Repair and Reinforcement of Historic Timber Structures with Stainless Steel—A Review

Abstract

:1. Introduction

2. Stainless Typologies for Structural Applications

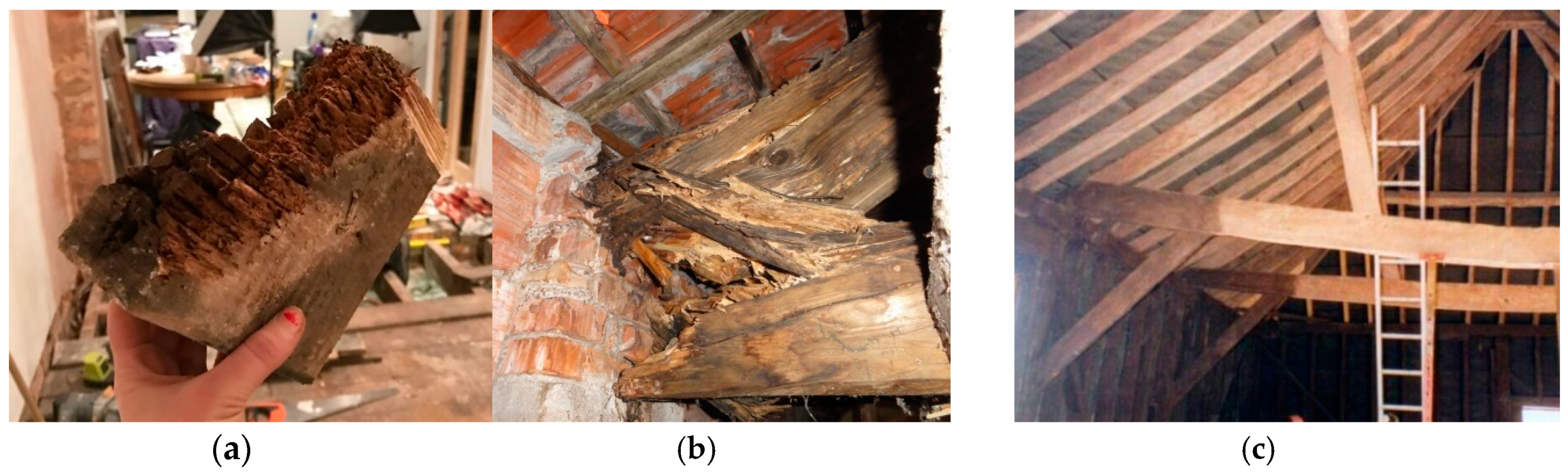

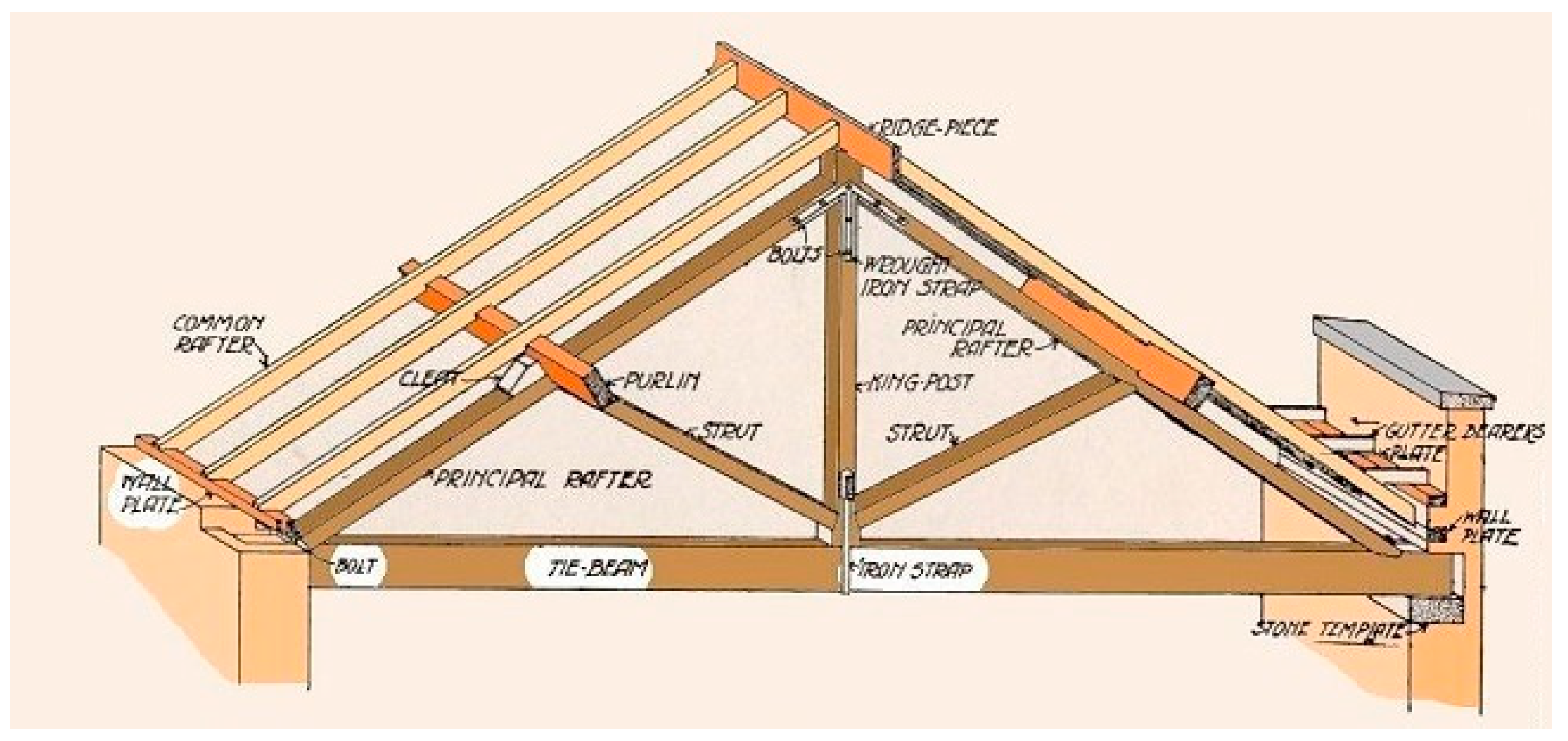

3. Typical Timber Historic Structures

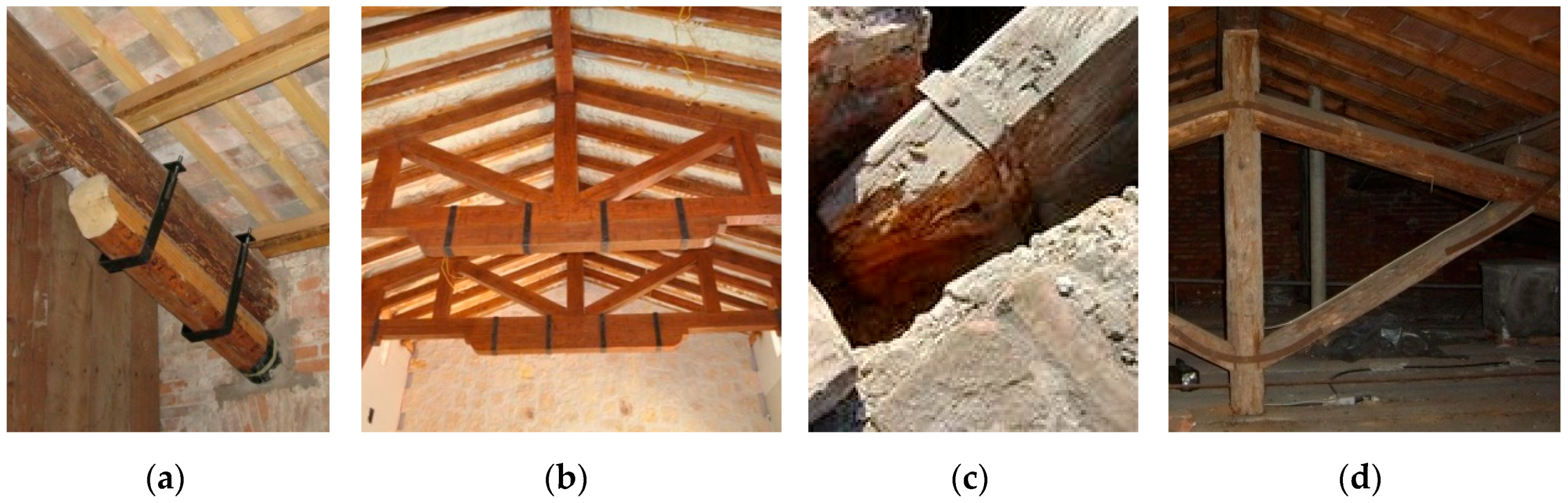

4. Repair Methods

4.1. Stainless Fasteners

4.2. Re-construction of Beam Ends

4.2.1. Use of Stainless Steel Sections

4.2.2. Use of Stainless Steel Rods

4.2.3. Use of Nail Plates

5. Reinforcement Methods

5.1. Reinforcement by Converting a Beam Element into a Trussed Girder

5.2. Reinforcement by Addition of Stainless Steel H-shaped Profiles

5.3. Reinforcement with Side Tension Rods or Plates

5.3.1. Reinforcement with Externally Attached Steel Plates or Cords

5.3.2. Reinforcement with Bonded-In Steel Rods or Strips

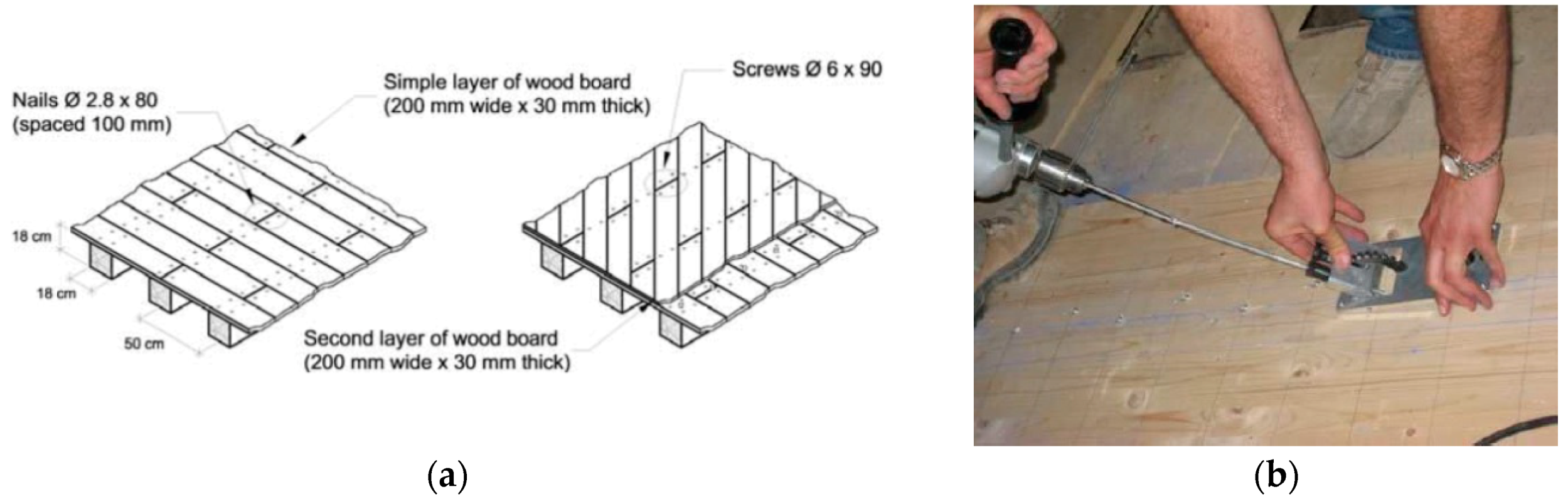

6. Reinforcement of Wooden Floors

7. Future Developments and Possibilities

8. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gedge, G. Structural uses of stainless steel—Buildings and civil engineering. J. Constr. Steel Res. 2008, 64, 1194–1198. [Google Scholar] [CrossRef]

- Gedge, G. Duplex steels for durable bridge construction. In Proceedings of the International Association for Bridge and Structural Engineering (IABSE) Conference, Weimar, Germany, 16–21 September 2007. [Google Scholar]

- Baddoo, N.R.; Burgan, B. Structural Design of Stainless Steel; Steel Construction Institute: London, UK, 2001; SCI P291. [Google Scholar]

- McGurn, J.F. Stainless steel reinforcing bars in concrete. In Proceedings of the Intern. Conference of Corrosion and Rehabilitation of Reinforced Concrete Structures FHWA, Orlando, FL, USA, 7–11 December 1998. [Google Scholar]

- Baddoo, N.R. Stainless steel in construction: A review of research, applications, challenges and opportunities. J. Constr. Steel Res. 2008, 64, 1199–1206. [Google Scholar] [CrossRef]

- Venice Charter. International charter for the conservation and restoration of monuments and sites. In Proceedings of the 2nd International Congress of Architects and Technicians of Historical Monuments, Venice, Italy, 25–31 May 1964. [Google Scholar]

- Krakow Charter. Principles for conservation and restoration of built heritage. In Proceedings of the International Conference on Conservation, Krakow, Poland, 23–24 November 1998. [Google Scholar]

- Pleviris, N.; Triantafillou, T.C. FRP-reinforced wood as structural material. J. Mater. Civ. Eng. 1992, 4, 300–317. [Google Scholar] [CrossRef]

- Triantafillou, T.C. Shear reinforcement of wood using FRP materials. J. Mater. Civ. Eng. 1997, 9, 65–69. [Google Scholar] [CrossRef]

- Borri, A.; Corradi, M.; Grazini, A. FRP reinforcement of wood elements under bending loads. In Proceedings of the 10th International Conference on Structural Faults + Repair, London, UK, 1–3 July 2003. [Google Scholar]

- Gentile, C.; Svecova, D.; Rizkalla, S.H. Timber beams strengthened with GFRP bars: Development and applications. J. Compos. Constr. 2002, 6, 11–20. [Google Scholar] [CrossRef]

- Borri, A.; Corradi, M.; Grazini, A. A method for flexural reinforcement of old wood beams with CFRP materials. Compos. Part B Eng. 2005, 39, 143–153. [Google Scholar] [CrossRef]

- Miceli, F.; Scialpi, V.; La Tegola, A. Flexural reinforcement of glulam timber beams and joints with Carbon Fiber-Reinforced Polymer rods. J. Compos. Constr. 2005, 9, 337–347. [Google Scholar] [CrossRef]

- Gilfillan, J.; Gilbert, S.; Patrick, G. The use of FRP composites in enhancing the structural behavior of timber beams. J. Reinf. Plast. Compos. 2003, 22, 1373–1388. [Google Scholar] [CrossRef]

- Chu, W.; Wu, L.; Karbhari, V.M. Durability evaluation of moderate temperature cured E-glass/vinylester systems. Compos. Struct. 2004, 66, 367–376. [Google Scholar] [CrossRef]

- Karbhari, V.M.; Chin, J.W.; Hunston, D.; Benmokrane, B.; Juska, T.; Morgan, R.; Lesko, J.J.; Sorathia, U.; Reynaud, D. Durability gap analysis for Fiber-Reinforced Polymer composites in civil infrastructure. J. Compos. Constr. ASCE 2003, 7, 238–247. [Google Scholar] [CrossRef]

- Krempl, E. An experimental study of room-temperature rate sensitivity, creep and relaxation of AISI 304 stainless steel. J. Mech. Phys. Solids 1979, 27, 363–375. [Google Scholar] [CrossRef]

- ICOMOS International Wood Committee. Principles for the Preservation of Historic Timber Structures; ICOMOS General Assembly: Guadalajara, Mexico, 1999. [Google Scholar]

- Camanho, P.; Hallett, S. Composite Joints and Connections: Principles, Modelling and Testing; Woodhead Publishing: Cambridge, UK, 2011. [Google Scholar]

- EN10088 Part 1 Stainless Steels Part 1—List of Stainless Steels; BSI: London, UK, 1995.

- EN10088 Part 2 Stainless Steels. Technical Delivery Conditions for Sheet/Plate and Strip of Corrosion Resisting Steels for General Purposes; BSI: London, UK, 2005.

- Sanstrom, R.; Bergqvist, H. Temperature dependence of tensile properties and strengthening of nitorgen alloyed austenitic stainless steels. Scand. J. Metall. 1977, 6, 156–169. [Google Scholar]

- Di Schino, A.; Longobardo, M.; Turconi, G.L.; Porcu, G.; Scoppio, L. Metallurgical design and development of C125 grade for mild sour service application. In Proceedings of the NACE—International Corrosion Conference, San Diego, CA, USA, 12–16 March 2006; pp. 061251–0612514. [Google Scholar]

- Di Schino, A.; Kenny, J.M.; Salvatori, I.; Abbruzzese, G. Modelling primary recrystallization and grain growth in a low nickel austenitic stainless steel. J. Mater. Sci. 2001, 36, 593–601. [Google Scholar] [CrossRef]

- International Molybdenum Association. Practical Guidelines for the Fabrication of Duplex Stainless Steels; IMOA: London, UK, 2014. [Google Scholar]

- Outokumpu. Available online: http://www.outokumpu.com/SiteCollectionDocuments/Outokumpu -Product-Range-Wallchart.pdf (accessed on 14 November 2018).

- European Standard EN ISO 15156-1:2015, NACE MR0175 Petroleum and Natural Gas Industries—Materials for Use in H2S-Containing Environments in Oil and Gas Production—Part 1: General Principles for Selection of Cracking-Resistant Materials; ISO: Geneva, Switzerland, 2015.

- National Association of Corrosion Engineers (NACE). TM-01-69:1995 (R2000)—Laboratory Corrosion Testing of Metals; NACE: Houston, TX, USA, 2000. [Google Scholar]

- Corradi, M.; Di Schino, A.; Borri, A.; Rufini, R. A review of the use of stainless steel for masonry repair and reinforcement. Constr. Build. Mater. 2018, 181, 335–346. [Google Scholar] [CrossRef]

- General Technical Delivery Conditions. European Standard EN 10025-1:2004 Hot Rolled Products of Structural Steels; CEN European Committee for Standardisation: Brussels, Belgium, 2004. [Google Scholar]

- Di Caprio, G. Gli Acciai Inossidabili; Hoepli: Milan, Italy, 2003. [Google Scholar]

- Panshin, A.J.; deZeeuw, C. Textbook of Wood Technology, 4th ed.; McGraw–Hill: New York, NY, USA, 1980. [Google Scholar]

- Parisi, M.A.; Piazza, M. Restoration and strengthening of timber structures: Principles, criteria, and examples. Pract. Period. Struct. Des. Constr. 2007, 12, 177–185. [Google Scholar] [CrossRef]

- Barbaro, D. I Dieci Libri Dell’architettura di M. Vitruvio; Il Polifilo: Milan, Italy, 1997. [Google Scholar]

- Tampone, G. Conservation of Historic Wooden Structures; Hoepli: Florence, Italy, 2005. [Google Scholar]

- Unalansusam. Available online: http://unalansusam.com/roof-struts/kptruss-digital-art-gallery-roof- struts/ (accessed on 23 November 2018).

- Tampone, G.; Mannucci, N.; Macchioni, N. Strutture di Legno. Cultura Conservazione Restauro; De Lettera: Rome, Italy, 2002. [Google Scholar]

- Mariani, M. Consolidamento Delle Strutture Lignee con L’acciaio; DEI: Rome, Italy, 2004. [Google Scholar]

- Charles, F.W.B. Dismantling, Repairing and Rebuilding as a Means of Conservation. In Proceedings of the ICOMOS UK: Timber Engineering Conference, London, UK, 8 April 1992. [Google Scholar]

- Bulleit, W.M. Reinforcement of wood materials: A review. Wood Fiber Sci. 2007, 16, 391–397. [Google Scholar]

- Giordano, G. Tecnica Delle Costruzioni in Legno; Hoepli: Milan, Italy, 1999. [Google Scholar]

- Franke, S.; Franke, B.; Harte, A.M. Failure modes and reinforcement techniques for timber beams–State of the art. Constr. Build. Mater. 2015, 97, 2–13. [Google Scholar] [CrossRef]

- Buildingconservation. Available online: http://www.buildingconservation.com/articles/structural-timber- repairs/structural-timber-repairs.htm (accessed on 21 October 2018).

- Joist-repair. Available online: https://www.joist-repair.co.uk/joistendrepair_diydoc.htm (accessed on 3 December 2018).

- Fiorentecnica. Available online: http://www.fiorentecnica.it/paginaintx02.html (accessed on 25 November 2018).

- Alessandri, C.; Mallardo, V.; Pizzo, B.; Ruocco, E. The roof of the Church of the Nativity in Bethlehem: Structural problems and intervention techniques. J. Cult. Herit. 2012, 13, 70–81. [Google Scholar] [CrossRef]

- Pizzo, B.; Gavioli, M.; Lauriola, M.P. Evaluation of a design approach to the on-site structural repair of decayed old timber end beams. Eng. Struct. 2013, 48, 611–622. [Google Scholar] [CrossRef]

- Resine-epossidiche. Available online: https://resine-epossidiche.it/edilizia-conservativa/ (accessed on 25 November 2018).

- Blass, H.J.; Schmid, M.; Litze, H.; Wagner, B. Nail plate reinforced joints with dowel-type fasteners. In Proceedings of the 6th World Conference on Timber Engineering, British Columbia, Canada, 31 July–3 August 2000. [Google Scholar]

- Karadelis, J.N.; Brown, P. Punched metal plate timber fasteners under fatigue loading. Constr. Build. Mater. 2000, 14, 99–108. [Google Scholar] [CrossRef]

- Fordevr. Available online: https://www.fordevr.com/nail-plate-construction.html (accessed on 10 January 2019).

- Beauty. Available online: http://beauty.fzl99.com/gang-nail-truss-plates/ (accessed on 10 January 2019).

- Studiofornale. Available online: http://www.studiofornale.it/intervento-di-consolidamento-trave-in-legno-lesionata-con-.contraffisso-metallico/ (accessed on 15 December 2018).

- Larsen, K.E.; Marstein, N. Conservation of historic timber structures: An ecological approach. In Butterworth-Heinemann Series in Conservation and Museology; Butterworth Heinemann: Oxford, UK, 2000. [Google Scholar]

- Jurina, L. L’uso Dell’acciaio nel Consolidamento delle Capriate e dei Solai in Legno. 2004. Available online: http://www.jurina.it/10/2012/02/2011_L%E2%80%99uso-dell%E2%80%99acciaio-nel-consolidamento-delle- capriate-e-dei-solai-in-legno.pdf (accessed on 21 January 2019).

- New South Wales State Heritage Office. The Maintenance Series, Timber Repairs, Information Sheet 5.2; New South Wales State Heritage Office: Sidney, Australia, 1998. [Google Scholar]

- Song, J.K.; Kim, S.Y.; Yang, K.H.; Han, S.A. Flexural behavior of post-tensioned glued-laminated timber with wire rope. In Proceedings of the International Conference on Sustainable Building Asia, Seoul, Korea, 27–29 June 2007. [Google Scholar]

- Corradi, M.; Borri, A. Fir and chestnut timber beams reinforced with GFRP pultruded Elements. J. Compos. Part B 2007, 38, 172–181. [Google Scholar] [CrossRef]

- Borgin, K.B.; Loedolff, G.F.; Saunders, G.R. Laminated wood beams reinforced with steel strips. J. Struct. Div. 1968, 94, 1681–1706. [Google Scholar]

- Alam, P.; Ansell, M.P.; Smedley, D. Mechanical repair of timber beams fractured in flexure using bonded-in reinforcements. Compos. Part B Eng. 2009, 40, 95–106. [Google Scholar] [CrossRef]

- Jasieńko, J.; Nowak, T.P. Solid timber beams strengthened with steel plates—Experimental studies. Constr. Build. Mater. 2014, 63, 81–88. [Google Scholar] [CrossRef]

- Corradi, M.; Borri, A.; Castori, G.; Speranzini, E. Fully reversible reinforcement of softwood beams with unbonded composite plates. Compos. Struct. 2016, 149, 54–68. [Google Scholar] [CrossRef] [Green Version]

- Corradi, M.; Vo, T.P.; Poologanathan, K.; Osofero, A.I. Flexural behaviour of hardwood and softwood beams with mechanically connected GFRP plates. Compos. Struct. 2018, 206, 610–620. [Google Scholar] [CrossRef]

- Resinproget. Available online: http://www.resinproget.it/bverona.html (accessed on 21 January 2019).

- Ghanbari Ghazijahani, T.; Jiao, H.; Holloway, D. Composite timber beams strengthened by steel and CFRP. J. Compos. Constr. 2017, 21, 04016059. [Google Scholar] [CrossRef]

- Borri, A.; Corradi, M. Strengthening of timber beams with high strength steel cords. Compos. Part B Eng. 2011, 42, 1480–1491. [Google Scholar] [CrossRef] [Green Version]

- Raftery, G.M.; Kelly, F. Basalt FRP rods for reinforcement and repair of timber. Compos. Part B Eng. 2015, 70, 9–19. [Google Scholar] [CrossRef]

- Bainbridge, R.; Mettem, C.; Harvey, K.; Ansell, M. Bonded-in rod connections for timber structures-development of design methods and test observations. Int. J. Adhes. Adhes. 2002, 22, 47–59. [Google Scholar] [CrossRef]

- Wu, W.; Gou, H. Analyzing of the timber beams of ancient buildings strengthened with NSM stainless steel bars. Int. J. Sci. 2015, 2, 77–87. [Google Scholar]

- Lantos, G. The flexural behavior of steel reinforced laminated timber beams. Wood Sci. 1970, 2, 136–143. [Google Scholar]

- Metelli, G.; Preti, M.; Giuriani, E. On the delamination phenomenon in the repair of timber beams with steel plates. Constr. Build. Mater. 2016, 102, 1018–1028. [Google Scholar] [CrossRef]

- Bulleit, W.M.; Sandberg, L.B.; Woods, G.J. Steel-reinforced glued laminated timber. J. Struct. Eng. 1989, 115, 433–444. [Google Scholar] [CrossRef]

- Branco, J.M.; Tomasi, R. Analysis and strengthening of timber floors and roofs. In Structural Rehabilitation of Old Buildings; Costa, A., Miranda Guedes, J., Varum, H., Eds.; Springer: Berlin, Germany, 2013; pp. 235–258. [Google Scholar]

- Turrini, G.; Piazza, M. Una tecnica di recupero dei solai in legno. Recuperare 1983, 5, 396–407. [Google Scholar]

- Modena, C.; Valluzzi, M.R.; Garbin, E.; da Porto, F. A strengthening technique for timber floors using traditional materials. In Proceedings of the 4th structural analysis of historical constructions, Padua, Italy, 10–13 November 2004. [Google Scholar]

- Piazza, M.; Tomasi, R.; Baldessari, C.; Acler, E. Behaviour of refurbished timber floors characterized by different in-plane stiffness. In Proceedings of the 6th International Conference on Structural Analysis of Historic Construction (SAHC), Bath, UK, 2–4 July 2008. [Google Scholar]

- Valluzzi, M.; Garbin, E.; Benetta, M.D.; Modena, C. Experimental assessment and modelling of in-plane behavior of timber floors. In Proceedings of the 6th International Conference on Structural Analysis of Historic Construction (SAHC), Bath, UK, 2–4 July 2008. [Google Scholar]

- Angeli, A.; Piazza, M.; Riggio, M.; Tomasi, R. Refurbishment of traditional timber floors by means of wood-wood composite structures assembled with inclined screw connectors. In Proceedings of the 11th world conference on timber engineering—WCTE 2010, Riva del Garda, Italy, 20–24 June 2010. [Google Scholar]

- Tomasi, R.; Baldessari, C.; Piazza, M. The refurbishment of existing timber floors: Characterization of the in-plane behaviour. In Proceedings of the 1st International Conference on Protection of Historical Constructions (PROHITECH), Rome, Italy, 21–24 June 2009. [Google Scholar]

- Parisi, M.A.; Piazza, M. Seismic strengthening and seismic improvement of timber structures. Constr. Build. Mater. 2015, 97, 55–66. [Google Scholar] [CrossRef] [Green Version]

- Gelfi, P.; Giuriani, E.; Marini, A. Stud shear connection design for composite concrete slab and wood beams. J. Struct. Eng. 2002, 128, 1544–1550. [Google Scholar] [CrossRef]

- Tecnaria. Available online: https://www.tecnaria.com/ (accessed on 13 December 2018).

- Albertani. Available online: https://www.albertani.com/sistemi-costruttivi/#h.s.b (accessed on 20 December 2018).

| Stainless Steel Grade | 1.4016 | 1.4301 | 1.4462 |

|---|---|---|---|

| Type | Ferritic | Austenitic | Duplex |

| Molybdenum (%) | - | - | 2.5 |

| Nickel (%) | - | 8 | 4.5 |

| Chromium (%) | 17 | 17 | 21 |

| Method | Appropriate for Historic Structures | Appropriate for Repair of Beam Ends | Appropriate for Repair/Reinforcement of Truss Joints |

|---|---|---|---|

| Fasteners | Yes | No | Yes |

| Press-bended sheets | Yes | Yes | No |

| H-, T-, L-, I-shaped Profiles | Yes | Yes | Yes |

| Rods and prostheses | Yes/No 1 | Yes | Yes |

| Nail-plates | No | No | Yes |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Corradi, M.; Osofero, A.I.; Borri, A. Repair and Reinforcement of Historic Timber Structures with Stainless Steel—A Review. Metals 2019, 9, 106. https://doi.org/10.3390/met9010106

Corradi M, Osofero AI, Borri A. Repair and Reinforcement of Historic Timber Structures with Stainless Steel—A Review. Metals. 2019; 9(1):106. https://doi.org/10.3390/met9010106

Chicago/Turabian StyleCorradi, Marco, Adelaja Israel Osofero, and Antonio Borri. 2019. "Repair and Reinforcement of Historic Timber Structures with Stainless Steel—A Review" Metals 9, no. 1: 106. https://doi.org/10.3390/met9010106

APA StyleCorradi, M., Osofero, A. I., & Borri, A. (2019). Repair and Reinforcement of Historic Timber Structures with Stainless Steel—A Review. Metals, 9(1), 106. https://doi.org/10.3390/met9010106