Effect of Parameters Change on the Weld Appearance in Stainless Steel Underwater Wet Welding with Flux-Cored Wire

Abstract

:1. Introduction

2. Materials and Methods

3. Results

4. Conclusions

- (1)

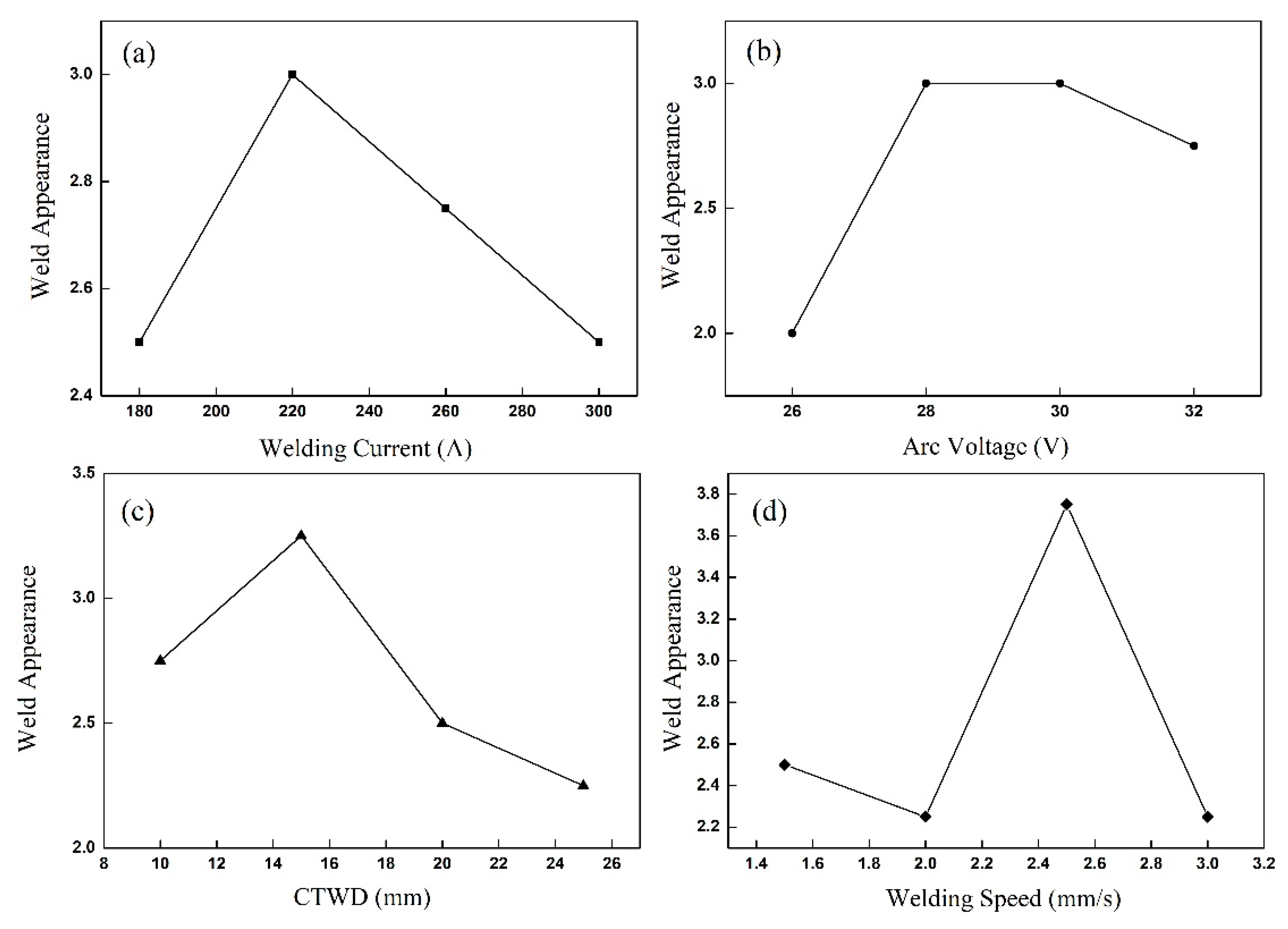

- Experiments have shown that the weld formation of stainless steel UWW increases as the parameters raising. When the welding parameters reach a certain size, the weld formation begins to deteriorate.

- (2)

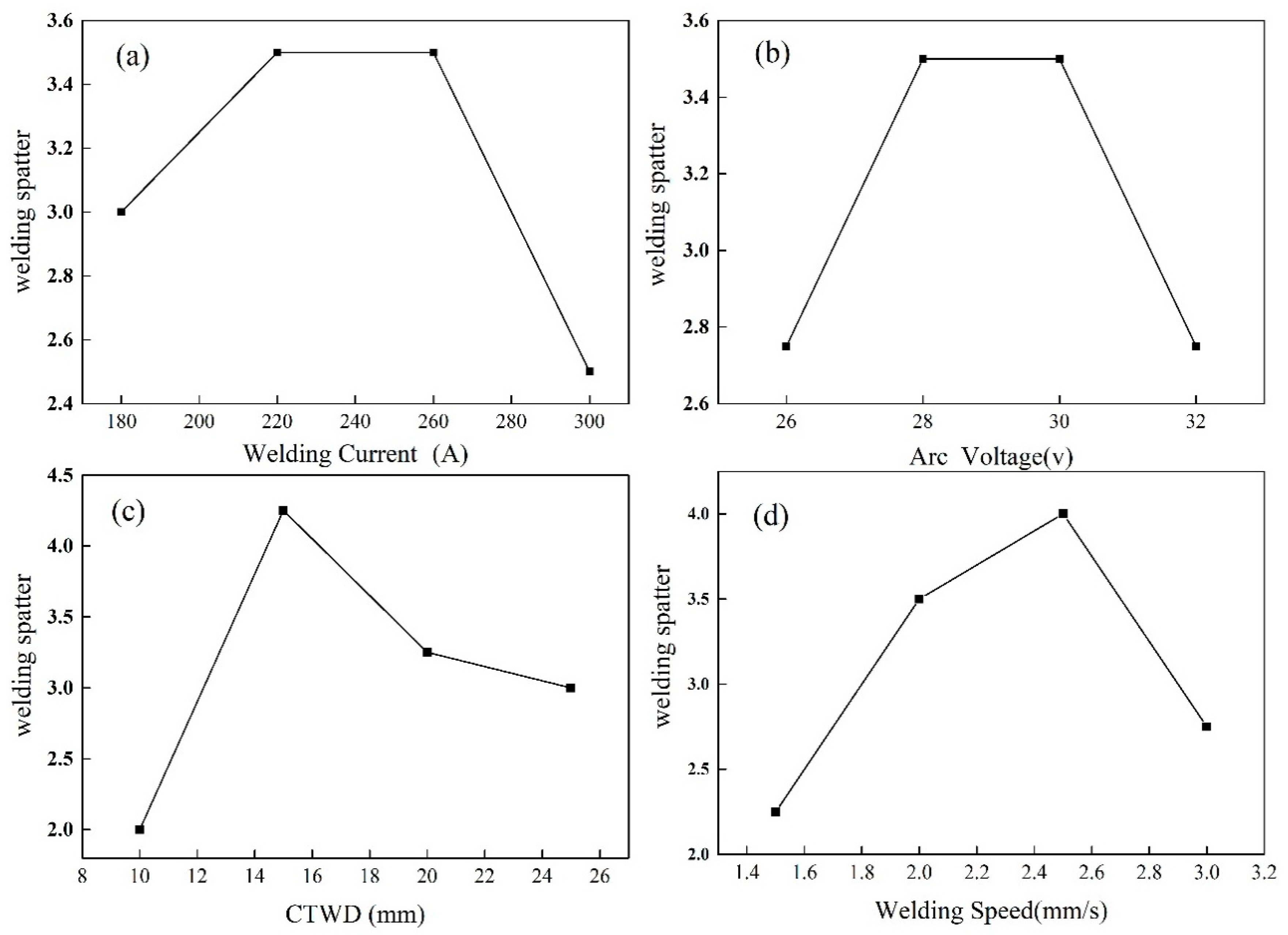

- The stainless steel UWW spatter is mainly affected by the welding speed. When the welding speed is low, it will produce more spatter. After the welding speed reaches 2.0 mm/s, the larger current and smaller voltage can reduce the welding spatter.

- (3)

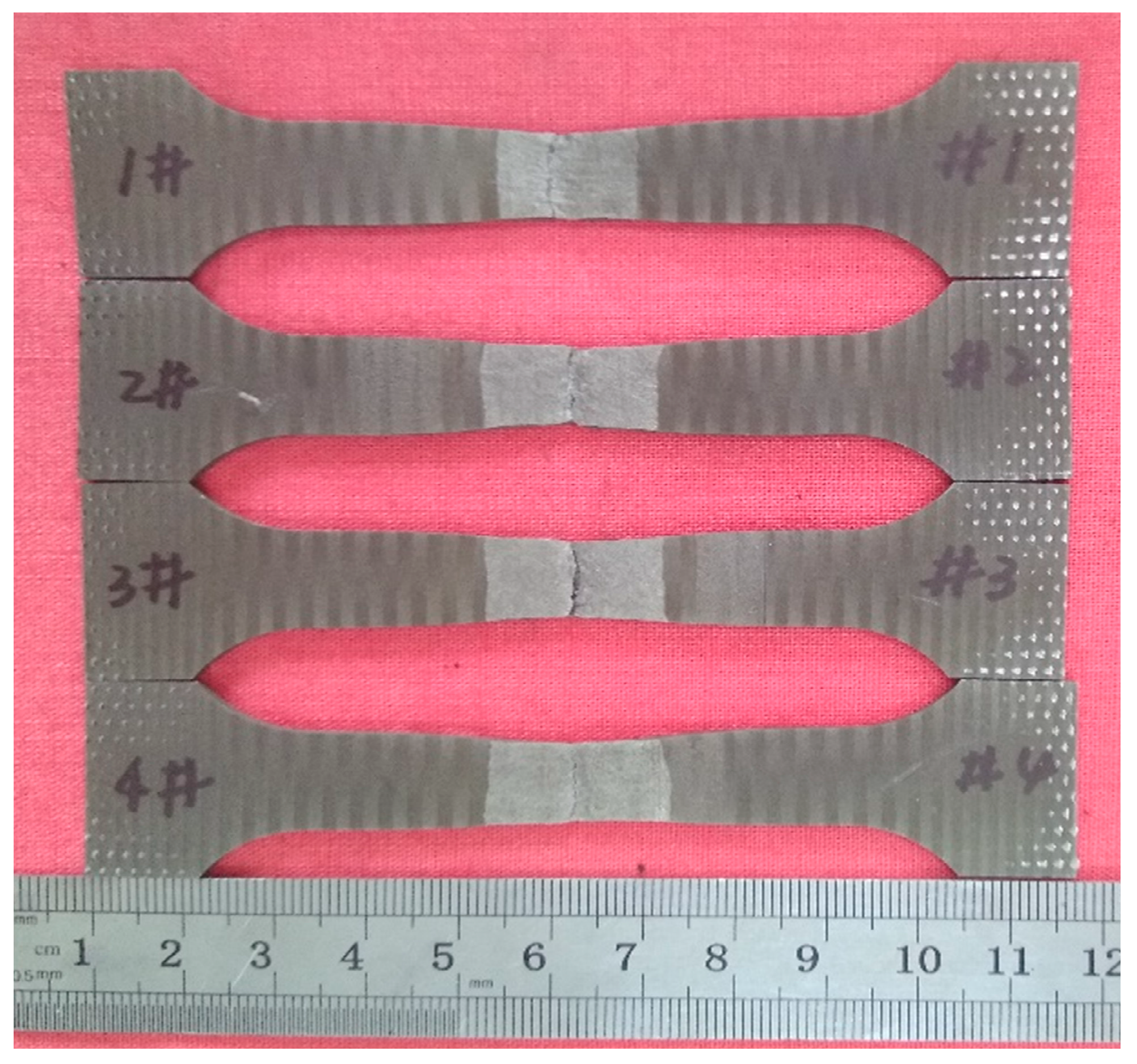

- The optimum parameters of weld appearance of stainless steel UWW were 200 A-29 V-15 mm-2.0 mm/s. Under this parameter, the maximum tensile strength is 545 MPa, and the maximum impact toughness is 132 J/cm2, which are 73% and 79% of the base metal, respectively.

Author Contributions

Funding

Conflicts of Interest

References

- Guo, N.; Xu, C.S.; Du, Y.P. Influence of calcium fluoride on underwater wet welding process stability. Weld. World 2018, 63, 107–116. [Google Scholar] [CrossRef]

- Kralj, S.; Garašić, I.; Kožuh, Z. Diffusible hydrogen in underwater wet welding. Weld. World 2008, 52, 687–692. [Google Scholar]

- Łabanowski, J. Development of under-water welding techniques. J. Weld. Int. 2011, 25, 933–937. [Google Scholar] [CrossRef]

- Nemchinsky, V.A. Plasma parameters near a small anode in a high-pressure arc (gas metal arc welding). J. Phys. D Appl. Phys. 1994, 27, 2515–2521. [Google Scholar] [CrossRef]

- Pessoa, E.C.P.; Bracarense, A.Q.; Zica, E.M.; Liu, S.; Perez-Guerrero, F. Porosity variation along multipass underwater wet welds and its influence on mechanical properties. J. Mater. Process. Technol. 2006, 179, 239–243. [Google Scholar] [CrossRef]

- Rowe, M.D.; Liu, S.; Reynolds, T.J. The effect of ferro-alloy additions and depth on the quality of underwater wet welds. Weld. J. 2002, 8, 156–S. [Google Scholar]

- Li, H.L.; Liu, D.; Ma, Q.; Guo, N.; Song, X.G.; Feng, J.C. Microstructure and mechanical properties of dissimilar welds between 16Mn and 304L in underwater wet welding. Sci. Technol. Weld. Join. 2018, 4, 1–7. [Google Scholar] [CrossRef]

- Richardson, I.M.; Bucknall, P.W.; Stares, I. The influence of power source dynamics on wire melting rate in pulsed GMA welding. Weld. J.-N. Y. 1994, 73, 32–37. [Google Scholar]

- Zhang, Y.; Jia, C.B.; Zhao, B.; Hu, J.K.; Wu, C.S. Heat input and metal transfer influences on the weld geometry and microstructure during underwater wet FCAW. J. Mater. Process. Technol. 2016, 238, 373–382. [Google Scholar] [CrossRef]

- Jia, C.B.; Zhang, T.; Maksimov, S.Y.; Yuan, X. Spectroscopic analysis of the arc plasma of underwater wet flux-cored arc welding. J. Mater. Process. Technol. 2013, 213, 1370–1377. [Google Scholar] [CrossRef]

- Shi, Y.H.; Zheng, Z.-P.; Huang, J. Sensitivity model for prediction of bead geometry in underwater wet flux cored arc welding. Trans. Nonferr. Met. Soc. China 2013, 23, 1977–1984. [Google Scholar] [CrossRef]

- Fu, Y.L.; Guo, N.; Du, Y.P.; Chen, H.; Xu, C.S.; Feng, J.C. Effect of metal transfer mode on spatter and arc stability in underwater flux cored wire wet welding. J. Manuf. Process. 2018, 35, 161–168. [Google Scholar] [CrossRef]

- Molleda, F.; Mora, J.; Molleda, J.R.; Mora, E.; Mellor, Y.B.G. The importance of spatter formed in shielded metal arc welding. Mater. Charact. 2007, 58, 936–940. [Google Scholar] [CrossRef]

- Guo, N.; Du, Y.P.; Maksimov, S.; Feng, J.C.; Yin, Z.Q.; Krazhanovskyi, D.; Fu, Y.L. Study of metal transfer control in underwater wet FCAW using pulsed wire feed method. Weld. Word 2018, 62, 87–94. [Google Scholar] [CrossRef]

- Chen, H.; Guo, N.; Huang, L.; Zhang, X.; Feng, J.C.; Wang, G.D. Effects of arc bubble behaviors and characteristics on droplet transfer in underwater wet welding using in-situ imaging method. Mater. Des. 2019, 170, 107696. [Google Scholar] [CrossRef]

- Zhang, X.; Guo, N.; Xu, C.S.; Du, Y.P.; Chen, B.; Feng, J.C. Influence of CaF2 on microstructural characteristics and mechanical properties of 304 stainless steel underwater wet welding using flux-cored wire. J. Manuf. Process. 2019, 9, 138–146. [Google Scholar] [CrossRef]

- Zhang, M.J.; Chen, S.; Zhang, Y.Z.; Chen, Y.Z.; Chen, G.Y.; Bi, Z.M. Mechanisms for improvement of weld appearance in autogenous fiber laser welding of thick stainless steels. Metals 2018, 8, 625. [Google Scholar] [CrossRef]

| Element | Cr | Ni | Si | Mn | C | P | S |

|---|---|---|---|---|---|---|---|

| Content (%) | 18.0–20.0 | 8.0–10.5 | ≤1.0 | ≤2.0 | ≤0.08 | ≤0.045 | ≤0.03 |

| Thickness | Tensile Strength | Impact Toughness | Hardness |

|---|---|---|---|

| 10 mm | 712 MPa | 182 J/cm2 | 235 HV |

| Specimen Number | Welding Current (A) | Arc Voltage (V) | CTWD (mm) | Welding Speed (mm/s) | Forming | Spatter |

|---|---|---|---|---|---|---|

| 1 | 180 | 26 | 25 | 1.5 | 1 | 2 |

| 2 | 180 | 28 | 20 | 2 | 2 | 4 |

| 3 | 180 | 30 | 15 | 2.5 | 5 | 5 |

| 4 | 180 | 32 | 10 | 3 | 2 | 1 |

| 5 | 220 | 26 | 20 | 2.5 | 3 | 4 |

| 6 | 220 | 28 | 25 | 3 | 3 | 3 |

| 7 | 220 | 30 | 10 | 1.5 | 3 | 2 |

| 8 | 220 | 32 | 15 | 2 | 3 | 5 |

| 9 | 260 | 26 | 15 | 3 | 2 | 4 |

| 10 | 260 | 28 | 10 | 2.5 | 4 | 4 |

| 11 | 260 | 30 | 25 | 2 | 2 | 4 |

| 12 | 260 | 32 | 20 | 1.5 | 3 | 2 |

| 13 | 300 | 26 | 10 | 2 | 2 | 1 |

| 14 | 300 | 28 | 15 | 1.5 | 3 | 3 |

| 15 | 300 | 30 | 20 | 3 | 2 | 3 |

| 16 | 300 | 32 | 25 | 2.5 | 3 | 3 |

| Welding Current | Arc Voltage | CTWD | Welding Speed |

|---|---|---|---|

| 200 A | 29 V | 15 mm | 2.0 mm/s |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, N.; Zhang, X.; Xu, C.; Chen, H.; Fu, Y.; Cheng, Q. Effect of Parameters Change on the Weld Appearance in Stainless Steel Underwater Wet Welding with Flux-Cored Wire. Metals 2019, 9, 951. https://doi.org/10.3390/met9090951

Guo N, Zhang X, Xu C, Chen H, Fu Y, Cheng Q. Effect of Parameters Change on the Weld Appearance in Stainless Steel Underwater Wet Welding with Flux-Cored Wire. Metals. 2019; 9(9):951. https://doi.org/10.3390/met9090951

Chicago/Turabian StyleGuo, Ning, Xin Zhang, Changsheng Xu, Hao Chen, Yunlong Fu, and Qi Cheng. 2019. "Effect of Parameters Change on the Weld Appearance in Stainless Steel Underwater Wet Welding with Flux-Cored Wire" Metals 9, no. 9: 951. https://doi.org/10.3390/met9090951

APA StyleGuo, N., Zhang, X., Xu, C., Chen, H., Fu, Y., & Cheng, Q. (2019). Effect of Parameters Change on the Weld Appearance in Stainless Steel Underwater Wet Welding with Flux-Cored Wire. Metals, 9(9), 951. https://doi.org/10.3390/met9090951