Alloys for Aeronautic Applications: State of the Art and Perspectives

Abstract

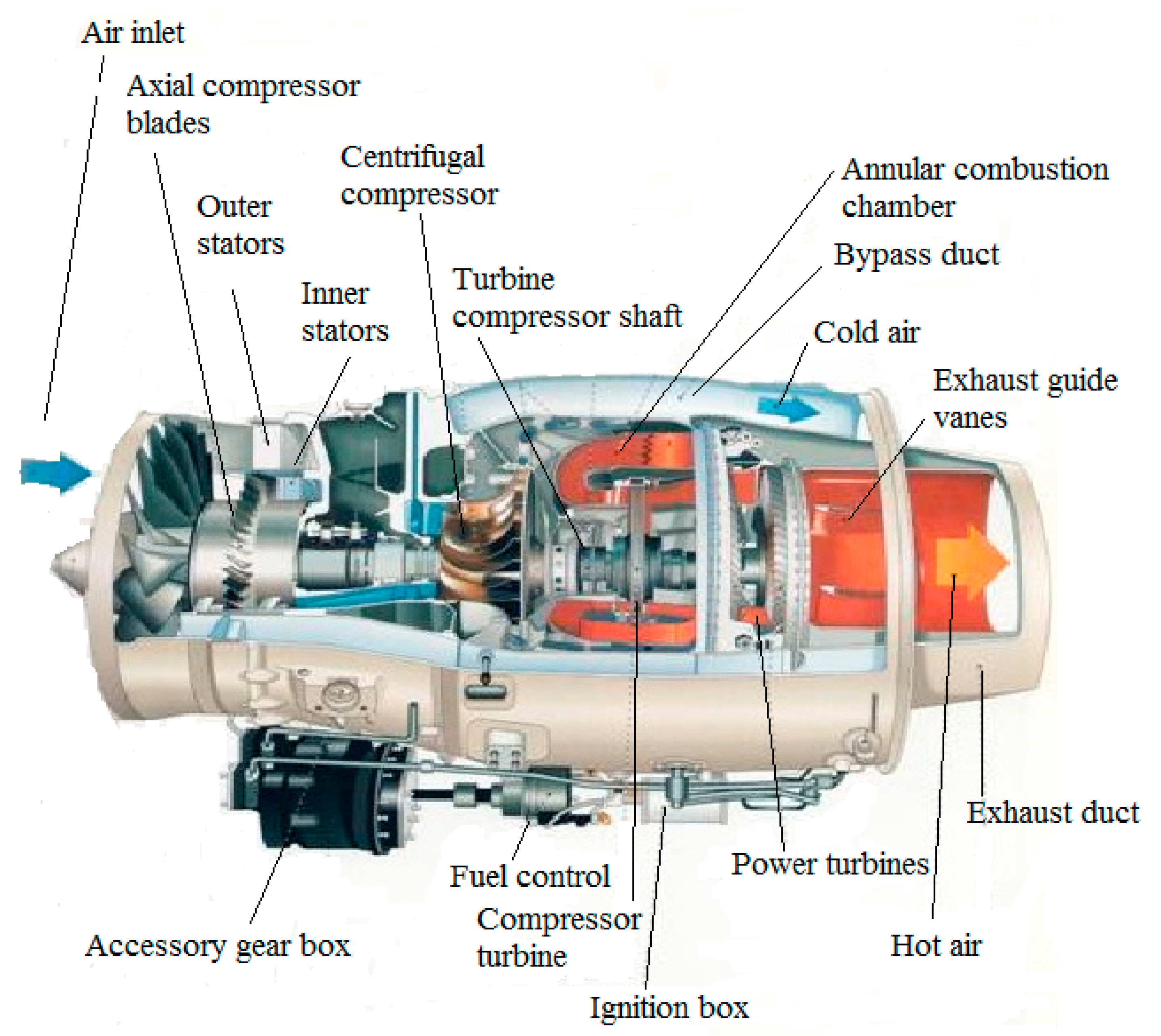

1. Introduction

2. Aluminum Alloys

2.1. 2XXX Series—(Al-Cu)

2.2. 7XXX Series—(Al-Zn)

2.3. Al-Li Alloys

2.4. Aluminum Composites

2.5. Advanced Joining Techniques for Aluminum Alloys

3. Titanium Alloys

3.1. α-Ti

3.2. β-Ti

3.3. α-β–Ti

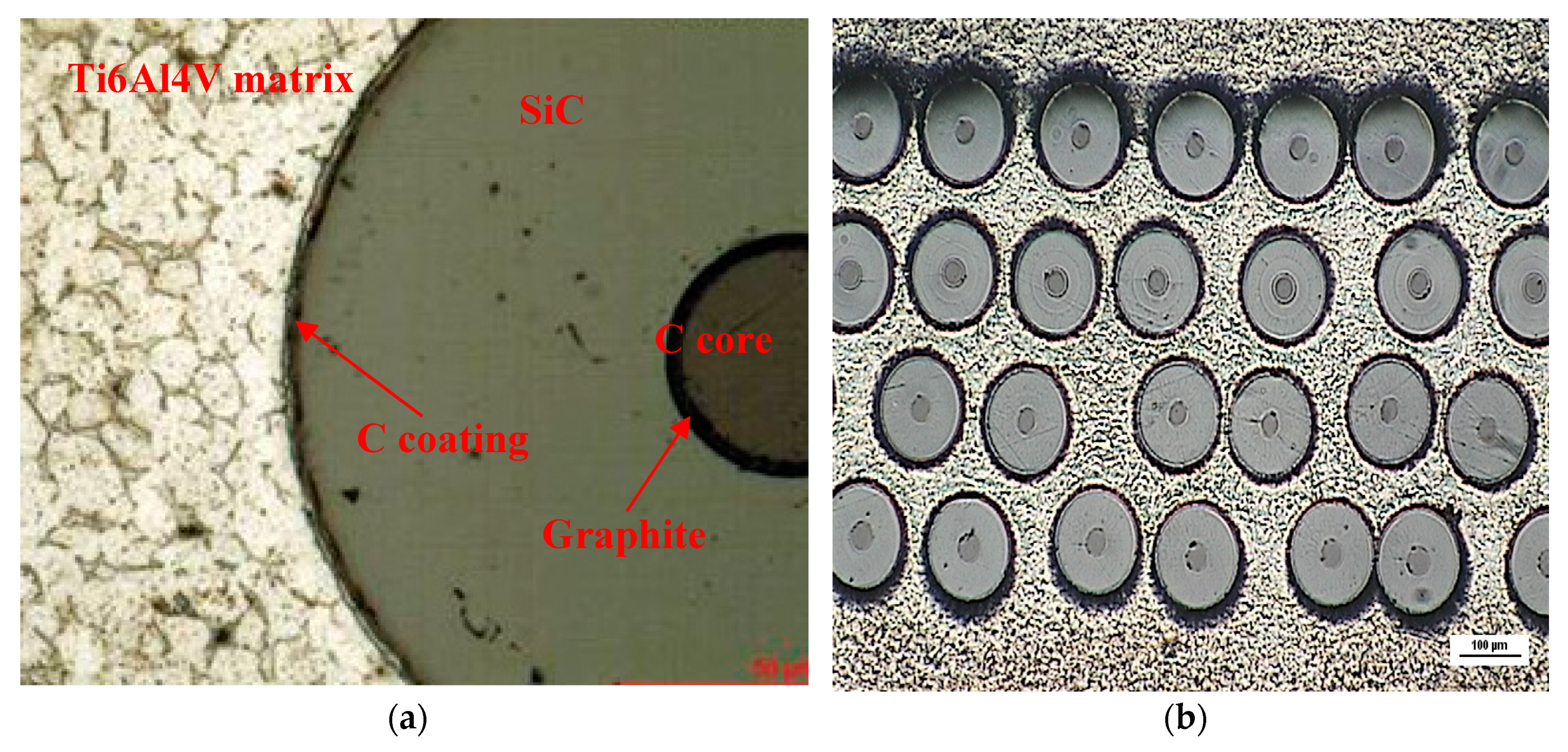

3.4. Ti Composites Reinforced with SiC Fibers

4. Magnesium Alloys

5. Steels

6. Ni-Based Superalloys

6.1. Microstructural Stability

6.2. Manufacturing Parts of Complex Geometry

6.3. Welding of Superalloys

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Campbell, F.C. Manufacturing Technology for Aerospace Structural Materials; Elsevier: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Zhang, X.; Chen, Y.; Hu, J. Recent advances in the development of aerospace materials. Prog. Aerosp. Sci. 2018, 97, 22–34. [Google Scholar] [CrossRef]

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminium alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Warren, A.S. Developments and challenges for aluminium—A Boeing perspective. Mater. Forum 2004, 28, 24–31. [Google Scholar]

- Huda, Z.; Edi, P. Materials selection in design of structures and engines of supersonic aircrafts: A review. Mater. Des. 2013, 46, 552–560. [Google Scholar] [CrossRef]

- Banerjee, S.; Robi, P.S.; Srinivasan, A.; Lakavath, P.K. Effect of trace additions of Sn on microstructure and mechanical properties of Al–Cu–Mg alloys. Mater. Des. 2010, 31, 4007–4015. [Google Scholar] [CrossRef]

- Yu, J.; Li, X. Modelling of the precipitated phases and properties of Al-Zn-Mg-Cu alloys. J. Phase Equilib. Diffus. 2011, 32, 350. [Google Scholar] [CrossRef]

- Schijve, J. Fatigue of Structures and Materials; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2001. [Google Scholar]

- Dowling, N.E. Mechanical Behavior of Materials, 3rd ed.; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2007. [Google Scholar]

- 3rd Annual Fatigue Summit; US Navy: Northern Virginia, VA, USA, 2014.

- Stanzl-Tschegg, S.E.; Meischel, M.; Arcari, A.; Iyyer, N.; Apetre, N.; Phan, N. Combined cycle fatigue of 7075 aluminum alloy—Fracture surface characterization and short crack propagation. Int. J. Fatigue 2016, 91, 352–362. [Google Scholar] [CrossRef]

- Merati, A.; Eastaugh, G. Determination of fatigue related discontinuity state of 7000 series of aerospace aluminum alloys. Eng. Fail. Anal. 2007, 14, 673–685. [Google Scholar] [CrossRef]

- Cirik, E.; Genel, K. Effect of anodic oxidation on fatigue performance of 7075-T6 alloy. Surf. Coat. Technol. 2008, 202, 5190–5201. [Google Scholar] [CrossRef]

- Angella, G.; Di Schino, A.; Donnini, R.; Richetta, M.; Testani, C.; Varone, A. AA7050 Al alloy hot-forging process for improved fracture toughness properties. Metals 2019, 9, 64. [Google Scholar] [CrossRef]

- El-Aty, A.A.; Xu, Y.; Guo, X.; Zhang, S.H.; Ma, Y.; Chen, D. Strengthening mechanisms, deformation behavior, and anisotropic mechanical properties of Al-Li alloys: A review. J. Adv. Res. 2018, 10, 49–67. [Google Scholar] [CrossRef] [PubMed]

- Noble, B.; Thompson, G.E. Precipitation characteristics of aluminium-lithium alloys. Met. Sci. J. 1971, 5, 114–120. [Google Scholar] [CrossRef]

- Noble, B.; Thompson, G.E. T1(Al2CuLi) precipitation in aluminium-copper-lithium alloys. Met. Sci. J. 1972, 6, 167–174. [Google Scholar] [CrossRef]

- Rinker, J.G.; Marek, M.; Sanders, T.H., Jr. Microstructure toughness and stress corrosion cracking behavior of aluminum alloy 2020. Mater. Sci. Eng. 1984, 64, 203–221. [Google Scholar] [CrossRef]

- Rioja, R.; Liu, J. The evolution of Al-Li base products for aerospace and space applications. Metall. Mater. Trans. A 2012, 43, 3325–3337. [Google Scholar] [CrossRef]

- Wanhill, R.J.H. Aerospace applications of aluminum-lithium alloys. In Aluminum-Lithium Alloys; Elsevier Inc.: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Singh, A.; Gokhale, A.A.; Saha, G.G.; Ray, R.K. Texture evolution and anisotropy in Al-Li-Cu-Mg alloys. Textures Mater. Res. 1999, 219–234. [Google Scholar]

- Giummarra, C.; Thomas, B.; Rioja, R.J. New aluminium lithium alloys for aerospace applications. In Proceedings of the Light Metals Technology Conference 2007, Saint-Saveur, QC, Canada, 24–26 September 2007; pp. 41–46. [Google Scholar]

- Warner, T. Recently developed aluminium solutions for aerospace applications. Mater. Sci. Forum 2006, 519–521, 1271–1278. [Google Scholar] [CrossRef]

- Tsivoulas, D.; Prangnell, P. The effect of Mn and Zr dispersoid-forming additions on recrystallization resistance in Al–Cu–Li AA2198 sheet. Acta Mater. 2014, 77, 1–16. [Google Scholar] [CrossRef]

- Gable, B.M.; Zhu, A.W.; Csontos, A.A.; Starke, E.A., Jr. The role of plastic deformation on the competitive microstructural evolution and mechanical properties of a novel Al–Li–Cu alloy. J. Light Met. 2001, 1, 1–14. [Google Scholar] [CrossRef]

- Decreus, B.; Deschamps, A.; De Geuser, F.; Donnadieu, P.; Sigli, C.; Weyland, M. The influence of Cu/Li ratio on precipitation in Al–Cu–Li–x alloys. Acta Mater. 2013, 61, 2207–2218. [Google Scholar] [CrossRef]

- Deschamps, A.; Decreus, B.; De Geuser, F.; Dorin, T.; Weyland, M. The influence of precipitation on plastic deformation of Al–Cu–Li-X alloys. Acta Mater. 2013, 61, 4010–4021. [Google Scholar] [CrossRef]

- Dorin, T.; De Geuser, F.; Lefebvre, W.; Sigli, C.; Deschamps, A. Strengthening mechanisms of T1 precipitates and their influence on the plasticity of an Al–Cu–Li alloy. Mater. Sci. Eng. A 2014, 605, 119–126. [Google Scholar] [CrossRef]

- Dorin, T.; Deschamps, A.; De Geuser, F.; Sigli, C. Quantification and modelling of the microstructure/strength relationship by tailoring the morphological parameters of the T1 phase in an Al–Cu–Li alloy. Acta Mater. 2014, 75, 134–146. [Google Scholar] [CrossRef]

- Rodgers, B.I.; Prangnell, P.B. Quantification of the influence of increased pre-stretching on microstructure-strength relationships in the Al–Cu–Li alloy AA2195. Acta Mater. 2016, 108, 55–67. [Google Scholar] [CrossRef]

- Lin, Y.; Zheng, Z.; Li, S.; Kong, X.; Han, Y. Microstructures and properties of 2099 Al-Li alloy. Mater. Charact. 2013, 84, 88–99. [Google Scholar] [CrossRef]

- Zhang, S.; Zeng, W.; Yang, W.; Shi, C.; Wang, H. Ageing response of a Al–Cu–Li 2198 alloy. Mater. Des. 2014, 63, 368–374. [Google Scholar] [CrossRef]

- Kang, S.J.; Kim, T.-H.; Yang, C.-W.; Lee, J.I.; Park, E.S.; Noh, T.W.; Kim, M. Atomic structure and growth mechanism of T1 precipitate in Al-Cu-Li-Mg-Ag alloy. Scr. Mater. 2015, 109, 68–71. [Google Scholar] [CrossRef]

- Li, H.Y.; Kang, W.; Lu, X.C. Effect of age-forming on microstructure, mechanical and corrosion properties of a novel Al-Li alloy. J. Alloys Compd. 2015, 640, 210–218. [Google Scholar] [CrossRef]

- Fan, X.; He, Z.; Lin, P.; Yuan, S. Microstructure, texture and hardness of Al-Cu-Li alloy sheet during hot gas forming with integrated heat treatment. Mater. Des. 2016, 94, 449–456. [Google Scholar] [CrossRef]

- Deschamps, A.; Garcia, M.; Chevy, J.; Davo, B.; De Geuser, F. Influence of Mg and Li content on the microstructure evolution of Al-Cu-Li alloys during long-term ageing. Acta Mater. 2017, 122, 32–46. [Google Scholar] [CrossRef]

- Djaaboube, H.; Thabet-Khireddine, D. TEM diffraction study of Al2CuMg (S’/S) precipitation in an Al-Li-Cu-Mg(Zr) alloy. Philos. Mag. 2012, 92, 1876–1889. [Google Scholar] [CrossRef]

- Araullo-Peters, V.; Gault, B.; de Geuser, F.; Deschamps, A.; Cairney, J.M. Microstructural evolution during ageing of Al-Cu-Li-X alloys. Acta Mater. 2014, 66, 199–208. [Google Scholar] [CrossRef]

- Rao, K.T.V.; Ritchie, R.O. Fracture toughness behavior of 2090-T83 aluminum–lithium alloy sheet at ambient and cryogenic temperatures. Scr. Metall. 1989, 23, 1129–1134. [Google Scholar] [CrossRef]

- Rao, K.T.V.; Ritchie, R.O. Fatigue crack-propagation and cryogenic fracture-toughness behavior in powder-metallurgy aluminum–lithium alloys. Metall. Trans. A 1991, 22, 191–202. [Google Scholar]

- Xu, Y.B.; Wang, L.; Zhang, Y.; Wang, Z.G.; Hu, Q.Z. Fatigue and fracture-behavior of an aluminum–lithium Alloy-8090-T6 at ambient and cryogenic temperature. Metall. Trans. A 1991, 22, 723–729. [Google Scholar] [CrossRef]

- Sohn, K.S.; Lee, S.; Kim, N.J. In situ observation of microfracture processes in an 8090 Al–Li alloy plate. Mater. Sci. Eng. A 1993, 163, 11–21. [Google Scholar] [CrossRef]

- Csontos, A.A.; Starke, E.A. The effect of processing and microstructure development on the slip and fracture behavior of the 2.1 wt. pct. Li AF/C489 and 1.8 wt. pct. Li AF/C458 Al–Li–Cu–X alloys. Metall. Mater. Trans. A 2000, 31, 1965–1976. [Google Scholar] [CrossRef]

- Kalyanam, S.; Beaudoin, A.J.; Dodds, R.H., Jr.; Barlat, F. Delamination cracking in advanced aluminum–lithium alloys—Experimental and computational studies. Eng. Fract. Mech. 2009, 76, 2174–2191. [Google Scholar] [CrossRef]

- Rawal, S. Metal-matrix composites for space applications. JOM 2001, 53, 14–17. [Google Scholar] [CrossRef]

- Kainer, K.U. Metal Matrix Composites; Wiley-Vch: Weinheim, Germany, 2006. [Google Scholar]

- Advances in Metal Matrix Composites; Ceschini, L., Montanari, R., Eds.; Trans Tech Publications: Zurich, Switzerland, 2011. [Google Scholar]

- Tjong, S.C. Recent progress in the development and properties of novel metal matrix nanocomposites reinforced with carbon nanotubes and grapheme nanosheets. Mater. Sci. Eng. R. Rep. 2013, 74, 281–350. [Google Scholar] [CrossRef]

- Liao, J.; Tan, M.J.; Sridhar, I. Spark plasma sintered multi-wall carbon nanotube reinforced aluminum matrix composites. Mater. Des. 2010, 31, S96–S100. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, C.; Liu, B.; Meng, Q.; Ma, S.; Dai, W. Reduced graphene oxide reinforced 7075 Al matrix composites: Powder synthesis and mechanical properties. Metals 2017, 7, 499. [Google Scholar] [CrossRef]

- Shimizu, Y.; Nishimura, T.; Matsushima, I. Corrosion resistance of Al-based metal matrix composites. Mater. Sci. Eng. A 1995, 198, 113–118. [Google Scholar] [CrossRef]

- Chen, C.; Mansfeld, F. Corrosion protection of an Al 6092/SiCP metal matrix composite. Corros. Sci. 1996, 39, 1075–1082. [Google Scholar] [CrossRef]

- Fang, C.K.; Huang, C.C.; Chuang, T.H. Synergistic effects of wear and corrosion for Al2O3 particulate-reinforced 6061 aluminum matrix composites. Metall. Mater. Trans. A 1999, 30, 643–651. [Google Scholar] [CrossRef]

- Hihara, L.H.; Latanision, R.M. Galvanic corrosion of aluminum-matrix composites. Corrosion 1992, 48, 546–552. [Google Scholar] [CrossRef]

- Pardo, A.; Merino, M.C.; Merino, S.; Viejo, F.; Carboneras, M.; Arrabal, R. Influence of reinforcement proportion and matrix composition on pitting corrosion behaviour of cast aluminium matrix composites (A3xx.x/SiCp). Corros. Sci. 2005, 47, 1750–1764. [Google Scholar] [CrossRef]

- Veeresh Kumar, G.M.; Rao, C.S.P.; Selvaraj, N.; Bhagyashekar, M.S. Studies on Al6061-SiC and Al7075-Al2O3 Metal Matrix Composites. J. Miner. Mater. Charact. Eng. 2010, 9, 43–55. [Google Scholar]

- Candan, S. An investigation on corrosion behaviour of pressure infiltrated Al–Mg alloy/SiCp composites. Corros. Sci. 2009, 51, 1392–1398. [Google Scholar] [CrossRef]

- Patil, C.; Patil, H.; Patil, H. Experimental investigation of hardness of FSW and TIG joints of Aluminium alloys of AA7075 and AA6061. Fract. Struct. Integr. 2016, 37, 325–332. [Google Scholar] [CrossRef]

- Hancock, R. Friction welding of aluminum cuts energy cost by 99%. Weld. J. 2004, 83, 40–45. [Google Scholar]

- Kenichiro, M.; Niels, B.; Livan, F.; Micari, F.; Tekkaya, A.E. Joining by plastic deformation. CIRP Ann. 2013, 62, 673–694. [Google Scholar]

- Aota, K.; Takahashi, M.; Ikeuchi, K. Friction stir spot welding of aluminum to steel by rotating tool without probe. Weld. Int. 2010, 24, 96–104. [Google Scholar] [CrossRef]

- Uematsu, Y.; Tokaji, K. Comparison of fatigue behaviour between resistance spot and friction stir spot welded aluminium alloy sheets. Sci. Technol. Weld. Join. 2009, 14, 62–71. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, X.; Zhang, J.; Zhou, G.; Xu, X.; Zou, B. Effect of welding parameters on microstructure and mechanical properties of friction stir spot welded 5052 aluminum alloy. Mater. Des. 2011, 32, 4461–4470. [Google Scholar] [CrossRef]

- Tutar, M.; Aydin, H.; Yuce, C.; Yavuz, N.; Bayram, A. The optimisation of process parameters for friction stir spot-welded AA3003-H12 aluminium alloy using a Taguchi orthogonal array. Mater. Des. 2014, 63, 789–797. [Google Scholar] [CrossRef]

- Tier, M.D.; Rosendo, T.S.; dos Santos, J.F.; Huber, N.; Mazzaferro, J.A.; Mazzaferro, C.P.; Strohaecker, T.R. The influence of refill FSSW parameters on the microstructure and shear strength of 5042 aluminium welds. J. Mater. Process. Technol. 2013, 213, 997–1005. [Google Scholar] [CrossRef]

- Yang, H.G.; Yang, H.J. Experimental investigation on refill friction stir spot welding process of aluminum alloys. Appl. Mech. Mater. 2013, 345, 243–246. [Google Scholar] [CrossRef]

- Lacki, P.; Derlatka, A. Experimental and numerical investigation of aluminium lap joints made by RFSSW. Meccanica 2016, 51, 455–462. [Google Scholar] [CrossRef]

- Kluz, R.; Kubit, A.; Wydrzyński, D. The effect of plunge depth on the strength properties of friction welded joints using the RFSSW method. Adv. Sci. Tech. Res. J. 2018, 12, 41–47. [Google Scholar] [CrossRef]

- Kluz, R.; Kubit, A.; Wydrzyński, D. The effect of RFSSW parameters on the load bearing capacity of aluminum 7075-T6 sheet metal joints. Adv. Sci. Tech. Res. J. 2018, 12, 35–41. [Google Scholar] [CrossRef]

- Yang, H.G.; Yang, H.J.; Hu, X. Simulation on the plunge stage in refill friction stir spot welding of Aluminum Alloys. In Proceedings of the 4th International Conference on Mechatronics, Materials, Chemistry and Computer Engineering, Xi’an, China, 12–13 December 2015; pp. 521–524. [Google Scholar]

- Simbi, D.J.; Schully, J.C. The effect of residual interstitial elements and iron on mechanical properties of commercially pure titanium. Mater. Lett. 1996, 26, 35–39. [Google Scholar] [CrossRef]

- Ouchi, C.; Iizumi, H.; Mitao, S. Effects of ultra-high purification and addition of interstitial elements on properties of pure titanium and titanium alloys. Mater. Sci. Eng. A 1998, 243, 186–195. [Google Scholar] [CrossRef]

- Malinov, S.; Sha, W.; Guo, Z.; Tang, C.C.; Long, A.E. Synchrotron X-ray diffraction study of the phase transformations in titanium alloys. Mater. Charact. 2002, 48, 279–295. [Google Scholar] [CrossRef]

- Choo, H.; Rangaswamy, P.; Bourke, M.A.M.; Larsen, J.M. Thermal expansion anisotropy in a Ti-6Al-4V/SiC composite. Mater. Sci. Eng. A 2002, 325, 236–241. [Google Scholar] [CrossRef]

- Pederson, R.; Babushkin, O.; Skystedt, F.; Warren, R. Use of high temperature X-ray diffractometry to study phase transitions and thermal expansion properties in Ti-6Al-4V. Mater. Sci. Technol. 2003, 19, 1533–1538. [Google Scholar] [CrossRef]

- Montanari, R.; Costanza, G.; Tata, M.E.; Testani, C. Lattice expansion of Ti-6Al-4V by nitrogen and oxygen absorption. Mater. Charact. 2008, 59, 334. [Google Scholar] [CrossRef]

- Che Haron, C.H.; Jawaid, A. The effect of machining on surface integrity of titanium alloy Ti–6%Al–4%V. J. Mater. Process. Technol. 2005, 166, 188–192. [Google Scholar] [CrossRef]

- Axinte, D.A.; Kritmanorot, M.; Axinte, M.; Gindy, N.N.Z. Investigations on belt polishing of heat-resistant titanium alloy. J. Mater. Process. Technol. 2005, 166, 398–404. [Google Scholar] [CrossRef]

- Ginting, A.; Nouari, M. Surface integrity of dry machined titanium alloys. Int. J. Mach. Tools Manuf. 2009, 49, 325–332. [Google Scholar] [CrossRef]

- Patil, S.; Jadhav, S.; Kekade, S.; Supare, A.; Powar, A.; Singh, R.K.P. The Influence of Cutting Heat on the Surface Integrity during Machining of Titanium Alloy Ti6Al4V. Procedia Manuf. 2016, 5, 857–869. [Google Scholar] [CrossRef]

- Veiga, C.; Davim, J.; Loureiro, A. Properties and applications of titanium alloys: A brief review. Rev. Adv. Mater. Sci. 2012, 32, 133–148. [Google Scholar]

- Jiang, X.J.; Jing, R.; Liu, C.Y.; Ma, M.Z.; Liu, R.P. Structure and mechanical properties of TiZr binary alloy after Al addition. Mater. Sci. Eng. A 2013, 586, 301–305. [Google Scholar] [CrossRef]

- Boyer, R.; Briggs, R. The use of beta titanium alloys in the aerospace industry. J. Mater. Eng. Perform. 2013, 22, 2916–2920. [Google Scholar]

- Cotton, J.D.; Briggs, R.D.; Boyer, R.R.; Tamirisakandala, S.; Russo, P.; Shchetnikov, N.; Fanning, J.C. State of the art in beta titanium alloys for airframe applications. JOM 2015, 67, 1281–1303. [Google Scholar] [CrossRef]

- Lu, J.; Zhao, Y.; Ge, P.; Zhang, Y.; Niu, H.; Zhang, W.; Zhang, P. Precipitation behavior and tensile properties of new high strength beta titanium alloy Ti-1300. J. Alloys Comp. 2015, 637, 1–4. [Google Scholar] [CrossRef]

- Wood, J.R.; Russo, P.A.; Welter, M.F.; Crist, E.M. Thermomechanical processing and heat treatment of Ti–6Al–2Sn–2Zr–2Cr–2Mo–Si for structural application. Mater. Sci. Eng. A 1998, 243, 109–118. [Google Scholar] [CrossRef]

- Cui, C.; Hu, B.M.; Zhao, L.; Liu, S. Titanium alloy production technology, market prospects and industry development. Mater. Des. 2011, 32, 1684–1691. [Google Scholar] [CrossRef]

- Jing, R.; Liang, S.X.; Liu, C.Y.; Ma, M.Z.; Zhang, X.Y.; Liu, R.P. Structure and mechanical properties of Ti–6Al–4V alloy after zirconium additio. Mater. Sci. Eng. A 2012, 552, 295–300. [Google Scholar] [CrossRef]

- Nourbakhsh, S.; Margolin, H. Fabrication of high temperature fiber reinforced intermetallic matrix composites. In Proceedings of the International Conference of Metal and Ceramic Matrix Composites: Processing, Modeling and Mechanical Behaviour, Anaheim, CA, USA, 19–22 February 1990; pp. 75–90. [Google Scholar]

- Mittnick, M.A. Continuous SiC Fibers Reinforced Metals. In Proceedings of the TMS Annual Meeting, Anaheim, CA, USA, 18–22 February 1990; p. 605. [Google Scholar]

- Upadhyaya, D.; Brydson, R.; Tsakiropoulos, P.; Ward-Close, C.M. A Comparison of SCS-6/Ti-6Al-4V and sigma SM1240/Ti-6Al-4V composite system: A microstructural characterization. In Recent Advances in Titanium Metal Matrix Composites; Froes, F.H., Storer, J., Eds.; TMS: Warrendale, PA, USA, 1994; pp. 139–154. [Google Scholar]

- Clyne, T.W. Metal matrix composites: Matrices and processing. In Encyclopaedia of Materials: Science and Technology, Composites: MMC, CMC, PMC; Mortensen, A., Ed.; Elsevier: Amsterdam, The Netherlands, 2001. [Google Scholar]

- Tata, M.E.; Montanari, R.; Testani, C.; Valdrè, G. Preparazione del composito Ti6Al4V+SiC fibre e sua evoluzione strutturale dopo trattamenti termici. Metall. Ital. 2005, 7–8, 43–50. [Google Scholar]

- Mezzi, A.; Donnini, R.; Kaciulis, S.; Montanari, R.; Testani, C. Composite of Ti6Al4V and SiC fibres: Evolution of fibre–matrix interface during heat treatments. Surf. Interface Anal. 2008, 40, 277–280. [Google Scholar]

- Donnini, R.; Kaciulis, S.; Mezzi, A.; Montanari, R.; Testani, C. Production and heat treatments of Ti6Al4V-SiCf composite. Part I- Microstructural characterization. Mater. Sci. Forum 2009, 604–605, 331–340. [Google Scholar]

- Deodati, P.; Donnini, R.; Montanari, R.; Testani, C.; Valente, T. Production and heat treatments of Ti6Al4V-SiCf composite. Part II- Mechanical characterization. Mater. Sci. Forum 2009, 604–605, 341–350. [Google Scholar]

- Deodati, P.; Donnini, R.; Montanari, R.; Testani, C. High temperature damping behaviour of Ti6Al4V+SiCf composite. Mater. Sci. Eng. A 2009, 521–522, 318–321. [Google Scholar] [CrossRef]

- Amadori, S.; Bonetti, E.; Deodati, P.; Donnini, R.; Montanari, R.; Pasquini, L.; Testani, C. Low temperature damping behaviour of Ti6Al4V+SiCf composite. Mater. Sci. Eng. A 2009, 521–522, 340–342. [Google Scholar] [CrossRef]

- Deodati, P.; Donnini, R.; Kaciulis, S.; Mezzi, A.; Montanari, R.; Testani, C. Microstructural characterisation of Ti6Al4V-SiCf composite produced by new roll-bonding process. Adv. Mater. Res. 2010, 89–91, 715–720. [Google Scholar] [CrossRef]

- Deodati, P.; Donnini, R.; Kaciulis, S.; Mezzi, A.; Montanari, R.; Testani, C.; Ucciardello, N. Anelastic phenomena at the fibre-matrix interface of the Ti6Al4V-SiCf composite. Key Eng. Mater. 2010, 425, 263–270. [Google Scholar] [CrossRef]

- Kaciulis, S.; Mezzi, A.; Donnini, R.; Deodati, P.; Montanari, R.; Ucciardello, N.; Amati, M.; Kazemian-Abyaneh, M.; Testani, C. Micro-chemical charaterization of carbon-metal interface in Ti6Al4V-SiCf composites. Surf. Interface Anal. 2010, 42, 707–711. [Google Scholar] [CrossRef]

- Testani, C.; Ferraro, F.; Deodati, P.; Donnini, R.; Montanari, R.; Kaciulis, S.; Mezzi, A. Comparison between roll diffusion bonding and hot isostatic pressing production processes of Ti6Al4V-SiCf metal matrix composites. Mater. Sci. Forum 2011, 678, 145–154. [Google Scholar] [CrossRef]

- Silvan, J.F.; Bihr, J.C.; Lepetitcorps, Y. EPMA and XPS studies of TiAlSiC interfacial chemical compatibility. Compos. Part A 1996, 27, 691–695. [Google Scholar] [CrossRef]

- Fu, Y.C.; Shi, N.L.; Zhang, D.Z.; Yang, R. Effect of C coating on the interfacial microstructure and properties of SiC fiber-reinforced Ti matrix composites. Mater. Sci. Eng. A 2006, 426, 278–282. [Google Scholar] [CrossRef]

- Van Vlack, L.H. Elements of Materials Science and Engineering, 5th ed.; Addison-Wesley: Boston, MA, USA, 1985. [Google Scholar]

- Swart, H.C.; Jonker, A.J.; Claassens, C.H.; Chen, R.; Venter, L.A.; Ramoshebe, P.; Wurth, E.; Terblans, J.J.; Roos, W.D. Extracting inter-diffusion parameters of TiC from AES depth profiles. Appl. Surf. Sci. 2003, 205, 231–239. [Google Scholar] [CrossRef]

- Luo, A.A. Magnesium casting technology for structural applications. J. Magn. Alloys 2013, 1, 2–22. [Google Scholar] [CrossRef]

- Luo, A.A.; Sadayappan, K. Technology for Magnesium Castings; American Foundry Society: Schaumburg, IL, USA, 2011; pp. 29–47. [Google Scholar]

- Bettles, C.; Gibson, M. Current wrought magnesium alloys: Strengths and weaknesses. JOM 2005, 57, 46–49. [Google Scholar] [CrossRef]

- Ostrovsky, I.; Henn, Y. Present state and future of magnesium application in aerospace industry. In Proceedings of the International Conference New Challenges in Aeronautics, ASTEC’07, Moscow, Russia, 19–22 August 2007. [Google Scholar]

- Mordike, B.L.; Ebert, T. Magnesium–properties–applications–potential. Mater. Sci. Eng. A 2001, 302, 37–45. [Google Scholar] [CrossRef]

- Pekguleryuz, M.; Labelle, P.; Argo, D. Magnesium die casting alloy AJ62x with superior creep resistance, ductility and die castability. J. Mater. Manuf. 2003, 112, 24–29. [Google Scholar]

- Yamashita, A.; Horita, Z.; Langdon, T.G. Improving the mechanical properties of magnesium and a magnesium alloy through severe plastic deformation. Mater. Sci. Eng. A 2001, 300, 142–147. [Google Scholar] [CrossRef]

- Jian, W.W.; Kang, Z.X.; Li, Y.Y. Effect of hot plastic deformation on microstructure and mechanical property of Mg–Mn–Ce magnesium alloy. Trans. Nonferr. Met. Soc. China 2007, 17, 1158–1163. [Google Scholar] [CrossRef]

- Ma, A.B.; Jiang, J.H.; Saito, N.; Shigematsu, I.; Yuan, Y.C.; Yang, D.H.; Nishida, Y. Improving both strength and ductility o f a Mg alloy through a large number of ECAP passes. Mater. Sci. Eng. A 2009, 513–514, 122–127. [Google Scholar] [CrossRef]

- Lian, J.S.; Valiev, R.Z.; Baudelet, B. On the enhanced grain growth in ultrafine grained metals. Acta Metall. Mater. 1995, 43, 4165–4170. [Google Scholar] [CrossRef]

- Wu, X.L.; Youssef, K.M.; Koch, C.C.; Mathaudhu, S.N.; Kecskes, L.J.; Zhu, Y.T. Deformation twinning in a nanocrystalline hcp Mg alloy. Scr. Mater. 2011, 64, 213–216. [Google Scholar] [CrossRef]

- Zhu, Y.T.; Liao, X.Z.; Wu, X.L. Deformation twinning in nanocrystalline materials. Prog. Mater. Sci. 2012, 57, 1–62. [Google Scholar] [CrossRef]

- Lu, K.; Lu, L.; Suresh, S. Strengthening materials by engineering coherent internal boundaries at the nanoscale. Science 2009, 324, 349–352. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Xu, Z.; Smith, C.; Sankar, J. Recent advances on the development of magnesium alloys for biodegradable implants. Acta Biomater. 2014, 10, 4561–4573. [Google Scholar] [CrossRef] [PubMed]

- Wen, Z.; Wu, C.; Dai, C.; Yang, F. Corrosion behaviors of Mg and its alloys with different Al contents in a modified simulated body fluid. J. Alloys Compd. 2009, 488, 392–399. [Google Scholar] [CrossRef]

- Zhang, B.; Geng, L.; Wang, Y. Research on Mg-Zn-Ca Alloy as Degradable Biomaterial. In Biomaterials Physics and Chemistry; Pignatello, R., Ed.; INTECH Open Access Publisher: Rijeka, Croatia, 2011; pp. 183–204. [Google Scholar]

- Song, Y.; Han, E.-H.; Shan, D.; Yim, C.D.; You, B.S. The effect of Zn concentration on the corrosion behavior of Mg–xZn alloys. Corros. Sci. 2012, 65, 322–330. [Google Scholar] [CrossRef]

- Homma, T.; Mendis, C.L.; Hono, K.; Kamado, S. Effect of Zr addition on the mechanical properties of as-extruded Mg–Zn–Ca–Zr alloys. Mater. Sci. Eng. A 2010, 527, 2356–2362. [Google Scholar] [CrossRef]

- Xu, D.K.; Tang, W.N.; Liu, L.; Xu, Y.B.; Han, E.H. Effect of Y concentration on the microstructure and mechanical properties of as-cast Mg–Zn–Y–Zr alloys. J. Alloys Compd. 2007, 432, 129–134. [Google Scholar] [CrossRef]

- Jian, W.W.; Cheng, G.M.; Xu, W.Z.; Yuan, H.; Tsai, M.H.; Wang, Q.D.; Koch, C.C.; Zhu, Y.T.; Mathaudhu, S.N. Ultrastrong Mg alloy via nano-spaced stacking faults. Mater. Res. Lett. 2013, 1, 61–66. [Google Scholar] [CrossRef]

- Inoue, A.; Kawamura, Y.; Matsushita, M.; Hayashi, K.; Koike, J. Novel hexagonal structure and ultrahigh strength of magnesium solid solution in the Mg–Zn–Y system. J. Mater. Res. 2001, 16, 1894–1900. [Google Scholar] [CrossRef]

- Cwiek, J. Prevention methods against hydrogen degradation of steel. J. Achiev. Mater. Manuf. Eng. 2010, 43, 214–221. [Google Scholar]

- Ukai, S.; Fujiwara, M. Perspective of ODS alloys application in nuclear environments. J. Nucl. Mater. 2002, 307–311, 749–757. [Google Scholar] [CrossRef]

- Klueh, R.L.; Gelles, D.S.; Jitsukawa, S.; Kimura, A.; Odette, G.R.; van der Schaaf, B.; Victoria, M. Ferritic/martensitic steels – overview of recent results. J. Nucl. Mater. 2002, 307–311, 455–465. [Google Scholar] [CrossRef]

- De Castro, V.; Leguey, T.; Muñoz, A.; Monge, M.A.; Fernández, P.; Lancha, A.M.; Pareja, R. Mechanical and microstructural behavior of Y2O3 ODS EUROFER 97. J. Nucl. Mater. 2007, 367–370, 196–201. [Google Scholar] [CrossRef]

- De Castro, V.; Leguey, T.; Auger, M.A.; Lozano-Perez, S.; Jenkins, M.L. Analytical characterization of secondary phases and void distributions in an ultrafine-grained ODS Fe-14Cr model alloy. J. Nucl. Mater. 2011, 417, 217–220. [Google Scholar] [CrossRef]

- De Carlan, Y.; Bechade, J.L.; Dubuisson, P.; Seran, J.L.; Billot, P.; Bougault, A.; Cozzika, T.; Doriot, S.; Hamon, D.; Henry, J.; et al. CEA developments of new ferritic ODS alloys for nuclear applications. J. Nucl. Mater. 2009, 386–388, 430–432. [Google Scholar] [CrossRef]

- Wang, M.; Zhou, Z.; Sun, H.; Hu, H.; Li, S. Microstructural observation and tensile properties of ODS-304 austenitic steel. Mater. Sci. Eng. A 2013, 559, 287–292. [Google Scholar] [CrossRef]

- Kasada, R.; Lee, S.G.; Isselin, J.; Lee, J.H.; Omura, T.; Kimura, A.; Okuda, T.; Inoue, M.; Ukai, S.; Ohnuki, S.; et al. Anisotropy in tensile and ductile–brittle transition behavior of ODS ferritic steels. J. Nucl. Mater. 2011, 417, 180–184. [Google Scholar] [CrossRef]

- Kawahara, M.; Kim, H.; Tokita, M. Fabrication of nano-materials by the spark plasma sintering (SPS) method. In Proceedings of the Powder Metallurgy World Congress, Kyoto, Japan, 12–16 November 2000; pp. 741–744. [Google Scholar]

- Zhang, H.W.; Gopalan, R.; Mukai, T.; Hono, K. Fabrication of bulk nanocrystalline Fe–C alloy by spark plasma sintering of mechanically milled powder. Scr. Mater. 2005, 53, 863–868. [Google Scholar] [CrossRef]

- De Sanctis, M.; Fava, A.; Lovicu, G.; Montanari, R.; Richetta, M.; Testani, C.; Varone, A. Mechanical characterization of a nano-ODS steel prepared by low-energy mechanical alloying. Metals 2017, 7, 283. [Google Scholar] [CrossRef]

- Fava, A.; Montanari, R.; Richetta, M.; Testani, C.; Varone, A. Analysis of strengthening mechanisms in nano-ODS steel depending on preparation route. J. Mater. Sci. Eng. 2018, 7, 1–10. [Google Scholar] [CrossRef]

- Serrano, M.; Hernández-Mayoral, M.; García-Junceda, A. Microstructural anisotropy effect on the mechanical properties of a 14Cr ODS steel. J. Nucl. Mater. 2012, 428, 103–109. [Google Scholar] [CrossRef]

- Deodati, P.; Montanari, R.; Tassa, O.; Ucciardello, N. Single crystal PWA 1483 superalloy: Dislocation rearrangement and damping phenomena. Mater. Sci. Eng. A 2009, 521–522, 102–105. [Google Scholar] [CrossRef]

- Costanza, G.; Montanari, R.; Richetta, M.; Tata, M.E.; Varone, A. Evaluation of structural stability of materials through Mechanical Spectroscopy. Four case studies. Metals 2016, 6, 306. [Google Scholar] [CrossRef]

- Montanari, R.; Tassa, O.; Varone, A. Early instability phenomena of IN792 DS superalloy. Mater. Sci. Forum 2017, 879, 2026–2031. [Google Scholar] [CrossRef]

- Pollock, T.M.; Argon, A.S. Creep resistance of CMSX-3 nickel base superalloy single crystals. Acta Metall. Mater. 1992, 40, 1. [Google Scholar] [CrossRef]

- Yeh, A.C.; Tin, S. Effects of Ru and Re additions on high temperature flow stresses of nickel-base single crystal superalloys. Scr. Mater. 2005, 52, 519–526. [Google Scholar] [CrossRef]

- Wang, W.-Z.; Jin, T.; Sun, X.-F.; Guan, H.-R.; Hu, Z.-Q. Role of Re and Co on microstructures and γ′ coarsening in single crystal superalloys. Mater. Sci. Eng. A 2008, 479, 148–158. [Google Scholar] [CrossRef]

- Tian, S.-G.; Liang, F.-S.; Li, A.-N.; Li, J.-J.; Qian, B.-J. Microstructure evolution and deformation features of single crystal nickel-based superalloy containing 4.2% Re during creep. Trans. Nonferrous Met. Soc. China 2011, 21, 1532–1537. [Google Scholar] [CrossRef]

- Kaciulis, S.; Mezzi, A.; Amati, M.; Montanari, R.; Angella, G.; Maldini, M. Relation between the Microstructure and Microchemistry in Ni-based Superalloy. Surf. Interf. Anal. 2012, 44, 982–985. [Google Scholar] [CrossRef]

- Rae, C.M.F.; Reed, R.C. The precipitation of topologically close-packed phases in rhenium-containing superalloys. Acta Mater. 2001, 49, 4113–4125. [Google Scholar] [CrossRef]

- Zhao, X.B.; Liu, L.; Yu, Z.H.; Zhang, W.G.; Fu, H.Z. Microstructure development of different orientated nickel-base single crystal superalloy in directional solidification. Mater. Charact. 2010, 61, 7. [Google Scholar] [CrossRef]

- Guan, X.; Liu, E.; Zheng, Z.; Yu, Y.; Tong, J.; Zhai, Y.; Zhai, Y. Solidification behavior and segregation of Re-containing cast Ni-base superalloy with different Cr content. J. Mater. Sci. Technol. 2011, 27, 113–117. [Google Scholar]

- Kearsey, R.M.; Beddoes, J.C.; Jones, P.; Au, P. Compositional design considerations for microsegregation in single crystal superalloy systems. Intermetallics 2004, 12, 903–910. [Google Scholar] [CrossRef]

- Zheng, L.; Gu, C.Q.; Zheng, Y.R. Investigation of the solidification behavior of a new Ru-containing cast Ni-base superalloy with high W content. Scr. Mater. 2004, 50, 435. [Google Scholar] [CrossRef]

- Huang, X.; Zhang, Y.; Liu, Y.; Hu, Z. Effect of small amount of nitrogen on carbide characteristics in unidirectional Ni-base superalloy. Metall. Mater. Trans. A 1997, 28, 2143–2147. [Google Scholar] [CrossRef]

- Bor, H.Y.; Chao, C.G.; Ma, C.Y. The influence of magnesium on carbide characteristics and creep behavior of the mar-m247 superalloy. Scr. Mater. 1998, 38, 329–335. [Google Scholar] [CrossRef]

- Kumar, M.; Schwartz, A.J.; King, W.E. Microstructural evolution during grain boundary engineering of low to medium stacking fault energy fcc materials. Acta Mater. 2002, 50, 2599–2612. [Google Scholar] [CrossRef]

- Jin, Y.; Bernacki, M.; Agnoli, A.; Lin, B.; Rohrer, G.S.; Rollett, A.D.; Bozzolo, N. Evolution of the annealing twin density during δ-supersolvus grain growth in the nickel-based superalloy Inconel 718. Metals 2016, 6, 5. [Google Scholar] [CrossRef]

- Kuppan, P.; Rajadurai, A.; Narayanan, S. Influence of EDM process parameters in deep hole drilling of Inconel 718. Int. J. Adv. Manuf. Technol. 2008, 38, 74–84. [Google Scholar] [CrossRef]

- Imran, M.; Mativenga, P.T.; Kannan, S.; Novovic, D. An experimental investigation of deep-hole microdrilling capability for a nickel-based superalloy. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2008, 222, 1589–1596. [Google Scholar] [CrossRef]

- Leigh, S.; Sezer, K.; Li, L.; Grafton-Reed, C.; Cuttell, M. Statistical analysis of recast formation in laser drilled acute blind holes in CMSX-4 nickel superalloy. Int. J. Adv. Manuf. Technol. 2009, 43, 1094–1105. [Google Scholar] [CrossRef]

- Okasha, M.M.; Mativenga, P.T.; Driver, N.; Li, L. Sequential laser and mechanical micro-drilling of Ni superalloy for aerospace application. CIRP Ann. 2010, 59, 199–202. [Google Scholar] [CrossRef]

- Soo, S.L.; Hood, R.; Aspinwall, D.K.; Voice, W.E.; Sage, C. Machinability and surface integrity of RR1000 nickel based superalloy. CIRP Ann. 2011, 60, 89–92. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Hao, L. Effect of Al alloys on selective laser melting behaviour and microstructure of in situ formed particle reinforced composites. J. Alloys Comp. 2012, 541, 328–334. [Google Scholar] [CrossRef]

- Song, B.; Dong, S.J.; Coddet, P.; Zhou, G.S.; Ouyang, S.; Liao, H.L.; Coddet, C. Microstructure and tensile behavior of hybrid nano-micro SiC reinforced iron matrix composites produced by selective laser melting. J. Alloys Compd. 2013, 579, 415–421. [Google Scholar] [CrossRef]

- Zhang, B.C.; Fenineche, N.E.; Liao, H.L.; Coddet, C. Microstructure and magnetic properties of Fe–Ni alloy fabricated by selective laser melting Fe/Ni mixed powders. J. Mater. Sci. Technol. 2013, 29, 757–760. [Google Scholar] [CrossRef]

- Zhang, B.C.; Liao, H.L.; Coddet., C. Microstructure evolution and density behavior of CP Ti parts elaborated by Self-developed vacuum selective laser melting system. Appl. Surf. Sci. 2013, 279, 310–316. [Google Scholar] [CrossRef]

- Murr, L.E.; Martinez, E.; Gaytan, S.M.; Ramirez, D.A.; Machado, B.I.; Shindo, P.W.; Martinez, J.L.; Medina, F.; Wooten, J.; Ciscel, D.; et al. Microstructural architecture, microstructures and mechanical properties for a Nickel-Base superalloy fabricated by electron beam melting. Metall. Mater. Trans. A 2011, 42, 3491–3508. [Google Scholar] [CrossRef]

- Helmer, H.E.; Körner, C.; Singer, R.F. Additive manufacturing of nickel-based superalloy Inconel 718 by selective electron beam melting: Processing window and microstructure. J. Mater. Res. 2014, 29, 1987–1996. [Google Scholar] [CrossRef]

- Ramsperger, M.; Singer, R.; Körner, C. Microstructure of the Nickel-Base superalloy CMSX-4 fabricated by selective electron beam melting. Metall. Mater. Trans. A 2016, 47, 1469–1480. [Google Scholar] [CrossRef]

- Jia, Q.; Gu, D. Selective laser melting additive manufacturing of Inconel 718 superalloy parts: Densification, microstructure and properties. J. Alloys Comp. 2014, 585, 713–721. [Google Scholar] [CrossRef]

- Song, B.; Dong, S.; Coddet, P.; Liao, H.; Coddet, C. Fabrication of NiCr alloy parts by selective laser melting: Columnar microstructure and anisotropic mechanical behaviour. Mater. Des. 2010, 53, 1–7. [Google Scholar] [CrossRef]

- Thijs, L.; Sistiaga, M.M.; Wauthlé, R.; Xie, Q.; Kruth, J.; Van Humbeeck, J. Strong morphological and crystallographic texture and resulting yield strength anisotropy in Selective Laser Melted tantalum. Acta Mater. 2013, 61, 4657–4668. [Google Scholar] [CrossRef]

- Geiger, F.; Kunze, K.; Etter, T. Tailoring the texture of IN738LC processed by selective laser melting (SLM) by specifc scanning strategies. Mater. Sci. Eng. 2016, 661, 240–246. [Google Scholar] [CrossRef]

- Popovich, V.A.; Borisov, E.V.; Popovich, A.A.; Suliarov, V.S.; Masaylo, D.V.; Alzina, L. Functionally graded Inconel 718 processed by additive manufacturing: Crystallographic texture, anisotropy of microstructure and mechanical properties. Mater. Des. 2017, 114, 441–449. [Google Scholar] [CrossRef]

- Parsa, A.B.; Ramsperger, M.; Kostka, A.; Somsen, C.; Körner, C.; Eggeler, G. Transmission electron microscopy of a CMSX-4 Ni-base superalloy produced by selective electron beam melting. Metals 2016, 6, 258. [Google Scholar] [CrossRef]

- David, S.A.; Vitek, J.M.; Babu, S.S.; Boatner, L.A.; Reed, R.W. Welding of nickel base superalloy single crystals. Sci. Technol. Weld. Join. 1997, 2, 79–88. [Google Scholar] [CrossRef]

- Ojo, O.A.; Richards, N.L.; Chaturvedi, M.C. Microstructural study of weld fusion zone of TIG welded IN 738LC nickel-based superalloy. Scr. Mater. 2004, 51, 683. [Google Scholar] [CrossRef]

- Henderson, M.B.; Arrell, D.; Heobel, M.; Larsson, R.; Marchanty, G. Nickel-based superalloy welding practices for industrial gas turbine applications. Sci. Technol. Weld. Join. 2013, 9, 13–21. [Google Scholar] [CrossRef]

- Jensen, M.V.R.S.; Dye, D.; James, K.E.; Korsunsky, A.M.; Roberts, S.M.; Reed, R.C. Residual stresses in a welded superalloy disc: Characterization using synchrotron diffraction and numerical process modeling. Metall. Trans. A 2002, 33, 2921. [Google Scholar] [CrossRef]

- Zapirain, F.; Zubiri, F.; Garciandía, F.; Tolosa, I.; Chueca, S.; Goiria, A. Development of laser welding of Ni based superalloys for aeronautic engine applications (experimental process and obtained properties). Phys. Procedia 2011, 12, 105–112. [Google Scholar] [CrossRef]

- Angella, G.; Barbieri, G.; Donnini, R.; Montanari, R.; Varone, A. Welding of IN792 DS superalloy by high energy density techniques. Mater. Sci. Forum 2017, 884, 166–177. [Google Scholar] [CrossRef]

- Barbieri, G.; Bifaretti, S.; Bonaiuto, V.; Montanari, R.; Richetta, M.; Varone, A. Laser beam welding of IN792 DS superalloy. Mater. Sci. Forum 2018, 941, 1149–1154. [Google Scholar] [CrossRef]

- Chen, G.Q.; Zhang, B.; Lu, T.; Feng, J.C. Causes and control of welding cracks in electron-beam-welded superalloy GH4169 joints. Trans. Nonferrous Met. Soc. China 2013, 23, 1971–1976. [Google Scholar] [CrossRef]

- Montanari, R.; Varone, A.; Barbieri, G.; Soltani, P.; Mezzi, A.; Kaciulis, S. Welding of IN792 DS superalloy by electron beam. Surf. Interface Anal. 2016, 48, 483–487. [Google Scholar] [CrossRef]

- Barbieri, G.; Soltani, P.; Kaciulis, S.; Montanari, R.; Varone, A. IN792 DS superalloy: Optimization of EB welding and post-welding heat treatments. Mater. Sci. Forum 2017, 879, 175–180. [Google Scholar] [CrossRef]

- Angella, G.; Barbieri, G.; Donnini, R.; Montanari, R.; Richetta, M.; Varone, A. Electron beam welding of IN792 DS: Effects of pass speed and PWHT on microstructure and hardness. Materials 2017, 10, 1033. [Google Scholar] [CrossRef]

- Huang, C.A.; Wang, T.H.; Lee, C.H.; Han, W. A study of the heat-affected zone (HAZ) of an Inconel 718 sheet welded with electron-beam welding (EBW). Mater. Sci. Eng. A 2005, 398, 275–281. [Google Scholar] [CrossRef]

- Ferro, P.; Zambon, A.; Bonollo, F. Investigation of electron-beam welding in wrought Inconel 706, experimental and numerical analysis. Mater. Sci. Eng. A 2005, 392, 94–105. [Google Scholar] [CrossRef]

| Aircraft Sections | Section Parts | Load Condition | Engineering Properties |

|---|---|---|---|

| Fuselage/Pressure cabin | Lower skin | Compression | CYS, E, CR |

| Upper skin | Tension | DT, YS | |

| Stringers/Frame | CYS, E, DT, YS | ||

| Seat/cargo tracks | YS, CR | ||

| Floor beams | E, YS | ||

| Upper wing | Skin/Stringers | Compression | High CYS, E, DT |

| Spars | CYS, E, CR | ||

| Lower wing | Skin/Stringers/Spars | Tension | High DT, YS |

| Horizontal stabilizers | Lower | Compression | CYS, E, DT |

| Upper | Tension | DT, YS |

| Boeing Series | Al Alloys | Ti Alloys | Steels | Composites | Others |

|---|---|---|---|---|---|

| 747 | 81 | 4 | 13 | 1 | 1 |

| 757 | 78 | 6 | 12 | 3 | 1 |

| 767 | 80 | 2 | 14 | 3 | 1 |

| 777 | 70 | 7 | 11 | 11 | 1 |

| 787 | 20 | 15 | 10 | 50 | 5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gloria, A.; Montanari, R.; Richetta, M.; Varone, A. Alloys for Aeronautic Applications: State of the Art and Perspectives. Metals 2019, 9, 662. https://doi.org/10.3390/met9060662

Gloria A, Montanari R, Richetta M, Varone A. Alloys for Aeronautic Applications: State of the Art and Perspectives. Metals. 2019; 9(6):662. https://doi.org/10.3390/met9060662

Chicago/Turabian StyleGloria, Antonio, Roberto Montanari, Maria Richetta, and Alessandra Varone. 2019. "Alloys for Aeronautic Applications: State of the Art and Perspectives" Metals 9, no. 6: 662. https://doi.org/10.3390/met9060662

APA StyleGloria, A., Montanari, R., Richetta, M., & Varone, A. (2019). Alloys for Aeronautic Applications: State of the Art and Perspectives. Metals, 9(6), 662. https://doi.org/10.3390/met9060662