Micro-Mechanical and 3D Fractal Analysis, Durability, and Thermal Behaviour of Nano-Modified Cementitious Lightweight Composites for Building Facades

Abstract

:1. Introduction

2. Experimental Program

2.1. Materials Used and Concrete Mixtures

2.2. Production of Concrete Mixtures

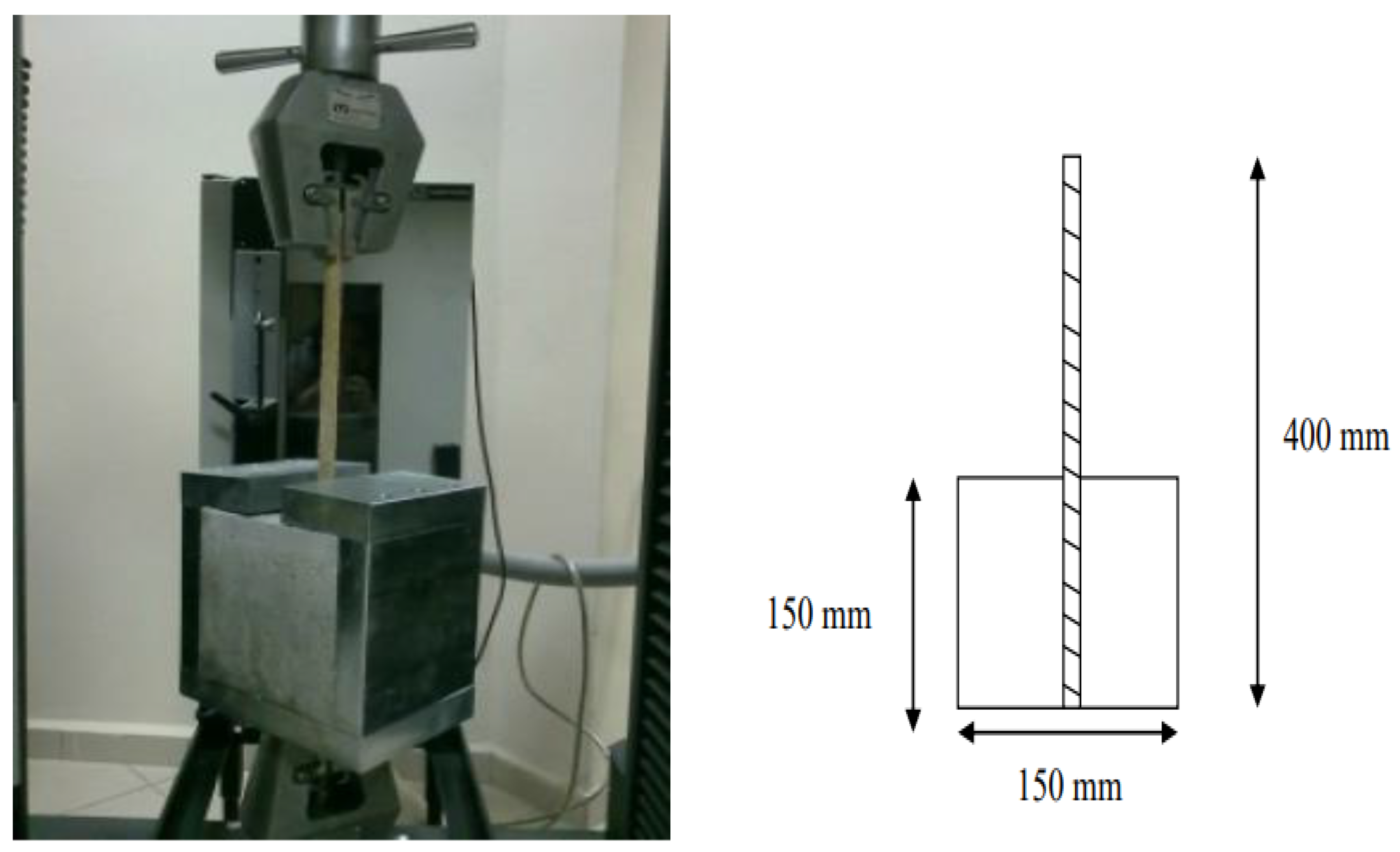

2.3. Tests Conducted

3. Results and Discussions

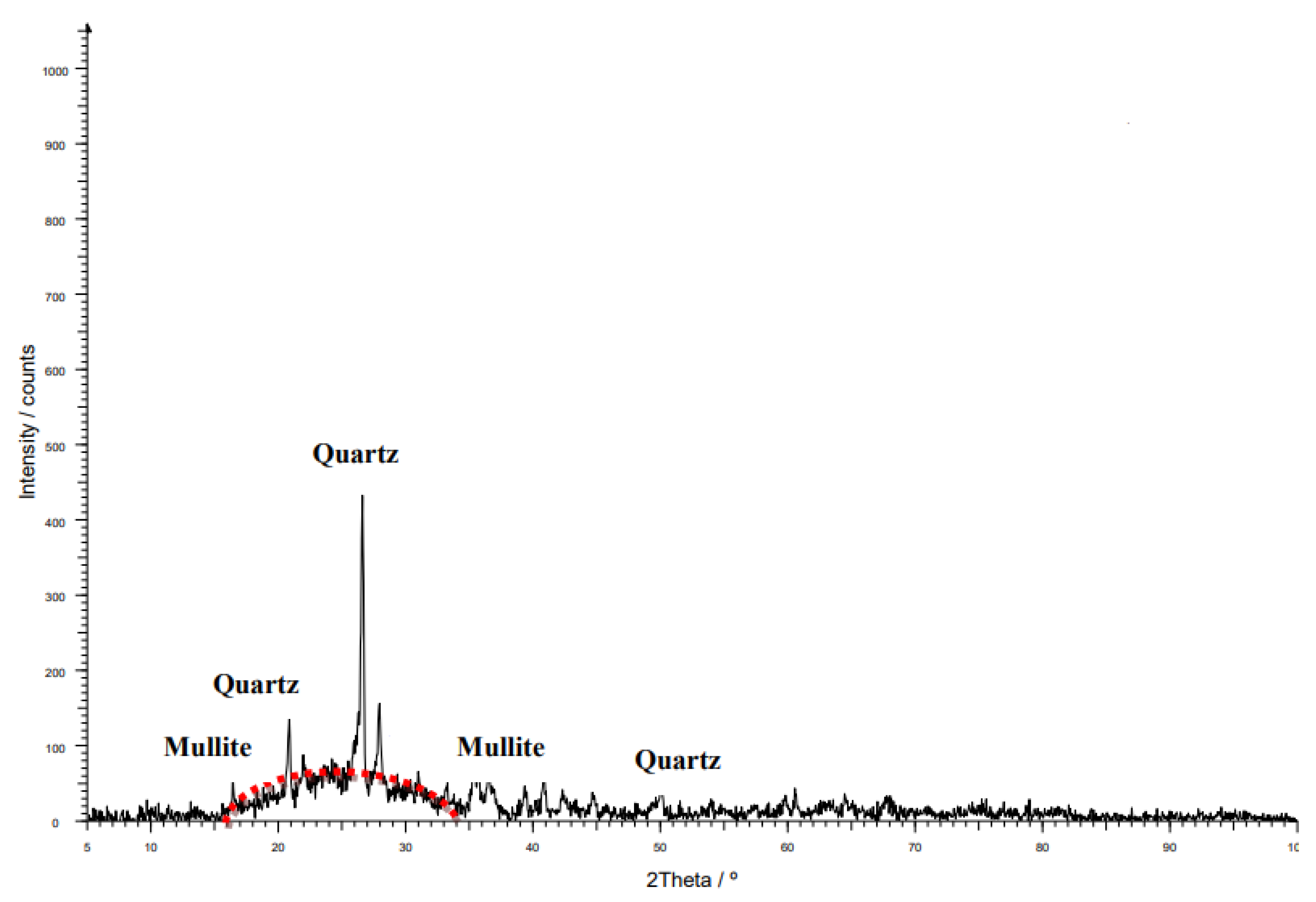

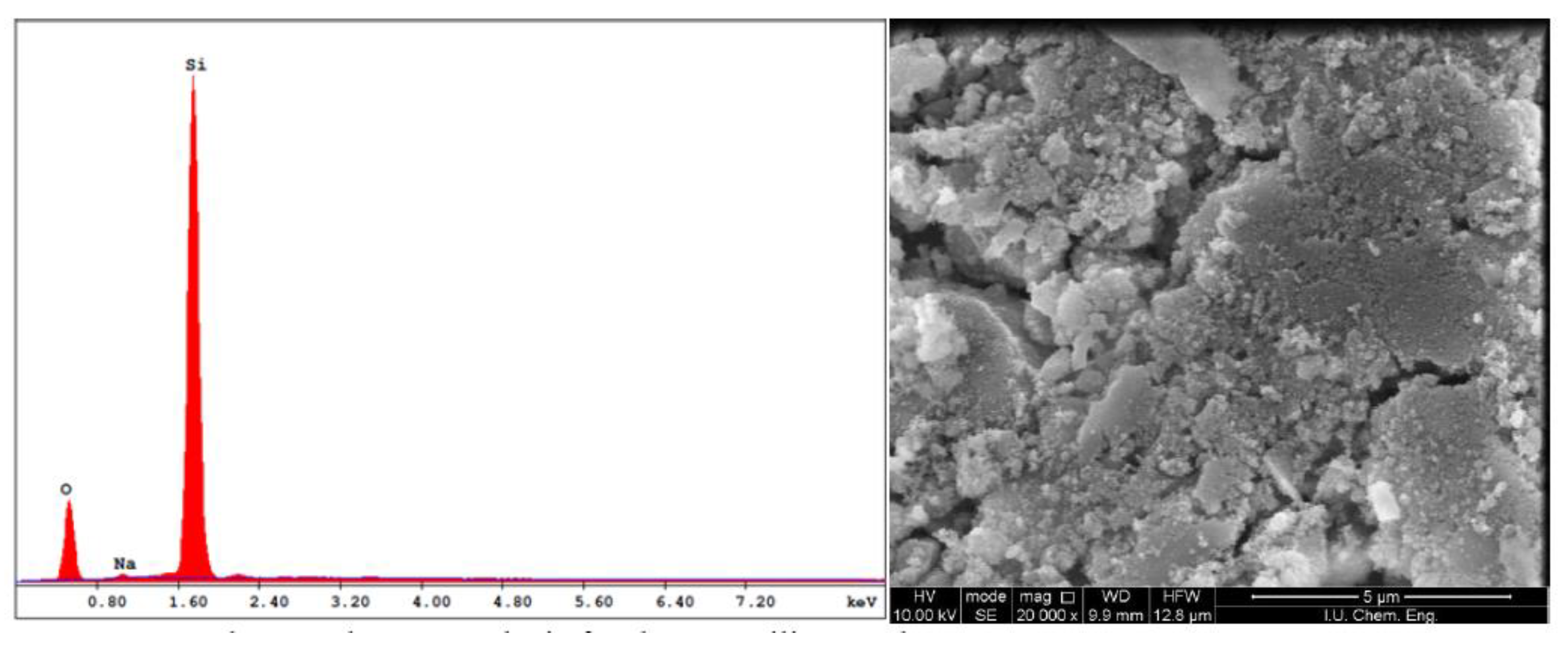

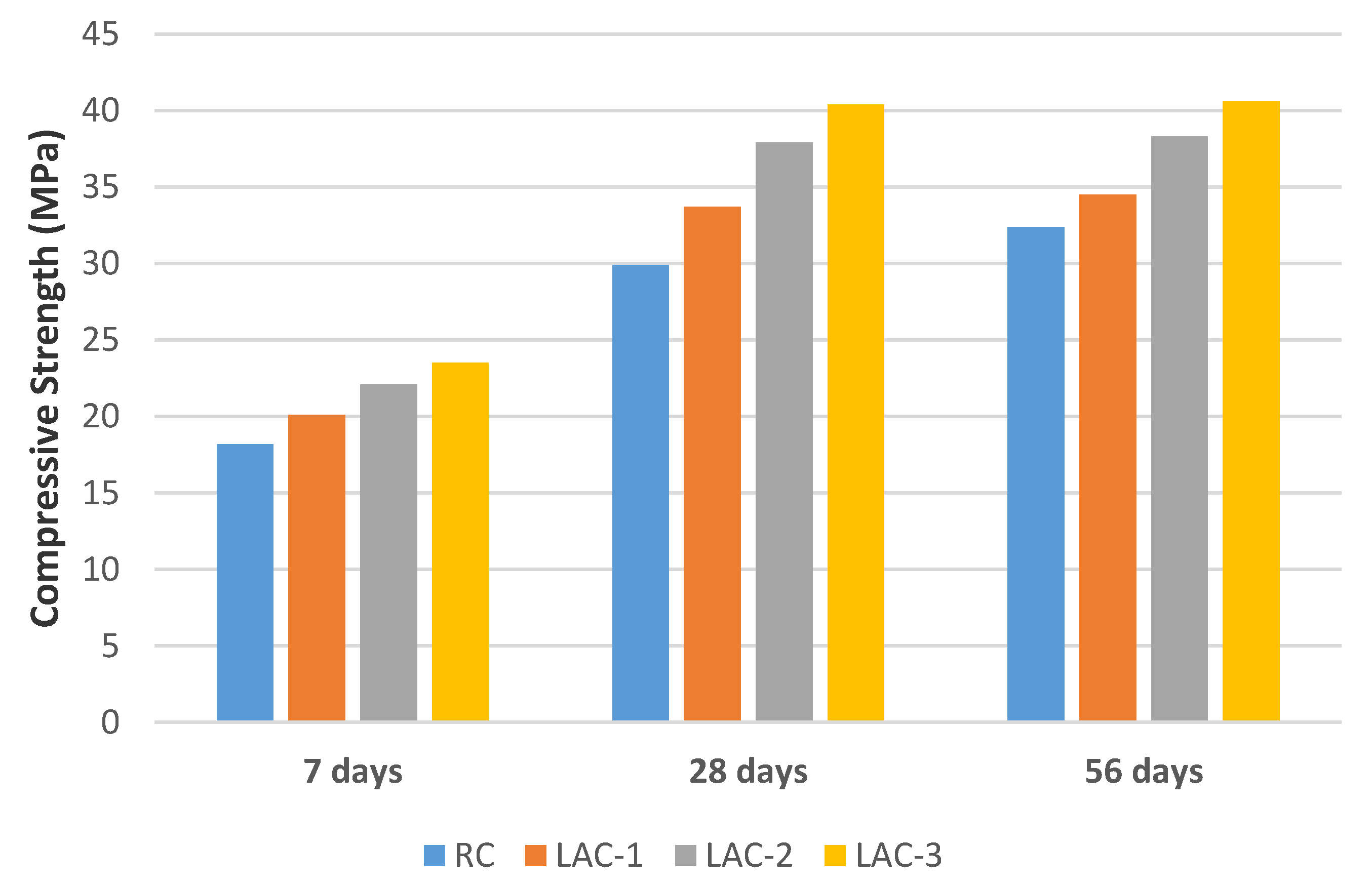

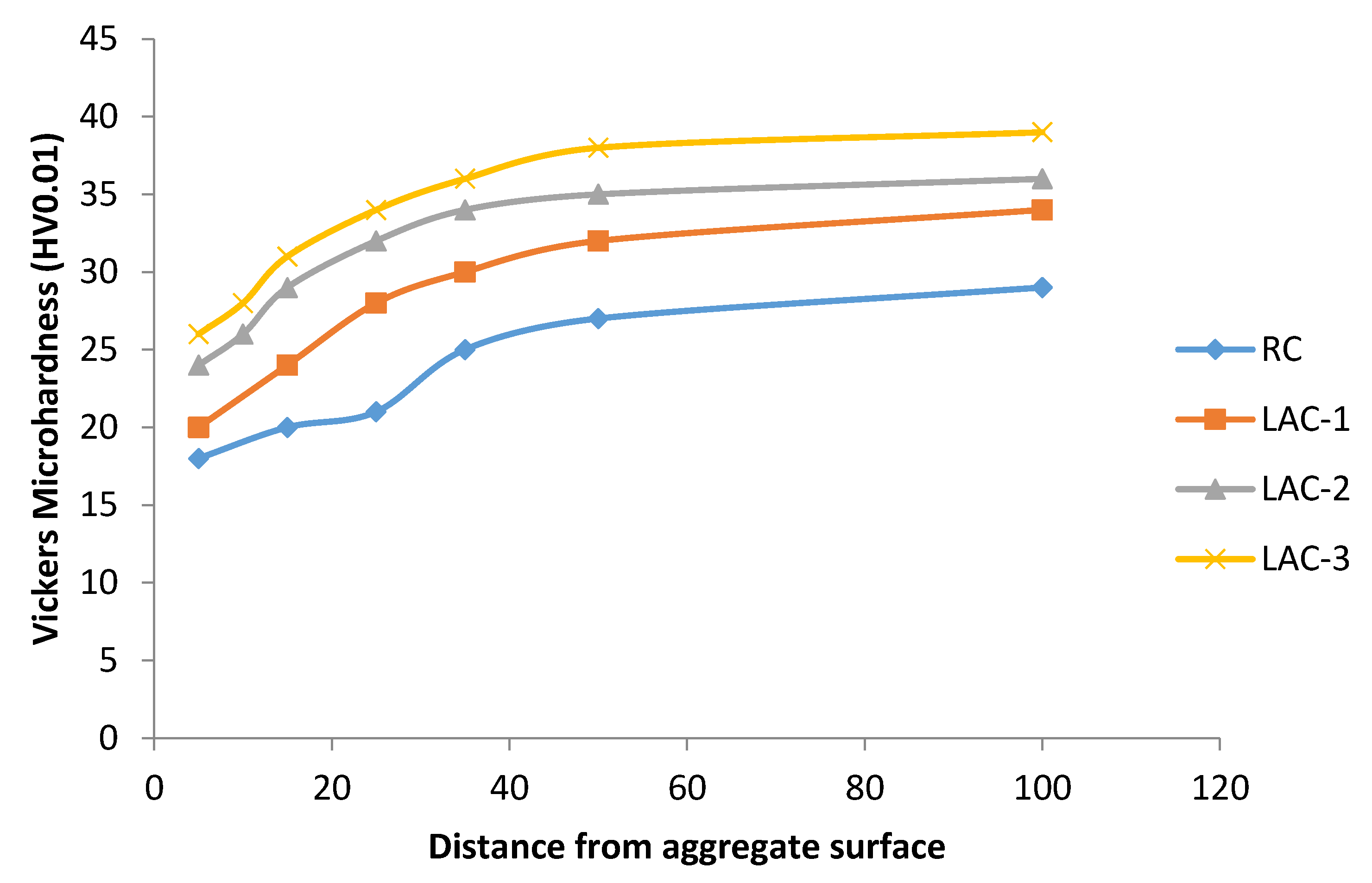

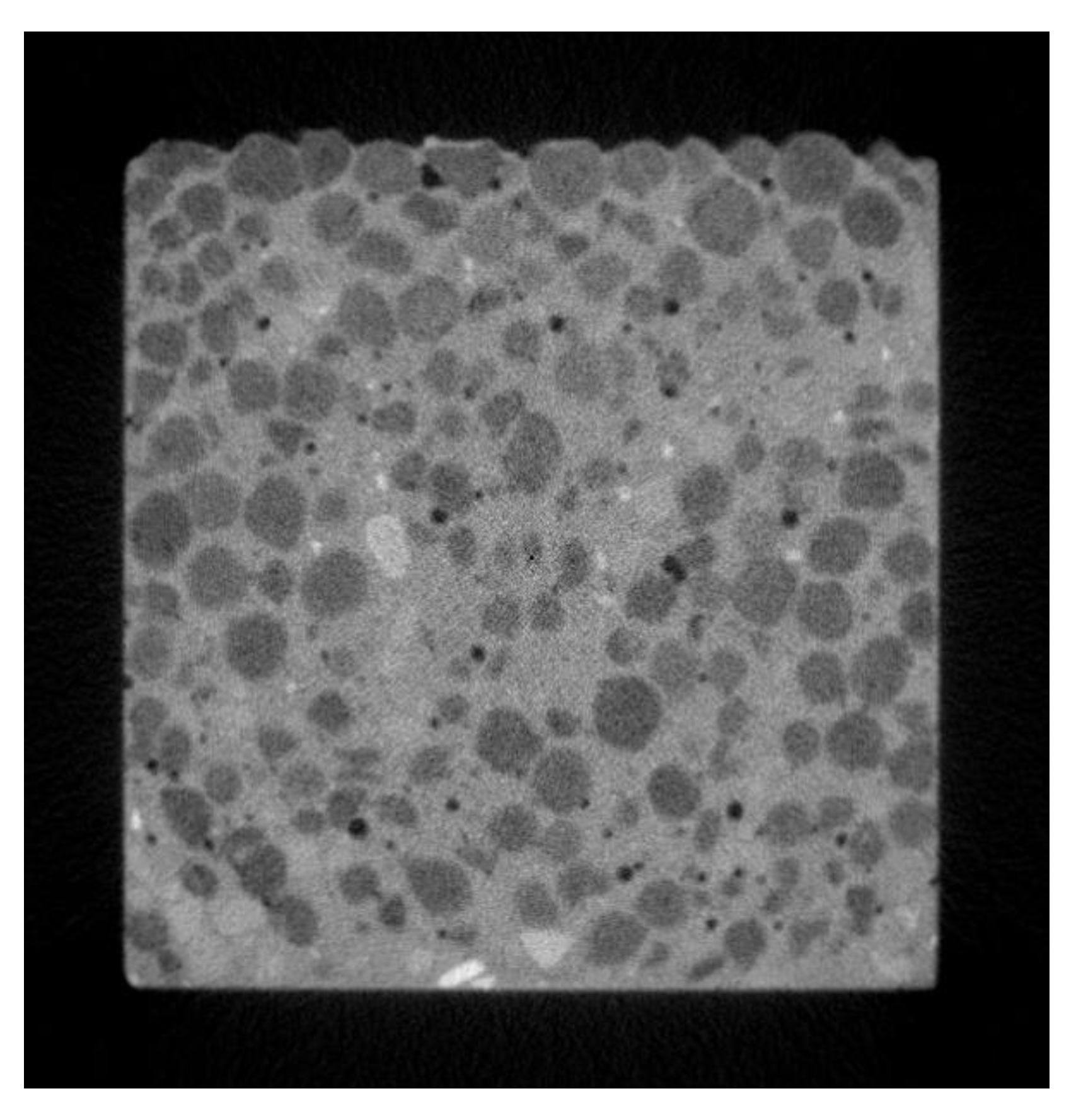

3.1. Micro-Structure Associated Compressive Strength

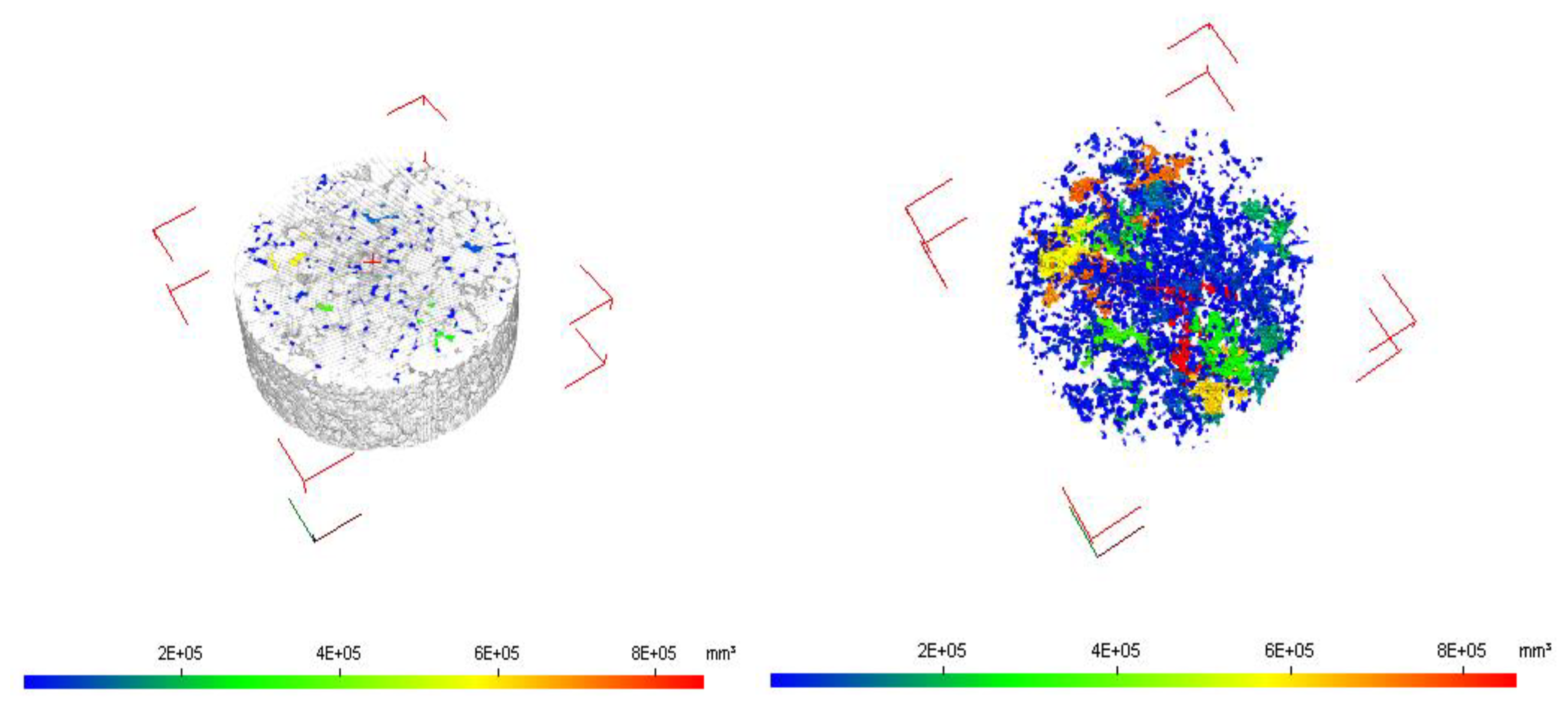

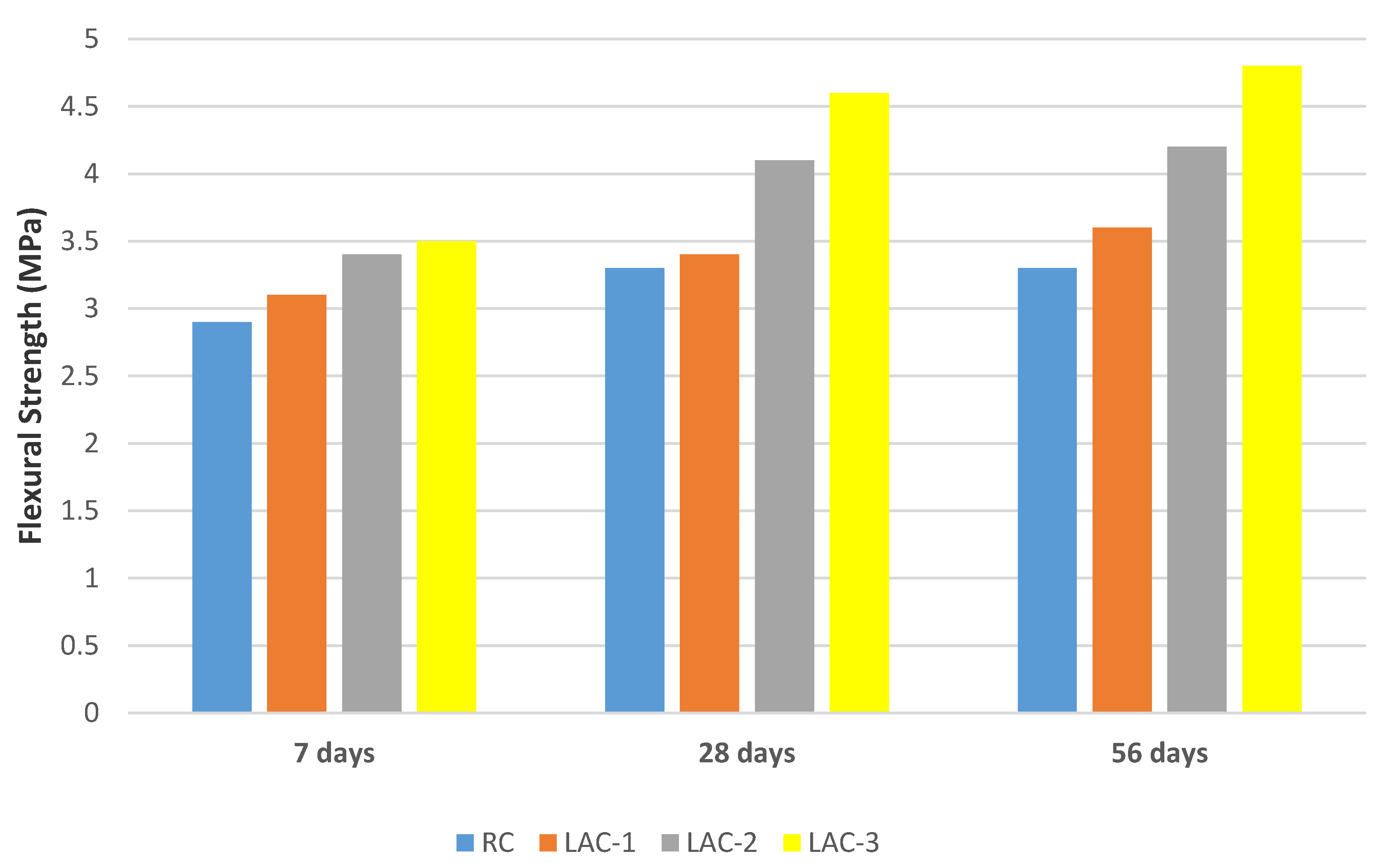

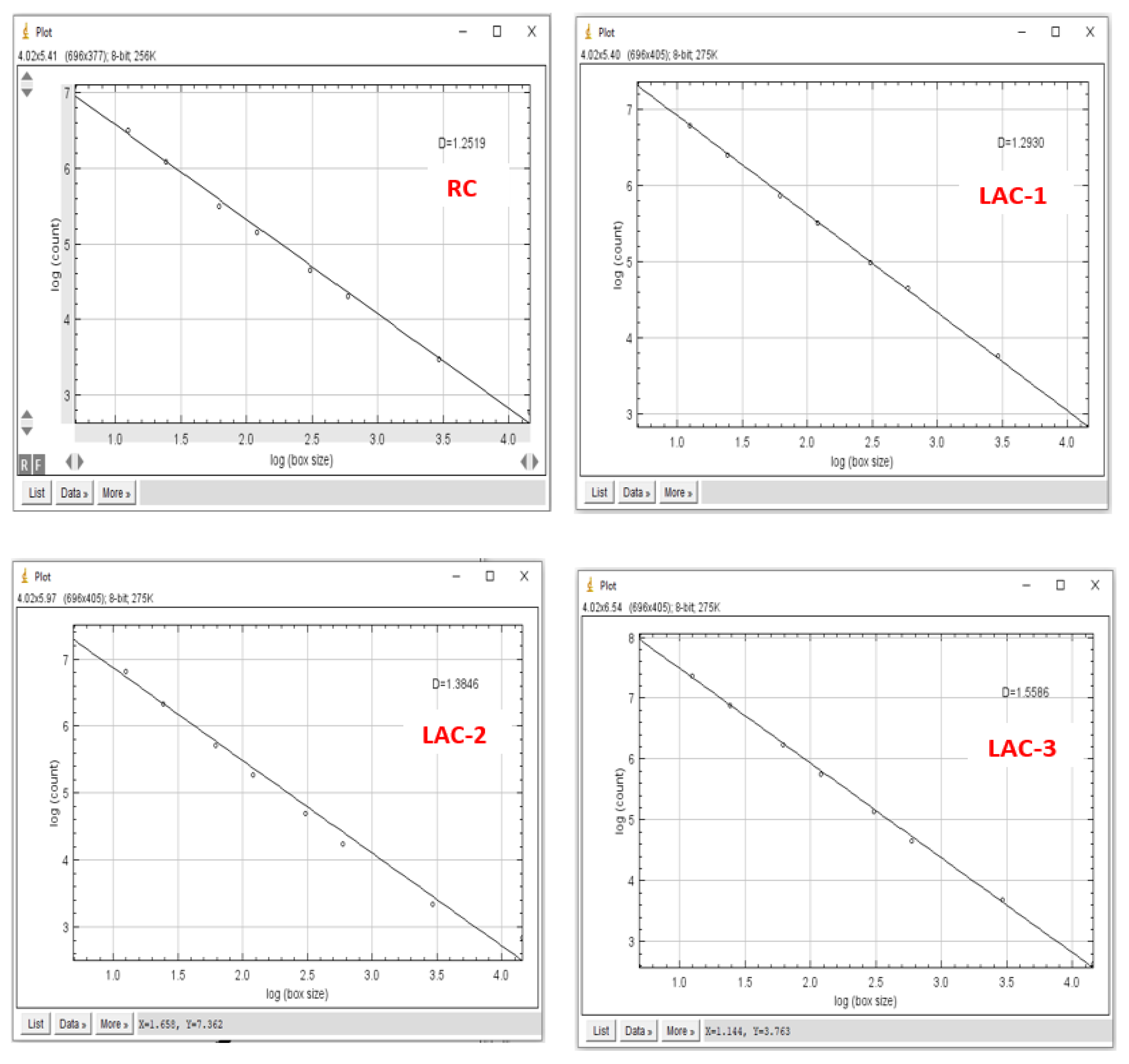

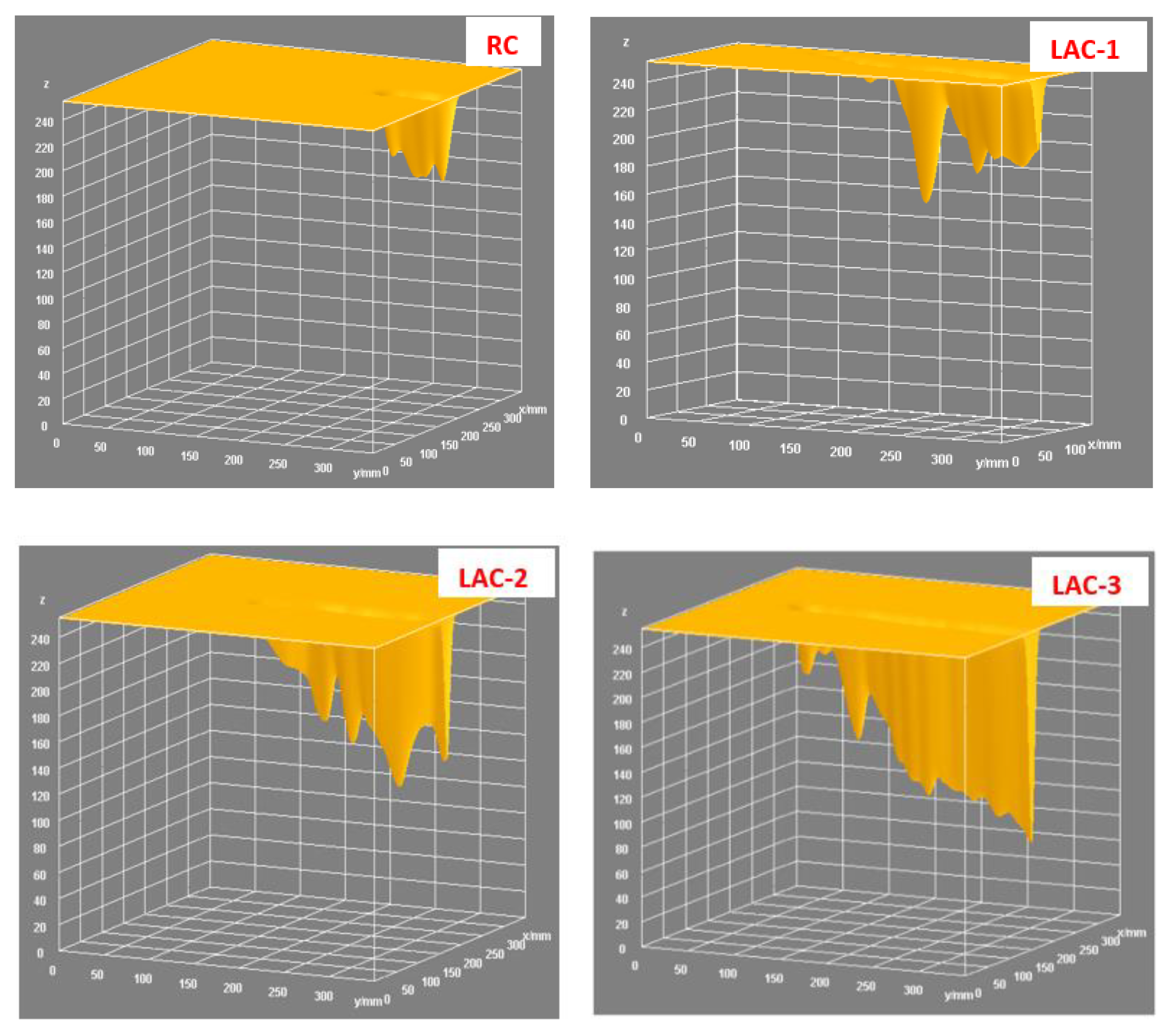

3.2. Flexural Strength and 3D Crack Analysis

3.3. Water Permeability and Chloride Migration

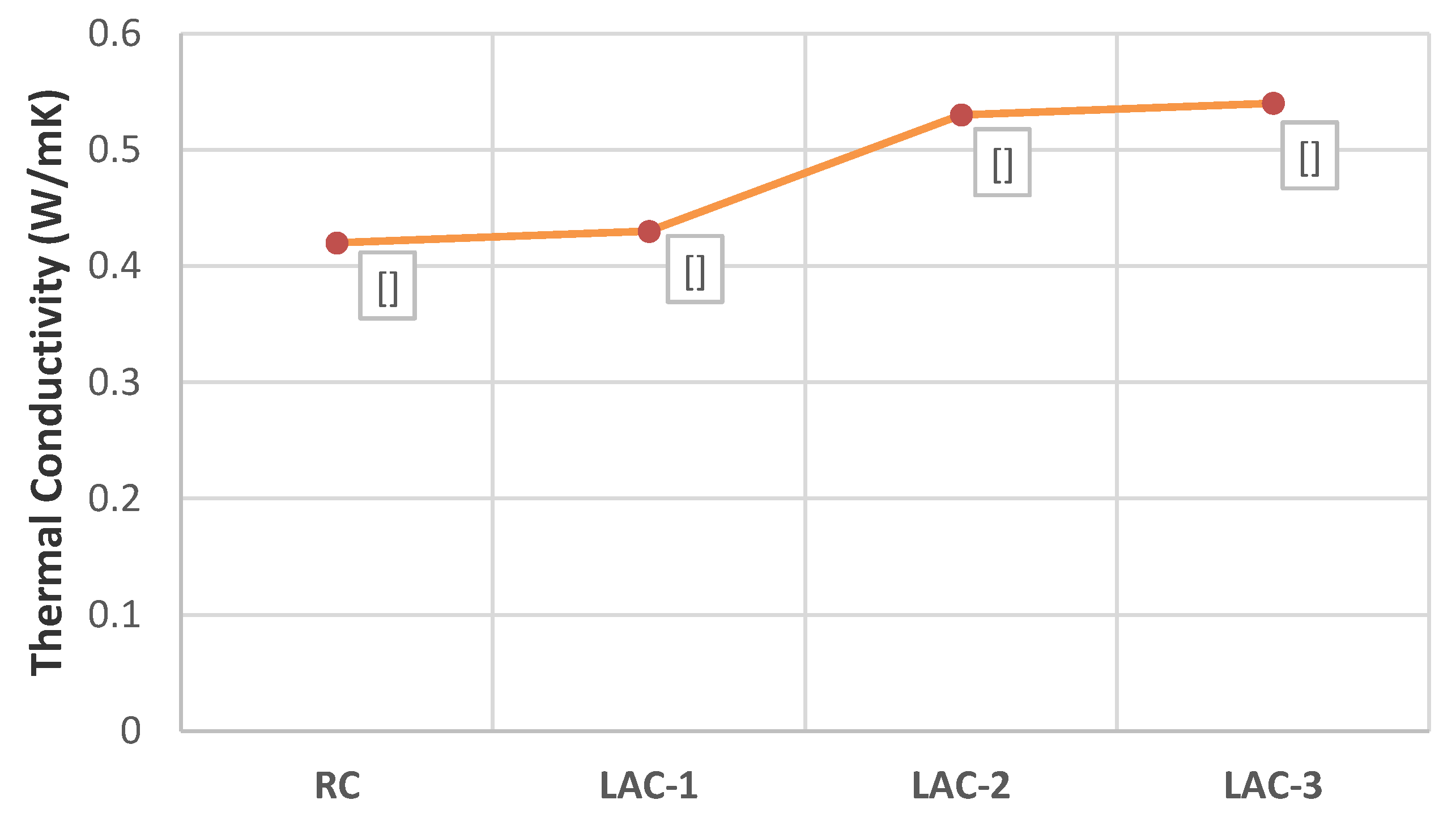

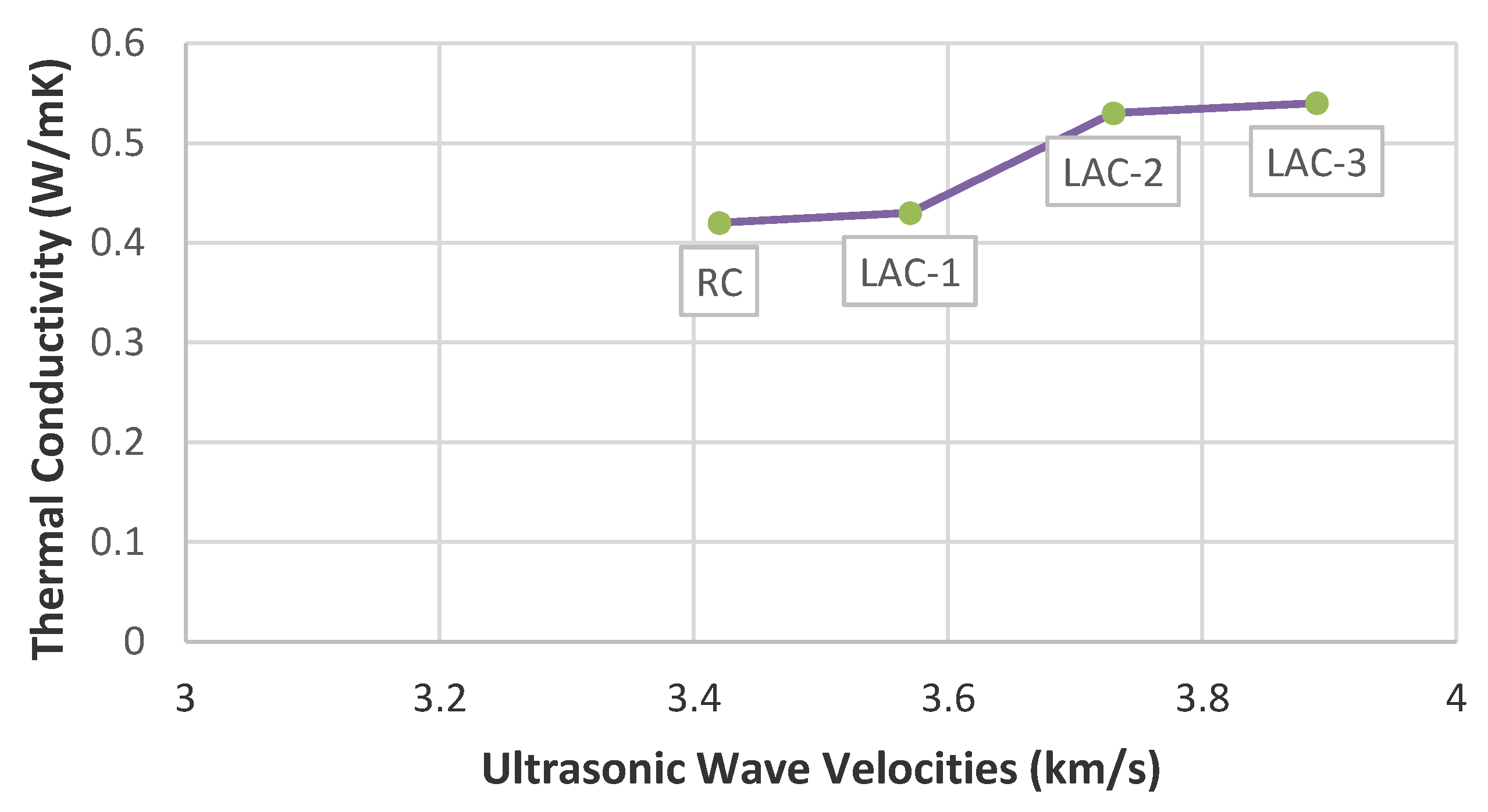

3.4. Thermal Conductivity

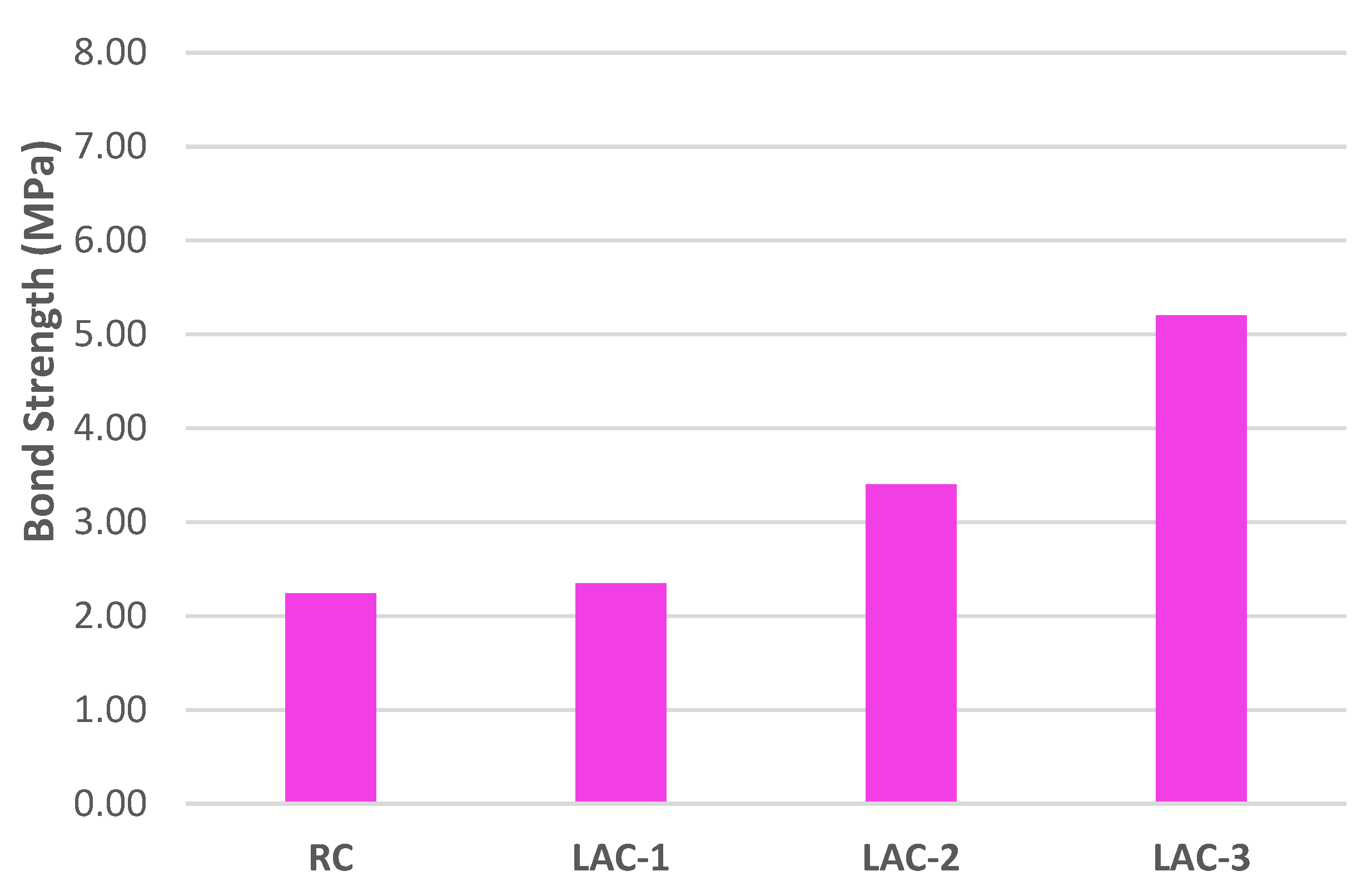

3.5. Bond Strength

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abd Elrahman, M.; Chung, S.-Y.; Sikora, P.; Rucinska, T.; Stephan, D. Influence of Nanosilica on Mechanical Properties, Sorptivity, and Microstructure of Lightweight Concrete. Materials 2019, 12, 3078. [Google Scholar] [CrossRef] [Green Version]

- Shannag, M.J. Characteristics of lightweight concrete containing mineral admixtures. Constr. Build. Mater. 2011, 25, 658–662. [Google Scholar] [CrossRef]

- Ali, M.R.; Maslehuddin, M.; Shameem, M.; Barry, M.S. Thermal-resistant lightweight concrete with polyethylene beads as coarse aggregates. Constr. Build. Mater. 2018, 164, 739–749. [Google Scholar] [CrossRef]

- Qadir, G.; Rashid, Y.; Hassan, A.; Mahmoud Vall, E.; Saleh, S.; Salim, K. Development and Mechanical Testing of Porous-Lightweight Geopolymer Mortar. Buildings 2021, 11, 1. [Google Scholar] [CrossRef]

- Soon-Ching, N.; Kaw-Sai, L. Thermal conductivity of newspaper sandwiched aerated lightweight concrete panel. Energy Build. 2010, 42, 2452–2456. [Google Scholar]

- Thomas, K.; Erika, S.; Till, V. Flexural behavior of a hybrid FRP and lightweight concrete sandwich bridge deck. Compos. Part A Appl. Sci. Manuf. 2007, 38, 879–889. [Google Scholar]

- Siong, K.L.; Cher, S.T.; Bo, L.; Tung-Chai, L.; Uzzal, H.; Chi, S.P. Utilizing high volumes quarry wastes in the production of lightweight foamed concrete. Constr. Build. Mater. 2017, 151, 441–448. [Google Scholar]

- Al-Jabri, K.S.; Hago, A.W.; Al-Nuaimi, A.S.; Al-Saidy, A.H. Concrete blocks for thermal insulation in hot climate. Cem. Concr. Res. 2005, 35, 1472–1479. [Google Scholar] [CrossRef]

- Osman Ünal, T.U.; Ahmet, Y. Investigation of properties of low-strength lightweight concrete for thermal insulation. Build. Environ. 2007, 42, 584–590. [Google Scholar] [CrossRef]

- Balendran, R.V.; Zhou, F.P.; Nadeem, A.; Leung, A.Y.T. Influence of steel fibres on strength and ductility of normal and lightweight high strength concrete. Build. Environ. 2002, 37, 1361–1367. [Google Scholar] [CrossRef]

- Jianqing, G.; Wenjie, Z. The effects of pozzolanic powder on foam concrete pore structure and frost resistance. Constr. Build. Mater. 2019, 208, 135–143. [Google Scholar]

- Poon, C.S.; Kou, S.C.; Lam, L. Compressive strength, chloride diffusivity and pore structure of high performance metakaolin and silica fume concrete. Constr. Build. Mater. 2006, 20, 858–865. [Google Scholar] [CrossRef]

- Du, H. Properties of ultra-lightweight cement composites with nano-silica. Constr. Build. Mater. 2019, 199, 696–704. [Google Scholar] [CrossRef]

- Atmaca, N.; Abbas, M.L.; Atmaca, A. Effects of nano-silica on the gas permeability, durability and mechanical properties of high-strength lightweight concrete. Constr. Build. Mater. 2017, 147, 17–26. [Google Scholar] [CrossRef]

- Ranjbar, M.M.; Mousavi, S.Y. Strength and durability assessment of self-compacting lightweight concrete containing expanded polystyrene. Mater Struc. 2015, 48, 1001–1011. [Google Scholar] [CrossRef]

- Vargas, P.; Marín, N.A.; Tobón, J.I. Performance and Microstructural Analysis of Lightweight Concrete Blended with Nanosilica under Sulfate Attack. Adv. Civ. Eng. 2018, 2018, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Yu, R.; Van Onna, D.; Spiesz, P.; Yu, Q.; Brouwers, H.; Yu, Q. Development of Ultra-Lightweight Fibre Reinforced Concrete applying expanded waste glass. J. Clean. Prod. 2016, 112, 690–701. [Google Scholar] [CrossRef]

- Liu, R.; Xiao, H.; Liu, J.; Guo, S.; Pei, Y. Improving the microstructure of ITZ and reducing the permeability of concrete with various water/cement ratios using nano-silica. J. Mater. Sci. 2019, 54, 444–456. [Google Scholar] [CrossRef]

- Samy, M.; El-Feky, P.; Youssef, A.; Maher El-Tair, S.; Ibrahim, M. Serag Effect of nano silica addition on enhancing the performance of cement composites reinforced with nano cellulose fibers. AIMS Mater. Sci. 2019, 6, 864–883. [Google Scholar] [CrossRef]

- Zhang, P.; Xie, N.; Cheng, X.; Feng, L.; Hou, P.; Wu, Y. Low dosage nano-silica modification on lightweight aggregate concrete. Nanomater. Nanotechnol. 2018, 8, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.F.; Huang, Y.J.; Wu, G.Y.; Fang, C.; Li, D.W.; Han, N.X. Effect of nano-SiO2 on strength, shrinkage and cracking sensitivity of lightweight aggregate concrete. Constr. Build. Mater. 2018, 175, 115–125. [Google Scholar] [CrossRef]

- Pawel, S.; Teresa, R.; Dietmar, S.; Sang-Yeop, C.; Mohamed, A. Evaluating the effects of nanosilica on the material properties of lightweight and ultra-lightweight concrete using image-based approaches. Constr. Build. Mater. 2020, 264, 1–15. [Google Scholar]

- Erdem, S.; Gürbüz, E.; Uysal, M. Micro-mechanical analysis and X-ray computed tomography quantification of damage in concrete with industrial by-products and construction waste. J. Clean. Prod. 2018, 189, 933–940. [Google Scholar] [CrossRef]

- Hosseini, P.; Booshehrian, A.; Delkash, M.; Ghavami, S.; Zanjani, M.K. Use of Nano-SiO2 to Improve Microstructure and Compressive Strength of Recycled Aggregate Concretes. Nanotechnol. Constr. 2009, 3, 215–221. [Google Scholar]

- Savaş, E.; Andrew, R.D.; Nicholas, H.T. Impact load-induced micro-structural damage and micro-structure associated mechanical response of concrete made with different surface roughness and porosity aggregates. Cem. Concr. Res. 2012, 42, 291–305. [Google Scholar]

- Testing Hardened Concrete-Part 3: Compressive strength of test specimens, Turkish Standards Institution. TS-EN 12390-3, 29 April 2010.

- Guo, L.P.; Sun, W.; Zheng, K.R.; Chen, H.J.; Liu, B. Study on the flexural fatigue performance and fractal mechanism of concrete with high proportions of ground granulated blast-furnace slag. Cem. Concr. Res. 2007, 37, 242–250. [Google Scholar] [CrossRef]

- Concrete, mortar and cement-based repair materials: Chloride migration coefficient from non-steady-state migration experiments. NT BUILD 492, 21 November 1999.

- Luo, L.; De Schutter, G. Influence of corrosion inhibitors on concrete transport properties. Mater. Struct. 2008, 41, 1571–1579. [Google Scholar] [CrossRef]

- Testing Hardened Concrete–Part 8: Depth of penetration of water under pressure. TS-EN 12390-8, 29 April 2010.

- Standard test method for thermal conductivity and thermal diffusivity by modulated temperature differential scanning calorimetry. ASTM E1952, 10 April 2001.

- ASTM E1512-01, Standard Test Methods for Testing Bond Performance of Bonded Anchors; Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2007.

- Erdem, S. Impact Load-Induced Microstructural Damage of Concrete Made with Unconventional Aggregates; University of Nottingham, Department of Civil Engineering: Nottingham, UK, 2012. [Google Scholar]

- Perkins, W.G. Polymer toughness and impact resistance. Polym. Eng. Sci. 1999, 39, 2445–2460. [Google Scholar] [CrossRef]

- Erdem, S.; Blankson, M.A. Fractal–fracture analysis and characterization of impact-fractured surfaces in different types of concrete using digital image analysis and 3D nanomap laser profilometery. Constr. Build. Mater. 2013, 40, 70–76. [Google Scholar] [CrossRef]

- Erdem, S.; Blankson, M.A. Chloride-Ion Penetrability and Mechanical Analysis of High Strength Concrete with Copper Slag. Int. J. Eng. Res. Appl. 2014, 4, 101–113. [Google Scholar]

| Mixture | Cement (kg) | Water (kg) | Fine Aggregate (kg) | Lightweight Coarse Aggregate (kg) | Nano-Silica (kg) | Density (kg/m3) |

|---|---|---|---|---|---|---|

| RC | 500 | 175 | 566 | 554 | - | 1645 |

| LAC-1 | 495 | 175 | 566 | 554 | 10 | 1633 |

| LAC-2 | 490 | 175 | 566 | 554 | 20 | 1622 |

| LAC-3 | 485 | 175 | 566 | 554 | 30 | 1664 |

| Mix ID | Fractal Dimension -D | Ws/Gf (mm) |

|---|---|---|

| RC | 1.2519 | 71.44 |

| LAC-1 | 1.2930 | 78.53 |

| LAC-2 | 1.3846 | 96.98 |

| LAC-3 | 1.5586 | 144.76 |

| Mix ID | Water Permeability (mm) | Chloride Penetration | ||

|---|---|---|---|---|

| Depth (mm) | Dnssm × 10−12 | Charge Passed (Coulombs) | ||

| RC | 37 | 12 | 12.4 | 2678 |

| LAC-1 | 32 | 9 | 9.56 | 1989 |

| LAC-2 | 26 | 7 | 7.12 | 1892 |

| LAC-3 | 18 | 6 | 6.42 | 1746 |

| Mix ID | Micro Pores (%) | Macro Pores (%) |

|---|---|---|

| RC | 68.40 | 31.6 |

| LAC-1 | 72.30 | 27.7 |

| LAC-2 | 77.40 | 22.6 |

| LAC-3 | 81.10 | 18.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Blankson, M.A.; Erdem, S.; Gürbüz, E. Micro-Mechanical and 3D Fractal Analysis, Durability, and Thermal Behaviour of Nano-Modified Cementitious Lightweight Composites for Building Facades. Buildings 2021, 11, 85. https://doi.org/10.3390/buildings11030085

Blankson MA, Erdem S, Gürbüz E. Micro-Mechanical and 3D Fractal Analysis, Durability, and Thermal Behaviour of Nano-Modified Cementitious Lightweight Composites for Building Facades. Buildings. 2021; 11(3):85. https://doi.org/10.3390/buildings11030085

Chicago/Turabian StyleBlankson, Marva Angela, Savaş Erdem, and Ezgi Gürbüz. 2021. "Micro-Mechanical and 3D Fractal Analysis, Durability, and Thermal Behaviour of Nano-Modified Cementitious Lightweight Composites for Building Facades" Buildings 11, no. 3: 85. https://doi.org/10.3390/buildings11030085

APA StyleBlankson, M. A., Erdem, S., & Gürbüz, E. (2021). Micro-Mechanical and 3D Fractal Analysis, Durability, and Thermal Behaviour of Nano-Modified Cementitious Lightweight Composites for Building Facades. Buildings, 11(3), 85. https://doi.org/10.3390/buildings11030085