A Systematic Review of Digital Technology Adoption in Off-Site Construction: Current Status and Future Direction towards Industry 4.0

Abstract

:1. Introduction

2. Materials and Methods

2.1. Research Process

2.2. Preliminary Search to Identify Keywords of Technologies

2.3. Database Search for Selecting Relevant Papers

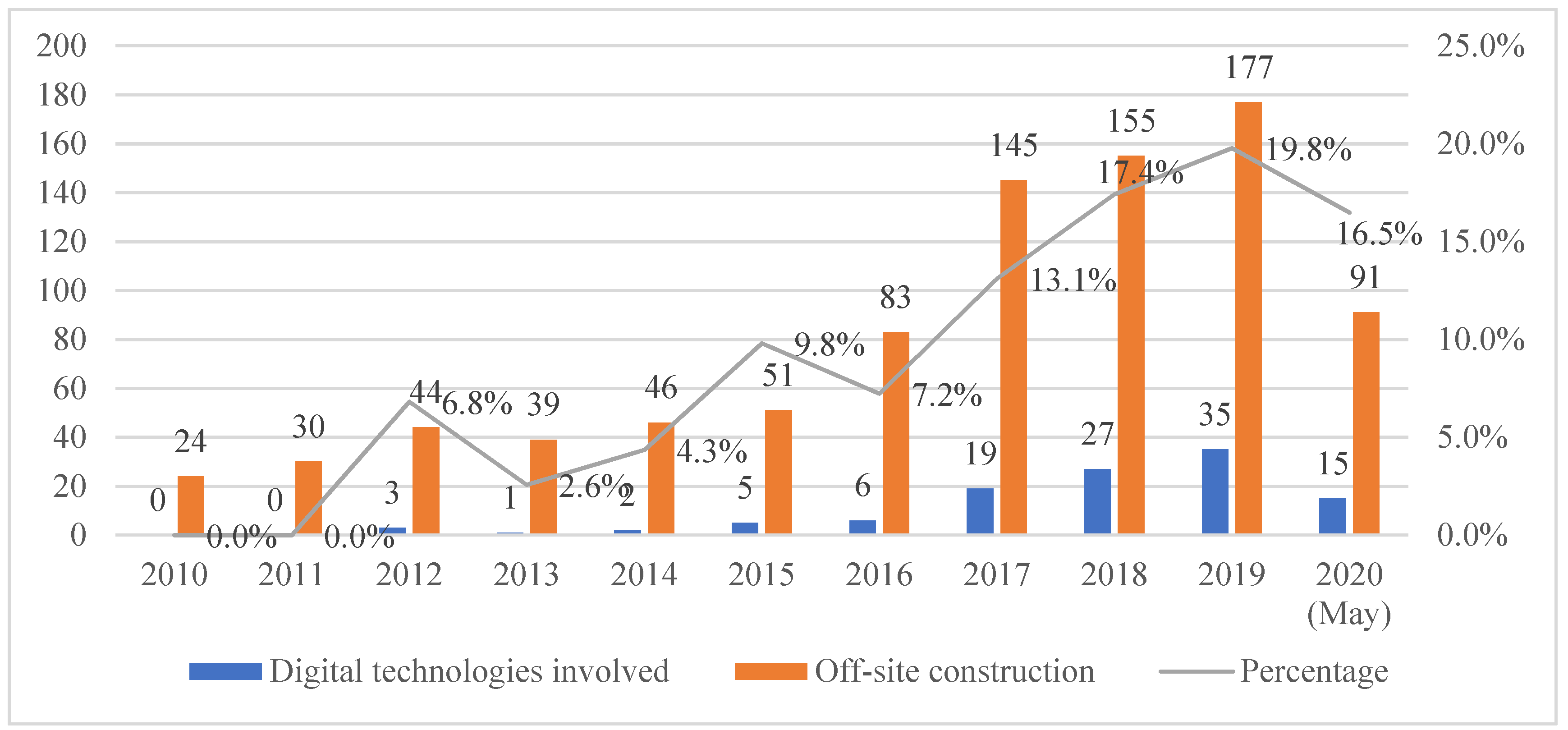

3. Results of Scientometric Analysis

3.1. Co-Occurrence of Keywords

- Design for manufacturing and assembly (DfMA) is significant in prefabricated project design. Lean construction aims to improve construction processes by reducing constraints or waste and accelerating construction cycles in OSC. Lean construction is closely linked to DfMA and digital technologies, such as BIM and RFID [56,57,58,59], as seen in the light blue circles in Figure 6a;

3.2. Analysis of Countries Involved in Research

4. Content Analysis

4.1. Overview and Relationship

4.2. Building Information Modelling (BIM)

- There is a lack of knowledge on how BIM could be used appropriately to fully achieve its benefit in OSC and a relevant assessment model for measuring those benefits is missing. For example, how BIM usage in conventional construction projects can benefit a specific area, such as cost estimating, has been discussed in the literature (e.g., [89]), but there has been no such evaluation for OSC;

- Current discussions on BIM application in OSC are for fragmented phases. How to integrate BIM throughout the OSC project life cycle needs further study;

- How BIM can be best utilised with other technologies in OSC and especially implemented in real construction practice, is still unclear.

- BIM-based automated design and optimized planning to coordinate prefabricated elements rather than separate parts design. AI is a promising technology to support an automated assembly process;

- Developing BIM standards for data exchange and delivery among different stakeholders considering the characteristics of OSC projects, as well as BIM integration and communication with other technologies data, such as sensors, RFID, point cloud to reduce information loss, and improve data processing efficiency;

- More functions can be added in BIM to reflect actual practices of supply chain management and on-site management of OSC, such as procurement processes, safety management, quality management, and environment issues;

- AI could be integrated into BIM to facilitate complex data processing and decision-making in project schedule risk identification and logistics optimization;

- Recycling strategies for end-of-life prefabrication materials should be further developed for sustainable development;

- BIM utilization throughout the entire life cycle in OSC needs to be streamlined;

- More case studies need to be conducted to evaluate the actual improvement resulting from BIM implementation, and to help develop an assessment model for measuring the benefits of BIM utilization in OSC projects;

- The integration and arrangement of other technologies (e.g., RFID, sensors) with BIM in OSC need to be developed in a more scientific way to be aligned with OSC processes and leverage the benefit of each technology with less effort.

4.3. Radio Frequency Identification Devices (RFID)

- Better performing devices need to be adopted in OSC with better signal range and strength, reduction of damage, faster reaction speed, such as active RFID, and improved working capacity in the concrete environment of prefabricated components;

- The design of a RFID arrangement plan of tags number, installation position, RFID selection should be detailed and analyzed before implementation;

- The RFID data reliability needs to be further tested and enhanced for accuracy to meet industry requirements for OSC projects—for supply chain management, logistics, and schedule risks identification;

- A more efficient way should be developed to simplify data processing from raw RFID data and reach global standardization of RFID data representation;

- Data security issues need to be addressed in logistics planning and asset management.

4.4. Global Positioning System (GPS)

- GPS data accuracy, data storage capacity analysis, and near-real-time data reaction speed should be further validated in actual prefabricated local OSC projects;

- A more automated way of GPS data collection and a more intelligent way of data extraction should be designed in logistics and supply chain management taking into consideration the OSC features.

4.5. Internet of Thing (IoT)

- Network signals need to be enhanced with higher stability for information exchange and delivery; data accuracy and delivery speed should be tested for actual OSC daily operation requirements;

- Security and privacy issues in project data exchange and storage for logistics management need to be addressed;

- The IoT system should be enhanced through a quality check of prefabricated components in manufacture, transportation and assembly processes, construction safety management, and environmental protection issues;

- Industrial standards, which are more applicable to OSC projects, should be developed among BIM, GPS, RFID, and other technologies;

- More practical tests need to be conducted for implementation in real-life, off-site projects rather than simulation by virtual models.

4.6. Sensors

- The application of sensors needs to be extended to other types of projects such as precast concrete components, and more suitable sensors need to be tested for the effective detection of other types of damage that occurs in prefabricated components;

- More effective methods need to be developed to link the physical sensors with virtual sensors for efficient information delivery and exchange;

- Installation and maintenance of sensors in prefabricated concrete components and steel needs to be improved, and sensor layout plans need to be detailed and costed before implementation in real cases;

- To develop cost reduction strategies by identifying critical prefabricated components rather than installing sensors on all prefabricated components.

4.7. Augmented Reality (AR)

- Integrating AI in AR algorithm development to encourage time and cost saving;

- Utilizing AR to improve efficiency and precision of the assembly process in OSC;

- Developing innovative methods which are less dependent on equipment and environmental conditions for OSC projects;

- Integrating laser scanning into AR for creating a near-real-time virtual environment for quality checking of OSC building components.

4.8. Virtual Reality (VR)

- Validate VR utilization in a real OSC environment for monitoring lift activities and near-real-time progress rather than relying on simulations;

- To enhance the fidelity of the VR environment and make the operators feel more immersed in linking VR with the real construction environment;

- Developing assessment models of VR performance to measure efficiency improvement and reduce errors.

4.9. Photogrammetry

- Extending photogrammetry usage in quality detection to precast concrete projects rather than only steel or wood projects, and recognition of the irregularly shaped precast components;

- Optimization of photogrammetric devices to improve image quality for higher accuracy and reduce the complexity of data processing based on the real OSC environment;

- Developing methods for automated data alignment and data exchange with BIM models to facilitate near-real-time lifting task optimization and construction progress monitoring;

- Further testing and enhancement of image data reliability for improving accuracy and processing speed to meet industry requirements for OSC projects;

- Improving the accuracy of on-site workers’ operations (e.g., for crane operators) and their status for safety purposes.

4.10. Laser Scanning

- Processing capability improvement to enhance data accuracy and efficiency for quality detection of both regular and irregular precast components;

- Utilizing AI technology to increase the level of automation to reduce dependency on manual intervention in data creation and data processing;

- Developing methods for more accurate data collection using laser scanning and data noise reduction;

- Increasing the adoption of laser scanning technology in the OSC practice in a wider range of construction quality control, progress monitoring, and safety management.

4.11. Artificial Intelligence (AI)

- AI-based design for topology analysis of prefabricated elements—configuration, segmentation, and optimization;

- Complex data analysis in logistics data processing;

- Distance determination of factory location and construction site before OSC and optimization of supply chain management to reduce costs;

- Prediction of various potential project risks based on historical and real-time data.

4.12. 3D Printing

- Enhance 3D printing to be able to handle complex and irregular prefabricated components effectively;

- Improve cost, accuracy, and mechanical performance of 3D printing for precast components;

- Implement 3D printing to real case OSC projects to validate the approach and demonstrate its efficiency.

4.13. Robotics

- Conducting cost analysis studies for robotic utilization in the manufacturing process;

- Testing the onsite assembly process of robotic utilization using physical prototypes before implementation to provide adequate information and evidence for decision making.

4.14. Big Data

4.15. Blockchain

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Staib, G.; Dörrhöfer, A.; Rosenthal, M. Components and Systems: Modular Construction–Design, Structure, New Technologies; Birkhauser Verlag AG: Basel, Switzerland, 2013. [Google Scholar]

- Arashpour, M.; Wakefield, R.; Abbasi, B.; Arashpour, M.; Hosseini, R. Optimal process integration architectures in off-site construction: Theorizing the use of multi-skilled resources. Archit. Eng. Des. Manag. 2018, 14, 46–59. [Google Scholar] [CrossRef]

- Fenner, A.E.; Zoloedova, V.; Kibert, C. Conference Report 2017: State-of-the-Art of Modular Construction; University of Florida: Gainesville, FL, USA, 2017. [Google Scholar] [CrossRef]

- Ferdous, W.; Bai, Y.; Ngo, T.D.; Manalo, A.; Mendis, P. New advancements, challenges and opportunities of multi-storey modular buildings—A state-of-the-art review. Eng. Struct. 2019, 183, 883–893. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K. Life cycle performance of modular buildings: A critical review. Renew. Sustain. Energ. Rev. 2016, 62, 1171–1183. [Google Scholar] [CrossRef]

- Lawson, M.; Ogden, R.; Goodier, C. Design in Modular Construction; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Li, C.Z.; Xue, F.; Li, X.; Hong, J.; Shen, G.Q. An Internet of Things-enabled BIM platform for on-site assembly services in prefabricated construction. Autom. Constr. 2018, 89, 146–161. [Google Scholar] [CrossRef]

- Gan, X.; Chang, R.; Zuo, J.; Wen, T.; Zillante, G. Barriers to the transition towards off-site construction in China: An Interpretive structural modeling approach. J. Clean. Prod. 2018, 197, 8–18. [Google Scholar] [CrossRef]

- Jin, R.Y.; Gao, S.; Cheshmehzangi, A.; Aboagye-Nimo, E. A holistic review of off-site construction literature published between 2008 and 2018. J. Clean. Prod. 2018, 202, 1202–1219. [Google Scholar] [CrossRef] [Green Version]

- Hwang, B.-G.; Shan, M.; Looi, K.-Y. Key constraints and mitigation strategies for prefabricated prefinished volumetric construction. J. Clean. Prod. 2018, 183, 183–193. [Google Scholar] [CrossRef]

- Gibb, A.G. Off-Site Fabrication: Prefabrication, Pre-Assembly and Modularisation; John Wiley & Sons: Hoboken, NJ, USA, 1999. [Google Scholar]

- Hwang, B.-G.; Shan, M.; Looi, K.-Y. Knowledge-based decision support system for prefabricated prefinished volumetric construction. Autom. Constr. 2018, 94, 168–178. [Google Scholar] [CrossRef]

- Goh, M.; Goh, Y.M. Lean production theory-based simulation of modular construction processes. Autom. Constr. 2019, 101, 227–244. [Google Scholar] [CrossRef]

- Akbarnezhad, A. Modular vs conventional construction: A multi-criteria framework approach. In Proceedings of the 34th International Symposium on Automation and Robotics in Construction (ISARC), Taipei, Taiwan, 28 June–1 July 2017; pp. 214–220. [Google Scholar]

- MBI. 2018 Permanent Modular Construction Report; Modular Building Institute: Charlottesville, VA, USA, 2018. [Google Scholar]

- Mah, D.; Al-Hussein, M. An integrated evaluation framework for sustainable residential construction. Int. J. Interdiscip. Soc. Sci. 2008, 3, 129–135. [Google Scholar] [CrossRef]

- Murtaza, M.B.; Fisher, D.J.; Skibniewski, M.J. Knowledge-based approach to modular construction decision support. J. Constr. Eng. Manag. 1993, 119, 115–130. [Google Scholar] [CrossRef]

- Liu, H.; Singh, G.; Lu, M.; Bouferguene, A.; Al-Hussein, M. BIM-based automated design and planning for boarding of light-frame residential buildings. Autom. Constr. 2018, 89, 235–249. [Google Scholar] [CrossRef]

- Alwisy, A.; Hamdan, S.B.; Barkokebas, B.; Bouferguene, A.; Al-Hussein, M. A BIM-based automation of design and drafting for manufacturing of wood panels for modular residential buildings. Int. J. Constr. Manag. 2019, 19, 187–205. [Google Scholar] [CrossRef]

- Banihashemi, S.; Tabadkani, A.; Hosseini, M.R. Integration of parametric design into modular coordination: A construction waste reduction workflow. Autom. Constr. 2018, 88, 1–12. [Google Scholar] [CrossRef]

- Lin, X.; Lu, Y.; Liu, J.B. Research on Mathematical Model of Cost Budget in the Early Stage of Assembly Construction Project Based on Improved Neural Network Algorithm. Math. Probl. Eng. 2020, 2020, 3674929. [Google Scholar] [CrossRef]

- Xie, L.; Chen, Y.; Xia, B.; Hua, C. Importance-Performance Analysis of Prefabricated Building Sustainability: A Case Study of Guangzhou. Adv. Civ. Eng. 2020, 2020, 8839118. [Google Scholar] [CrossRef]

- Shahpari, M.; Saradj, F.M.; Pishvaee, M.S.; Piri, S. Assessing the productivity of prefabricated and in-situ construction systems using hybrid multi-criteria decision making method. J. Build. Eng. 2020, 27. [Google Scholar] [CrossRef]

- Sabine, H.; Paul, T.; Ethan, C. Prefabrication: The Changing Face of Engineering and Construction, 2017 FMI/BIMForum Prefabrication Survey; FMI: Raleigh, NC, USA, 2017. [Google Scholar]

- Hong, J.; Shen, G.Q.; Li, Z.; Zhang, B.; Zhang, W. Barriers to promoting prefabricated construction in China: A cost–benefit analysis. J. Clean. Prod. 2018, 172, 649–660. [Google Scholar] [CrossRef]

- Mao, C.; Xie, F.; Hou, L.; Wu, P.; Wang, J.; Wang, X. Cost analysis for sustainable off-site construction based on a multiple-case study in China. Habitat Int. 2016, 57, 215–222. [Google Scholar] [CrossRef]

- Qi, Y.; Chang, S.; Ji, Y.; Qi, K. BIM-based incremental cost analysis method of prefabricated buildings in China. Sustainability 2018, 10, 4293. [Google Scholar] [CrossRef] [Green Version]

- Arashpour, M.; Kamat, V.; Bai, Y.; Wakefield, R.; Abbasi, B. Optimization modeling of multi-skilled resources in prefabrication: Theorizing cost analysis of process integration in off-site construction. Autom. Constr. 2018, 95, 1–9. [Google Scholar] [CrossRef]

- Razkenari, M.; Fenner, A.; Shojaei, A.; Hakim, H.; Kibert, C. Perceptions of offsite construction in the United States: An investigation of current practices. J. Build. Eng. 2020, 29. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Mao, C.; Li, Z.; Li, K. Life-cycle energy analysis of prefabricated building components: An input–output-based hybrid model. J. Clean. Prod. 2016, 112, 2198–2207. [Google Scholar] [CrossRef] [Green Version]

- Kabirifar, K.; Mojtahedi, M.; Wang, C.; Tam, V.W.Y. Construction and demolition waste management contributing factors coupled with reduce, reuse, and recycle strategies for effective waste management: A review. J. Clean. Prod. 2020, 263. [Google Scholar] [CrossRef]

- Wang, C.C.; Sepasgozar, S.M.E.; Wang, M.; Sun, J.; Ning, X. Green performance evaluation system for energy-efficiency-based planning for construction site layout. Energies 2019, 12, 4620. [Google Scholar] [CrossRef] [Green Version]

- Alazzaz, F.; Whyte, A. Linking employee empowerment with productivity in off-site construction. Eng. Constr. Archit. Manag. 2015, 22, 21–37. [Google Scholar] [CrossRef]

- Gan, X.L.; Chang, R.D.; Wen, T. Overcoming barriers to off-site construction through engaging stakeholders: A two-mode social network analysis. J. Clean. Prod. 2018, 201, 735–747. [Google Scholar] [CrossRef]

- Alaloul, W.S.; Liew, M.S.; Zawawi, N.A.W.A.; Kennedy, I.B. Industrial Revolution 4.0 in the construction industry: Challenges and opportunities for stakeholders. Ain Shams Eng. J. 2020, 11, 225–230. [Google Scholar] [CrossRef]

- Maskuriy, R.; Selamat, A.; Maresova, P.; Krejcar, O.; David, O.O. Industry 4.0 for the construction industry: Review of management perspective. Economies 2019, 7, 68. [Google Scholar] [CrossRef] [Green Version]

- Cheng, D.; Ma, J. Research on the restrictive factors of the development of Chinese prefabricated buildings. In Proceedings of the 2020 3rd International Conference of Green Buildings and Environmental Management (GBEM), Qingdao, China, 12–14 June 2020. [Google Scholar]

- Voordijk, J.T. Technological Mediation in Construction: Postphenomenological Inquiry into Digital Technologies. J. Constr. Eng. Manag. 2019, 145. [Google Scholar] [CrossRef]

- Hofmann, E.; Rüsch, M. Industry 4.0 and the current status as well as future prospects on logistics. Comput. Ind. 2017, 89, 23–34. [Google Scholar] [CrossRef]

- Shirowzhan, S.; Sepasgozar, S.; Zaini, I.; Wang, C. An integrated GIS and Wi-Fi based Locating system for improving construction labor communications. In Proceedings of the 34th International Symposium on Automation and Robotics in Construction, Taipei, Taiwan, 28 June–1 July 2017; pp. 1052–1059. [Google Scholar]

- Sepasgozar, S.M. Digital technology utilisation decisions for facilitating the implementation of Industry 4.0 technologies. Constr. Innov. 2020. [Google Scholar] [CrossRef]

- Woodhead, R.; Stephenson, P.; Morrey, D. Digital construction: From point solutions to IoT ecosystem. Autom. Constr. 2018, 93, 35–46. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Greenwood, D.; Kassem, M. Blockchain in the built environment and construction industry: A systematic review, conceptual models and practical use cases. Autom. Constr. 2019, 102, 288–307. [Google Scholar] [CrossRef]

- Andre, L.; Michael, B.; Daniel, R.; Christian, K. Framework for the identification and demand-orientated classification of digital technologies. In Proceedings of the 2018 IEEE International Conference on Technology Management, Operations and Decisions (ICTMOD 2018), Marrakech, Morocco, 21–23 November 2018; pp. 31–36. [Google Scholar]

- Leviäkangas, P.; Mok Paik, S.; Moon, S. Keeping up with the pace of digitization: The case of the Australian construction industry. Technol. Soc. 2017, 50, 33–43. [Google Scholar] [CrossRef]

- Yin, X.; Liu, H.; Chen, Y.; Al-Hussein, M. Building information modelling for off-site construction: Review and future directions. Autom. Constr. 2019, 101, 72–91. [Google Scholar] [CrossRef]

- Shirowzhan, S.; Sepasgozar, S.M.E.; Edwards, D.J.; Li, H.; Wang, C. BIM compatibility and its differentiation with interoperability challenges as an innovation factor. Autom. Constr. 2020, 112, 103086. [Google Scholar] [CrossRef]

- Baldini, G.; Desruelle, P.; Bono, F.; Delipetrev, B.; Gkoumas, K.; Sanchez, I.; Pagano, A.; Nepelski, D.; Prettico, G.; Urzi Brancati, C.; et al. Digital Transformation in Transport, Construction, Energy, Government and Public Administration; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar] [CrossRef]

- Calvetti, D.; Mêda, P.; Gonçalves, M.C.; Sousa, H. Worker 4.0: The future of sensored construction sites. Buildings 2020, 10, 169. [Google Scholar] [CrossRef]

- Borrmann, A.; König, M.; Koch, C.; Beetz, J. Building Information Modeling: Technology Foundations and Industry Practice; Springer International Publishing: Berlin/Heidelberg, Germany, 2018; pp. 1–584. [Google Scholar] [CrossRef]

- Darko, A.; Chan, A.P.C.; Adabre, M.A.; Edwards, D.J.; Hosseini, M.R.; Ameyaw, E.E. Artificial intelligence in the AEC industry: Scientometric analysis and visualization of research activities. Autom. Constr. 2020, 112, 103081. [Google Scholar] [CrossRef]

- Gimeno, J.; Morillo, P.; Orduña, J.M.; Fernández, M. An occlusion-aware AR authoring tool for assembly and repair tasks. In Proceedings of the International Conference on Computer Graphics Theory and Applications (GRAPP 2012) and International Conference on Information Visualization Theory and Applications (IVAPP 2012), Rome, Italy, 24–26 February 2012; pp. 377–386. [Google Scholar]

- Sepasgozaar, S.M.E.; Shirowzhan, S.; Wang, C. A Scanner Technology Acceptance Model for Construction Projects. Procedia Eng. 2017, 180, 1237–1246. [Google Scholar] [CrossRef]

- Jin, R.; Zou, Y.; Gidado, K.; Ashton, P.; Painting, N. Scientometric analysis of BIM-based research in construction engineering and management. Eng. Constr. Archit. Manag. 2019, 26, 1750–1776. [Google Scholar] [CrossRef] [Green Version]

- Akbarieh, A.; Jayasinghe, L.B.; Waldmann, D.; Teferle, F.N. BIM-based end-of-lifecycle decision making and digital deconstruction: Literature review. Sustainability 2020, 12, 2670. [Google Scholar] [CrossRef] [Green Version]

- Alfieri, E.; Seghezzi, E.; Sauchelli, M.; Di Giuda, G.M.; Masera, G. A BIM-based approach for DfMA in building construction: Framework and first results on an Italian case study. Archit. Eng. Des. Manag. 2020. [Google Scholar] [CrossRef]

- Gbadamosi, A.Q.; Mahamadu, A.M.; Oyedele, L.O.; Akinade, O.O.; Manu, P.; Mahdjoubi, L.; Aigbavboa, C. Offsite construction: Developing a BIM-Based optimizer for assembly. J. Clean. Prod. 2019, 215, 1180–1190. [Google Scholar] [CrossRef]

- Yuan, Z.; Sun, C.; Wang, Y. Design for Manufacture and Assembly-oriented parametric design of prefabricated buildings. Autom. Constr. 2018, 88, 13–22. [Google Scholar] [CrossRef]

- Samarasinghe, T.; Gunawardena, T.; Mendis, P.; Sofi, M.; Aye, L. Dependency Structure Matrix and Hierarchical Clustering based algorithm for optimum module identification in MEP systems. Autom. Constr. 2019, 104, 153–178. [Google Scholar] [CrossRef]

- Han, C.; Ye, H. A novel IoT-Cloud-BIM based intelligent information management system in building industrialization. In Proceedings of the 2018 International Conference on Construction and Real Estate Management: Innovative Technology and Intelligent Construction (ICCREM 2018), Charleston, SC, USA, 9–10 August 2018; pp. 72–77. [Google Scholar]

- Vernikos, V.K.; Goodier, C.I.; Broyd, T.W.; Robery, P.C.; Gibb, A.G.F. Building information modelling and its effect on off-site construction in UK civil engineering. Proc. Inst. Civ. Eng. Manag. Procure. Law 2014, 167, 152–159. [Google Scholar] [CrossRef] [Green Version]

- Xu, Z.; Abualdenien, J.; Liu, H.; Kang, R. An IDM-Based Approach for Information Requirement in Prefabricated Construction. Adv. Civ. Eng. 2020, 2020, 8946530. [Google Scholar] [CrossRef] [Green Version]

- Sepasgozar, S.; Huang, T.; Wang, C.; Tahmasebinia, F. Energy optimization in modular buildings made from 3D printing. In Proceedings of the 2017 Modular and Offsite Construction Summit & the 2nd International Symposium on Industrialized Construction Technology, Shanghai, China, 10–12 November 2017. [Google Scholar]

- Mao, C.; Tao, X.; Yang, H.; Chen, R.; Liu, G. Real-time carbon emissions monitoring tool for prefabricated construction: An IoT-based system framework. In Proceedings of the 2018 International Conference on Construction and Real Estate Management: Sustainable Construction and Prefabrication (ICCREM 2018), Charleston, SC, USA, 9–10 August 2018; pp. 121–127. [Google Scholar]

- Liu, G.; Yang, H.; Fu, Y.; Mao, C.; Xu, P.; Hong, J.; Li, R. Cyber-physical system-based real-time monitoring and visualization of greenhouse gas emissions of prefabricated construction. J. Clean. Prod. 2020, 246. [Google Scholar] [CrossRef]

- Li, Z.; Shen, G.Q.; Xue, X. Critical review of the research on the management of prefabricated construction. Habitat Int. 2014, 43, 240–249. [Google Scholar] [CrossRef] [Green Version]

- Charnwasununth, P.; Yabuki, N.; Tongthong, T. Dynamic information support system for the process of prefabricated member installation using RFID technology and multi-agent system. In Proceedings of the 17th International Workshop on Intelligent Computing in Engineering (EG-ICE 2010), Nottingham, UK, 30 June–2 July 2010. [Google Scholar]

- Xu, G.; Li, M.; Chen, C.H.; Wei, Y. Cloud asset-enabled integrated IoT platform for lean prefabricated construction. Autom. Constr. 2018, 93, 123–134. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, H.; Zhou, W. RFID Enabled Knowledge-Based Precast Construction Supply Chain. Comput. Aided Civ. Infrastruct. Eng. 2017, 32, 499–514. [Google Scholar] [CrossRef]

- Wang, C.C.; Chien, O. The use of BIM in project planning and scheduling in the australian construction industry. In Proceedings of the 2014 International Conference on Construction and Real Estate Management: Smart Construction and Management in the Context of New Technology (ICCREM 2014), Kunming, China, 27–28 September 2014; pp. 126–133. [Google Scholar]

- Senthilvel, M.; Varghese, K.; Ramesh Babu, N. Building information modeling for precast construction: A review of research and practice. In Proceedings of the Construction Research Congress 2016: Old and New Construction Technologies Converge in Historic San Juan (CRC 2016), San Juan, Puerto Rico, 31 May–2 June 2016; pp. 2250–2259. [Google Scholar]

- Garg, A.; Kamat, V.R. Virtual Prototyping for Robotic Fabrication of Rebar Cages in Manufactured Concrete Construction. J. Archit. Eng. 2014, 20, 06013002. [Google Scholar] [CrossRef] [Green Version]

- Krieg, O.D.; Lang, O. Adaptive automation strategies for robotic prefabrication of parametrized mass timber building components. In Proceedings of the 36th International Symposium on Automation and Robotics in Construction (ISARC 2019), Banff, AB, Canada, 21–24 May 2019; pp. 521–528. [Google Scholar]

- Naranje, V.; Swarnalatha, R. Design of tracking system for prefabricated building components using RFID technology and CAD model. In Proceedings of the 12th International Conference Interdisciplinarity in Engineering (INTER-ENG 2018), Tirgu Mures, Romania, 4–5 October 2018; pp. 928–935. [Google Scholar]

- Liu, H.; Sydora, C.; Altaf, M.S.; Han, S.; Al-Hussein, M. Towards sustainable construction: BIM-enabled design and planning of roof sheathing installation for prefabricated buildings. J. Clean. Prod. 2019, 235, 1189–1201. [Google Scholar] [CrossRef]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L.; Colling, M. Strategies for applying the circular economy to prefabricated buildings. Buildings 2018, 8, 125. [Google Scholar] [CrossRef] [Green Version]

- Bataglin, F.S.; Viana, D.D.; Formoso, C.T.; Bulhões, I.R. Model for planning and controlling the delivery and assembly of engineer-to-order prefabricated building systems: Exploring synergies between lean and BIM. Can. J. Civ. Eng. 2020, 47, 165–177. [Google Scholar] [CrossRef]

- Moghadam, M.; Alwisy, A.; Al-Hussein, M. Integrated BIM/Lean base production line schedule model for modular construction manufacturing. In Proceedings of the Construction Research Congress 2012, West Lafayette, IN, USA, 21–23 May 2012; pp. 1271–1280. [Google Scholar]

- Xu, Z.; Wang, S.; Wang, E. Integration of BIM and Energy Consumption Modelling for Manufacturing Prefabricated Components: A Case Study in China. Adv. Civ. Eng. 2019, 2019, 1609523. [Google Scholar] [CrossRef]

- Ji, Y.; Chang, S.; Qi, Y.; Li, Y.; Li, H.X.; Qi, K.; Pellicer, E. A BIM-Based Study on the Comprehensive Benefit Analysis for Prefabricated Building Projects in China. Adv. Civ. Eng. 2019, 2019, 3720191. [Google Scholar] [CrossRef]

- Li, D.; Li, X.; Feng, H.; Wang, Y.; Fan, S. ISM-based relationship among critical factors that affect the choice of prefabricated concrete buildings in China. Int. J. Constr. Manag. 2019. [Google Scholar] [CrossRef]

- Tan, T.; Chen, K.; Xue, F.; Lu, W. Barriers to Building Information Modeling (BIM) implementation in China’s prefabricated construction: An interpretive structural modeling (ISM) approach. J. Clean. Prod. 2019, 219, 949–959. [Google Scholar] [CrossRef]

- Abanda, F.H.; Tah, J.H.M.; Cheung, F.K.T. BIM in off-site manufacturing for buildings. J. Build. Eng. 2017, 14, 89–102. [Google Scholar] [CrossRef] [Green Version]

- Luo, M.; Chen, D. Application of BIM technology in prefabricated building. In Proceedings of the 2018 International Conference on Construction and Real Estate Management: Innovative Technology and Intelligent Construction (ICCREM 2018), Charleston, SC, USA, 9–10 August 2018; pp. 263–270. [Google Scholar]

- Zhang, T.; Man, Q. A review of the application of BIM in the assembly construction. In Proceedings of the 2018 International Conference on Construction and Real Estate Management: Innovative Technology and Intelligent Construction (ICCREM 2018), Charleston, SC, USA, 9–10 August 2018; pp. 125–131. [Google Scholar]

- Vilutiene, T.; Kalibatiene, D.; Hosseini, M.R.; Pellicer, E.; Zavadskas, E.K. Building information modeling (BIM) for structural engineering: A bibliometric analysis of the literature. Adv. Civ. Eng. 2019, 2019, 5290690. [Google Scholar] [CrossRef]

- Liu, G.; Nzige, J.H.; Li, K. Trending topics and themes in offsite construction(OSC) research: The application of topic modelling. Constr. Innov. 2019, 19, 343–366. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E.; Costin, A.; Wang, C. Challenges of migrating from desktop-based BIM in construction. In Proceedings of the 33th International Symposium on Automation and Robotics in Construction, Auburn, AL, USA, 18–21 July 2016; pp. 934–942. [Google Scholar]

- Zhao, P.A.; Wang, C.C. A comparison of using traditional cost estimating software and BIM for construction cost control. In Proceedings of the ICCREM 2014, Kunming, China, 27–28 September 2014; pp. 256–264. [Google Scholar]

- Singh, M.M.; Sawhney, A.; Borrmann, A. Integrating rules of modular coordination to improve model authoring in BIM. Int. J. Constr. Manag. 2019, 19, 15–31. [Google Scholar] [CrossRef]

- Brown, R.; Barkokebas, B.; Ritter, C.; Al-Hussein, M. Predicting performance indicators using BIM and simulation for a wall assembly line. In Proceedings of the 27th Annual Conference of the International Group for Lean Construction (IGLC 2019), Dublin, Ireland, 3–5 July 2019; pp. 853–862. [Google Scholar]

- Ramaji, I.J.; Memari, A.M. Information exchange standardization for BIM application to multi-story modular residential buildings. In Proceedings of the Architectural Engineering National Conference 2015: Birth and Life of the Integrated Building (AEI 2015), Milwaukee, WI, USA, 24–27 March 2015; pp. 13–24. [Google Scholar]

- Ramaji, I.J.; Memari, A.M. Extending the current model view definition standards to support multi-storey modular building projects. Archit. Eng. Des. Manag. 2018, 14, 158–176. [Google Scholar] [CrossRef]

- Ramaji, I.J.; Memari, A.M.; Messner, J.I. Product-Oriented Information Delivery Framework for Multistory Modular Building Projects. J. Comput. Civ. Eng. 2017, 31. [Google Scholar] [CrossRef]

- Sharma, S.; Sawhney, A.; Arif, M. Parametric modelling for designing offsite construction. In Proceedings of the Creative Construction Conference (CCC 2017), Primosten, Croatia, 19–22 June 2017; pp. 1114–1121. [Google Scholar]

- Zhong, R.Y.; Peng, Y.; Xue, F.; Fang, J.; Zou, W.; Luo, H.; Thomas Ng, S.; Lu, W.; Shen, G.Q.P.; Huang, G.Q. Prefabricated construction enabled by the Internet-of-Things. Autom. Constr. 2017, 76, 59–70. [Google Scholar] [CrossRef]

- Zhai, Y.; Chen, K.; Zhou, J.X.; Cao, J.; Lyu, Z.; Jin, X.; Shen, G.Q.P.; Lu, W.; Huang, G.Q. An Internet of Things-enabled BIM platform for modular integrated construction: A case study in Hong Kong. Adv. Eng. Inform. 2019, 42, 100997. [Google Scholar] [CrossRef]

- Ke, C.; Gangyan, X.; Fan, X.; Zhong, R.Y.; Diandian, L.; Weisheng, L. A physical internet-enabled building information modelling system for prefabricated construction. Int. J. Comput. Integr. Manuf. 2018, 31, 349–361. [Google Scholar] [CrossRef] [Green Version]

- Sun, S.; Ge, J. Research on risk evaluation of BIM application in prefabricated buildings. In Proceedings of the 7th International Symposium on Project Management (ISPM 2019), Chongqing, China, 6 July 2019; pp. 600–606. [Google Scholar]

- Wang, J.; Yin, X.; Tian, Y.; Li, X.; Al-Hussein, M. Simulation of production line improvements in panelised floor manufacturing. In Proceedings of the 30th European Modeling and Simulation Symposium (EMSS 2018), Budapest, Hungary, 17–19 September 2018; pp. 157–164. [Google Scholar]

- Li, C.Z.; Hong, J.; Xue, F.; Shen, G.Q.; Xu, X.; Mok, M.K. Schedule risks in prefabrication housing production in Hong Kong: A social network analysis. J. Clean. Prod. 2016, 134, 482–494. [Google Scholar] [CrossRef] [Green Version]

- Altaf, M.S.; Bouferguene, A.; Liu, H.; Al-Hussein, M.; Yu, H. Integrated production planning and control system for a panelized home prefabrication facility using simulation and RFID. Autom. Constr. 2018, 85, 369–383. [Google Scholar] [CrossRef]

- Li, C.Z.; Zhong, R.Y.; Xue, F.; Xu, G.; Chen, K.; Huang, G.G.; Shen, G.Q. Integrating RFID and BIM technologies for mitigating risks and improving schedule performance of prefabricated house construction. J. Clean. Prod. 2017, 165, 1048–1062. [Google Scholar] [CrossRef]

- Bortolini, R.; Formoso, C.T.; Viana, D.D. Site logistics planning and control for engineer-to-order prefabricated building systems using BIM 4D modeling. Autom. Constr. 2019, 98, 248–264. [Google Scholar] [CrossRef]

- Xu, G.; Li, M.; Luo, L.; Chen, C.H.; Huang, G.Q. Cloud-based fleet management for prefabrication transportation. Enterp. Inf. Syst. 2019, 13, 87–106. [Google Scholar] [CrossRef]

- Qi, B.; Chen, K.; Costin, A. RFID and BIM-enabled prefabricated component management system in prefabricated housing production. In Proceedings of the Construction Research Congress 2018: Construction Information Technology (CRC 2018), New Orleans, LA, USA, 2–4 April 2018; pp. 591–601. [Google Scholar]

- Zeng, N.; Dichtl, M.; Konig, M. A scenario-based simulation framework of on- and off-site construction logistics. In Proceedings of the 2017 Winter Simulation Conference (WSC 2017), Crystal City, VA, USA, 3–6 December 2017; pp. 2348–2359. [Google Scholar]

- Tang, X.; Chong, H.Y.; Zhang, W. Relationship between BIM Implementation and Performance of OSM Projects. J. Manag. Eng. 2019, 35. [Google Scholar] [CrossRef]

- Jia, M.; Komeily, A.; Wang, Y.; Srinivasan, R.S. Adopting Internet of Things for the development of smart buildings: A review of enabling technologies and applications. Autom. Constr. 2019, 101, 111–126. [Google Scholar] [CrossRef]

- Li, X.; Shen, G.Q.; Wu, P.; Fan, H.; Wu, H.; Teng, Y. RBL-PHP: Simulation of Lean Construction and Information Technologies for Prefabrication Housing Production. J. Manag. Eng. 2018, 34. [Google Scholar] [CrossRef]

- Ritter, C.; Abaeian, H.; Sirbu, V.; Al-Hussein, M. Radio-frequency identification based process management for production line balancing. In Proceedings of the 35th International Symposium on Automation and Robotics in Construction and International AEC/FM Hackathon: The Future of Building Things (ISARC 2018), Berlin, Germany, 20–25 July 2018. [Google Scholar]

- Li, X.; Chi, H.L.; Wu, P.; Shen, G.Q. Smart work packaging-enabled constraint-free path re-planning for tower crane in prefabricated products assembly process. Adv. Eng. Inform. 2020, 43. [Google Scholar] [CrossRef]

- Kang, J.; Ganapathi, A.; Lee, J.; Faghihi, V. BIM to field: Robotic total station and BIM for quality control. In Proceedings of the European Conference on Product and Process Modelling (ECPPM 2012), Reykjavik, Iceland, 25–27 July 2012; pp. 717–722. [Google Scholar]

- Ahn, S.; Han, S.; Al-Hussein, M. Improvement of transportation cost estimation for prefabricated construction using geo-fence-based large-scale GPS data feature extraction and support vector regression. Adv. Eng. Inform. 2020, 43. [Google Scholar] [CrossRef]

- Li, C.Z.; Hong, J.; Xue, F.; Shen, G.Q.; Xu, X.; Luo, L. SWOT analysis and Internet of Things-enabled platform for prefabrication housing production in Hong Kong. Habitat Int. 2016, 57, 74–87. [Google Scholar] [CrossRef]

- Zhai, Y.; Chen, K.; Zhou, J.X.; Cao, J.; Lyu, Z.; Jin, X.; Fang, X.; Zhong, R.Y.; Shen, G.Q.P.; Lu, W.; et al. An internet of things-enabled BIM platform for modular integrated construction. In Proceedings of the 48th International Conference on Computers and Industrial Engineering (CIE 2018), Auckland, New Zealand, 2–5 December 2018. [Google Scholar]

- Valinejadshoubi, M.; Bagchi, A.; Moselhi, O. Development of a BIM-Based Data Management System for Structural Health Monitoring with Application to Modular Buildings: Case Study. J. Comput. Civ. Eng. 2019, 33, 05019003. [Google Scholar] [CrossRef]

- García-Pereira, I.; Portalés, C.; Gimeno, J.; Casas, S. A collaborative augmented reality annotation tool for the inspection of prefabricated buildings. Multimed Tools Appl. 2020, 79, 6483–6501. [Google Scholar] [CrossRef]

- Zhou, Y.; Luo, H.; Yang, Y. Implementation of augmented reality for segment displacement inspection during tunneling construction. Autom. Constr. 2017, 82, 112–121. [Google Scholar] [CrossRef]

- Raimbaud, P.; Lou, R.; Merienne, F.; Danglade, F.; Figueroa, P.; Hernandez, J.T. BIM-based mixed reality application for supervision of construction. In Proceedings of the 26th IEEE Conference on Virtual Reality and 3D User Interfaces (VR 2019), Osaka, Japan, 23–27 March 2019; pp. 1903–1907. [Google Scholar]

- Goh, J.; Hu, S.; Fang, Y. Human-in-the-loop simulation for crane lift planning in modular construction on-site assembly. In Proceedings of the ASCE International Conference on Computing in Civil Engineering 2019: Visualization, Information Modeling, and Simulation (i3CE 2019), Atlanta, GA, USA, 17–19 June 2019; pp. 71–78. [Google Scholar]

- Zhang, Z.; Pan, W. Virtual reality (Vr) supported lift planning for modular integrated construction (mic) of high-rise buildings. Hong Kong Inst. Eng. Trans. 2019, 26, 136–143. [Google Scholar] [CrossRef]

- Martinez, P.; Ahmad, R.; Al-Hussein, M. A vision-based system for pre-inspection of steel frame manufacturing. Autom. Constr. 2019, 97, 151–163. [Google Scholar] [CrossRef]

- Li, X.; Chi, H.L.; Zhang, W.F.; Shen, G.Q. Monitoring and alerting of crane operator fatigue using hybrid deep neural networks in the prefabricated products assembly process. In Proceedings of the 36th International Symposium on Automation and Robotics in Construction (ISARC 2019), Banff, AB, Canada, 21–24 May 2019; pp. 680–687. [Google Scholar]

- Guo, J.; Wang, Q.; Park, J.H. Geometric quality inspection of prefabricated MEP modules with 3D laser scanning. Autom. Constr. 2020, 111. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.; Forsythe, P.; Shirowzhan, S. Evaluation of terrestrial and mobile scanner technologies for part-built information modeling. J. Constr. Eng. Manag. 2018, 144, 04018110. [Google Scholar] [CrossRef]

- Shirowzhan, S.; Sepasgozar, S.M. Spatial analysis using temporal point clouds in advanced GIS: Methods for ground elevation extraction in slant areas and building classifications. ISPRS Int. J. Geo-Inf. 2019, 8, 120. [Google Scholar] [CrossRef] [Green Version]

- Arashpour, M.; Heidarpour, A.; Akbar Nezhad, A.; Hosseinifard, Z.; Chileshe, N.; Hosseini, R. Performance-based control of variability and tolerance in off-site manufacture and assembly: Optimization of penalty on poor production quality. Constr. Manag. Econ. 2020, 38, 502–514. [Google Scholar] [CrossRef]

- Kalasapudi, V.S.; Tang, P. Automated tolerance analysis of curvilinear components using 3D point clouds for adaptive construction quality control. In Proceedings of the 2015 ASCE International Workshop on Computing in Civil Engineering (IWCCE 2015), Austin, TX, USA, 21–23 June 2015; pp. 57–65. [Google Scholar]

- Chai, J.; Chi, H.-L.; Wang, X.; Wu, C.; Jung, K.H.; Lee, J.M. Automatic as-built modeling for concurrent progress tracking of plant construction based on laser scanning. Concurr. Eng. 2016, 24, 369–380. [Google Scholar] [CrossRef]

- Zhang, C.; Arditi, D. Automated progress control using laser scanning technology. Autom. Constr. 2013, 36, 108–116. [Google Scholar] [CrossRef]

- Che, E.; Jung, J.; Olsen, M.J. Object recognition, segmentation, and classification of mobile laser scanning point clouds: A state of the art review. Sensors 2019, 19, 810. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shirowzhan, S.; Sepasgozar, S.M.; Li, H.; Trinder, J.; Tang, P. Comparative analysis of machine learning and point-based algorithms for detecting 3D changes in buildings over time using bi-temporal lidar data. Autom. Constr. 2019, 105, 102841. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E.; Lim, S.; Shirowzhan, S.; Kim, Y.M. Implementation of As-Built Information Modelling Using Mobile and Terrestrial Lidar Systems. In Proceedings of the 31st International Symposium on Automation and Robotics in Construction and Mining (ISARC 2014), Sydney, Australia, 9–11 July 2014. [Google Scholar]

- Sepasgozar, S.M.E.; Wang, C.C.; Shirowzhan, S. Challenges and opportunities for implementation of laser scanners in building construction. In Proceedings of the 33rd International Symposium on Automation and Robotics in Construction (ISARC 2016), Auburn, AL, USA, 18–21 July 2016; pp. 742–751. [Google Scholar]

- Baghdadi, A.; Heristchian, M.; Kloft, H. Design of prefabricated wall-floor building systems using meta-heuristic optimization algorithms. Autom. Constr. 2020, 114. [Google Scholar] [CrossRef]

- Hamdan, S.B.; Alwisy, A.; Al-Hussein, M.; Abourizk, S.; Ajweh, Z. Simulation based multi-objective cost-time trade-off for multi-family residential off-site construction. In Proceedings of the Winter Simulation Conference (WSC 2015), Huntington Beach, CA, USA, 6–9 December 2015; pp. 3391–3401. [Google Scholar]

- Daget, Y.T.; Zhang, H. Decision-making model for the evaluation of industrialized housing systems in Ethiopia. Eng. Constr. Archit. Manag. 2019, 27, 296–320. [Google Scholar] [CrossRef]

- Arashpour, M.; Bai, Y.; Aranda-mena, G.; Bab-Hadiashar, A.; Hosseini, R.; Kalutara, P. Optimizing decisions in advanced manufacturing of prefabricated products: Theorizing supply chain configurations in off-site construction. Autom. Constr. 2017, 84, 146–153. [Google Scholar] [CrossRef]

- Zhu, L.; Meng, X.; Shi, Z.; Huang, Y. Selection of prefabricated concrete factories’ location based on triangular fuzzy numbers and fuzzy group decision-making. In Proceedings of the 3rd International Conference on Computational Intelligence and Applications (ICCIA 2018), Hong Kong, China, 28–30 July 2018; pp. 26–30. [Google Scholar]

- Han, D.; Yin, H.; Qu, M.; Zhu, J.; Wickes, A. Technical Analysis and Comparison of Formwork-Making Methods for Customized Prefabricated Buildings: 3D Printing and Conventional Methods. J. Archit. Eng. 2020, 26. [Google Scholar] [CrossRef]

- Yang, H.; Chung, J.K.H.; Chen, Y.; Li, Y. The cost calculation method of construction 3D printing aligned with internet of things. EURASIP J. Wirel. Commun. Netw. 2018, 2018, 147. [Google Scholar] [CrossRef] [Green Version]

- Pan, M.; Pan, W. Determinants of Adoption of Robotics in Precast Concrete Production for Buildings. J. Manag. Eng. 2019, 35. [Google Scholar] [CrossRef]

- Han, Z.; Wang, Y. The applied exploration of big data technology in prefabricated construction project management. In Proceedings of the 2017 International Conference on Construction and Real Estate Management: Prefabricated Buildings, Industrialized Construction, and Public-Private Partnerships (ICCREM 2017), Guangzhou, China, 10–12 November 2017; pp. 71–78. [Google Scholar]

- Wang, Z.; Wang, T.; Hu, H.; Gong, J.; Ren, X.; Xiao, Q. Blockchain-based framework for improving supply chain traceability and information sharing in precast construction. Autom. Constr. 2020, 111, 103063. [Google Scholar] [CrossRef]

- Maskuriy, R.; Selamat, A.; Ali, K.; Maresova, P.; Krejcar, O. Industry 4.0 for the Construction Industry—How Ready Is the Industry? Appl. Sci. 2019, 9, 2819. [Google Scholar] [CrossRef] [Green Version]

| Country | Documents | Citations | Average Citation | Total Link Strength 1 |

|---|---|---|---|---|

| Mainland China | 47 | 623 | 13.3 | 3766 |

| Canada | 18 | 93 | 5.2 | 494 |

| Hong Kong (China) | 17 | 487 | 28.6 | 2250 |

| Australia | 15 | 81 | 5.4 | 1494 |

| United States | 15 | 99 | 6.6 | 616 |

| United Kingdom | 10 | 60 | 6 | 698 |

| Singapore | 8 | 101 | 12.6 | 1211 |

| Germany | 7 | 18 | 2.6 | 203 |

| Brazil | 6 | 34 | 5.7 | 240 |

| Technology | Number of Papers | Proportion | |

|---|---|---|---|

| None (BIM only) | 56 | 70% | |

| Co-occurring with other technologies (Total 24 papers, 30%) | RFID | 20 | 25.0% |

| GPS | 14 | 17.5% | |

| IoT | 10 | 12.5% | |

| Sensor | 8 | 10.0% | |

| Laser scanning | 5 | 6.3% | |

| VR | 4 | 5.0% | |

| Photogrammetry | 4 | 3.8% | |

| AI | 3 | 3.8% | |

| Big data | 2 | 2.5% | |

| AR | 1 | 1.3% | |

| Blockchain | 1 | 1.3% | |

| GIS | 0 | 0.0% | |

| 3D printing | 0 | 0.0% | |

| Robotic | 0 | 0.0% | |

| Review Focus | Main Findings | Limitations | Literature |

|---|---|---|---|

| Comprehensive review of BIM in the off-site manufacturing stage | Emphasis on technology potential, lack of knowledge about clear benefits of BIM and off-site manufacturing is a huge barrier towards OSC’s uptake. | It does not discuss how BIM could be used appropriately to fully achieve the benefits. | |

| Review focus on identifying future directions of BIM for OSC | Through quantitative analysis and in-depth discussion of BIM for OSC, research gaps are identified and future directions are proposed: BIM-based generative design for prefabrication, cloud BIM-based data exchange for OSC, robotics and 3D printing for OSC, BIM-enabled big data analytics toward the best OSC practice. | The directions are more focused on fragment phases or activities. There is a lack of systematic assessment model of BIM in OSC. | [46] |

| Trending topics and themes in off-site construction research | Used topic-modelling techniques to identify the distribution of topic and themes. Machine learning for language toolkits was used to get topic posterior word distribution and word composition. Identified 50 main topics in OSC, and BIM can be used for organizational management. | Too general or academic in nature with limited practical significance. | [87] |

| BIM implementation and benefits in different stages of OSC | Examined the potential applications and benefits of BIM in various stages of the entire project lifecycle. Pointed out that most existing research is fragmented with a focus on a specific phase and not on workflow integration. | These reviews are not carried out systematically. They provide a summary or a mapping framework. The conclusions lack quantitative analysis or validation through case analysis. | [71,84,85] |

| BIM in structural engineering in OSC | Bibliometric analysis of the literature. Current situation: Isolated, disjointed, and fragmented research. Future research should be on modelling of structural components, automation of assembly sequence, planning and optimization of OSC, and dynamic structural health monitoring. | Lacks discussion on practical utilization of BIM, just pointed out that BIM could be a beneficial technology in OSC from a structural engineering viewpoint. | [86] |

| End-of-life: Minimize construction and demolition | Pointed out the importance of standardized prefabricated modules for rapid on-site assembly. Reusability, circular economy business model, standardization of material types and sizes through prefabrication. MEP prefabrication, RFID-enabled BIM, and traceability regarding features that can enhance end-of-life management. | Not a review focusing on prefabrication construction. Prefabrication/off-site construction is discussed in one section only, and the benefit of reusability of components is also discussed. | [55] |

| Topic | Purpose of Utilizing BIM | Outcome Achieved | Issues Identified | Key Relevant Literature | Total Number |

|---|---|---|---|---|---|

| DfMA | To check and review current plans and find optimal solutions by simulation. | Bathroom pods, wall panels, beams, column, roof, MEP system design and assembly sequence and lift planning optimization, AI technology integrated. | Limited to separate building elements. Less automation of elements’ development in BIM, manual intervention. | [56,59,75,90,91] | 14 |

| Information delivery and exchange | To visualize information of prefabrication with stakeholders. | Integrate RFID, GPS, sensors, image, scan data with designed BIM model for near-real-time construction monitoring and communication. | Lack of standardization, information loss. Poor understanding among different stakeholders. | [10,92,93,94,95] | 20 |

| Carbon emissions | To carry out carbon emission analysis. | Emissions reduction, labour and cost saving, accuracy of decision-making improved. | Lack of data accuracy test. | [64,65] | 2 |

| Supply chain management | To streamline and visualize components production, transportation, and on-site assembly activities. | Visualize real construction progress. Automation and information sharing level improved. Cost and time saving. | Lack of procurement process, safety management, and fidelity with actual practice. Poor connections among RFID, sensors. Different data format brings poor communication. | [7,74,96,97,98] | 9 |

| Schedule risks | To detect quality of components by comparison with near-real-time collected data. | Cost and labour saving, time saving, e.g., 20%. Schedule risks reduction, rework reduction onsite, information sharing efficiency improved. | Complexity of data processing, manual intervention, poor automation in data alignment with others, e.g., RFID data. | [99,100,101,102,103] | 15 |

| Logistics | To make collaboration in planning and control meetings, reviewing logistics plans. | Productivity improves, e.g., 38% labour reduction, waiting time reduced, e.g., 20%, work-in-progress inventory reduced, on-time delivery rate improved, e.g., 7.3%. | Lack of intelligent decision-making models, lack of components library and optimization algorithms, limited case validation, manual intervention. | [68,104,105,106,107] | 6 |

| Sustainable construction | To make energy reduction analysis, integrated with leanness concepts for simulation analysis. | Waste reduction and reusing components strategies, life cycle management of elements. | Limited BIM usage in end-of-life of precast elements and recycle strategies, manual intervention, skilled labour needed. | [75,76,77] | 13 |

| Integration management | To conduct empirical analysis on effects of BIM in OSC. | BIM is able to improve the performance of OSC through its integration management and cooperation. | Lacks an estimate of the actual improved performance from BIM implementation. | [108] | 1 |

| Topic | Purpose of Utilizing RFID | Outcome Achieved | Issues Identified | Relevant Literature |

|---|---|---|---|---|

| Supply chain management | To automatically identify near-real-time object information. | Simulation validated the improvement of efficiency, e.g., 62.0% saving of operational costs; streamlined process. | Well-designed BIM model required. Disjointed connections among RFID and BIM. | [69,74,76,101,110] |

| To track status of material. | Reduction of information loss, efficiency improved, time and labour cost savings. | Limited range of signals, and inaccurate data from damaged 1.5% RFID tags, manual intervention. | [96,97,98] | |

| Carbon emissions | To identify each component with material usage. | Rough emission calculation and emission risks reduction. | Lack of data reliability test, e.g., accuracy and reaction speed. | [64] |

| Schedule risks | To track labour, materials, and equipment use. | 50%-time reduction of façade installation. Overall 20% reduction of scheduled time. | Complexity of raw RFID data processes. Lack of detailed tags arrangement plan. | [102,103,106,111] |

| Logistics | To detect the status of elements for asset management. | Low cost and timely transportation data collection. | Complexity of raw RFID data process, data security issues. | [68,105] |

| Information delivery and exchange | To collect the near-real-time status of components. | Near-real-time progress and cost information integrated with BIM. | Lack of global standards for RFID data exchange. | [7,67,112] |

| Topic | Purpose of Utilizing GPS | Outcome Achieved | Issues Identified | Relevant Literature |

|---|---|---|---|---|

| Supply chain management | To detect coordinates of precast components for load and unloading information. | Efficiency improved, cost and time saving for information collection. | Temporary data storage and not real-time, e.g., 1–2 min waiting time for data collection. | [69,96,97,98,103] |

| Carbon emissions | To measure transportation route and distance. | Material consumption and emissions can be estimated rapidly. | Lack of data reliability, e.g., accuracy and reaction speed. | [64,65] |

| Schedule risks | To collect coordinates information of building elements to compare with BIM. | Timely decision-making, errors reduction, time saving. | Lak of data reliability test, e.g., accuracy and response speed. | [7,103,112,113] |

| Logistics | To capture near-real-time information about components. | Time saving, information sharing improved. | Time consuming data extraction and process, manual intervention. | [68,105,114] |

| Topic | Purpose of Utilizing IoT | Outcome Achieved | Issues Identified | Relevant Literature |

|---|---|---|---|---|

| Supply chain management | To achieve near-real-time visibility and traceability in OSC. | Time and cost saving, information sharing, and automation level improved. | Delays caused by unstable network signals, complexity in data processing. | [96,97,98] |

| Logistics | To realize automatic data collection and item-level management. | Information and automation level of cost and progress information improved, efficiency increased. | Time and money consumed to develop IoT, and security and privacy issues. | [68,105] |

| Information delivery and exchange | To monitor progress and cost in on-site assembly. | Efficiency improvement by timely information sharing. | Incomplete function modules for daily operations, e.g., quality, safety, without industrial standards among technologies. | [7,60] |

| Carbon emissions | To collect and visualize emissions. | Emissions reduction, labour and cost saving, accuracy of decision-making improved. | Lack of data reliability test, e.g., accuracy and reaction speed. | [64] |

| Sensor Type | Function | Reference |

|---|---|---|

| GPS sensors | Location identification of components; detect and transmit the running time of construction machineries. | [64,65,116] |

| Strain sensors | Measure the near-real-time strain on structural elements. | [117] |

| Acceleration sensors | Monitor the operational status of tower cranes. | [64,65] |

| Barometric sensors | Monitor the running state of construction elevators. | [64,65] |

| Wind-sensor, rain-sensor | Monitor wind speed and rain load. | [112] |

| Fibre optic sensor | Automate processes by activating the RFID reader and GPS receiver. | [69] |

| Laser sensor | Determine manufacturing time of equipment. | [64] |

| Topics | Purpose of Utilizing Sensors | Outcome Achieved | Issues Identified | Relevant Literature |

|---|---|---|---|---|

| Information delivery and exchange | To monitor the structural health of prefabricated components. | Damage identification of buckled or yielded steel in near-real-time, visualized based on BIM system. | Difficulty in full integration between physical sensors and data uploading, and data processing. | [117] |

| Carbon emissions | Near-real-time monitoring of carbon emissions of material usage and machinery operation. | Timely reduction of irregular emissions and labour cost. | Lack of data reliability, e.g., accuracy and reaction speed. | [64,65] |

| Supply chain management | To create smart construction objects for virtual environment development. | Location identification of prefabricated components. | Lack of practical analysis, and needs to improve ease of installation and maintenance. | [69,97,98] |

| Topic | Purpose of Utilizing AR | Outcome Achieved | Issues Identified | Relevant Literature |

|---|---|---|---|---|

| Schedule risks | To reduce errors of on-site assembly and repair tasks. | 75% reduction of errors on assembly tasks and 90% time saving for developing the same type of prototype. | Software based and lack of model accuracy validation with real world. | [52] |

| Inspect prefabrication element with the 3D AR model. | Monitor quality of precast elements and make photographic, scanned 3D model, and stroke-type annotates with the AR-based tool. | AR makers are required, high requirement of equipment and environment conditions, time consuming for algorithm design and manual intervention, complexity of device operation. | [118,120]. |

| Topic | Purpose of Utilizing VR | Outcome Achieved | Issues Identified | Relevant Literature |

|---|---|---|---|---|

| Schedule risks and logistics | To guide production process, e.g., crane lifting in a safer and more efficient way. | Enhancement of site safety and productivity with VR-supported tool. | Based on virtual environment simulation which may not accurately replicate real situations, and operators are not able to see themselves on the screen. | [72,121,122] |

| To present near-real-time construction progress. | Integrated as a functional module in a platform. | Mainly at conceptual and virtual model presentation stage. Lack of practical outcomes and tests in real cases. | [7,96,103] |

| Topic | Purpose of Utilizing Photogrammetry | Outcome Achieved | Issues Identified | Relevant Literature |

|---|---|---|---|---|

| Schedule risks | Quality detection by identifying geometry deviation. | Quality detection for light-gauge steel frame, intersection, and stud detection of rectangular forms. | Inaccurate for irregular components, e.g., door or window, and limitations of camera location, and lack of accurate analysis. | [123] |

| To detect crane operators’ fatigue. | 93.6% overall accuracy could be achieved in fatigue detection. | Insufficient features related to fatigue identified from images. | [124] | |

| Information delivery and exchange | To capture near-real-time information of objects for development of a virtual environment. | Re-optimizing crane lifting paths simulated in a BIM environment. | Lack of analysis and photographic data of real cases and how the image data are exchanged with the BIM model. | [112] |

| To capture the construction site and integrate with a BIM model for supervision. | Combine near-real-time on-site data with BIM model and detect progress differences by superimposing building elements in an A/VR environment. | Pre-set markers required for information extraction from images or videos. Alignment with BIM model is not automated. | [118,120] |

| Topic | Purpose of Utilizing Laser Scanning | Outcome Achieved | Issues Identified | Relevant Literature |

|---|---|---|---|---|

| Schedule risks | Quality detection by identifying geometric deviation. | Improved efficiency in detecting modular elements in the shape of a cylinder and rectangle, in comparison with the as-designed BIM model. | Incomplete collected data with occlusion or noise. Complex data process in need of skilled manual processing. Limited elements identification. | [125,128,129] |

| Information delivery and exchange | Height measurement. | To determine the height of a single steel frame in the loading area, and data exchange with the BIM model. | Laser scanner system may not be suitable for large-size manufactured parts due to high cost and complex implementation process. | [123,125] |

| To capture the specific construction scene for a virtual environment creation. | Safety improvement by identifying potential obstacles during the construction lifting process. | The objects from a point cloud are created manually and approximately. | [121] |

| Topic | Purpose of Utilizing AI | Outcome Achieved | Issues Identified | Relevant Literature |

|---|---|---|---|---|

| DfMA | To assist optimizing the design of prefabricated components. | Reduced effort and cost; high process speed in components’ segmentation with optimization algorithms. | Time consuming on preparation of topology analysis; limited elements configuration design. | [12,136,137,138] |

| Logistics | To estimate transportation cost. | Improved estimation method; 14% calculation error reduction. | Complex calculation with a large amount of data. | [114] |

| Schedule risks | To optimize or predict the construction tasks. | Monitoring the on-site construction progress by automated comparison between actual and planned model, variability and tolerance control on product quality, and identifying on-site risks e.g., crane operator fatigue. | lack of real practice validation. In need of large amounts of data for training, and time consuming. | [7,124,128,137] |

| Supply chain management | To optimize supply chain management and assist selecting factory locations. | Test on decision making of cost reduction and effectiveness of alternative methods. | Lack of consideration of real projects and the context conditions. | [139,140] |

| Topic | Purpose of Utilizing 3D Printing | Outcome Achieved | Issues Identified | Relevant Literature |

|---|---|---|---|---|

| Sustainable construction | To make formwork with 3D printing and compare the results with traditional methods. | 3D printing could improve accuracy and save time and costs for curved formwork compared with the conventional method. | Limited to regular shapes and materials, and needs to be extended to complex precast components. | [141] |

| To clarify the confused attributes between construction, 3D printing, and traditional construction. | Put forward the method of cost calculation of 3D printing in OSC, and it contributed in solving the problems of cost calculation among different construction technologies. | Lack of real case validation for the proposed approach. | [142] |

| Topic | Purpose of Utilizing Robotics | Outcome Achieved | Issues Identified | Relevant Literature |

|---|---|---|---|---|

| Sustainable construction | To design a robotic machine or automation strategies for manufacturing. | Rebar cages or precast timber—automated production simulated, e.g., VR model simulating the proposed mechanism with optimum performance. | Design at a virtual level. Lack of physical prototypes validation. Lack of cost analysis for adoption. | [72,73] |

| To explore the determinants of robotics adoption in precast concrete production. | Environmental and organizational contexts are more critical than technological advancements for adoption. | Only four cases are available for analysis. | [143] |

| Topic | Purpose of Utilizing Big Data | Outcome Achieved | Issues Identified | Relevant Literature |

|---|---|---|---|---|

| Supply chain management | To analyze big data utilization in OSC. | An introductory paper on big data application in design, production, and on-site assembly stages. | Lack of empirical validation and case study. Mainly at a conceptual level. | [144] |

| Topic | Purpose of Utilizing Blockchain | Outcome Achieved | Issues Identified | Relevant Literature |

|---|---|---|---|---|

| Supply chain management | To realize near-real-time traceability and information sharing with all precast components information in smart contracts. | Reduction of supply chain cost, ranging from 38 to 99.8% in different scenarios improved efficiency. | Currently at a simulation level, and lack of validation in real case studies. Processing time consuming with the approval of all stakeholders needed. Data security issues. | [145] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, M.; Wang, C.C.; Sepasgozar, S.; Zlatanova, S. A Systematic Review of Digital Technology Adoption in Off-Site Construction: Current Status and Future Direction towards Industry 4.0. Buildings 2020, 10, 204. https://doi.org/10.3390/buildings10110204

Wang M, Wang CC, Sepasgozar S, Zlatanova S. A Systematic Review of Digital Technology Adoption in Off-Site Construction: Current Status and Future Direction towards Industry 4.0. Buildings. 2020; 10(11):204. https://doi.org/10.3390/buildings10110204

Chicago/Turabian StyleWang, Mudan, Cynthia Changxin Wang, Samad Sepasgozar, and Sisi Zlatanova. 2020. "A Systematic Review of Digital Technology Adoption in Off-Site Construction: Current Status and Future Direction towards Industry 4.0" Buildings 10, no. 11: 204. https://doi.org/10.3390/buildings10110204

APA StyleWang, M., Wang, C. C., Sepasgozar, S., & Zlatanova, S. (2020). A Systematic Review of Digital Technology Adoption in Off-Site Construction: Current Status and Future Direction towards Industry 4.0. Buildings, 10(11), 204. https://doi.org/10.3390/buildings10110204