Mechanical Properties of Ultra-High Performance Concrete with Partial Utilization of Waste Foundry Sand

Abstract

1. Introduction

2. Materials and Methods

2.1. Cementing Materials

2.2. Natural Aggregates and Waste Foundry Sand

2.3. Mixture Proportions

2.4. Preparation and Casting of UHPC Specimens

3. Results and Discussion

3.1. Physical Properties

3.2. Compressive Strength

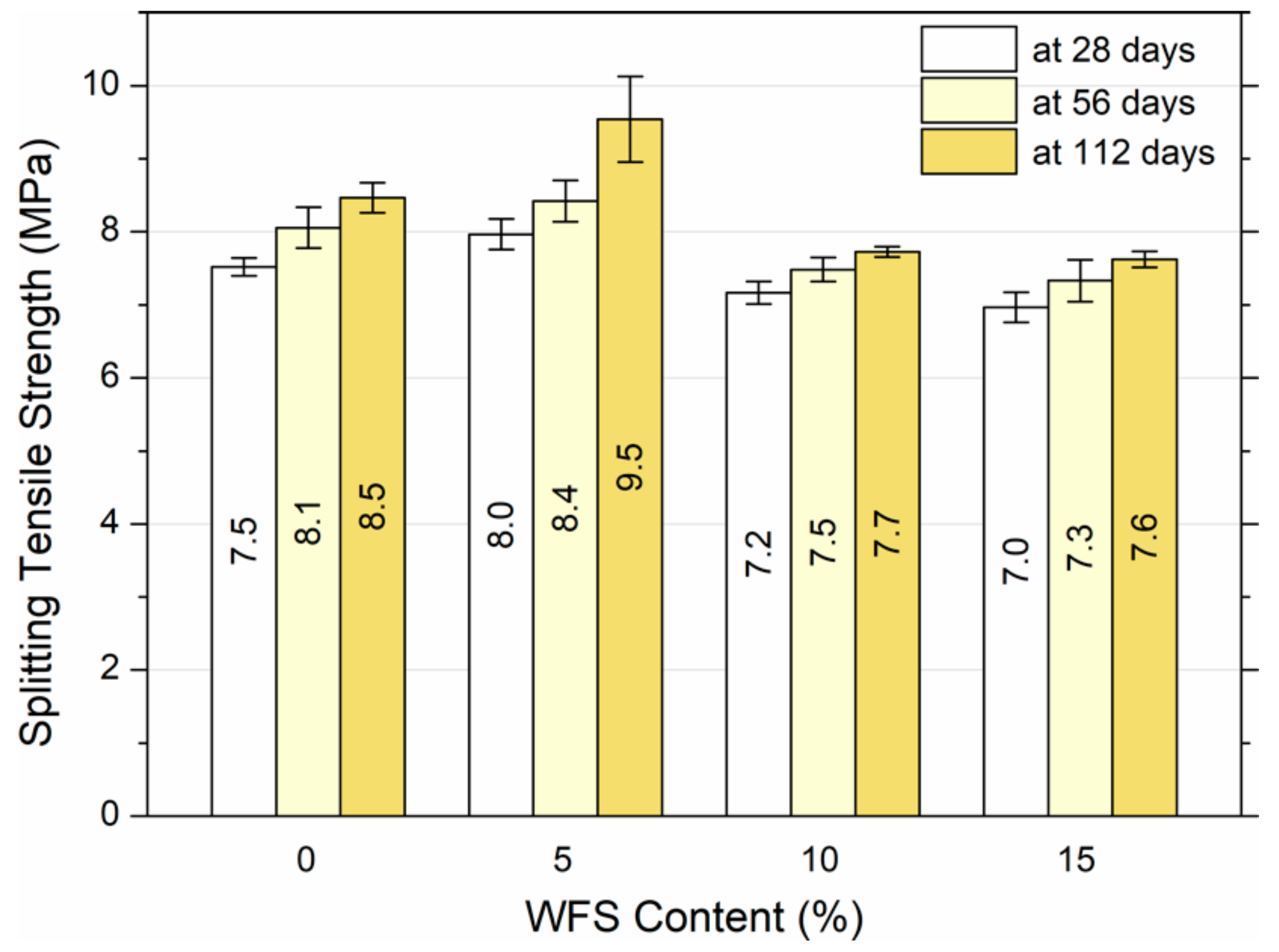

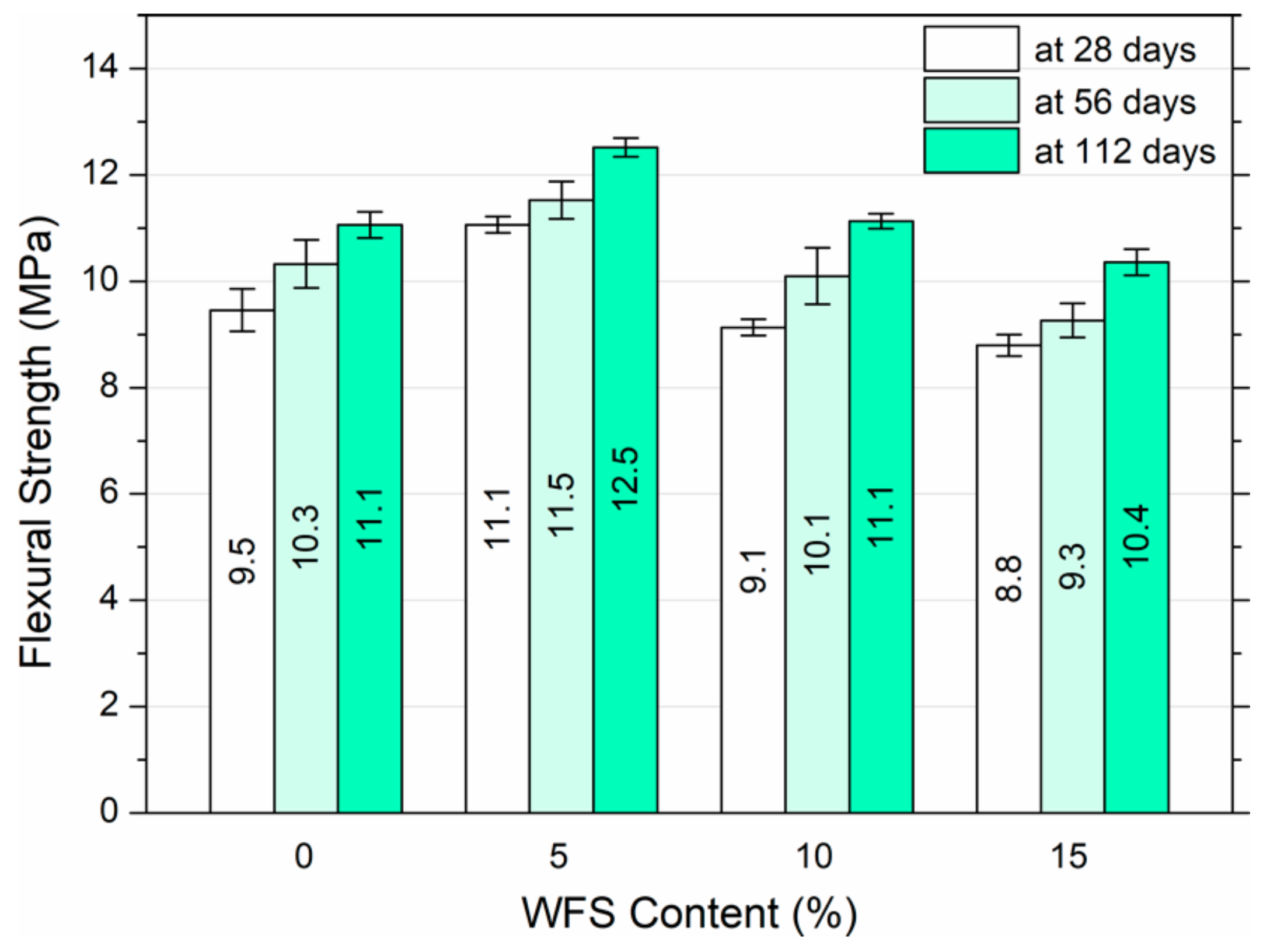

3.3. Splitting Tensile and Flexural Strength

3.4. Modulus of Elasticity

3.5. Microsturucture

4. Conclusions

- The workability falls with a rise in WFS content. Therefore, the reduced workability affects the consolidation, fresh density, as well as the mechanical and physical properties of UHPC.

- The compressive, splitting tensile, flexural strengths as well as elastic modulus of UHPC increase with 5% WFS replacement.

- None of the tested properties of UHPC exhibit decreases more than 10% with a 10% WFS replacement.

- The compressive, flexural, and splitting tensile strengths, as well as the elastic modulus of UHPC decrease in the specimens produced with 15% WFS.

- Improvement in the microstructure of UHPC is observed due to the large C-S-H gel formation up to 5% WFS replacement. When the WFS level is increased a reduction in mechanical strength is noted because of excess WFS fine particles and insoluble residues.

- Based on the results gathered in this study, the optimum replacement amount of WFS in UHPC is about 5% by weight of quartz sand.

Funding

Acknowledgments

Conflicts of Interest

References

- Foundry Industry Recycling Starts Today. Foundry Sand Facts for Civil Engineers; Technical Report No. FHWA-IF-04-004; EPA: Washington, DC, USA, 2004. [Google Scholar]

- Siddique, R.; Schutter, G.; Noumowe, A. Effect of used-foundry sand on the mechanical properties of concrete. Constr. Build. Mater. 2009, 23, 976–980. [Google Scholar] [CrossRef]

- Etxeberria, M.; Pacheco, C.; Meneses, J.M.; Berridi, I. Properties of concrete using metallurgical industrial by-products as aggregates. Constr. Build. Mater. 2010, 24, 1594–1600. [Google Scholar] [CrossRef]

- Siddique, R.; Singh, G. Utilization of waste foundry sand (WFS) in concrete manufacturing. Resour. Conserv. Recycl. 2011, 55, 885–892. [Google Scholar] [CrossRef]

- ABIFA. ABIFA 2016 Directory; Brazilian Foundry Association: Sao Paolo, Brazil, 2016. [Google Scholar]

- Żmudzińska, M.; Latała-Holtzer, M. Odpadowe masy formierskie—Możliwości ich utylizacji. Archiwum Odlewnictwa 2004, 4, 261–268. (In Polish) [Google Scholar]

- Dańko, J.; Dańko, R.; Łucarz, M. Procesy i Urządzenia do Regeneracji Osnowy Zużytych mas Odlewniczych; Wydawnictwo Naukowe AKAPIT: Kraków, Poland, 2007. (In Polish) [Google Scholar]

- Siddique, R.; Noumowe, A. Utilization of spent foundry sand in controlled low-strength materials and concrete. Resources, Conservation and Recycling 2008, 53, 27–35. [Google Scholar] [CrossRef]

- Guney, Y.; Sari, Y.D.; Yalcin, M.; Tuncan, A.; Donmez, S. Re-usage of waste foundry sand in high-strength concrete. Waste Manag. 2010, 30, 1705–1713. [Google Scholar] [CrossRef]

- Basar, H.M.; Aksoy, N.D. The effect of waste foundry sand (WFS) as partial replacement of sand on the mechanical, leaching and micro-structural characteristics of ready-mixed concrete. Constr. Build. Mater. 2012, 35, 508–515. [Google Scholar] [CrossRef]

- Prabhu, G.G.; Hyun, J.H.; Kim, Y.Y. Effects of foundry sand as a fine aggregate in concrete production. Constr. Build. Mater. 2014, 70, 514–521. [Google Scholar] [CrossRef]

- Aggarwal, Y.; Siddique, R. Microstructure and properties of concrete using bottom ash and waste foundry sand as partial replacement of fine aggregates. Constr. Build. Mater. 2014, 54, 210–223. [Google Scholar] [CrossRef]

- Siddique, R.; Singh, G.; Belarbi, R.; Ait-Mokhtar, K. Comparative investigation on the influence of spent foundry sand as partial replacement of fine aggregates on the properties of two grades of concrete. Constr. Build. Mater. 2015, 83, 216–222. [Google Scholar] [CrossRef]

- Bhardwaj, B.; Kumar, P. Waste foundry sand in concrete: A review. Constr. Build. Mater. 2017, 156, 661–674. [Google Scholar] [CrossRef]

- Manoharan, T.; Laksmanan, D.; Mylsamy, K.; Sivakumar, P. Engineering properties of concrete with partial utilization of used foundry sand. Waste Manag. 2018, 71, 454–460. [Google Scholar] [CrossRef] [PubMed]

- De Matos, P.R.; Marcon, M.F.; Schankoski, R.A.; Prudêncio, L.R., Jr. Novel applications of waste foundry sand in conventional and dry-mix concretes. J. Environ. Manag. 2019, 244, 294–303. [Google Scholar] [CrossRef] [PubMed]

- Balázs, G.L.; Bigaj-van Vliet, A.; Corres Peiretti, H.; Eligehausen, R.; Haist, M.; León, J.; Lima, L.J.; Müller, H.S.; Pérez Caldentey, A.; Randl, N.; et al. Structural Concrete: Textbook on Behaviour, Design and Performance, 2nd ed.; fib Bulletin No. 51; International Federation for Structural Concrete: Lausanne, Switzerland, 2009; Volume 1. [Google Scholar]

- Subcommittee C09.61 on Testing for Strength. Standard Specification for Fabricating and Testing Specimens of Ultra-High Performance Concrete; ASTM C1856/C1856-17; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar] [CrossRef]

- Smarzewski, P. Effect of curing period on properties of steel and polypropylene fibre reinforced ultra-high performance concrete. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 32059. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Z.; Xiao, J.; Wang, D.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part I. Raw materials and mixture design. Constr. Build. Mater. 2015, 101, 741–751. [Google Scholar] [CrossRef]

- Yoo, D.; Banthia, N. Mechanical properties of ultra-high-performance fiber-reinforced concrete: A review. Cem. Concr. Compos. 2016, 73, 267–280. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Yoon, Y.S. A review on structural behavior, design, and application of ultra-high-performance fiber-reinforced concrete. Int. J. Concr. Struct. Mater. 2016, 10, 125–142. [Google Scholar] [CrossRef]

- Smarzewski, P. Study of toughness and macro/micro-crack development of fibre-reinforced ultra-high performance concrete after exposure to elevated temperature. Materials 2019, 12, 1210. [Google Scholar] [CrossRef]

- Abbas, S.; Nehdi, M.L.; Saleem, M.A. Ultra-high performance concrete: Mechanical performance, durability, sustainability and implementation challenges. Int. J. Concr. Struct. Mater. 2016, 10, 271–295. [Google Scholar] [CrossRef]

- Camacho, E.; López, J.Á.; Serna Ros, P. Definition of three levels of performance for UHPFRC-VHPFRC with available materials. In Ultra-High Performance Concrete and Nanotechnology in Construction; Kassel University Press: Kassel, Germany, 2012; pp. 249–256. [Google Scholar]

- Habel, K.; Viviani, M.; Denarié, E.; Brühwiler, E. Development of the mechanical properties of an Ultra-High Performance Fiber Reinforced Concrete (UHPFRC). Cem. Concr. Res. 2006, 36, 1362–1370. [Google Scholar] [CrossRef]

- Bøhnsdalen Eide, M.; Hisdal, J.-M. Ultra High Performance Fibre Reinforced Concrete (UHPFRC)—State of the Art; COIN Project report 44—2012; SINTEF Building and Infrastructure: Oslo, Norway, 2012. [Google Scholar]

- Yang, J.; Peng, G.-F.; Gao, Y.-X.; Zhang, H. Characteristics of mechanical properties and durability of ultra-high performance concrete incorporating coarse aggregate. In Ultra-High Performance Concrete and Nanotechnology in Construction; Kassel University Press: Kassel, Germany, 2012; pp. 257–264. [Google Scholar]

- Wang, C.; Yang, C.; Liu, F.; Wan, C.; Pu, X. Preparation of ultra-high performance concrete with common technology and materials. Cem. Concr. Compos. 2012, 34, 538–544. [Google Scholar] [CrossRef]

- Torres, A.; Aguayo, F.; Allena, S.; Ellis, M. Mechanical properties of ultra high performance fiber reinforced concrete made with foundry sand. J. Civ. Eng. Constr. 2019, 8, 157–167. [Google Scholar] [CrossRef]

- Polish Committee for Standardization. PN-EN 197-1. Cement. Composition, Specifications and Conformity Criteria for Common Cements. 2012. Available online: http://sklep.pkn.pl/pn-en-197-1-2012p.html (accessed on 20 September 2019).

- Polish Committee for Standardization. PN-B-19707:2013-10. Cement. Special Cement. Composition, Specifications and Conformity Criteria. 2013. Available online: http://sklep.pkn.pl/pn-b-19707-2013-10p.html (accessed on 20 September 2019).

- Sahmaran, M.; Lachemi, M.; Erdem, T.K.; Yucel, H.E.; Yu, H.E. Use of spent foundry sand and fly ash for the development of green self-consolidating concrete. Mat. Struct. 2011, 44, 1193–1204. [Google Scholar] [CrossRef]

- Khatib, J.M.; Herki, B.A.; Kenai, S. Capillarity of concrete incorporating waste foundry sand. Constr. Build. Mater. 2013, 47, 867–871. [Google Scholar] [CrossRef]

- Monosi, S.; Tittarelli, F.; Giosuè, C.; Ruello, M.L. Effect of two different sources and washing treatment on the properties of UFS by-products for mortar and concrete production. Constr. Build. Mater. 2013, 44, 260–266. [Google Scholar] [CrossRef]

- Polish Committee for Standardization. PN-EN 933-1. Tests for Geometrical Properties of Aggregates. Determination of Particle Size Distribution. Sieving Method. 2012. Available online: http://sklep.pkn.pl/pn-en-933-1-2012e.html (accessed on 20 September 2019).

- Shaheen, E.; Shrive, N.J. Optimization of mechanical properties and durability of reactive powder concrete. ACI Mater. J. 2006, 103, 444–451. [Google Scholar] [CrossRef]

- Smarzewski, P. Influence of silica fume on mechanical and fracture properties of high performance concrete. Procedia Struct. Integr. 2019, 17, 5–12. [Google Scholar] [CrossRef]

- Smarzewski, P. Influence of basalt-polypropylene fibres on fracture properties of high performance concrete. Compos. Struct. 2019, 209, 23–33. [Google Scholar] [CrossRef]

- Polish Committee for Standardization. PN-EN 12390-7. Testing Hardened Concrete, Density of Hardened Concrete. 2011. Available online: http://sklep.pkn.pl/pn-en-12390-7-2011p.html (accessed on 20 September 2019).

- Polish Committee for Standardization. PN-EN 13755. Natural Stone Test Methods. Determination of Water Absorption at Atmospheric Pressure. 2008. Available online: http://sklep.pkn.pl/pn-en-13755-2008e.html (accessed on 20 September 2019).

- Polish Committee for Standardization. PN-EN 12390-3. Testing Hardened Concrete. Compressive Strength of Test Specimens. 2011. Available online: http://sklep.pkn.pl/pn-en-12390-3-2011p.html (accessed on 20 September 2019).

- de Matos, P.R.; de Oliveira, A.L.; Pelisser, F.; Prudêncio, L.R. Rheological behavior of Portland cement pastes and self-compacting concretes containing porcelain polishing residue. Constr. Build. Mater. 2018, 175, 508–518. [Google Scholar] [CrossRef]

- Berodier, E.; Scrivener, K. Understanding the filler effect on the nucleation and growth of C-S-H. J. Am. Ceram. Soc. 2014, 97, 3764–3773. [Google Scholar] [CrossRef]

- Leemann, A.; Lura, P.; Loser, R. Shrinkage and creep of SCC—The influence of paste volume and binder composition. Constr. Build. Mater. 2011, 25, 2283–2289. [Google Scholar] [CrossRef]

- Polish Committee for Standardization. PN-EN 12390-6. Testing Hardened Concrete. Tensile Splitting Strength of Test Specimens. 2011. Available online: http://sklep.pkn.pl/pn-en-12390-6-2011p.html (accessed on 20 September 2019).

- Polish Committee for Standardization. PN-EN 12390-5. Testing Hardened Concrete. Flexural Strength of Test Specimens. 2011. Available online: http://sklep.pkn.pl/pn-en-12390-5-2011p.html (accessed on 20 September 2019).

- ASTM. C469/C469M-14 Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar] [CrossRef]

- Hewlett, P.C. Lea’s Chemistry of Cement and Concrete, 4th ed.; Butterworth-Heinemann: Oxford, UK, 2003. [Google Scholar] [CrossRef]

- Yazici, H. Utilization of coal combustion byproducts in building blocks. Fuel 2007, 86, 929–937. [Google Scholar] [CrossRef]

| Material Characteristics | Cement |

|---|---|

| Specific surface area (m2/kg) | 443 |

| Water demand (%) | 30 |

| Start of setting (min) | 120 |

| End of setting (min) | 180 |

| Volume stability acc. to Le Chateliere (mm) | 2 |

| Compressive strength at 2 days (N/mm2) | 27.7 |

| Compressive strength at 28 days (N/mm2) | 57.1 |

| Tensile strength at 2 days (N/mm2) | 5.3 |

| Tensile strength at 28 days (N/mm2) | 8.2 |

| Compound | Cement | Silica Fume |

|---|---|---|

| SiO2 | 20.92 | 94.80 |

| Al2O3 | 3.50 | 1.30 |

| Fe2O3 | 4.38 | 0.83 |

| CaO | 64.69 | 0.56 |

| MgO | 1.20 | 0.71 |

| SO3 | 3.07 | NA |

| K2O | 0.38 | 1.26 |

| Na2O | 0.22 | 0.41 |

| Cl | 0.08 | NA |

| Loss on ignition | 1.27 | 0.12 |

| Insoluble matter | 0.20 | NA |

| Material Characteristics | Basalt | Quartz Sand | Waste Foundry Sand |

|---|---|---|---|

| Unit weight (kg/m3) | 3086 | 1585 | 1521 |

| Specific gravity | 2.95 | 2.67 | 2.45 |

| Absorption (%) | 0.2 | 1.12 | 1.4 |

| Fineness modulus | 5.92 | 1.84 | 1.80 |

| Compressive strength (N/mm2) | 196 | ― | ― |

| Compound | Basalt | Quartz Sand | Waste Foundry Sand |

|---|---|---|---|

| SiO2 | 42.86 | 98.0 | 95.3 |

| Al2O3 | 11.46 | 0.8 | 1.9 |

| Fe2O3 | 13.42 | 0.2 | 0.7 |

| CaO | 11.13 | 0.1 | 0.35 |

| MgO | 9.71 | ― | ― |

| SO3 | 0.01 | ― | ― |

| Na2O | 2.93 | ― | ― |

| K2O | 0.89 | ― | ― |

| P2O5 | 0.64 | ― | ― |

| TiO2 | 2.36 | 0.8 | ― |

| MnO | 0.21 | ― | ― |

| Compound | Etxeberria et al. [3] | Guney et al. [9] | Sahmaran et al. [33] | Basar et al. [10] | Khatib et al. [34] | Smarzewski [This Study] |

|---|---|---|---|---|---|---|

| SiO2 | 84.90 | 98.00 | 76.00 | 81.85 | 87.91 | 95.30 |

| Al2O3 | 5.21 | 0.80 | 4.45 | 10.41 | 4.70 | 1.90 |

| Fe2O3 | 3.22 | 0.25 | 5.06 | 1.82 | 0.94 | 0.70 |

| CaO | 0.58 | 0.04 | 3.56 | 1.21 | 0.14 | 0.35 |

| MgO | 0.67 | 0.02 | 1.98 | 1.97 | 0.30 | ― |

| SO3 | 0.29 | 0.01 | ― | 0.84 | 0.09 | ― |

| Na2O | 0.50 | 0.04 | 0.38 | 0.76 | 0.19 | ― |

| K2O | 0.97 | 0.04 | 1.20 | 0.49 | 0.25 | ― |

| P2O5 | 0.05 | ― | 0.05 | ― | ― | ― |

| TiO2 | 0.19 | ― | 0.17 | ― | ― | ― |

| Mn2O3 | 0.08 | 0.01 | 0.46 | ― | ― | ― |

| Cr2O3 | 0.37 | ― | ― | ― | ― | ― |

| LOI | 2.87 | ― | 5.85 | 6.93 | 5.15 | ― |

| Designation | CWFS0 | CWFS5 | CWFS10 | CWFS15 |

|---|---|---|---|---|

| Cement (kg/m3) | 670.5 | 670.5 | 670.5 | 670.5 |

| Silica fume (kg/m3) | 74.5 | 74.5 | 74.5 | 74.5 |

| Quartz sand (kg/m3) | 500 | 475 | 450 | 425 |

| Waste foundry sand (kg/m3) | 0 | 25 | 50 | 75 |

| WFS content (%) | 0 | 5 | 10 | 15 |

| Basalt (kg/m3) | 990 | 990 | 990 | 990 |

| Water (l/m3) | 178 | 178 | 178 | 178 |

| Superplasticizer (l/m3) | 20 | 20 | 20 | 20 |

| Slump (mm) | 120 | 118 | 115 | 111 |

| Unite weight (kg/m3) | 2434 | 2432 | 2429 | 2425 |

| Test | Shape | Dimensions (mm) | Number |

|---|---|---|---|

| Compression | Cube | 100 × 100 × 100 | 48 |

| Splitting tensile | Cube | 100 × 100 × 100 | 48 |

| Flexural | Beam | 50 × 50 × 250 | 48 |

| Modulus of elasticity | Cylinder | 150 × 300 | 48 |

| Designation | CWFS0 | CWFS5 | CWFS10 | CWFS15 |

|---|---|---|---|---|

| Apparent density (g/cm3) | 2.42 | 2.42 | 2.44 | 2.48 |

| Standard deviation (g/cm3) | 0.02 | 0.02 | 0.02 | 0.03 |

| Absorbability (%) | 3.11 | 2.98 | 2.78 | 2.70 |

| Standard deviation (%) | 0.04 | 0.04 | 0.03 | 0.03 |

| Open porosity (%) | 7.58 | 7.20 | 6.88 | 6.58 |

| Standard deviation (%) | 0.08 | 0.07 | 0.08 | 0.06 |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Smarzewski, P. Mechanical Properties of Ultra-High Performance Concrete with Partial Utilization of Waste Foundry Sand. Buildings 2020, 10, 11. https://doi.org/10.3390/buildings10010011

Smarzewski P. Mechanical Properties of Ultra-High Performance Concrete with Partial Utilization of Waste Foundry Sand. Buildings. 2020; 10(1):11. https://doi.org/10.3390/buildings10010011

Chicago/Turabian StyleSmarzewski, Piotr. 2020. "Mechanical Properties of Ultra-High Performance Concrete with Partial Utilization of Waste Foundry Sand" Buildings 10, no. 1: 11. https://doi.org/10.3390/buildings10010011

APA StyleSmarzewski, P. (2020). Mechanical Properties of Ultra-High Performance Concrete with Partial Utilization of Waste Foundry Sand. Buildings, 10(1), 11. https://doi.org/10.3390/buildings10010011