Evaluating the Vertical Extension Module of a Building with Installed Rotary Dampers at Joints

Abstract

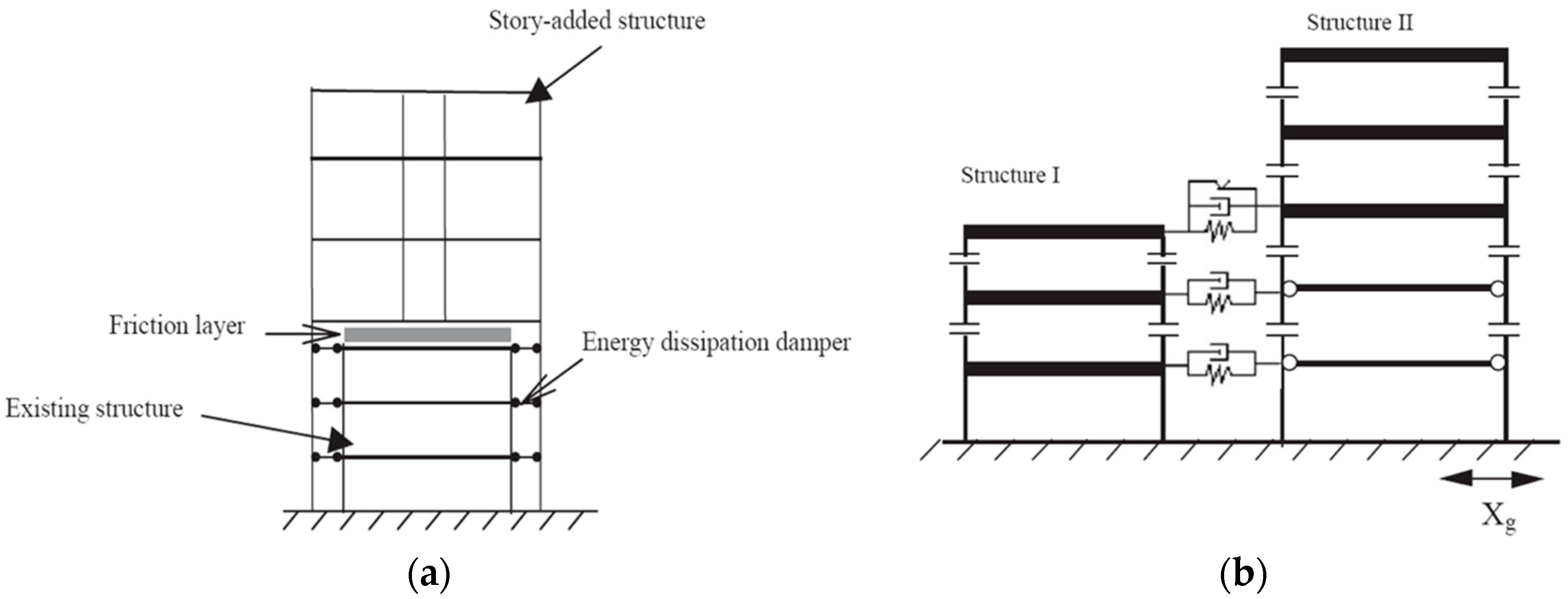

:1. Introduction

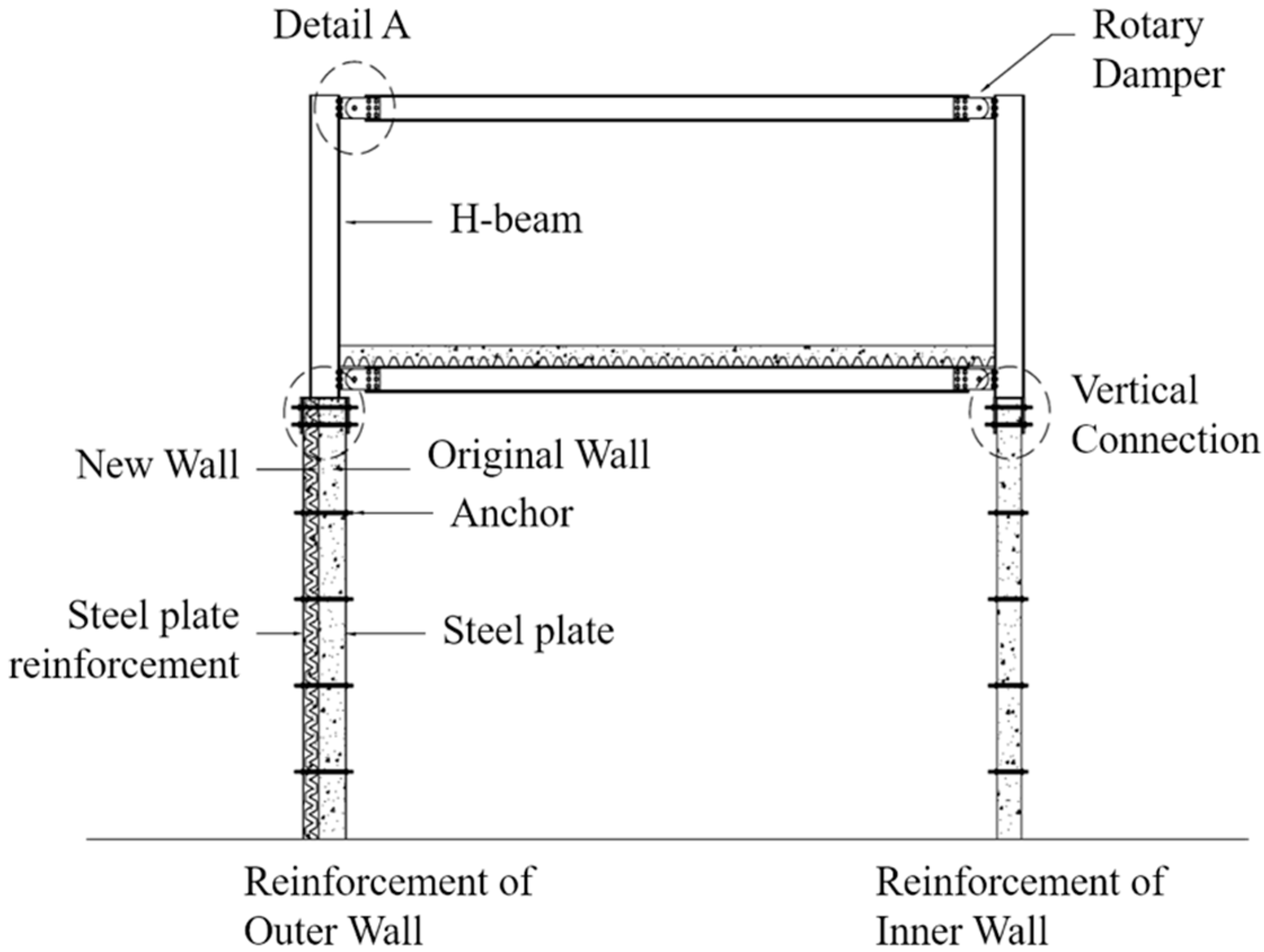

2. Proposal of Vertical Expansion Module Shape

3. Numerical Analysis

3.1. Single Degree of Freedom System Numerical Analysis and Results

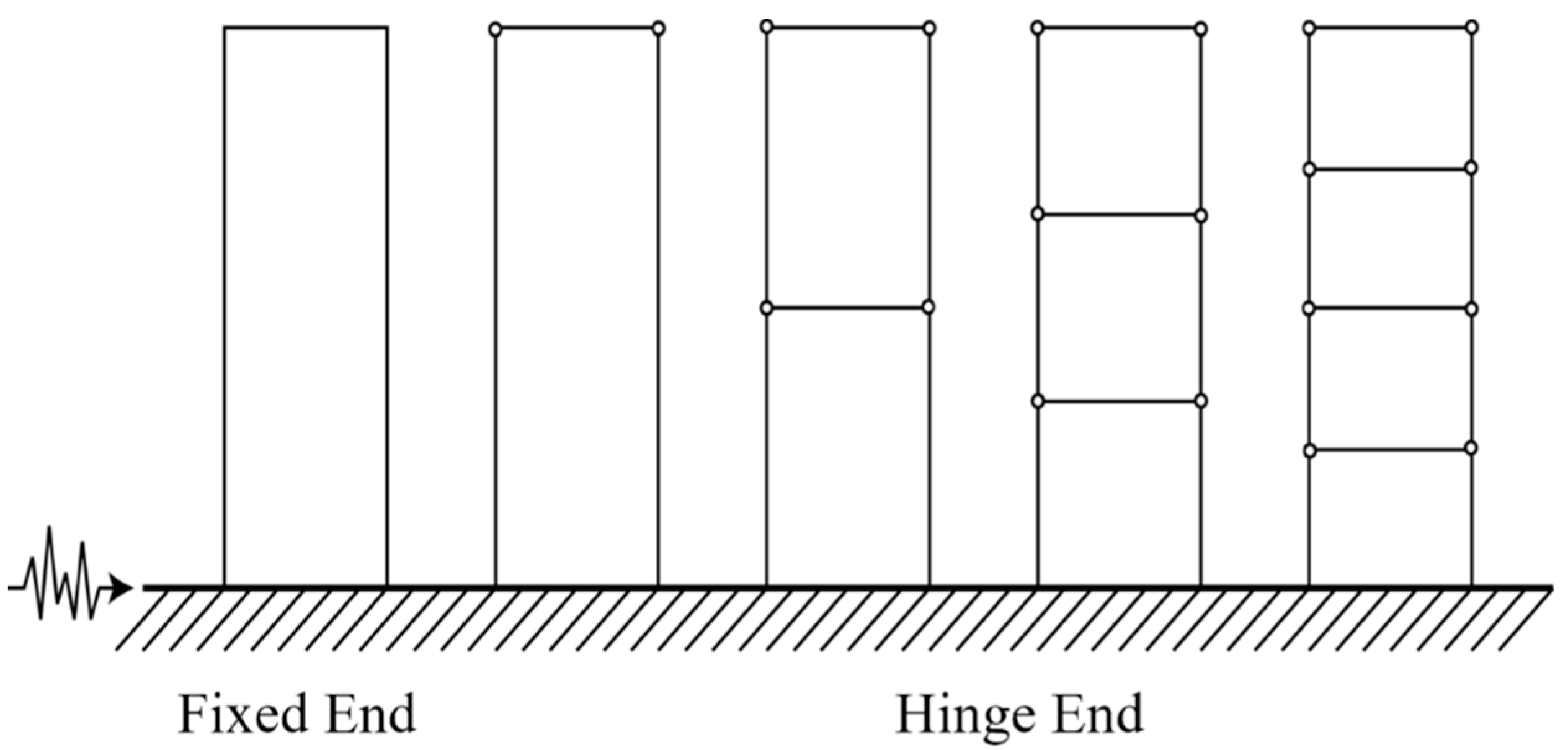

3.2. Numerical Analysis and Results of Multi-Degree-of-Freedom System

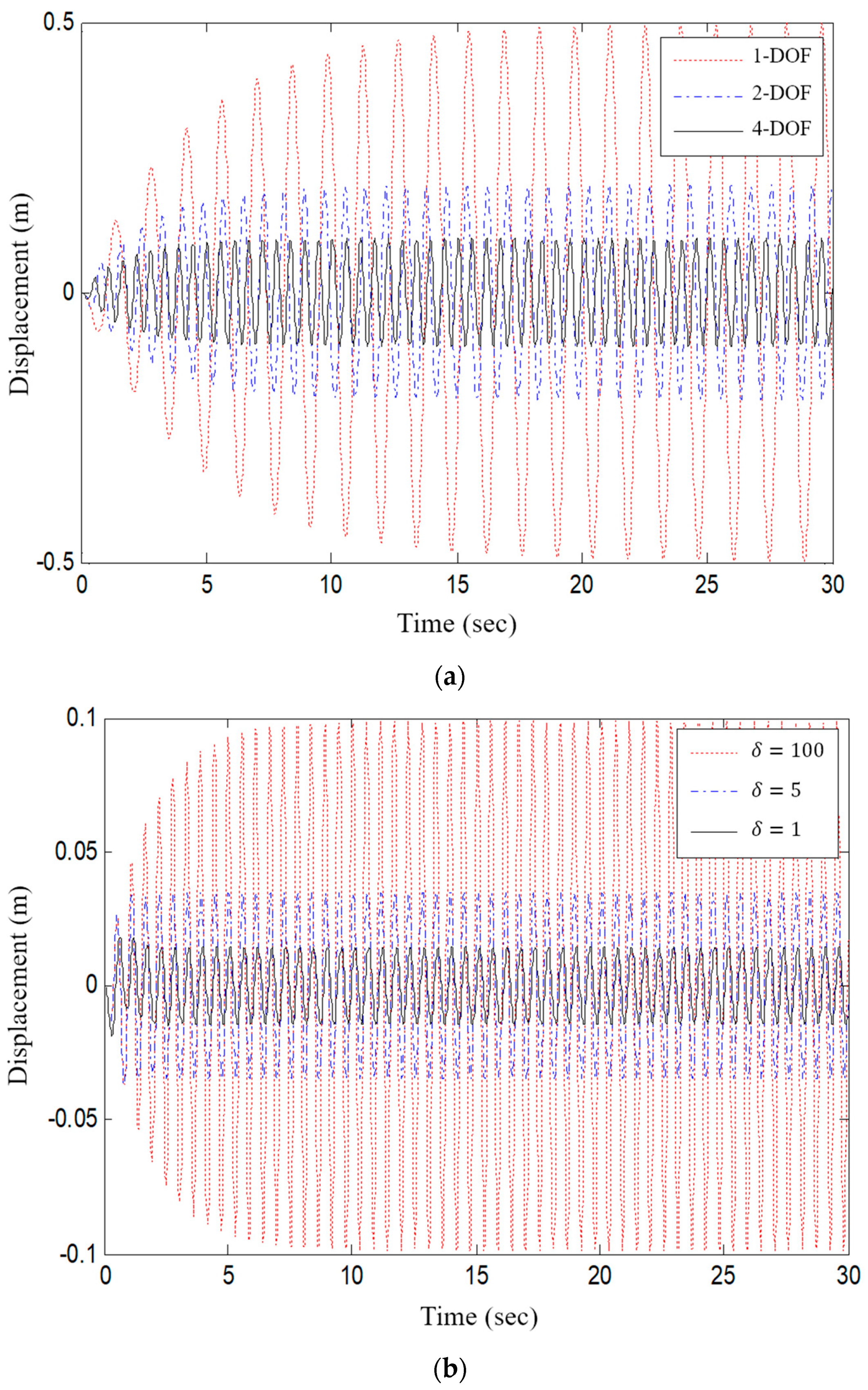

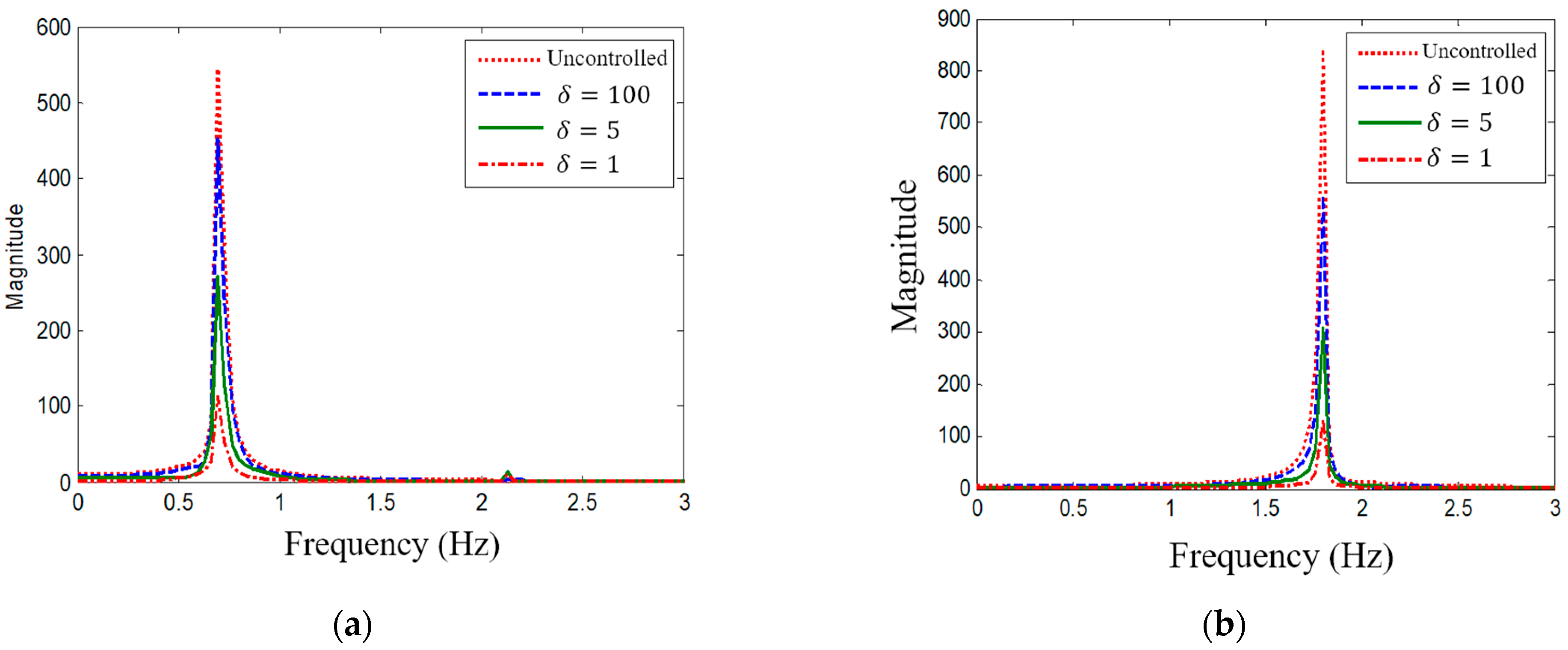

3.2.1. Multi-DOF Structure Response to Harmonic Load

3.2.2. Structural Response to Seismic Load

4. Experiment of Energy Dissipation Capacity of Rotary-Type Damping Device

4.1. Experimental Model and Method

4.2. Experimental Results and Variable Analysis

5. Conclusions

- The rotary damper is more effective in reducing the displacement, shear force, and moment when the joint is free and fixed. In the pushover analysis of the system modeled by the moment hinge of the rotary damper of the joint, the best response reduction effect was obtained when the yield moment of the hinge was defined as 1% of the frame plastic moment, and when δ is less than 5.

- The time history analysis results for the harmonic load of the multi-DOF system showed that it is effective for the hinge to yield after the displacement and the acceleration response of the resonant structure to reach steady state.

- As a result of the non-linear time history analysis using data of the El Centro earthquake, the bilinear system with inelastic behavior, after the yielding of the hinge of the joint, showed an asymmetric displacement response that oscillates around the position deviating from the initial position, as the member was not restored after yielding. The displacement response was reduced by the energy dissipated by the rotation when the hinge end is at the end of the joint, but the displacement response increased when the hinge yields at a bending moment that is too small.

- As in the previous pushover analysis, when the yield moment of the joint hinge corresponds to 5% of the plastic moment of the beam, it is deemed to have the optimum energy dissipation capacity, due to the deformation caused by the seismic load. By comparing the maximum base shear force and the maximum displacement response according to the value of δ, we confirmed that the optimum yield moment of the joint hinge of the analytical model is 1% of the fixed end.

- In the multi-degree-of-freedom system with the slab connection added to the analytical model, the natural period of the structure became smaller, and the displacement response of the uppermost layer gradually decreased as the joint increased. The same phenomenon was observed for the general structure, indicating that the rotary damper does not affect the overall behavior of the structure. The maximum energy dissipation at the joint hinge occurs only under the occurrence of a large deformation, such as resonance through force-displacement history behavior.

- The rotary-type damper has a constant yielding moment without being influenced by the excitation frequency. Even if the displacement is changed, the yielding moment of the damping device is not affected by the excitation frequency. In further research, more cases would be tested to acquire more reliable results of this study for practical application to the buildings.

- Furthermore, the yielding moment of the damping device increases linearly with the tightening force of the bolt. Thus, the relationship between the tightening force and the friction surface was determined to be a very important parameter in the design.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jeong, G.H.; Lee, H.S.; Hwang, K.R.; Kwon, O.-S.; Kim, S.-J. Seismic Fragility Analysis of High-Rise RC Box-Type Wall Building Structures. J. Earthq. Eng. Soc. Korea 2016, 20, 155–162. [Google Scholar] [CrossRef]

- Cho, W.-S.; Lee, S.-H.; Chung, L.; Kim, H.-J.; Kim, S.-J.; Yu, E.-J. Seismic Performance Evaluation of Reinforced Concrete Frame with Unreinforced Masonry Infill. J. Archit. Inst. Korea Struct. Constr. 2012, 28, 31–41. [Google Scholar]

- Hur, M.-W.; Lee, S.-H.; Chun, Y.-S. Vibration Control of the Framed Building Structures Using KGDS System with Iso-tropic Damping Devices. J. Korea Inst. Struct. Maint. Insp. 2015, 19, 52–59. [Google Scholar]

- Seismic Retrofitting and Remodeling Research Center. Grading of Seismic Performance and Development of Seismic Strengthening Design Methods for Remodeling of Deteriorated Apartment Houses. In National Research Laboratory Final Report; Dankook University: Yongin-si, Korea, 2007. [Google Scholar]

- Bae, C.-H.; Kim, Y.-W.; Lee, S.-H.; Park, Y.-P. Shaking Table Test of a Full Scale 3 Story Steel Frame with Friction Dampers. Trans. Korean Soc. Noise Vib. Eng. 2007, 17, 862–873. [Google Scholar]

- Chun, Y.; Hur, M. Exo-type damping system with isotropic dampers. In Advances in Civil, Architectural, Structural and Constructional Engineering: Proceedings of the International Conference on Civil, Architectural, Structural and Constructional Engineering, Dong-A University, Busan, Korea, 21–23 August 2015; CRC Press: Boca Raton, FL, USA, 2016; pp. 281–284. [Google Scholar]

- Council, B.S.S.; Council, A.T. NEHRP Guidelines for the Seismic Rehabilitation of Buildings; Federal Emergency Management Agency: Washington, DC, USA, 1997; Volume 1. [Google Scholar]

- Paulay, T. Coupling Beams of Reinforced Concrete Shear Walls. J. Struct. Div. 1971, 97, 843–862. [Google Scholar] [CrossRef]

- Bielak, J. Dynamic behaviour of structures with embedded foundations. Earthq. Eng. Struct. Dyn. 1974, 3, 259–274. [Google Scholar] [CrossRef]

- Macrae, G.A.; Kimura, Y.; Roeder, C. Effect of Column Stiffness on Braced Frame Seismic Behavior. J. Struct. Eng. 2004, 130, 381–391. [Google Scholar] [CrossRef] [Green Version]

- American Society of Civil Engineers. Seismic Evaluation and Retrofit of Existing Buildings; American Society of Civil Engineers: Reston, VA, USA, 2017. [Google Scholar]

- Bruneau, M.; Uang, C.-M.; Whittaker, A. Ductile Design of Steel Structures; McGraw-Hill: New York, NY, USA, 1998; Volume 389. [Google Scholar]

- Oh, Y.-H.; Han, S.W.; Lee, L.-H. Effect of boundary element details on the seismic deformation capacity of structural walls. Earthq. Eng. Struct. Dyn. 2002, 31, 1583–1602. [Google Scholar] [CrossRef]

- Hwang, J.-S.; Park, S.-C.; Kang, K.-J. A study on the hysteresis properties and mathematical model of Kagome truss damper. J. Archit. Inst. Korea Struct. Constr. 2013, 29, 21–29. [Google Scholar]

- Hyun, C.-K. Structural Design for Remodeling in Vertical Extension of Apartment Building. Mag. Korea Inst. Struct. Maint. Insp. 2014, 18, 9–13. [Google Scholar]

- Oh, S.-H. Effective Seismic Structural System for Vertical Extension Remodeling of Apartment. Mag. Korea Inst. Struct. Maint. Insp. 2014, 18, 3–8. [Google Scholar]

- Li, H.; Wang, S.-Y.; Song, G.; Liu, G. Reduction of seismic forces on existing buildings with newly constructed additional stories including friction layer and dampers. J. Sound Vib. 2004, 269, 653–667. [Google Scholar] [CrossRef]

- Li, H.-N.; Yin, Y.-W.; Wang, S.-Y. Studies on seismic reduction of story-increased buildings with friction layer and energy-dissipated devices. Earthq. Eng. Struct. Dyn. 2003, 32, 2143–2160. [Google Scholar] [CrossRef]

- Chopra, A.K. Dynamics of Structures: Theory and Applications to Earthquake Engineering, 5th ed.; Pearson: London UK, 2016. [Google Scholar]

- Mahin, S.A. Lessons from damage to steel buildings during the Northridge earthquake. Eng. Struct. 1998, 20, 261–270. [Google Scholar] [CrossRef]

- Fukumoto, T.; Fukuzawa, E.; Yamada, T.; Tanaka, N.; Amana, A.; Maeda, Y. Elasto-Plastic Damper for Structure. U.S. Patent 5163256, 17 November 1992. [Google Scholar]

- Hwang, J.-S.; Tsai, C.-H.; Wang, S.-J.; Huang, Y.-N. Experimental study of RC building structures with supplemental viscous dampers and lightly reinforced walls. Eng. Struct. 2006, 28, 1816–1824. [Google Scholar] [CrossRef]

| ss | Yielding | Joint Yielding Moment (kN-m) | Response of Time History Analysis | |||

|---|---|---|---|---|---|---|

| Peak Base Shear (kN) | Variation (%) | Peak Displacement (m) | Variation (%) | |||

| Fixed | Elastic | 3368.15 | 271.2 | 0 | 0.2928 | 0 |

| δ = 5 | Plastic | 168.09 | 198.9 | −27 | 0.3077 | 5 |

| δ = 2 | 67.36 | 96.02 | −65 | 0.208 | −29 | |

| δ = 1 | 33.68 | 68.2 | −75 | 0.1804 | −39 | |

| δ = 0.5 | 16.84 | 70.82 | −73 | 0.2483 | −15 | |

| δ = 0.1 | 3.37 | 77.49 | −71 | 0.3213 | 10 | |

| Hinged | 0 | 83.78 | −69 | 0.3512 | 20 | |

| δ | Number of DOF | Peak Displacement (m) | Peak Base Shear (kN) |

|---|---|---|---|

| 100 | 1 | 0.090 | 18.43 |

| 2 | 0.102 | 94.47 | |

| 3 | 0.084 | 166.7 | |

| 4 | 0.076 | 251.2 | |

| 10 | 1 | 0.090 | 18.43 |

| 2 | 0.111 | 99.6 | |

| 3 | 0.087 | 129.8 | |

| 4 | 0.08 | 194.6 | |

| 5 | 1 | 0.090 | 18.43 |

| 2 | 0.078 | 59.05 | |

| 3 | 0.065 | 86.53 | |

| 4 | 0.059 | 116.5 | |

| 3 | 1 | 0.090 | 18.43 |

| 2 | 0.066 | 40.5 | |

| 3 | 0.065 | 62.54 | |

| 4 | 0.057 | 85.12 | |

| 1 | 1 | 0.074 | 9.54 |

| 2 | 0.081 | 27.37 | |

| 3 | 0.068 | 35.76 | |

| 4 | 0.072 | 42.66 |

| Experimental Variable | Oscillation Frequency (Hz) | Actuator Displacement (mm) | Tightening Force of Bolt (N-mm) |

|---|---|---|---|

| Change in frequency | 0.5 | ±4 | 600 |

| 1 | ±4 | 600 | |

| 2 | ±4 | 600 | |

| 3 | ±4 | 600 | |

| 4 | ±4 | 600 | |

| Size of deformation | 0.5 | ±2 | 1400 |

| 0.5 | ±3 | 1400 | |

| 0.5 | ±6 | 1400 | |

| 0.5 | ±8 | 1400 | |

| 0.5 | ±10 | 1400 | |

| 2 | ±2 | 1400 | |

| 2 | ±4 | 1400 | |

| 2 | ±6 | 1400 | |

| 2 | ±8 | 1400 | |

| 2 | ±10 | 1400 | |

| Change of tightening force | 0.5 | ±4 | 0 |

| 0.5 | ±4 | 800 | |

| 0.5 | ±4 | 1000 | |

| 0.5 | ±4 | 1200 | |

| 0.5 | ±4 | 1400 | |

| 0.5 | ±4 | 1600 | |

| 0.5 | ±4 | 1800 | |

| 0.5 | ±4 | 2000 | |

| 0.5 | ±4 | 2200 | |

| 0.5 | ±4 | 2400 | |

| 0.5 | ±4 | 2600 | |

| 0.5 | ±4 | 2800 | |

| 0.5 | ±4 | 3000 | |

| 0.5 | ±4 | 4500 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heo, S.; Na, S.; Hur, M.-W.; Lee, S. Evaluating the Vertical Extension Module of a Building with Installed Rotary Dampers at Joints. Buildings 2021, 11, 536. https://doi.org/10.3390/buildings11110536

Heo S, Na S, Hur M-W, Lee S. Evaluating the Vertical Extension Module of a Building with Installed Rotary Dampers at Joints. Buildings. 2021; 11(11):536. https://doi.org/10.3390/buildings11110536

Chicago/Turabian StyleHeo, Seokjae, Seunguk Na, Moo-Won Hur, and Sanghyun Lee. 2021. "Evaluating the Vertical Extension Module of a Building with Installed Rotary Dampers at Joints" Buildings 11, no. 11: 536. https://doi.org/10.3390/buildings11110536

APA StyleHeo, S., Na, S., Hur, M.-W., & Lee, S. (2021). Evaluating the Vertical Extension Module of a Building with Installed Rotary Dampers at Joints. Buildings, 11(11), 536. https://doi.org/10.3390/buildings11110536