Root Cause Analysis of Surface Cracks in Heavy Steel Plates during the Hot Rolling Process

Abstract

:1. Introduction

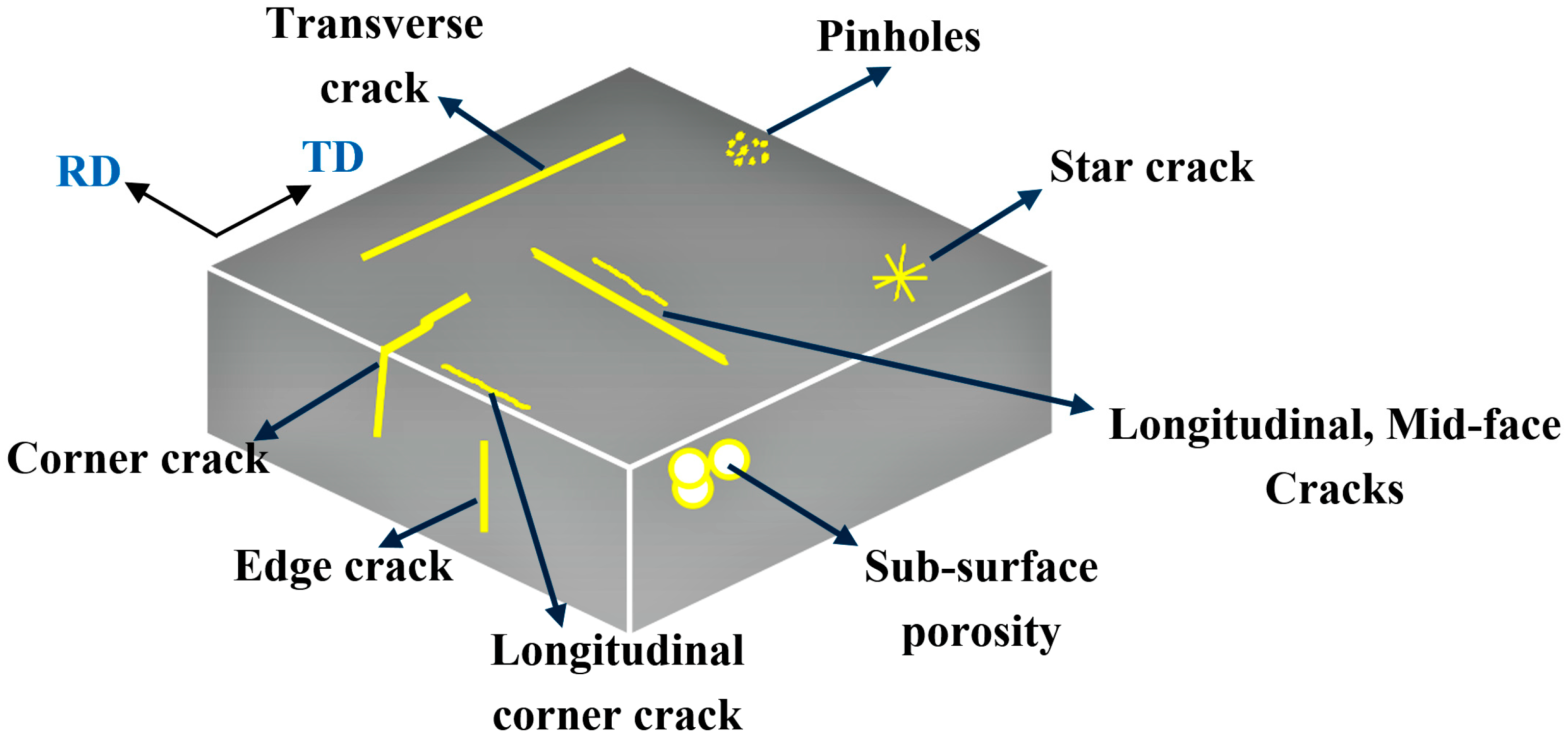

2. Background

3. Experimental

4. Results and Discussion

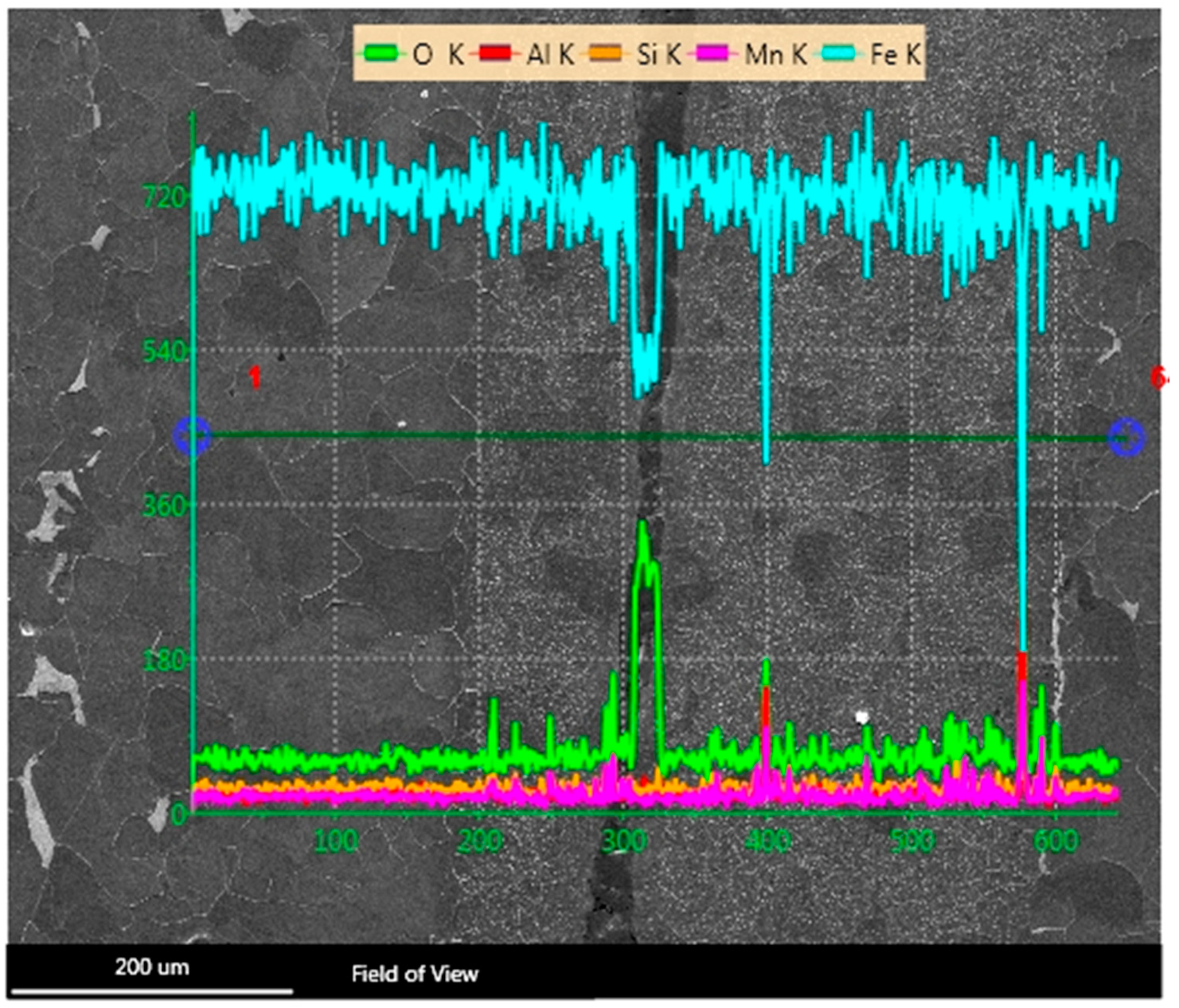

4.1. Microstructure of As-Received Slabs (before Hot Rolling)

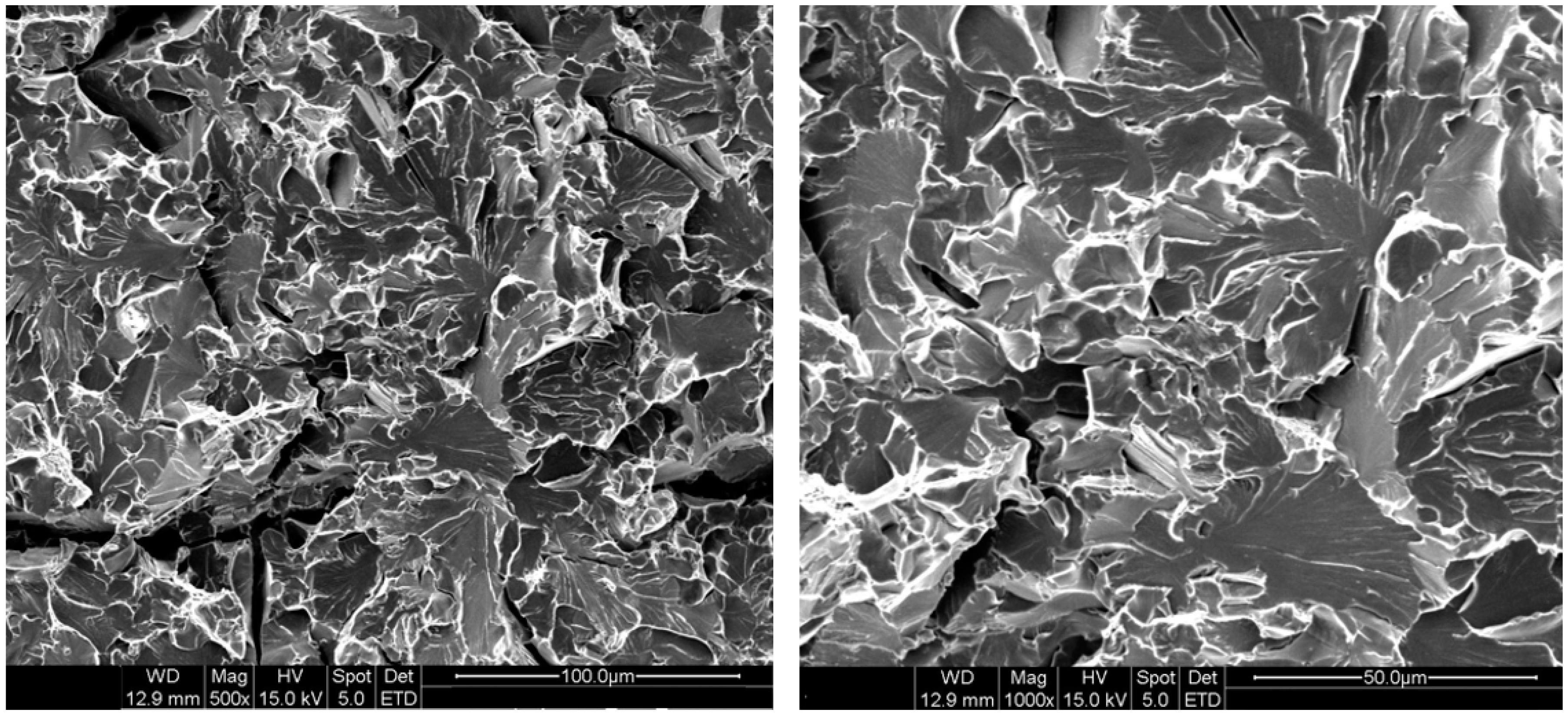

4.2. Microstructure of Heavy Plates

5. Concluding Remarks

- (1)

- Cracks are evenly distributed all over the surface of heavy plates and are oriented in the rolling direction.

- (2)

- Cracks are more accumulated in isolated colonies, with their sizes ranging from a few centimetres to a few tens of centimetres. The depths of cracks are up to a few hundred micrometres.

- (3)

- Cracks are nucleated at the tip of V-notches, existing at the surface of slabs.

- (4)

- Cracks end up in deer-horn branching.

- (5)

- In most cases cracks are fully filled with an iron oxide.

- (6)

- The area at the vicinity of cracks are heavily de-carburized, in such a way that in most cases the structure adjacent to the crack is fully ferritic.

- (7)

- Cracking in this case has nothing to do with the chemistry of the alloy and inclusions.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- BrimacombeK, J.K.; Sorimachi, K. Crack formation in the continuous casting of steel. Metall. Trans. B 1977, 8, 489–505. [Google Scholar] [CrossRef]

- Veitch-Michaelis, J.; Tao, Y.; Walton, D.; Muller, J.-P.; Crutchley, B.; Storey, J.; Paterson, C.; Chown, A. Crack detection in "as-cast" steel using laser triangulation and machine learning. In Proceedings of the 13th Conference on Computer and Robot Vision (CRV), Victoria, BC, Canada, 1–3 June 2016. [Google Scholar]

- Tang, Z.; Huang, J.; Lu, X.; Ding, H.; Zhang, D.; Misra, D. Superior mechanical properties and work-hardening ability of ultrafine-grained quenched and partitioned steels processed by a novel approach involving asymmetric hot rolling. Metals 2018, 8, 872. [Google Scholar] [CrossRef]

- Pandey, J.C.; Raj, M.; Choubey, P.N. Split ends and cracking problem during hot rolling of continuously cast steel billets. J. Fail. Anal. Preven. 2009, 9, 88–96. [Google Scholar] [CrossRef]

- Srikanth, S.; Ray, A.; Chaudhuri, S.K. On the occurrences of ‘‘frizzle-type’’ surface defects in a hot-rolled steel plate. J. Fail. Anal. Preven. 2009, 9, 275–281. [Google Scholar] [CrossRef]

- Yu, H.; Tieu, K.; Lu, C.; Deng, G.Y.; Liu, X.H. Occurrence of surface defects on strips during hot rolling process by FEM. Int. J. Adv. Manuf. Technol. 2013, 67, 1161–1170. [Google Scholar] [CrossRef]

- Hwang, B.; Lee, H.S.; Kim, Y.G.; Lee, S. Analysis and prevention of side cracking phenomenon occurring during hot rolling of thick low-carbon steel plates. Mat. Sci. Eng. A 2005, 402, 177–187. [Google Scholar] [CrossRef]

- Sarkar, P.P.; Dhua, S.K.; Thakur, S.K.; Rath, S. Analysis of the surface defects in a hot-rolled low-carbon C–Mn steel plate. J. Fail. Anal. Preven. 2017, 17, 545–553. [Google Scholar] [CrossRef]

- Kwon, H.C.; Lee, H.W.; Kim, H.Y.; Im, Y.T.; Park, H.D.; Lee, D.L. Surface wrinkle defect of carbon steel in the hot bar rolling process. J. Mater. Processing. Techol. 2009, 209, 4476–4483. [Google Scholar] [CrossRef]

- Papaefthymiou, S.A. Root cause analysis of surface and internal defects of micro-alloyed S355 heavy plates. Int. J. Struct. Integrity 2013, 4, 91–107. [Google Scholar] [CrossRef]

- Mukherjee, M.; Pal, T.K. Role of microstructural constituents on surface crack formation during hot rolling of standard and low nickel austenitic stainless steels. Acta Metall. Sinica 2013, 26, 206–216. [Google Scholar] [CrossRef] [Green Version]

- Thomas, B.G.; Jenkins, M.S.; Mahapatra, R.B. Investigation of strand surface defects using mould instrumentation and modelling. Ironmak. Steelmak. 2004, 31, 485–494. [Google Scholar] [CrossRef]

- Manojlovic, R.; Ilievski, R. Influence of the processing conditions on the hot-rolled manganese steel sheet surface quality. TEM J. 2013, 2, 166–169. [Google Scholar]

- Utsunomiya, H.; Hara, K.; Matsumoto, R.; Azushima, A. Formation mechanism of surface scale defects in hot rolling process. CIRP Ann. Manuf. Technol. 2104, 63, 261–264. [Google Scholar] [CrossRef]

- Kiani Khouzani, M.; Bahrami, A.; Eslami, A. Metallurgical aspects of failure in a broken femoral HIP prosthesis. Eng. Fail. Anal. 2018, 90, 168–178. [Google Scholar] [CrossRef]

- Ervasti, E.; Ståhlberg, U. Behaviour of longitudinal surface cracks in the hot rolling of steel slabs. J. Mater. Process. Technol. 1999, 94, 141–150. [Google Scholar] [CrossRef]

- Kudoh, M.; Itoh, Y. Trials for reducing depth of oscillation marks in continuous casting. Steel Res. Int. 2016, 74, 147–152. [Google Scholar] [CrossRef]

- TakeuchiJ, E.; Brimacombe, K. The formation of oscillation marks in the continuous casting of steel slabs. Metall. Trans. B 1984, 15, 493–509. [Google Scholar] [CrossRef]

- Porter, D.A.; Easterling, K.E. Phase Transformations in Metals and Alloys; Van Nostrand Reinhold Co Ltd.: Wokingham, UK, 1984.

- Callister, W.D., Jr.; Rethwisch, D.G. Materials Science and Engineering: an Introduction, 8th ed.; John Wiley and Sons: New York, NY, USA, 2009. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bahrami, A.; Kiani Khouzani, M.; Mokhtari, S.A.; Zareh, S.; Yazdan Mehr, M. Root Cause Analysis of Surface Cracks in Heavy Steel Plates during the Hot Rolling Process. Metals 2019, 9, 801. https://doi.org/10.3390/met9070801

Bahrami A, Kiani Khouzani M, Mokhtari SA, Zareh S, Yazdan Mehr M. Root Cause Analysis of Surface Cracks in Heavy Steel Plates during the Hot Rolling Process. Metals. 2019; 9(7):801. https://doi.org/10.3390/met9070801

Chicago/Turabian StyleBahrami, Abbas, Mahdi Kiani Khouzani, Seyed Amirmohammad Mokhtari, Shahin Zareh, and Maryam Yazdan Mehr. 2019. "Root Cause Analysis of Surface Cracks in Heavy Steel Plates during the Hot Rolling Process" Metals 9, no. 7: 801. https://doi.org/10.3390/met9070801

APA StyleBahrami, A., Kiani Khouzani, M., Mokhtari, S. A., Zareh, S., & Yazdan Mehr, M. (2019). Root Cause Analysis of Surface Cracks in Heavy Steel Plates during the Hot Rolling Process. Metals, 9(7), 801. https://doi.org/10.3390/met9070801