Copper Tailing Flocculation in Seawater: Relating the Yield Stress with Fractal Aggregates at Varied Mixing Conditions

Abstract

1. Introduction

2. Methodology

2.1. Materials

2.2. Flocculation Test: Aggregate Size and Settling

2.3. Yield Stress of Sediment

2.4. Fractal Dimension

- : Hidered settling rate, m/s

- : Diameter of aggregate, m

- : Diameter of prymere particle, m

- : Density of solid and liquid phase, respectively, kg m−3,

- : Gravity acceleration constant, (9.81 m/s2)

- : Fluid viscosity, Ns/m2

- : Volumetric solid concentration

- : Fractal dimension of mass length.

3. Results

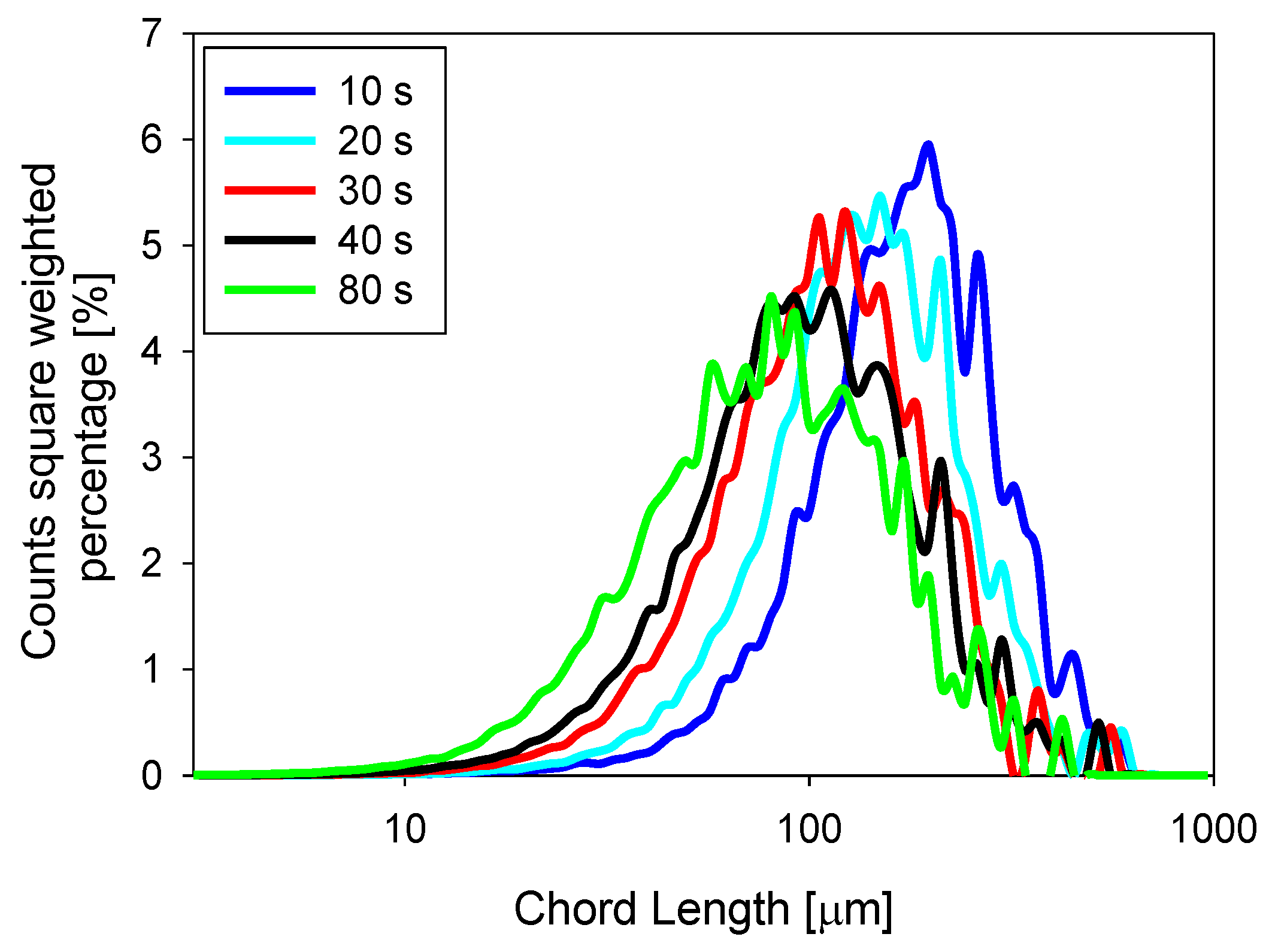

3.1. Aggregate Size

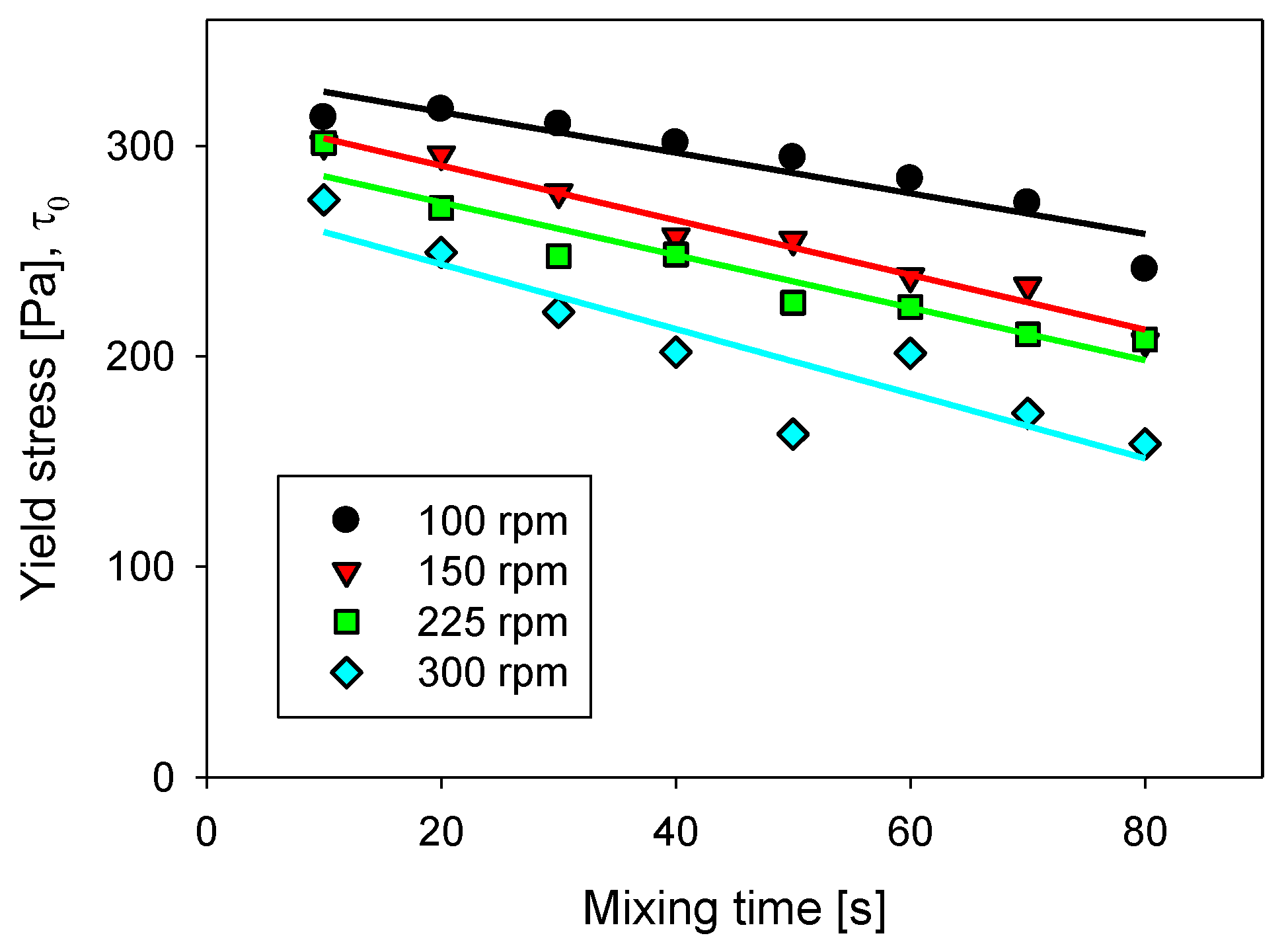

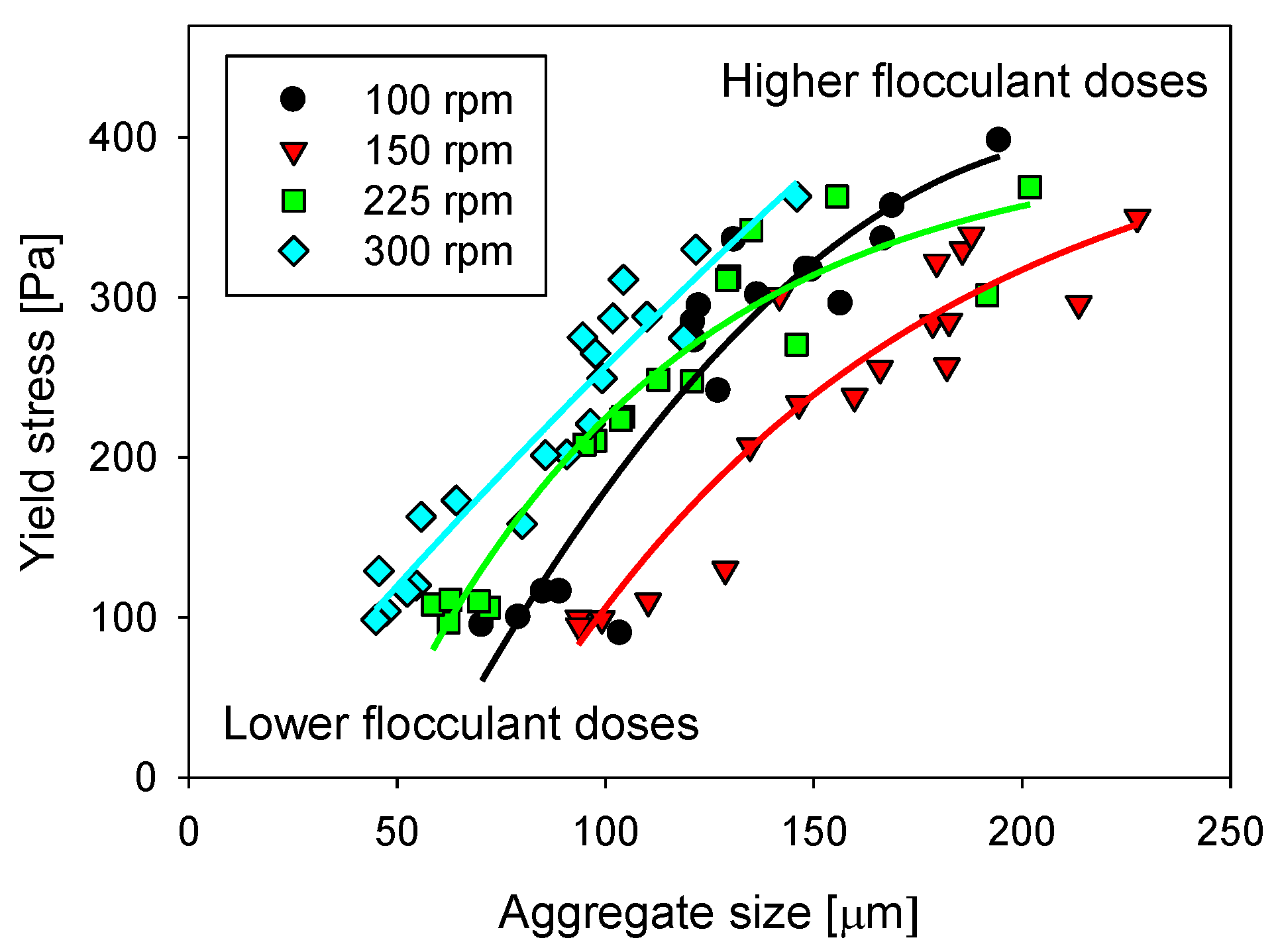

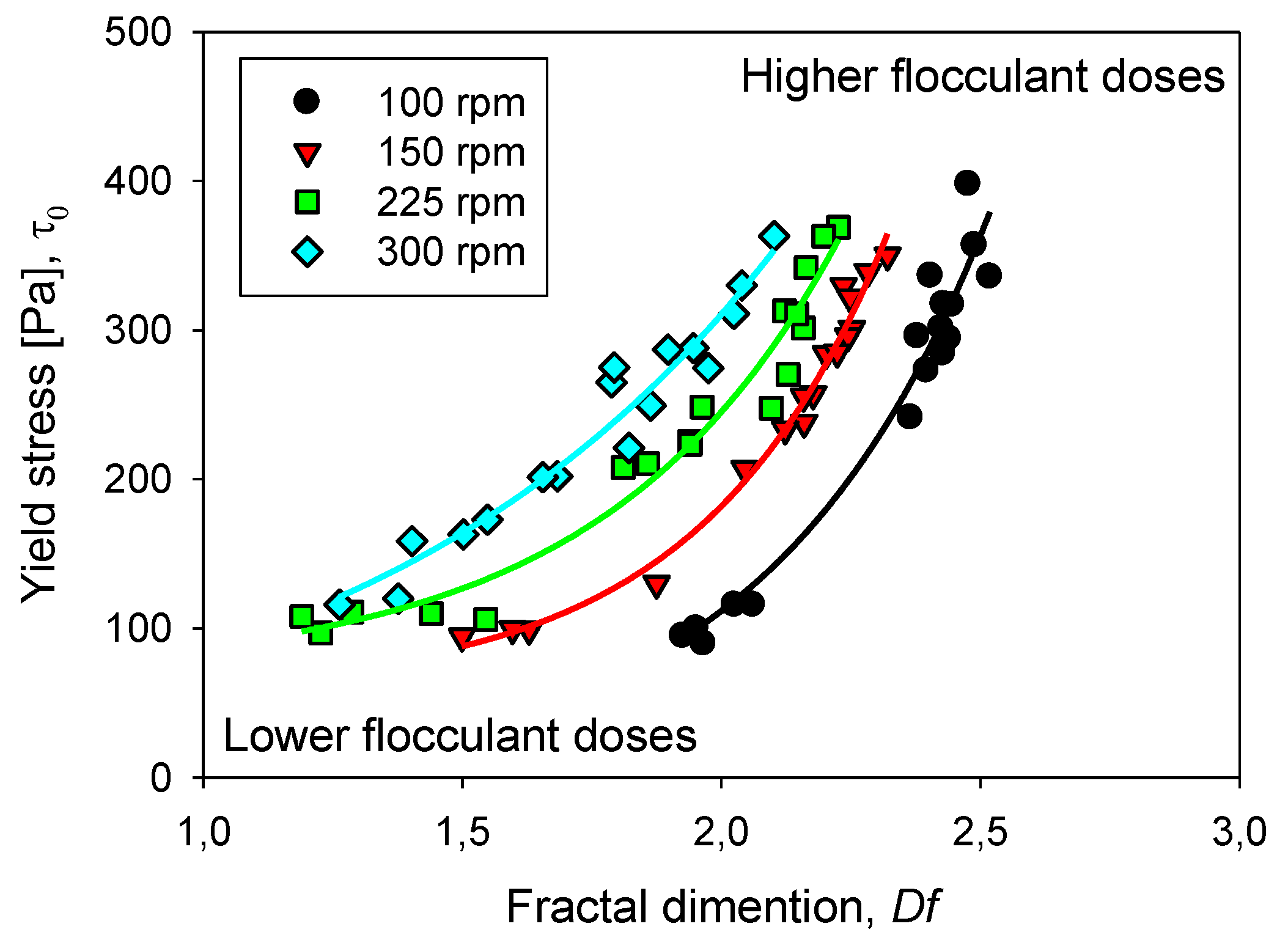

3.2. Analysis of Yield Stress

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kane, J.C.; La Mer, V.K.; Linford, H.B. The effect of solid content on the adsorption and flocculation behavior of silica suspensions. J. Phys. Chem. 1964, 68, 3539–3544. [Google Scholar] [CrossRef]

- Rudman, M.; Simic, K.; Paterson, D.A.; Strode, P.; Brent, A.; Šutalo, I.D. Raking in gravity thickeners. Int. J. Miner. Process. 2008, 86, 114–130. [Google Scholar] [CrossRef]

- Gladman, B.R.; Rudman, M.; Scales, P.J. The effect of shear on gravity thickening: Pilot scale modelling. Chem. Eng. Sci. 2010, 65, 4293–4301. [Google Scholar] [CrossRef]

- De Kretser, R.; Scales, P.J.; Boger, D.V. Improving clay-based tailings disposal: Case study on coal tailings. AIChE J. 1997, 43, 1894–1903. [Google Scholar] [CrossRef]

- Castillo, C.; Ihle, C.F.; Jeldres, R.I. Chemometric optimisation of a copper sulphide tailings flocculation process in the presence of clays. Minerals 2019, 9, 582. [Google Scholar] [CrossRef]

- Du, J.; Morris, G.; Pushkarova, R.A.; Roger, S.C.S. Effect of surface structure of kaolinite on aggregation, settling rate, and bed density. Langmuir 2010, 26, 13227–13235. [Google Scholar] [CrossRef]

- Liu, D.; Edraki, M.; Berry, L. Investigating the settling behaviour of saline tailing suspensions using kaolinite, bentonite, and illite clay minerals. Powder Technol. 2018, 326, 228–236. [Google Scholar] [CrossRef]

- Jeldres, R.I.; Piceros, E.C.; Wong, L.; Leiva, W.H.; Herrera, N.; Toledo, P.G. Dynamic moduli of flocculated kaolinite sediments: Effect of salinity, flocculant dose, and settling time. Colloid Polym. Sci. 2018, 296, 1935–1943. [Google Scholar] [CrossRef]

- Teh, E.J.; Leong, Y.K.; Liu, Y.; Fourie, A.B.; Fahey, M. Differences in the rheology and surface chemistry of kaolin clay slurries: The source of the variations. Chem. Eng. Sci. 2009, 64, 3817–3825. [Google Scholar] [CrossRef]

- Nabzar, L.; Pefferkorn, E.; Varoqui, R. Polyacrylamide-sodium kaolinite interactions: Flocculation behavior of polymer clay suspensions. J. Colloid Interface Sci. 1984, 102, 380–388. [Google Scholar] [CrossRef]

- Lee, L.T.; Rahbari, R.; Lecourtier, J.; Chauveteau, G. Adsorption of polyacrylamides on the different faces of kaolinites. J. Colloid Interface Sci. 1991, 147, 351–357. [Google Scholar] [CrossRef]

- Heath, A.R.; Bahri, P.A.; Fawell, P.D.; Farrow, J.B. Polymer flocculation of calcite: Experimental results from turbulent pipe flow. AIChE J. 2006, 52, 1284–1293. [Google Scholar] [CrossRef]

- Spicer, P.T.; Pratsinis, S.E. Shear-induced flocculation: The evolution of floc structure and the shape of the size distribution at steady state. Water Res. 1996, 30, 1049–1056. [Google Scholar] [CrossRef]

- Vaezi, G.F.; Sanders, R.S.; Masliyah, J.H. Flocculation kinetics and aggregate structure of kaolinite mixtures in laminar tube flow. J. Colloid Interface Sci. 2011, 355, 96–105. [Google Scholar] [CrossRef]

- Kousaka, Y.; Okuyama, K.; Payatakes, A. Physical meaning and evaluation of dynamic shape factor of aggregate particles. J. Colloid Interface Sci. 1981, 84, 91–99. [Google Scholar] [CrossRef]

- Gabitto, J.; Tsouris, C. Drag coefficient and settling velocity for particles of cylindrical shape. Powder Technol. 2008, 183, 314–322. [Google Scholar] [CrossRef]

- Nguyen, Q.D.; Boger, D.V. Application of rheology to solving tailings disposal problems. Int. J. Miner. Process. 1998, 54, 217–233. [Google Scholar] [CrossRef]

- Zhou, Y.; Yu, H.; Wanless, E.J.; Jameson, G.J.; Franks, G.V. Influence of polymer charge on the shear yield stress of silica aggregated with adsorbed cationic polymers. J. Colloid Interface Sci. 2009, 336, 533–543. [Google Scholar] [CrossRef]

- Johnson, S.B.; Franks, G.V.; Scales, P.J.; Boger, D.V.; Healy, T.W. Surface chemistry–rheology relationships in concentrated mineral suspensions. Int. J. Miner. Process. 2000, 58, 267–304. [Google Scholar] [CrossRef]

- Neelakantan, R.; Vaezi, G.F.; Sanders, R.S. Effect of shear on the yield stress and aggregate structure of flocculant-dosed, concentrated kaolinite suspensions. Miner. Eng. 2018, 123, 95–103. [Google Scholar] [CrossRef]

- Suyantara, G.P.W.; Hirajima, T.; Miki, H.; Sasaki, K. Floatability of molybdenite and chalcopyrite in artificial seawater. Miner. Eng. 2018, 115, 117–130. [Google Scholar] [CrossRef]

- Jeldres, R.I.; Arancibia-Bravo, M.P.; Reyes, A.; Aguirre, C.E.; Cortes, L.; Cisternas, L.A. The impact of seawater with calcium and magnesium removal for the flotation of copper-molybdenum sulphide ores. Miner. Eng. 2017, 109, 10–13. [Google Scholar] [CrossRef]

- Castro, S. Physico-chemical factors in flotation of Cu-Mo-Fe ores with seawater: A critical review. Physicochem. Probl. Miner. Process. 2018, 54, 1223–1236. [Google Scholar] [CrossRef]

- Cambridge, M.L.; Zavala-Perez, A.; Cawthray, G.R.; Statton, J.; Mondon, J.; Kendrick, G.A. Effects of desalination brine and seawater with the same elevated salinity on growth, physiology and seedling development of the seagrass Posidonia australis. Mar. Pollut. Bull. 2019, 140, 462–471. [Google Scholar] [CrossRef]

- Uddin, S. Environmental impacts of desalination activities in the Arabian gulf. Int. J. Environ. Sci. Dev. 2014, 5, 114–117. [Google Scholar] [CrossRef]

- Reyes, C.; Álvarez, M.; Ihle, C.F.; Contreras, M.; Kracht, W. The influence of seawater on magnetite tailing rheology. Miner. Eng. 2019, 131, 363–369. [Google Scholar] [CrossRef]

- Jeldres, R.I.; Piceros, E.C.; Leiva, W.H.; Toledo, P.G.; Herrera, N. Viscoelasticity and yielding properties of flocculated kaolinite sediments in saline water. Colloids Surf. A Physicochem. Eng. Asp. 2017, 529, 1009–1015. [Google Scholar] [CrossRef]

- Quezada, G.R.; Jeldres, R.I.; Fawell, P.D.; Toledo, P.G. Use of molecular dynamics to study the conformation of an anionic polyelectrolyte in saline medium and its adsorption on a quartz surface. Miner. Eng. 2018, 129, 102–105. [Google Scholar] [CrossRef]

- Gladman, B.; de Kretser, R.G.; Rudman, M.; Scales, P.J. Effect of shear on particulate suspension dewatering. Chem. Eng. Res. Des. 2005, 83, 933–936. [Google Scholar] [CrossRef]

- Bubakova, P.; Pivokonsky, M.; Filip, P. Effect of shear rate on aggregate size and structure in the process of aggregation and at steady state. Powder Technol. 2013, 235, 540–549. [Google Scholar] [CrossRef]

- Biggs, C. Activated sludge flocculation: On-line determination of floc size and the effect of shear. Water Res. 2000, 34, 2542–2550. [Google Scholar] [CrossRef]

- Kyoda, Y.; Costine, A.D.; Fawell, P.D.; Bellwood, J.; Das, G.K. Using focused beam reflectance measurement (FBRM) to monitor aggregate structures formed in flocculated clay suspensions. Miner. Eng. 2019, 138, 148–160. [Google Scholar] [CrossRef]

- Heath, A.R.; Bahri, P.A.; Fawell, P.D.; Farrow, J.B. Polymer flocculation of calcite: Relating the aggregate size to the settling rate. AIChE J. 2006, 52, 1987–1994. [Google Scholar] [CrossRef]

- Benn, F.A.; Fawell, P.D.; Halewood, J.; Austin, P.J.; Costine, A.D.; Jones, W.G.; Francis, N.S.; Druett, D.C.; Lester, D. Sedimentation and consolidation of different density aggregates formed by polymer-bridging flocculation. Chem. Eng. Sci. 2018, 184, 111–125. [Google Scholar] [CrossRef]

- Heath, A.R.; Fawell, P.D.; Bahri, P.A.; Swift, J.D. Estimating average particle size by focused beam reflectance measurement (FBRM). Part. Part. Syst. Charact. 2002, 19, 84. [Google Scholar] [CrossRef]

- Fawell, P.D.; Nguyen, T.V.; Solnordal, C.B.; Stephens, D.W. Enhancing gravity thickener feedwell design and operation for optimal flocculation through the application of computational fluid dynamics. Miner. Process. Extr. Metall. Rev. 2019, 1–15. [Google Scholar] [CrossRef]

- Deng, X.; Davé, R.N. Breakage of fractal agglomerates. Chem. Eng. Sci. 2017, 161, 117–126. [Google Scholar] [CrossRef]

- Kendall, K.; Stainton, C. Adhesion and aggregation of fine particles. Powder Technol. 2001, 121, 223–229. [Google Scholar] [CrossRef]

- Zhou, Y.; Gan, Y.; Wanless, E.J.; Jameson, G.J.; Franks, G.V. Interaction forces between silica surfaces in aqueous solutions of cationic polymeric flocculants: Effect of polymer charge. Langmuir 2008, 24, 10920–10928. [Google Scholar] [CrossRef]

- Tang, P.; Greenwood, J.; Raper, J.A. A model to describe the settling behavior of fractal aggregates. J. Colloid Interface Sci. 2002, 247, 210–219. [Google Scholar] [CrossRef]

- Ofori, P.; Nguyen, A.V.; Firth, B.; McNally, C.; Ozdemir, O. Shear-induced floc structure changes for enhanced dewatering of coal preparation plant tailings. Chem. Eng. J. 2011, 172, 914–923. [Google Scholar] [CrossRef]

| Test | Flocculant Doses (g/t) | Mixing Rate (rpm) | Mixing Time (s) | Df | Agregate Size (µm) | Initial Settling Rate (m/h) | Yield Stress (Pa) | Solid Concentrate (%) |

|---|---|---|---|---|---|---|---|---|

| 1 | 8 | 100 | 15 | 2.03 | 85 | 2.6 | 116 | 41.9 |

| 2 | 8 | 100 | 30 | 1.96 | 104 | 2.1 | 90.0 | 41.9 |

| 3 | 8 | 100 | 45 | 2.06 | 89 | 2.8 | 116 | 43.0 |

| 4 | 8 | 100 | 60 | 1.95 | 79 | 2.2 | 100 | 42.5 |

| 5 | 8 | 100 | 75 | 1.93 | 70 | 2.1 | 95.0 | 43.3 |

| 6 | 8 | 150 | 15 | 1.87 | 129 | 2.4 | 130 | 43.2 |

| 7 | 8 | 150 | 45 | 1.63 | 99 | 1.5 | 99.1 | 43.8 |

| 8 | 8 | 150 | 60 | 1.60 | 94 | 1.5 | 99.6 | 43.1 |

| 9 | 8 | 150 | 75 | 1.50 | 94 | 1.1 | 94.6 | 43.2 |

| 10 | 8 | 225 | 15 | 1.55 | 72 | 1.7 | 106 | 45.6 |

| 11 | 8 | 225 | 30 | 1.44 | 70 | 1.4 | 110 | 45.2 |

| 12 | 8 | 225 | 45 | 1.23 | 62 | 1.2 | 97.0 | 45.0 |

| 13 | 8 | 225 | 60 | 1.19 | 59 | 1.3 | 108 | 45.0 |

| 14 | 8 | 225 | 75 | 1.29 | 63 | 1.3 | 111 | 44.4 |

| 15 | 8 | 300 | 15 | 1.38 | 55 | 1.5 | 120 | 45.6 |

| 16 | 8 | 300 | 30 | 1.26 | 52 | 1.4 | 116 | 45.2 |

| 17 | 14 | 100 | 10 | 3.95 | 48 | 11.4 | 314 | 43.5 |

| 18 | 14 | 100 | 20 | 2.43 | 148 | 10.4 | 318 | 44.2 |

| 19 | 14 | 100 | 30 | 2.40 | 167 | 10.5 | 337 | 42.9 |

| 20 | 14 | 100 | 40 | 2.42 | 137 | 9.5 | 302 | 43.9 |

| 21 | 14 | 100 | 50 | 2.44 | 123 | 8.9 | 295 | 43.7 |

| 22 | 14 | 100 | 60 | 2.43 | 121 | 8.5 | 285 | 43.1 |

| 23 | 14 | 100 | 70 | 2.40 | 121 | 7.8 | 273 | 42.9 |

| 24 | 14 | 100 | 80 | 2.36 | 127 | 7.4 | 242 | 42.8 |

| 25 | 14 | 150 | 10 | 2.25 | 142 | 7.3 | 301 | 44.1 |

| 26 | 14 | 150 | 20 | 2.24 | 214 | 8.1 | 296 | 43.3 |

| 27 | 14 | 150 | 30 | 2.24 | 186 | 7.6 | 330 | 42.7 |

| 28 | 14 | 150 | 40 | 2.18 | 182 | 5.9 | 257 | 43.5 |

| 29 | 14 | 150 | 50 | 2.16 | 166 | 5.4 | 256 | 42.8 |

| 30 | 14 | 150 | 60 | 2.16 | 160 | 5.4 | 238 | 44.0 |

| 31 | 14 | 150 | 70 | 2.12 | 146 | 4.7 | 234 | 42.7 |

| 32 | 14 | 150 | 80 | 2.04 | 135 | 3.6 | 207 | 44.1 |

| 33 | 14 | 225 | 10 | 2.16 | 192 | 5.5 | 302 | 43.3 |

| 34 | 14 | 225 | 20 | 2.13 | 146 | 5.0 | 271 | 44.6 |

| 35 | 14 | 225 | 30 | 2.10 | 121 | 3.5 | 248 | 44.0 |

| 36 | 14 | 225 | 40 | 1.96 | 113 | 3.0 | 249 | 44.5 |

| 37 | 14 | 225 | 50 | 1.94 | 104 | 2.9 | 226 | 44.6 |

| 38 | 14 | 225 | 60 | 1.94 | 104 | 2.9 | 224 | 44.8 |

| 39 | 14 | 225 | 70 | 1.86 | 98 | 2.4 | 211 | 45.5 |

| 40 | 14 | 225 | 80 | 1.81 | 95 | 2.2 | 208 | 43.4 |

| 41 | 14 | 300 | 10 | 1.97 | 119 | 3.8 | 275 | 44.8 |

| 42 | 14 | 300 | 20 | 1.86 | 99 | 3.0 | 250 | 44.2 |

| 43 | 14 | 300 | 30 | 1.82 | 96 | 2.8 | 221 | 44.6 |

| 44 | 14 | 300 | 40 | 1.68 | 91 | 2.1 | 202 | 44.1 |

| 45 | 14 | 300 | 50 | 1.50 | 86 | 1.5 | 163 | 42.5 |

| 46 | 14 | 300 | 60 | 1.66 | 86 | 2.1 | 202 | 45.6 |

| 47 | 14 | 300 | 70 | 1.55 | 84 | 1.7 | 173 | 44.2 |

| 48 | 14 | 300 | 80 | 1.40 | 80 | 1.3 | 159 | 42.8 |

| 49 | 21 | 100 | 10 | 2.77 | 133 | 23.0 | 538 | 41.2 |

| 50 | 21 | 100 | 20 | 2.48 | 195 | 15.5 | 398 | 42.0 |

| 51 | 21 | 100 | 30 | 2.49 | 169 | 14.1 | 357 | 41.8 |

| 52 | 21 | 100 | 45 | 2.38 | 157 | 8.7 | 296 | 44.1 |

| 53 | 21 | 100 | 60 | 2.44 | 149 | 10.6 | 317 | 42.7 |

| 54 | 21 | 100 | 75 | 2.52 | 131 | 11.6 | 336 | 42.9 |

| 55 | 21 | 150 | 15 | 2.32 | 228 | 10.1 | 350 | 41.7 |

| 56 | 21 | 150 | 30 | 2.28 | 188 | 7.9 | 339 | 41.5 |

| 57 | 21 | 150 | 45 | 2.25 | 180 | 6.7 | 322 | 43.4 |

| 58 | 21 | 150 | 60 | 2.20 | 179 | 5.3 | 284 | 42.8 |

| 59 | 21 | 150 | 75 | 2.22 | 183 | 5.9 | 285 | 45.9 |

| 60 | 21 | 225 | 15 | 2.23 | 202 | 7.5 | 369 | 42.7 |

| 61 | 21 | 225 | 30 | 2.20 | 156 | 6.4 | 363 | 42.6 |

| 62 | 21 | 225 | 45 | 2.16 | 135 | 5.5 | 342 | 43.7 |

| 63 | 21 | 225 | 60 | 2.12 | 130 | 4.8 | 313 | 41.6 |

| 64 | 21 | 225 | 75 | 2.14 | 129 | 5.1 | 311 | 43.7 |

| 65 | 21 | 300 | 15 | 2.10 | 146 | 5.7 | 363 | 44.1 |

| 66 | 21 | 300 | 30 | 2.04 | 122 | 4.7 | 330 | 42.3 |

| 67 | 21 | 300 | 40 | 1.95 | 110 | 3.8 | 288 | 43.3 |

| 68 | 21 | 300 | 50 | 2.02 | 104 | 4.5 | 311 | 43.2 |

| 69 | 21 | 300 | 60 | 1.90 | 102 | 3.4 | 287 | 43.1 |

| 70 | 21 | 300 | 70 | 1.79 | 98 | 2.7 | 265 | 42.4 |

| 71 | 21 | 300 | 80 | 1.79 | 95 | 2.8 | 275 | 44.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeldres, M.; Piceros, E.C.; Toro, N.; Torres, D.; Robles, P.; Leiva, W.H.; Jeldres, R.I. Copper Tailing Flocculation in Seawater: Relating the Yield Stress with Fractal Aggregates at Varied Mixing Conditions. Metals 2019, 9, 1295. https://doi.org/10.3390/met9121295

Jeldres M, Piceros EC, Toro N, Torres D, Robles P, Leiva WH, Jeldres RI. Copper Tailing Flocculation in Seawater: Relating the Yield Stress with Fractal Aggregates at Varied Mixing Conditions. Metals. 2019; 9(12):1295. https://doi.org/10.3390/met9121295

Chicago/Turabian StyleJeldres, Matías, Eder C. Piceros, Norman Toro, David Torres, Pedro Robles, Williams H. Leiva, and Ricardo I. Jeldres. 2019. "Copper Tailing Flocculation in Seawater: Relating the Yield Stress with Fractal Aggregates at Varied Mixing Conditions" Metals 9, no. 12: 1295. https://doi.org/10.3390/met9121295

APA StyleJeldres, M., Piceros, E. C., Toro, N., Torres, D., Robles, P., Leiva, W. H., & Jeldres, R. I. (2019). Copper Tailing Flocculation in Seawater: Relating the Yield Stress with Fractal Aggregates at Varied Mixing Conditions. Metals, 9(12), 1295. https://doi.org/10.3390/met9121295