Influence of Size on the Fractal Dimension of Dislocation Microstructure

Abstract

:1. Introduction

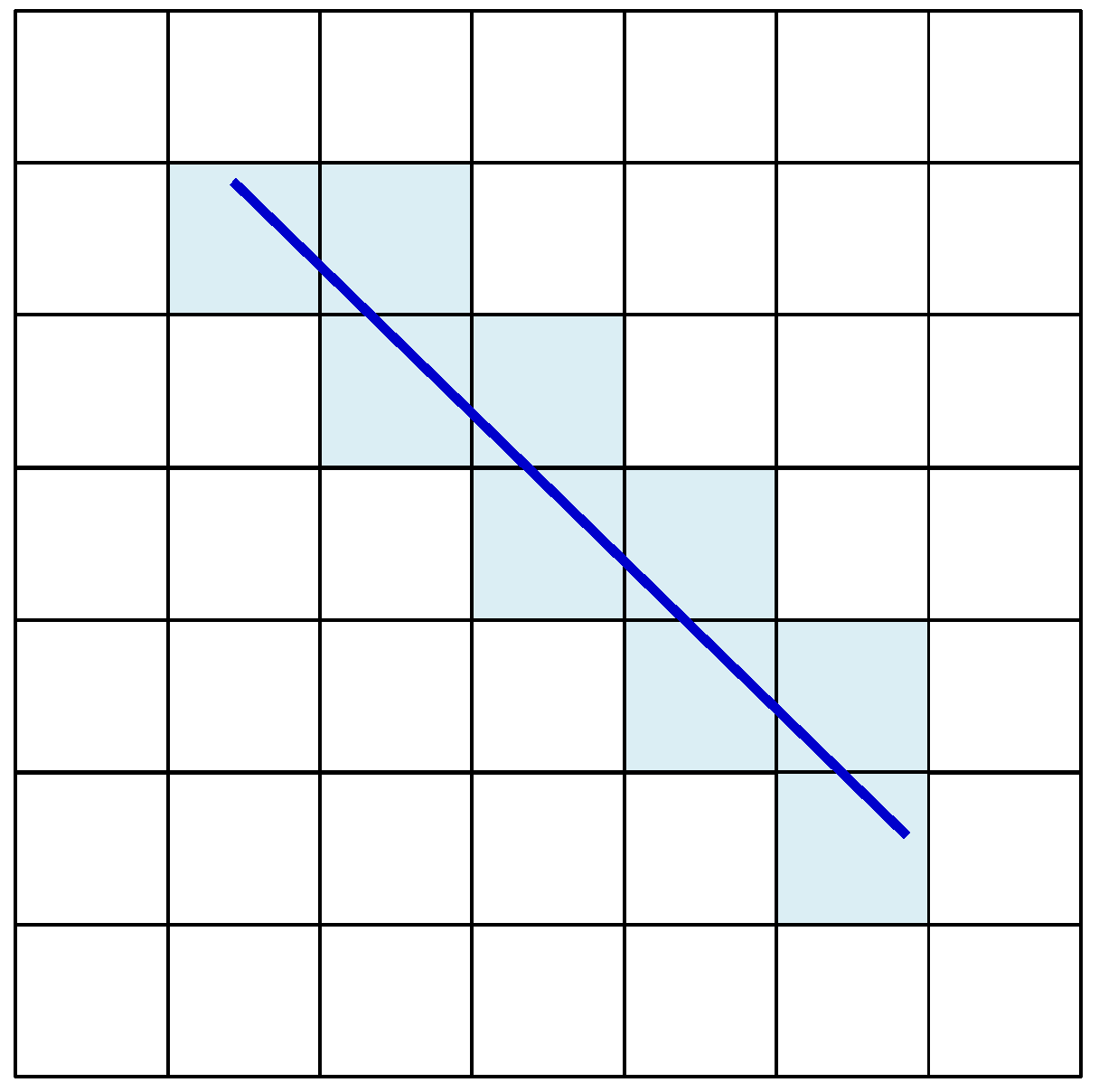

2. Investigation Method

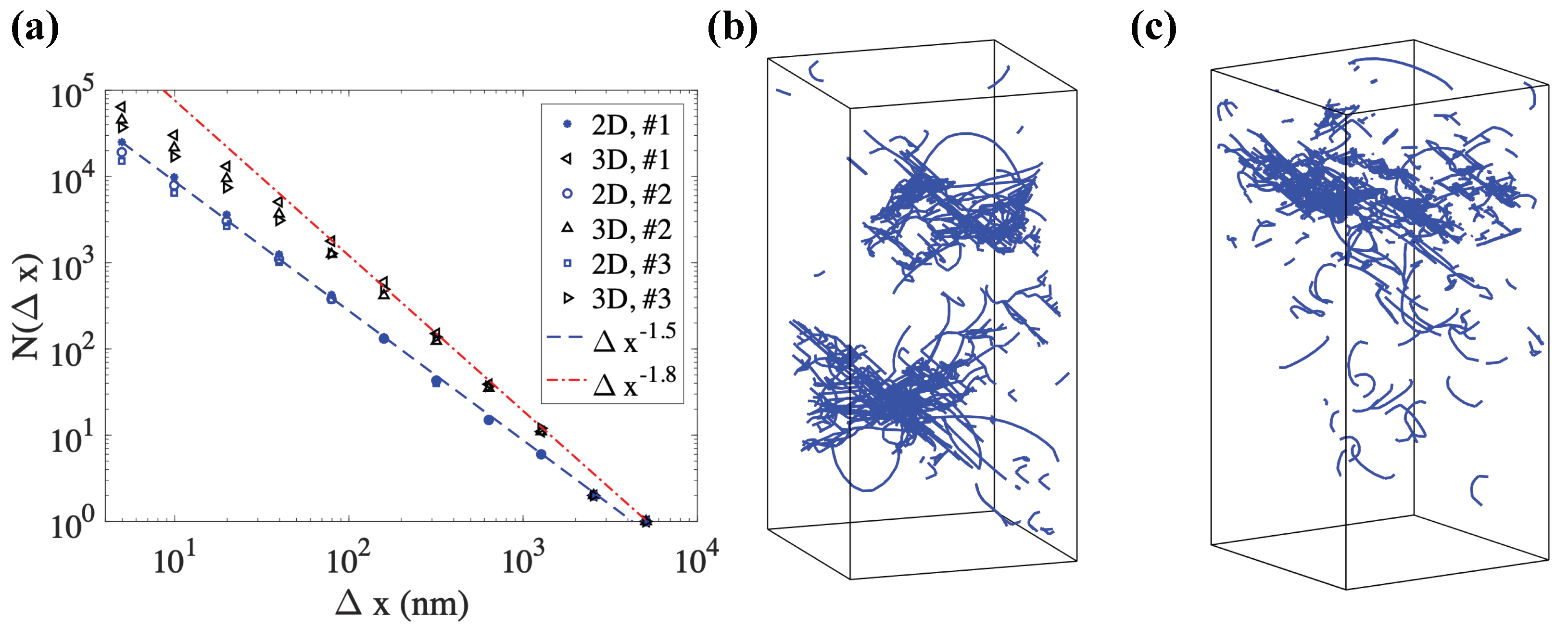

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kratochvil, J. Dislocation pattern formation in metals. Rev. Phys. Appl. 1988, 23, 419–429. [Google Scholar] [CrossRef]

- Ghoniem, N.M.; Amodeo, R. Computer Simulaltion of Dislocation Pattern Formation; Trans Tech Publ.: Zurich, Switzerland, 1988; Volume 3. [Google Scholar]

- Sandfeld, S.; Zaiser, M. Pattern formation in a minimal model of continuum dislocation plasticity. Model. Simul. Mater. Sci. Eng. 2015, 23, 065005. [Google Scholar] [CrossRef] [Green Version]

- Groma, I.; Zaiser, M.; Ispánovity, P.D. Dislocation patterning in a two-dimensional continuum theory of dislocations. Phys. Rev. B 2016, 93, 214110. [Google Scholar] [CrossRef]

- Xia, S.; El-Azab, A. Computational modelling of mesoscale dislocation patterning and plastic deformation of single crystals. Model. Simul. Mater. Sci. Eng. 2015, 23, 055009. [Google Scholar] [CrossRef]

- Ngan, A.; Siu, K.; Leung, H.; Cheng, B. Dislocation patterning-meso-scale interactive behavior of dislocations studied through dislocation density-function dynamics. In Proceedings of the 2017 Materials Research Society (MRS) Spring Meeting & Exhibit, Phoenix, AZ, USA, 17–21 April 2017. [Google Scholar]

- Li, P.; Zhang, Z. Standing wave effect and fractal structure in dislocation evolution. Sci. Rep. 2017, 7, 4062. [Google Scholar] [CrossRef] [Green Version]

- Papanikolaou, S.; Cui, Y.; Ghoniem, N. Avalanches and plastic flow in crystal plasticity: An overview. Model. Simul. Mater. Sci. Eng. 2017, 26, 013001. [Google Scholar] [CrossRef]

- Cao, L.; Koslowski, M. Effect of microstructural uncertainty on the yield stress of nanocrystalline nickel. Acta Mater. 2013, 61, 1413–1420. [Google Scholar] [CrossRef]

- Lyu, D.; Li, S. A multiscale dislocation pattern dynamics: Towards an atomistic-informed crystal plasticity theory. J. Mech. Phys. Solids 2019, 122, 613–632. [Google Scholar] [CrossRef]

- Irastorza-Landa, A.; Van Swygenhoven, H.; Van Petegem, S.; Grilli, N.; Bollhalder, A.; Brandstetter, S.; Grolimund, D. Following dislocation patterning during fatigue. Acta Mater. 2016, 112, 184–193. [Google Scholar] [CrossRef] [Green Version]

- Armstrong, R.W. Size effects on material yield strength/deformation/fracturing properties. J. Mater. Res. 2019, 1–16. [Google Scholar] [CrossRef]

- Zaiser, M.; Bay, K.; Hähner, P. Fractal analysis of deformation-induced dislocation patterns. Acta Mater. 1999, 47, 2463–2476. [Google Scholar] [CrossRef]

- Hornbogen, E. Fractals in microstructure of metals. Int. Mater. Rev. 1989, 34, 277–296. [Google Scholar] [CrossRef]

- Groma, I.; Bakó, B. Dislocation patterning: From micro-to mesoscale description. Phys. Rev. Lett. 2000, 84, 1487. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Wu, J.; Chiu, Y.; Jones, I.; Gu, R.; Ngan, A. Critical dimension for the dislocation structure in deformed copper micropillars. Scr. Mater. 2019, 163, 137–141. [Google Scholar] [CrossRef]

- Mandelbrot, B. How long is the coast of Britain? Statistical self-similarity and fractional dimension. Science 1967, 156, 636–638. [Google Scholar] [CrossRef] [PubMed]

- Bak, P. How Nature Works: The Science of Self-Organized Criticality; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Iliopoulos, A. Complex systems: Phenomenology, modeling, analysis. Int. J. Appl. Exp. Math. 2016, 1, 105. [Google Scholar] [CrossRef] [PubMed]

- Vinogradov, A.; Yasnikov, I.; Estrin, Y. Evolution of fractal structures in dislocation ensembles during plastic deformation. Phys. Rev. Lett. 2012, 108, 205504. [Google Scholar] [CrossRef]

- Hähner, P.; Bay, K.; Zaiser, M. Fractal dislocation patterning during plastic deformation. Phys. Rev. Lett. 1998, 81, 2470. [Google Scholar] [CrossRef]

- Hähner, P.; Zaiser, M. Dislocation dynamics and work hardening of fractal dislocation cell structures. Mater. Sci. Eng. A 1999, 272, 443–454. [Google Scholar] [CrossRef]

- Sevillano, J.G.; Arizcorreta, I.O.; Kubin, L. Intrinsic size effects in plasticity by dislocation glide. Mater. Sci. Eng. A 2001, 309, 393–405. [Google Scholar] [CrossRef]

- Koslowski, M.; LeSar, R.; Thomson, R. Dislocation structures and the deformation of materials. Phys. Rev. Lett. 2004, 93, 265503. [Google Scholar] [CrossRef]

- Chen, Y.S.; Choi, W.; Papanikolaou, S.; Sethna, J.P. Bending crystals: Emergence of fractal dislocation structures. Phys. Rev. Lett. 2010, 105, 105501. [Google Scholar] [CrossRef]

- Bakó, B.; Hoffelner, W. Cellular dislocation patterning during plastic deformation. Phys. Rev. B 2007, 76, 214108. [Google Scholar] [CrossRef]

- Ludwig, W.; Cloetens, P.; Härtwig, J.; Baruchel, J.; Hamelin, B.; Bastie, P. Three-dimensional imaging of crystal defects bytopo-tomography’. J. Appl. Crystall. 2001, 34, 602–607. [Google Scholar] [CrossRef]

- Tanaka, M.; Honda, M.; Mitsuhara, M.; Hata, S.; Kaneko, K.; Higashida, K. Three-dimensional observation of dislocations by electron tomography in a silicon crystal. Mater. Trans. 2008, 49, 1953–1956. [Google Scholar] [CrossRef]

- Liu, G.; Robertson, I. Three-dimensional visualization of dislocation-precipitate interactions in a Al–4Mg–0.3 Sc alloy using weak-beam dark-field electron tomography. J. Mater. Res. 2011, 26, 514–522. [Google Scholar] [CrossRef]

- Chen, C.C.; Zhu, C.; White, E.R.; Chiu, C.Y.; Scott, M.; Regan, B.; Marks, L.D.; Huang, Y.; Miao, J. Three-dimensional imaging of dislocations in a nanoparticle at atomic resolution. Nature 2013, 496, 74. [Google Scholar] [CrossRef]

- Yamasaki, S.; Mitsuhara, M.; Ikeda, K.; Hata, S.; Nakashima, H. 3D visualization of dislocation arrangement using scanning electron microscope serial sectioning method. Scr. Mater. 2015, 101, 80–83. [Google Scholar] [CrossRef] [Green Version]

- Madec, R.; Devincre, B.; Kubin, L. Simulation of dislocation patterns in multislip. Scr. Mater. 2002, 47, 689–695. [Google Scholar] [CrossRef] [Green Version]

- Cui, Y.; Po, G.; Ghoniem, N. Size-Tuned Plastic Flow Localization in Irradiated Materials at the Submicron Scale. Phys. Rev. Lett. 2018, 120, 215501. [Google Scholar] [CrossRef]

- Arsenlis, A.; Cai, W.; Tang, M.; Rhee, M.; Oppelstrup, T.; Hommes, G.; Pierce, T.G.; Bulatov, V.V. Enabling strain hardening simulations with dislocation dynamics. Model. Simul. Mater. Sci. Eng. 2007, 15, 553. [Google Scholar] [CrossRef]

- Po, G.; Ghoniem, N. Mechanics of Defect Evolution Library, MODEL. Available online: https://bitbucket.org/model/model/wiki/home (accessed on 29 March 2019).

- Ghoniem, N.M.; Tong, S.H.; Sun, L. Parametric dislocation dynamics: A thermodynamics-based approach to investigations of mesoscopic plastic deformation. Phys. Rev. B 2000, 61, 913. [Google Scholar] [CrossRef]

- Po, G.; Mohamed, M.S.; Crosby, T.; Erel, C.; El-Azab, A.; Ghoniem, N. Recent Progress in Discrete Dislocation Dynamics and Its Applications to Micro Plasticity. JOM 2014, 66, 2108–2120. [Google Scholar] [CrossRef]

- Cui, Y.; Po, G.; Ghoniem, N.M. A coupled dislocation dynamics-continuum barrier field model with application to irradiated materials. Int. J. Plast. 2018, 104, 54–67. [Google Scholar] [CrossRef]

- Cui, Y.; Po, G.; Ghoniem, N. Suppression of Localized Plastic Flow in Irradiated Materials. Scr. Mater. 2018, 154, 34–39. [Google Scholar] [CrossRef]

- Po, G.; Cui, Y.; Rivera, D.; Cereceda, D.; Swinburne, T.D.; Marian, J.; Ghoniem, N. A phenomenological dislocation mobility law for bcc metals. Acta Mater. 2016, 119, 123–135. [Google Scholar] [CrossRef] [Green Version]

- Uchic, M.D.; Dimiduk, D.M.; Florando, J.N.; Nix, W.D. Sample dimensions influence strength and crystal plasticity. Science 2004, 305, 986–989. [Google Scholar] [CrossRef]

- Schurch, R.; González, C.; Aguirre, P.; Zuniga, M.; Rowland, S.M.; Iddrissu, I. Calculating the fractal dimension from 3D images of electrical trees. In Proceedings of the 2017 International Symposium on High Voltage Engineering, Buenos Aires, Argentina, 28 August–1 September 2017. [Google Scholar]

| Fractal Dimension n | Remarks | Reference |

|---|---|---|

| 1.64∼1.79 | TEM images of [100]-oriented Cu single crystal, n depends on stress. | [13,21,22] |

| 1.371∼1.695 | STEM images of [011]-oriented Cu, n depends on sizes and strain. | [16] |

| 1.33 | 2D dislocation glide through obstacles. | [23] |

| 0.9∼1.8 | Phase-field simulations, n initially increases with applied stress. | [24] |

| 1.5 | Using 2D continuum model for mesoscale plasticity. | [25] |

| 1.87 | 2D dislocation pattern simulation for FCC single crystals oriented for multiple slip without climb under cyclic loading. | [26] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, Y.; Ghoniem, N. Influence of Size on the Fractal Dimension of Dislocation Microstructure. Metals 2019, 9, 478. https://doi.org/10.3390/met9040478

Cui Y, Ghoniem N. Influence of Size on the Fractal Dimension of Dislocation Microstructure. Metals. 2019; 9(4):478. https://doi.org/10.3390/met9040478

Chicago/Turabian StyleCui, Yinan, and Nasr Ghoniem. 2019. "Influence of Size on the Fractal Dimension of Dislocation Microstructure" Metals 9, no. 4: 478. https://doi.org/10.3390/met9040478

APA StyleCui, Y., & Ghoniem, N. (2019). Influence of Size on the Fractal Dimension of Dislocation Microstructure. Metals, 9(4), 478. https://doi.org/10.3390/met9040478