Dynamic Uniform Deformation for Electromagnetic Uniaxial Tension

Abstract

:1. Introduction

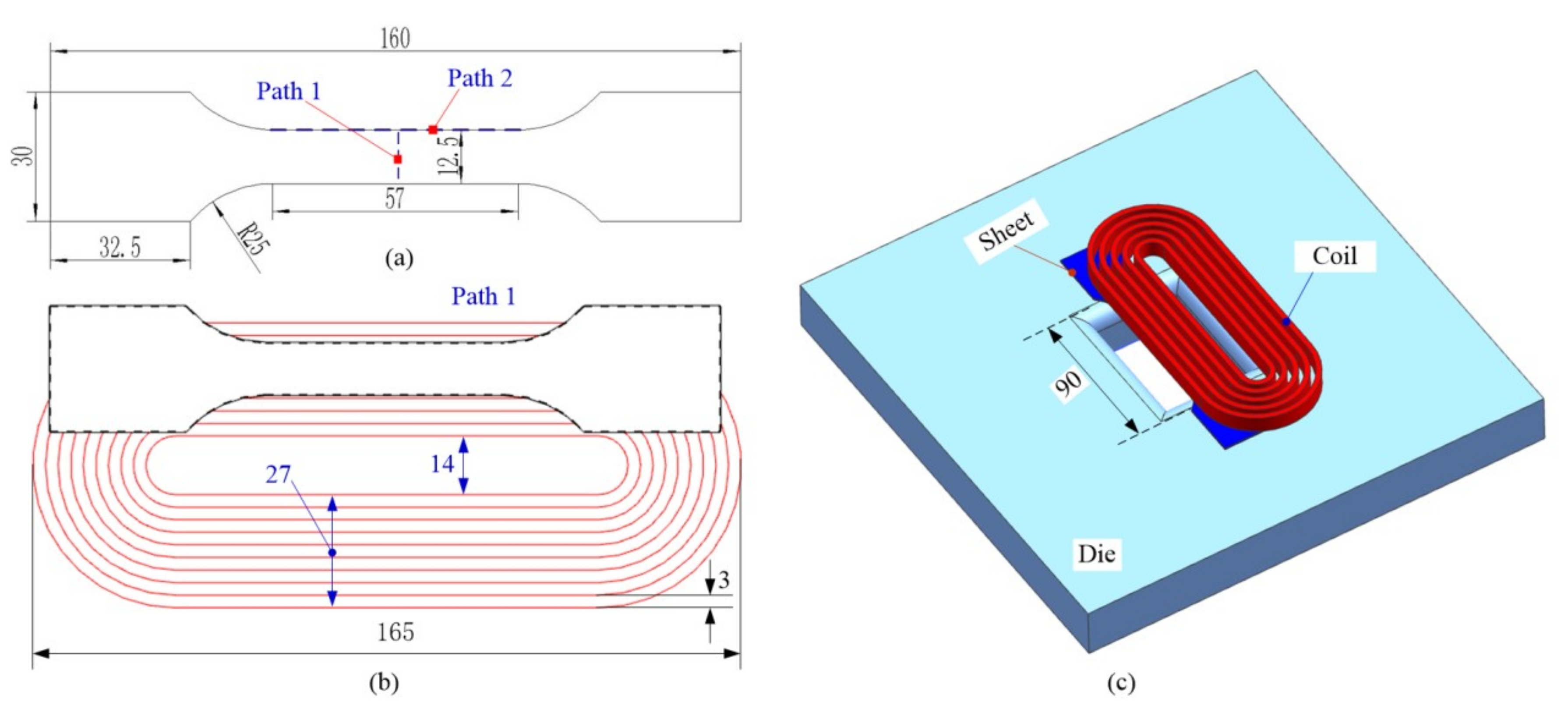

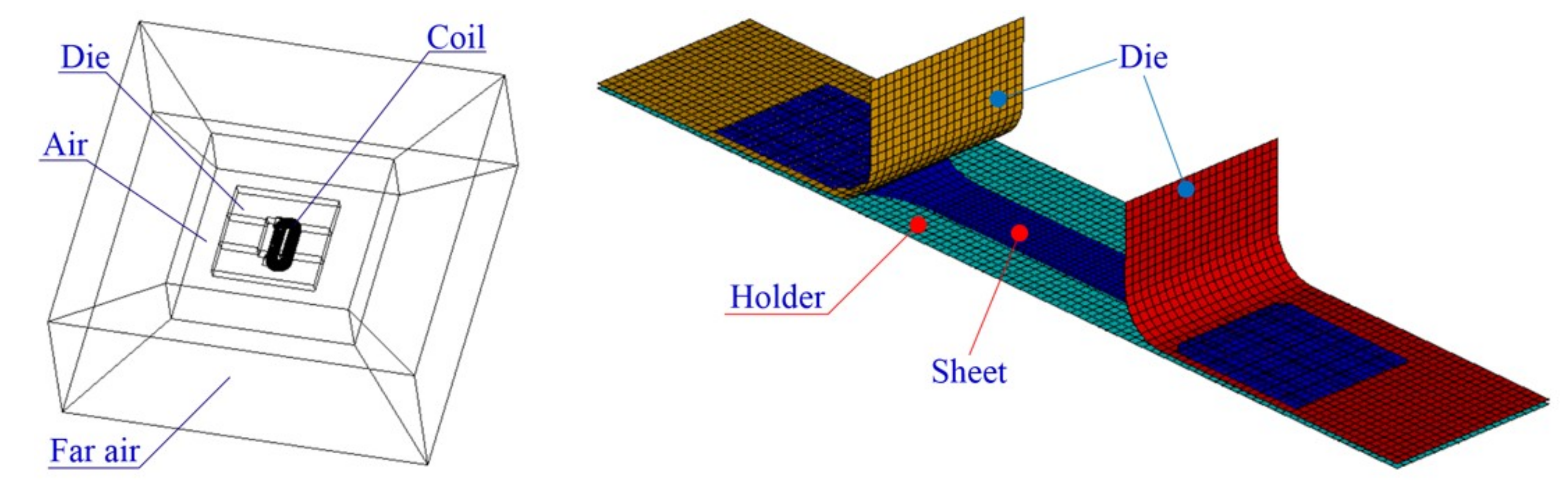

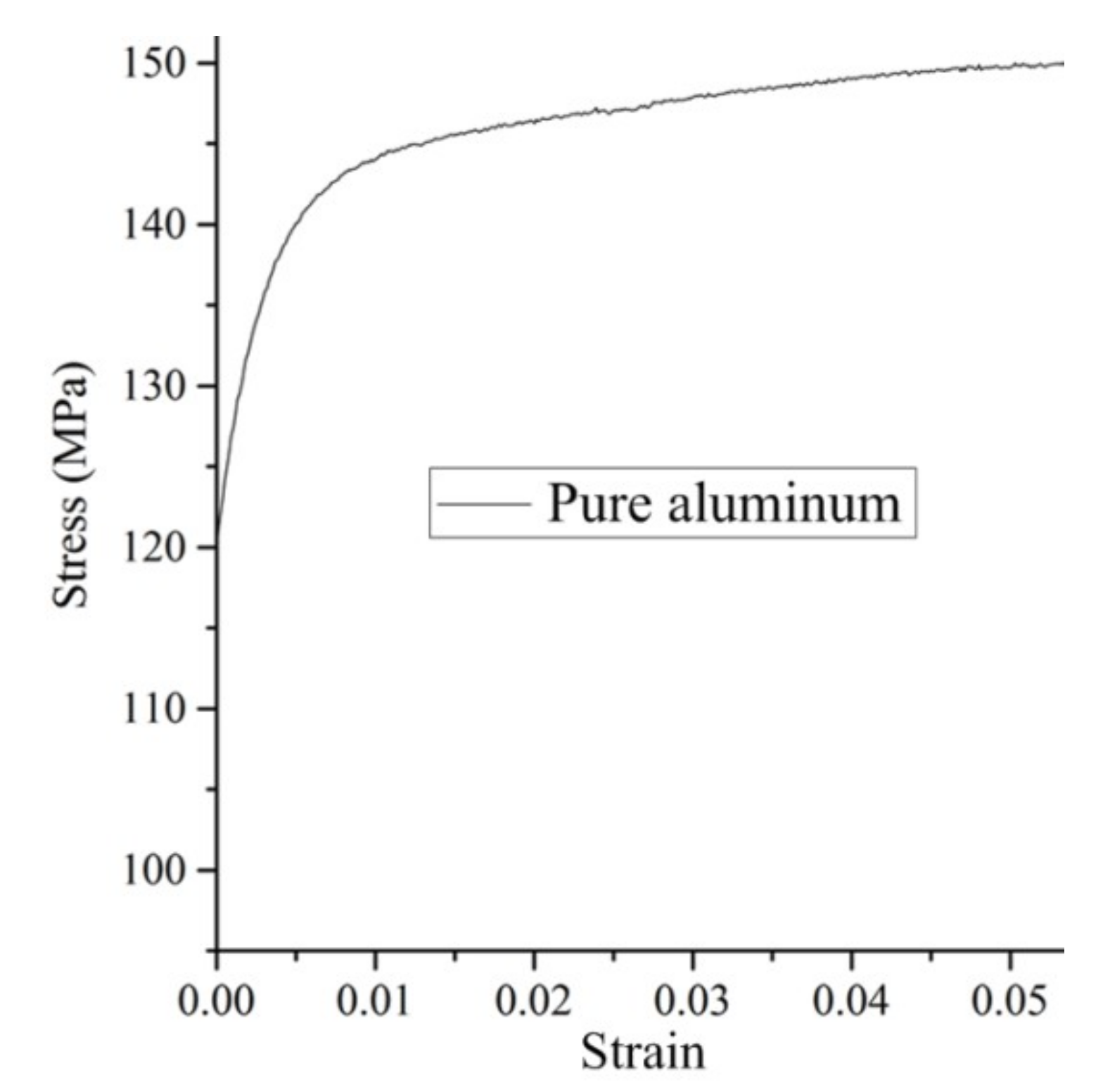

2. Experimental and Finite Element Simulation

3. Results

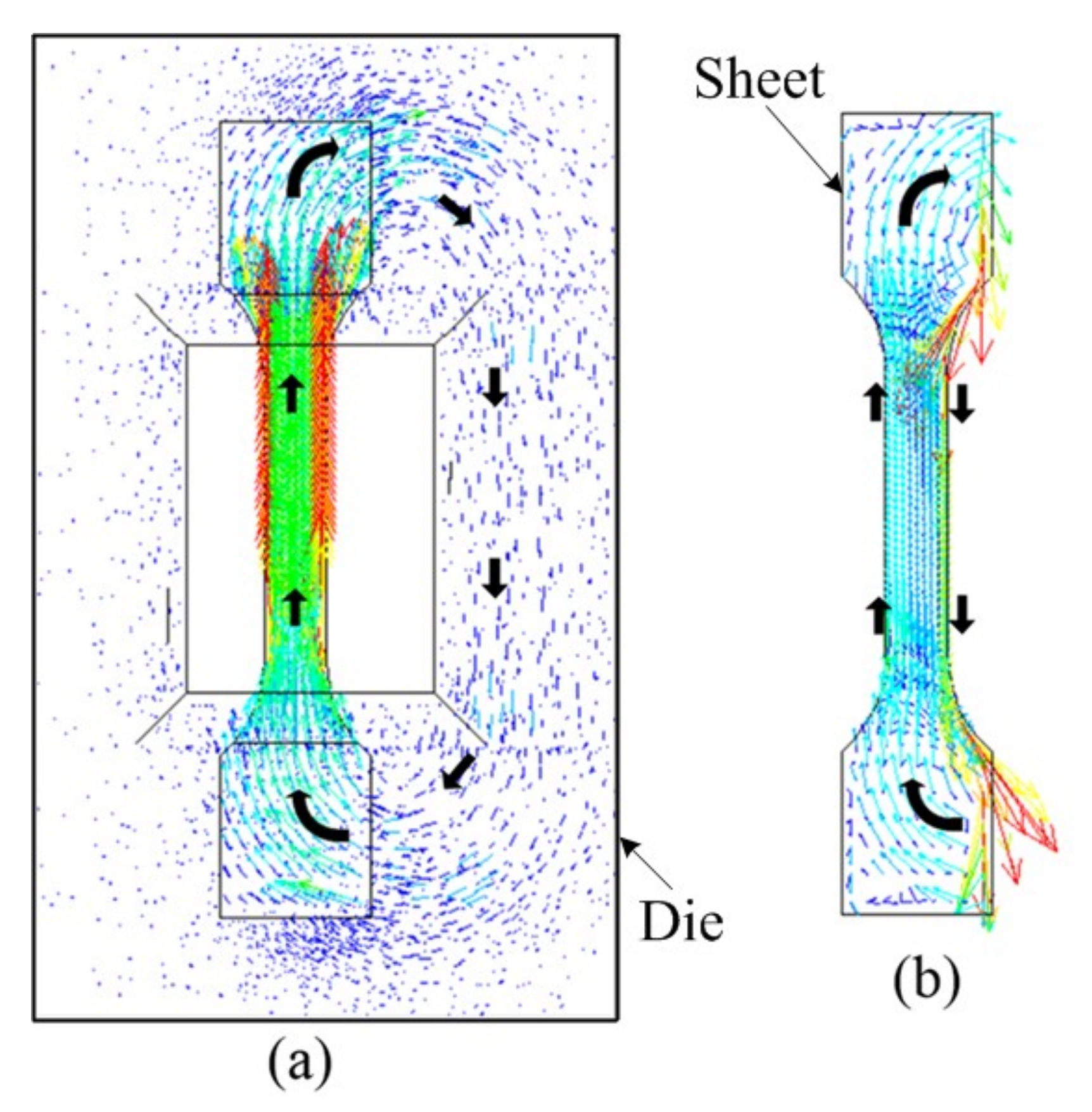

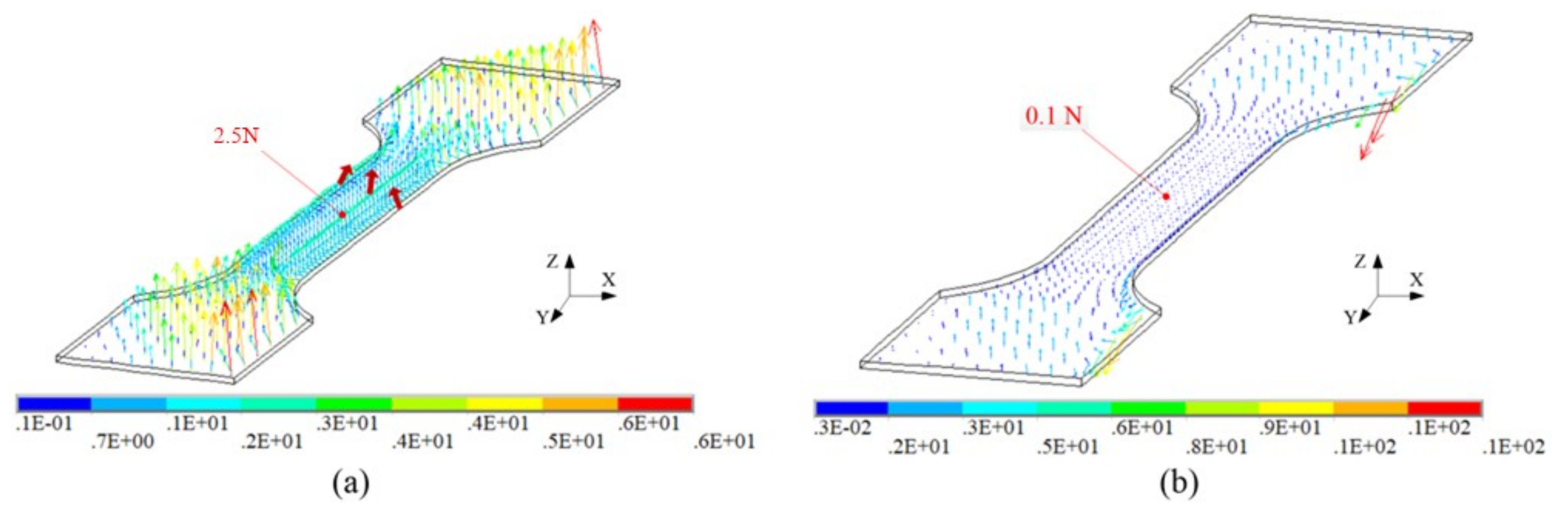

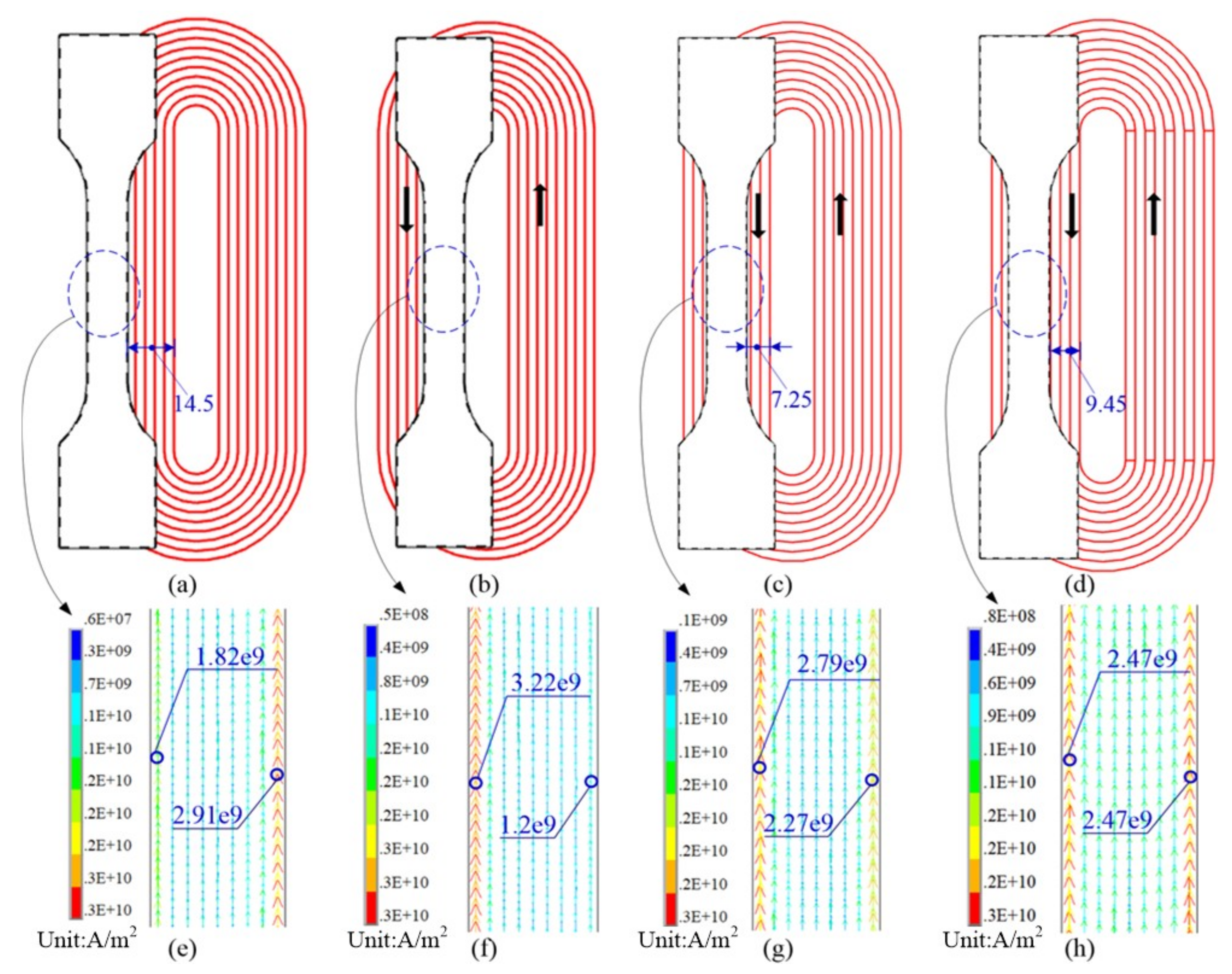

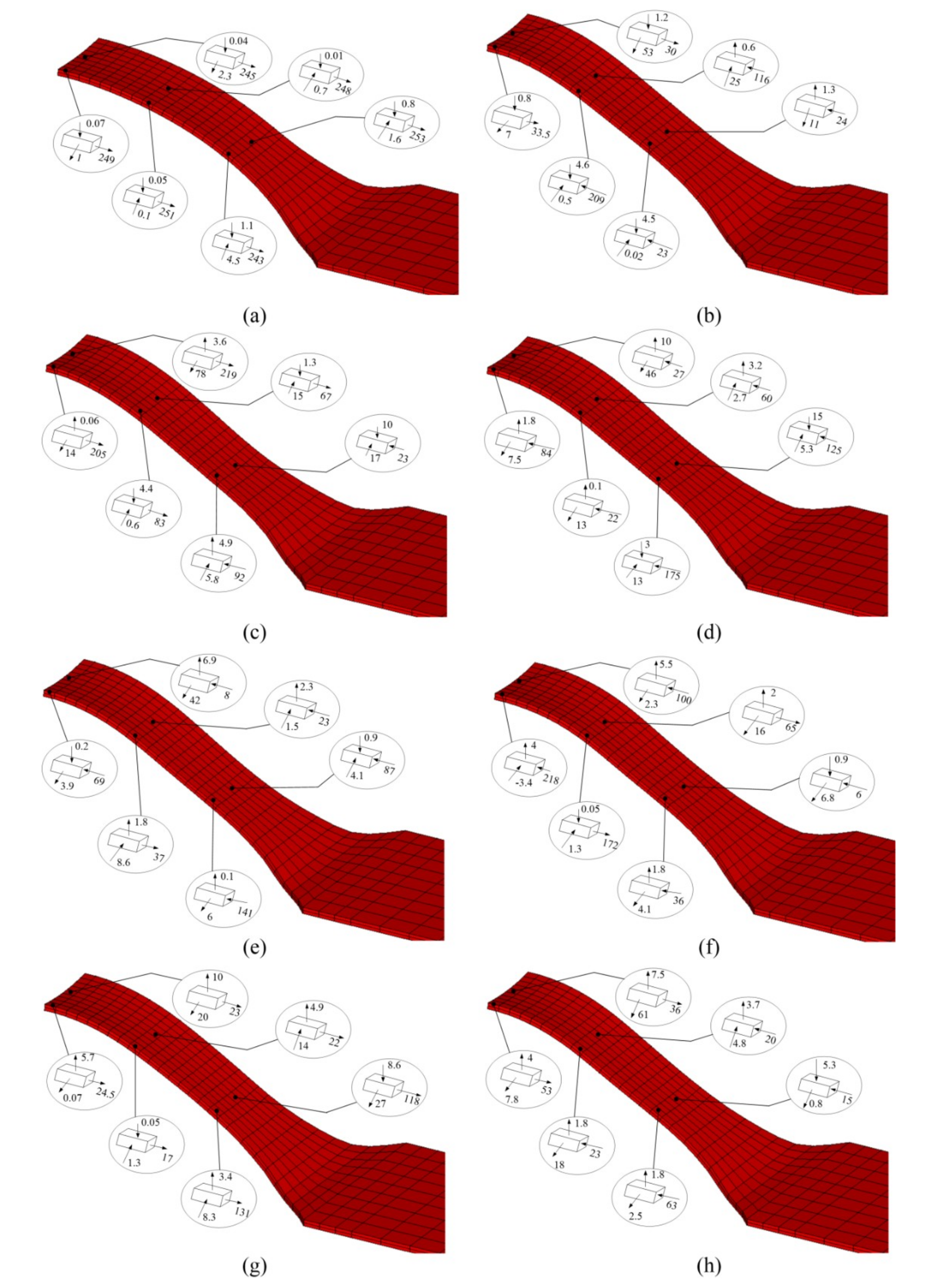

3.1. Effect of Die on Current Distribution and Magnetic Force

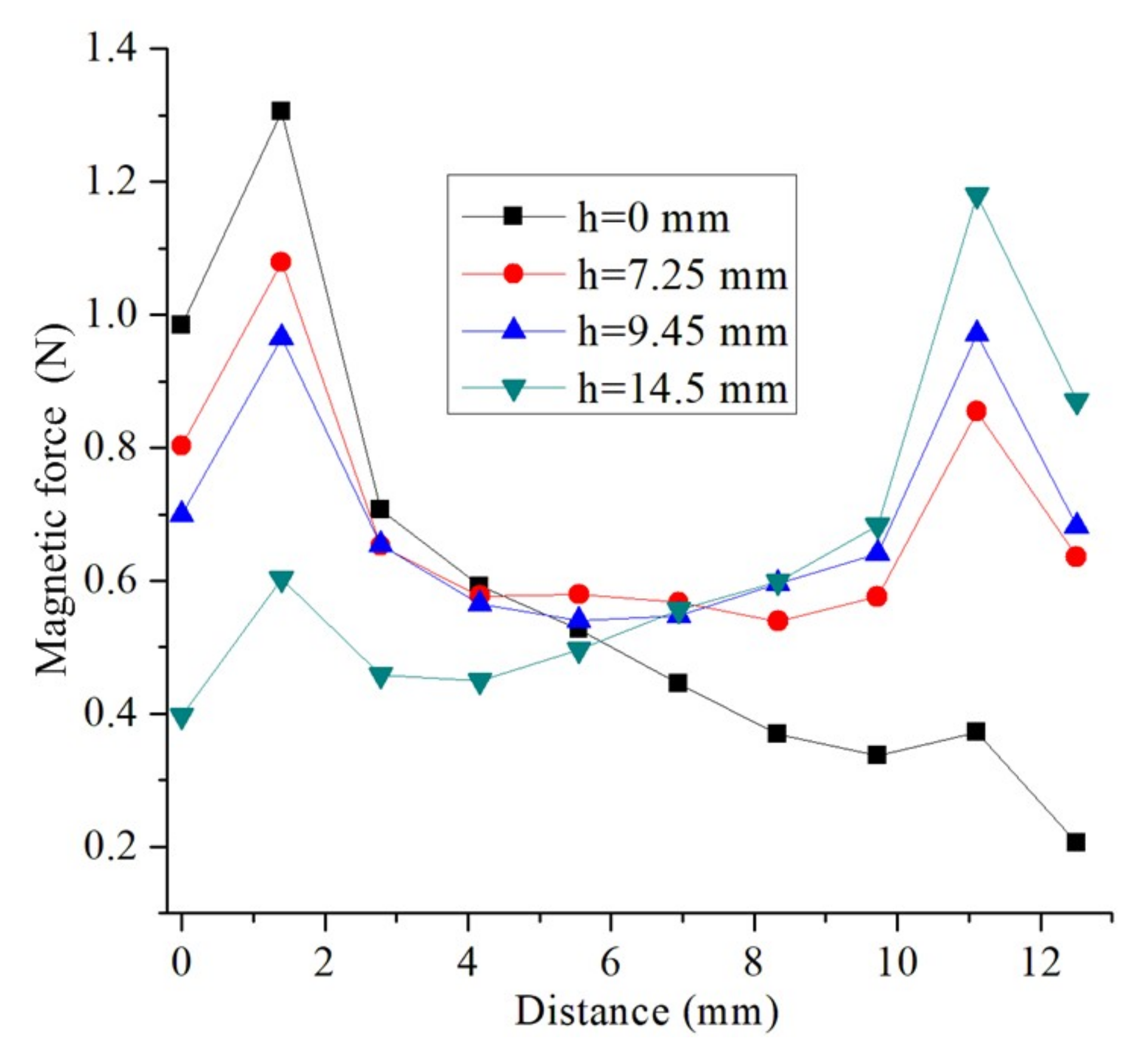

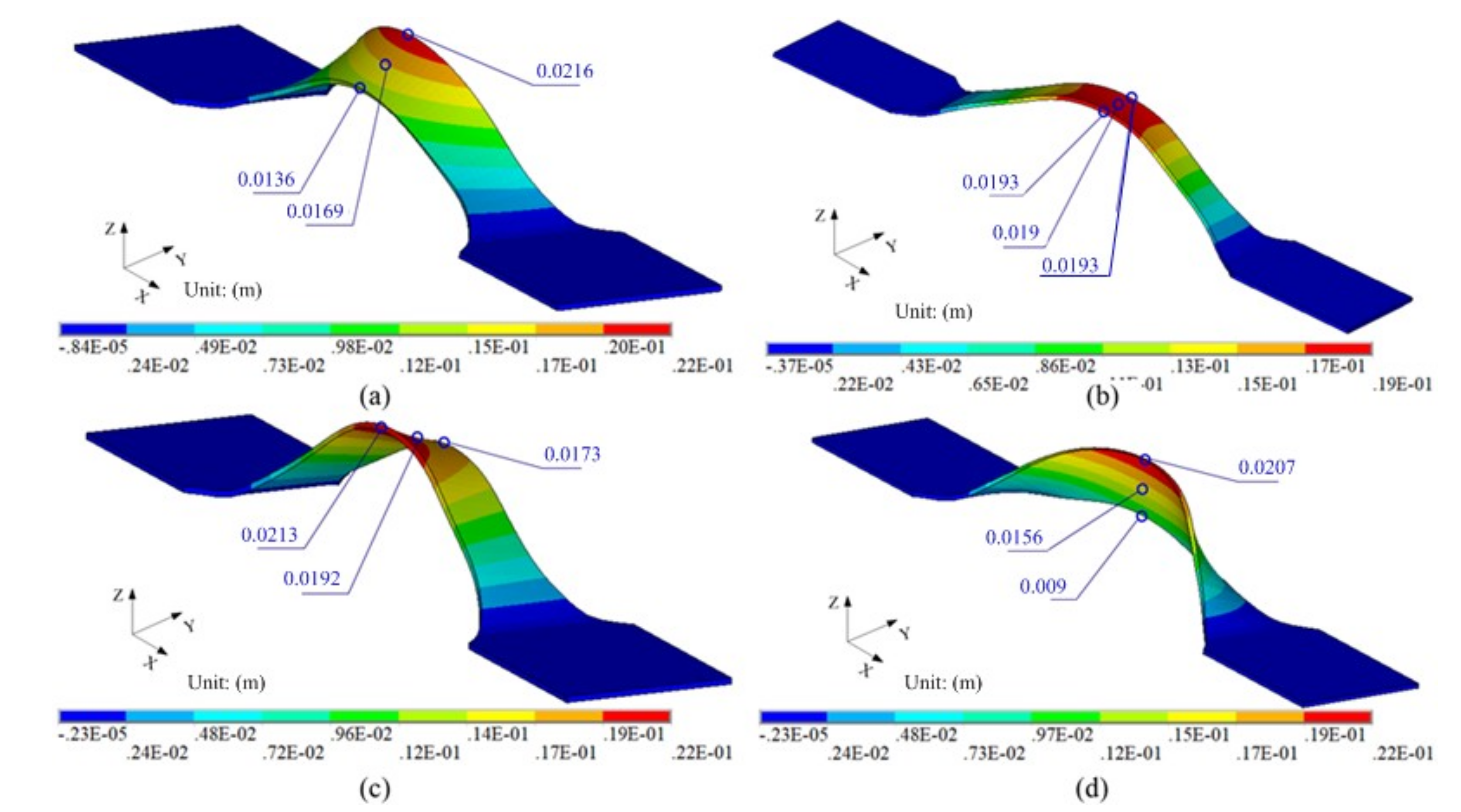

3.2. Effect of the Relative Position of the Coil and Sample on the Deformation

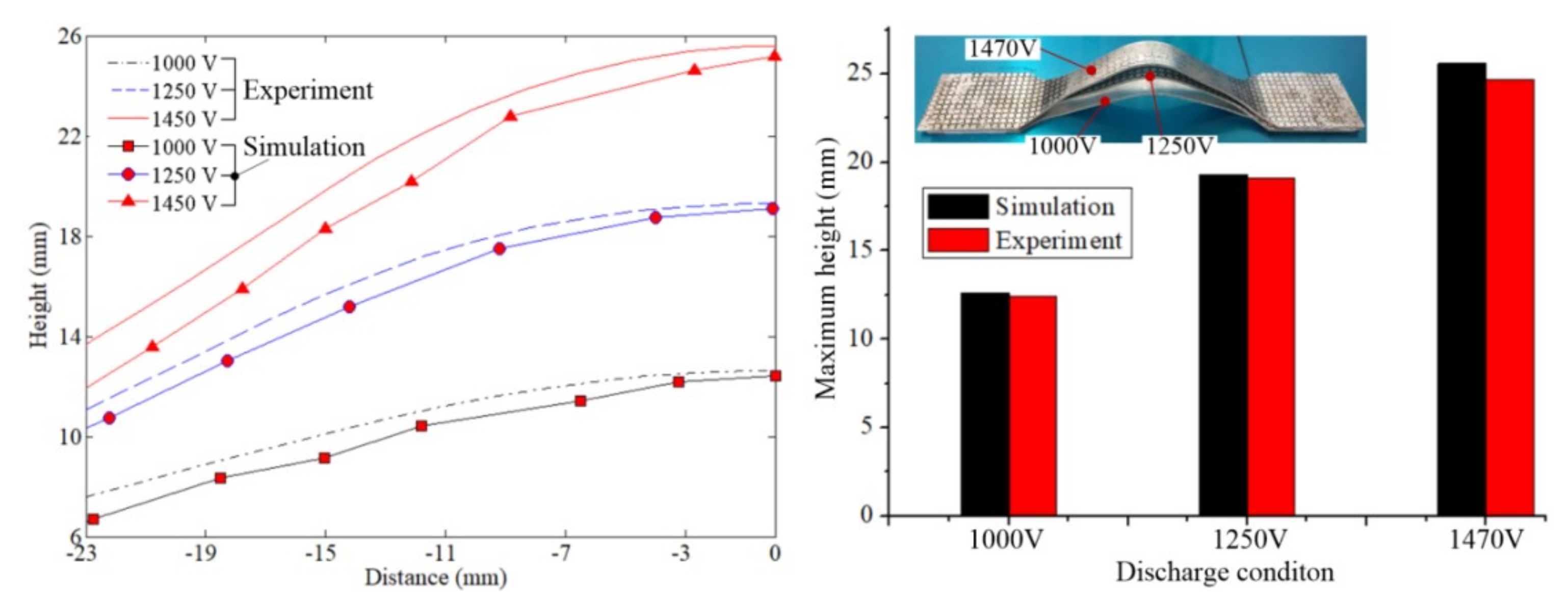

3.3. Comparison of Experimental and Simulation Results

4. Discussion

5. Conclusions

- (1)

- The die has a significant effect on the current distribution in the sample. Compared with a nonconductive die, the same current direction with similar current intensity in the sample can be obtained with a steel die.

- (2)

- The symmetrical distribution of magnetic force on path 1 can be obtained by adjusting the relative position of the sample and coil. Subsequently, the sheet deforms with a uniform 3D shape.

- (3)

- The deformation process can be approximately considered as a uniaxial tensile stress state before 240 μs. After 240 μs, the three main stresses at the special nodes showed significant oscillations.

Author Contributions

Funding

Conflicts of Interest

References

- Psyk, V.; Risch, D.; Kinsey, B.L; Tekkaya, A.E.; Kleiner, M. Electromagnetic forming—A review. J. Mater. Process. Technol. 2011, 211, 787–829. [Google Scholar] [CrossRef]

- Imbert, J.M.; Winkler, S.L.; Worswick, M.J.; Oliveira, D.A.; Golovashchenko, S. The effect of tool-sheet interaction on damage evolution in electromagnetic forming of aluminum alloy sheet. J. Eng. Mater. Technol. 2005, 127, 145–153. [Google Scholar] [CrossRef]

- Seth, M.; Vohnout, V.J.; Daehn, G.S. Formability of steel sheet in high velocity impact. J. Mater. Process. Technol. 2005, 168, 390–400. [Google Scholar] [CrossRef]

- Meng, Z.H.; Huang, S.Y.; Hu, J.H.; Huang, W.; Xia, Z.L. Effects of process parameters on warm and electromagnetic hybrid forming of magnesium alloy sheets. J. Mater. Process. Technol. 2011, 211, 863–867. [Google Scholar] [CrossRef]

- Jiang, H.W.; Ni, L.; Xiong, Y.Y.; Li, Z.G.; Liu, L. Deformation behavior and microstructure evolution of pure Cu subjected to electromagnetic bulging. Mater. Sci. Eng. A 2014, 593, 127–135. [Google Scholar] [CrossRef]

- Li, F.Q.; Mo, J.H.; Li, J.J.; Zhou, H.Y. Formability of Ti-6Al-4V titanium alloy sheet in magnetic pulse bulging. Mater. Des. 2013, 52, 337–344. [Google Scholar] [CrossRef]

- Fang, J.X.; Mo, J.H.; Cui, X.H.; Li, J.J.; Zhou, B. Electromagnetic pulse-assisted incremental drawing of aluminum cylindrical cup. J. Mater. Process. Technol. 2016, 238, 395–408. [Google Scholar] [CrossRef]

- Li, G.Y.; Deng, H.K.; Mao, Y.F.; Zhang, X.; Cui, J.J. Study on AA5182 aluminum sheet formability using combined quasi-staticdynamic tensile processes. J. Mater. Process. Technol. 2018, 255, 373–386. [Google Scholar] [CrossRef]

- Li, C.; Liu, D.; Yu, H.; Ji, Z. Research on formability of 5052 aluminum alloy sheet in a quasi-static–dynamic tensile process. Int. J. Mach. Tools Manuf. 2009, 49, 117–124. [Google Scholar] [CrossRef]

- Xu, J.R.; Yu, H.P.; Li, C.F. An Experiment on Magnetic Pulse Uniaxial Tension of AZ31 Magnesium Alloy Sheet at Room Temperature. J. Mater. Eng. Perform. 2013, 22, 1179–1185. [Google Scholar] [CrossRef]

- Xu, J.R.; Lin, Q.Q.; Cui, J.J.; Li, C.F. Formability of magnetic pulse uniaxial tension of AZ31magnesium alloy sheet. Int. J. Adv. Manuf. Technol. 2014, 72, 665–676. [Google Scholar] [CrossRef]

- Cui, X.H.; Mo, J.H.; Li, J.J.; Huang, L.; Zhu, Y.; Li, Z.W.; Zhong, K. Effect of second current pulse and different algorithms on simulation accuracy for electromagnetic sheet forming. Int. J. Adv. Manuf. Technol. 2013, 69, 1137–1146. [Google Scholar] [CrossRef]

- Cui, X.H.; Mo, J.H.; Han, F. 3D Multi-physics field simulation of electromagnetic tube forming. Int. J. Adv. Manuf. Technol. 2012, 59, 521–529. [Google Scholar] [CrossRef]

| Element | Fe | Cu | Mg | Mn | Ga | Cr | K |

|---|---|---|---|---|---|---|---|

| wt. % | 0.24 | 0.013 | 0.011 | 0.0055 | 0.019 | 0.0099 | 0.01 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, X.; Zhang, Z.; Yu, H.; Cheng, Y.; Xiao, X. Dynamic Uniform Deformation for Electromagnetic Uniaxial Tension. Metals 2019, 9, 425. https://doi.org/10.3390/met9040425

Cui X, Zhang Z, Yu H, Cheng Y, Xiao X. Dynamic Uniform Deformation for Electromagnetic Uniaxial Tension. Metals. 2019; 9(4):425. https://doi.org/10.3390/met9040425

Chicago/Turabian StyleCui, Xiaohui, Zhiwu Zhang, Hailiang Yu, Yongqi Cheng, and Xiaoting Xiao. 2019. "Dynamic Uniform Deformation for Electromagnetic Uniaxial Tension" Metals 9, no. 4: 425. https://doi.org/10.3390/met9040425

APA StyleCui, X., Zhang, Z., Yu, H., Cheng, Y., & Xiao, X. (2019). Dynamic Uniform Deformation for Electromagnetic Uniaxial Tension. Metals, 9(4), 425. https://doi.org/10.3390/met9040425