Characterization of Buriti (Mauritia flexuosa) Foam for Thermal Insulation and Sound Absorption Applications in Buildings

Abstract

1. Introduction

2. Materials and Methods

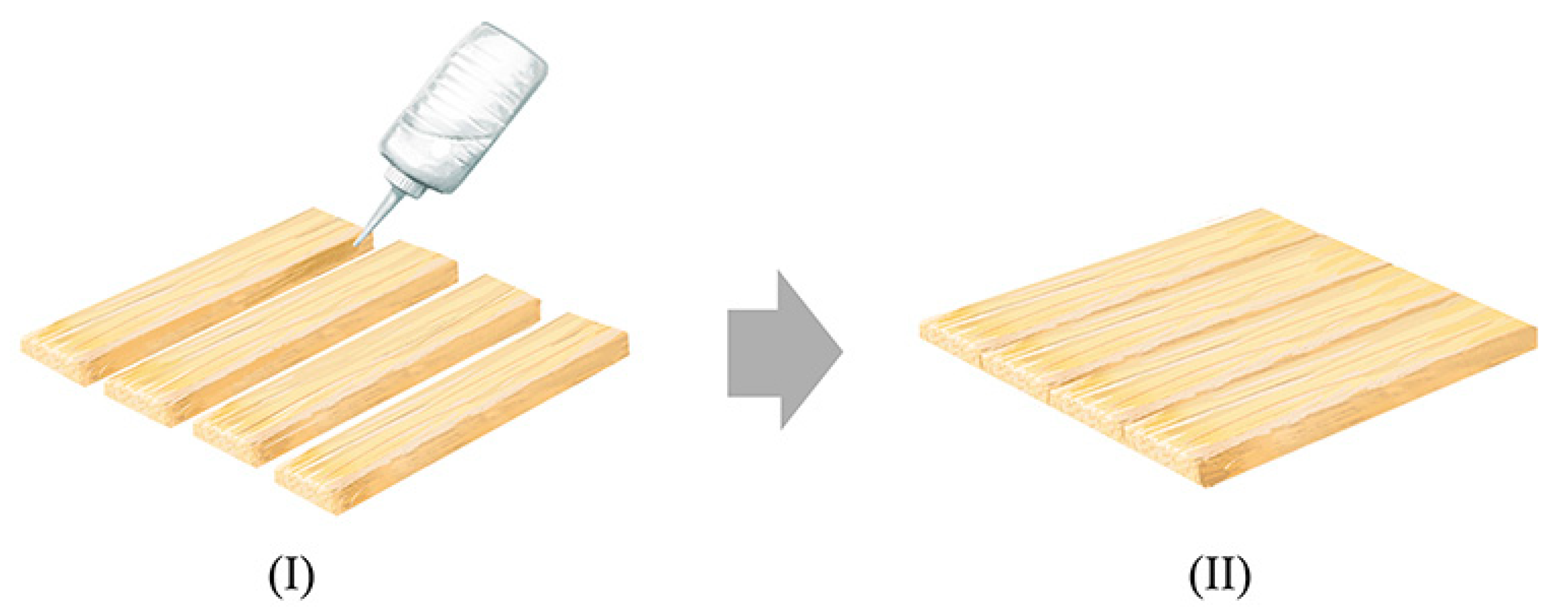

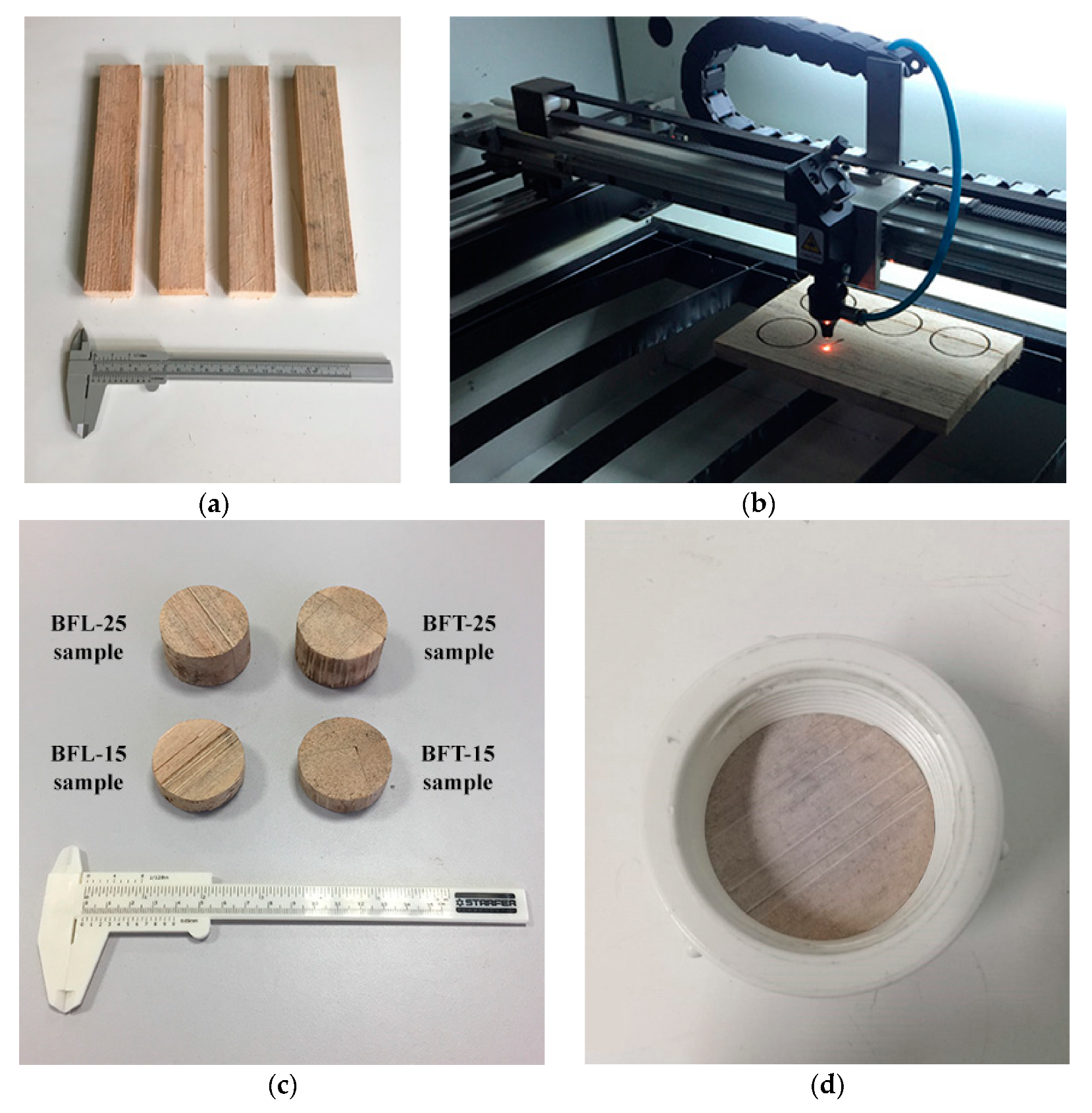

2.1. Materials

2.2. Characterizations and Tests

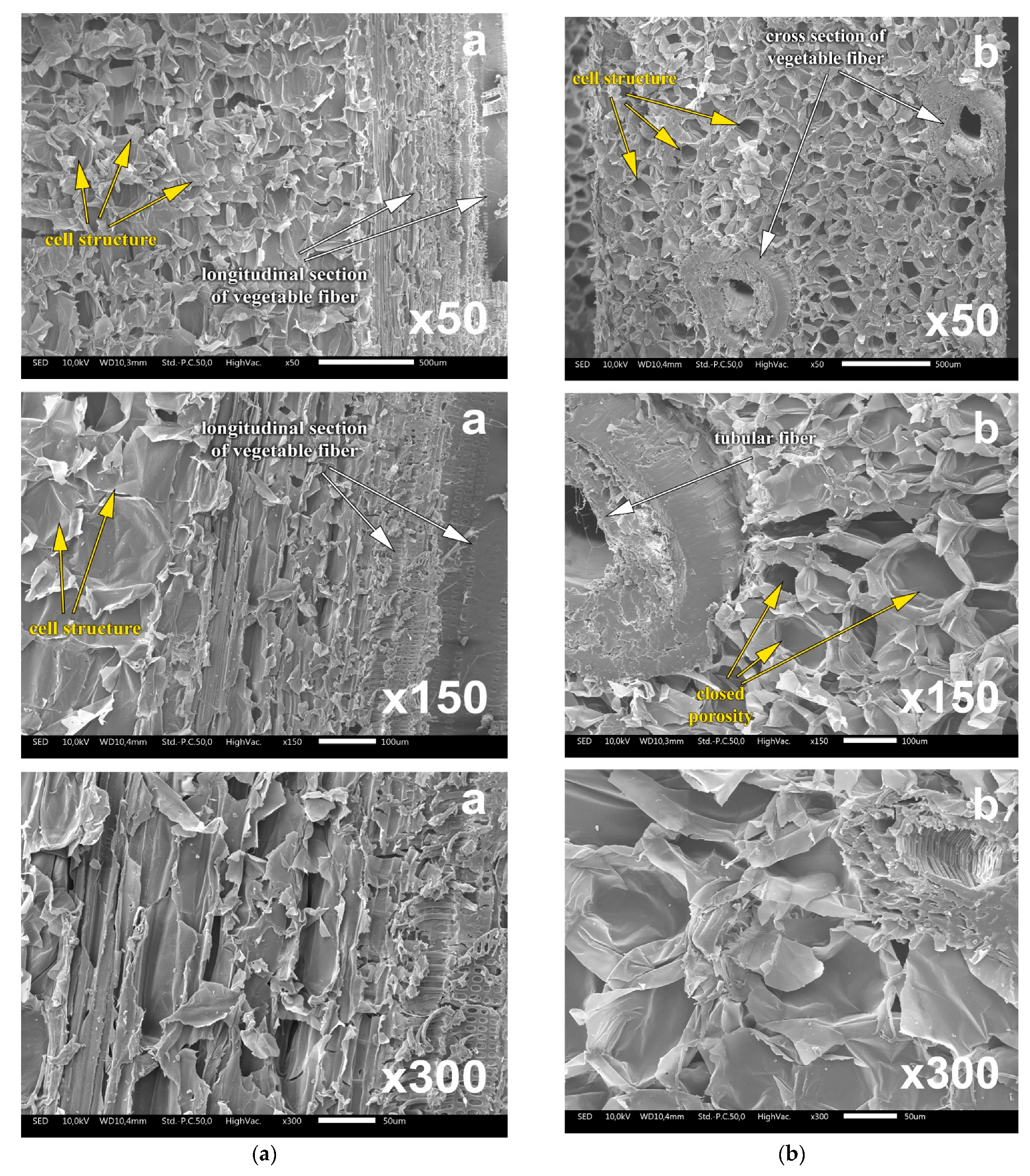

2.2.1. Morphological Characterization

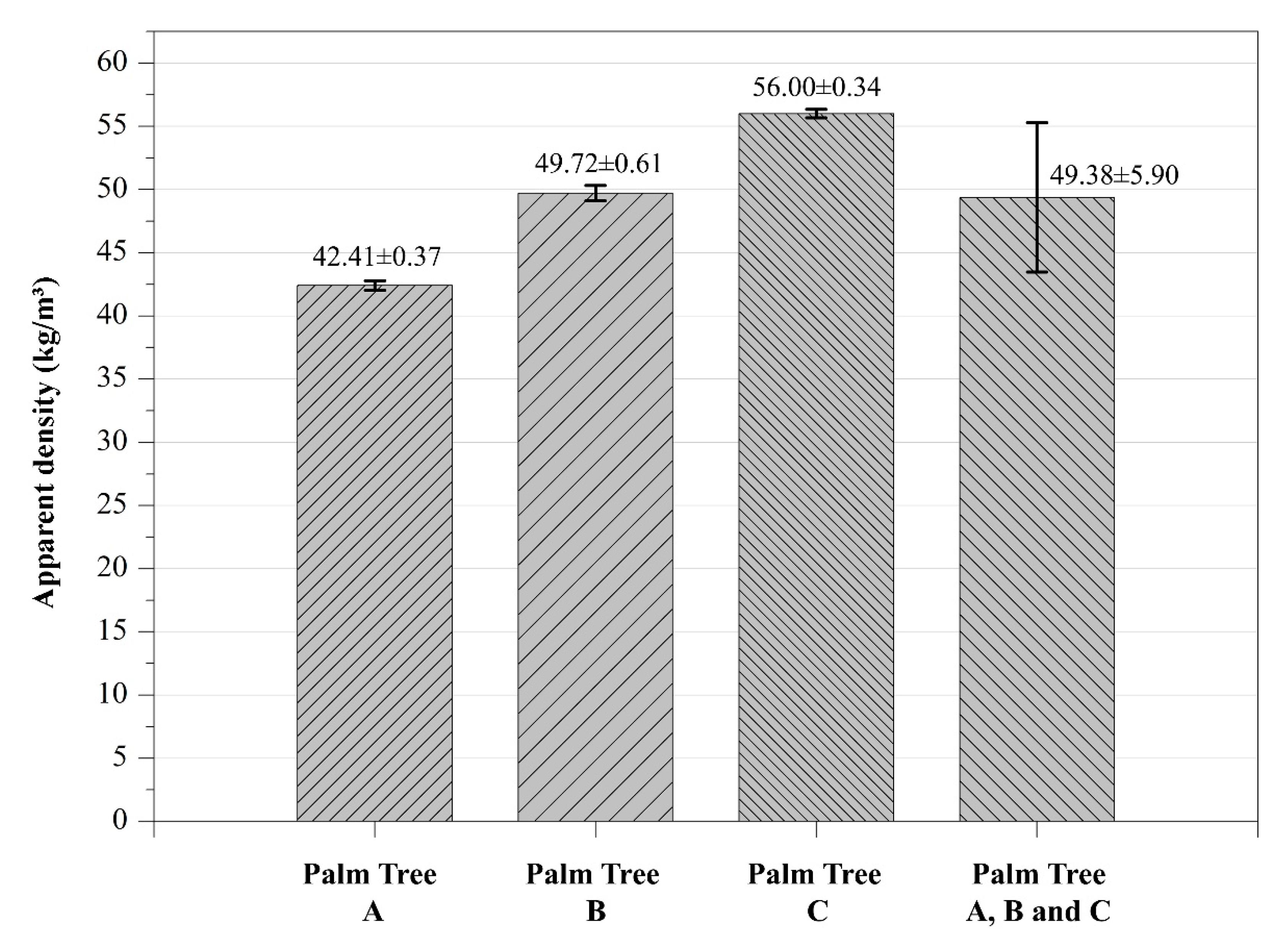

2.2.2. Apparent Density Test

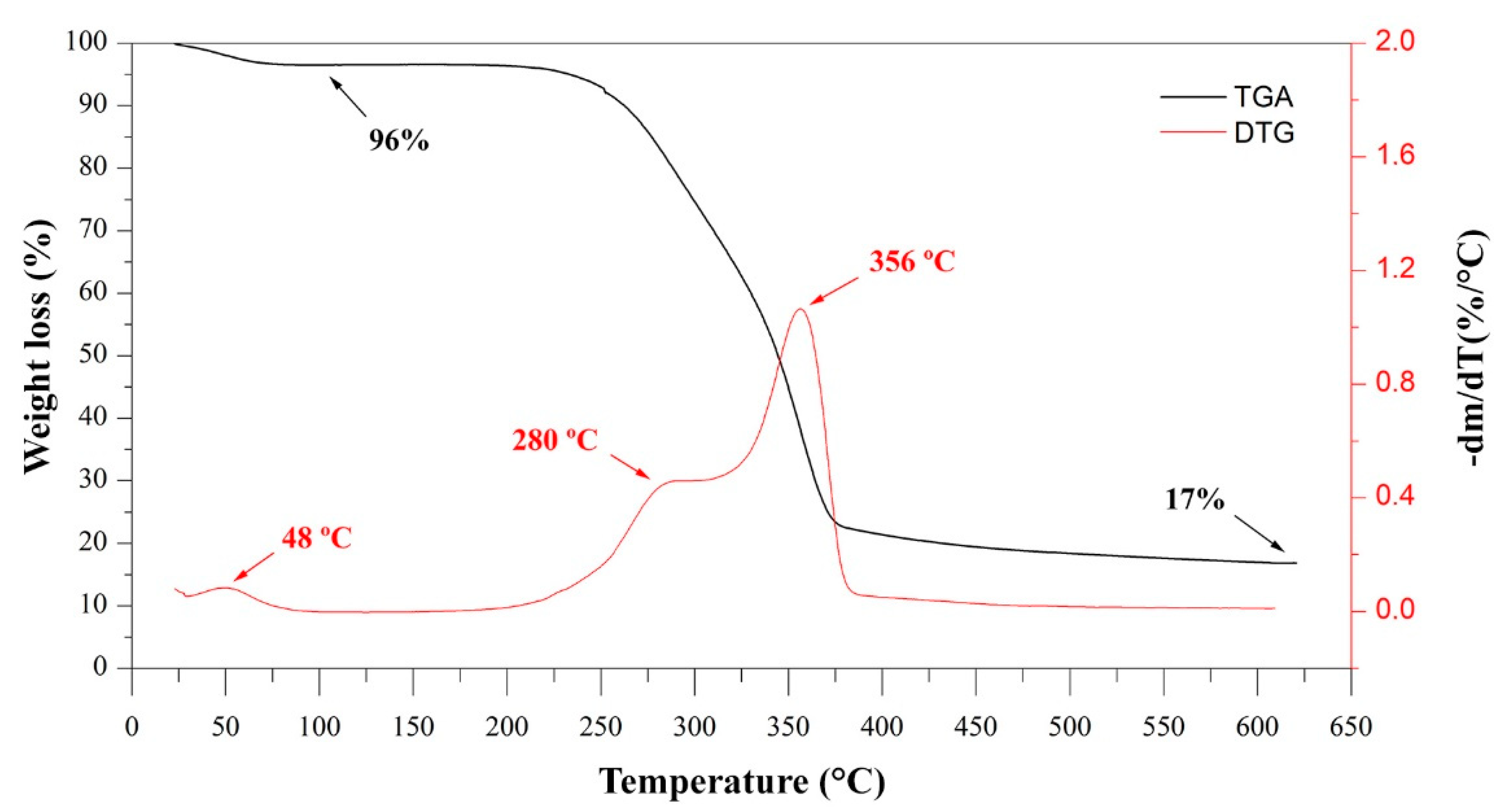

2.2.3. Thermogravimetric Characterization (TGA/DTG)

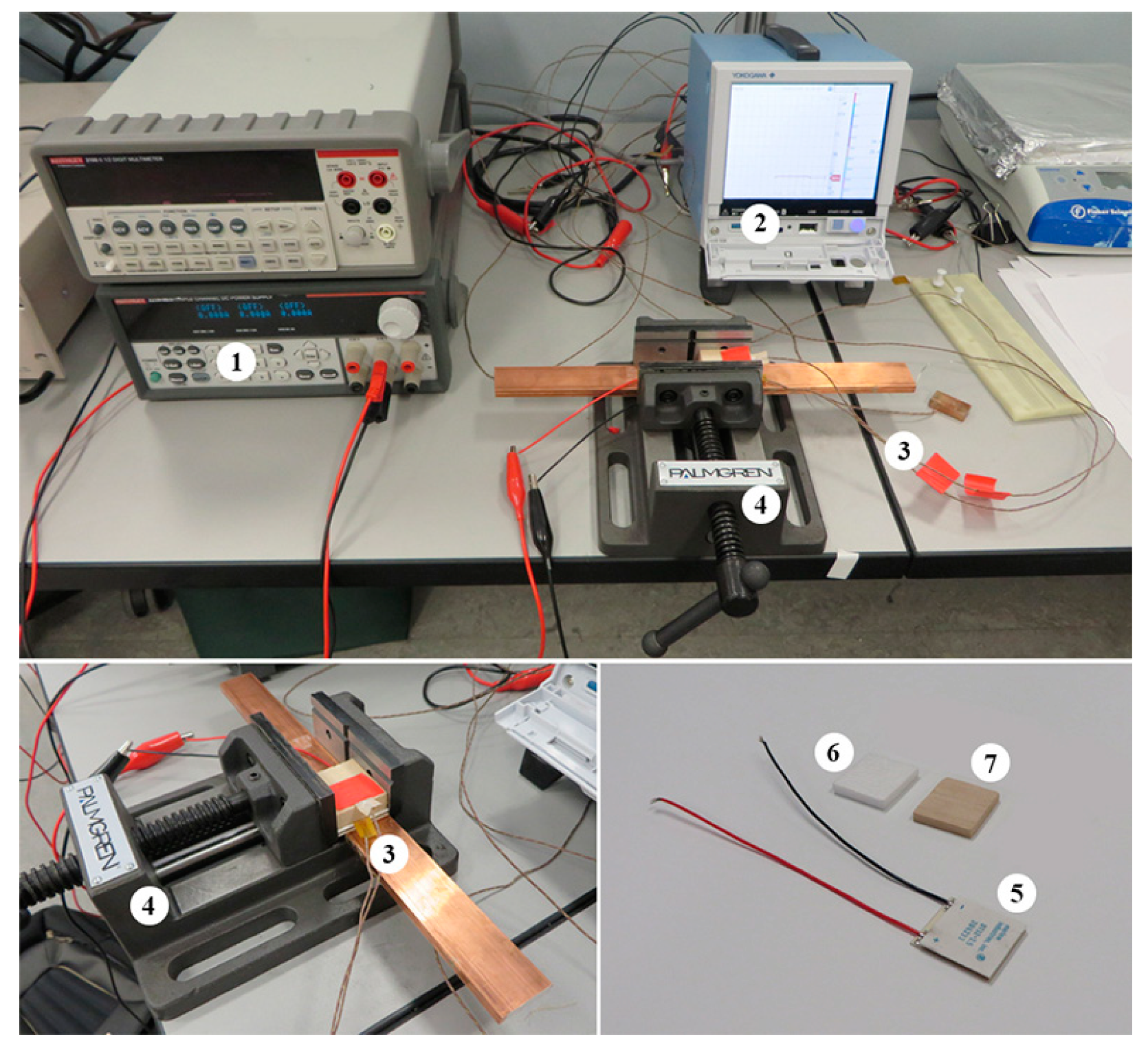

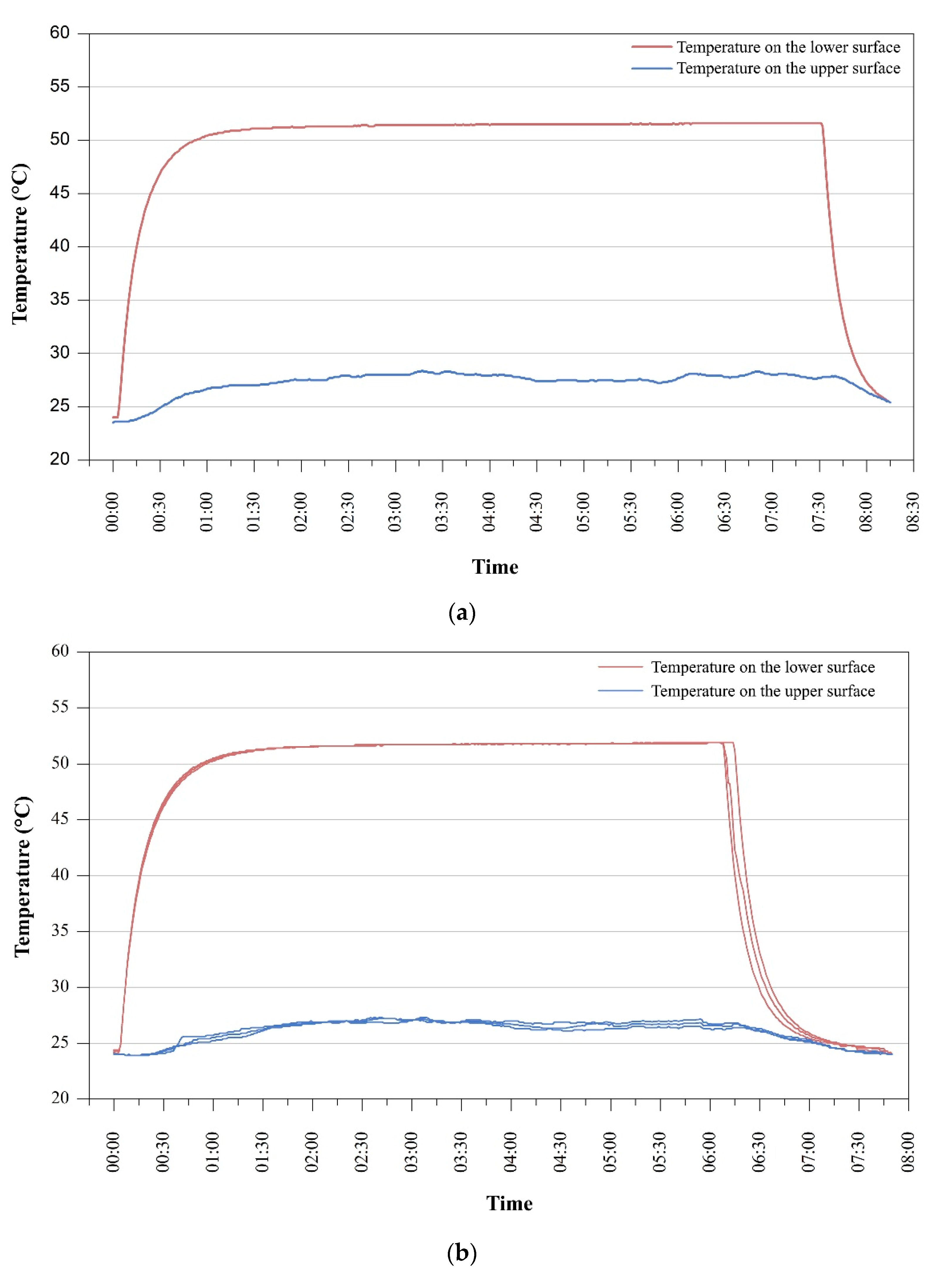

2.2.4. Thermal Conductivity Test

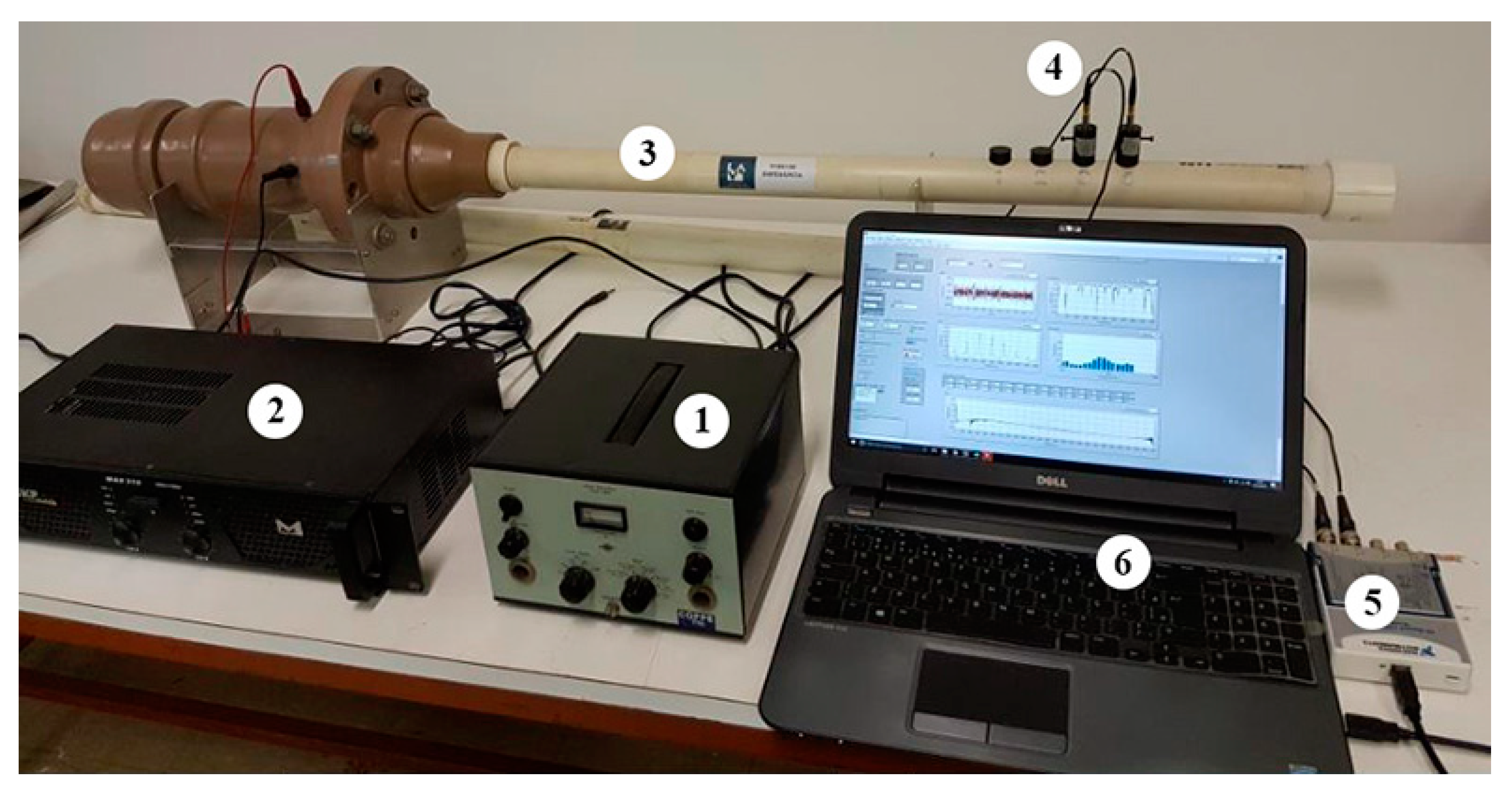

2.2.5. Sound Absorption Test

3. Results and Discussion

3.1. Morphological Characterization

3.2. Apparent Density Test

3.3. Thermogravimetric Characterization (TGA/DTG)

3.4. Thermal Conductivity Test

3.5. Sound Absorption Test

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Onésippe, C.; Passe-Coutrin, N.; Toro, F.; Desvasto, S.; Bilba, K.; Arsène, M. Sugar cane bagasse fibers reinforced cement composites: Thermal considerations. Compos. Part A 2010, 41, 49–556. [Google Scholar] [CrossRef]

- Benmansour, N.; Agoudjil, B.; Gherabli, A.; Kareche, A.; Boudenne, A. Thermal and mechanical performance of natural mortar reinforced with date palm fibers for use as insulating materials in building. Energy Build. 2014, 81, 98–104. [Google Scholar] [CrossRef]

- Berardi, U.; Iannace, G. Predicting the sound absorption of natural materials: Best-fit inverse laws for the acoustic impedance and the propagation constant. Appl. Acoust. 2017, 115, 131–138. [Google Scholar] [CrossRef]

- Lafond, C.; Blanchet, P. Technical Performance Overview of Bio-Based Insulation Materials Compared to Expanded Polystyrene. Buildings 2020, 10, 9–16. [Google Scholar] [CrossRef]

- Boukhattem, L.; Boumhaout, M.; Hamdi, H.; Benhamou, B.; Nouh, F.A. Moisture content influence on the thermal conductivity of insulating building materials made from date palm fibers mesh. Constr. Build. Mater. 2017, 148, 818–823. [Google Scholar] [CrossRef]

- Bakatovich, A.; Davydenko, N.; Gaspar, F. Thermal insulating plates produced on the basis of vegetable agricultural waste. Energy Build. 2018, 180, 72–82. [Google Scholar] [CrossRef]

- Yang, T.; Hu, L.; Xiong, X.; Petru, M.; Noman, M.T.; Mishra, R.; Militký, J. Sound Absorption Properties of Natural Fibers: A Review. Sustainability 2020, 12, 8477. [Google Scholar] [CrossRef]

- Arenas, J.P.; del Rey, R.; Alba, J.; Oltra, R. Sound-Absorption Properties of Materials Made of Esparto Grass Fibers. Sustainability 2020, 12, 5533. [Google Scholar] [CrossRef]

- Belhadj, B.; Bederina, M.; Makhloufi, Z.; Dheilly, R.M.; Montrelay, N.; Quéneudéc, M. Contribution to the development of a sand concrete lightened by the addition of barley straws. Constr. Build. Mater. 2016, 113, 513–522. [Google Scholar] [CrossRef]

- Belakroum, R.; Gherfi, A.; Kadja, M.; Maalouf, C.; Lachi, M.; El Wakil, N.; Mai, T.H. Design and properties of a new sustainable construction material based on date palm fibers and lime. Constr. Build. Mater. 2018, 184, 330–343. [Google Scholar] [CrossRef]

- Arenas, J.P.; Asdrubali, F. Eco-Materials with Noise Reduction Properties. In Handbook of Ecomaterials; Martínez, L., Kharissova, O., Kharisov, B., Eds.; Springer: Cham, Switzerland, 2018; pp. 1–26. [Google Scholar] [CrossRef]

- del Rey, R.; Alba, J.; Rodríguez, J.C.; Bertó, L. Characterization of New Sustainable Acoustic Solutions in a Reduced Sized Transmission Chamber. Buildings 2019, 9, 60. [Google Scholar] [CrossRef]

- Khalaf, Y.; El Hage, P.; Mihajlova, J.D.; Bergeret, A.; Lacroix, P.; El Hage, R. Influence of agricultural fibers size on mechanical and insulating properties of innovative chitosan-based insulators. Constr. Build. Mater. 2021, 287, 123071. [Google Scholar] [CrossRef]

- Mrajji, O.; El Wazna, M.; Boussoualem, Y.; El Bouari, A.; Cherkaoui, O. Feather waste as a thermal insulation solution: Treatment, elaboration and characterization. J. Ind. Text. 2021, 50, 1674–1697. [Google Scholar] [CrossRef]

- Caniato, M.; Cozzarini, L.; Schmid, C.; Gasparella, A. Acoustic and thermal characterization of a novel sustainable material incorporating recycled microplastic waste. Sustain. Mater. Technol. 2021, 28, e00274. [Google Scholar] [CrossRef]

- Buratti, C.; Belloni, E.; Merli, F.; Zanella, V.; Robazza, P.; Cornaro, C. An innovative multilayer wall composed of natural materials: Experimental characterization of thermal properties and comparasion with other solutions. Energy Procedia 2018, 148, 892–899. [Google Scholar] [CrossRef]

- Portela, T.G.R.; Costa, L.L.; Santos, N.S.S.; Lopes, F.P.D.; Monteiro, S.N. Tensile behavior of lignocellulosic fiber reinforced polymer composites: Part II buriti petiole/polyester. Rev. Matéria 2010, 15, 195–201. [Google Scholar] [CrossRef][Green Version]

- Karthik Babu, N.B.; Muthukumaran, S.; Arokiasamy, S.; Ramesh, T. Thermal and mechanical behavior of the coir powder filled polyester micro-composites. J. Nat. Fibers 2018, 17, 1058–1068. [Google Scholar] [CrossRef]

- Santos, R.S.; Souza, A.A.; De Paoli, M.; Souza, C.M.L. Cardanol–formaldehyde thermoset composites reinforced with buriti fibers: Preparation and characterization. Compos. Part A 2010, 41, 1123–1129. [Google Scholar] [CrossRef]

- Lorenzi, H.; Souza, H.M.; Costa, J.T.M.; Cerqueira, L.S.C.; Ferreira, E. Palmeiras Brasileiras e Exóticas Cultivadas; Plantarum: São Paulo, Brasil, 2004; p. 420. [Google Scholar]

- Cattani, I.M.; Baruque-Ramos, J. Brazilian Buriti Palm Fiber (Mauritia flexuosa Mart.). In Natural Fibres: Advances in Science and Technology towards Industrial Applications; Fangueiro, R., Rana, S., Eds.; Springer: Dordrecht, The Netherlands, 2016; Volume 12, pp. 89–98. [Google Scholar] [CrossRef]

- Sampaio, M.B.; Schmidt, I.B.; Figueiredo, I.B. Harvesting Effects and Population Ecology of the Buriti Palm (Mauritia flexuosa L. f., Arecaceae) in the Jalapão Region, Central Brazil. Econ. Bot. 2008, 62, 171–181. [Google Scholar] [CrossRef]

- ASTM D1622. Standard Test Method for Apparent Density of Rigid Cellular Plastics; American Society for Testing and Materials: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Kreith, F.; Manglik, R.M.; Bohn, M.S. Principles of Heat Transfer, 7th ed.; Cengage Learning: Stamford, NY, USA, 2011. [Google Scholar]

- ASTM E1050. Standard Test Method for Impedance and Absorption of Acoustical Materials Using A Tube, Two Microphones and a Digital Frequency Analysis System; American Society for Testing and Materials: West Conshohocken, PA, USA, 2012. [Google Scholar]

- ISO 10534. Acoustics—Determination of Sound Absorption Coefficient and Impedance in Impedance Tubes—Part 2: Transfer-Function Method; International Organization for Standardization: Geneve, Switzerland, 1998. [Google Scholar]

- Cardoso, M.S.; Gonçalez, J.C. Aproveitamento da casca do coco-verde (Cocos nucifera L.) para produção de polpa celulósica. Ciência Florest. 2016, 26, 330–331. [Google Scholar] [CrossRef]

- Schiavoni, S.; D’Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Li, Y.; Ren, S. Acoustic and Thermal Insulating Materials. In Building Decorative Materials; Li, Y., Ren, S., Eds.; Woodhead Publishing: Shaxton, UK, 2011; pp. 359–374. [Google Scholar] [CrossRef]

- Lavoratti, A.; Daiane, R.; Amico, S.C.; Zattera, A.J. Influence of fibre treatment on the characteristics of buriti and ramie polyester composites. Polym. Polym. Compos. 2017, 25, 818–823. [Google Scholar] [CrossRef]

- Knapic, S.; Oliveira, V.; Machado, J.S.; Pereira, H. Cork as a building material: A review. Eur. J. Wood Wood Prod. 2016, 74, 775–791. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Ornaghi Júnior, H.L.; Moraes, A.G.O.; Poletto, M.; Zattera, A.J.; Amico, S.C. Chemical composition, tensile properties and structural characterization of buriti fiber. Cellul. Chem. Technol. 2016, 50, 15–22. Available online: https://www.cellulosechemtechnol.ro/pdf/CCT1(2016)/p.15-22.pdf (accessed on 3 November 2020).

- Souza, S.A.V.; Silva, M.C.; Silva Júnior, O.G.; Mottin, A.C.; Oréfice, R.L.; Ayres, E. Design and characterization of bio-composites from poly (lactic acid) (pla) and buriti petiole (Mauritia flexuosa). J. Renew. Mater. 2017, 5, 251–257. [Google Scholar] [CrossRef]

- Moura, A.S.; Demori, R.; Leão, R.M.; Frankenberg, C.L.C.; Santana, R.M.C. The influence of the coconut fiber treated as reinforcement in PHB (polyhydroxybutyrate) composites. Mater. Today Commun. 2019, 18, 191–198. [Google Scholar] [CrossRef]

- Sánchez, M.L.; Capote, G.; Carrillo, J. Composites reinforced with guadua fibers: Physical and mechanical properties. Constr. Build. Mater. 2019, 228, 116749. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Rodriguez, R.J.S.; Costa, L.L.; Portela, T.G.R.; Santos, N.S.S. Thermal behavior of buriti biofoam. Rev. Matéria 2010, 15, 104–109. [Google Scholar] [CrossRef][Green Version]

- Martins, M.A.; Mattoso, L.H.C.; Pessoa, J.D.C. Comportamento térmico e caracterização morfológica das fibras de mesocarpo e caroço do açaí (Euterpe oleracea Mart.). Rev. Bras. Frutic. 2009, 31, 1150–1157. [Google Scholar] [CrossRef]

- Neira, D.S.M.; Marinho, G.S. Nonwoven sisal fiber as thermal insulator material. J. Nat. Fibers 2009, 6, 115–126. [Google Scholar] [CrossRef]

- Kosiński, P.; Brzyski, P.; Szewczyk, A.; Motacki, W. Thermal properties of raw hemp fiber as a loose fill insulation material. J. Nat. Fibers 2018, 15, 717–730. [Google Scholar] [CrossRef]

- Damfeu, J.C.; Meukam, P.; Jannot, Y. Modeling and measuring of the thermal properties of insulating vegetable fibers by the asymmetrical hot plate method and the radial flux method: Kapok, coconut, groundnut shell fiber and rattan. Thermochim. Acta 2016, 630, 64–77. [Google Scholar] [CrossRef]

- Asdrubali, F.; Ferracuti, B.; Lombardi, L.; Guattari, C.; Evangelisti, L.; Grazieschi, G. A review of structural, thermo-physical, acoustical, and environmental properties of wooden materials for building applications. Build. Environ. 2017, 114, 307–332. [Google Scholar] [CrossRef]

- Huang, Z.; Sun, Y.; Musso, F. Hygrothermal performance of natural bamboo fiber and bamboo charcoal as local construction infills in building envelope. Constr. Build. Mater. 2018, 177, 342–357. [Google Scholar] [CrossRef]

- António, J. Acoustic behavior of fibrous materials. In Fibrous and Composite Materials for Civil Engineering Applications; Fangueiro, R., Ed.; Woodhead Publishing: Shaxton, UK, 2011; pp. 306–324. [Google Scholar] [CrossRef]

- Amares, S.; Sujatmika, E.; Hong, T.W.; Durairaj, R.; Hamid, H.S.H.B. A review: Characteristics of noise absorption material. J. Phys. Conf. Ser. 2017, 908, 012005. [Google Scholar] [CrossRef]

- ASTM C423. Standard Test Method for Sound Absorption and Sound Absorption Coefficients by the Reverberation Room Method; American Society for Testing and Materials: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Lim, Z.Y.; Putra, A.; Nor, M.J.M.; Yaakob, M.Y. Sound absorption performance of natural kenaf fibres. Appl. Acoust. 2018, 130, 107–114. [Google Scholar] [CrossRef]

- Yeon, J.; Kim, K. Analysis of Absorption Coefficient for Eco-Friendly Acoustical Absorbers. Adv. Mater. Res. 2013, 831, 58–61. [Google Scholar] [CrossRef]

- Yeon, J.O.; Kim, K.; Yang, K.; Kim, J.; Kim, M. Physical properties of cellulose sound absorbers produced using recycled paper. Constr. Build. Mater. 2014, 70, 494–500. [Google Scholar] [CrossRef]

- Chen, S.; Jiang, Y. The acoustic property study of polyurethane foam with addition of bamboo leaves particles. Polym. Compos. 2016, 39, 1370–1381. [Google Scholar] [CrossRef]

- Or, K.H.; Putra, A.; Selamat, M.Z. Oil palm empty fruit bunch fibers as sustainable acoustic absorber. Appl. Acoust. 2017, 119, 9–16. [Google Scholar] [CrossRef]

| Properties | EPS Isopor® |

|---|---|

| Apparent density (kg/m3) | 14 |

| Thermal Conductivity (W/mK) | 0.042 |

| Flammability | Flame resistant |

| Sample Configuration | Cutting Direction | Thickness (mm) |

|---|---|---|

| BFL-15 | Longitudinal | 15 |

| BFL-25 | Longitudinal | 25 |

| BFT-15 | Transverse | 15 |

| BFT-25 | Transverse | 25 |

| Sample | Weight | Apparent Density | |

|---|---|---|---|

| Palm Tree A | 1 | 1.1556 g (1.1556 × 10−3 kg) | 0.04280 g/cm3 (42.80 kg/m3) |

| 2 | 1.1440 g (1.1440 × 10−3 kg) | 0.04237 g/cm3 (42.37 kg/m3) | |

| 3 | 1.1358 g (1.1358 × 10−3 kg) | 0.04207 g/cm3 (42.07 kg/m3) | |

| Palm Tree B | 1 | 1.3599 g (1.3599 × 10−3 kg) | 0.05037 g/cm3 (50.37 kg/m3) |

| 2 | 1.3401g (1.3401 × 10−3 kg) | 0.04963 g/cm3 (49.63 Kg/m3) | |

| 3 | 1.3272 g (1.3272 × 10−3 kg) | 0.04916 g/cm3 (49.16 kg/m3) | |

| Palm Tree C | 1 | 1.5019 g (1.5019 × 10−3 kg) | 0.05563 g/cm3 (55.63 kg/m3) |

| 2 | 1.5197 g (1.5197 × 10−3 kg) | 0.05629 g/cm3 (56.29 kg/m3) | |

| 3 | 1.5742 g (1.5742 × 10−3 kg) | 0.05608 g/cm3 (56.08 kg/m3) |

| Thermal Conductivity (λ) | Temperature Difference between Sample Surfaces (∆T) | Thickness (L) |

|---|---|---|

| 0.042 W/mK | 23.68 °C | 5 mm |

| Samples | Temperature Difference between Sample Surfaces (∆T) | Heat Flow (qk) | Thickness (L) |

|---|---|---|---|

| Sample 1 | 25.17 °C | 198.91 W/m2 | 5 mm |

| Sample 2 | 24.86 °C | ||

| Sample 3 | 24.90 °C |

| Material | Thermal Conductivity (W/mK) | Apparent Density (kg/m3) | References |

|---|---|---|---|

| Buriti Foam | 0.0398 ± 0.0003 | 49.38 ± 5.9 | Present Work |

| Hemp fiber | 0.039–0.076 | 18–85 | [5,40] |

| Date palm fiber | 0.033–0.085 | 121–389 | [5,10,28] |

| Sisal fiber | 0.042–0.044 | – | [39] |

| Coir fiber | 0.040–0.055 | 75–125 | [28,41] |

| Flax fiber | 0.038–0.075 | 20–100 | [5,28] |

| Oil palm fiber | 0.055–0.091 | 20–120 | [28,32] |

| Pineapple leaf fiber | 0.035–0.043 | 178–232 | [28,32] |

| Cane bagasse | 0.046–0.055 | 70–350 | [32,42] |

| Bamboo fiber | 0.042–0.046 | 70–170 | [43] |

| Jute | 0.046–0.055 | 26–350 | [5,28,32] |

| Cork | 0.037–0.050 | 110–170 | [28] |

| Sample Configuration | Frequency (Hz) | NRC | |||

|---|---|---|---|---|---|

| 250 | 500 | 1000 | 2000 | ||

| BFL-15 | 0.24 | 0.20 | 0.22 | 0.19 | 0.20 |

| BFL-25 | 0.17 | 0.18 | 0.26 | 0.21 | 0.20 |

| BFT-15 | 0.21 | 0.19 | 0.23 | 0.20 | 0.20 |

| BFT-25 | 0.22 | 0.24 | 0.33 | 0.29 | 0.25 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Siqueira, F.F.d.S.; Cosse, R.L.; Pinto, F.A.d.N.C.; Mareze, P.H.; Silva, C.F.e.; Nunes, L.C.C. Characterization of Buriti (Mauritia flexuosa) Foam for Thermal Insulation and Sound Absorption Applications in Buildings. Buildings 2021, 11, 292. https://doi.org/10.3390/buildings11070292

Siqueira FFdS, Cosse RL, Pinto FAdNC, Mareze PH, Silva CFe, Nunes LCC. Characterization of Buriti (Mauritia flexuosa) Foam for Thermal Insulation and Sound Absorption Applications in Buildings. Buildings. 2021; 11(7):292. https://doi.org/10.3390/buildings11070292

Chicago/Turabian StyleSiqueira, Felippe Fabrício dos Santos, Renato Lemos Cosse, Fernando Augusto de Noronha Castro Pinto, Paulo Henrique Mareze, Caio Frederico e Silva, and Lívio César Cunha Nunes. 2021. "Characterization of Buriti (Mauritia flexuosa) Foam for Thermal Insulation and Sound Absorption Applications in Buildings" Buildings 11, no. 7: 292. https://doi.org/10.3390/buildings11070292

APA StyleSiqueira, F. F. d. S., Cosse, R. L., Pinto, F. A. d. N. C., Mareze, P. H., Silva, C. F. e., & Nunes, L. C. C. (2021). Characterization of Buriti (Mauritia flexuosa) Foam for Thermal Insulation and Sound Absorption Applications in Buildings. Buildings, 11(7), 292. https://doi.org/10.3390/buildings11070292