Development of New Cobalt-Free Maraging Steel with Superior Mechanical Properties via Electro-Pulsing Technology

Abstract

:1. Introduction

2. Experimental

2.1. Materials and Methods

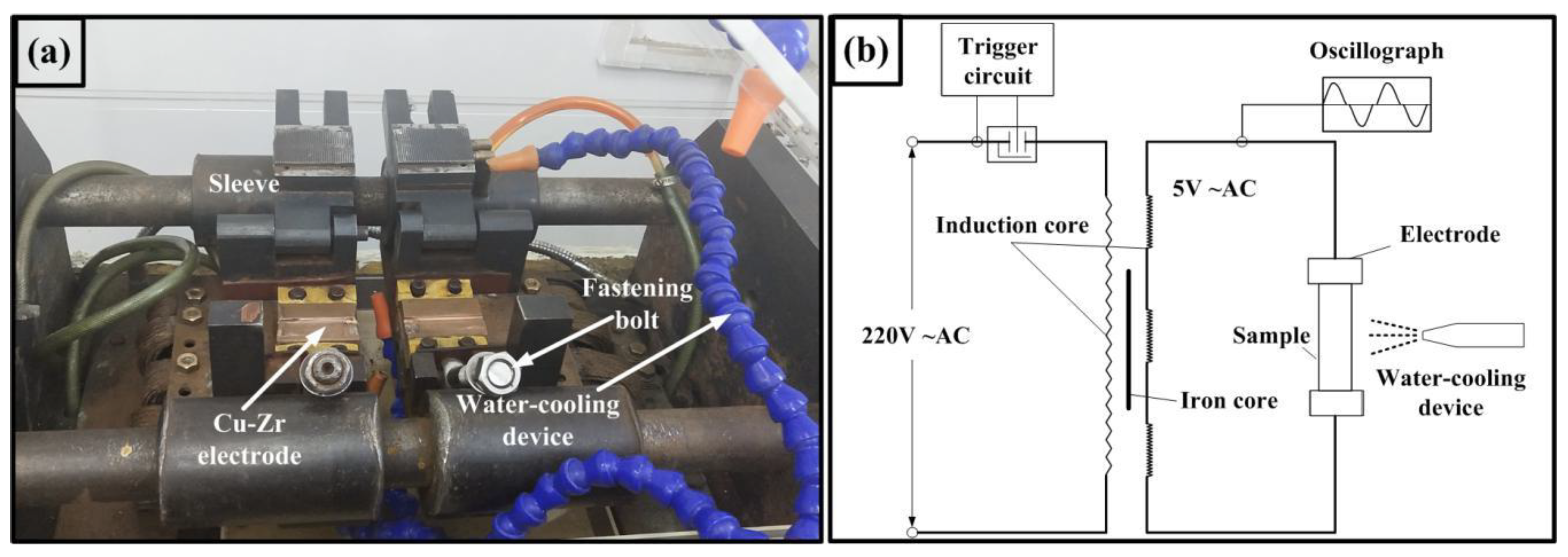

2.2. Technological Parameters and the Electro-Pulsing Apparatus

2.3. Microstructural Analysis and Property Measurement

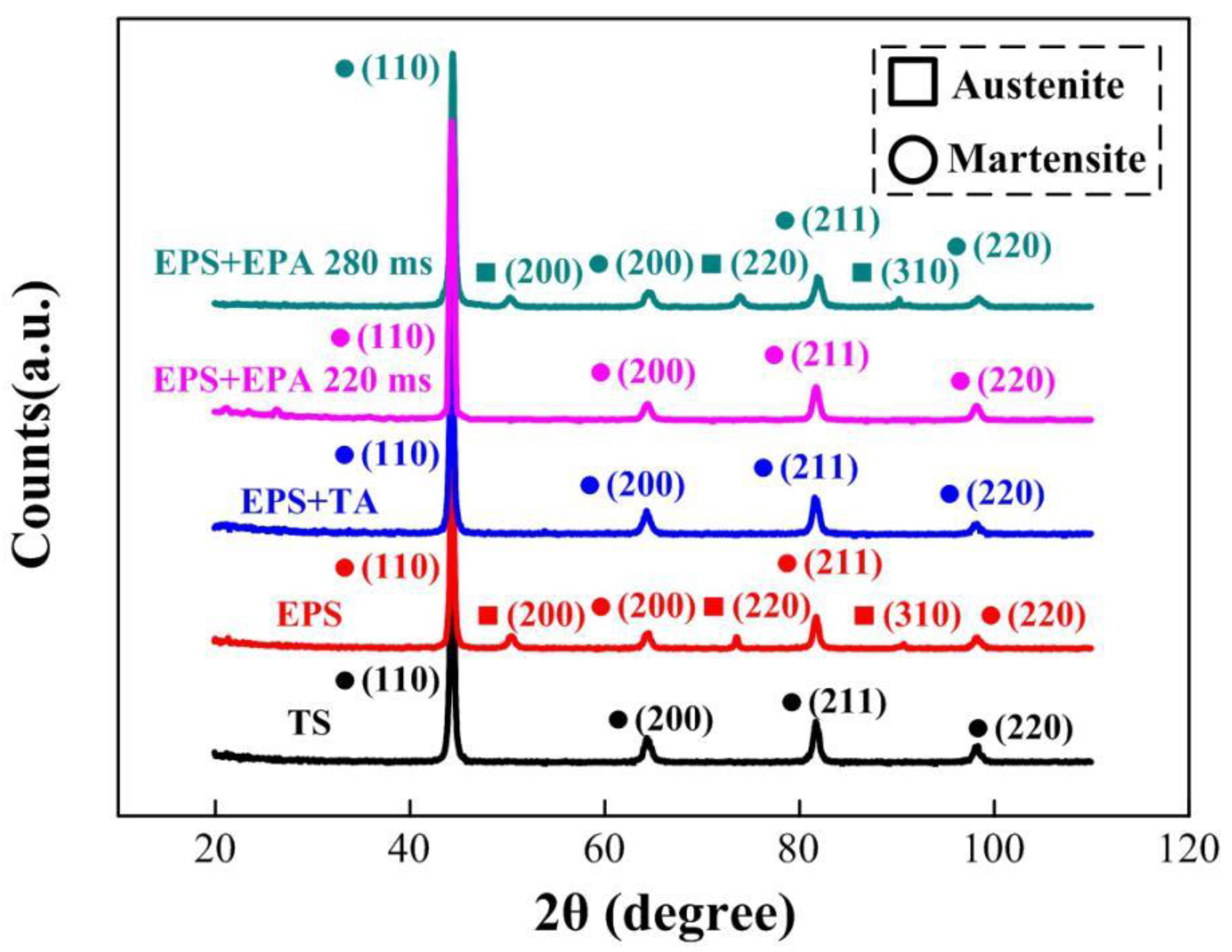

3. Results and Discussion

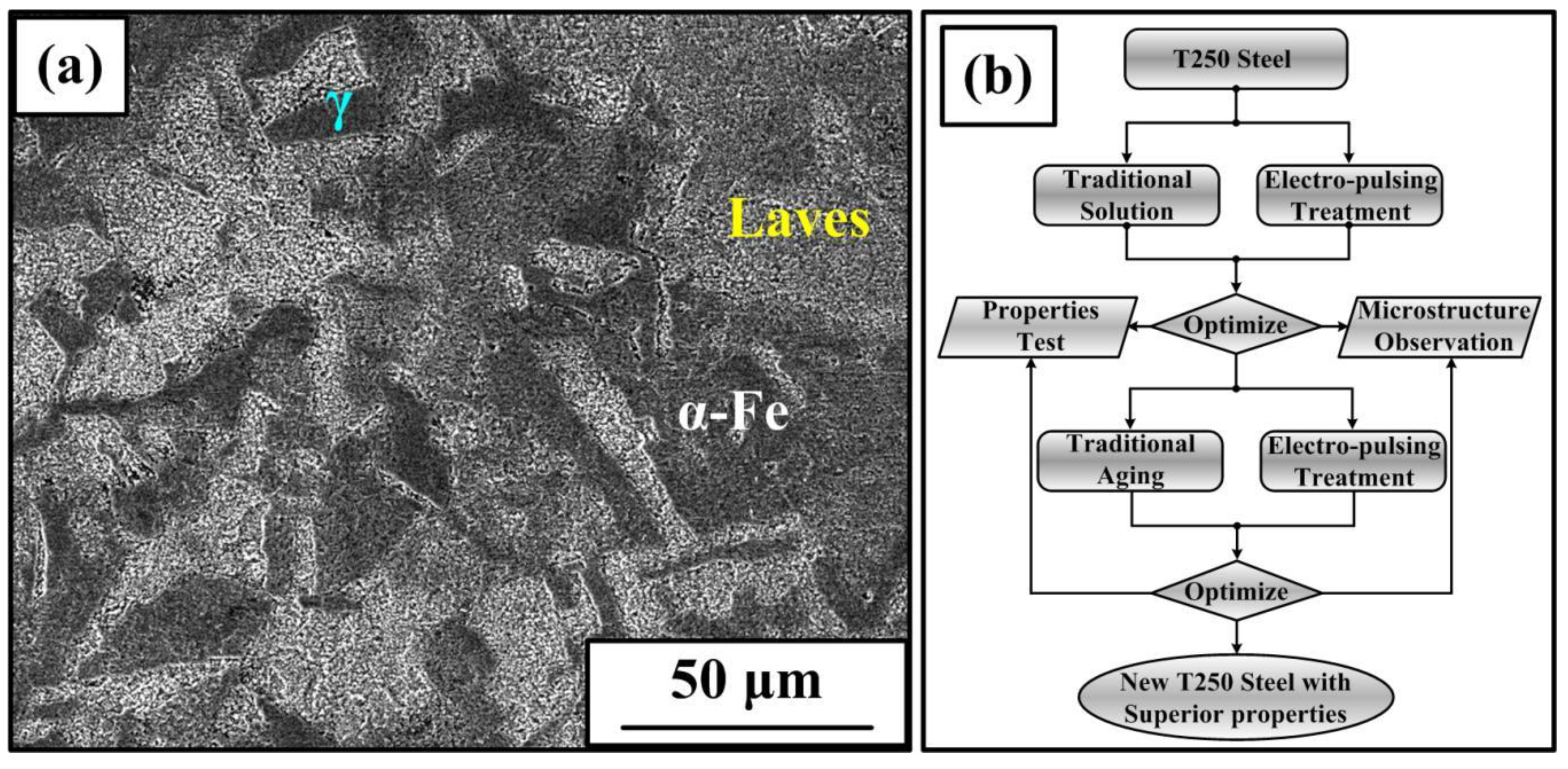

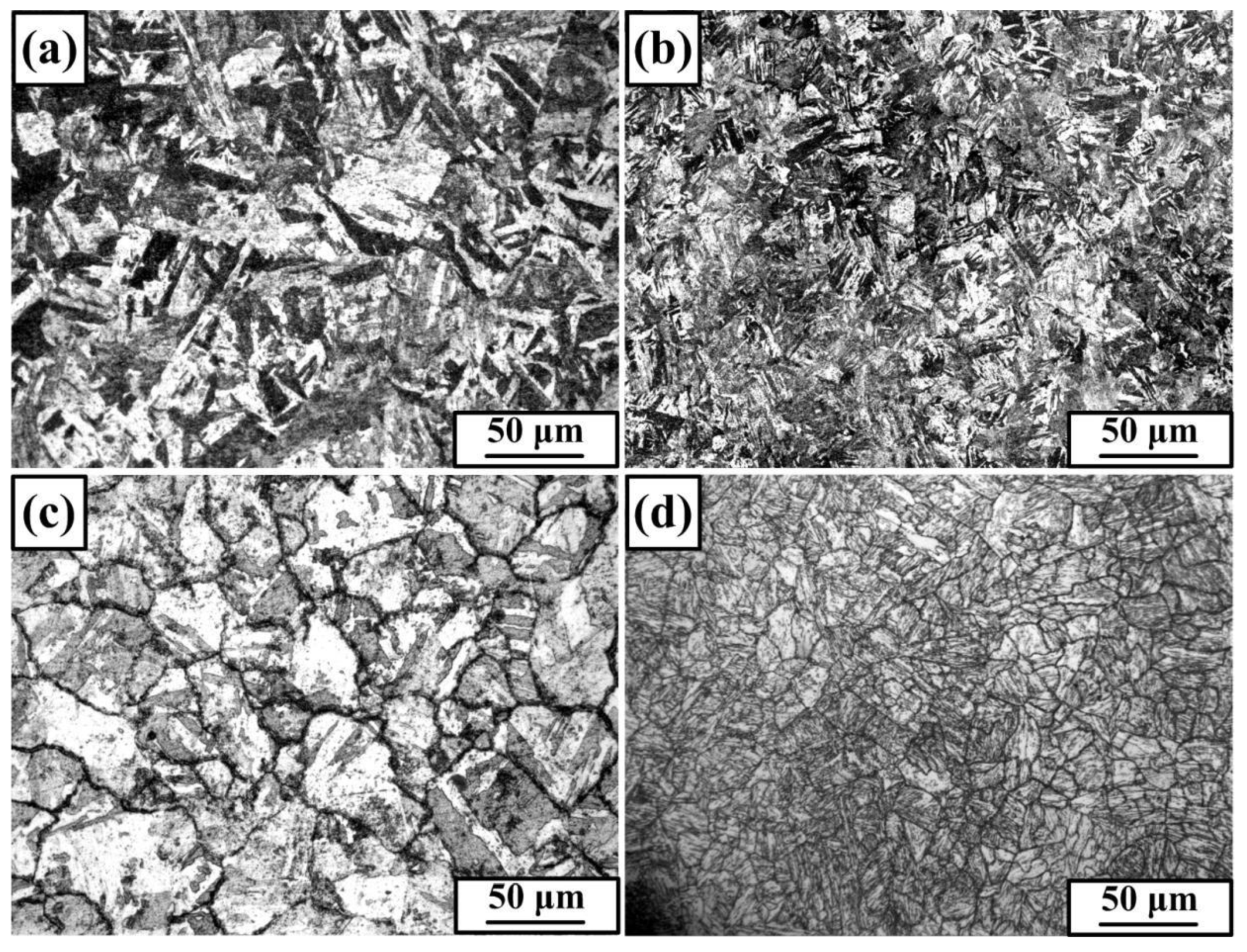

3.1. Optimization of Solid-Solution Treatment

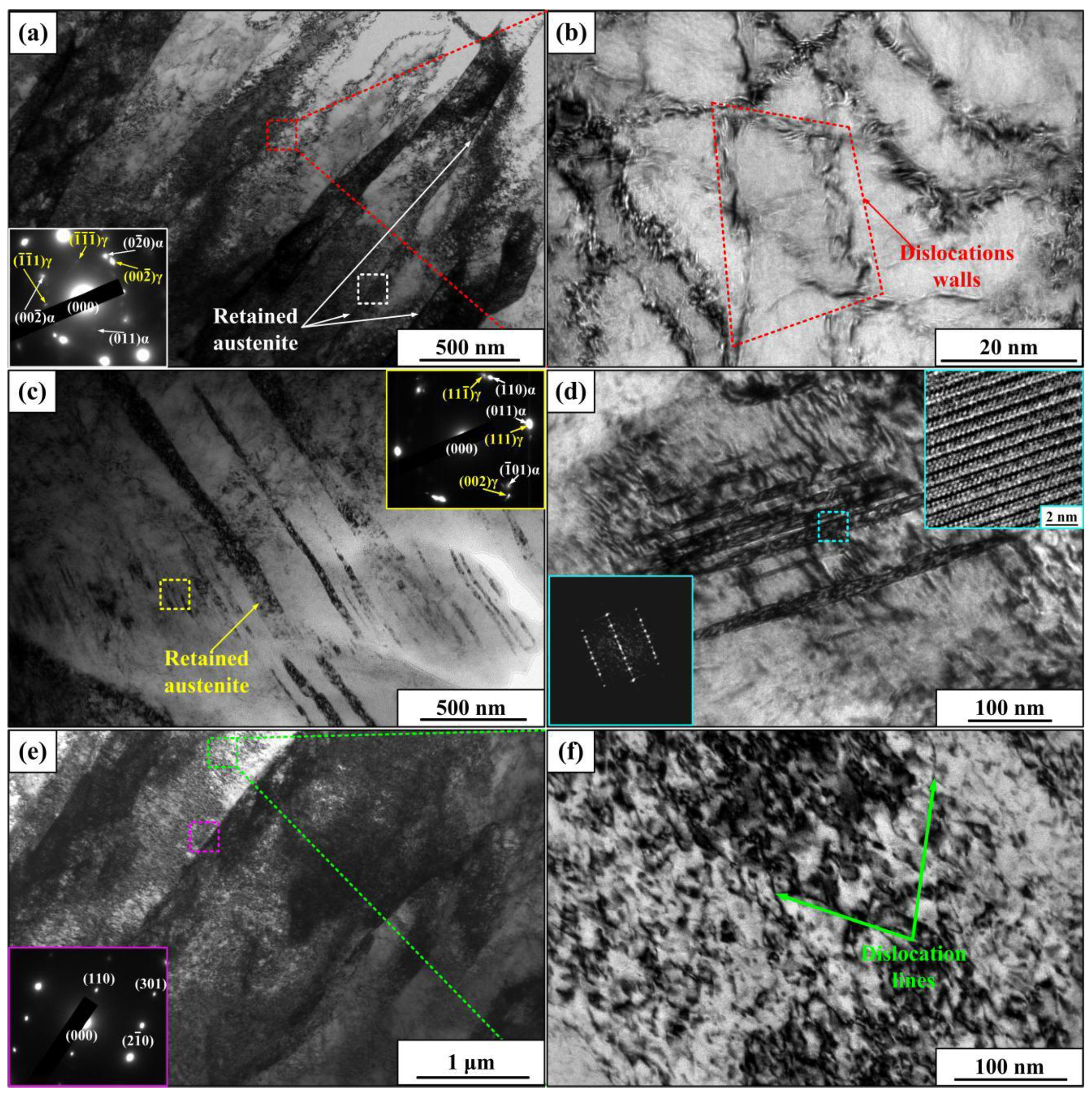

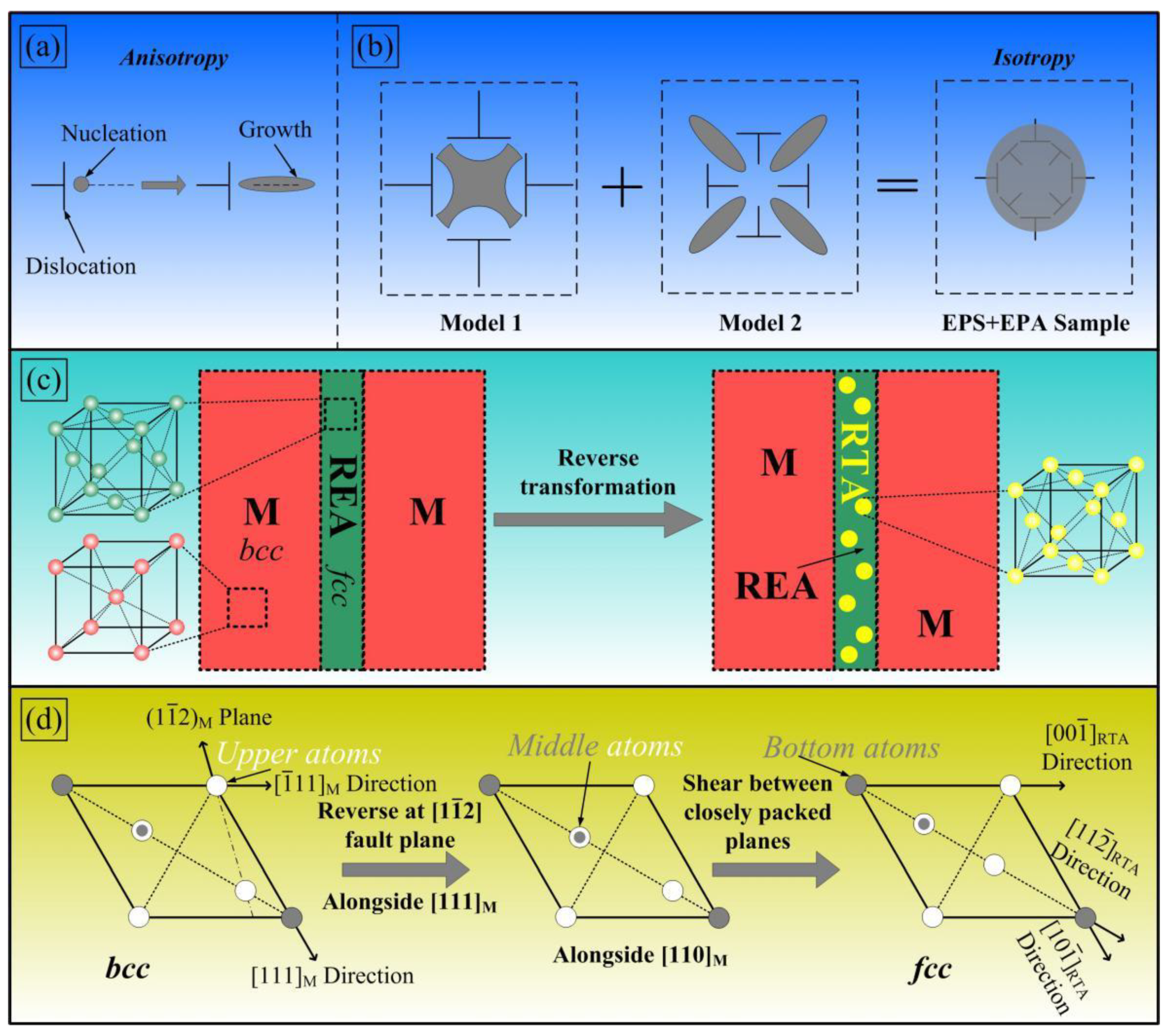

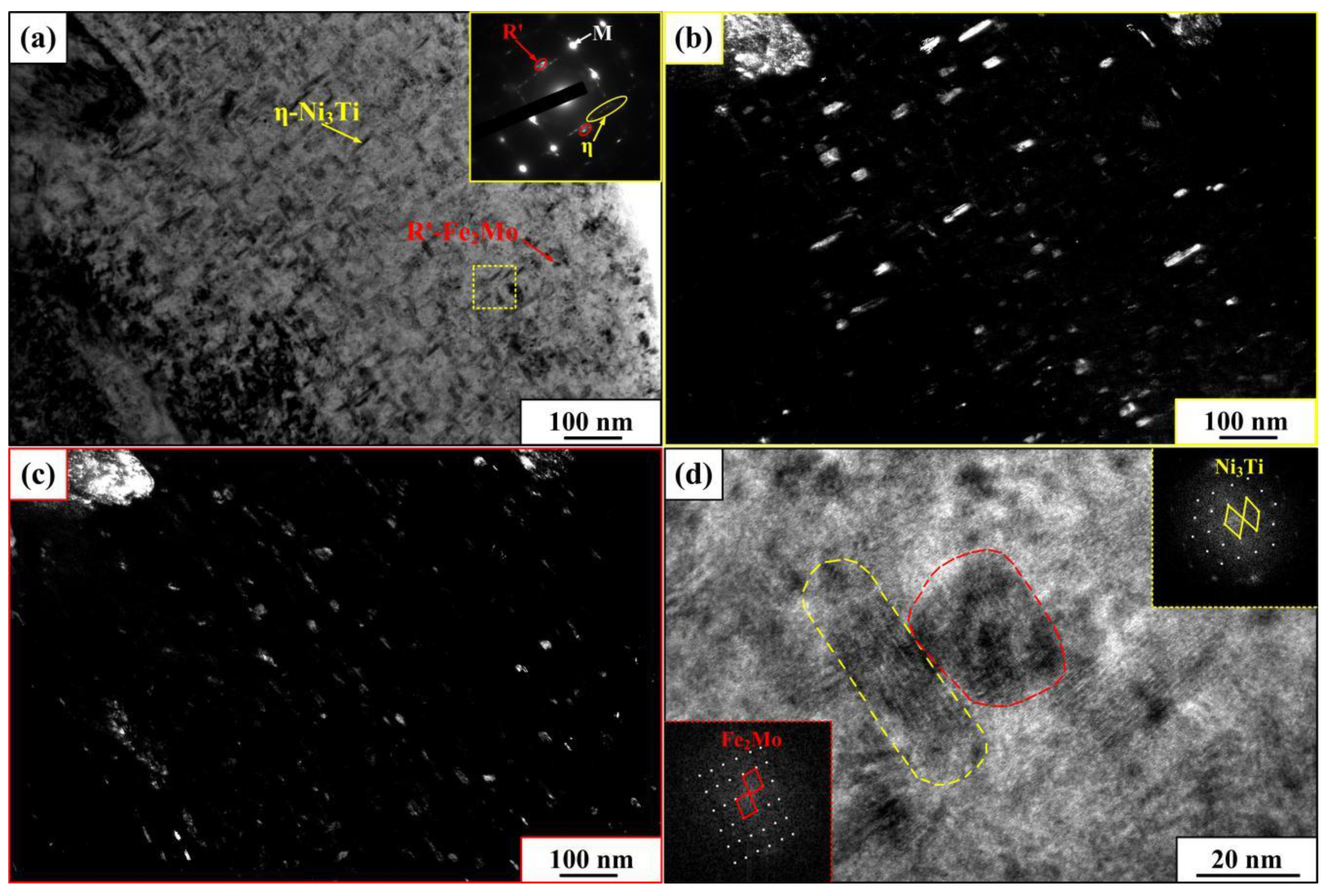

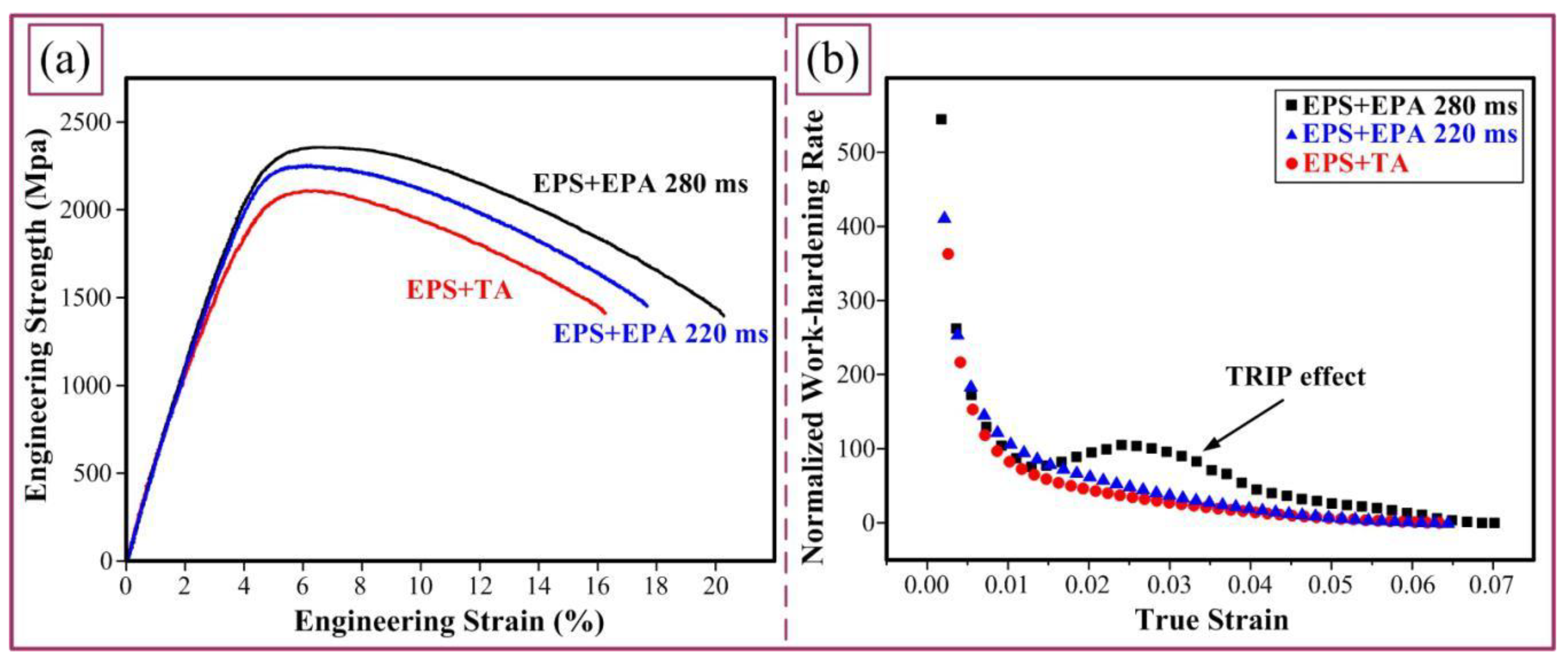

3.2. Optimization of Aging Treatment

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Guo, Z.; Sha, W.; Vaumousse, D. Microstructural evolution in a PH 13–8 stainless steel after aging. Acta Mater. 2003, 51, 101–116. [Google Scholar] [CrossRef]

- Luo, H.; Shi, J.; Wang, C.; Gao, W.; Sun, X.; Dong, H. Experimental and numerical analysis on formation of stable austenite during the intercritical annealing of 5Mn steel. Acta Mater. 2011, 59, 4002–4014. [Google Scholar] [CrossRef]

- Liu, H.W.; Liu, J.W.; Luo, C.P.; Liu, Z.J. Microstructure, crystallography of phase transformation and multiple precipitations in PH 15-7 Mo stainless steel. J. Alloys Compd. 2016, 672, 386–392. [Google Scholar] [CrossRef]

- Xu, W.; Rivera-Díaz-del-Castillo, P.E.J.; Yan, W.; Yang, K.; San Martín, D.; Kestens, L.A.I.; van der Zwaag, S. A new ultra-high strength stainless steel strengthened by various coexisting nanoprecipitates. Acta Mater. 2010, 58, 4067–4075. [Google Scholar] [CrossRef]

- Rajkumar, K.V.; Rao, B.P.C.; Sasi, B.; Kumar, A.; Jayakumar, T.; Raj, B.; Ray, K.K. Characterization of aging behaviour in M250 grade maraging steel using eddy current non-destructive methodology. Mater. Sci. Eng. A 2007, 464, 233–240. [Google Scholar] [CrossRef]

- Tharian, K.T.; Sivakumar, D.; Ganesa, R.; Balakrishnan, P.; Sinha, P.P. Development of new low nickel, cobalt free maraging steel. Mater. Sci. Technol. 1991, 7, 1082–1088. [Google Scholar] [CrossRef]

- Li, K.; Wei, L.; An, B.; Yu, B.; Misra, R.D.K. Aging phenomenon in low lattice-misfit cobalt-free maraging steel: Microstructural evolution and strengthening behavior. Mater. Sci. Eng. A 2019, 739, 445–454. [Google Scholar] [CrossRef]

- Squire, R.; Wilson, E.A. Effect of cobalt on impact toughness of steels. Mater. Sci. Technol. 1994, 10, 52–55. [Google Scholar] [CrossRef]

- Li, Y.C.; Yan, W.; Cotton, J.D.; Ryan, G.J.; Shen, Y.F.; Wang, W.; Shan, Y.Y.; Yang, K. A new 1.9 GPa maraging stainless steel strengthened by multiple precipitating species. Mater. Des. 2015, 82, 56–63. [Google Scholar] [CrossRef]

- Shekhter, A.; Aaronson, H.; Miller, M.; Ringer, S.; Pereloma, E. Effect of aging and deformation on the microstructure and properties of Fe-Ni-Ti maraging steel. Metall. Mater. Trans. A 2004, 35, 973–983. [Google Scholar]

- Wang, C.C.; Zhang, C.; Yang, Z.G. Austenite layer and precipitation in high Co-Ni maraging steel. Micron 2014, 67, 112–116. [Google Scholar] [CrossRef] [PubMed]

- Masoumi, M.; de Barrous, I.F.; Herculano, L.F.G.; Coelho, H.L.F.; de Abreu, H.F.G. Effect of microstructure and crystallographic texture on charpy impact test for maraging 300 steel. Mater. Charact. 2016, 120, 203–209. [Google Scholar] [CrossRef]

- Du, P.J.; Yang, D.P.; Bai, M.K.; Xiong, X.C.; Wu, D.; Wang, G.D.; Yi, H.L. Austenite stabilisation by two step partitioning of manganese and carbon in a Mn-TRIP steel. Mater. Sci. Technol. 2019, 17, 2084–2091. [Google Scholar] [CrossRef]

- Harding, I.; Mouton, I.; Gault, B.; Raabe, D.; Kumar, K.S. Carbon partitioning and microstructure evolotion during tempering of an Fe-Ni-C steel. Scripta Mater. 2019, 172, 38–42. [Google Scholar] [CrossRef]

- Pereloma, E.; Shekhter, A.; Miller, M.; Ringer, S. Aging behaviour of an Fe-20Ni-1.8Mn-1.6Ti-0.59Al (wt.%) maraging alloy: Clustering, precipitation and hardening. Acta Mater. 2004, 52, 5589–5602. [Google Scholar] [CrossRef]

- Li, K.; Yu, B.; Misra, R.D.K.; Han, G.; Liu, S.; Shang, C.J. Strengthening of cobalt-free 19Ni3Mo1.5Ti maraging steel through high-density and low lattice-misfit nanoscale precipitates. Mater. Sci. Eng. A 2018, 715, 174–185. [Google Scholar] [CrossRef]

- Jiang, S.H.; Wang, H.; Wu, Y.; Liu, X.J.; Chen, H.H.; Yao, M.J.; Gault, B.; Ponge, D.; Raabe, D.; Hirata, A.; et al. Ultrastrong steel via minimal misfit and high-density nanoprecipitation. Nature 2017, 544, 460–465. [Google Scholar] [CrossRef]

- Yang, M.X.; Yang, G.; Liu, Z.D.; Wang, C.; Huang, C.X. Significant enhancement of strength in a lamellar-type nanostructured maraging steel subjected to equal-channel angular pressing for 12 passes. Mater. Sci. Eng. A 2012, 550, 429–433. [Google Scholar] [CrossRef]

- Yang, M.X.; Yang, G.; Liu, Z.D.; Wang, C.; Hu, C.; Huang, C.X. Effect of equal-channel angular pressing on the microstructures and properties of 18Ni(C250) maraging steel. Acta Metall. Sin. 2012, 48, 164–169. [Google Scholar] [CrossRef]

- Zhang, W.; Zou, D.N.; Qiao, G.J. Hot deformation behavior and microstructural evolution of as-cast co containing maraging stainless steel. Mater. Res. Express 2019, 6, 086586. [Google Scholar] [CrossRef]

- Mizubayashi, H.; Okuda, S. Structural relaxation induced by passing electric current in amorphous Cu50Ti50 at low temperature. Phys. Rev. B 1989, 40, 8057–8060. [Google Scholar] [CrossRef] [PubMed]

- Song, H.; Wang, Z.J.; He, X.D.; Duan, J. Self-healing of damage inside metal triggered by electropulsing stimuli. Sci. Rep. 2017, 7, 7097. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.G.; Zhang, J.T.; Tan, J.; Ma, B.D. Microstructure refinement and property improvement of metastable austenitic manganese steel induced by electro-pulsing. J. Iron Steel Res. Int. 2014, 21, 685–689. [Google Scholar] [CrossRef]

- Zhou, Y.; Chen, G.Q.; Fu, X.S.; Zhou, W.L. Effect of electropulsing on deformation behavior of Ti-6Al-4V alloy during cold drawing. Trans. Nonferrous Met. Soc. China 2014, 24, 1012–1021. [Google Scholar] [CrossRef]

- Zhang, X.; Li, H.W.; Zhan, M. Mechanism for macro and micro behaviors of the Ni-based superalloy during electrically-assisted tension: Local Joule of heating effect. J. Alloys Compd. 2018, 742, 480–489. [Google Scholar] [CrossRef]

- Zhao, Y.G.; Ma, B.D.; Guo, H.C.; Ma, J.; Yang, Q.; Song, J.S. Electropulsing strengthened 2GPa boron steel with good ductility. Mater. Des. 2013, 43, 195–199. [Google Scholar] [CrossRef]

- Ma, B.D.; Zhao, Y.G.; Bai, H.; Ma, J.; Zhang, J.T.; Xu, X.F. Gradient distribution of mechanical properties in the high carbon steel induced by the detour effect of the pulse current. Mater. Des. 2013, 49, 168–172. [Google Scholar] [CrossRef]

- Pan, D.; Zhao, Y.G.; Xu, X.F.; Wang, Y.T.; Jiang, W.Q.; Chong, X.Y. A novel strengthening and toughening strategy for T250 maraging steel: Cluster-orientation governed higher strength-ductility combination induced by electropulsing. Mater. Des. 2019, 169, 107686. [Google Scholar] [CrossRef]

- Pan, D.; Zhao, Y.G.; Wang, Y.T.; Xu, X.F.; Yin, P.L.; Chong, X.Y. Formation of ultrafine pearlites in tempered 42CrMo steel induced by electro-pulsing. Mater. Lett. 2019, 251, 73–77. [Google Scholar] [CrossRef]

- Gui, B.C.; Yang, Z.Y.; Jiang, Y.H.; Ding, Y.L. Effect of solution temperature on mechanical properties of corrosion-resistant maraging steel. J. Iron Steel Res. 2012, 24, 45–48. [Google Scholar]

- Loewy, S.; Rheingans, B.; Meka, S.R.; Mittemeijer, E.J. Modulated martensite formation behavior in Fe-Ni-based alloys; athermal and thermally activated mechanisms. J. Mater. Res. 2015, 30, 2101–2107. [Google Scholar] [CrossRef]

- Pan, D.; Wang, Y.T.; Zhao, Y.G.; Xu, X.F.; Chong, X.Y.; Yin, P.L. Completely wetted α/α grain boundaries in electro-pulsing treated DP600 steel under different cooling conditions. Mater. Lett. 2019, 252, 264–267. [Google Scholar] [CrossRef]

- Zhang, M.X.; Kelly, P.M. Accurate orientation relationship between ferrite and austenite in low carbon martensite and granular bainite. Scripta Mater. 2002, 47, 749–755. [Google Scholar] [CrossRef]

- Wang, Y.T.; Pan, D.; Zhao, Y.G.; Sun, L.Y.; Xu, X.F.; Yin, P.L.; Chong, X.Y.; Jiang, W.Q.; Wang, Z. Enhanced stability of retained austenites in quenched 25SiMn2MoV steel by electro-pulsing current. Mater. Sci. Eng. A 2019, in press. [Google Scholar] [CrossRef]

- Strife, J.R.; Carr, M.J.; Ansell, G.S. The effect of austenite prestrain above the Md temperature on the martensitic transformation in Fe-Ni-Cr-C alloys. Metall. Trans. A 1977, 8, 1471–1484. [Google Scholar] [CrossRef]

- Yang, H.S.; Bhadeshia, H.K.D.H. Austenite grain size and the martensite-start temperature. Scr. Mater. 2009, 60, 493–495. [Google Scholar] [CrossRef]

- Zhang, W.; Sui, M.L.; Zhou, Y.Z.; He, G.H.; Guo, J.D.; Li, D.X. Electro-pulsing induced evolution of microstructures in materials. Acta Metall. Sin. 2003, 39, 1009–1018. [Google Scholar]

- Tang, D.W.; Zhou, B.L.; Gao, H.; He, G.H. Thermal stress relaxation behavior in thin films under transient laser-pulse heating. J. Appl. Phys. 1993, 73, 3749–3752. [Google Scholar] [CrossRef]

- Huang, C.X.; Wang, K.; Wu, S.D.; Zhang, Z.F.; Li, G.Y.; Li, S.X. Deformation twinning in polycrystalline copper at room temperature and low strain rate. Acta Mater. 2006, 54, 655–665. [Google Scholar] [CrossRef]

- Pan, D.; Zhao, Y.G.; Xu, X.F.; Wang, Y.T.; Jiang, W.Q.; Ju, H. Effect of high-energy and instantaneous electropulsing treatment on microstructure and properties of 42CrMo steel. Acta Metall. Sin. 2018, 54, 1245–1252. [Google Scholar]

- Wang, Y.T.; Zhao, Y.G.; Xu, X.F.; Pan, D.; Jiang, W.Q.; Yang, X.H.; Wang, Z. Superior mechanical properties induced by the interaction between dislocations and precipitates in the electro-pulsing treated Al-Mg-Si alloys. Mater. Sci. Eng. A 2018, 735, 154–161. [Google Scholar] [CrossRef]

- Zhu, J.; Zhao, Y.W.; Pan, T.X.; Cai, Q.G. Investigation on reverse austenite in 18Ni(250 grade) maraging steel. Iron Steel 1981, 16, 41–45. [Google Scholar]

- Tian, J.L.; Li, Y.C.; Wang, W.; Yan, W.; Shan, Y.T.; Jiang, Z.H.; Yang, K. Alloying element segregation effect in a multi-phase strengthened maraging stainless steel. Acta Metall. Sin. 2016, 52, 1517–1526. [Google Scholar]

- Zhang, X.; Li, H.W.; Zhan, M.; Shao, G.D.; Ma, P.Y. Extraordinary effect of the δ phase on the electrically-assisted deformation responses of a Ni-based superalloy. Mater. Charact. 2018, 144, 597–604. [Google Scholar] [CrossRef]

- Srivatsan, T.S. Dispersion strengthened aluminum alloys. Mater. Manuf. Process. 1991, 6, 565–568. [Google Scholar] [CrossRef]

- Ashby, M.F. Work hardening of dispersion-hardened crystals. Philos. Mag. 1966, 14, 1157–1178. [Google Scholar] [CrossRef]

| Element | Ni | Cr | Mo | Ti | Al | Si | Mn | Fe |

|---|---|---|---|---|---|---|---|---|

| wt.% | 18.86 | 0.37 | 3.06 | 1.20 | 0.11 | 0.01 | 0.01 | Bal. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, D.; Zhao, Y.; Wang, Y.; Xu, X.; Chong, X. Development of New Cobalt-Free Maraging Steel with Superior Mechanical Properties via Electro-Pulsing Technology. Metals 2019, 9, 1299. https://doi.org/10.3390/met9121299

Pan D, Zhao Y, Wang Y, Xu X, Chong X. Development of New Cobalt-Free Maraging Steel with Superior Mechanical Properties via Electro-Pulsing Technology. Metals. 2019; 9(12):1299. https://doi.org/10.3390/met9121299

Chicago/Turabian StylePan, Dong, Yuguang Zhao, Yitong Wang, Xiaofeng Xu, and Xueying Chong. 2019. "Development of New Cobalt-Free Maraging Steel with Superior Mechanical Properties via Electro-Pulsing Technology" Metals 9, no. 12: 1299. https://doi.org/10.3390/met9121299