Exploring the Correlation between Subsurface Residual Stresses and Manufacturing Parameters in Laser Powder Bed Fused Ti-6Al-4V

Abstract

1. Introduction

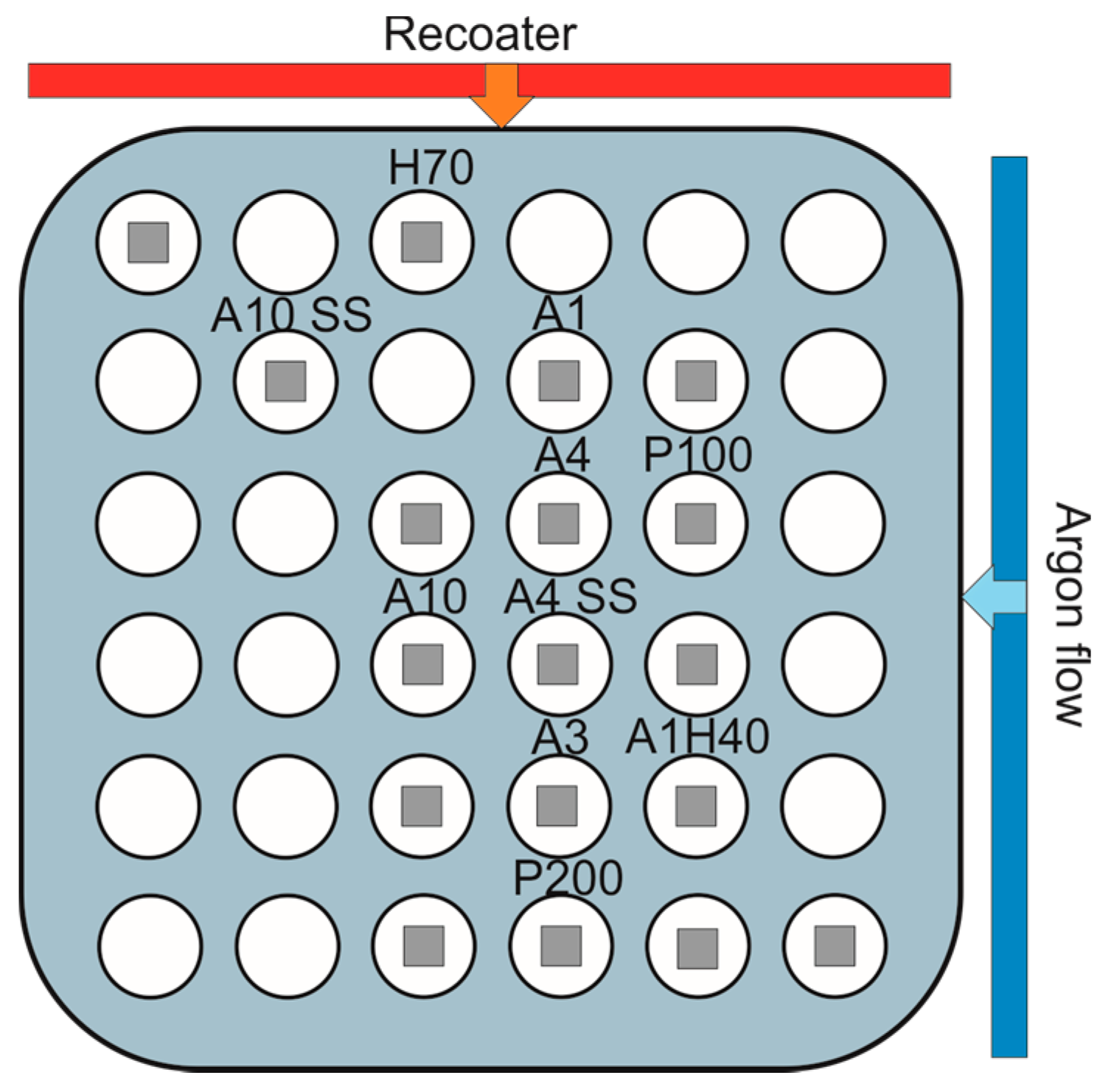

2. Materials and Methods

2.1. Materials

2.2. Synchrotron X-ray Diffraction

2.3. Roughness Measurements

3. Results and Discussion

3.1. Effect of Surface Roughness

3.2. Effect of Sample Orientation with Respect to Ar Flow

3.3. Effect of Velocity Variation and of Support Structure

3.4. Effect of Power and Hatch Distance Variation

4. Summary

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dutta, B.; Froes, F.H. Chapter 1—The Additive Manufacturing of Titanium Alloys. In Additive Manufacturing of Titanium Alloys; Dutta, B., Froes, F.H., Eds.; Elsevier: Amsterdam, The Netherlands, 2016; ISBN 978-0-12-804782-8. [Google Scholar]

- Boyer, R.; Collings, E.W.; Welsch, G. Materials Properties Handbook: Titanium Alloys Materials Properties Handbook; ASM International: Materials Park, OH, USA, 1994; ISBN 978-0-87170-481-8. [Google Scholar]

- Chahine, G.; Koike, M.; Okabe, T.; Smith, P.; Kovacevic, R. The design and production of Ti-6Al-4V ELI customized dental implants. JOM 2008, 60, 50–55. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Yadroitsava, I. Evaluation of residual stress in stainless steel 316L and Ti6Al4V samples produced by selective laser melting. Virtual Phys. Prototyping 2015, 10, 67–76. [Google Scholar] [CrossRef]

- Patterson, A.E.; Messimer, S.L.; Farrington, P.A. Overhanging Features and the SLM/DMLS Residual Stresses Problem: Review and Future Research Need. Technologies 2017, 5, 15. [Google Scholar] [CrossRef]

- Mercelis, P.; Kruth, J.P. Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyping J. 2006, 12, 254–265. [Google Scholar] [CrossRef]

- Kruth, J.P.; Deckers, J.; Yasa, E.; Wauthle, R. Assessing and comparing influencing factors of residual stresses in selective laser melting using a novel analysis method. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2012, 226, 980–991. [Google Scholar] [CrossRef]

- Mishurova, T.; Cabeza, S.; Artzt, K.; Haubrich, J.; Klaus, M.; Genzel, C.; Requena, G.; Bruno, G. An Assessment of Subsurface Residual Stress Analysis in SLM Ti-6Al-4V. Materials 2017, 10, 348. [Google Scholar] [CrossRef] [PubMed]

- Mishurova, T.; Cabeza, S.; Thiede, T.; Nadammal, N.; Kromm, A.; Klaus, M.; Genzel, C.; Haberland, C.; Bruno, G. The Influence of the Support Structure on Residual Stress and Distortion in SLM Inconel 718 Parts. Metall. Mater. Trans. A 2018, 49, 3038–3046. [Google Scholar] [CrossRef]

- Ahmad, B.; van der Veen, S.O.; Fitzpatrick, M.E.; Guo, H. Residual stress evaluation in selective-laser-melting additively manufactured titanium (Ti-6Al-4V) and inconel 718 using the contour method and numerical simulation. Addit. Manuf. 2018, 22, 571–582. [Google Scholar] [CrossRef]

- Taguchi, G. System of Experimental Design; Kraus International Publication: New York, NY, USA, 1982. [Google Scholar]

- Scipioni Bertoli, U.; Wolfer, A.J.; Matthews, M.J.; Delplanque, J.-P.R.; Schoenung, J.M. On the limitations of Volumetric Energy Density as a design parameter for Selective Laser Melting. Mater. Des. 2017, 113, 331–340. [Google Scholar] [CrossRef]

- Mishurova, T.; Artzt, K.; Haubrich, J.; Requena, G.; Bruno, G. New aspects about the search for the most relevant parameters optimizing SLM materials. Addit. Manuf. 2019, 25, 325–334. [Google Scholar] [CrossRef]

- Song, J.; Wu, W.; Zhang, L.; He, B.; Lu, L.; Ni, X.; Long, Q.; Zhu, G. Role of scanning strategy on residual stress distribution in Ti-6Al4V alloy prepared by selective laser melting. Optik 2018, 170, 342–352. [Google Scholar] [CrossRef]

- Vastola, G.; Zhang, G.; Pei, Q.X.; Zhang, Y.W. Controlling of residual stress in additive manufacturing of Ti6Al4V by finite element modeling. Addit. Manuf. 2016, 12, 231–239. [Google Scholar] [CrossRef]

- Simson, T.; Emmel, A.; Dwars, A.; Böhm, J. Residual stress measurements on AISI 316L samples manufactured by selective laser melting. Addit. Manuf. 2017, 17, 183–189. [Google Scholar] [CrossRef]

- Korsunsky, A.M.; Sebastiani, M.; Bemporad, E. Residual stress evaluation at the micrometer scale: Analysis of thin coatings by FIB milling and digital image correlation. Surf. Coat. Technol. 2010, 205, 2393–2403. [Google Scholar] [CrossRef]

- Ali, H.; Ghadbeigi, H.; Mumtaz, K. Effect of scanning strategies on residual stress and mechanical properties of Selective Laser Melted Ti6Al4V. Mater. Sci. Eng. A 2018, 712, 175–187. [Google Scholar] [CrossRef]

- van Zyl, I.; Yadroitsava, I.; Yadroitsev, I. Residual Stress in Ti6al4v Objects Produced by Direct Metal Laser Sintering. S. Afr. J. Ind. Eng. 2016, 27, 134–141. [Google Scholar] [CrossRef]

- Salmi, A.; Atzeni, E.; Iuliano, L.; Galati, M. Experimental Analysis of Residual Stresses on AlSi10Mg Parts Produced by Means of Selective Laser Melting (SLM). Procedia CIRP 2017, 62, 458–463. [Google Scholar] [CrossRef]

- Thiede, T.; Cabeza, S.; Mishurova, T.; Nadammal, N.; Kromm, A.; Bode, J.; Haberland, C.; Bruno, G. Residual Stress in Selective Laser Melted Inconel 718: Influence of the Removal from Base Plate and Deposition Hatch Length. Mater. Perform. Charact. 2018, 4, 717–735. [Google Scholar] [CrossRef]

- Laquai, R.; Müller, B.R.; Kasperovich, G.; Haubrich, J.; Requena, G.; Bruno, G. X-ray refraction distinguishes unprocessed powder from empty pores in selective laser melting Ti-6Al-4V. Mater. Res. Lett. 2017, 6, 130–135. [Google Scholar] [CrossRef]

- Kasperovich, G.; Haubrich, J.; Gussone, J.; Requena, G. Correlation between porosity and processing parameters in TiAl6V4 produced by selective laser melting. Mater. Des. 2016, 105, 160–170. [Google Scholar] [CrossRef]

- Genzel, C.; Denks, I.A.; Gibmeier, J.; Klaus, M.; Wagener, G. The materials science synchrotron beamline EDDI for energy-dispersive diffraction analysis. Nucl. Instrum. Methods Phys. Res. Sect. A 2007, 578, 23–33. [Google Scholar] [CrossRef]

- Giessen, B.C.; Ordon, G.E. New high-speed technique based on X-ray spectrography. Science 1968, 159, 973–975. [Google Scholar] [CrossRef] [PubMed]

- Fernàndez, P.; Bruno, G.; Gonzàlez-Doncel, G. Macro and micro-residual stress distribution in 6061 Al-15 vol.% SiCw under different heat treatment conditions. Compos. Sci. Technol. 2006, 66, 1738–1748. [Google Scholar] [CrossRef]

- Pesach, A.; Tiferet, E.; Vogel, S.C.; Chonin, M.; Diskin, A.; Zilberman, L.; Rivin, O.; Yeheskel, O.; Caspi, E.N. Texture analysis of additively manufactured Ti-6Al-4V using neutron diffraction. Addit. Manuf. 2018, 23, 394–401. [Google Scholar] [CrossRef]

- Nadammal, N.; Cabeza, S.; Mishurova, T.; Thiede, T.; Kromm, A.; Seyfert, C.; Farahbod, L.; Haberland, C.; Schneider, J.A.; Portella, P.D.; et al. Effect of hatch length on the development of microstructure, texture and residual stresses in selective laser melted superalloy Inconel 718. Mater. Des. 2017, 134, 139–150. [Google Scholar] [CrossRef]

- Barriobero-Vila, P.; Gussone, J.; Stark, A.; Schell, N.; Haubrich, J.; Requena, G. Peritectic titanium alloys for 3D printing. Nat. Commun. 2018, 9, 3426. [Google Scholar] [CrossRef] [PubMed]

- Simonelli, M.; Tse, Y.Y.; Tuck, C. On the Texture Formation of Selective Laser Melted Ti-6Al-4V. Metall. Mater. Trans. A 2014, 45, 2863–2872. [Google Scholar] [CrossRef]

- Gnäupel-Herold, T.; Creuziger, A.A.; Iadicola, M. A model for calculating diffraction elastic constants. J. Appl. Crystallogr. 2012, 45, 197–206. [Google Scholar] [CrossRef]

- Oliver, E.C.; Daymond, M.R.; Quinta da Fonseca, J.; Withers, P.J. Intergranular Stress Evolution in Titanium Studied by Neutron Diffraction and Self-consistent Modelling. J. Neutron Res. 2004, 12, 33–37. [Google Scholar] [CrossRef]

- ISO Standard 21432. Non-destructive testing—Standard test method for determining residual stresses by neutron diffraction; ISO: Geneva, Switzerland, 2019; in press. [Google Scholar]

- Koutiri, I.; Pessard, E.; Peyre, P.; Amlou, O.; De Terris, T. Influence of SLM process parameters on the surface finish, porosity rate and fatigue behavior of as-built Inconel 625 parts. J. Mater. Process. Technol. 2018, 255, 536–546. [Google Scholar] [CrossRef]

- Li, B.-Q.; Li, Z.; Bai, P.; Liu, B.; Kuai, Z. Research on Surface Roughness of AlSi10Mg Parts Fabricated by Laser Powder Bed Fusion. Metals 2018, 8, 524. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, Y.; Wang, D. A study on the residual stress during selective laser melting (SLM) of metallic powder. Int. J. Adv. Manuf. Technol. 2016, 87, 647–656. [Google Scholar] [CrossRef]

- Xu, W.; Sun, S.; Elambasseril, J.; Liu, Q.; Brandt, M.; Qian, M. Ti-6Al-4V Additively Manufactured by Selective Laser Melting with Superior Mechanical Properties. JOM 2015, 67, 668–673. [Google Scholar] [CrossRef]

- Xu, W.; Brandt, M.; Sun, S.; Elambasseril, J.; Liu, Q.; Latham, K.; Xia, K.; Qian, M. Additive manufacturing of strong and ductile Ti-6Al-4V by selective laser melting via in situ martensite decomposition. Acta Mater. 2015, 85, 74–84. [Google Scholar] [CrossRef]

- Haubrich, J.; Gussone, J.; Barriobero-Vila, P.; Kürnsteiner, P.; Jägle, E.A.; Raabe, D.; Schell, N.; Requena, G. The role of lattice defects, element partitioning and intrinsic heat effects on the microstructure in selective laser melted Ti-6Al-4V. Acta Mater. 2019, 167, 136–148. [Google Scholar] [CrossRef]

- Barriobero-Vila, P.; Gussone, J.; Haubrich, J.; Sandlöbes, S.; Da Silva, J.; Cloetens, P.; Schell, N.; Requena, G. Inducing Stable α + β Microstructures during Selective Laser Melting of Ti-6Al-4V Using Intensified Intrinsic Heat Treatments. Materials 2017, 10, 268. [Google Scholar] [CrossRef] [PubMed]

| Sample Groups | Name | Power, p | Hatch Distance, h | Velocity, v | Volumetric Energy Density | Line Energy, p/v |

|---|---|---|---|---|---|---|

| W | mm | mm/s | J/mm3 | J/mm | ||

| Surface roughness | A4 * | 175 | 0.1 | 500 | 116.7 | 0.35 |

| A4 without contour | 175 | 0.1 | 500 | 116.7 | 0.35 | |

| Different surfaces | A4 * | 175 | 0.1 | 500 | 116.7 | 0.35 |

| Support structure | A4 * | 175 | 0.1 | 500 | 116.7 | 0.35 |

| A4 SS | 175 | 0.1 | 500 | 116.7 | 0.35 | |

| A10 | 175 | 0.1 | 1100 | 53 | 0.16 | |

| A10 SS | 175 | 0.1 | 1100 | 53 | 0.16 | |

| Velocity variation | A1 * | 175 | 0.1 | 200 | 291.7 | 0.88 |

| A3 | 175 | 0.1 | 400 | 145.8 | 0.44 | |

| A4 * | 175 | 0.1 | 500 | 116.7 | 0.35 | |

| A10 | 175 | 0.1 | 1100 | 53.0 | 0.35 | |

| Power variation | P100 | 100 | 0.1 | 500 | 66.7 | 0.2 |

| A4 * | 175 | 0.1 | 500 | 116.7 | 0.35 | |

| P200 | 200 | 0.1 | 500 | 133.3 | 0.4 | |

| Hatch distance variation | A1H40 * | 175 | 0.04 | 500 | 291.7 | 0.35 |

| H70 | 175 | 0.07 | 500 | 166.7 | 0.35 | |

| A4 * | 175 | 0.1 | 500 | 116.7 | 0.35 |

| Parameter | Surface 1 | Surface 2 | Surface 3 | Surface 4 |

|---|---|---|---|---|

| Sa, µm | 11.2 | 9.68 | 9.87 | 9.08 |

| Sq, µm | 16.3 | 16.5 | 14.1 | 13.7 |

| Sp, µm | 64.7 | 54.8 | 64.6 | 70.2 |

| Sz, µm | 156 | 176 | 133 | 158 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mishurova, T.; Artzt, K.; Haubrich, J.; Requena, G.; Bruno, G. Exploring the Correlation between Subsurface Residual Stresses and Manufacturing Parameters in Laser Powder Bed Fused Ti-6Al-4V. Metals 2019, 9, 261. https://doi.org/10.3390/met9020261

Mishurova T, Artzt K, Haubrich J, Requena G, Bruno G. Exploring the Correlation between Subsurface Residual Stresses and Manufacturing Parameters in Laser Powder Bed Fused Ti-6Al-4V. Metals. 2019; 9(2):261. https://doi.org/10.3390/met9020261

Chicago/Turabian StyleMishurova, Tatiana, Katia Artzt, Jan Haubrich, Guillermo Requena, and Giovanni Bruno. 2019. "Exploring the Correlation between Subsurface Residual Stresses and Manufacturing Parameters in Laser Powder Bed Fused Ti-6Al-4V" Metals 9, no. 2: 261. https://doi.org/10.3390/met9020261

APA StyleMishurova, T., Artzt, K., Haubrich, J., Requena, G., & Bruno, G. (2019). Exploring the Correlation between Subsurface Residual Stresses and Manufacturing Parameters in Laser Powder Bed Fused Ti-6Al-4V. Metals, 9(2), 261. https://doi.org/10.3390/met9020261