Effect of Forced Air Cooling on the Microstructures, Tensile Strength, and Hardness Distribution of Dissimilar Friction Stir Welded AA5A06-AA6061 Joints

Abstract

:1. Introduction

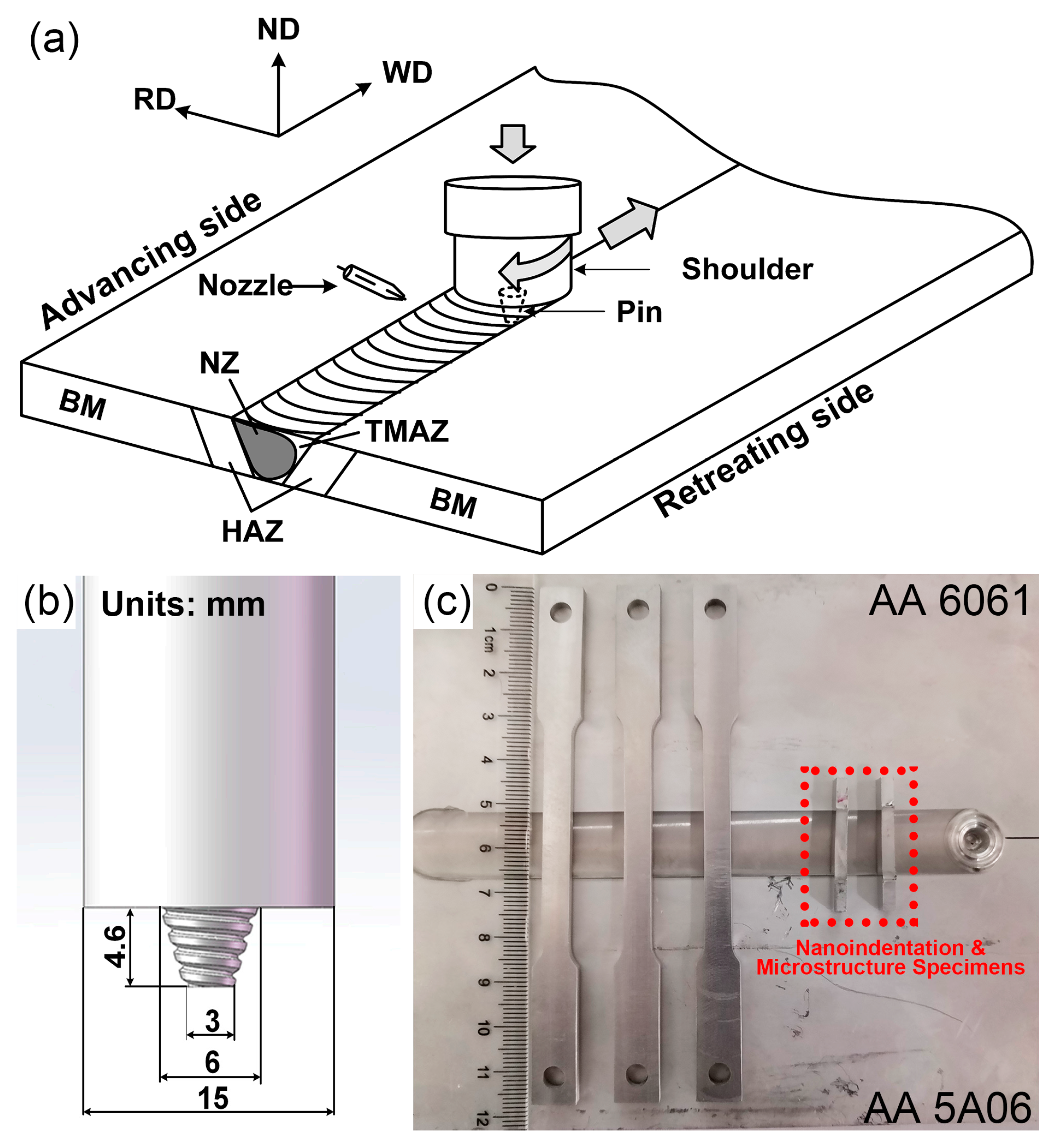

2. Materials and Methods

3. Results and Discussion

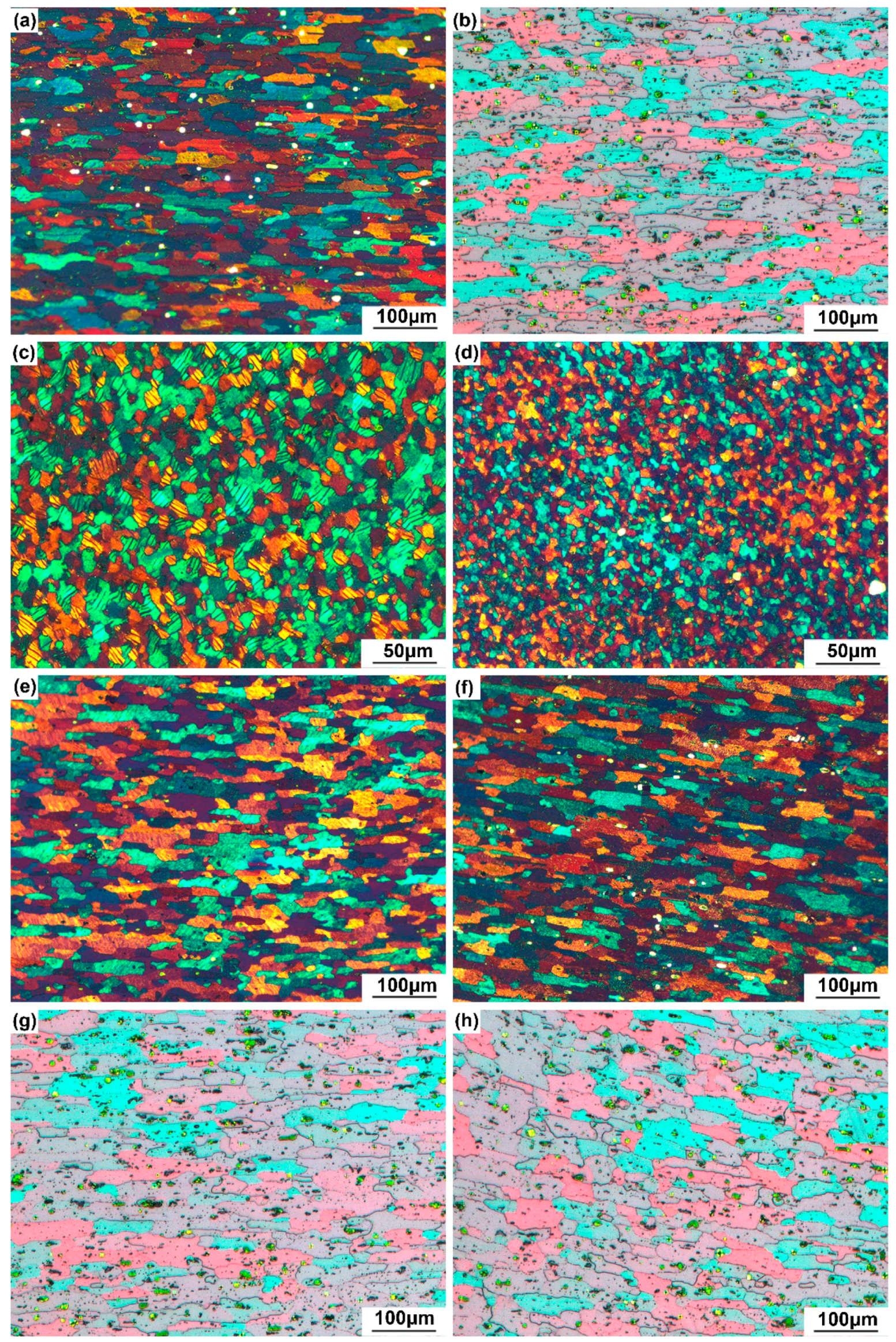

3.1. Microstructures

3.2. Uniaxial Tensile Properties

3.3. Nanoindentation Hardness Distribution

3.4. Fracture Characteristics

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminium alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Gharavi, F.; Matori, K.A.; Yunus, R.; Othman, N.K.; Fadaeifard, F. Corrosion Evaluation of Friction Stir Welded Lap Joints of AA6061-T6 Aluminum Alloy. Trans. Nonferr. Metals Soc. Chin. 2016, 26, 672–681. [Google Scholar] [CrossRef]

- Hassan, K.A.A.; Prangnell, P.B.; Norman, A.F.; Price, D.A.; Williams, S.W. Effect of welding parameters on nugget zone microstructure and properties in high strength aluminium alloy friction stir welds. Sci. Technol. Weld. Join. 2003, 8, 257–268. [Google Scholar] [CrossRef]

- Biradar, N.S. Investigation of hot cracking behavior in transverse mechanically arc oscillated autogenous AA2014 T6 TIG welds. Metall. Mater. Trans. A 2012, 43, 3179–3191. [Google Scholar] [CrossRef]

- Ericsson, M.; Sandström, R. Influence of welding speed on the fatigue of friction stir welds, and comparison with MIG and TIG. Int. J. Fatigue 2003, 25, 1379–1387. [Google Scholar] [CrossRef]

- Threadgill, P.L.; Leonard, A.J.; Shercliff, H.R.; Withers, P.J. Friction stir welding of aluminium alloys. Metall. Rev. 2009, 54, 49–93. [Google Scholar] [CrossRef]

- Elangovan, K.; Balasubramanian, V.; Babu, S. Predicting tensile strength of friction stir welded AA6061 aluminium alloy joints by a mathematical model. Mater. Des. 2009, 30, 188–193. [Google Scholar] [CrossRef]

- Kalemba-Rec, I.; Kopyscianski, M.; Miara, D.; Krasnowski, K. Effect of process parameters on mechanical properties of friction stir welded dissimilar 7075-T651 and 5083-H111 aluminum alloys. Int. J. Adv. Manuf. Technol. 2018, 97, 2767–2779. [Google Scholar] [CrossRef]

- Rafiei, R.; Shamanian, M.; Fathi, M.H.; Khodabakhshi, F. Dissimilar friction-stir lap-welding of aluminum-magnesium (AA5052) and aluminum-copper (AA2024) alloys: Microstructural evolution and mechanical properties. Int. J. Adv. Manuf. Technol. 2018, 94, 3713–3730. [Google Scholar] [CrossRef]

- Tamadon, A.; Pons, D.J.; Sued, K.; Clucas, D. Thermomechanical Grain Refinement in AA6082-T6 Thin Plates under Bobbin Friction Stir Welding. Met.-Basel 2018, 8. [Google Scholar] [CrossRef]

- Zeng, X.H.; Xue, P.; Wang, D.; Ni, D.R.; Xiao, B.L.; Ma, Z.Y. Realising equal strength welding to parent metal in precipitation-hardened Al-Mg-Si alloy via low heat input friction stir welding. Sci. Technol. Weld. Join. 2018, 23, 478–486. [Google Scholar] [CrossRef]

- Zeng, X.H.; Xue, P.; Wang, D.; Ni, D.R.; Xiao, B.L.; Wang, K.S.; Ma, Z.Y. Material flow and void defect formation in friction stir welding of aluminium alloys. Sci. Technol. Weld. Join. 2018, 23, 677–686. [Google Scholar] [CrossRef]

- Zhang, Q.; Lang, L.; Zhang, Y.; Sun, G. Application of the modified critical voids expansion ratio criterion to the prediction of the forming limit of 6016-O aluminum alloy. Int. J. Adv. Manuf. Technol. 2018, 98, 2069–2082. [Google Scholar] [CrossRef]

- Fratini, L.; Buffa, G.; Shivpuri, R. In-process heat treatments to improve FS-welded butt joints. Int. J. Adv. Manuf. Technol. 2009, 43, 664–670. [Google Scholar] [CrossRef]

- Peng, G.; Ma, Y.; Hu, J.; Jiang, W.; Huan, Y.; Chen, Z.; Zhang, T. Nanoindentation Hardness Distribution and Strain Field and Fracture Evolution in Dissimilar Friction Stir-Welded AA 6061-AA 5A06 Aluminum Alloy Joints. Adv. Mater. Sci. Eng. 2018, 2018, 1–11. [Google Scholar] [CrossRef]

- Zhang, Z.; Xiao, B.L.; Ma, Z.Y. Influence of water cooling on microstructure and mechanical properties of friction stir welded 2014Al-T6 joints. Mater. Sci. Eng. A 2014, 614, 6–15. [Google Scholar] [CrossRef]

- Sharma, C.; Dwivedi, D.K.; Kumar, P. Influence of in-process cooling on tensile behaviour of friction stir welded joints of AA7039. Mater. Sci. Eng. A 2012, 556, 479–487. [Google Scholar] [CrossRef]

- Benavides, S.; Li, Y.; Murr, L.E.; Brown, D.; Mcclure, J.C. Low-temperature friction-stir welding of 2024 aluminum. Scr. Mater. 1999, 41, 809–815. [Google Scholar] [CrossRef]

- Heirani, F.; Abbasi, A.; Ardestani, M. Effects of processing parameters on microstructure and mechanical behaviors of underwater friction stir welding of Al5083 alloy. J. Manuf. Process. 2017, 25, 77–84. [Google Scholar] [CrossRef]

- Zhang, H. Characteristics and formation mechanisms of welding defects in underwater friction stir welded aluminum alloy. Metall. Microst. Anal. 2012, 1, 269–281. [Google Scholar] [CrossRef]

- Sinhmar, S.; Dwivedi, D.K. Enhancement of mechanical properties and corrosion resistance of friction stir welded joint of AA2014 using water cooling. Mater. Sci. Eng. A 2017, 684, 413–422. [Google Scholar] [CrossRef]

- Sabari, S.S.; Malarvizhi, S.; Balasubramanian, V. Influences of tool traverse speed on tensile properties of air cooled and water cooled friction stir welded AA2519-T87 aluminium alloy joints. J. Mater. Process. Technol. 2016, 237, 286–300. [Google Scholar] [CrossRef]

- Mofid, M.A.; Abdollah-Zadeh, A.; Gür, C.H. Submerged friction-stir welding (SFSW) underwater and under liquid nitrogen: An improved method to join Al alloys to Mg alloys. Metall. Mater. Trans. A 2012, 43, 5106–5114. [Google Scholar] [CrossRef]

- Kim, J.R.; Ahn, E.Y.; Das, H.; Jeong, Y.H.; Hong, S.T.; Miles, M.; Lee, K.J. Effect of tool geometry and process parameters on mechanical properties of friction stir spot welded dissimilar aluminum alloys. Int. J. Precis. Eng. Man. 2017, 18, 445–452. [Google Scholar] [CrossRef]

- Chowdhury, S.M.; Chen, D.L.; Bhole, S.D.; Cao, X. Tensile properties of a friction stir welded magnesium alloy: Effect of pin tool thread orientation and weld pitch. Mater. Sci. Eng. A 2010, 527, 6064–6075. [Google Scholar] [CrossRef]

- Ouyang, J.H.; Kovacevic, R. Material flow and microstructure in the friction stir butt welds of the same and dissimilar aluminum alloys. J. Mater. Eng. Perform. 2002, 11, 51–63. [Google Scholar] [CrossRef]

- Rodriguez, R.I.; Jordon, J.B.; Allison, P.G.; Rushing, T.; Garcia, L. Microstructure and mechanical properties of dissimilar friction stir welding of 6061-to-7050 aluminum alloys. Mater. Des. 2015, 83, 60–65. [Google Scholar] [CrossRef]

- Peel, M.; Steuwer, A.; Preuss, M.; Withers, P.J. Microstructure, mechanical properties and residual stresses as a function of welding speed in aluminium AA5083 friction stir welds. Acta. Mater. 2003, 51, 4791–4801. [Google Scholar] [CrossRef]

- MetalsBahemmat, P.; Haghpanahi, M.; Besharati, M.K.; Ahsanizadeh, S.; Rezaei, H. Study on mechanical, micro-, and macrostructural characteristics of dissimilar friction stir welding of AA6061-T6 and AA7075-T6. Proc. Inst. Mech. Eng. B-J. Eng. 2010, 1, 1–12. [Google Scholar]

- Leitao, C.; Leal, R.M.; Rodrigues, D.M.; Loureiro, A.; Vilaca, P. Mechanical behaviour of similar and dissimilar AA5182-H111 and AA6016-T4 thin friction stir welds. Mater. Des. 2009, 30, 101–108. [Google Scholar] [CrossRef] [Green Version]

- Tronci, A.; Mckenzie, R.; Leal, R.M.; Rodrigues, D.M. Microstructural and mechanical characterisation of 5XXX-H111 friction stir welded tailored blanks. Sci. Technol. Weld. Join. 2013, 16, 433–439. [Google Scholar] [CrossRef]

- Lee, W.B.; Yeon, Y.M.; Jung, S.B. Mechanical Properties Related to Microstructural Variation of 6061 Al Alloy Joints by Friction Stir Welding. Mater Trans. 2004, 45, 1700–1705. [Google Scholar] [CrossRef] [Green Version]

- Liu, F.J.; Fu, L.; Chen, H.Y. Effect of high rotational speed on temperature distribution, microstructure evolution, and mechanical properties of friction stir welded 6061-T6 thin plate joints. Int. J. Mach. Tool. Manuf. 2018, 96, 1823–1833. [Google Scholar] [CrossRef]

- Leitao, C.; Emilio, B.; Chaparro, B.M.; Rodrigues, D.M. Formability of similar and dissimilar friction stir welded AA 5182-H111 and AA 6016-T4 tailored blanks. Mater. Des. 2009, 30, 3235–3242. [Google Scholar] [CrossRef] [Green Version]

- Netto, N.; Tiryakioglu, M.; Eason, P.D. Characterization of Microstructural Refinement and Hardness Profile Resulting from Friction Stir Processing of 6061-T6 Aluminum Alloy Extrusions. Met.-Basel 2018, 8, 552. [Google Scholar] [CrossRef]

- Liu, H.; Pan, Q.; Yu, L. Effect of friction stir welding parameters on microstructural characteristics and mechanical properties of 2219-T6 aluminum alloy joints. Int. J. Mater. Form. 2012, 5, 235–241. [Google Scholar] [CrossRef]

| Materials | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| AA5A06 | 0.40 | 0.26 | 0.06 | 0.86 | 5.37 | - | 0.10 | 0.11 | 92.84 |

| AA6061 | 0.79 | 0.70 | 0.35 | 0.08 | 1.46 | 0.17 | 0.08 | 0.21 | 96.16 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, G.; Yan, Q.; Hu, J.; Chen, P.; Chen, Z.; Zhang, T. Effect of Forced Air Cooling on the Microstructures, Tensile Strength, and Hardness Distribution of Dissimilar Friction Stir Welded AA5A06-AA6061 Joints. Metals 2019, 9, 304. https://doi.org/10.3390/met9030304

Peng G, Yan Q, Hu J, Chen P, Chen Z, Zhang T. Effect of Forced Air Cooling on the Microstructures, Tensile Strength, and Hardness Distribution of Dissimilar Friction Stir Welded AA5A06-AA6061 Joints. Metals. 2019; 9(3):304. https://doi.org/10.3390/met9030304

Chicago/Turabian StylePeng, Guangjian, Qi Yan, Jiangjiang Hu, Peijian Chen, Zhitong Chen, and Taihua Zhang. 2019. "Effect of Forced Air Cooling on the Microstructures, Tensile Strength, and Hardness Distribution of Dissimilar Friction Stir Welded AA5A06-AA6061 Joints" Metals 9, no. 3: 304. https://doi.org/10.3390/met9030304

APA StylePeng, G., Yan, Q., Hu, J., Chen, P., Chen, Z., & Zhang, T. (2019). Effect of Forced Air Cooling on the Microstructures, Tensile Strength, and Hardness Distribution of Dissimilar Friction Stir Welded AA5A06-AA6061 Joints. Metals, 9(3), 304. https://doi.org/10.3390/met9030304