. As the distance from the free edge increases, i.e., the degree of self-restraint increases, the susceptibility to cracking decreases.

- The FE simulation study shows that macroscopic transverse strain near the mushy zone can be used as an indicator to explain the experimentally-observed cracking susceptibility with regards to crack length.

- A threshold transverse strain at a point close to the fusion boundary is determined for which no cracking was observed. It is further validated by varying the heat input both in the model and the experiments.

- Reducing the heat input decreases the susceptibility to solidification cracking or, in other words, it decreases the critical distance from the free edge at which cracking does not occur.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pumphrey, W.I.; Jennings, P.H. A consideration of the nature of brittleness and temperature above the solidus in castings and welds in aluminum alloys. J. Inst. Met. 1948, 75, 235–256. [Google Scholar]

- Pellini, W.S. Strain Theory of Hot-tearing. Foundry 1952, 80, 124–133. [Google Scholar]

- Prokhorov, N.N. The problem of the strength of metals while solidifying during welding. Svar. Proiz. 1956, 6, 5–11. [Google Scholar]

- Coniglio, N.; Cross, C.E. Mechanisms for Solidification Crack Initiation and Growth in Aluminum Welding. Metall. Mater. Trans. A 2009, 40, 2718–2728. [Google Scholar] [CrossRef]

- Agarwal, G.; Amirthalingam, M.; Moon, S.C.; Dippenaar, R.J.; Richardson, I.M.; Hermans, M.J.M. Experimental evidence of liquid feeding during solidification of a steel. Scr. Mater. 2018, 146, 105–109. [Google Scholar] [CrossRef]

- Rappaz, M.; Dantzig, J. Solidification, 1st ed.; EFPL Press: Lausanne, Switzerland, 2009; pp. 519–563. [Google Scholar]

- Kou, S. Welding Metallurgy, 2nd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2003; pp. 263–296. [Google Scholar]

- Agarwal, G.; Kumar, A.; Gao, H.; Amirthalingam, M.; Moon, S.C.; Dippenaar, R.J.; Richardson, I.M.; Hermans, M.J.M. Study of Solidification Cracking in a Transformation-Induced Plasticity-Aided Steel. Metall. Mater. Trans. A 2018, 49, 1015–1020. [Google Scholar] [CrossRef]

- Zacharia, T. Dynamic stresses in weld metal hot cracking. Weld. J. 1994, 73, 164S–172S. [Google Scholar]

- Eskin, D.G.; Katgerman, L. A Quest for a New Hot Tearing Criterion. Metall. Mater. Trans. A 2007, 38, 1511–1519. [Google Scholar] [CrossRef]

- Rappaz, M.; Drezet, J.M.; Gremaud, M. A new hot-tearing criterion. Metall. Mater. Trans. A 1999, 30, 449–455. [Google Scholar] [CrossRef]

- Kou, S. A criterion for cracking during solidification. Acta Mater. 2015, 88, 366–374. [Google Scholar] [CrossRef]

- Matsuda, F.; Nakagawa, H.; Nakata, K.; Okada, H. The VDR cracking test for solidification crack susceptibility on weld metals and its application to aluminum alloys. Trans. JWRI 1979, 8, 85–95. [Google Scholar]

- Katgerman, L. A Mathematical Model for Hot Cracking of Aluminum Alloys During D.C. Casting. JOM 1982, 34, 46–49. [Google Scholar] [CrossRef]

- Boesenkool, R.; van der Aa, E.M.; van der Veldt, T. (Tata Steel IJmuiden, The Netherlands). Personal communication, 2018.

- Larsson, J.K. Avoidance of crack inducement when laser welding hot-formed car body components—A variable analysis. Phys. Procedia 2010, 5, 115–124. [Google Scholar] [CrossRef]

- VDEh. SEP 1220-3: Testing and Documentation Guideline for the Joinability of Thin Sheet of Steel—Part 3: Laser Beam Welding; Verlag Stahleisen GmbH: Düsseldorf, Germany, 2011. [Google Scholar]

- Omar, M.A. Automotive Joining. In The Automotive Body Manufacturing Systems and Processes; Wiley-Blackwell: Hoboken, NJ, USA, 2011; Chapter 3; pp. 107–176. [Google Scholar] [CrossRef]

- Hong, K.M.; Shin, Y.C. Prospects of laser welding technology in the automotive industry: A review. J. Mater. Process. Technol. 2017, 245, 46–69. [Google Scholar] [CrossRef]

- Agarwal, G.; Gao, H.; Amirthalingam, M.; Hermans, M. In-situ strain investigation during laser welding using digital image correlation and finite element based numerical simulation. Sci. Technol. Weld. Join. 2018, 23, 134–139. [Google Scholar] [CrossRef]

- Shanmugam, N.B.; Buvanashekaran, G.; Sankaranarayanasamy, K.; Kumar, S.R. A transient finite element simulation of the temperature and bead profiles of T-joint laser welds. Mater. Des. 2010, 31, 4528–4542. [Google Scholar] [CrossRef]

- Ma, J.; Kong, F.; Kovacevic, R. Finite-element thermal analysis of laser welding of galvanized high-strength steel in a zero-gap lap joint configuration and its experimental verification. Mater. Des. 2012, 36, 348–358. [Google Scholar] [CrossRef]

- Zain-ul-abdein, M.; Nélias, D.; Jullien, J.F.; Deloison, D. Experimental investigation and finite element simulation of laser beam welding induced residual stresses and distortions in thin sheets of AA 6056-T4. Mater. Sci. Eng. A 2010, 527, 3025–3039. [Google Scholar] [CrossRef]

- Hibbitt, H.D.; Marcal, P.V. A numerical, thermo-mechanical model for the welding and subsequent loading of a fabricated structure. Comput. Struct. 1973, 3, 1145–1174. [Google Scholar] [CrossRef]

- Friedman, E. Thermomechanical Analysis of the Welding Process Using the Finite Element Method. J. Press. Vessel Technol. 1975, 97, 206–213. [Google Scholar] [CrossRef]

- Gao, H.; Dutta, R.K.; Huizenga, R.M.; Amirthalingam, M.; Hermans, M.J.M.; Buslaps, T.; Richardson, I.M. Pass-by-pass stress evolution in multipass welds. Sci. Technol. Weld. Join. 2014, 19, 256–264. [Google Scholar] [CrossRef]

- Feulvarch, E.; Robin, V.; Bergheau, J.M. Thermometallurgical and mechanical modeling of welding—Application to multipass dissimilar metal girth welds. Sci. Technol. Weld. Join. 2011, 16, 221–231. [Google Scholar] [CrossRef]

- Pan, Y. Laser welding of Zinc Coated Steel without Pre-Set Gap. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2011. [Google Scholar]

- Ahmed, E.A.A. Laser Welding of Advanced High Strength Steels. Ph.D. Thesis, RWTH Aachen University, Aachen, Germany, 2011. [Google Scholar]

- M’Hamdi, M.; Mo, A.; Fjær, H.G. TearSim: A two-phase model addressing hot tearing formation during aluminum direct chill casting. Metall. Mater. Trans. A 2006, 37, 3069–3083. [Google Scholar] [CrossRef]

- Safari, A.R.; Forouzan, M.R.; Shamanian, M. Hot cracking in stainless steel 310s, numerical study and experimental verification. Comput. Mater. Sci. 2012, 63, 182–190. [Google Scholar] [CrossRef]

- Cross, C.E.; Boellinghaus, T. The Effect of Restraint on Weld Solidification Cracking in Aluminium. Weld. World 2006, 50, 51–54. [Google Scholar] [CrossRef]

- Goodwin, G.M. Development of a new hot-cracking test—The sigmajig. Weld. J. 1987, 66, 33s–38s. [Google Scholar]

- Feng, Z. A computational analysis of thermal and mechanical conditions for weld metal solidification cracking. Weld. World 1994, 33, 340–347. [Google Scholar]

- Cross, C.E. On the Origin of Weld Solidification Cracking. In Hot Cracking Phenomena in Welds; Böllinghaus, T., Herold, H., Eds.; Springer: Berlin/Heidelberg, Germany, 2005; pp. 3–18. [Google Scholar]

- Senda, T.; Matsuda, F.; Takano, G.; Watanabe, K.; Kobayashi, T.; Matsuzaka, T. Fundamental Investigations on Solidification Crack Susceptibility for Weld Metals with Trans-Varestraint Test. Trans. Jpn. Weld. Soc. 1971, 2, 141–162. [Google Scholar]

- Matsuda, F.; Nakagawa, H.; Sorada, K. Dynamic Observation of Solidification and Solidification Cracking during Welding with Optical Microscope (I): Solidification Front and Behavior of Cracking. Trans. Jpn. Weld. Soc. 1982, 11, 67–77. [Google Scholar]

- Coniglio, N.; Cross, C.E. Towards Establishment of Weldability Testing Standards for Solidification Cracking. In Cracking Phenomena in Welds IV; Boellinghaus, T., Lippold, J.C., Cross, C.E., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 37–66. [Google Scholar]

- Clyne, T.W.; Wolf, M.; Kurz, W. The effect of melt composition on solidification cracking of steel, with particular reference to continuous casting. Metall. Trans. B 1982, 13, 259–266. [Google Scholar] [CrossRef]

- Feng, Z.; David, S.A.; Zacharia, T.; Tsai, C.L. Quantification of thermomechanical conditions for weld solidification cracking. Sci. Technol. Weld. Join. 1997, 2, 11–19. [Google Scholar] [CrossRef]

| Elements, wt. % | C | Mn | Al | Si | Cr | P | Fe |

|---|---|---|---|---|---|---|---|

| TRIP | 0.19 | 1.63 | 1.1 | 0.35 | 0.019 | 0.089 | bal. |

| Welding Distance (Yordinate, mm) | Welding Parameters | |

|---|---|---|

| Laser Power (W) | Speed (mm s−1) | |

| 3, 5, 7, 9 and 11 | 10 | |

| 1100 | 11 | |

| 12 | ||

| 13 | 1100 | 9 |

| 10 | ||

| 11 | ||

| 12 | ||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Agarwal, G.; Gao, H.; Amirthalingam, M.; Hermans, M. Study of Solidification Cracking Susceptibility during Laser Welding in an Advanced High Strength Automotive Steel. Metals 2018, 8, 673. https://doi.org/10.3390/met8090673

Agarwal G, Gao H, Amirthalingam M, Hermans M. Study of Solidification Cracking Susceptibility during Laser Welding in an Advanced High Strength Automotive Steel. Metals. 2018; 8(9):673. https://doi.org/10.3390/met8090673

Chicago/Turabian StyleAgarwal, Gautam, He Gao, Murugaiyan Amirthalingam, and Marcel Hermans. 2018. "Study of Solidification Cracking Susceptibility during Laser Welding in an Advanced High Strength Automotive Steel" Metals 8, no. 9: 673. https://doi.org/10.3390/met8090673

APA StyleAgarwal, G., Gao, H., Amirthalingam, M., & Hermans, M. (2018). Study of Solidification Cracking Susceptibility during Laser Welding in an Advanced High Strength Automotive Steel. Metals, 8(9), 673. https://doi.org/10.3390/met8090673