Evaluation of Support Structure Removability for Additively Manufactured Ti6Al4V Overhangs via Electron Beam Melting

Abstract

:1. Introduction and Literature Review

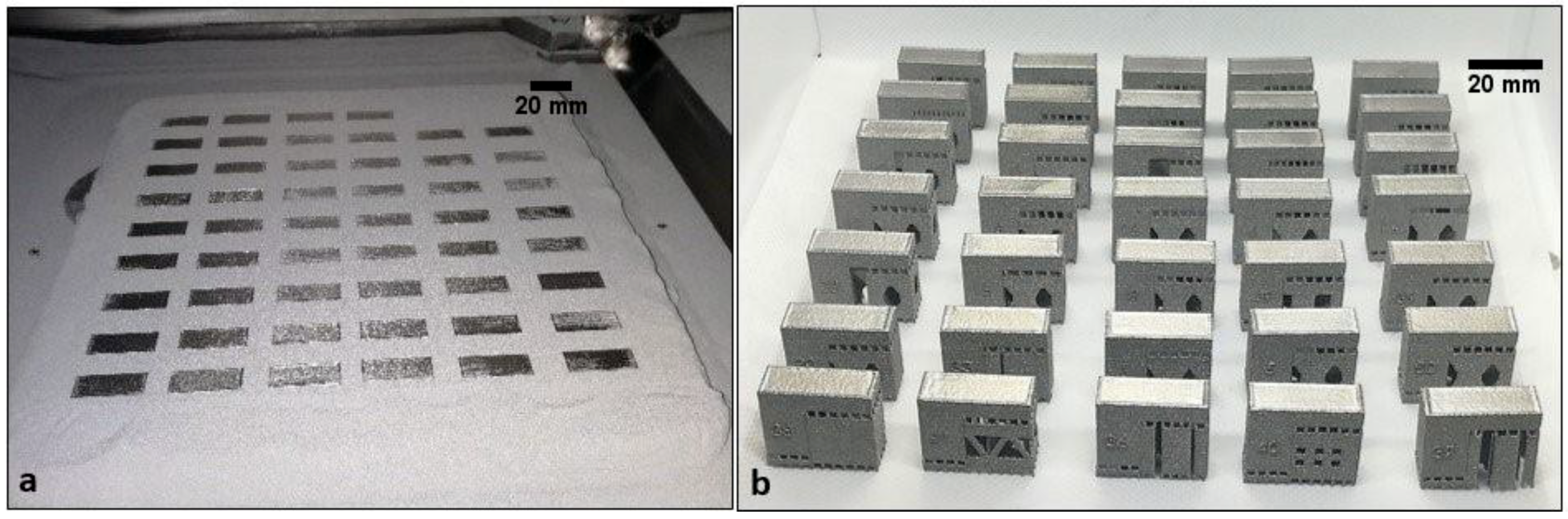

2. Experimental Procedures

3. Results Analysis

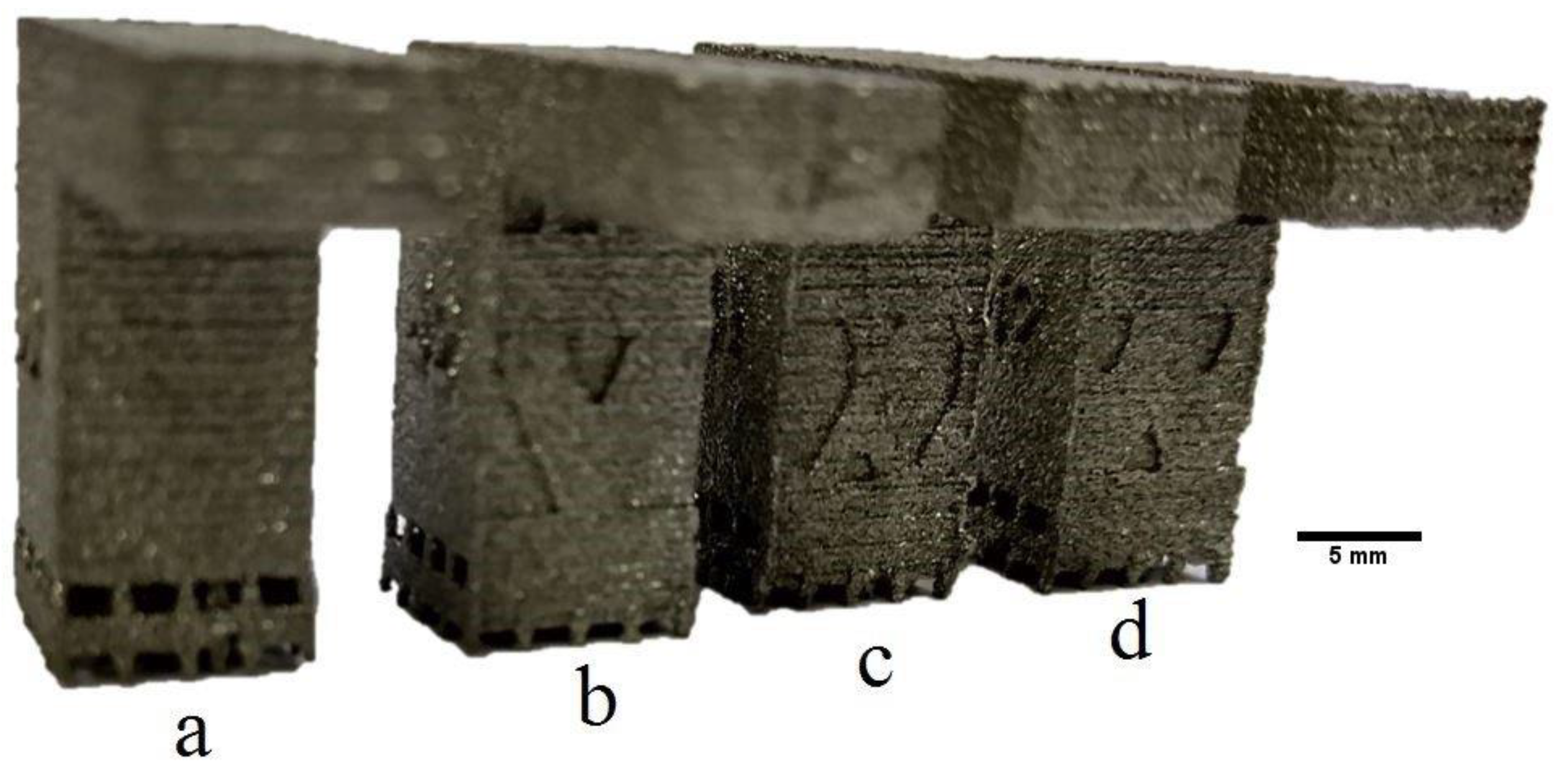

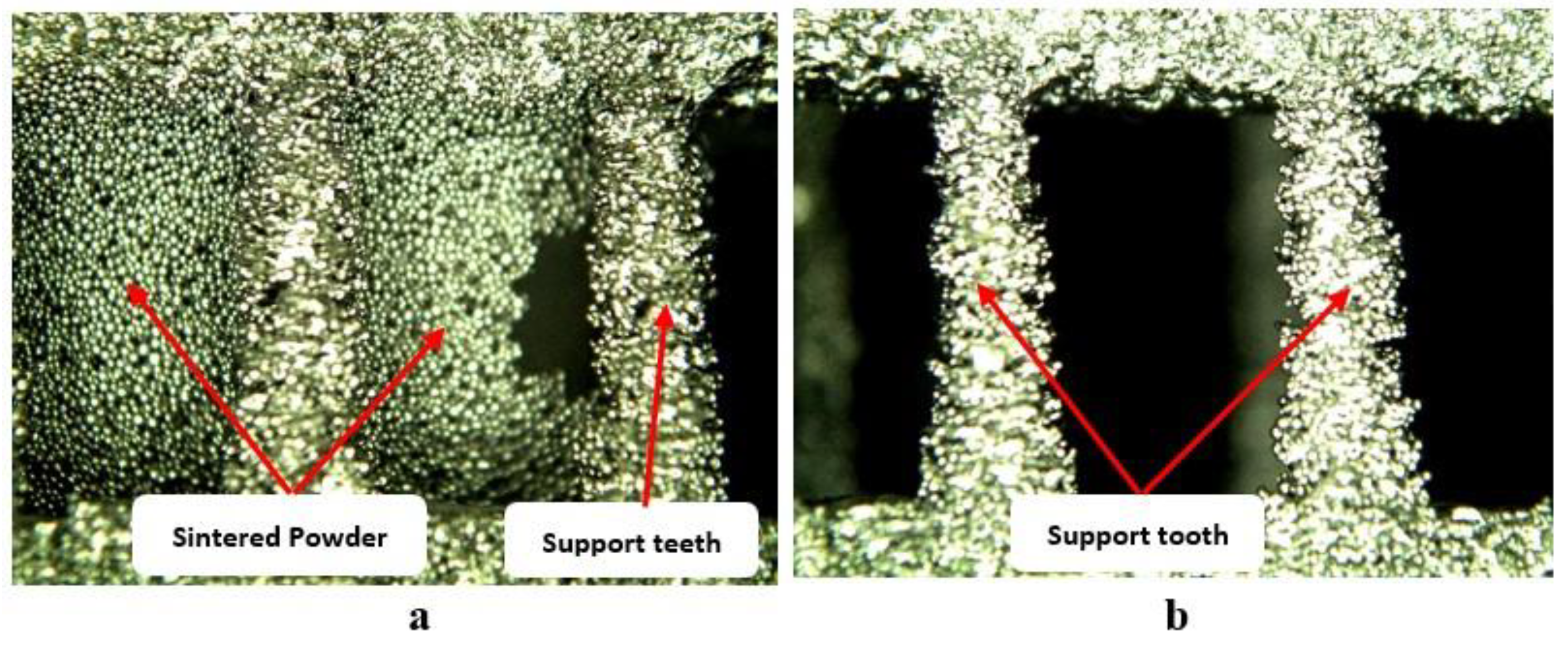

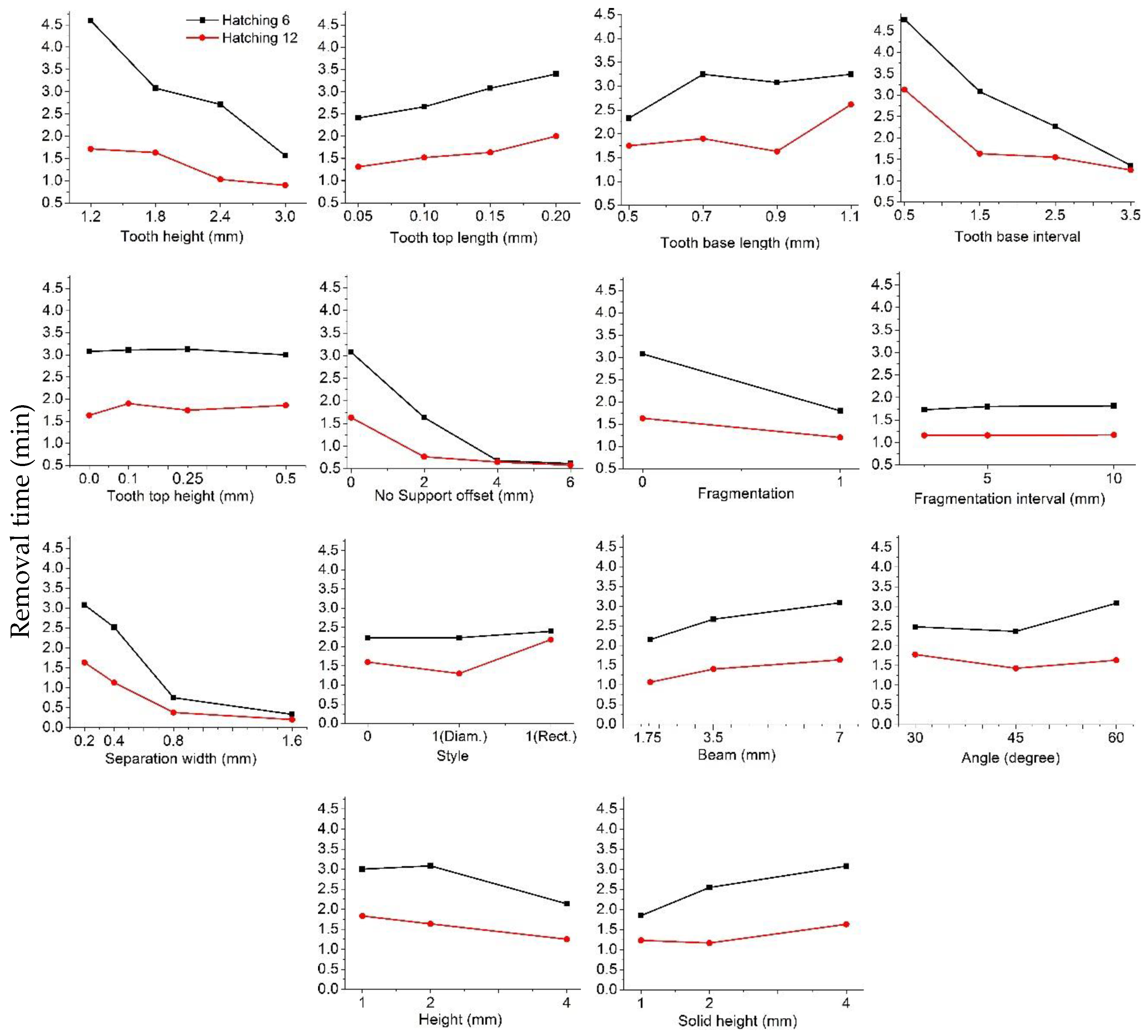

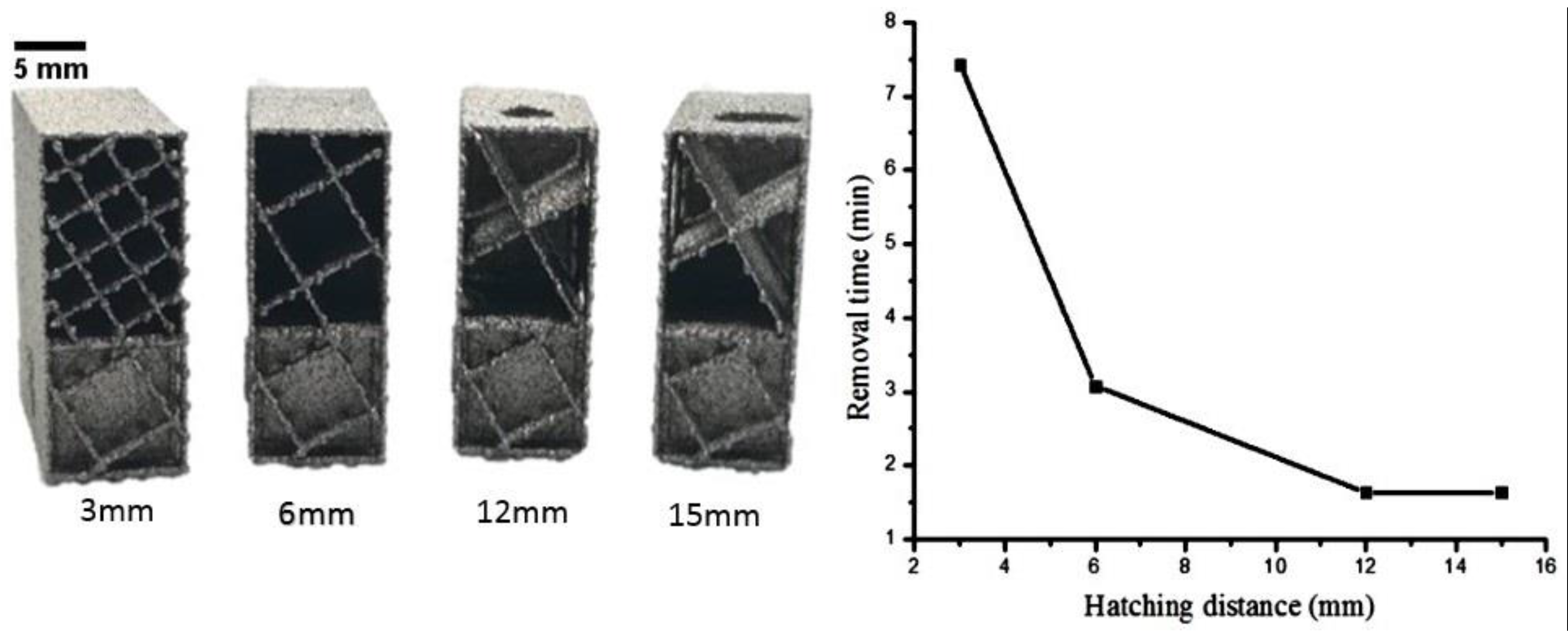

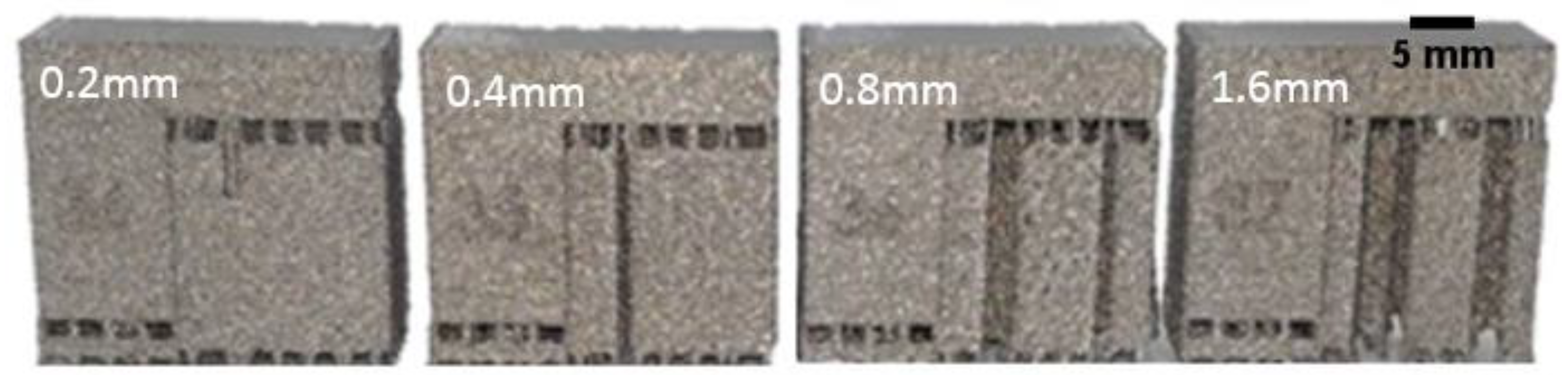

3.1. Effect of Design Parameters

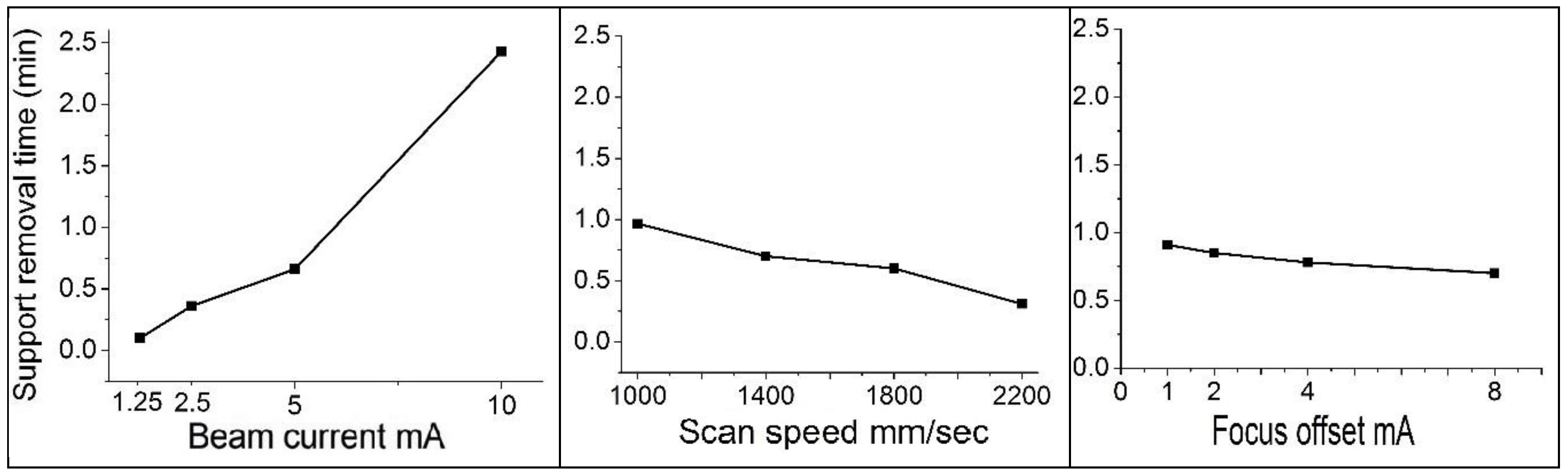

3.2. The Influence of Process Parameters

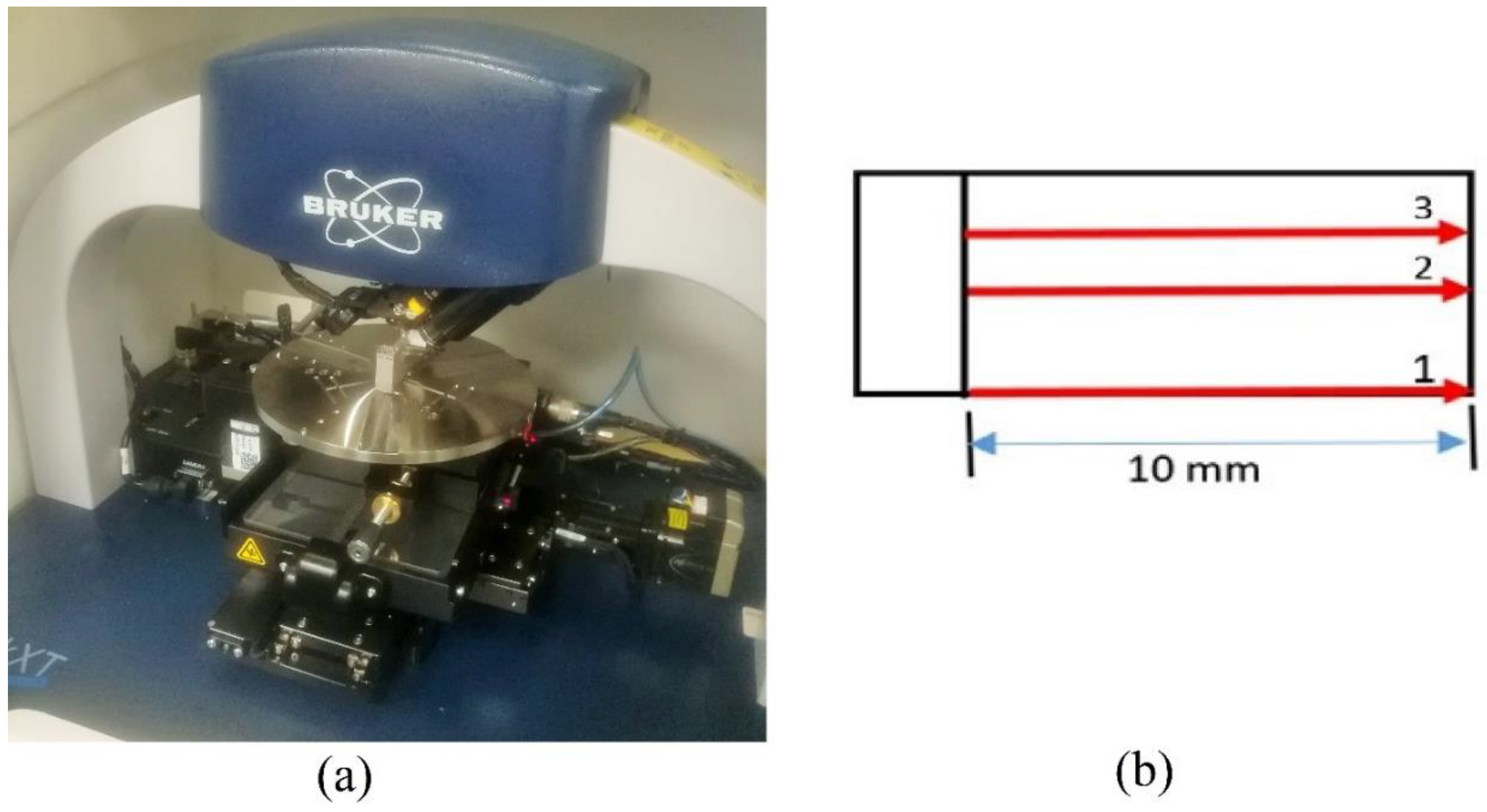

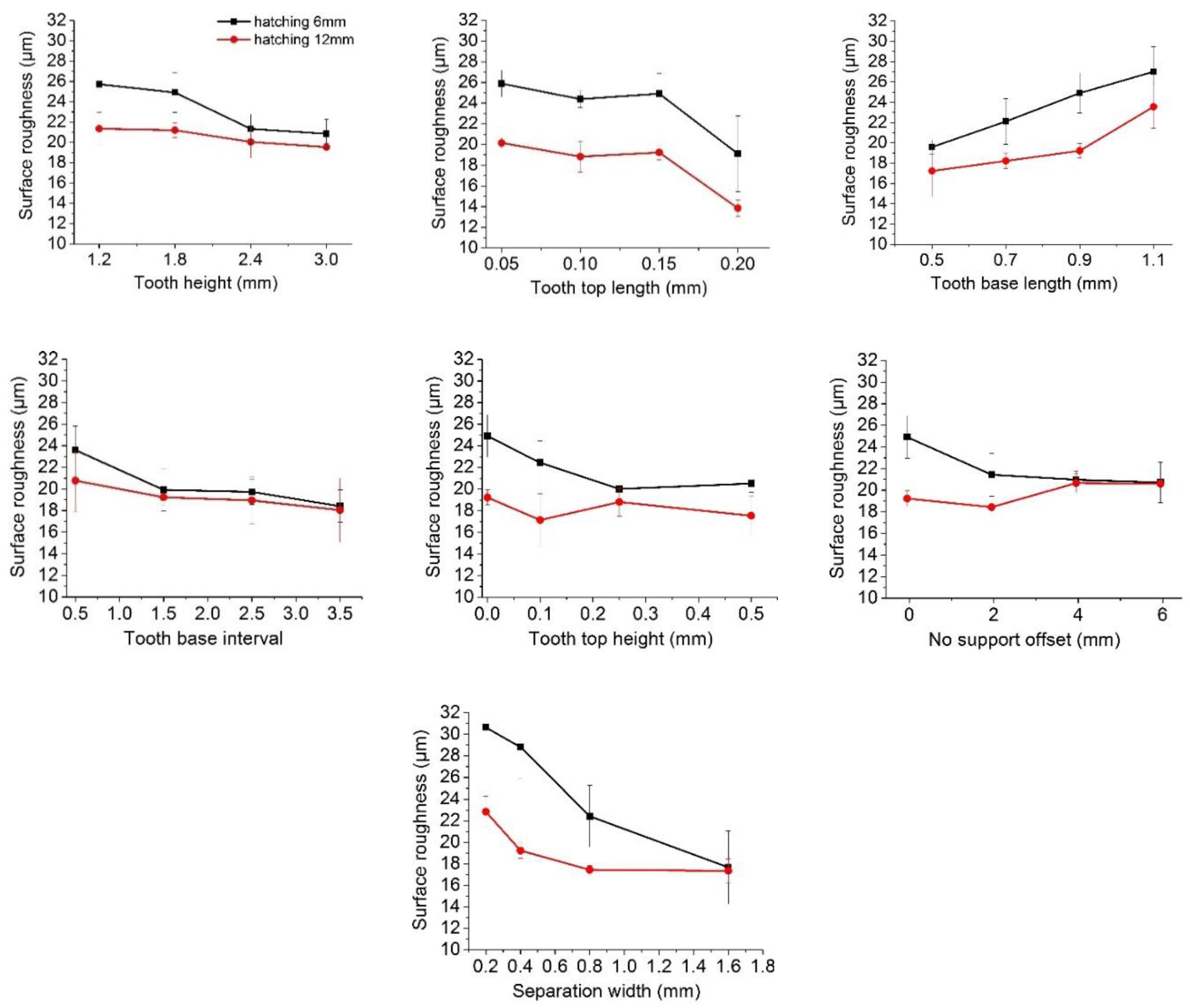

3.3. Surface Roughness

4. Conclusions

- As compared to the default support tooth parameters, 3 mm tooth height, 0.05 mm tooth top length and 3.5 mm tooth base interval were found to significantly reduce the support removal time.

- The fragmented support structure with separation width of 1.6 mm was found to decrease the support removal time by about 80%.

- The perforation parameters such as 1.75 mm perforation beam, 60° angle, 4 mm height, and 1 mm solid height resulted in around 20% reduction in support removal time, as compared to the default parameters.

- In case of EBM process parameters, as compared to the default parameters, the beam current of 1.25 mA and scan speed of 2200 mm/sec resulted in more than 80% reduction of support removal time.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gu, D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Bobbio, L.D.; Qin, S.; Dunbar, A.; Michaleris, P.; Beese, A.M. Characterization of the strength of support structures used in powder bed fusion additive manufacturing of Ti-6Al-4V. Addit. Manuf. 2017, 14, 60–68. [Google Scholar] [CrossRef]

- Umer, U.; Ameen, W.; Abidi, M.H.; Moiduddin, K.; Alkhalefah, H.; Alkahtani, M.; Al-Ahmari, A. Modeling the Effect of Different Support Structures in Electron Beam Melting of Titanium Alloy Using Finite Element Models. Metals 2019, 9, 806. [Google Scholar] [CrossRef]

- Poyraz, Ö.; Yasa, E.; Akbulut, G.; Orhangul, A.; Pilatin, S. Investigation of Support. Structures for Direct Metal. Laser Sintering (DMLS) of IN625 Parts; International Solid Freeform Fabrication Symposium: Austin, TX, USA, 2015. [Google Scholar]

- Cheng, B.; Chou, Y.K. Overhang Support Structure Design for Electron Beam Additive Manufacturing. In Proceedings of the ASME 2017 12th International Manufacturing Science and Engineering Conference Collocated with the JSME/ASME 2017 6th International Conference on Materials and Processing, Los Angeles, CA, USA, 4–8 June 2017. [Google Scholar]

- Jhabvala, J.; Boillat, E.; André, C.; Glardon, R. An innovative method to build support structures with a pulsed laser in the selective laser melting process. Int. J. Adv. Manuf. Technol. 2012, 59, 137–142. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies; Springer: Berlin, Germany, 2010. [Google Scholar]

- Thomas, D. The Development of Design Rules for Selective Laser Melting; University of Wales: Wales, UK, 2009. [Google Scholar]

- Pullin, J.; Offen, A. Back to the Drawing Board-Addressing the design issues of RM. In Proceedings of the Time Compression Technologies Rapid Manufacturing Conference 2008, Coventry, West Midlands, October 2008. [Google Scholar]

- Sames, W.J.; List, F.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Das, P.; Mhapsekar, K.; Chowdhury, S.; Samant, R.; Anand, S. Selection of build orientation for optimal support structures and minimum part errors in additive manufacturing. Comput. Aided Des. Appl. 2017, 14, 1–13. [Google Scholar] [CrossRef]

- Bibb, R.; Eggbeer, D.; Williams, R. Rapid manufacture of removable partial denture frameworks. Rapid Prototyp. J. 2006, 12, 95–99. [Google Scholar] [CrossRef]

- Ameen, W.; Al-Ahmari, A.; Mohammed, M.K.; Mian, S.H. Manufacturability of Overhanging Holes Using Electron Beam Melting. Metals 2018, 8, 397. [Google Scholar] [CrossRef]

- Williams, R.E.; Melton, V.L. Abrasive flow finishing of stereolithography prototypes. Rapid Prototyp. J. 1998, 4, 56–67. [Google Scholar] [CrossRef]

- Byun, H.-S.; Lee, K.H. Determination of the optimal part orientation in layered manufacturing using a genetic algorithm. Int. J. Prod. Res. 2005, 43, 2709–2724. [Google Scholar] [CrossRef]

- Piili, H.; Happonen, A.; Väistö, T.; Venkataramanan, V.; Partanen, J.; Salminen, A. Cost Estimation of Laser Additive Manufacturing of Stainless Steel. Phys. Procedia 2015, 78, 388–396. [Google Scholar] [CrossRef]

- Calignano, F. Design optimization of supports for overhanging structures in aluminum and titanium alloys by selective laser melting. Mater. Des. 2014, 64, 203–213. [Google Scholar] [CrossRef]

- Kuo, Y.-H.; Cheng, C.-C.; Lin, Y.-S.; San, C.-H. Support structure design in additive manufacturing based on topology optimization. Struct. Multidiscip. Optim. 2017, 57, 1–13. [Google Scholar] [CrossRef]

- Järvinen, J.P.; Matilainen, V.; Li, X.; Piili, H.; Salminen, A.; Mäkelä, I.; Nyrhilä, O. Characterization of effect of support structures in laser additive manufacturing of stainless steel. Phys. Procedia 2014, 56, 72–81. [Google Scholar] [CrossRef]

- Safdar, A.; He, H.; Wei, L.-Y.; Snis, A.; Chavez de Paz, L.E. Effect of process parameters settings and thickness on surface roughness of EBM produced Ti-6Al-4V. Rapid Prototyp. J. 2012, 18, 401–408. [Google Scholar] [CrossRef]

- Schwerdtfeger, J.; Singer, R.F.; Körner, C. In situ flaw detection by IR-imaging during electron beam melting. Rapid Prototyp. J. 2012, 18, 259–263. [Google Scholar] [CrossRef]

- Mahale, T.R. Electron Beam Melting of Advanced Materials and Structures, Mass Customization, Mass Personalization. Ph.D. Thesis, North Carolina State University, Raleigh, CA, USA, 2009. [Google Scholar]

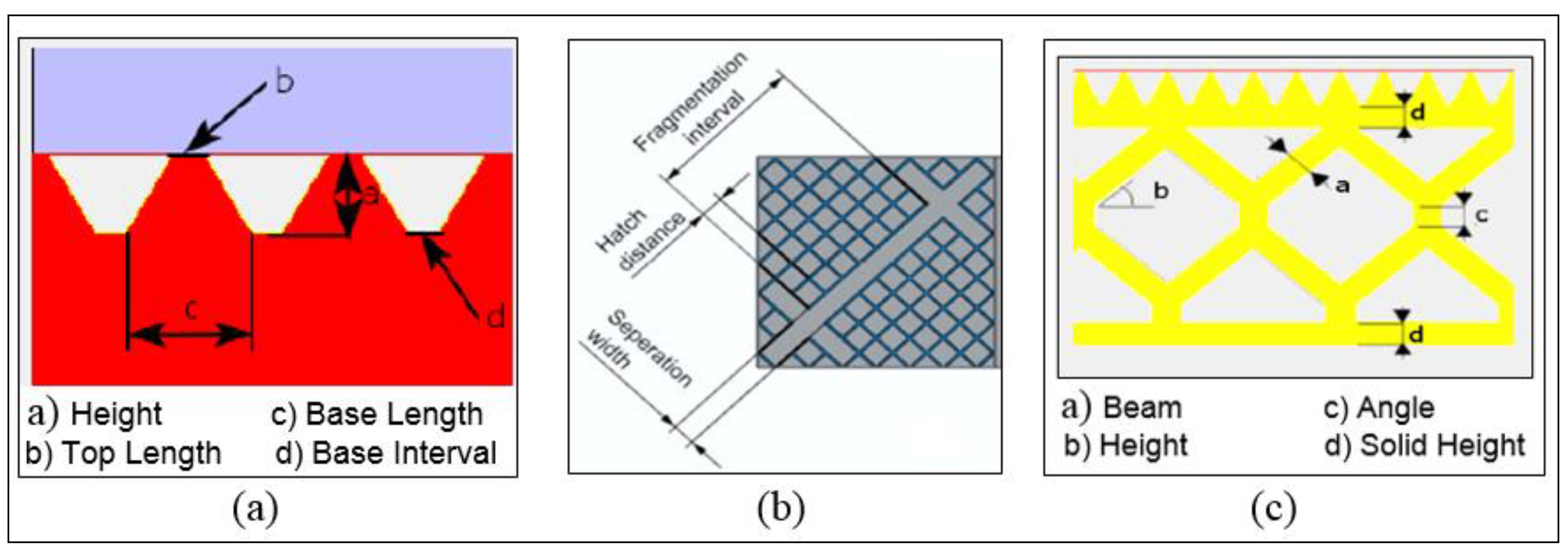

| Support Structure Parameters | Level 1 | Level 2 | Level 3 | Level 4 | ||

|---|---|---|---|---|---|---|

| Design parameters | Tooth and No Support Offset Parameters | Tooth height (mm) | 1.2 | 1.80 | 2.4 | 3 |

| Tooth top length (mm) | 0.05 | 0.1 | 0.15 | 0.2 | ||

| Tooth base length (mm) | 0.5 | 0.7 | 0.90 | 1.1 | ||

| Tooth base interval | 0.5 | 1.50 | 2.5 | 3.5 | ||

| Z offset (mm) | 0 | 0.5 | 0.1 | 0.25 | ||

| No support offset (mm) | 0 | 2 | 4 | 6 | ||

| Hatching and Fragmentation Parameters | X and Y hatching (mm) | 3 | 6 | 12 | 15 | |

| Fragmentation | 0 | 1 | - | - | ||

| Fragmentation interval (mm) | 2.5 | 5 | 10 | - | ||

| Separation width (mm) | 0.2 | 0.4 | 0.8 | 1.6 | ||

| Perforation Parameters | Perforation style | 0 | 1 (Diam.) | 1 (Rect.) | - | |

| Perforation beam (mm) | 1.75 | 3.5 | 7 | - | ||

| Perforation angle | 30 | 45 | 60 | - | ||

| Perforation height (mm) | 1 | 2 | 4 | - | ||

| Perforation solid height (mm) | 1 | 2 | 4 | - | ||

| Process parameters | Processes Parameters | Current (mA) | 1.5 | 2.5 | 5 | 10 |

| Scan speed (mm/s) | 1000 | 1400 | 1800 | 2200 | ||

| Focus offset (mA) | 1 | 2 | 4 | 4 | ||

| Source | df | Sum of Squares | Mean Square | F-Value | p-Value Prob > F |

|---|---|---|---|---|---|

| Model | 34 | 36.411 | 1.071 | 13.88 | <0.0001 |

| Linear | 34 | 36.411 | 1.071 | 13.88 | <0.0001 |

| Tooth height | 3 | 4.698 | 1.566 | 20.29 | <0.0001 |

| Tooth top length | 3 | 0.613 | 0.204 | 2.65 | 0.093 |

| Tooth base length | 3 | 0.575 | 0.192 | 2.48 | 0.107 |

| Tooth base interval | 3 | 6.341 | 2.114 | 27.39 | <0.0001 |

| Tooth top height | 3 | 0.022 | 0.007 | 0.09 | 0.962 |

| No support offset | 3 | 10.558 | 3.519 | 45.60 | <0.0001 |

| Fragmentation | 1 | 2.255 | 2.255 | 29.23 | <0.0001 |

| Fragmentation interval | 2 | 0.089 | 0.045 | 0.58 | 0.575 |

| separation width | 3 | 5.021 | 1.674 | 21.69 | <0.0001 |

| Style | 2 | 0.837 | 0.419 | 5.42 | 0.019 |

| Beam | 2 | 0.753 | 0.377 | 4.88 | 0.026 |

| Angle | 2 | 0.592 | 0.296 | 3.84 | 0.049 |

| Height | 2 | 0.712 | 0.356 | 4.61 | 0.031 |

| Solid height | 2 | 1.368 | 0.684 | 8.86 | 0.004 |

| Error | 13 | 1.003 | 0.077 | - | - |

| Total | 47 | 37.415 | - | - | - |

| Source | df | Sum of Squares | Mean Square | F-Value | p-Value Prob > F |

|---|---|---|---|---|---|

| Model | 34 | 12.275 | 0.361 | 45.08 | <0.0001 |

| Linear | 34 | 12.275 | 0.361 | 45.08 | <0.0001 |

| Tooth height | 3 | 0.746 | 0.249 | 31.06 | <0.0001 |

| Tooth top length | 3 | 0.250 | 0.083 | 10.42 | 0.001 |

| Tooth base length | 3 | 0.989 | 0.330 | 41.17 | <0.0001 |

| Tooth base interval | 3 | 2.371 | 0.790 | 98.70 | <0.0001 |

| Tooth top height | 3 | 0.141 | 0.047 | 5.85 | 0.009 |

| No support offset | 3 | 2.133 | 0.711 | 88.77 | <0.0001 |

| Fragmentation | 1 | 0.469 | 0.469 | 58.52 | <0.0001 |

| Fragmentation interval | 2 | 0.000 | 0.000 | 0.00 | 0.997 |

| separation width | 3 | 1.490 | 0.497 | 62.03 | <0.0001 |

| Style | 2 | 0.310 | 0.155 | 19.38 | <0.0001 |

| Beam | 2 | 0.293 | 0.147 | 18.31 | <0.0001 |

| Angle | 2 | 0.061 | 0.031 | 3.82 | 0.049 |

| Height | 2 | 0.176 | 0.088 | 10.96 | 0.002 |

| Solid height | 2 | 0.284 | 0.142 | 17.71 | <0.0001 |

| Error | 13 | 0.104 | 0.008 | - | - |

| Total | 47 | 12.379 | - | - | - |

| Source | df | Sum of Squares | Mean Square | F-Value | p-Value Prob > F |

|---|---|---|---|---|---|

| Model | 9 | 3.691 | 0.410 | 109.84 | 0.009 |

| Linear | 9 | 3.691 | 0.410 | 109.84 | 0.009 |

| Current | 3 | 3.354 | 1.118 | 299.48 | 0.003 |

| Scan speed | 3 | 0.228 | 0.076 | 20.33 | 0.047 |

| Focus offset | 3 | 0.040 | 0.013 | 3.61 | 0.224 |

| Error | 2 | 0.007 | 0.004 | - | - |

| Total | 11 | 3.698 | - | - | - |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ameen, W.; Khan Mohammed, M.; Al-Ahmari, A. Evaluation of Support Structure Removability for Additively Manufactured Ti6Al4V Overhangs via Electron Beam Melting. Metals 2019, 9, 1211. https://doi.org/10.3390/met9111211

Ameen W, Khan Mohammed M, Al-Ahmari A. Evaluation of Support Structure Removability for Additively Manufactured Ti6Al4V Overhangs via Electron Beam Melting. Metals. 2019; 9(11):1211. https://doi.org/10.3390/met9111211

Chicago/Turabian StyleAmeen, Wadea, Muneer Khan Mohammed, and Abdulrahman Al-Ahmari. 2019. "Evaluation of Support Structure Removability for Additively Manufactured Ti6Al4V Overhangs via Electron Beam Melting" Metals 9, no. 11: 1211. https://doi.org/10.3390/met9111211

APA StyleAmeen, W., Khan Mohammed, M., & Al-Ahmari, A. (2019). Evaluation of Support Structure Removability for Additively Manufactured Ti6Al4V Overhangs via Electron Beam Melting. Metals, 9(11), 1211. https://doi.org/10.3390/met9111211