The Influence of Casein Protein Admixture on Pore Size Distribution and Mechanical Properties of Lime-Metakaolin Paste

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials Used in Investigation

2.2. Sample Preparation

2.3. Pore Size Distribution

2.4. Flexural and Compressive Strengths

3. Results

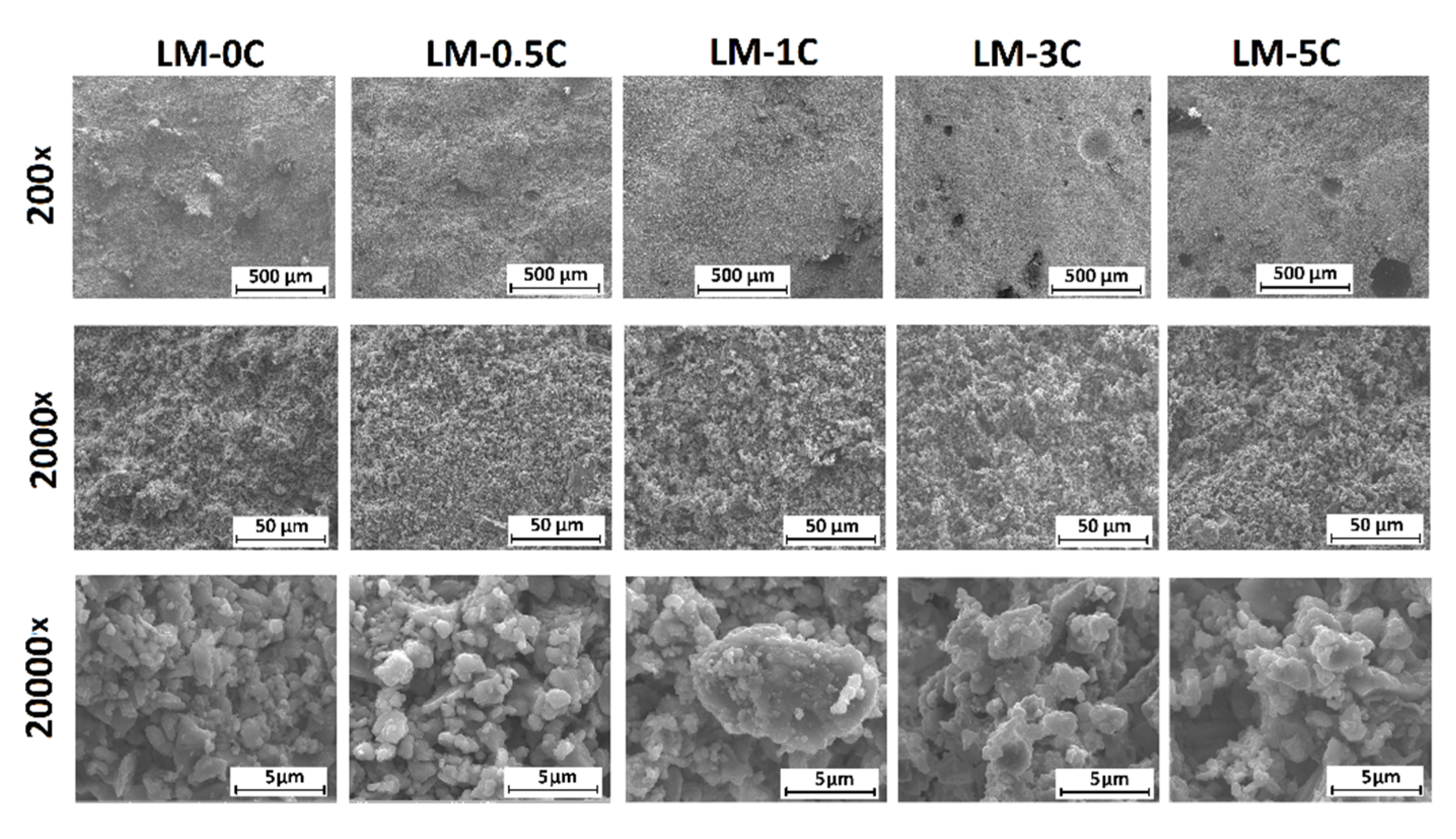

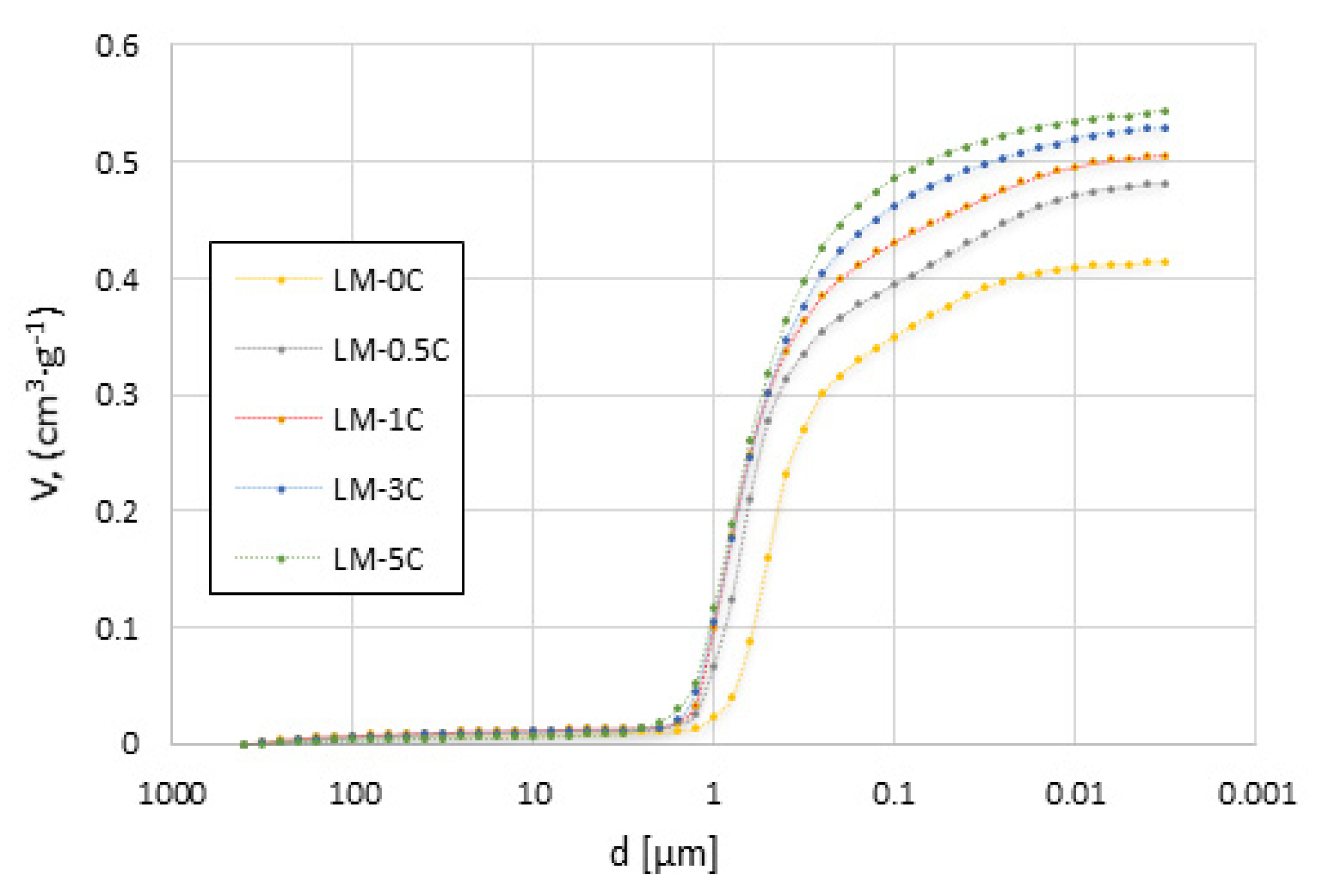

3.1. Pore Size Distribution

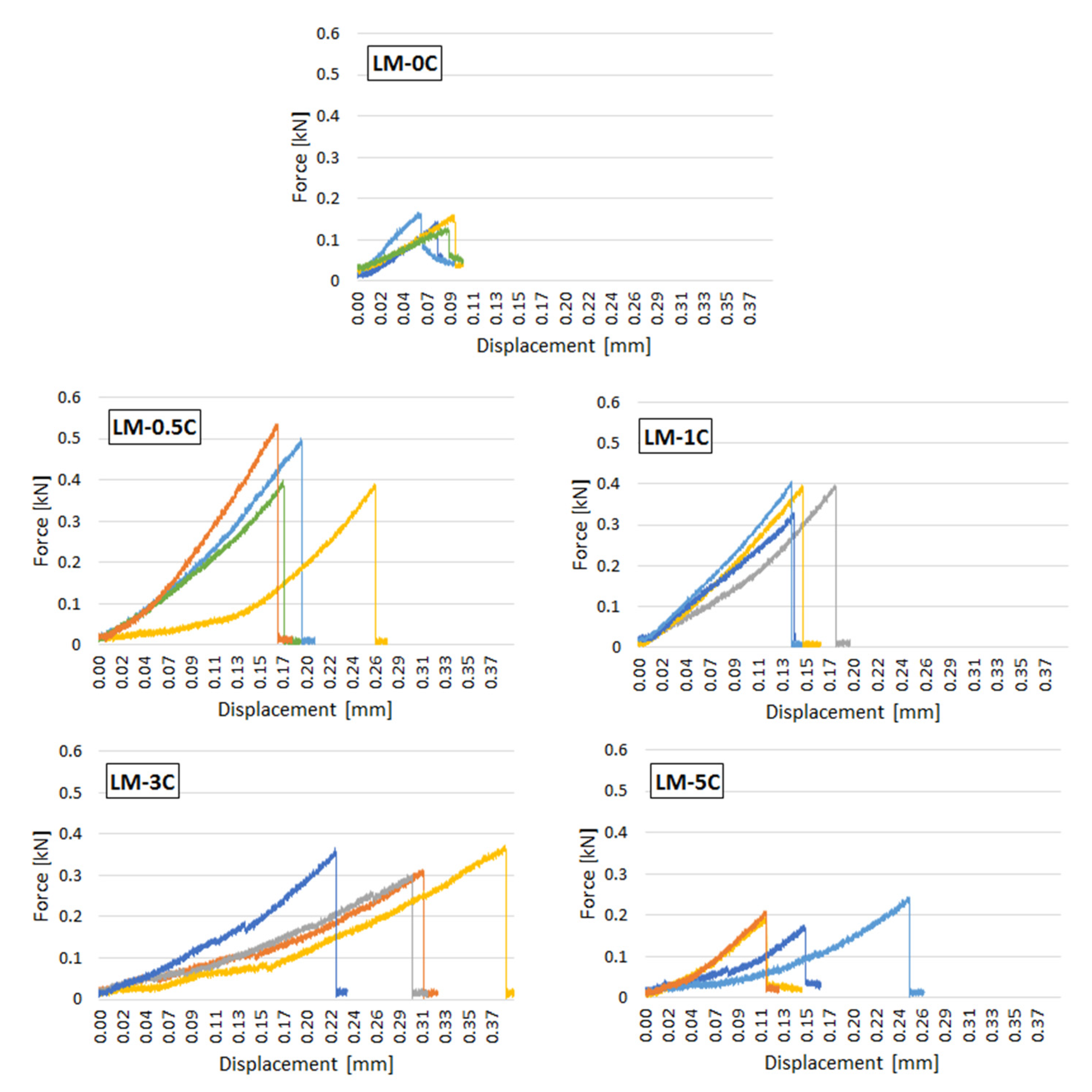

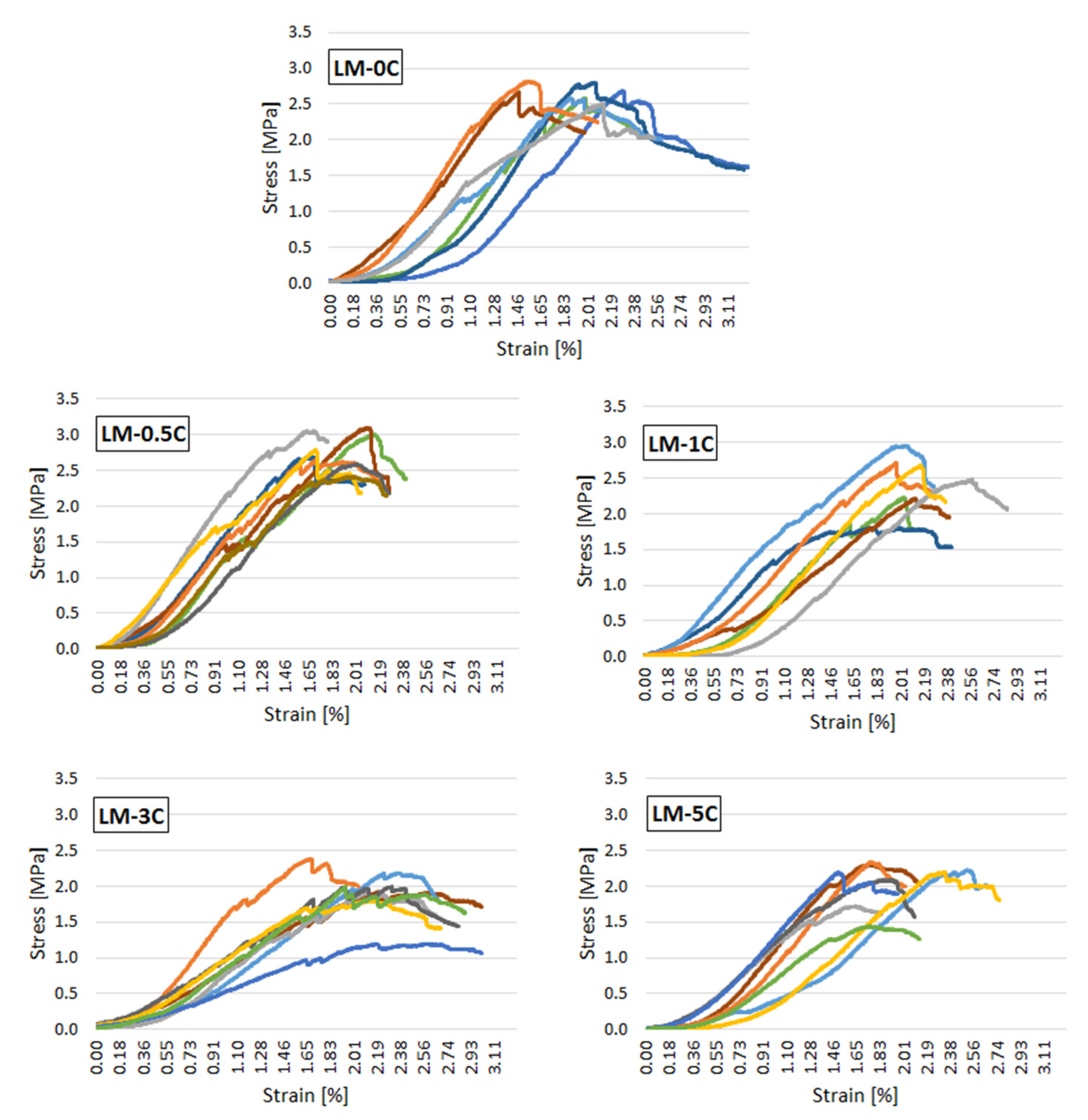

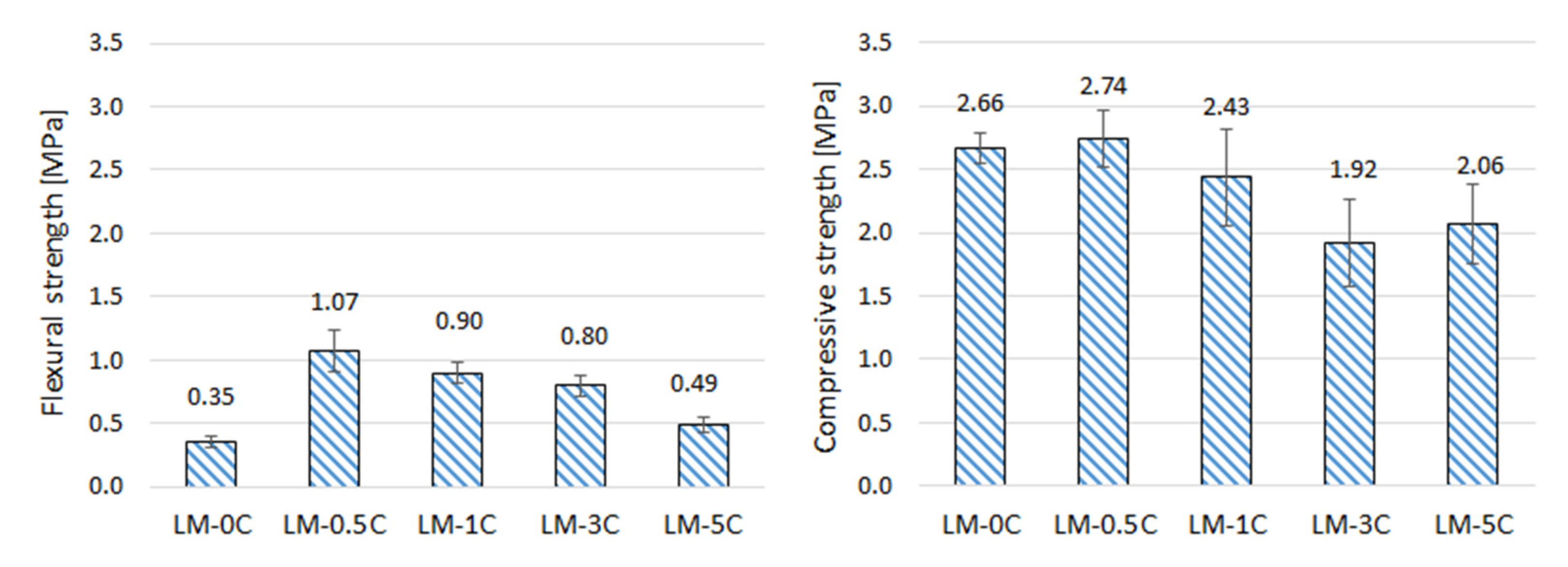

3.2. Flexural and Compressive Strengths

4. Discussion

4.1. Pore Size Distribution

4.2. Flexural and Compressive Strengths

5. Conclusions

- Casein addition affects the pore size distribution and total porosity within the lime-metakaolin paste. The casein addition in the amount of 0.5% and 1% reduced the pore diameter while substantially increasing the total pore area. In turn, the 3% and 5% addition increased the mean pore diameter compared to the paste used as reference. The porosity increased as a result of air bubbles being introduced in the course of ingredient mixing;

- The admixture of casein significantly increased the flexural strength of the pastes. The admixture in the amount of 0.5% turned out to be the most effective, and with the increase in the casein content, the flexural strength decreased;

- Only the 0.5% casein admixture improved the compressive strength of the lime-metakaolin paste. In general, the strength decreased with the increasing casein content, with the samples containing 3% casein having the lowest strength;

- The results show a clear dependence of the strength parameters on porosity. Total porosity of the pastes increases along with the casein content, whereas the compressive and flexural strengths decrease. The increase in pore diameter with casein content may also cause a decrease in strength;

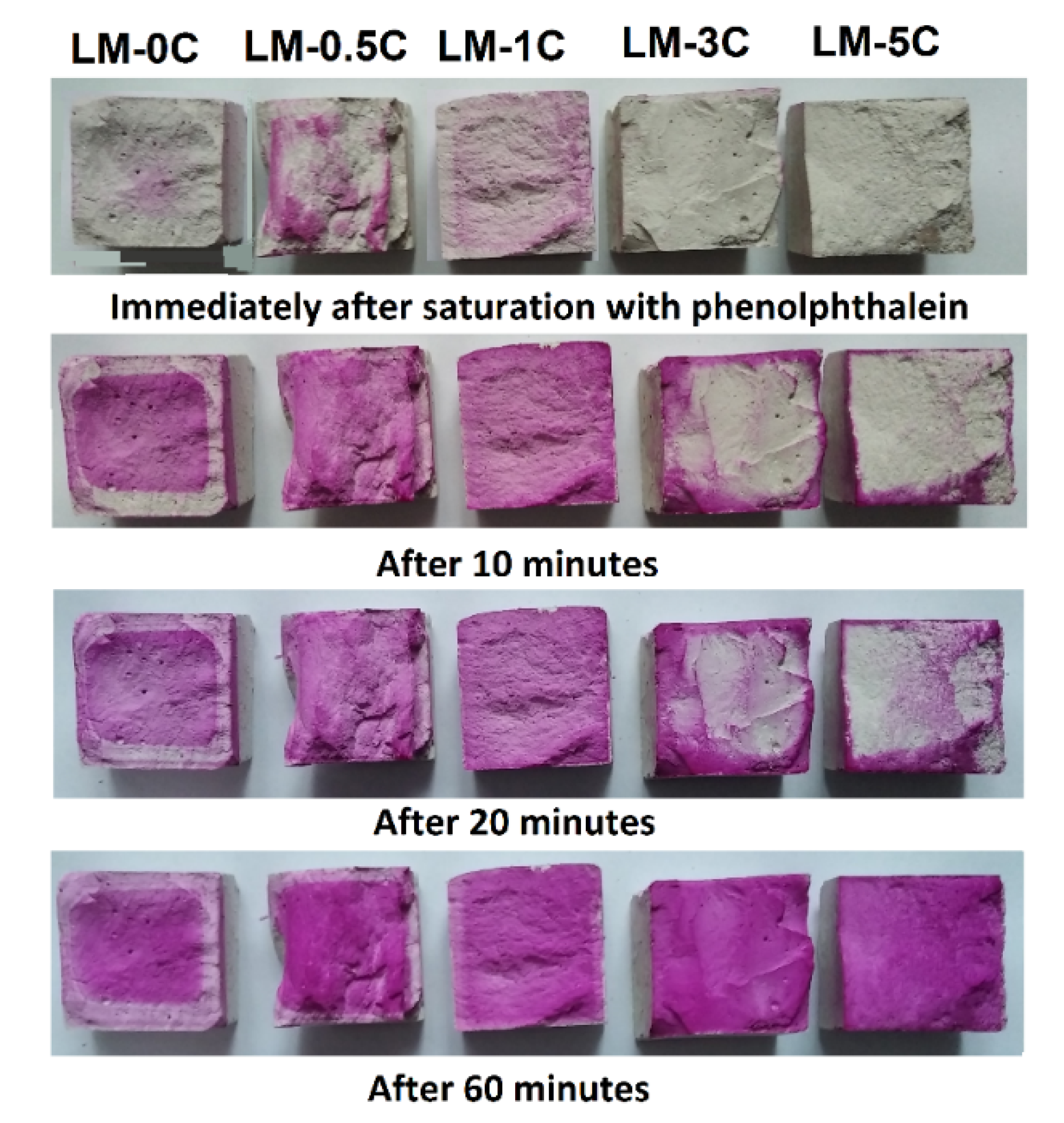

- The phenolphthalein test showed no significant differences in the progress of the carbonation process of the pastes. In addition, the SEM observations did not show any significant differences in the structure of the pastes with a variable amount of casein.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Osiecka, E. Wapno w Budownictwie-Tradycja i Nowoczesność; Stowarzyszenie Przemysłu Wapienniczego: Kraków, Poland, 2005. (In Polish) [Google Scholar]

- Neuberger, A. Die Technik des Altertums; R. Voigtlander’s Verlag: Leipzig, Germany, 1921. (In German) [Google Scholar]

- Sayre, E.V. Deterioration and Restoration of Plasters, Concrete and Mortar, Preservation and Conservations. In Proceedings of the North American International Regional Conference, Williamsburg, VA, USA, 10–16 September 1976; pp. 191–201. [Google Scholar]

- Ventolà, L.; Vendrell, M.; Giraldez, P.; Merino, L. Traditional organic additives improve lime mortars: New old materials for restoration and building natural stone fabrics. Constr. Build. Mater. 2011, 25, 3313–3318. [Google Scholar] [CrossRef]

- Qiang Fang, S.; Zhang, H.; Jian Zhang, B.; Zheng, Y. The identification of organic additives in traditional lime mortar. J. Cult. Herit. 2014, 15, 144–150. [Google Scholar] [CrossRef]

- Vyšvařil, M.; Hegrová, M.; Žižlavský, T. Rheological Properties of Lime Mortars with Guar Gum Derivatives. Key Eng. Mater. 2018, 760, 257–265. [Google Scholar]

- Mbugua, R.; Salim, R.; Ndambuki, J. Effect of Gum Arabic Karroo as a water-reducing admixture in cement mortar. Case Stud. Constr. Mater. 2016, 5, 100–111. [Google Scholar] [CrossRef][Green Version]

- Wei, G.; Zhang, H.; Wang, H.; Fang, S.; Zhang, B.; Yang, F. An experimental study on application of sticky rice–lime mortar in conservation. Constr. Build. Mater 2012, 28, 624–632. [Google Scholar] [CrossRef]

- Minke, G. Building with Earth: Design and Technology of a Sustainable Architecture; Birkhäuser Architecture: Basel, Switzerland, 2012. [Google Scholar]

- Minke, G.; Mahlke, F. Building with Straw, 1st ed.; Birkhäuser Architecture: Basel, Switzerland, 2005. [Google Scholar]

- Jasiczak, J.; Zieliński, K. Effect of protein additive on properties of mortar. Cem. Concr. Compos. 2006, 28, 451–457. [Google Scholar] [CrossRef]

- Mydin, M.A.O. Preliminary studies on the development of lime-based mortar with added egg white. Int. J. Technol. 2017, 5, 800–810. [Google Scholar] [CrossRef]

- Mydin, M.A.O. Physico-Mechanical Properties of Lime Mortar by Adding Exerted Egg Albumen for Plastering Work in Conservation Work. J. Mater. Environ. Sci. 2018, 9, 376–384. [Google Scholar]

- Salavessa, E.; Jalali, S.; Sousa, L.M.O.; Fernandes, L.; Duarte, A.M. Historical plasterwork techniques inspire new formulations. Constr. Build. Mater. 2013, 48, 858–867. [Google Scholar] [CrossRef]

- Chandra, S.; Eklund, L.; Villarreal, R. Use of cactus in mortars and concrete. Cem.Concr. Res. 1988, 28, 41–51. [Google Scholar] [CrossRef]

- Thirumalini, S.; Ravi, R.; Rajesh, M. Experimental investigation on physical and mechanical properties of lime mortar: Effect of organic addition. J. Cult. Herit. 2018, 31, 97–104. [Google Scholar] [CrossRef]

- Park, S.S.; Woo, S.W.; Jeong, S.W.; Lee, D.E. Durability and Strength Characteristics of Casein-Cemented Sand with Slag. Materials 2020, 13, 3182. [Google Scholar] [CrossRef] [PubMed]

- Vick, C.B. Adhesive bonding of wood materials. In Wood Handbook: Wood as an Engineering Material; General Technical Report FPL for Forest Service; Forest Products Laboratory: Madison, WI, USA, 1999. [Google Scholar]

- Chang, I.; Im, J.; Chung, M.K.; Cho, G.C. Bovine casein as a new soil strengthening binder from diary wastes. Constr. Build. Mater. 2018, 160, 1–9. [Google Scholar] [CrossRef]

- Chandra, S.; Aavik, J. Influence of proteins on some properties of portland cement mortar. Int. J. Cem. Compos. Lightweight Concr. 1987, 9, 91–94. [Google Scholar] [CrossRef]

- Brzyski, P.; Suchorab, Z. Physical properties of clay mortars based on insulating aggregates. AIP Conf. Proc. 2018, 1988, 020007. [Google Scholar]

- Vares, O.; Ruus, A.; Raamets, J.; Tungel, E. Determination of hygrothermal performance of clay-sand plaster: Influence of covering on sorption and water vapour permeability. Energy Procedia 2017, 132, 267–272. [Google Scholar] [CrossRef]

- Lermen, R.T.; Favaretto, P.; de Almeida Silva, R.; Navarro Hidalgo, G.E.; Tubino, R.M.C.; Tiecher, F. Effect of Additives, Cement Type, and Foam Amount on the Properties of Foamed Concrete Developed with Civil Construction Waste. Appl. Sci. 2019, 9, 2998. [Google Scholar] [CrossRef]

- Panesar, D.K. Cellular concrete properties and the effect of synthetic and protein foaming agents. Constr. Build. Mater. 2013, 44, 575–584. [Google Scholar] [CrossRef]

- Plank, J.; Bian, H. Method to assess the quality of casein used as superplasticizer in self-levelling compounds. Cem. Concr. Res. 2010, 40, 710–715. [Google Scholar] [CrossRef]

- Brzyski, P.; Gleń, P.; Gładecki, M.; Rumińska, M.; Suchorab, Z.; Łagód, G. Influence of the direction of mixture compaction on the selected properties of a hemp-lime composite. Materials 2021, 14, 4629. [Google Scholar] [CrossRef] [PubMed]

- Brzyski, P.; Gładecki, M.; Rumińska, M.; Pietrak, K.; Kubiś, M.; Łapka, P. Influence of hemp shives size on hygro-thermal and mechanical properties of a hemp-lime composite. Materials 2020, 13, 5383. [Google Scholar] [CrossRef] [PubMed]

- Walker, R.; Pavía, S.; Mitchell, R. Mechanical properties and durability of hemp-lime concretes. Constr. Build. Mater. 2014, 61, 340–348. [Google Scholar] [CrossRef]

- Walker, R.; Pavía, S. Moisture transfer and thermal properties of hemp–lime concretes. Constr. Build. Mater. 2014, 64, 270–276. [Google Scholar] [CrossRef]

- Brzyski, P.; Suchorab, Z. Capillary uptake monitoring in lime-hemp-perlite composite using the time domain reflectometry sensing technique for moisture detection in building composites. Materials 2020, 13, 1677. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Wang, D.; Zhao, J.; Wang, Y.; Liu, Z.; Ma, X. Assessment of the thermal and microstructural properties of metakaolin-air lime based materials at an early age. Appl. Clay Sci. 2020, 191, 105619. [Google Scholar] [CrossRef]

- Lawrence, M.; Mays, T.; Rigby, S.; Walker, P.; D’Ayala, D. Effects of carbonation on the pore structure of non-hydraulic lime mortars. Cem. Concr. Res. 2007, 37, 1059–1069. [Google Scholar] [CrossRef]

- Pipilikaki, P.; Beazi-Katsioti, M. The assessment of porosity and pore size distribution of limestone Portland cement pastes. Constr. Build. Mater. 2009, 23, 1966–1970. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Widomski, M.; Szafraniec, M.; Łagód, G. Impact of Different Binders on the Roughness, Adhesion Strength, and Other Properties of Mortars with Expanded Cork. Materials 2018, 11, 364. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Siddique, R.; Łagód, G. Properties of hydrophobised lightweight mortars with expanded cork. Constr. Build. Mater. 2017, 155, 15–25. [Google Scholar] [CrossRef]

- Puri, B.R.; Mohindroo, U.; Malik, R.C. Studies on physico-chemical properties of casein. III. Viscosities of casein solutions in different alkalies. J. Indian Chem. Soc. 1972, 49, 855–863. [Google Scholar]

| Recipe Symbol | Components | ||

|---|---|---|---|

| Binder | Casein/Binder Ratio | Water/Binder Ratio | |

| LM-0C | Hydrated lime 90% Metakaolin 10% | 0 | 0.68 |

| LM-0.5C | 0.005 | ||

| LM-1C | 0.01 | ||

| LM-3C | 0.03 | ||

| LM-5C | 0.05 | ||

| Constituents | LM-0C | LM-0.5C | LM-1C | LM-3C | LM-5C |

|---|---|---|---|---|---|

| Composition (g per 100 g) | |||||

| MgO | 0.34 | 0.32 | 0.34 | 0.34 | 0.32 |

| Al2O3 | 3.00 | 3.08 | 3.08 | 2.99 | 2.63 |

| SiO2 | 5.42 | 5.64 | 5.66 | 5.12 | 4.64 |

| SO3 | 0.19 | 0.20 | 0.21 | 0.26 | 0.28 |

| K2O | - | 0.07 | 0.06 | 0.07 | 0.11 |

| CaO | 90.33 | 89.43 | 88.89 | 87.47 | 86.30 |

| TiO2 | 0.21 | 0.23 | 0.24 | 0.23 | 0.22 |

| MnO | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 |

| Fe2O3 | 0.49 | 0.51 | 0.50 | 0.49 | 0.48 |

| ZnO | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| Parameter | Unit | LM-0C | LM-0.5C | LM-1C | LM-3C | LM-5C |

|---|---|---|---|---|---|---|

| Total pore surface | m2/g | 13.70 | 20.13 | 18.78 | 17.16 | 15.81 |

| Average pore diameter | nm | 120.90 | 95.67 | 107.88 | 123.15 | 137.27 |

| Total pore volume | ml/g | 0.41 | 0.48 | 0.51 | 0.53 | 0.54 |

| Total porosity | [%] | 49.50 | 48.62 | 52.23 | 53.36 | 53.94 |

| Density | g/ml | 2.37 | 2.19 | 2.18 | 2.16 | 2.16 |

| Bulk density | g/ml | 1.20 | 1.01 | 1.03 | 1.01 | 0.99 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brzyski, P.; Suchorab, Z.; Łagód, G. The Influence of Casein Protein Admixture on Pore Size Distribution and Mechanical Properties of Lime-Metakaolin Paste. Buildings 2021, 11, 530. https://doi.org/10.3390/buildings11110530

Brzyski P, Suchorab Z, Łagód G. The Influence of Casein Protein Admixture on Pore Size Distribution and Mechanical Properties of Lime-Metakaolin Paste. Buildings. 2021; 11(11):530. https://doi.org/10.3390/buildings11110530

Chicago/Turabian StyleBrzyski, Przemysław, Zbigniew Suchorab, and Grzegorz Łagód. 2021. "The Influence of Casein Protein Admixture on Pore Size Distribution and Mechanical Properties of Lime-Metakaolin Paste" Buildings 11, no. 11: 530. https://doi.org/10.3390/buildings11110530

APA StyleBrzyski, P., Suchorab, Z., & Łagód, G. (2021). The Influence of Casein Protein Admixture on Pore Size Distribution and Mechanical Properties of Lime-Metakaolin Paste. Buildings, 11(11), 530. https://doi.org/10.3390/buildings11110530