Characterization of Buriti (Mauritia flexuosa) Foam for Thermal Insulation and Sound Absorption Applications in Buildings

Abstract

:1. Introduction

2. Materials and Methods

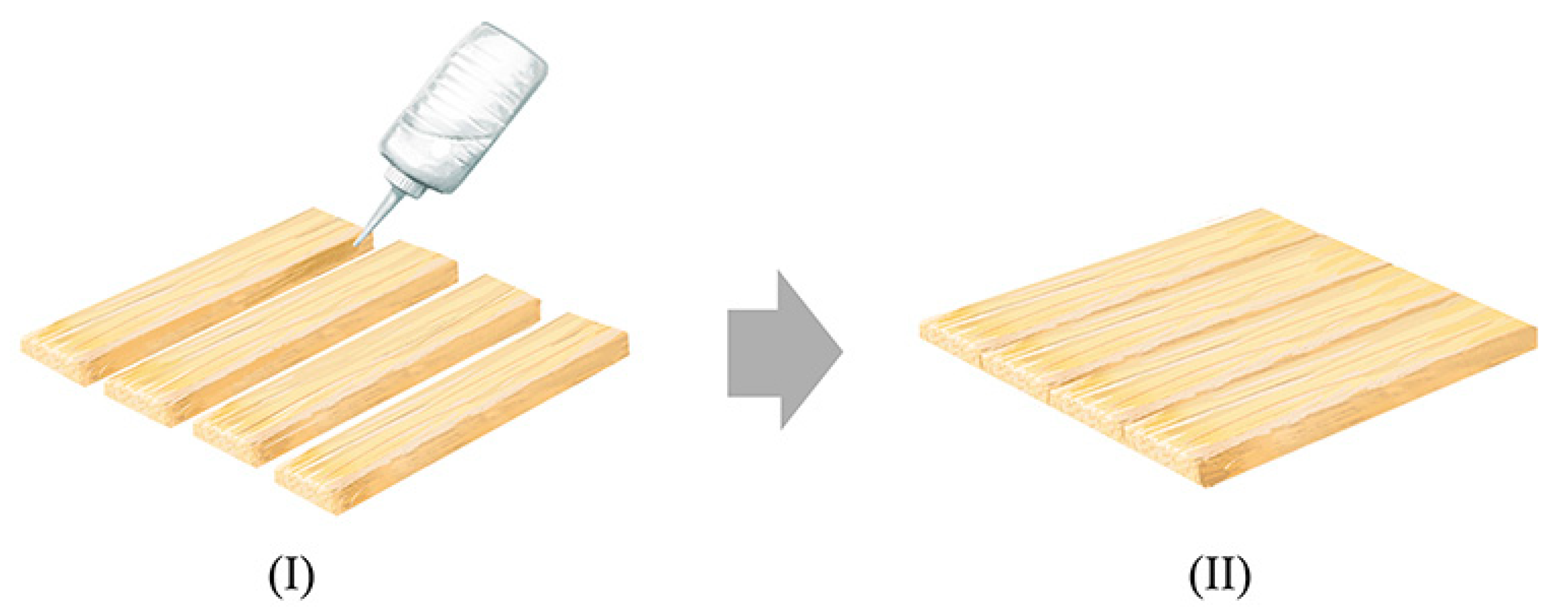

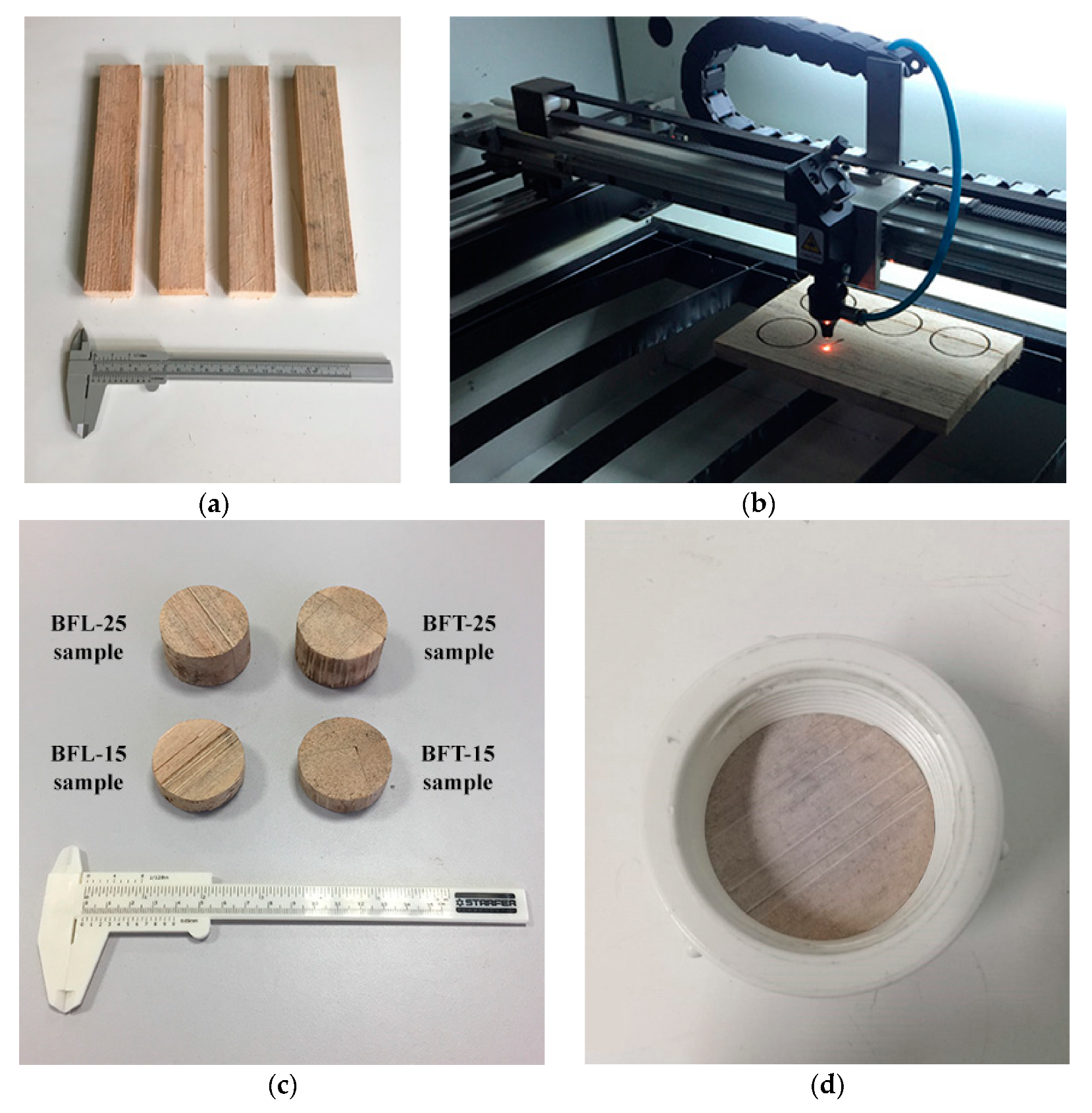

2.1. Materials

2.2. Characterizations and Tests

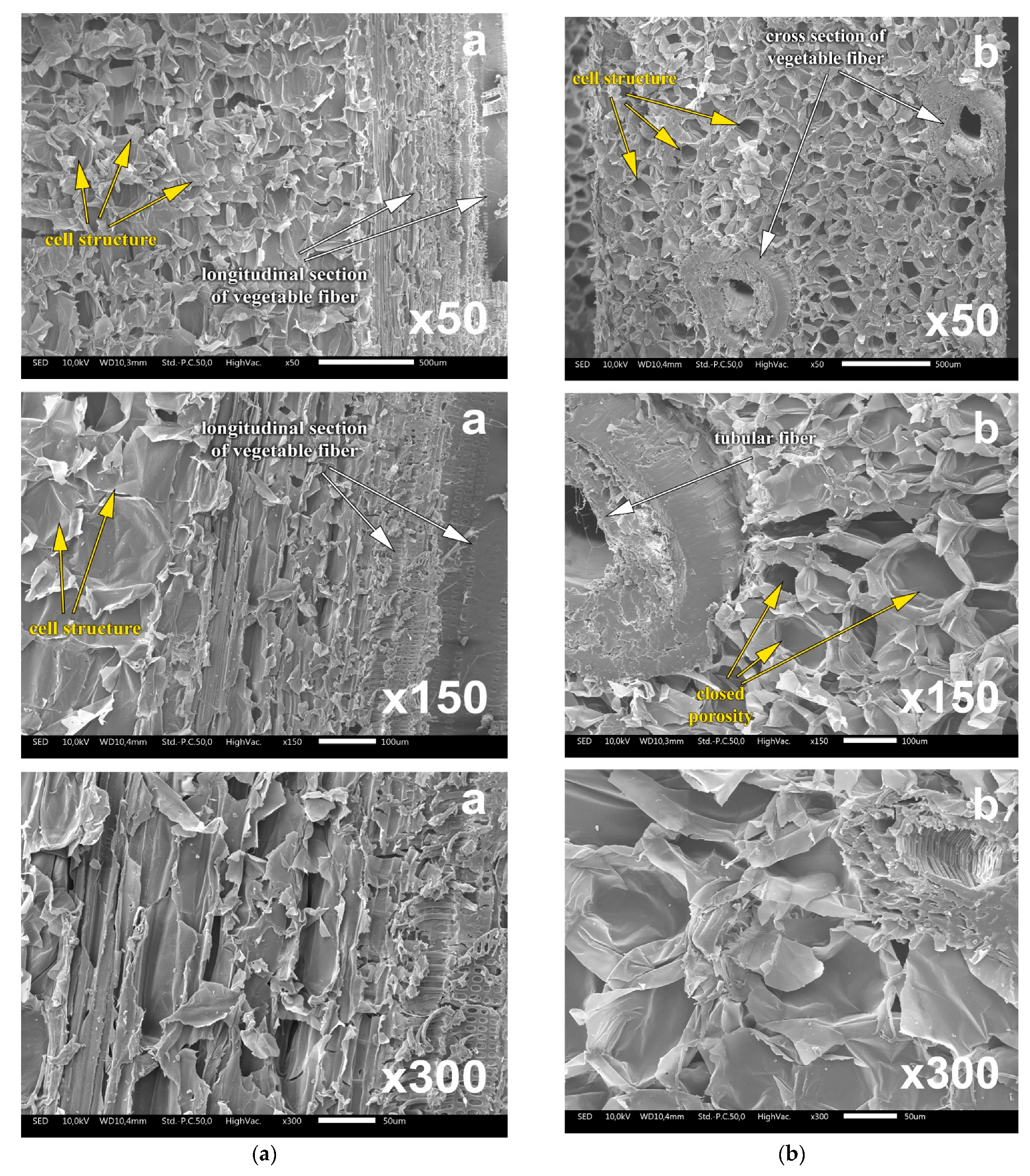

2.2.1. Morphological Characterization

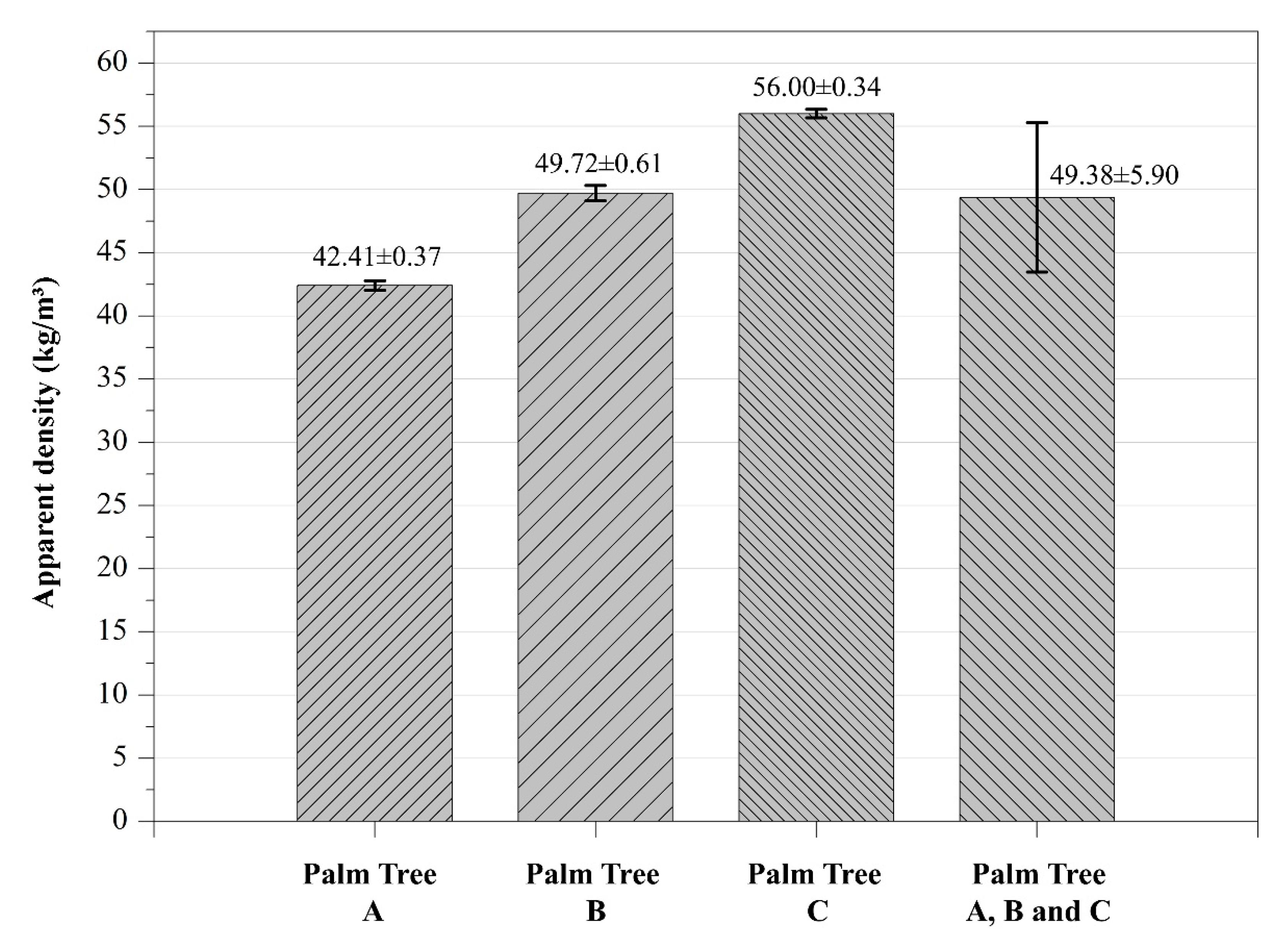

2.2.2. Apparent Density Test

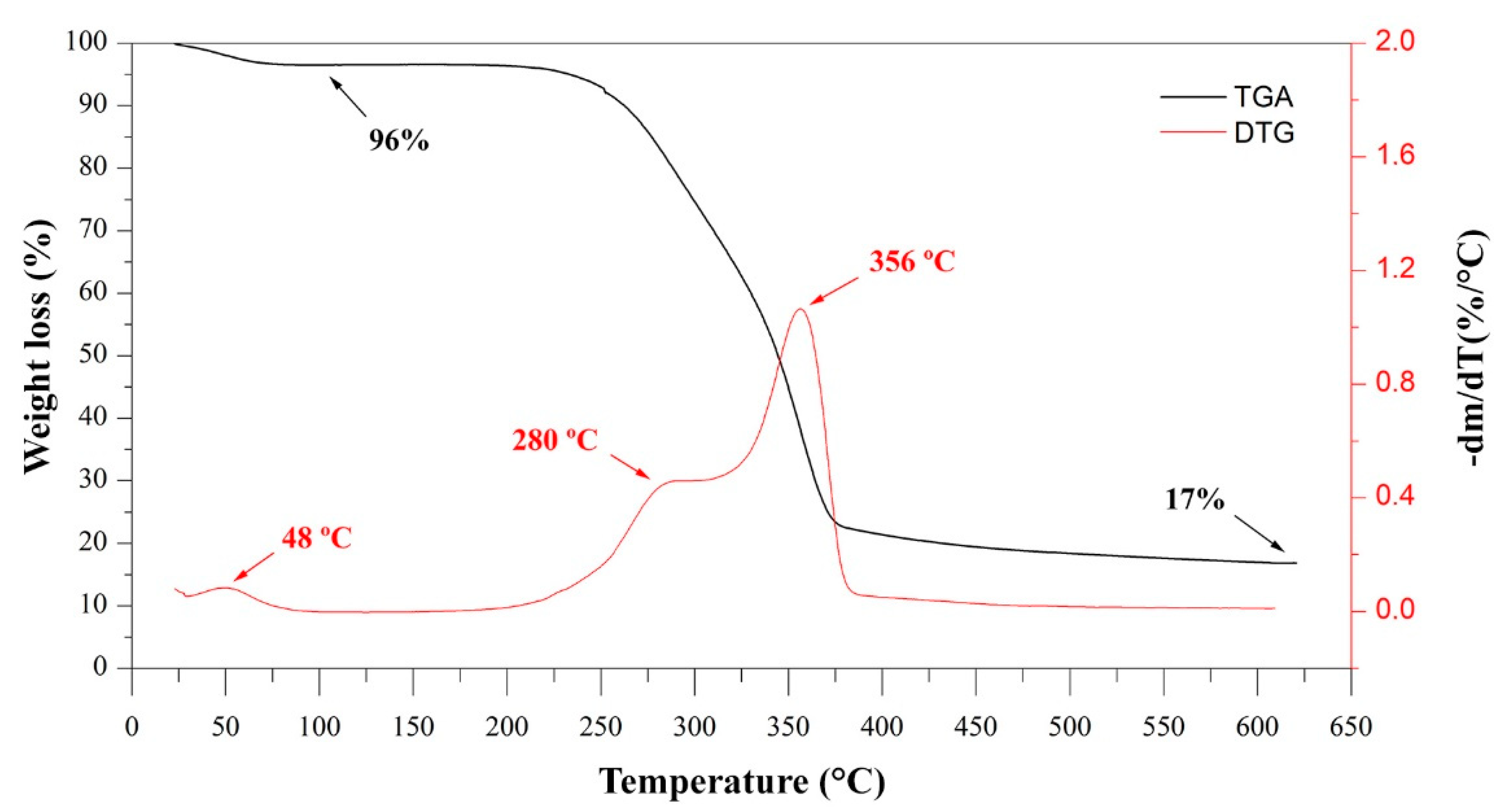

2.2.3. Thermogravimetric Characterization (TGA/DTG)

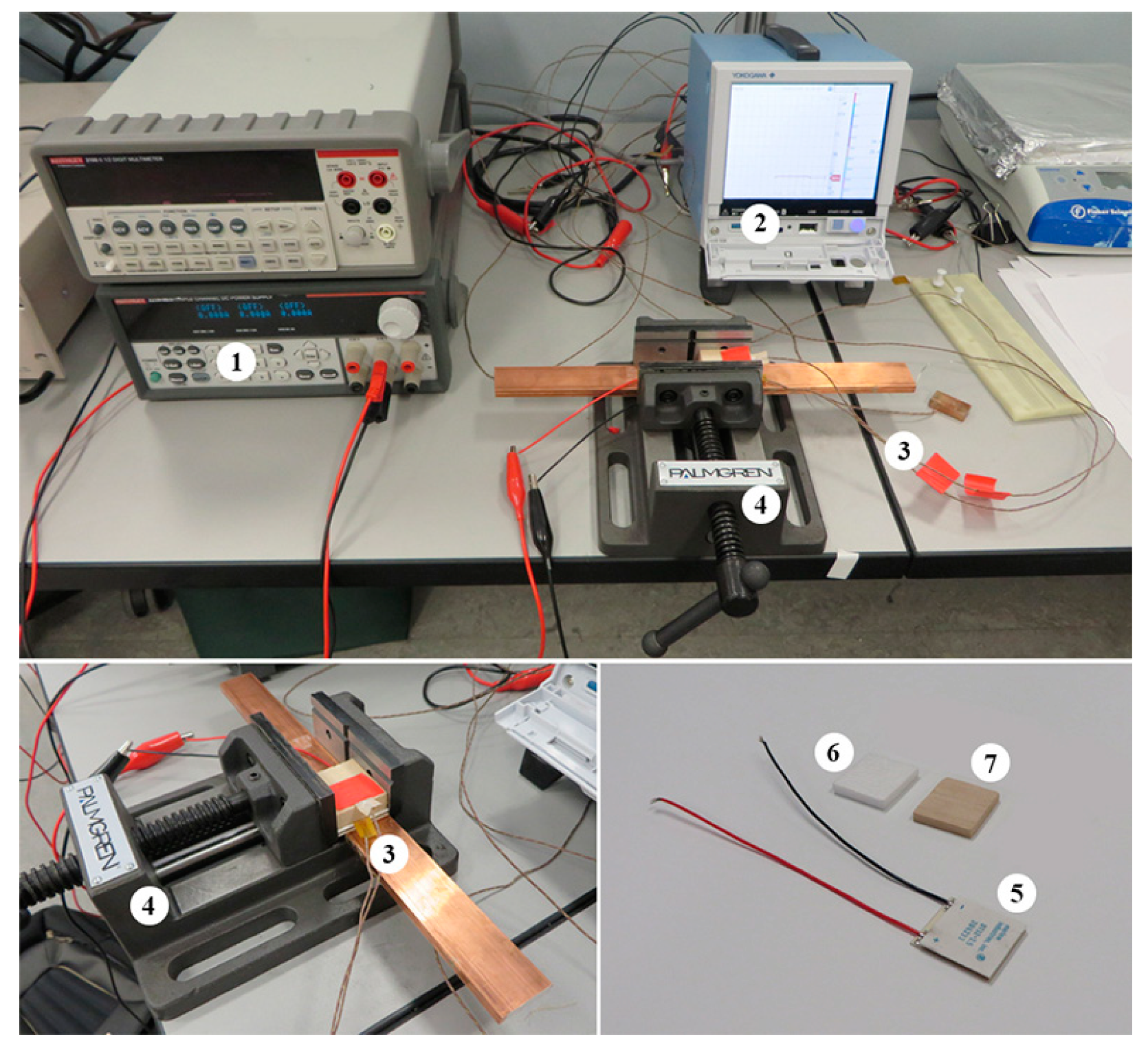

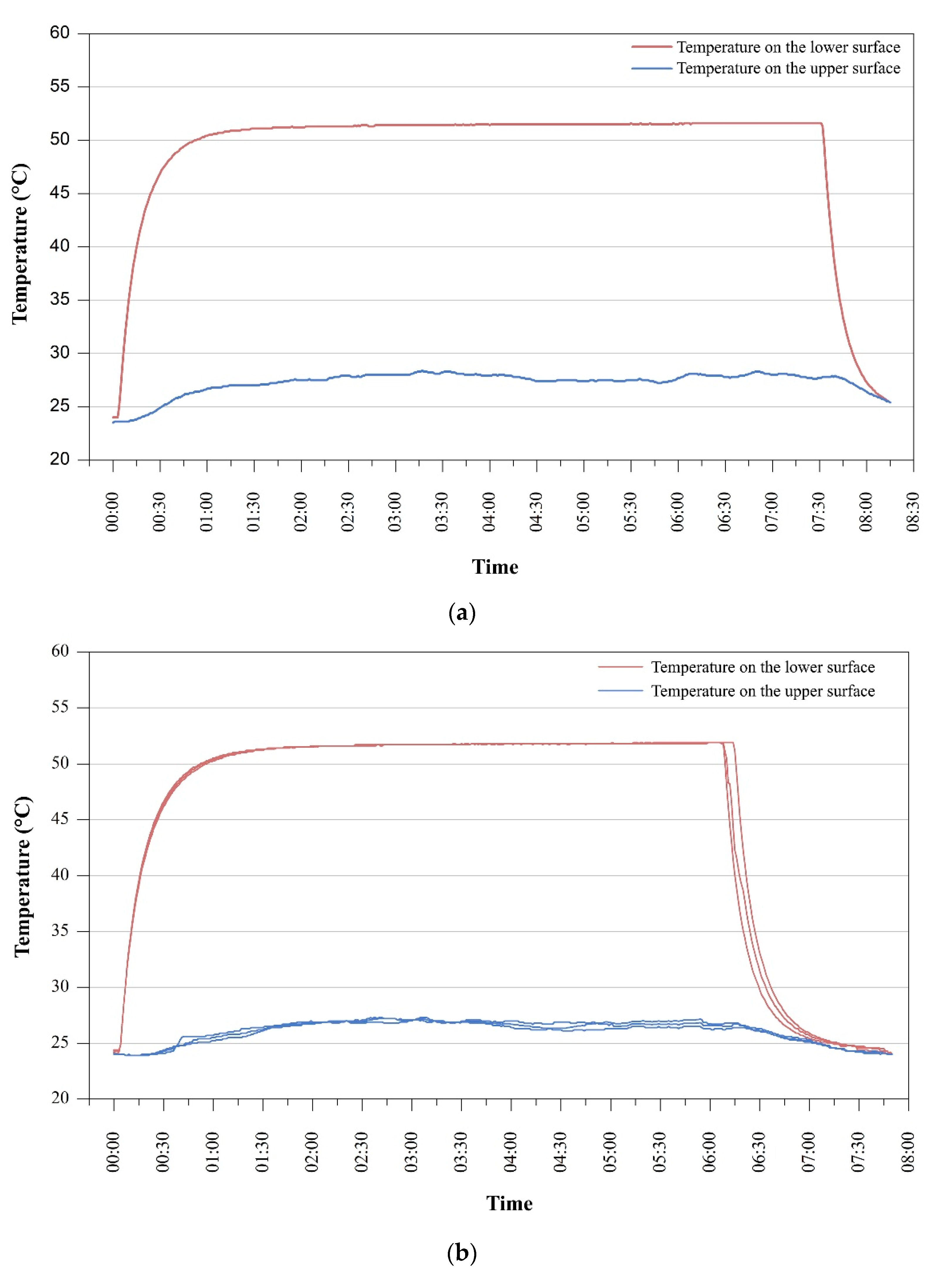

2.2.4. Thermal Conductivity Test

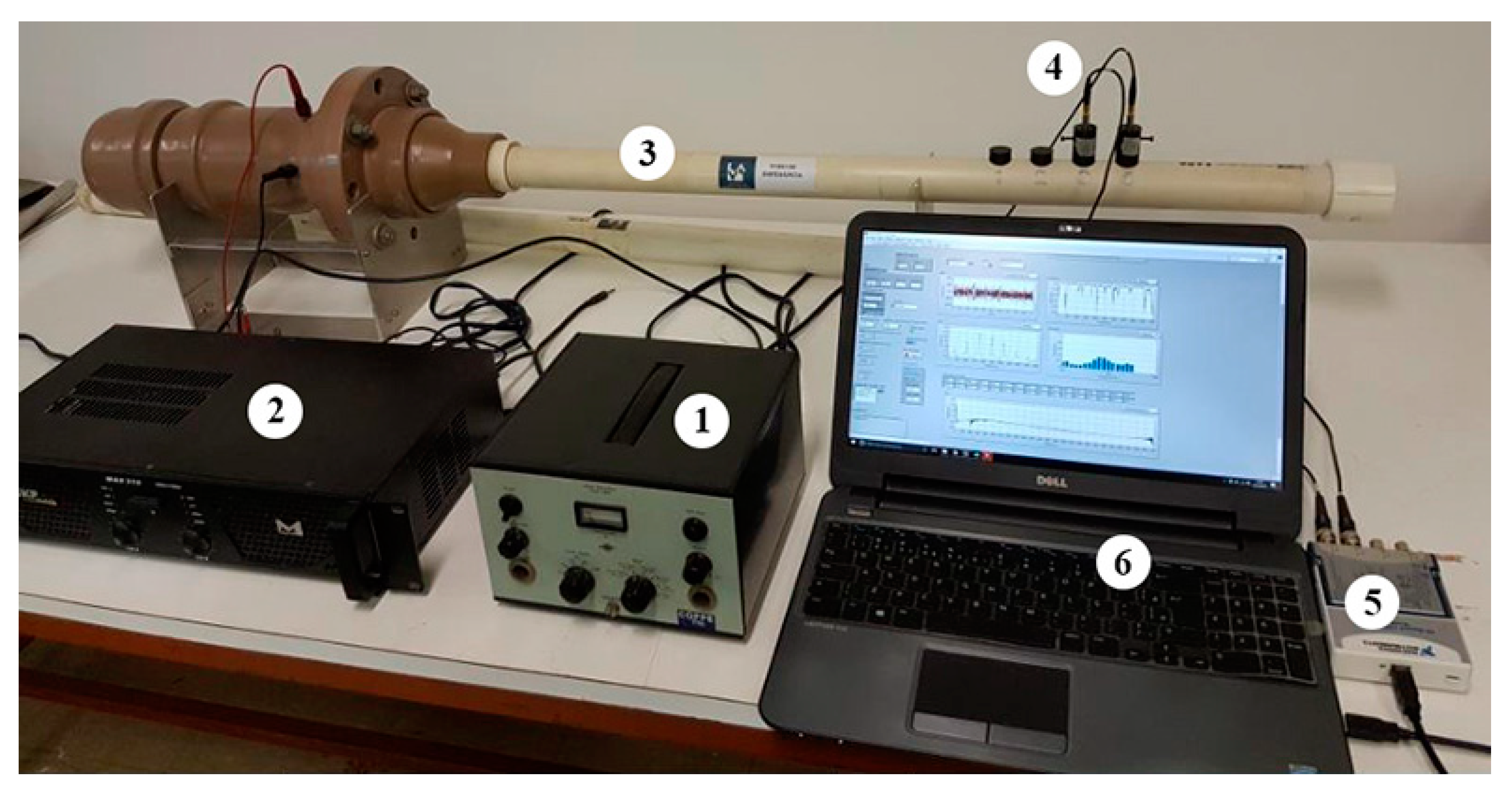

2.2.5. Sound Absorption Test

3. Results and Discussion

3.1. Morphological Characterization

3.2. Apparent Density Test

3.3. Thermogravimetric Characterization (TGA/DTG)

3.4. Thermal Conductivity Test

3.5. Sound Absorption Test

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Onésippe, C.; Passe-Coutrin, N.; Toro, F.; Desvasto, S.; Bilba, K.; Arsène, M. Sugar cane bagasse fibers reinforced cement composites: Thermal considerations. Compos. Part A 2010, 41, 49–556. [Google Scholar] [CrossRef]

- Benmansour, N.; Agoudjil, B.; Gherabli, A.; Kareche, A.; Boudenne, A. Thermal and mechanical performance of natural mortar reinforced with date palm fibers for use as insulating materials in building. Energy Build. 2014, 81, 98–104. [Google Scholar] [CrossRef]

- Berardi, U.; Iannace, G. Predicting the sound absorption of natural materials: Best-fit inverse laws for the acoustic impedance and the propagation constant. Appl. Acoust. 2017, 115, 131–138. [Google Scholar] [CrossRef]

- Lafond, C.; Blanchet, P. Technical Performance Overview of Bio-Based Insulation Materials Compared to Expanded Polystyrene. Buildings 2020, 10, 9–16. [Google Scholar] [CrossRef]

- Boukhattem, L.; Boumhaout, M.; Hamdi, H.; Benhamou, B.; Nouh, F.A. Moisture content influence on the thermal conductivity of insulating building materials made from date palm fibers mesh. Constr. Build. Mater. 2017, 148, 818–823. [Google Scholar] [CrossRef]

- Bakatovich, A.; Davydenko, N.; Gaspar, F. Thermal insulating plates produced on the basis of vegetable agricultural waste. Energy Build. 2018, 180, 72–82. [Google Scholar] [CrossRef] [Green Version]

- Yang, T.; Hu, L.; Xiong, X.; Petru, M.; Noman, M.T.; Mishra, R.; Militký, J. Sound Absorption Properties of Natural Fibers: A Review. Sustainability 2020, 12, 8477. [Google Scholar] [CrossRef]

- Arenas, J.P.; del Rey, R.; Alba, J.; Oltra, R. Sound-Absorption Properties of Materials Made of Esparto Grass Fibers. Sustainability 2020, 12, 5533. [Google Scholar] [CrossRef]

- Belhadj, B.; Bederina, M.; Makhloufi, Z.; Dheilly, R.M.; Montrelay, N.; Quéneudéc, M. Contribution to the development of a sand concrete lightened by the addition of barley straws. Constr. Build. Mater. 2016, 113, 513–522. [Google Scholar] [CrossRef]

- Belakroum, R.; Gherfi, A.; Kadja, M.; Maalouf, C.; Lachi, M.; El Wakil, N.; Mai, T.H. Design and properties of a new sustainable construction material based on date palm fibers and lime. Constr. Build. Mater. 2018, 184, 330–343. [Google Scholar] [CrossRef]

- Arenas, J.P.; Asdrubali, F. Eco-Materials with Noise Reduction Properties. In Handbook of Ecomaterials; Martínez, L., Kharissova, O., Kharisov, B., Eds.; Springer: Cham, Switzerland, 2018; pp. 1–26. [Google Scholar] [CrossRef]

- del Rey, R.; Alba, J.; Rodríguez, J.C.; Bertó, L. Characterization of New Sustainable Acoustic Solutions in a Reduced Sized Transmission Chamber. Buildings 2019, 9, 60. [Google Scholar] [CrossRef] [Green Version]

- Khalaf, Y.; El Hage, P.; Mihajlova, J.D.; Bergeret, A.; Lacroix, P.; El Hage, R. Influence of agricultural fibers size on mechanical and insulating properties of innovative chitosan-based insulators. Constr. Build. Mater. 2021, 287, 123071. [Google Scholar] [CrossRef]

- Mrajji, O.; El Wazna, M.; Boussoualem, Y.; El Bouari, A.; Cherkaoui, O. Feather waste as a thermal insulation solution: Treatment, elaboration and characterization. J. Ind. Text. 2021, 50, 1674–1697. [Google Scholar] [CrossRef]

- Caniato, M.; Cozzarini, L.; Schmid, C.; Gasparella, A. Acoustic and thermal characterization of a novel sustainable material incorporating recycled microplastic waste. Sustain. Mater. Technol. 2021, 28, e00274. [Google Scholar] [CrossRef]

- Buratti, C.; Belloni, E.; Merli, F.; Zanella, V.; Robazza, P.; Cornaro, C. An innovative multilayer wall composed of natural materials: Experimental characterization of thermal properties and comparasion with other solutions. Energy Procedia 2018, 148, 892–899. [Google Scholar] [CrossRef]

- Portela, T.G.R.; Costa, L.L.; Santos, N.S.S.; Lopes, F.P.D.; Monteiro, S.N. Tensile behavior of lignocellulosic fiber reinforced polymer composites: Part II buriti petiole/polyester. Rev. Matéria 2010, 15, 195–201. [Google Scholar] [CrossRef] [Green Version]

- Karthik Babu, N.B.; Muthukumaran, S.; Arokiasamy, S.; Ramesh, T. Thermal and mechanical behavior of the coir powder filled polyester micro-composites. J. Nat. Fibers 2018, 17, 1058–1068. [Google Scholar] [CrossRef]

- Santos, R.S.; Souza, A.A.; De Paoli, M.; Souza, C.M.L. Cardanol–formaldehyde thermoset composites reinforced with buriti fibers: Preparation and characterization. Compos. Part A 2010, 41, 1123–1129. [Google Scholar] [CrossRef]

- Lorenzi, H.; Souza, H.M.; Costa, J.T.M.; Cerqueira, L.S.C.; Ferreira, E. Palmeiras Brasileiras e Exóticas Cultivadas; Plantarum: São Paulo, Brasil, 2004; p. 420. [Google Scholar]

- Cattani, I.M.; Baruque-Ramos, J. Brazilian Buriti Palm Fiber (Mauritia flexuosa Mart.). In Natural Fibres: Advances in Science and Technology towards Industrial Applications; Fangueiro, R., Rana, S., Eds.; Springer: Dordrecht, The Netherlands, 2016; Volume 12, pp. 89–98. [Google Scholar] [CrossRef]

- Sampaio, M.B.; Schmidt, I.B.; Figueiredo, I.B. Harvesting Effects and Population Ecology of the Buriti Palm (Mauritia flexuosa L. f., Arecaceae) in the Jalapão Region, Central Brazil. Econ. Bot. 2008, 62, 171–181. [Google Scholar] [CrossRef]

- ASTM D1622. Standard Test Method for Apparent Density of Rigid Cellular Plastics; American Society for Testing and Materials: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Kreith, F.; Manglik, R.M.; Bohn, M.S. Principles of Heat Transfer, 7th ed.; Cengage Learning: Stamford, NY, USA, 2011. [Google Scholar]

- ASTM E1050. Standard Test Method for Impedance and Absorption of Acoustical Materials Using A Tube, Two Microphones and a Digital Frequency Analysis System; American Society for Testing and Materials: West Conshohocken, PA, USA, 2012. [Google Scholar]

- ISO 10534. Acoustics—Determination of Sound Absorption Coefficient and Impedance in Impedance Tubes—Part 2: Transfer-Function Method; International Organization for Standardization: Geneve, Switzerland, 1998. [Google Scholar]

- Cardoso, M.S.; Gonçalez, J.C. Aproveitamento da casca do coco-verde (Cocos nucifera L.) para produção de polpa celulósica. Ciência Florest. 2016, 26, 330–331. [Google Scholar] [CrossRef] [Green Version]

- Schiavoni, S.; D’Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Li, Y.; Ren, S. Acoustic and Thermal Insulating Materials. In Building Decorative Materials; Li, Y., Ren, S., Eds.; Woodhead Publishing: Shaxton, UK, 2011; pp. 359–374. [Google Scholar] [CrossRef]

- Lavoratti, A.; Daiane, R.; Amico, S.C.; Zattera, A.J. Influence of fibre treatment on the characteristics of buriti and ramie polyester composites. Polym. Polym. Compos. 2017, 25, 818–823. [Google Scholar] [CrossRef] [Green Version]

- Knapic, S.; Oliveira, V.; Machado, J.S.; Pereira, H. Cork as a building material: A review. Eur. J. Wood Wood Prod. 2016, 74, 775–791. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Ornaghi Júnior, H.L.; Moraes, A.G.O.; Poletto, M.; Zattera, A.J.; Amico, S.C. Chemical composition, tensile properties and structural characterization of buriti fiber. Cellul. Chem. Technol. 2016, 50, 15–22. Available online: https://www.cellulosechemtechnol.ro/pdf/CCT1(2016)/p.15-22.pdf (accessed on 3 November 2020).

- Souza, S.A.V.; Silva, M.C.; Silva Júnior, O.G.; Mottin, A.C.; Oréfice, R.L.; Ayres, E. Design and characterization of bio-composites from poly (lactic acid) (pla) and buriti petiole (Mauritia flexuosa). J. Renew. Mater. 2017, 5, 251–257. [Google Scholar] [CrossRef]

- Moura, A.S.; Demori, R.; Leão, R.M.; Frankenberg, C.L.C.; Santana, R.M.C. The influence of the coconut fiber treated as reinforcement in PHB (polyhydroxybutyrate) composites. Mater. Today Commun. 2019, 18, 191–198. [Google Scholar] [CrossRef]

- Sánchez, M.L.; Capote, G.; Carrillo, J. Composites reinforced with guadua fibers: Physical and mechanical properties. Constr. Build. Mater. 2019, 228, 116749. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Rodriguez, R.J.S.; Costa, L.L.; Portela, T.G.R.; Santos, N.S.S. Thermal behavior of buriti biofoam. Rev. Matéria 2010, 15, 104–109. [Google Scholar] [CrossRef] [Green Version]

- Martins, M.A.; Mattoso, L.H.C.; Pessoa, J.D.C. Comportamento térmico e caracterização morfológica das fibras de mesocarpo e caroço do açaí (Euterpe oleracea Mart.). Rev. Bras. Frutic. 2009, 31, 1150–1157. [Google Scholar] [CrossRef] [Green Version]

- Neira, D.S.M.; Marinho, G.S. Nonwoven sisal fiber as thermal insulator material. J. Nat. Fibers 2009, 6, 115–126. [Google Scholar] [CrossRef]

- Kosiński, P.; Brzyski, P.; Szewczyk, A.; Motacki, W. Thermal properties of raw hemp fiber as a loose fill insulation material. J. Nat. Fibers 2018, 15, 717–730. [Google Scholar] [CrossRef]

- Damfeu, J.C.; Meukam, P.; Jannot, Y. Modeling and measuring of the thermal properties of insulating vegetable fibers by the asymmetrical hot plate method and the radial flux method: Kapok, coconut, groundnut shell fiber and rattan. Thermochim. Acta 2016, 630, 64–77. [Google Scholar] [CrossRef]

- Asdrubali, F.; Ferracuti, B.; Lombardi, L.; Guattari, C.; Evangelisti, L.; Grazieschi, G. A review of structural, thermo-physical, acoustical, and environmental properties of wooden materials for building applications. Build. Environ. 2017, 114, 307–332. [Google Scholar] [CrossRef]

- Huang, Z.; Sun, Y.; Musso, F. Hygrothermal performance of natural bamboo fiber and bamboo charcoal as local construction infills in building envelope. Constr. Build. Mater. 2018, 177, 342–357. [Google Scholar] [CrossRef]

- António, J. Acoustic behavior of fibrous materials. In Fibrous and Composite Materials for Civil Engineering Applications; Fangueiro, R., Ed.; Woodhead Publishing: Shaxton, UK, 2011; pp. 306–324. [Google Scholar] [CrossRef]

- Amares, S.; Sujatmika, E.; Hong, T.W.; Durairaj, R.; Hamid, H.S.H.B. A review: Characteristics of noise absorption material. J. Phys. Conf. Ser. 2017, 908, 012005. [Google Scholar] [CrossRef] [Green Version]

- ASTM C423. Standard Test Method for Sound Absorption and Sound Absorption Coefficients by the Reverberation Room Method; American Society for Testing and Materials: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Lim, Z.Y.; Putra, A.; Nor, M.J.M.; Yaakob, M.Y. Sound absorption performance of natural kenaf fibres. Appl. Acoust. 2018, 130, 107–114. [Google Scholar] [CrossRef]

- Yeon, J.; Kim, K. Analysis of Absorption Coefficient for Eco-Friendly Acoustical Absorbers. Adv. Mater. Res. 2013, 831, 58–61. [Google Scholar] [CrossRef]

- Yeon, J.O.; Kim, K.; Yang, K.; Kim, J.; Kim, M. Physical properties of cellulose sound absorbers produced using recycled paper. Constr. Build. Mater. 2014, 70, 494–500. [Google Scholar] [CrossRef]

- Chen, S.; Jiang, Y. The acoustic property study of polyurethane foam with addition of bamboo leaves particles. Polym. Compos. 2016, 39, 1370–1381. [Google Scholar] [CrossRef]

- Or, K.H.; Putra, A.; Selamat, M.Z. Oil palm empty fruit bunch fibers as sustainable acoustic absorber. Appl. Acoust. 2017, 119, 9–16. [Google Scholar] [CrossRef]

| Properties | EPS Isopor® |

|---|---|

| Apparent density (kg/m3) | 14 |

| Thermal Conductivity (W/mK) | 0.042 |

| Flammability | Flame resistant |

| Sample Configuration | Cutting Direction | Thickness (mm) |

|---|---|---|

| BFL-15 | Longitudinal | 15 |

| BFL-25 | Longitudinal | 25 |

| BFT-15 | Transverse | 15 |

| BFT-25 | Transverse | 25 |

| Sample | Weight | Apparent Density | |

|---|---|---|---|

| Palm Tree A | 1 | 1.1556 g (1.1556 × 10−3 kg) | 0.04280 g/cm3 (42.80 kg/m3) |

| 2 | 1.1440 g (1.1440 × 10−3 kg) | 0.04237 g/cm3 (42.37 kg/m3) | |

| 3 | 1.1358 g (1.1358 × 10−3 kg) | 0.04207 g/cm3 (42.07 kg/m3) | |

| Palm Tree B | 1 | 1.3599 g (1.3599 × 10−3 kg) | 0.05037 g/cm3 (50.37 kg/m3) |

| 2 | 1.3401g (1.3401 × 10−3 kg) | 0.04963 g/cm3 (49.63 Kg/m3) | |

| 3 | 1.3272 g (1.3272 × 10−3 kg) | 0.04916 g/cm3 (49.16 kg/m3) | |

| Palm Tree C | 1 | 1.5019 g (1.5019 × 10−3 kg) | 0.05563 g/cm3 (55.63 kg/m3) |

| 2 | 1.5197 g (1.5197 × 10−3 kg) | 0.05629 g/cm3 (56.29 kg/m3) | |

| 3 | 1.5742 g (1.5742 × 10−3 kg) | 0.05608 g/cm3 (56.08 kg/m3) |

| Thermal Conductivity (λ) | Temperature Difference between Sample Surfaces (∆T) | Thickness (L) |

|---|---|---|

| 0.042 W/mK | 23.68 °C | 5 mm |

| Samples | Temperature Difference between Sample Surfaces (∆T) | Heat Flow (qk) | Thickness (L) |

|---|---|---|---|

| Sample 1 | 25.17 °C | 198.91 W/m2 | 5 mm |

| Sample 2 | 24.86 °C | ||

| Sample 3 | 24.90 °C |

| Material | Thermal Conductivity (W/mK) | Apparent Density (kg/m3) | References |

|---|---|---|---|

| Buriti Foam | 0.0398 ± 0.0003 | 49.38 ± 5.9 | Present Work |

| Hemp fiber | 0.039–0.076 | 18–85 | [5,40] |

| Date palm fiber | 0.033–0.085 | 121–389 | [5,10,28] |

| Sisal fiber | 0.042–0.044 | – | [39] |

| Coir fiber | 0.040–0.055 | 75–125 | [28,41] |

| Flax fiber | 0.038–0.075 | 20–100 | [5,28] |

| Oil palm fiber | 0.055–0.091 | 20–120 | [28,32] |

| Pineapple leaf fiber | 0.035–0.043 | 178–232 | [28,32] |

| Cane bagasse | 0.046–0.055 | 70–350 | [32,42] |

| Bamboo fiber | 0.042–0.046 | 70–170 | [43] |

| Jute | 0.046–0.055 | 26–350 | [5,28,32] |

| Cork | 0.037–0.050 | 110–170 | [28] |

| Sample Configuration | Frequency (Hz) | NRC | |||

|---|---|---|---|---|---|

| 250 | 500 | 1000 | 2000 | ||

| BFL-15 | 0.24 | 0.20 | 0.22 | 0.19 | 0.20 |

| BFL-25 | 0.17 | 0.18 | 0.26 | 0.21 | 0.20 |

| BFT-15 | 0.21 | 0.19 | 0.23 | 0.20 | 0.20 |

| BFT-25 | 0.22 | 0.24 | 0.33 | 0.29 | 0.25 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Siqueira, F.F.d.S.; Cosse, R.L.; Pinto, F.A.d.N.C.; Mareze, P.H.; Silva, C.F.e.; Nunes, L.C.C. Characterization of Buriti (Mauritia flexuosa) Foam for Thermal Insulation and Sound Absorption Applications in Buildings. Buildings 2021, 11, 292. https://doi.org/10.3390/buildings11070292

Siqueira FFdS, Cosse RL, Pinto FAdNC, Mareze PH, Silva CFe, Nunes LCC. Characterization of Buriti (Mauritia flexuosa) Foam for Thermal Insulation and Sound Absorption Applications in Buildings. Buildings. 2021; 11(7):292. https://doi.org/10.3390/buildings11070292

Chicago/Turabian StyleSiqueira, Felippe Fabrício dos Santos, Renato Lemos Cosse, Fernando Augusto de Noronha Castro Pinto, Paulo Henrique Mareze, Caio Frederico e Silva, and Lívio César Cunha Nunes. 2021. "Characterization of Buriti (Mauritia flexuosa) Foam for Thermal Insulation and Sound Absorption Applications in Buildings" Buildings 11, no. 7: 292. https://doi.org/10.3390/buildings11070292

APA StyleSiqueira, F. F. d. S., Cosse, R. L., Pinto, F. A. d. N. C., Mareze, P. H., Silva, C. F. e., & Nunes, L. C. C. (2021). Characterization of Buriti (Mauritia flexuosa) Foam for Thermal Insulation and Sound Absorption Applications in Buildings. Buildings, 11(7), 292. https://doi.org/10.3390/buildings11070292