Mechanical Behavior of Inconel 625 at Elevated Temperatures

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Material Characterization

3.2. Tensile Tests

3.3. Creep Tests

4. Conclusions

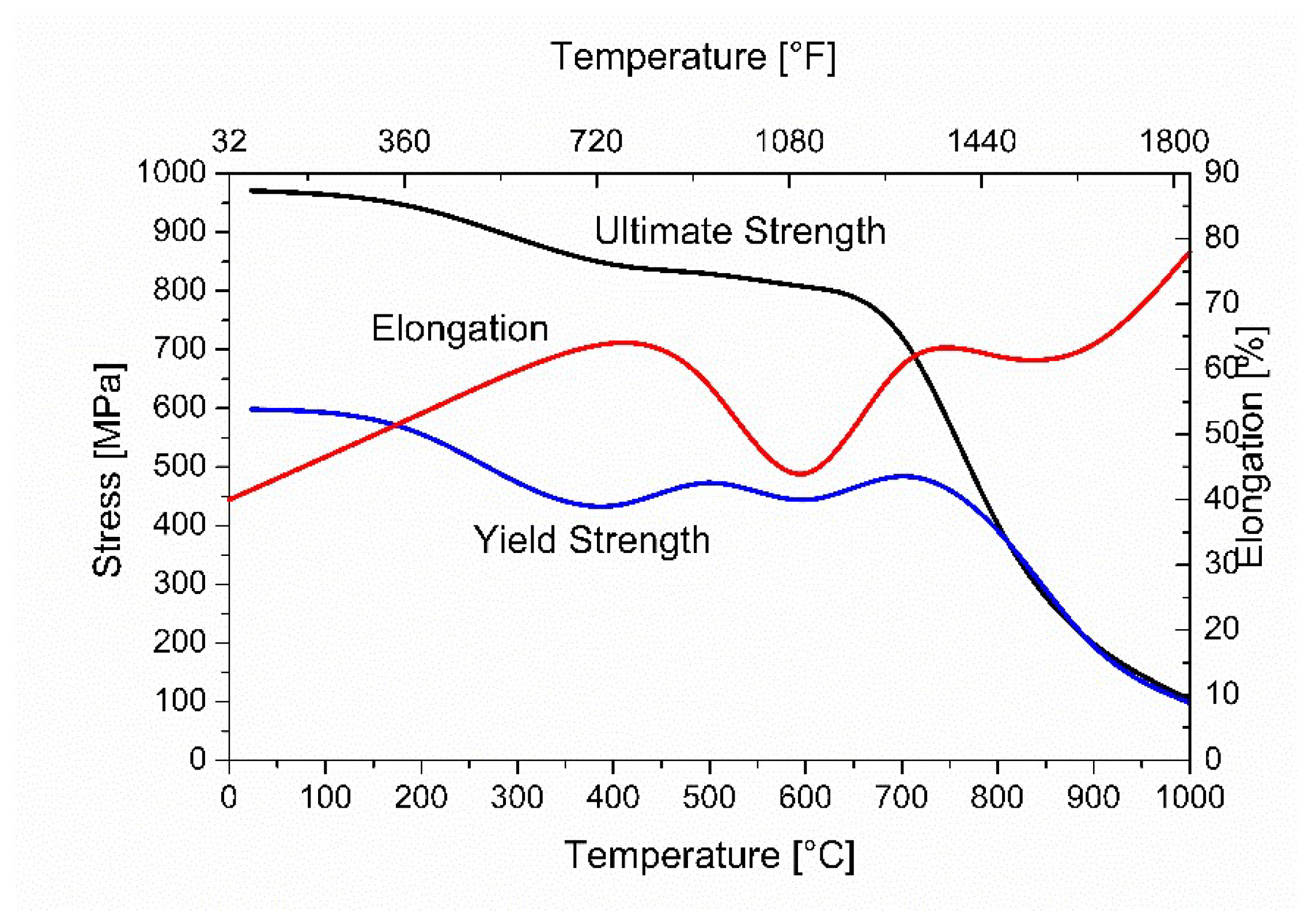

- The yield strength values show an anomalous behavior as a function of the temperature. From the room temperature until around 600 °C, there occurs a decrease in the yield strength and a slight increase up to 700 °C, decreasing sharply at temperatures above 700 °C. In relation to the elongation, an anomaly is also present, with a significant decrease in the elongation at temperatures close to 600 °C.

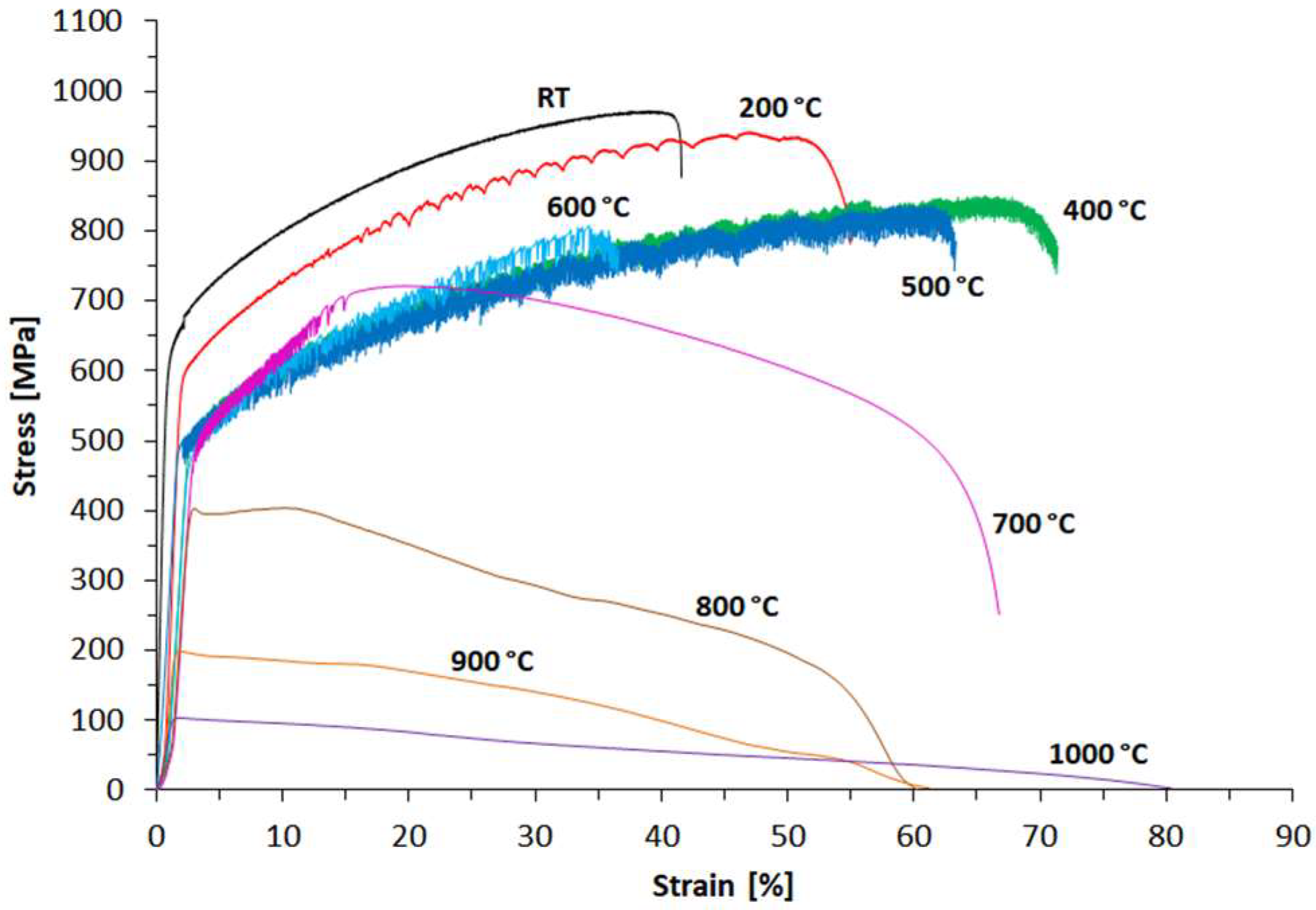

- In the tensile tests performed at temperatures between 200 and 700 °C, it was possible to observe a serrated curve in the region of plastic deformation in the stress-strain curves. The stress-strain curve at 200 °C showed an A-type serration, while in the test temperature range around 400 and 700 °C it was observed that there was a B-type serration. In the tensile tests at 300 °C, a transition appears to occur, with a serrated A + B-type.

- In all specimens in which the Portevin-Le Chatelier effect was observed on the stress-strain curve (serrated) it can be noted that the fracture occurred on a macroscopic plane inclined at 45° to the tensile axis.

- An intergranular cracking was observed in the specimen tensile tested at 500 °C which can be attributed to the decohesion of the carbides along the grain boundaries. The fracture surface of the specimen tensile tested at 700 °C showed the predominance of transgranular cracking with tear dimples with a parabolic shape. Several slip lines can be seen inside the grains and the presence of carbides along the grain boundaries.

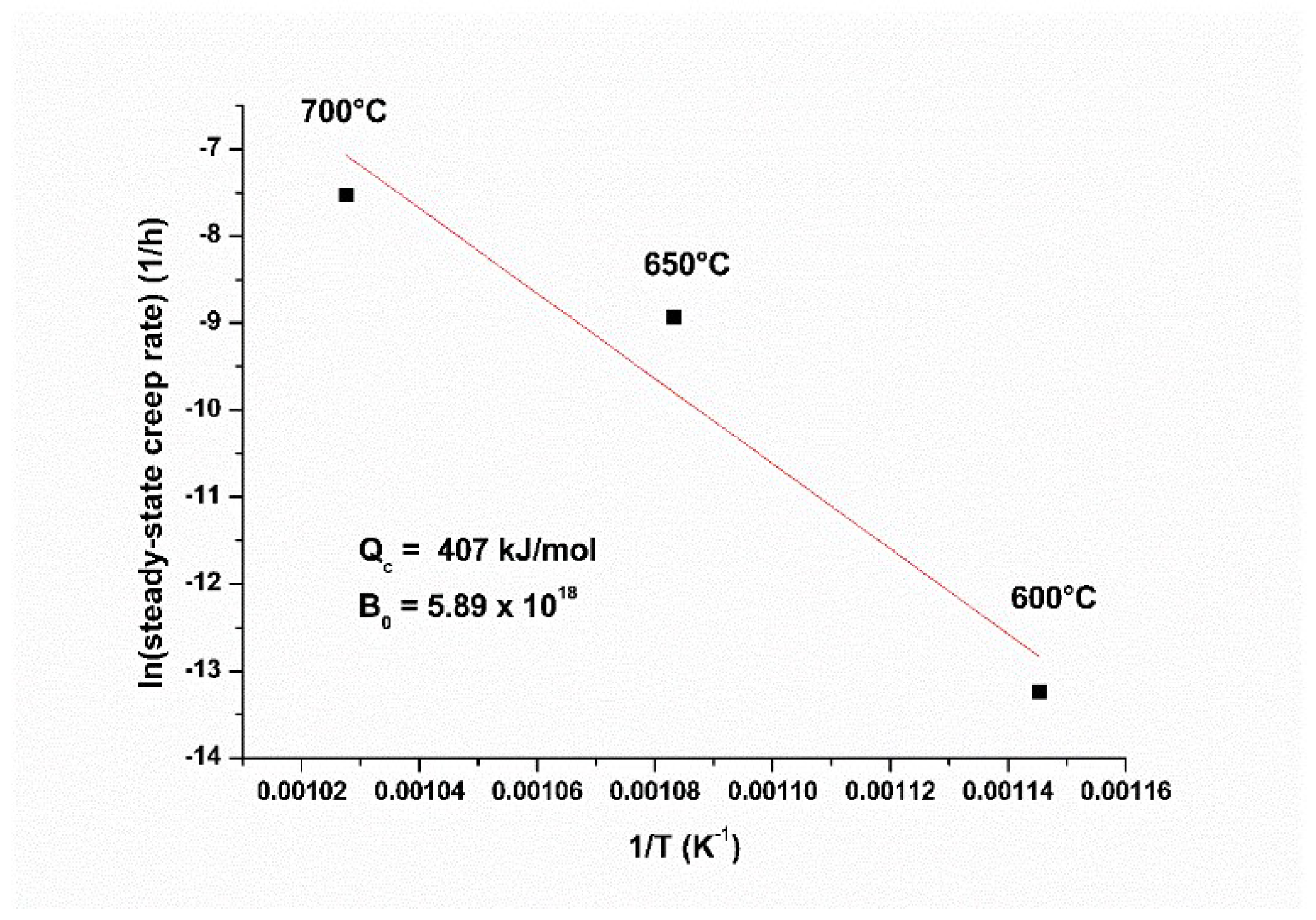

- The values of n = 11.76 and Qc = 407 kJ/mol found in this work suggest that the dominant mechanism is dislocation creep. This significantly higher value of the activation energy was attributed to a high driving force, and the solute stops the grain boundary migration process operating within the alloy and may be related to the DSA effect present in Inconel 625.

Author Contributions

Funding

Conflicts of Interest

References

- Shankar, V.; Valsan, M.; Rao, K.B.S.; Mannan, S.L. Effects of temperature and strain rate on tensile properties and activation energy for dynamic strain aging in alloy 625. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2004, 35A, 3129–3139. [Google Scholar] [CrossRef]

- Korrapati, P.K.; Avasarala, V.K.; Bhushan, M.; Ramkumar, K.D.; Arivazhagan, N.N.; Narayanan, S. Assessment of Mechanical Properties of PCGTA Weldments of Inconel 625. Procedia Eng. 2014, 75, 9–13. [Google Scholar] [CrossRef]

- Dokme, F.; Kulekci, M.K.; Esme, U. Microstructural and Mechanical Characterization of Dissimilar Metal Welding of Inconel 625 and AISI 316L. Metals 2018, 8, 797. [Google Scholar] [CrossRef]

- Han, F.F.; Zhou, B.M.; Huang, H.F.; Leng, B.; Lu, Y.L.; Dong, J.S.; Li, Z.J.; Zhou, X.T. The tensile behavior of GH3535 superalloy at elevated temperature. Mater. Chem. Phys. 2016, 182, 22–31. [Google Scholar] [CrossRef]

- Tian, C.; Cui, C.; Xu, L.; Gu, Y.; Sun, X. Dynamic strain aging in a newly developed Ni-Co-Base superalloy with low stacking fault energy. J. Mater. Sci. Technol. 2013, 29, 873–878. [Google Scholar] [CrossRef]

- Chatterjee, A.; Sharma, G.; Tewari, R.; Chakravartty, J.K. Investigation of the Dynamic Strain Aging and Mechanical Properties in Alloy-625 with Different Microstructures. Metall. Mater. Trans. A 2015, 46, 1097–1107. [Google Scholar] [CrossRef]

- Maj, P.; Zdunek, J.; Mizera, J.; Kurzydlowski, K.J.; Sakowicz, B.; Kaminski, M. Microstructure and strain-stress analysis of the dynamic strain aging in inconel 625 at high temperature. Met. Mater. Int. 2017, 23, 54–67. [Google Scholar] [CrossRef]

- Maj, P.; Zdunek, J.; Gizynski, M.; Mizera, J.; Kurzydlowski, K.J. Statistical analysis of the Portevin-Le Chatelier effect in Inconel 718 at high temperature. Mater. Sci. Eng. A 2014, 619, 158–164. [Google Scholar] [CrossRef]

- Yu, W.; Liu, S.; Wang, Y.; Sun, L. Recent Development in the Characteristics of Alloy 625 for A-USC Steam Turbine Casting. Energy Mater. 2017, 213–223. [Google Scholar] [CrossRef]

- Zhang, Y.C.; Jiang, W.; Tu, S.T.; Zhang, X.C.; Ye, Y.J.; Wang, R.Z. Experimental investigation and numerical prediction on creep crack growth behavior of the solution treated Inconel 625 superalloy. Eng. Fract. Mech. 2018, 199, 327–342. [Google Scholar] [CrossRef]

- American Society for Testing and Materials (ASTM) ASTM B443—00(2014). Standard Specification for Nickel-Chromium-Molybdenum-Columbium Alloy(UNS N06625) and Nickel-Chromium-Molybdenum-SiliconAlloy (UNS N06219) Plate, Sheet, and Strip; ASTM: West Conshohocken, PN, USA, 2014. [Google Scholar]

- American Society for Testing and Materials (ASTM) ASTM E139-11. Standard Test Methods for Conducting Creep, Creep Rupture, and Stress Rupture Tests of Metallic Materials; ASTM: West Conshohocken, PN, USA, 2011. [Google Scholar]

- Hrutkay, K.; Kaoumi, D. Tensile deformation behavior of a nickel based superalloy at different temperatures. Mater. Sci. Eng. A 2014, 599, 196–203. [Google Scholar] [CrossRef]

- Hale, C.; Rollings, W.; Weaver, M. Activation energy calculations for discontinuous yielding in Inconel 718SPF. Mater. Sci. Eng. A 2001, 300, 153–164. [Google Scholar] [CrossRef]

- Rahman, M.S.; Priyadarshan, G.; Raja, K.S.; Nesbitt, C.; Misra, M. Characterization of high temperature deformation behavior of INCONEL 617. Mech. Mater. 2009, 41, 261–270. [Google Scholar] [CrossRef]

- Wright, J.K.; Carroll, L.J.; Cabet, C.; Lillo, T.M.; Benz, J.K.; Simpson, J.A.; Lloyd, W.R.; Chapman, J.A.; Wright, R.N. Characterization of elevated temperature properties of heat exchanger and steam generator alloys. Nucl. Eng. Des. 2012, 251, 252–260. [Google Scholar] [CrossRef]

- Fournier, L.; Delafosse, D.; Magnin, T. Oxidation induced intergranular cracking and Portevin-Le Chatelier effect in nickel base superalloy 718. Mater. Sci. Eng. A 2001, 316, 166–173. [Google Scholar] [CrossRef]

- Kaoumi, D.; Hrutkay, K. Tensile deformation behavior and microstructure evolution of Ni-based superalloy 617. J. Nucl. Mater. 2014, 454, 265–273. [Google Scholar] [CrossRef]

- Mo, K.; Lovicu, G.; Chen, X.; Tung, H.M.; Hansen, J.B.; Stubbins, J.F. Mechanism of plastic deformation of a Ni-based superalloy for VHTR applications. J. Nucl. Mater. 2013, 441, 695–703. [Google Scholar] [CrossRef]

- Nalawade, S.A.; Sundararaman, M.; Kishore, R.; Shah, J.G. The influence of aging on the serrated yielding phenomena in a nickel-base superalloy. Scr. Mater. 2008, 59, 991–994. [Google Scholar] [CrossRef]

- Lee, K.O.; Lee, S.B. Modeling of materials behavior at various temperatures of hot isostatically pressed superalloys. Mater. Sci. Eng. A 2012, 541, 81–87. [Google Scholar] [CrossRef]

- Cottrell, A.H. LXXXVI. A note on the Portevin-Le Chatelier effect. London Edinburgh Dublin Philos. Mag. J. Sci. 1953, 44, 829–832. [Google Scholar] [CrossRef]

- Nagesha, A.; Goyal, S.; Nandagopal, M.; Parameswaran, P.; Sandhya, R.; Mathew, M.D.; Mannan, S.K. Dynamic strain ageing in Inconel® Alloy 783 under tension and low cycle fatigue. Mater. Sci. Eng. A 2012, 546, 34–39. [Google Scholar] [CrossRef]

- Sleeswyk, A.W. Slow strain-hardening of ingot iron. Acta Metall. 1958, 6, 598–603. [Google Scholar] [CrossRef]

- Cuddy, L.; Leslie, W.C. Some aspects of serrated yielding in substitutional solid solutions of iron. Acta Metall. 1972, 20, 1157–1167. [Google Scholar] [CrossRef]

- Cheng, J.; Nemat-Nasser, S. Model for experimentally-observed high-strain-rate dynamic strain aging in titanium. Acta Mater. 2000, 48, 3131–3144. [Google Scholar] [CrossRef]

- Van Liempt, P.; Onink, M.; Bodin, A. Modelling the Influence of Dynamic Strain Ageing on Deformation Behaviour. Adv. Eng. Mater. 2002, 4, 225–232. [Google Scholar] [CrossRef]

- McCormigk, P.G. A model for the Portevin-Le Chatelier effect in substitutional alloys. Acta Metall. 1972, 20, 351–354. [Google Scholar] [CrossRef]

- Van den Beukel, A. Theory of the effect of dynamic strain aging on mechanical properties. Phys. Status Solidi 1975, 30, 197–206. [Google Scholar] [CrossRef]

- Wycliffe, P.; Kocks, U.F.; Embury, J.D. On dynamic and static ageing in substitutional and interstitial alloys. Scr. Metall. 1980, 14, 1349–1354. [Google Scholar] [CrossRef]

- Van Den Beukel, A.; Kocks, U.F. The strain dependence of static and dynamic strain-aging. Acta Metall. 1982, 30, 1027–1034. [Google Scholar] [CrossRef]

- Estrin, Y.; McCormick, P.G. Modelling the transient flow behaviour of dynamic strain ageing materials. Acta Metall. Mater. 1991, 39, 2977–2983. [Google Scholar] [CrossRef]

- Estrin, Y. A versatile unified constitutive model based on dislocation density evolution. In High Temperature Constitutive Modeling: Theory and Application; Freed, A.D., Walker, K.P., Eds.; American Society of Mechanical Engineers: New York, NY, USA, 1991; pp. 65–83. [Google Scholar]

- Schlipf, J. Dislocation dynamics in strain aging alloys. Acta Metall. Mater. 1992, 40, 2075–2084. [Google Scholar] [CrossRef]

- Gilat, A.; Wu, X. Plastic deformation of 1020 steel over a wide range of strain rates and temperatures. Int. J. Plast. 1997, 13, 611–632. [Google Scholar] [CrossRef]

- Rodriguez, P. Serrated plastic flow. Bull. Mater. Sci. 1984, 6, 653–663. [Google Scholar] [CrossRef]

- Rodriguez, P.; Venkadesan, S. Serrated Plastic Flow Revisited. Solid State Phenom. 1995, 42–43, 257–266. [Google Scholar] [CrossRef]

- Evans, R.W.; Wilshire, B. Introduction to Creep; The Institute of Materials: London, UK, 1993. [Google Scholar]

- Ashby, M.F.; Frost, H.J. Deformation-mechanism Maps: The Plasticity and Creep of Metals and Ceramics; Pergamon Press: Oxford, UK, 1982. [Google Scholar]

- Moore, I.J.; Taylor, J.I.; Tracy, M.W.; Burke, M.G.; Palmiere, E.J. Grain coarsening behaviour of solution annealed Alloy 625 between 600–800 °C. Mater. Sci. Eng. A 2017, 682, 402–409. [Google Scholar] [CrossRef]

- Caliari, F.R.; Candioto, K.C.G.; Couto, A.A.; Nunes, C.Â.; Reis, D.A.P. Effect of Double Aging Heat Treatment on the Short-Term Creep Behavior of the Inconel 718. J. Mater. Eng. Perform. 2016, 25, 2307–2317. [Google Scholar] [CrossRef]

- Rodriguez, R.; Hayes, R.W.; Berbon, P.B.; Lavernia, E.J. Tensile and creep behavior of cryomilled Inco 625. Acta Mater. 2003, 51, 911–929. [Google Scholar] [CrossRef]

- Sun, F.; Gu, Y.F.; Yan, J.B.; Zhong, Z.H.; Yuyama, M. Phenomenological and microstructural analysis of intermediate temperatures creep in a Ni-Fe-based alloy for advanced ultra-supercritical fossil power plants. Acta Mater. 2016, 102, 70–78. [Google Scholar] [CrossRef]

| Element | Ni | Cr | Mo | Nb + Ta | Fe | Mn | Si | Ti | Al | C | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| wt % | Required | Min. 58.0 | 20.0–23.0 | 8.0/10.0 | 3.15–4.15 | Max. 5.0 | Max. 0.5 | Max. 0.5 | Max. 0.4 | Max. 0.4 | Max. 0.1 |

| Obtained | Balance | 21.5 | 9.4 | 3.6 | 2.5 | 0.25 | - | 0.27 | 0.29 | 0.05 | |

| Test Temperature (°C) | YS (MPa) | UTS (MPa) | EL (%) |

|---|---|---|---|

| 23 | 598 | 971 | 40 |

| 200 | 556 | 940 | 53 |

| 400 | 434 | 845 | 67 |

| 500 | 473 | 829 | 61 |

| 600 | 444 | 807 | 34 |

| 700 | 484 | 722 | 67 |

| 800 | 392 | 403 | 61 |

| 900 | 195 | 199 | 61 |

| 1000 | 98 | 104 | 78 |

| Temperature (°C) | σ (MPa) | tp (h) | |

|---|---|---|---|

| 600 | 500 | 235.5 | 1.78 × 10−6 |

| 650 | 500 | 23.6 | 1.32 × 10−4 |

| 550 | 12.5 | 3.74 × 10−4 | |

| 600 | 10.0 | 1.13 × 10−3 | |

| 700 | 500 | 17.1 | 5.39 × 10−4 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Oliveira, M.M.; Couto, A.A.; Almeida, G.F.C.; Reis, D.A.P.; de Lima, N.B.; Baldan, R. Mechanical Behavior of Inconel 625 at Elevated Temperatures. Metals 2019, 9, 301. https://doi.org/10.3390/met9030301

de Oliveira MM, Couto AA, Almeida GFC, Reis DAP, de Lima NB, Baldan R. Mechanical Behavior of Inconel 625 at Elevated Temperatures. Metals. 2019; 9(3):301. https://doi.org/10.3390/met9030301

Chicago/Turabian Stylede Oliveira, Mauro M., Antônio A. Couto, Gisele F. C. Almeida, Danieli A. P. Reis, Nelson B. de Lima, and Renato Baldan. 2019. "Mechanical Behavior of Inconel 625 at Elevated Temperatures" Metals 9, no. 3: 301. https://doi.org/10.3390/met9030301

APA Stylede Oliveira, M. M., Couto, A. A., Almeida, G. F. C., Reis, D. A. P., de Lima, N. B., & Baldan, R. (2019). Mechanical Behavior of Inconel 625 at Elevated Temperatures. Metals, 9(3), 301. https://doi.org/10.3390/met9030301