Assessing the Condition of Gas Turbine Rotor Blades with the Optoelectronic and Thermographic Methods

Abstract

1. Introduction

2. Materials and Methods

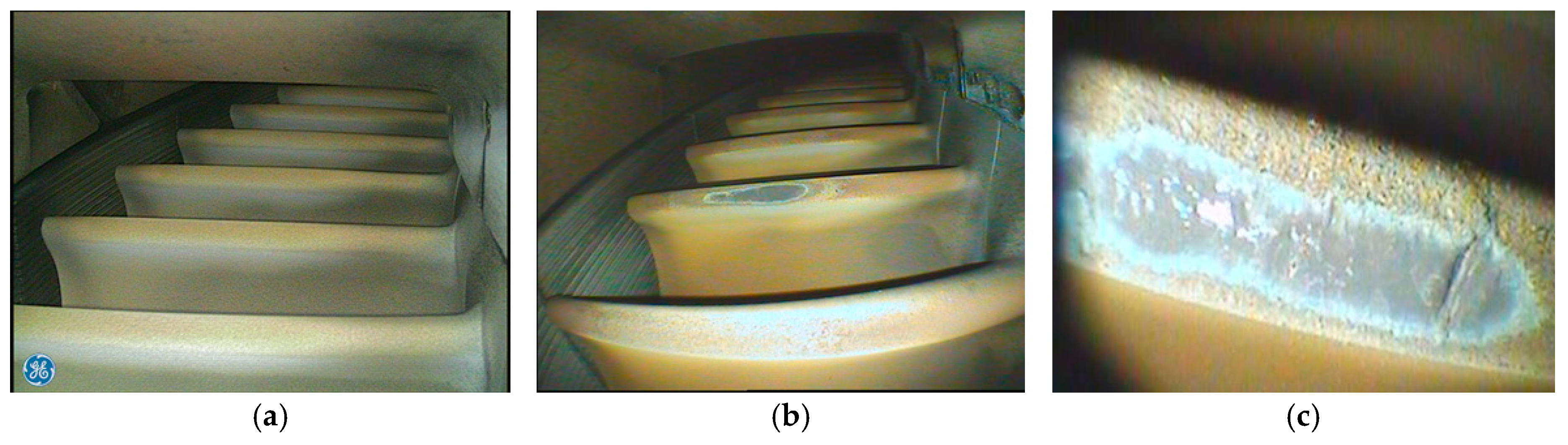

2.1. Characteristics of the Object and Description of Material Tests

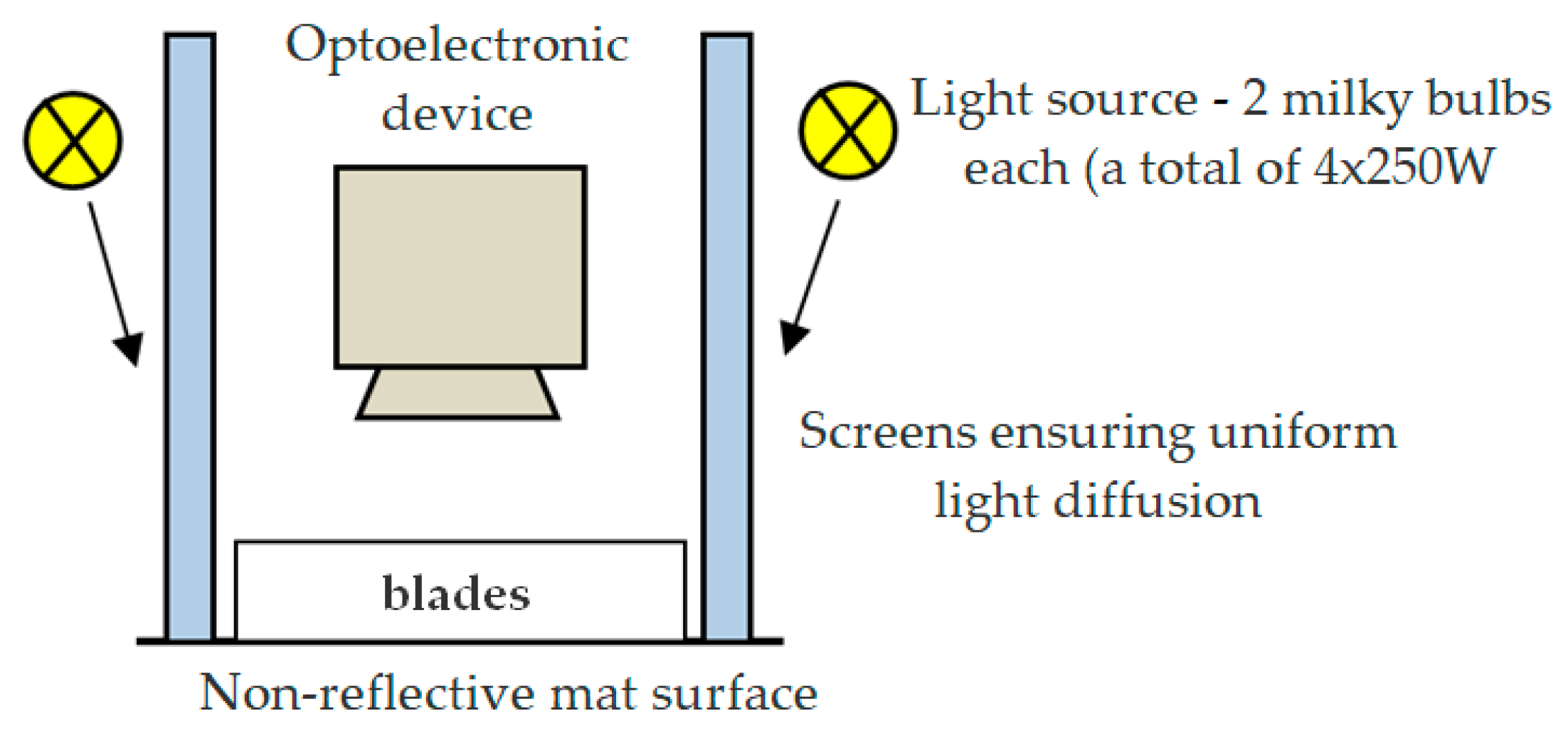

2.2. Characteristics of the Optoelectronic Method

- Colour moments: General surface properties defined by basic values, such as the average value, standard deviation, and variance;

- colour histogram parameters: The characteristics of parameters describing the histograms for individual colour components in an adopted colour model. A histogram is an effective and concise representation of the visual content of a digital image. Its advantages include determination simplicity, resistance to translation and rotation of the view axis, limited sensitivity to scale changes, and a changing image view angle. However, a histogram does not include information about the spatial structure of an image; and

- colour coherence vector (CCV): Is an expansion of the histogram concept with spatial information. A given colour (histogram bar, colour component) is classified as coherent or incoherent, depending on whether the pixels representing it form a coherent, closed area in an image or are dispersed. The coherence vector is in the form of: {(a1,b1), (a2,b2), …, (aN,bN)}, where ai means the number of pixels forming a coherent area and bi the number of pixels in non-coherent areas.

2.3. Characteristics of the Thermographic Method

3. Results and Discussion

3.1. The Optoelectronic Method and Test Results

3.2. Thermographic Method and Test Results

3.3. Blade Microstructure Tests

3.4. Discussion of the Test Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sims, C.T.; Stoloff, N.S.; Hagel, W.C. Superalloys II–High-Temperature Materials for Aerospace and Industrial Applications; John Wiley & Sons: New York, NY, USA, 1987. [Google Scholar]

- El-Sayed, A.F. Performance Parameters of Jet Engines. In Aircraft Propulsion and Gas Turbine Engines; CRC Press: Bocaton, FL, USA, 2008; ISBN 9780849391965. [Google Scholar]

- Carter, T.J. Common failures in gas turbine blades. Eng. Fail. Anal. 2005, 12, 237–247. [Google Scholar] [CrossRef]

- Soares, C. Gas Turbines: A Handbook of Air, Land and Sea Applications, 2nd ed.; Elselvier: Oxford, UK, 2014; ISBN 9780124104853. [Google Scholar]

- Pollock, T.M.; Tin, S. Nickel-based superalloys for advanced turbine engines: Chemistry, microstructure and properties. J. Propuls. Power 2006, 22, 361–374. [Google Scholar] [CrossRef]

- Matzkanin, G.A. Selecting a nondestructive testing method, Part II: Visual inspection. AMMTIAC Q. 2007, 1, 7–10. [Google Scholar]

- Korczewski, Z. Operational causes of fatigue failures within passages of gas turbine engines. Pol. Marit. Res. 2010, 17, 57–61. [Google Scholar] [CrossRef]

- Artamonov, V.V.; Artamonov, V.P. Diagnostics of the causes of the operational destruction of rotor blades of gas turbines. Russ. J. Nondestruct. 2013, 49, 538–542. [Google Scholar] [CrossRef]

- Kim, S.G.; Hwang, Y.H.; Kim, T.G.; Shu, C.M. Failure analysis of J85 Engine turbine blades. Eng. Fail. Anal. 2008, 15, 394–400. [Google Scholar] [CrossRef]

- Reed, R.C. The physical metallurgy of nickel and its alloys. In The Superalloys Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2006; pp. 33–114. ISBN 9780511541285. [Google Scholar]

- Sujata, M.; Madan, M.; Raghavendra, K.; Venkataswamy, M.A.; Bhaumik, S.K. Identification of failure mechanisms in nickel base superalloy turbine blades through microstructural study. Eng. Fail. Anal. 2010, 17, 1436–1446. [Google Scholar] [CrossRef]

- Błachnio, J.; Bogdan, M.; Zasada, D. Increased temperature impact on durability of gas turbine blades. Eksploat. Niezawodn. 2017, 19, 48–53. [Google Scholar] [CrossRef]

- Błachnio, J.; Bogdan, M. A non-destructive method to assess condition of gas turbine blades based on the analysis of blade surface image. Russ. J. Nondestruct. 2010, 46, 860–866. [Google Scholar] [CrossRef]

- Błachnio, J.; Bogdan, M.; Kułaszka, A. New non-destructive methods of diagnosing health of gas turbine blades. In Advances in Gas Turbine Technology; Benini, E., Ed.; InTech: London, UK, 2011; pp. 465–498. ISBN 9789533076119. [Google Scholar]

- Carl, V.; Becker, E.; Sperling, A. Thermography inspection system for gas turbine blades. In Proceedings of the 7th European Conference on non-destructive testing, Copenhagen, Denmark, 26–29 May 1998; pp. 2658–2665. [Google Scholar]

- Marinetti, S.; Robba, D.; Cernuschi, F.; Bison, P.G.; Grinzato, E. Thermographic inspection of TBC coated gas turbine blades: Discrimination between coating over-thicknesses and adhesion defects. Infrared Phys. Technol. 2007, 49, 281–285. [Google Scholar] [CrossRef]

- Kułaszka, A.; Błachnio, J. Analysis of applicability of thermography to assess health of gas turbine blades. J. KONES 2013, 20, 237–244. [Google Scholar]

- Ptaszek, G.; Cawley, P.; Almond, D.; Pickering, S. Transient thermography testing of unpainted thermal barrier coating (TBC) systems. NDT E Int. 2013, 59, 48–56. [Google Scholar] [CrossRef]

- Tajra, S.; Otani, R. The Theory of High-Temperature Strength of Materials; Mietałurgija: Moscow, Soviet Union, 1986. (In Russian) [Google Scholar]

- Poznańska, A. Lifetime of Aircraft Engine Blades Made of EI-867 Alloy upon Aspect of Non-Uniform Distortion and Structural Changes. Ph D. Thesis, University of Technology in Rzeszów, Rzeszów, Poland, 2000. (In Polish). [Google Scholar]

- Sieniawski, J. Criteria and Methods of Evaluation of Materials for Elements of Aircraft Turbine Engines; Technical University Rzeszów: Rzeszów, Poland, 1995. (In Polish) [Google Scholar]

- Salam, I.; Tauqir, A.; Khan, A.Q. Creep-fatigue failure of an aero engine turbine blades. Eng. Fail. Anal. 2002, 9, 335–347. [Google Scholar] [CrossRef]

- Silveira, E.; Atxaga, G.; Erauzkin, E.; Irisarri, A.M. Study on the root causes for the premature failure of an aircraft turbine blade. Eng. Fail. Anal. 2009, 16, 639–647. [Google Scholar] [CrossRef]

- Gevers, T.; Gijsenij, A.; Weijer, J.; Geusebroek, J.M. Color in Computer Vision: Fundamentals and Applications; Wiley: Hoboken, NJ, USA, 2012. [Google Scholar]

- Koschan, A.; Abidi, M.A. Digital Color Image Processing; Wiley-Interscience: New York, NY, USA, 2008; ISBN 9780470147085. [Google Scholar]

- Pass, G.; Zabih, R.; Miller, J. Comparing Images Using Color Coherence Vectors. In Proceedings of the ACM International Multimedia Conference & Exhibition, San Jose, CA, USA, 6–10 February 1997. [Google Scholar]

- Brunelli, R.; Mich, O. Histograms Analysis for Image Retrieval. Pattern Recognit. 2001, 34, 1625–1637. [Google Scholar] [CrossRef]

- Kodituwakku, S.R.; Selvarajah, S. Comparison of Color Features for Image Retrieval. Ind. J. Comput. Sci. Eng. 2004, 1, 207–211. [Google Scholar]

- Sharma, G. Color fundamentals for digital imaging. In Digital Color Imaging Handbook; Sharma, G., Bala, R., Eds.; CRC Press, Taylor and Francis Group: Boca Raton, FL, USA, 2003; ISBN 139781420041484. [Google Scholar]

- Maldague, X.P. Theory and Practice of Infrared Thermography for Non-Destructive Testing; Willey-Interscience: New York, NY, USA, 2001. [Google Scholar]

- Oliferuk, W. Infrared Thermography for Non-Destructive Testing of Materials and Equipment; Gamma Office: Warsaw, Poland, 2008. (In Polish) [Google Scholar]

- Bagavathiappan, S.; Lahiri, B.B.; Saravanan, T.; Philip, J.; Jayakumar, T. Infrared thermography for condition monitoring—A review. Infrared Phys. Technol. 2013, 60, 35–55. [Google Scholar] [CrossRef]

- Czichos, H. Handbook of Technical Diagnostics: Fundamentals and Application to Structures and Systems; Springer Science & Business Media: Berlin, Germany, 2013. [Google Scholar]

- Yang, L.Y.; Zhu, Z.W.; Ming, J.T.; Zhang, A.B.; Zhang, W. Investigation on the damage evolution in the impacted composite material based on active infrared thermography. NDT E Int. 2016, 83, 114–122. [Google Scholar]

- Gao, C.; Meeker, W.Q.; Mayton, D. Detecting cracks in aircraft engine fan blades using vibrothermography nondestructive evaluation. Reliabil. Eng. Syst. Saf. 2014, 131, 229–235. [Google Scholar] [CrossRef]

- Tang, Q.; Dai, J.; Bu, C.; Qi, L.; Li, D. Experimental study on debonding defects detection in thermal barrier coating structure using infrared lock-in thermographic technique. Appl. Therm. Eng. 2016, 107, 463–468. [Google Scholar] [CrossRef]

- Shepard, S.M.; Lhota, J.R.; Rubadeux, B.A.; Wang, D.; Ahmed, T. Reconstruction and enhancement of active thermographic image sequences. Opt. Eng. 2003, 42, 1337–1342. [Google Scholar] [CrossRef]

- Goldammer, M. Active Thermography for Dimensional Measurements on Gas Turbine Components. In Proceedings of the European Conference of non-destructive Testing ECNDT, Berlin, Germany, 25–29 September 2006. [Google Scholar]

- Yang, R.; He, Y. Optically and non-optically excited thermography for composites: A review. Infrared. Phys. Technol. 2016, 75, 26–50. [Google Scholar] [CrossRef]

- Bejan, A.; Krauss, A.D. Heat Transfer Handbook; John Willey & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

| C | Mo | Si | Cr | Ni | Co | Mo | W | Al | B | Fe | Other |

|---|---|---|---|---|---|---|---|---|---|---|---|

| max | max | max | rest | max | |||||||

| 0.1 | 0.3 | 0.6 | 9.0 | 14 | 10.3 | 5.0 | 4.5 | 0.02 | 4.0 | 0.3 V, 01 Ba max |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bogdan, M.; Błachnio, J.; Kułaszka, A.; Derlatka, M. Assessing the Condition of Gas Turbine Rotor Blades with the Optoelectronic and Thermographic Methods. Metals 2019, 9, 31. https://doi.org/10.3390/met9010031

Bogdan M, Błachnio J, Kułaszka A, Derlatka M. Assessing the Condition of Gas Turbine Rotor Blades with the Optoelectronic and Thermographic Methods. Metals. 2019; 9(1):31. https://doi.org/10.3390/met9010031

Chicago/Turabian StyleBogdan, Mariusz, Józef Błachnio, Artur Kułaszka, and Marcin Derlatka. 2019. "Assessing the Condition of Gas Turbine Rotor Blades with the Optoelectronic and Thermographic Methods" Metals 9, no. 1: 31. https://doi.org/10.3390/met9010031

APA StyleBogdan, M., Błachnio, J., Kułaszka, A., & Derlatka, M. (2019). Assessing the Condition of Gas Turbine Rotor Blades with the Optoelectronic and Thermographic Methods. Metals, 9(1), 31. https://doi.org/10.3390/met9010031