Investigation on Mechanical and Durability Properties of Concrete Mixed with Silica Fume as Cementitious Material and Coal Bottom Ash as Fine Aggregate Replacement Material

Abstract

:1. Introduction

2. Experimental Program

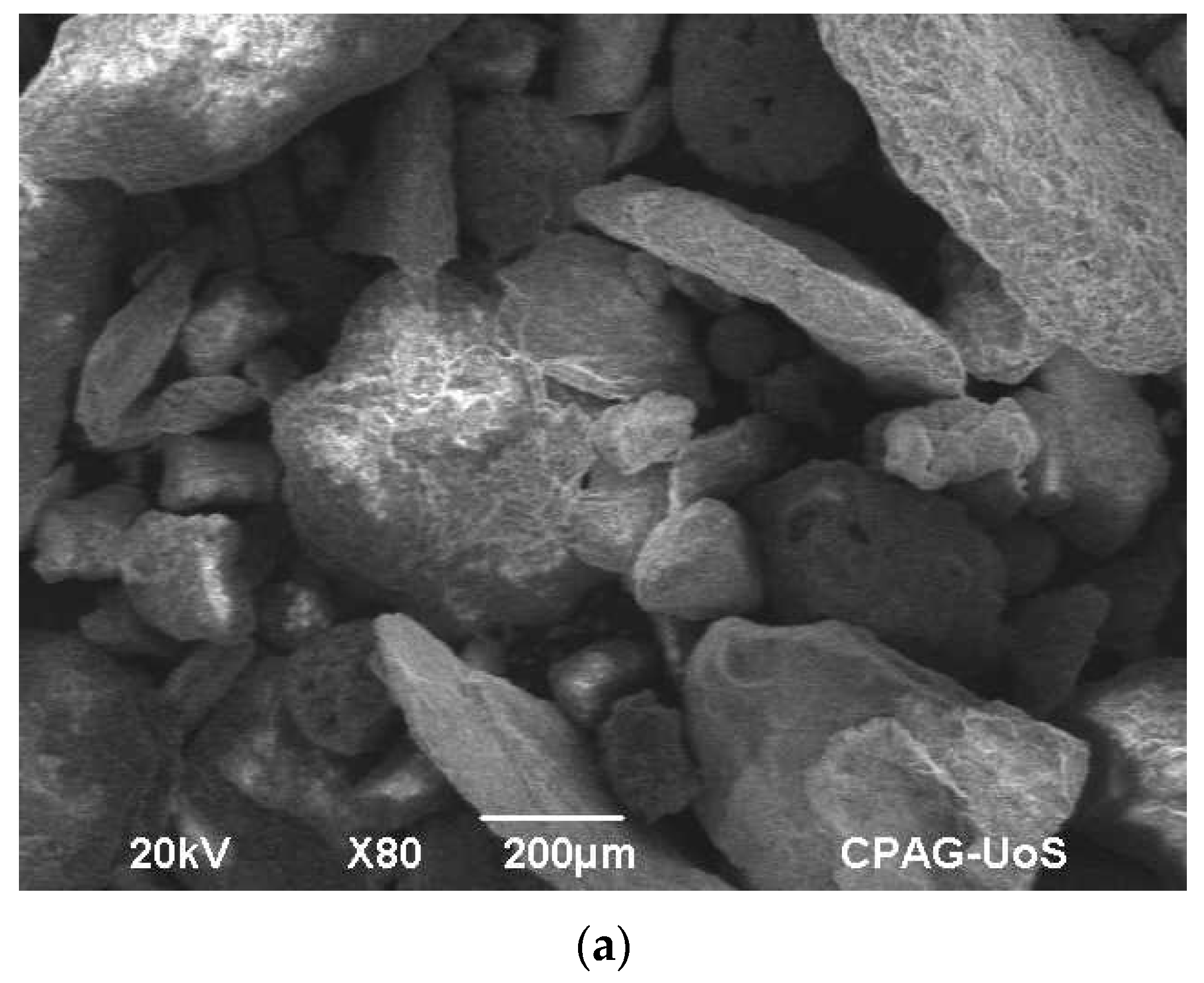

2.1. Materials and Mix Proportions

2.2. Specimen Preparations and Test Method

3. Results and Discussions

3.1. Workability

3.2. Compressive Strength

3.3. Split Tensile Strength

3.4. Corrosion Analysis

3.5. Sulfate Attack

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rafieizonooz, M.; Mirza, J.; Salim, M.R.; Hussin, M.W.; Khankhaje, E. Investigation of coal bottom ash and fly ash in concrete as replacement for sand and cement. Constr. Build. Mater. 2016, 116, 15–24. [Google Scholar] [CrossRef]

- Humphreys, K.; Mahasenan, M. Towards a Sustainable Cement Industry. Substudy 8: Climate Change; World Buisness Council for Sustainable Development: Geneva, Switzerland, 2002. [Google Scholar]

- Buller, A.S.; Abro, F.u.R.; Lee, K.M.; Jang, S.Y. Mechanical recovery of cracked fiber-reinforced mortar incorporating crystalline admixture, expansive agent, and geomaterial. Adv. Mater. Sci. Eng. 2019, 2019. [Google Scholar] [CrossRef] [Green Version]

- Abro, F.u.R.; Buller, A.S.; Ali, T.; Ul-Abdin, Z.; Ahmed, Z.; Memon, N.A.; Lashari, A.R. Autogenous Healing of Cracked Mortar Using Modified Steady-State Migration Test against Chloride Penetration. Sustainability 2021, 13, 9519. [Google Scholar] [CrossRef]

- Mardani-Aghabaglou, A.; Tuyan, M.; Ramyar, K. Mechanical and durability performance of concrete incorporating fine recycled concrete and glass aggregates. Mater. Struct. 2015, 48, 2629–2640. [Google Scholar] [CrossRef]

- Singh, M.; Siddique, R. Strength properties and micro-structural properties of concrete containing coal bottom ash as partial replacement of fine aggregate. Constr. Build. Mater. 2014, 50, 246–256. [Google Scholar] [CrossRef]

- Argiz, C.; Moragues, A.; Menéndez, E. Use of ground coal bottom ash as cement constituent in concretes exposed to chloride environments. J. Clean. Prod. 2018, 170, 25–33. [Google Scholar] [CrossRef]

- Singh, M.; Siddique, R. Effect of coal bottom ash as partial replacement of sand on workability and strength properties of concrete. J. Clean. Prod. 2016, 112, 620–630. [Google Scholar] [CrossRef]

- Singh, N.; Mithulraj, M.; Arya, S. Influence of coal bottom ash as fine aggregates replacement on various properties of concretes: A review. Resour. Conserv. Recycl. 2018, 138, 257–271. [Google Scholar] [CrossRef]

- Siddique, R.; Cachim, P. Waste and Supplementary Cementitious Materials in Concrete: Characterisation, Properties and Applications; Woodhead Publishing: Cambridge, UK, 2018; ISBN 0081021577. [Google Scholar]

- Kim, H.-K.; Lee, H.-K. Use of power plant bottom ash as fine and coarse aggregates in high-strength concrete. Constr. Build. Mater. 2011, 25, 1115–1122. [Google Scholar] [CrossRef]

- Ghafoori, N.; Bucholc, J. Investigation of lignite-based bottom ash for structural concrete. J. Mater. Civ. Eng. 1996, 8, 128–137. [Google Scholar] [CrossRef]

- Ghafoori, N.; Buchole, J. Properties of High-Calcium Dry Bottom Ash for Structural Concrete. Mater. J. 1997, 94, 90–101. [Google Scholar]

- Bai, Y.; Darcy, F.; Basheer, P.A.M. Strength and drying shrinkage properties of concrete containing furnace bottom ash as fine aggregate. Constr. Build. Mater. 2005, 19, 691–697. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S. Properties of concrete prepared with crushed fine stone, furnace bottom ash and fine recycled aggregate as fine aggregates. Constr. Build. Mater. 2009, 23, 2877–2886. [Google Scholar] [CrossRef]

- Liao, W.; Sun, X.; Kumar, A.; Sun, H.; Ma, H. Hydration of binary portland cement blends containing silica fume: A decoupling method to estimate degrees of hydration and pozzolanic reaction. Front. Mater. 2019, 6, 78. [Google Scholar] [CrossRef]

- Duval, R.; Kadri, E.H. Influence of silica fume on the workability and the compressive strength of high-performance concretes. Cem. Concr. Res. 1998, 28, 533–547. [Google Scholar] [CrossRef]

- Sanjuán, M.Á.; Argiz, C.; Gálvez, J.C.; Moragues, A. Effect of silica fume fineness on the improvement of Portland cement strength performance. Constr. Build. Mater. 2015, 96, 55–64. [Google Scholar] [CrossRef]

- De Belie, N.; Soutsos, M.; Gruyaert, E. Properties of Fresh and Hardened Concrete Containing Supplementary Cementitious Materials: State-of-the-Art Report of the RILEM Technical Committee 238-SCM, Working Group 4; Springer: Berlin/Heidelberg, Germany, 2017; Volume 25, ISBN 3319706063. [Google Scholar]

- Yang, J.; Wang, Q.; Zhou, Y. Influence of curing time on the drying shrinkage of concretes with different binders and water-to-binder ratios. Adv. Mater. Sci. Eng. 2017, 2017, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Sharaky, I.A.; Megahed, F.A.; Seleem, M.H.; Badawy, A.M. The influence of silica fume, nano silica and mixing method on the strength and durability of concrete. SN Appl. Sci. 2019, 1, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Toutanji, H.; Delatte, N.; Aggoun, S.; Duval, R.; Danson, A. Effect of supplementary cementitious materials on the compressive strength and durability of short-term cured concrete. Cem. Concr. Res. 2004, 34, 311–319. [Google Scholar] [CrossRef] [Green Version]

- Wille, K.; El-Tawil, S.; Naaman, A.E. Properties of strain hardening ultra high performance fiber reinforced concrete (UHP-FRC) under direct tensile loading. Cem. Concr. Compos. 2014, 48, 53–66. [Google Scholar] [CrossRef]

- Arora, A.; Aguayo, M.; Hansen, H.; Castro, C.; Federspiel, E.; Mobasher, B.; Neithalath, N. Microstructural packing-and rheology-based binder selection and characterization for Ultra-high Performance Concrete (UHPC). Cem. Concr. Res. 2018, 103, 179–190. [Google Scholar] [CrossRef]

- Bheel, N.; Kumar, A.; Shahzaib, J.; Ali, Z.; Ali, M. An investigation on fresh and hardened properties of concrete blended with rice husk ash as cementitious ingredient and coal bottom ash as sand replacement material. Silicon 2021, 1–12. [Google Scholar] [CrossRef]

- ASTM C618. Standard specification for coal fly ash and raw or calcined natural pozzolan for use in concrete. In American Society for Testing and Materials; ASTM International: West Conshohocken, PA, USA, 2003. [Google Scholar]

- ASTM International. Standard Test Method for Corrosion Potentials of Uncoated Reinforcing Steel in Concrete; ASTM International: West Conshohocken, PA, USA, 2003. [Google Scholar]

- ASTM C1012/C1012M-12; Standard test method for length change of hydraulic-cement mortars exposed to a sulfate solution. ASTM International: West Conshohocken, PA, USA, 2012.

- Kurama, H.; Kaya, M. Usage of coal combustion bottom ash in concrete mixture. Constr. Build. Mater. 2008, 22, 1922–1928. [Google Scholar] [CrossRef]

- Mangi, S.A.; Wan Ibrahim, M.H.; Jamaluddin, N.; Arshad, M.F.; Ramadhansyah, P.J. Effects of ground coal bottom ash on the properties of concrete. J. Eng. Sci. Technol. 2019, 14, 338–350. [Google Scholar]

- Singh, M.; Siddique, R. Effect of coal bottom ash as partial replacement of sand on properties of concrete. Resour. Conserv. Recycl. 2013, 72, 20–32. [Google Scholar] [CrossRef]

- Zainal Abidin, N.E.; Wan Ibrahim, M.H.; Jamaluddin, N.; Kamaruddin, K.; Hamzah, A.F. The effect of bottom ash on fresh characteristic, compressive strength and water absorption of self-compacting concrete. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2014; Volume 660, pp. 145–151. [Google Scholar]

- Keerio, M.A.; Abbasi, S.A.; Kumar, A.; Bheel, N.; ur Rehaman, K.; Tashfeen, M. Effect of silica fume as cementitious material and waste glass as fine aggregate replacement constituent on selected properties of concrete. Silicon 2020, 1–12. [Google Scholar] [CrossRef]

- Almusallam, A.A.; Beshr, H.; Maslehuddin, M.; Al-Amoudi, O.S.B. Effect of silica fume on the mechanical properties of low quality coarse aggregate concrete. Cem. Concr. Compos. 2004, 26, 891–900. [Google Scholar] [CrossRef]

- Behnood, A.; Ziari, H. Effects of silica fume addition and water to cement ratio on the properties of high-strength concrete after exposure to high temperatures. Cem. Concr. Compos. 2008, 30, 106–112. [Google Scholar] [CrossRef]

- Hasim, A.M.; Shahid, K.A.; Ariffin, N.F.; Nasrudin, N.N.; Zaimi, M.N.S. Properties of high volume coal bottom ash in concrete production. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Roy, D.K.S.; Sil, A. Effect of partial replacement of cement by silica fume on hardened concrete. Int. J. Emerg. Technol. Adv. Eng. 2012, 2, 472–475. [Google Scholar]

- Hanumesh, B.M.; Varun, B.K.; Harish, B.A. The mechanical properties of concrete incorporating silica fume as partial replacement of cement. Int. J. Emerg. Technol. Adv. Eng. 2015, 5, 270. [Google Scholar]

- Yazıcı, H. The effect of silica fume and high-volume Class C fly ash on mechanical properties, chloride penetration and freeze–thaw resistance of self-compacting concrete. Constr. Build. Mater. 2008, 22, 456–462. [Google Scholar] [CrossRef]

- Detwiler, R.J.; Fapohunda, C.A.; Natale, J. Use of supplementary cementing materials to increase the resistance to chloride ion penetration of concretes cured at elevated temperatures. Mater. J. 1994, 91, 63–66. [Google Scholar]

- Al-Saadoun, S.S.; Al-Gahtani, A.S. Reinforcement corrosion-resisting characteristics of silica-fume blended-cement concrete. Mater. J. 1992, 89, 337–344. [Google Scholar]

- Berke, N.S. Resistance of microsilica concrete to steel corrosion erosion and chemical attack. Spec. Publ. 1989, 114, 861–886. [Google Scholar]

- Khedr, S.A.; Idriss, A.F. Resistance of silica-fume concrete to corrosion-related damage. J. Mater. Civ. Eng. 1995, 7, 102–107. [Google Scholar] [CrossRef]

- Singh, M.; Siddique, R. Compressive strength, drying shrinkage and chemical resistance of concrete incorporating coal bottom ash as partial or total replacement of sand. Constr. Build. Mater. 2014, 68, 39–48. [Google Scholar] [CrossRef]

- Ghafoori, N.; Cai, Y. Laboratory-made roller compacted concretes containing dry bottom ash: Part ii—long-term durability. Mater. J. 1998, 95, 244–251. [Google Scholar]

- Ghafoori, N.; Cai, Y. Laboratory-Made RCC containing Dry Bottom Ash: Part I—Mechanical Properties. Mater. J. 1998, 95, 121–130. [Google Scholar]

- Mangat, P.S.; Khatib, J.M. Influence of fly ash, silica fume, and slag on sulfate resistance of concrete. Mater. J. 1993, 92, 542–552. [Google Scholar]

- Cohen, M.D.; Bentur, A. Durability of portland cement-silica fume pastes in magnesium and sodium sulfate solutions. Mater. J. 1988, 85, 148–157. [Google Scholar]

- Mangi, S.A.; Ibrahim, M.H.W.; Jamaluddin, N.; Arshad, M.F.; Jaya, R.P. Short-term effects of sulphate and chloride on the concrete containing coal bottom ash as supplementary cementitious material. Eng. Sci. Technol. Int. J. 2019, 22, 515–522. [Google Scholar] [CrossRef]

| Material | Physical Properties | Chemical Analysis (% Age) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Blaine (cm2/g) | Specific Gravity | SiO2 | CaO | Al2O3 | MgO | K2O | Fe2O3 | LOI | |

| Cement | 3008 | 3.14 | 20.78 | 60.89 | 5.11 | 3.00 | 0.00 | 3.17 | 1.71 |

| CBA | - | 2.30 | 35.37 | 3.307 | 28.18 | 1.956 | 0.976 | 20.64 | - |

| Silica Fume | - | 2.22 | 93.28 | 0.23 | 0.49 | 0.9 | 0.98 | 1.3 | - |

| S.No | Mix Type | OPC (kg) | Sand (kg) | CBA (kg) | SF (kg) | C.A (kg) | Water (kg) | W/C (kg) |

|---|---|---|---|---|---|---|---|---|

| 01 | Plain | 20 | 40 | 0 | 0 | 80 | 10 | 0.5 |

| 02 | 10CBA | 20 | 38 | 2 | 0 | 80 | 10 | 0.5 |

| 03 | 20CBA | 20 | 36 | 4 | 0 | 80 | 10 | 0.5 |

| 04 | 30CBA | 20 | 34 | 6 | 0 | 80 | 10 | 0.5 |

| 05 | 7.5SF | 18.5 | 32 | 0 | 1.5 | 80 | 10 | 0.5 |

| 06 | 10SF | 18 | 30 | 0 | 2 | 80 | 10 | 0.5 |

| 07 | 12.5SF | 17.5 | 28 | 0 | 2.5 | 80 | 10 | 0.5 |

| 08 | 7.5SF10CBA | 18.5 | 38 | 2 | 1.5 | 80 | 10 | 0.5 |

| 09 | 7.5SF20CBA | 18.5 | 36 | 4 | 1.5 | 80 | 10 | 0.5 |

| 10 | 7.5SF30CBA | 18.5 | 34 | 6 | 1.5 | 80 | 10 | 0.5 |

| 11 | 10SF10CBA | 18 | 38 | 2 | 2 | 80 | 10 | 0.5 |

| 12 | 10SF20CBA | 18 | 36 | 4 | 2 | 80 | 10 | 0.5 |

| 13 | 10SF20CBA | 18 | 34 | 6 | 2 | 80 | 10 | 0.5 |

| 14 | 12.5SF10CBA | 17.5 | 38 | 2 | 2.5 | 80 | 10 | 0.5 |

| 15 | 12.5SF20CBA | 17.5 | 36 | 4 | 2.5 | 80 | 10 | 0.5 |

| 16 | 12.5SF20CBA | 17.5 | 34 | 6 | 2.5 | 80 | 10 | 0.5 |

| Sr. | CBA and SF % Replacement | Corrosion Potential (mV) |

|---|---|---|

| M 1 | 12.5 SF 0 CBA | −287 |

| M 2 | 12.5 SF 10 CBA | −261 |

| M 3 | 12.5 SF 20 CBA | −234 |

| M 4 | 12.5 SF 30 CBA | −211 |

| Sr.No | CBA % Replacement | Initial Length (mm) | Final Length (mm) | % Increment |

|---|---|---|---|---|

| M 1 | 12.5 SF 0 CBA | 285.2 ± 0.03 | 286.7 ± 0.04 | 0.52 |

| M 2 | 12.5 SF 10 CBA | 285.4 ± 0.04 | 286.5 ± 0.05 | 0.39 |

| M 3 | 12.5 SF 20 CBA | 285.7 ± 0.02 | 286.7 ± 0.04 | 0.35 |

| M 4 | 12.5 SF 30 CBA | 285.0 ± 0.05 | 285.9 ± 0.05 | 0.32 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, T.; Buller, A.S.; Abro, F.u.R.; Ahmed, Z.; Shabbir, S.; Lashari, A.R.; Hussain, G. Investigation on Mechanical and Durability Properties of Concrete Mixed with Silica Fume as Cementitious Material and Coal Bottom Ash as Fine Aggregate Replacement Material. Buildings 2022, 12, 44. https://doi.org/10.3390/buildings12010044

Ali T, Buller AS, Abro FuR, Ahmed Z, Shabbir S, Lashari AR, Hussain G. Investigation on Mechanical and Durability Properties of Concrete Mixed with Silica Fume as Cementitious Material and Coal Bottom Ash as Fine Aggregate Replacement Material. Buildings. 2022; 12(1):44. https://doi.org/10.3390/buildings12010044

Chicago/Turabian StyleAli, Tariq, Abdul Salam Buller, Fahad ul Rehman Abro, Zaheer Ahmed, Samreen Shabbir, Ali Raza Lashari, and Ghulam Hussain. 2022. "Investigation on Mechanical and Durability Properties of Concrete Mixed with Silica Fume as Cementitious Material and Coal Bottom Ash as Fine Aggregate Replacement Material" Buildings 12, no. 1: 44. https://doi.org/10.3390/buildings12010044

APA StyleAli, T., Buller, A. S., Abro, F. u. R., Ahmed, Z., Shabbir, S., Lashari, A. R., & Hussain, G. (2022). Investigation on Mechanical and Durability Properties of Concrete Mixed with Silica Fume as Cementitious Material and Coal Bottom Ash as Fine Aggregate Replacement Material. Buildings, 12(1), 44. https://doi.org/10.3390/buildings12010044