Experimental and Seismic Response Study of Laminated Rubber Bearings Considering Different Friction Interfaces

Abstract

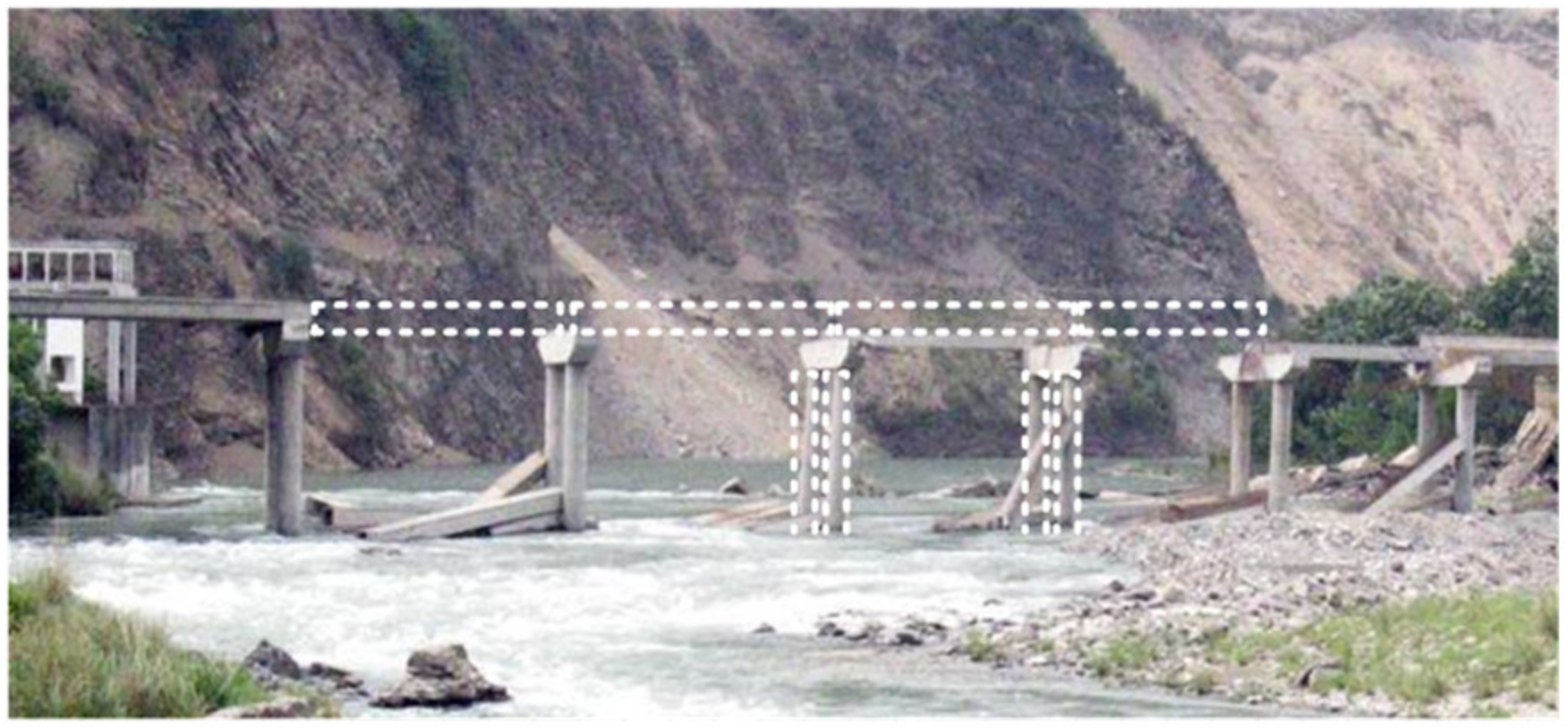

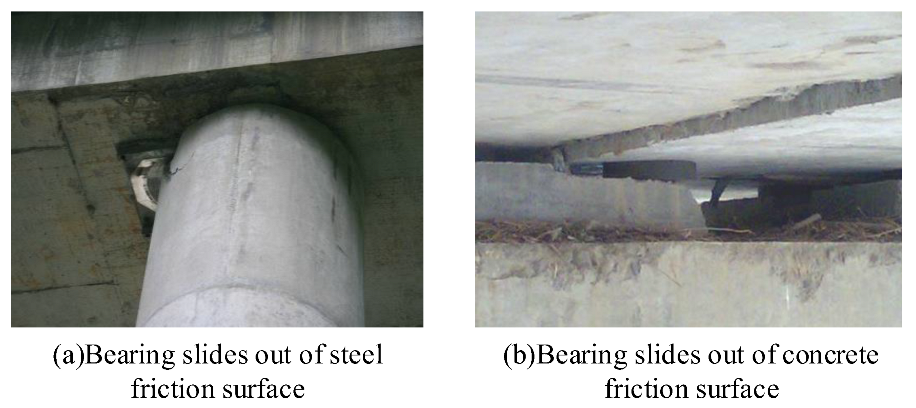

:1. Introduction

2. Experimental Tests

2.1. Test Specimens

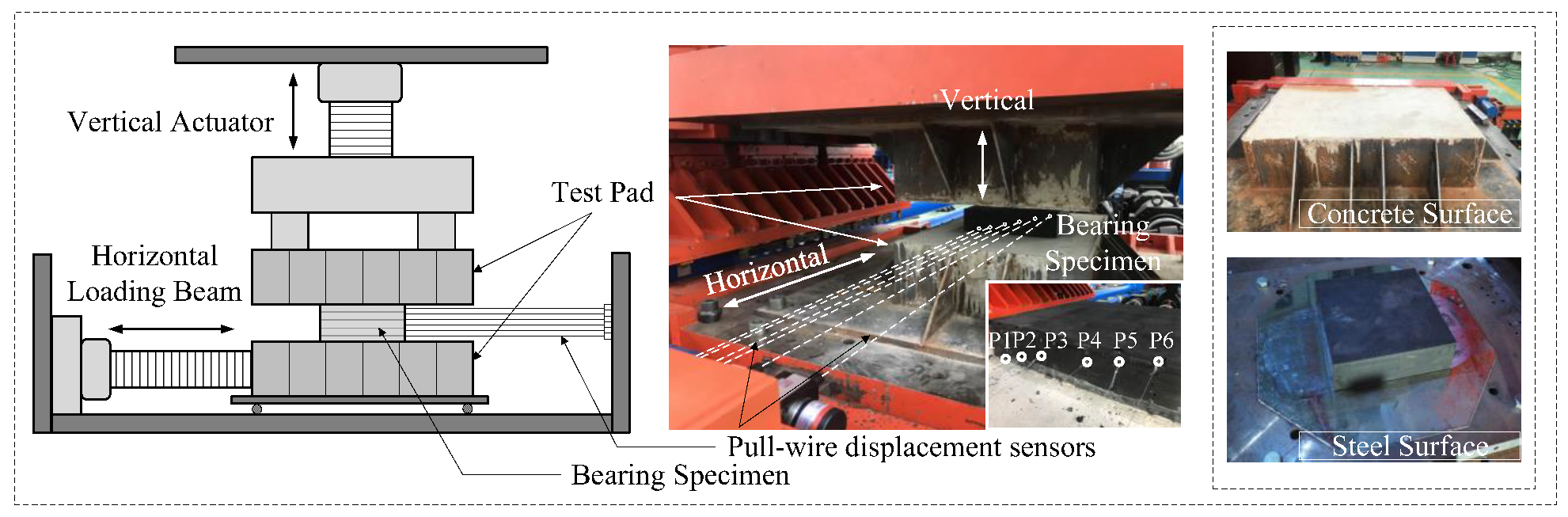

2.2. Experimental Installation

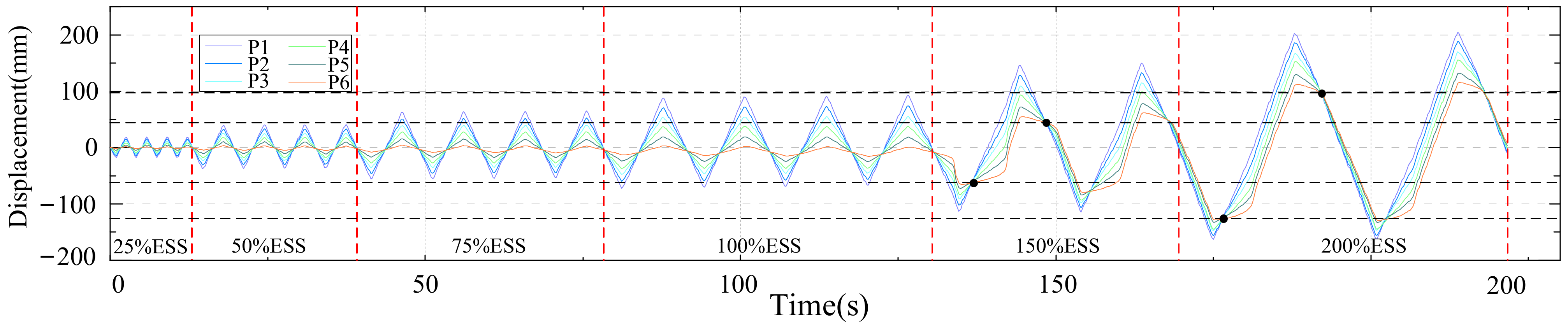

2.3. Test Program

3. Results

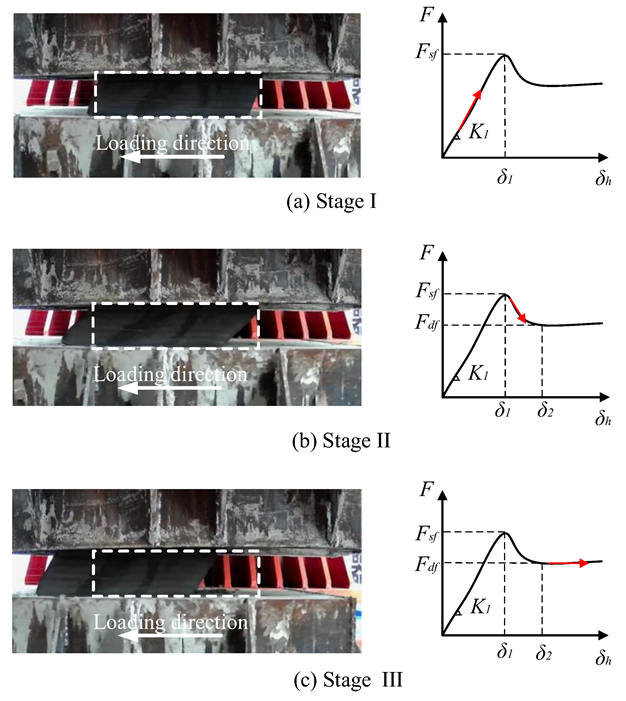

3.1. Overview of the Experimental Response

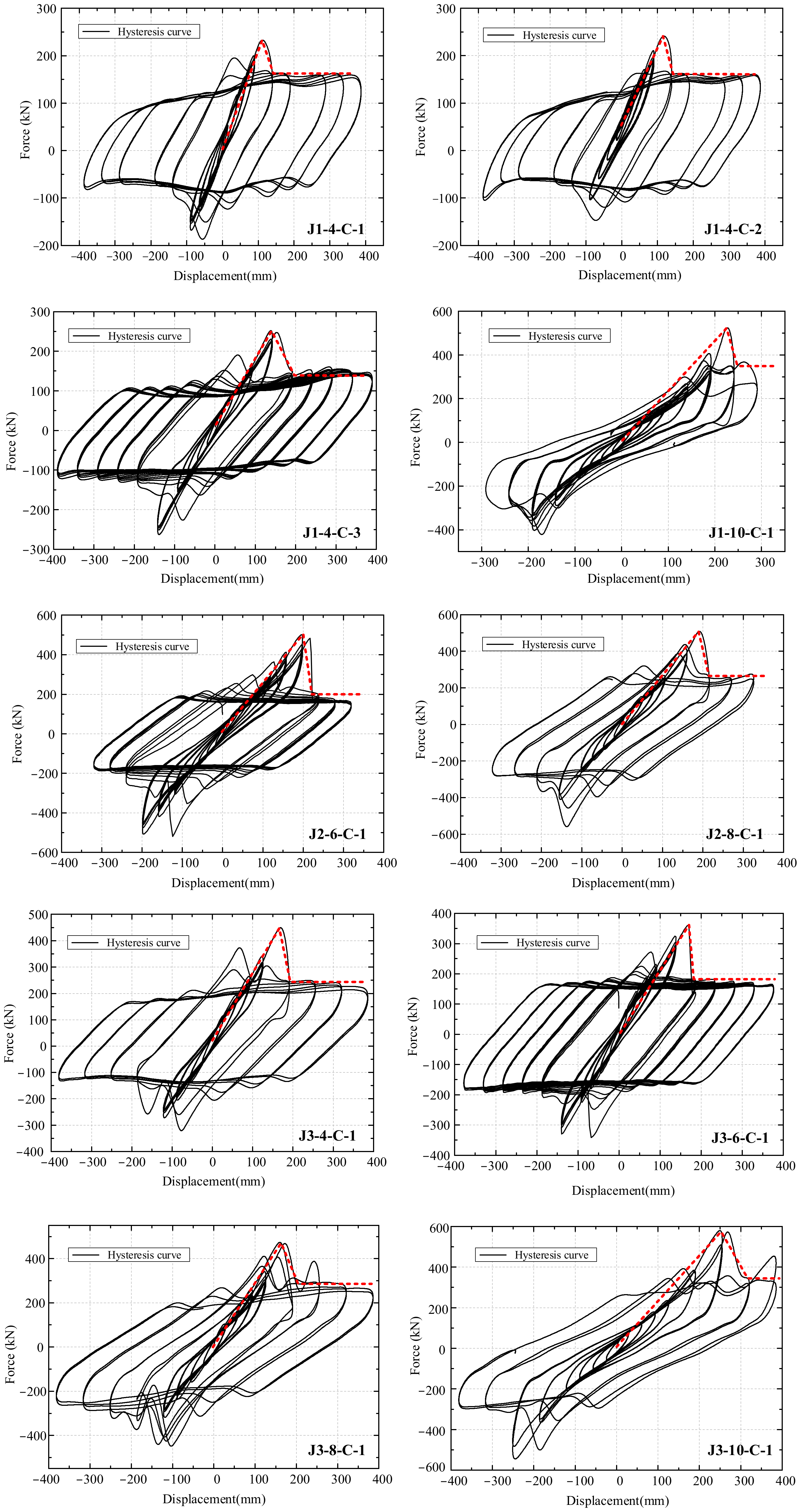

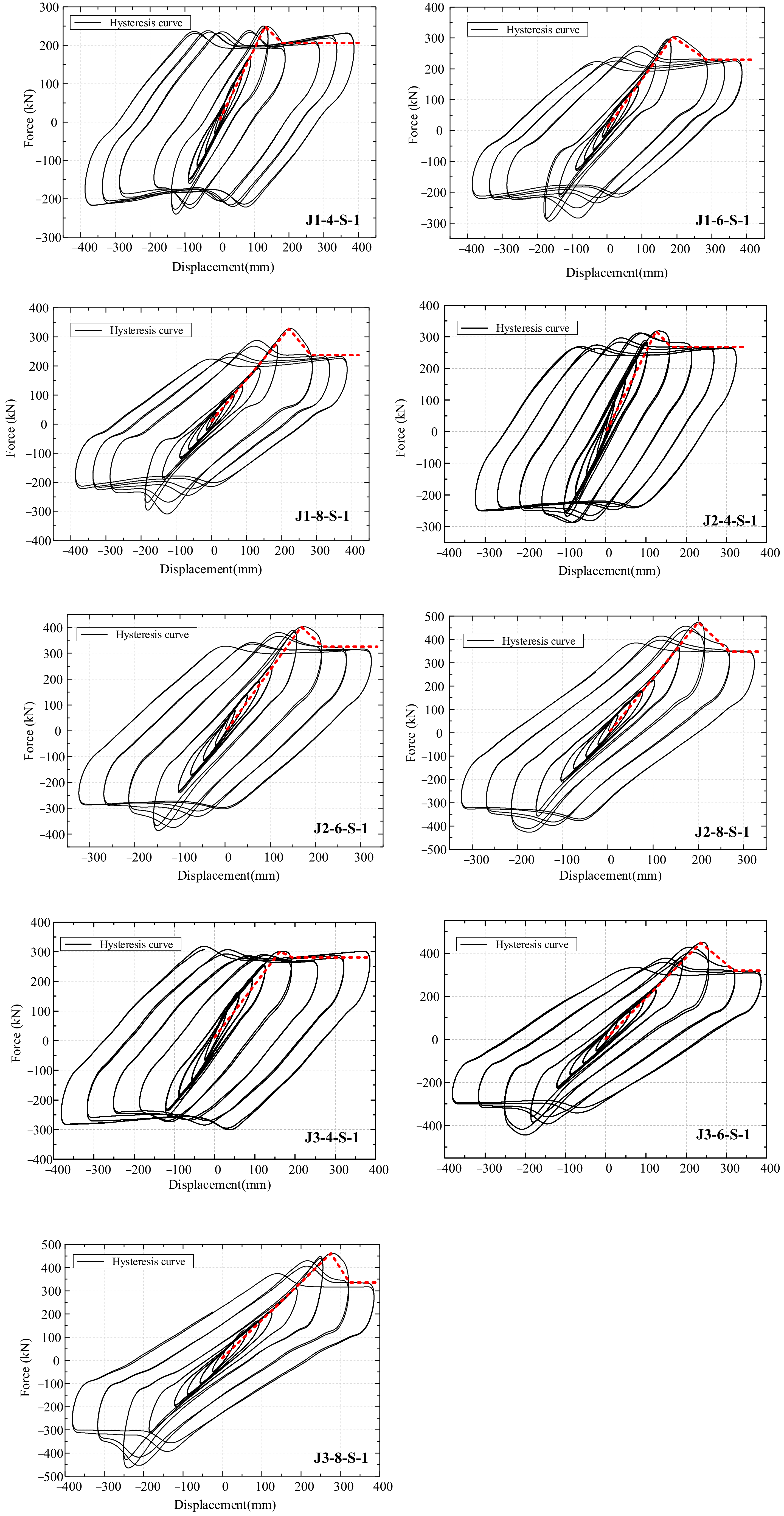

3.2. LRBs Response at the Concrete Interface

3.3. LRBs Response at the Steel Interface

4. Analysis and Discussion

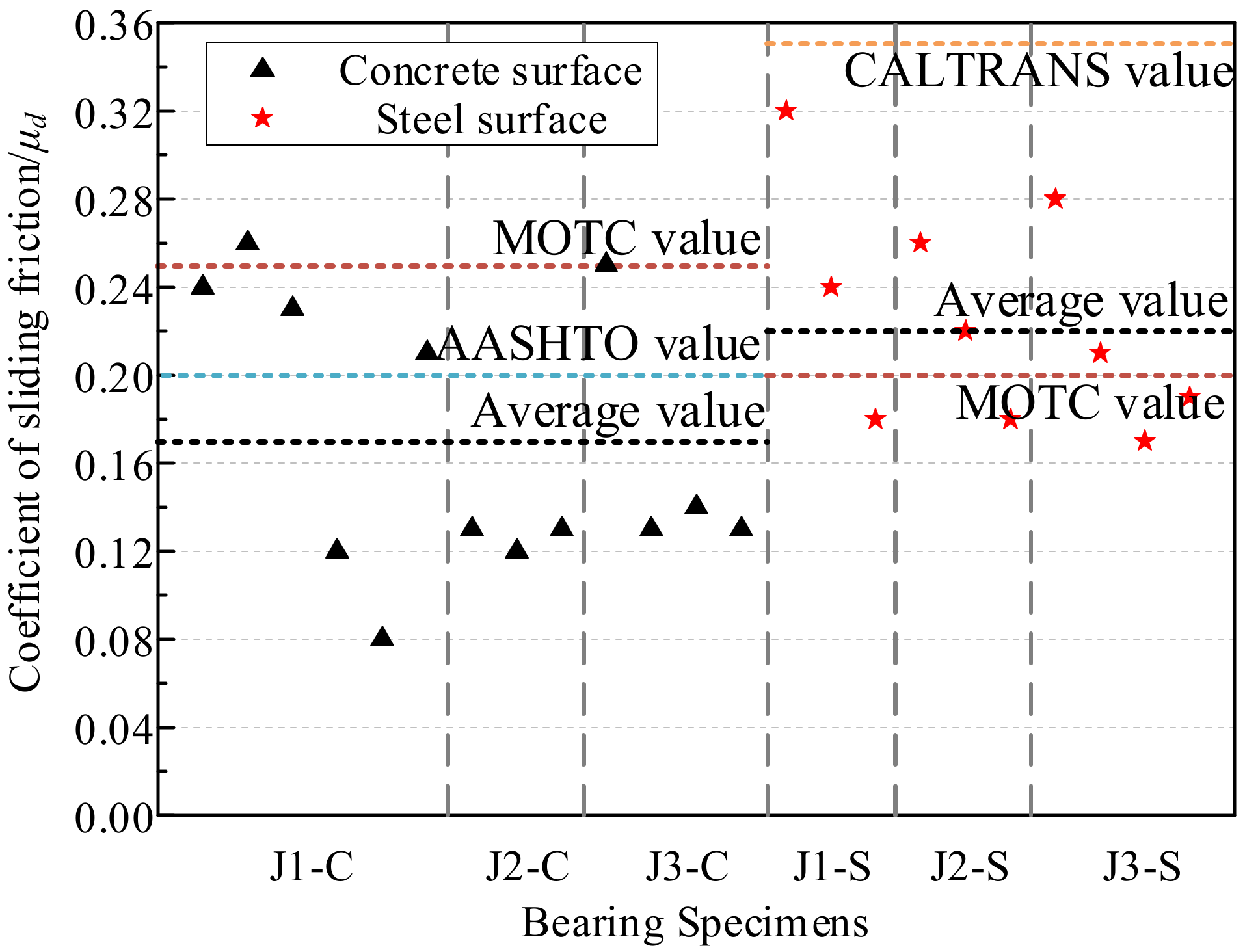

4.1. Analysis of LRB Frictional Characteristics

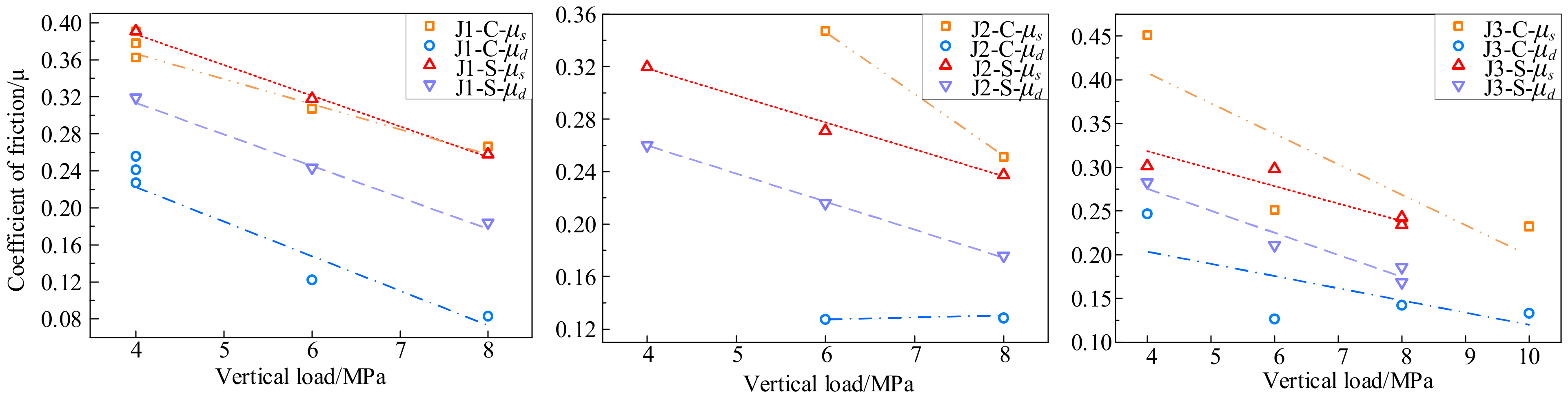

4.2. Effect of Vertical Loads on the Friction Coefficient

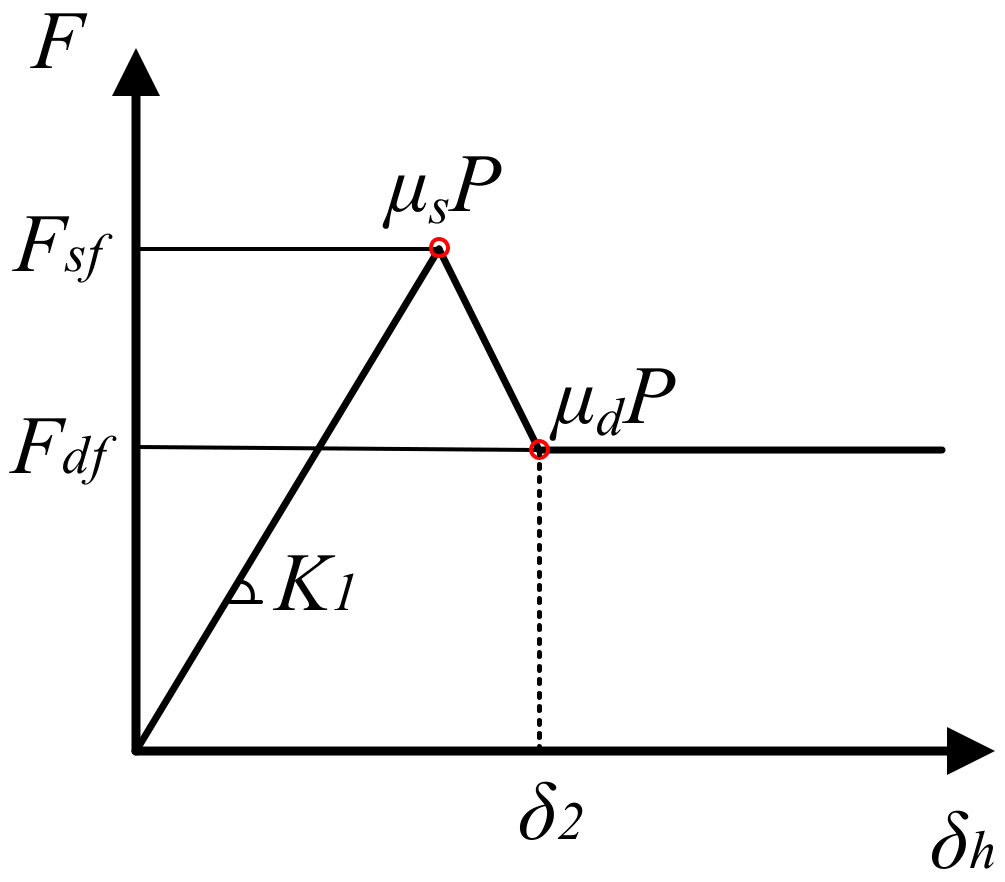

4.3. Mechanical Constitutive Model of the LRBs

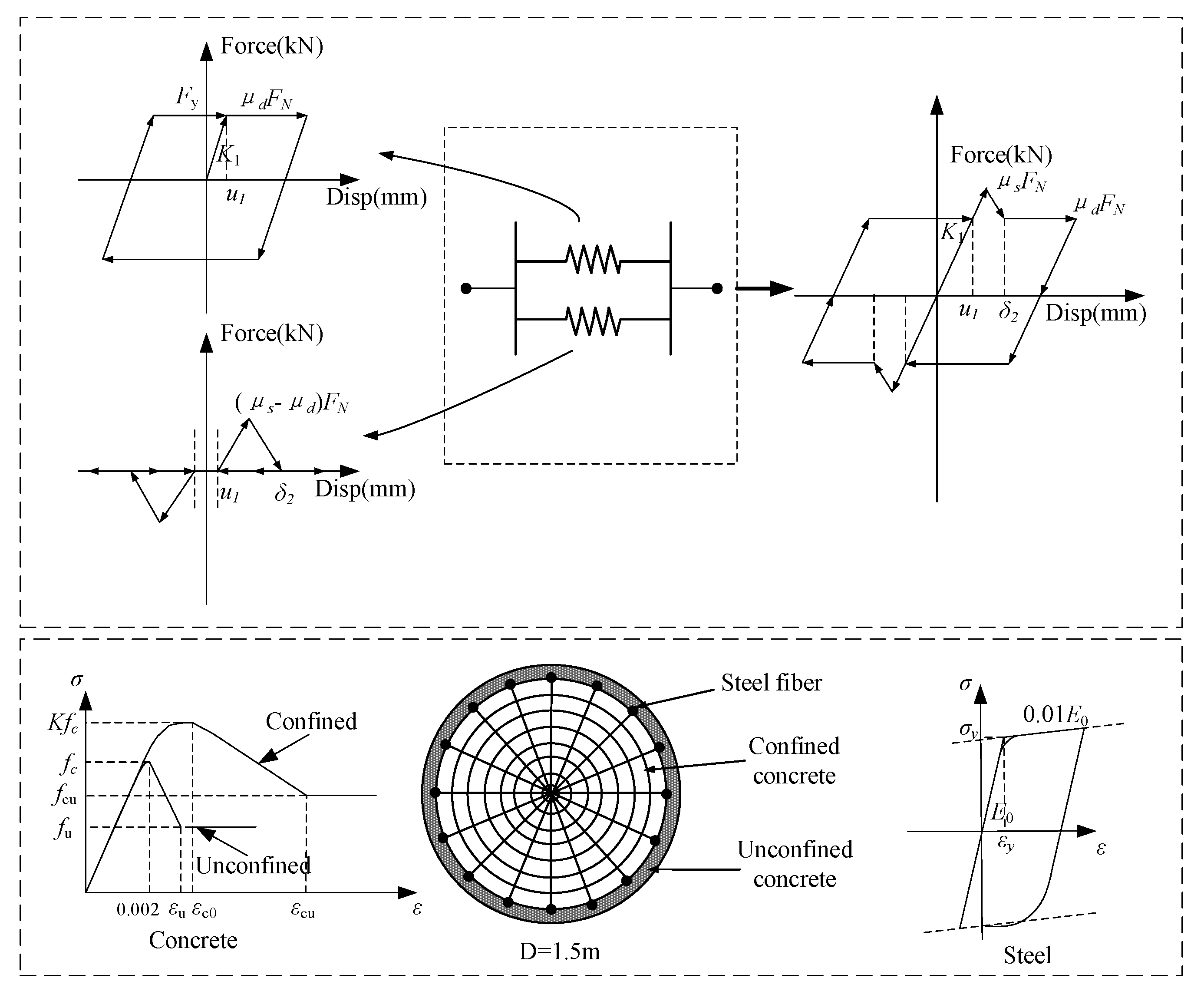

5. Bridge Seismic Response at Different Friction Interfaces

5.1. Finite Element Model and Ground Motion

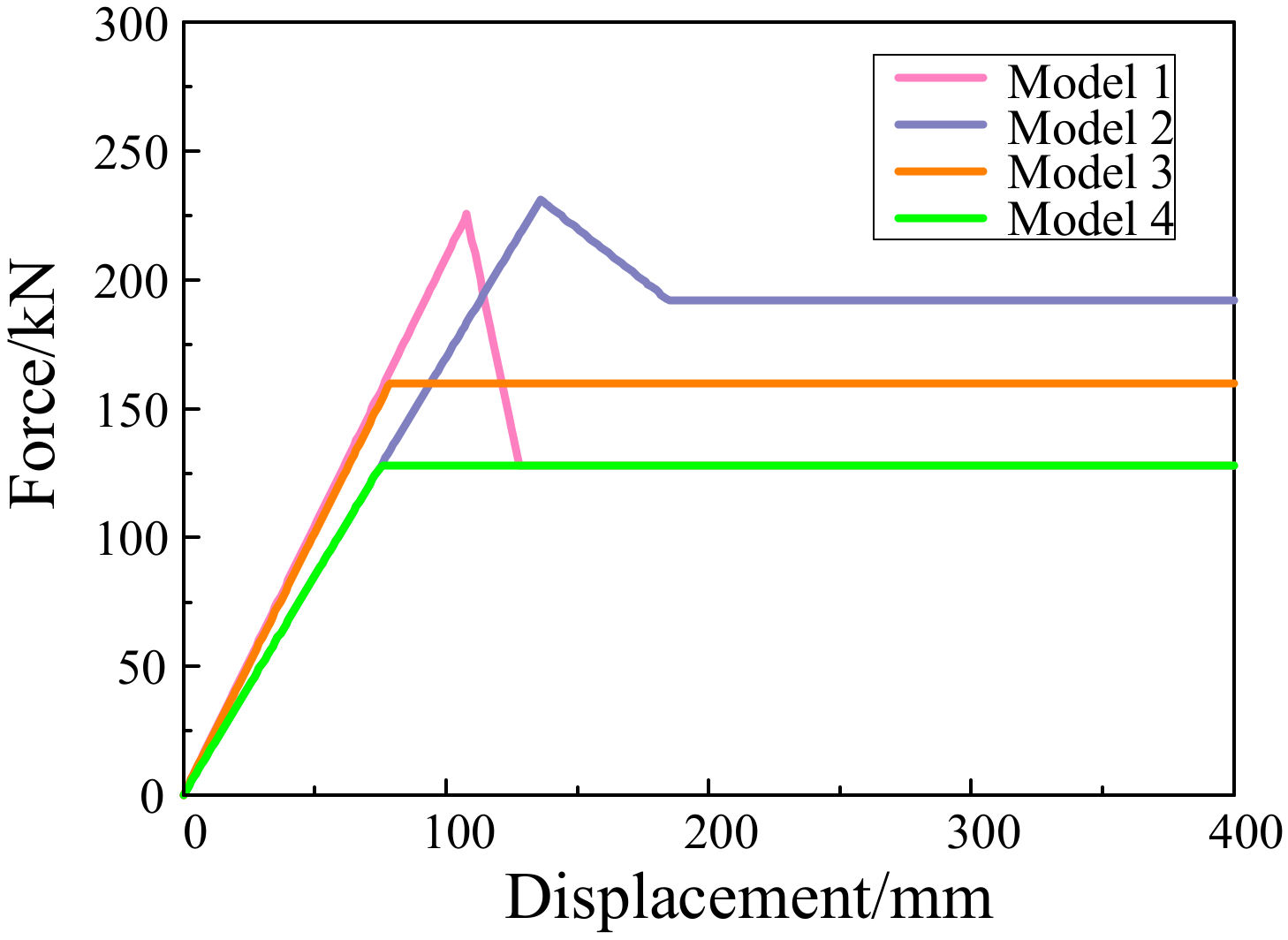

5.2. Comparison of Seismic Response under Different LRB Models

6. Conclusions

- By the observation of the quasi-static cycle test of the LRBs, it was found that the friction coefficient of the bearing will experience a non-negligible decrease in the coefficient of friction with the growth of the displacement loading. The breakaway coefficient of friction of the bearing at the concrete surface is generally greater than that at the steel surface, but when the bearing slides, the sliding coefficient of friction of the bearing at the steel surface is greater than that at the concrete surface.

- The results of the force-displacement hysteresis curve of the LRBs were investigated. A three-fold mechanical constitutive model of the LRBs considering breakaway-sliding friction is established, which is determined by four parameters: the shear stiffness (K1), the breakaway coefficient of friction (μs), the displacement corresponding to stable sliding (δ2) and the sliding coefficient of friction (μd).

- The sliding performance of the LRBs at the steel friction interface has stable characteristics, which can effectively reduce the seismic demand of the substructure and ensure the seismic safety of the bridge. Therefore, it is recommended to choose steel friction pads for LRB-supported bridges, but attention needs to be paid to the bearing displacement requirements under strong earthquakes.

- For bridges supported by LRBs with steel friction interfaces, failure to take into account the breakaway-sliding friction effect of the bearing will undervalue the pier top displacement requirements. The piers were designed to be vulnerable. For bridges supported by LRBs at concrete friction interfaces, if the breakaway-sliding friction effect of the bearings is not taken into account, it will overestimate the pier displacement requirements, as the displacement requirements of the bearings were underestimated.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Filipov, E.T.; Revell, J.R.; Fahnestock, L.A.; LaFave, J.M.; Hajjar, J.F.; Foutch, D.A.; Steelman, J.S. Seismic performance of highway bridges with fusing bearing components for quasi-isolation. Earthq. Eng. Struct. Dyn. 2013, 42, 1375–1394. [Google Scholar] [CrossRef]

- Han, Q.; Du, X.L.; Liu, J.B.; Li, Z.X.; Li, L.Y.; Zhao, J.F. Seismic damage of highway bridges during the 2008 Wenchuan earthquake. Earthq. Eng. Eng. Vib. 2009, 8, 263–273. [Google Scholar] [CrossRef]

- Li, J.Z.; Peng, T.B.; Xu, Y. Damage investigation of girder bridges under the Wenchuan earthquake and corresponding seismic design recommendations. Earthq. Eng. Eng. Vib. 2008, 7, 337–344. [Google Scholar] [CrossRef]

- Wang, K. Seismic Research of Bridge, 2nd ed.; China Railway Publishing House: Beijing, China, 2014; pp. 107–113. [Google Scholar]

- Kelly, J.M. Earthquake-Resistant Design with Rubber, 2nd ed.; Springer: London, UK, 1997; pp. 20–34. [Google Scholar]

- Nagarajaiah, S.; Reinhorn, A.M.; Constantinou, M.C. Experimental-study of sliding isolated structures with uplift restraint. J. Struct. Eng.-ASCE 1992, 118, 1666–1682. [Google Scholar] [CrossRef]

- Xiang, N.L.; Li, J.Z. Experimental and numerical study on seismic sliding mechanism of laminated-rubber bearings. Eng. Struct. 2017, 141, 159–174. [Google Scholar] [CrossRef]

- Calabrese, A.; Spizzuoco, M.; Galano, S.; Tran, N.; Strano, S.; Terzo, M. A parametric study on the stability of fiber reinforced rubber bearings under combined axial and shear loads. Eng. Struct. 2021, 227, 111441. [Google Scholar] [CrossRef]

- Osgooei, P.M.; Van Engelen, N.C.; Konstantinidis, D.; Tait, M.J. Experimental and finite element study on the lateral response of modified rectangular fiber-reinforced elastomeric isolators (MR-FREIs). Eng. Struct. 2015, 85, 293–303. [Google Scholar] [CrossRef]

- Van Engelen, N.C.; Tait, M.J.; Konstantinidis, D. Model of the Shear Behavior of Unbonded Fiber-Reinforced Elastomeric Isolators. J. Struct. Eng. 2015, 141, 04014169. [Google Scholar] [CrossRef]

- Calabrese, A.; Losanno, D.; Barjani, A.; Spizzuoco, M.; Strano, S. Effects of the long-term aging of glass-fiber reinforced bearings (FRBs) on the seismic response of a base-isolated residential building. Eng. Struct. 2020, 221, 110735. [Google Scholar] [CrossRef]

- Wang, S.Q.; Yuan, Y.; Tan, P.; Zhu, H.P.; Luo, K.T. Experimental study on mechanical properties of casting high-capacity polyurethane elastomeric bearings. Constr. Build. Mater. 2020, 265, 120725. [Google Scholar] [CrossRef]

- Deng, P.R.; Gan, Z.P.; Hayashikawa, T.; Matsumoto, T. Seismic response of highway viaducts equipped with lead-rubber bearings under low temperature. Eng. Struct. 2020, 209, 110008. [Google Scholar] [CrossRef]

- Toopchi-Nezhad, H.; Drysdale, R.G.; Tait, M.J. Parametric study on the response of stable unbonded-fiber reinforced elastomeric isolators (SU-FREIs). J. Compos. Mater. 2009, 43, 1569–1587. [Google Scholar] [CrossRef]

- Wu, G.; Wang, K.H.; Lu, G.Y.; Zhang, P.P. An experimental investigation of unbonded laminated elastomeric bearings and the seismic evaluations of highway bridges with tested bearing components. Shock. Vib. 2018, 2018, 8439321. [Google Scholar] [CrossRef]

- Steelman, J.S.; Fahnestock, L.A.; Hajjar, J.F.; LaFave, J.M. Cyclic experimental behavior of nonseismic elastomeric bearings with stiffened angle side retainer fuses for quasi- isolated seismic bridge response. J. Bridge Eng. 2018, 23, 04017120. [Google Scholar] [CrossRef]

- Ministry of Transport of the People’s Republic of China (MOTC). Specifications for Seismic Design of Highway Bridges; China Communication Press: Beijing, China, 2020.

- Zhang, B.Z.; Wang, K.H.; Lu, G.Y.; Guo, W.Z. Seismic Response Analysis and Evaluation of Laminated Rubber Bearing Supported Bridge Based on the Artificial Neural Network. Shock. Vib. 2021, 2021, 5566874. [Google Scholar] [CrossRef]

- Mordini, A.; Strauss, A. An innovative earthquake isolation system using fiber reinforced rubber bearings. Eng. Struct. 2008, 30, 2739–2751. [Google Scholar] [CrossRef]

- Kalfas, K.N.; Mitoulis, S.A.; Konstantinidis, D. Influence of steel reinforcement on the performance of elastomeric bearings. J. Struct. Eng. 2020, 146, 04020195. [Google Scholar] [CrossRef]

- Billah, A.H.M.M.; Todorov, B. Effects of subfreezing temperature on the seismic response of lead rubber bearing isolated bridge. Soil Dyn. Earthq. Eng. 2019, 126, 105814. [Google Scholar] [CrossRef]

- Zhang, J.; Huo, Y.L. Evaluating effectiveness and optimum design of isolation devices for highway bridges using the fragility function method. Eng. Struct. 2009, 31, 1648–1660. [Google Scholar] [CrossRef]

- Shoaei, P.; Orimi, H.T.; Zahrai, S.M. Seismic reliability-based design of inelastic base-isolated structures with lead-rubber bearing systems. Soil Dyn. Earthq. Eng. 2018, 115, 589–605. [Google Scholar] [CrossRef]

- Yuan, K.; Zhang, J.; Guo, J.; Tian, W. Study on seismic response characteristics and design parameters of composite isolation system for rural buildings. KSCE J. Civ. Eng. 2019, 23, 1747–1755. [Google Scholar] [CrossRef]

- Li, H.; Xie, Y.Z.; Gu, Y.T.; Tian, S.Z.; Yuan, W.C.; DesRoches, R. Shake table tests of highway bridges installed with unbonded steel mesh reinforced rubber bearings. Eng. Struct. 2020, 206, 110124. [Google Scholar] [CrossRef]

- Zhang, C.W.; Ali, A. The advancement of seismic isolation and energy dissipation mechanisms based on friction. Soil Dyn. Earthq. Eng. 2021, 146, 106746. [Google Scholar] [CrossRef]

- Filipov, E.T.; Fahnestock, L.A.; Steelman, J.S.; Hajjar, J.F.; LaFave, J.M.; Foutch, D.A. Evaluation of quasi-isolated seismic bridge behavior using nonlinear bearing models. Eng. Struct. 2013, 49, 168–181. [Google Scholar]

- Ministry of Transport of the People’s Republic of China (MOTC). Laminated Bearing for Highway Bridge; China Communication Press: Beijing, China, 2019.

- Fukahori, Y.; Gabriel, P.; Liang, H.; Busfield, J.J.C. A new generalized philosophy and theory for rubber friction and wear. Wear 2020, 446, 203166. [Google Scholar] [CrossRef]

- Coronado, J.J. Abrasive size effect on friction coefficient of AISI 1045 steel and 6061-T6 aluminum alloy in two-body abrasive wear. Tribol. Lett. 2015, 60, 40. [Google Scholar] [CrossRef]

- American Association of State Highway and Transportation Officials. American Association of State Highway and Transportation Officials (AASHTO) LRFD BRIDGE. In Design Specifications; Washington, DC, USA, 2012. Available online: https://www.oaxaca.gob.mx/sinfra/wp-content/uploads/sites/14/2016/02/AASHTO-LRFD_Bridge_Design_Specifications_2010.pdf (accessed on 3 September 2022).

- California Department of Transportation. CALTRANS. In Seismic Design Criteria Version 2.0; Sacramento, CA, USA, 2019. Available online: https://dot.ca.gov/-/media/dot-media/programs/engineering/documents/seismicdesigncriteria-sdc/sdc20april2019final.pdf (accessed on 3 September 2022).

- Kent, D.C. Inelastic Behavior of Reinforced Concrete Members with Cyclic Loading. Ph.D. Thesis, University of Canterbury, Christchurch, New Zealand, 1969. [Google Scholar]

- Filippou, F.C.; Popov, E.P.; Bertero, V.V. Effects of Bond Deterioration on Hysteretic Behavior of Reinforced Concrete Joints; Technical Report for Pacific Earthquake Engineering Research Center; University of California: Berkeley, CA, USA, 1983. [Google Scholar]

- Ahmad, N.; Shakeel, H.; Masoudi, M. Design and development of low-cost HDRBs seismic isolation of structures. Bull. Earthq. Eng. 2020, 18, 1107–1138. [Google Scholar] [CrossRef]

- Lu, G.; Wang, K.; Qiu, W. Fragility-based improvement of system seismic performance for long-span suspension bridges. Adv. Civ. Eng. 2020, 2020, 8693729. [Google Scholar] [CrossRef]

| Type | Mark | L/mm | Rubber Layer | Steel Plate | h1/mm | h2/mm | H/mm | Sum | ||

|---|---|---|---|---|---|---|---|---|---|---|

| hr/mm | Number of Layers | hs/mm | Number of Layers | |||||||

| T1 | GJZ400 × 400 × 99 | 400 | 11 | 6 | 4 | 7 | 2.5 | 5 | 99 | 3 |

| T2 | GJZ500 × 500 × 110 | 500 | 15 | 5 | 5 | 6 | 2.5 | 5 | 110 | 3 |

| T3 | GJZ500 × 500 × 130 | 500 | 15 | 6 | 5 | 7 | 2.5 | 5 | 130 | 3 |

| Test Specimen | Type | Loading Displacement | Vertical Load | Interface | |

|---|---|---|---|---|---|

| Concrete Slabs | Steel Plates | ||||

| J1-4-C-1 | T1 | 400% ESS | 4 MPa | X | |

| J1-4-C-2 | T1 | 400% ESS | 4 MPa | X | |

| J1-4-C-3 | T1 | 400% ESS | 4 MPa | X | |

| J1-6-C-1 | T1 | 300% ESS | 6 MPa | X | |

| J1-8-C-1 | T1 | 300% ESS | 8 MPa | X | |

| J1-10-C-1 | T1 | 300% ESS | 10 MPa | X | |

| J1-4-S-1 | T1 | 400% ESS | 4 MPa | X | |

| J1-6-S-1 | T1 | 400% ESS | 6 MPa | X | |

| J1-8-S-1 | T1 | 400% ESS | 8 MPa | X | |

| J2-6-C-1 | T2 | 300% ESS | 6 MPa | X | |

| J2-6-C-2 | T2 | 300% ESS | 6 MPa | X | |

| J2-8-C-1 | T2 | 300% ESS | 8 MPa | X | |

| J2-4-S-1 | T2 | 300% ESS | 4 MPa | X | |

| J2-6-S-1 | T2 | 300% ESS | 6 MPa | X | |

| J2-8-S-1 | T2 | 300% ESS | 8 MPa | X | |

| J3-4-C-1 | T3 | 300% ESS | 4 MPa | X | |

| J3-6-C-1 | T3 | 300% ESS | 6 MPa | X | |

| J3-8-C-1 | T3 | 300% ESS | 8 MPa | X | |

| J3-10-C-1 | T3 | 300% ESS | 10 MPa | X | |

| J3-4-S-1 | T3 | 300% ESS | 4 MPa | X | |

| J3-6-S-1 | T3 | 300% ESS | 6 MPa | X | |

| J3-8-S-1 | T3 | 300% ESS | 8 MPa | X | |

| J3-8-S-2 | T3 | 300% ESS | 8 MPa | X | |

| Test Specimen | δ1/mm | Fsf/kN | δ2/mm | Fdf/kN | K1/kN/m | μs | μd | γ |

|---|---|---|---|---|---|---|---|---|

| J1-4-C-1 | 114.90 | 231.90 | 140.00 | 154.40 | 2018.28 | 0.36 | 0.24 | 1.50 |

| J1-4-C-2 | 116.90 | 241.70 | 137.80 | 163.70 | 2067.58 | 0.38 | 0.26 | 1.48 |

| J1-4-C-3 | 137.20 | 249.90 | 193.30 | 145.30 | 1821.43 | 0.39 | 0.23 | 1.72 |

| J1-6-C-1 | 155.40 | 279.90 | 173.60 | 111.50 | 1801.16 | 0.31 | 0.12 | 2.51 |

| J1-8-C-1 | 159.60 | 323.90 | 182.90 | 100.90 | 2029.45 | 0.27 | 0.08 | 3.21 |

| J1-10-C-1 | 226.80 | 523.38 | 240.66 | 334.09 | 2307.67 | 0.33 | 0.21 | 1.57 |

| J1-4-S-1 | 133.00 | 250.10 | 183.70 | 204.30 | 1880.45 | 0.39 | 0.32 | 1.22 |

| J1-6-S-1 | 196.14 | 305.17 | 276.10 | 233.60 | 1555.88 | 0.32 | 0.24 | 1.31 |

| J1-8-S-1 | 221.90 | 329.90 | 284.60 | 235.60 | 1486.71 | 0.26 | 0.18 | 1.40 |

| J2-6-C-1 | 197.10 | 499.90 | 221.30 | 183.50 | 2536.28 | 0.35 | 0.13 | 2.72 |

| J2-6-C-2 | 101.49 | 347.80 | 113.87 | 173.20 | 3426.94 | 0.24 | 0.12 | 2.01 |

| J2-8-C-1 | 192.10 | 502.20 | 215.30 | 256.80 | 2614.26 | 0.25 | 0.13 | 1.96 |

| J2-4-S-1 | 129.70 | 319.60 | 209.81 | 259.96 | 2464.15 | 0.32 | 0.26 | 1.23 |

| J2-6-S-1 | 167.50 | 406.50 | 212.90 | 324.10 | 2426.87 | 0.27 | 0.22 | 1.25 |

| J2-8-S-1 | 202.80 | 474.80 | 265.00 | 351.62 | 2341.22 | 0.24 | 0.18 | 1.35 |

| J3-4-C-1 | 168.80 | 451.00 | 189.60 | 246.80 | 2671.80 | 0.45 | 0.25 | 1.83 |

| J3-6-C-1 | 170.56 | 361.39 | 178.10 | 182.20 | 2118.84 | 0.25 | 0.13 | 1.98 |

| J3-8-C-1 | 159.20 | 474.30 | 203.10 | 284.10 | 2979.27 | 0.24 | 0.14 | 1.67 |

| J3-10-C-1 | 249.40 | 581.03 | 321.50 | 333.10 | 2329.71 | 0.23 | 0.13 | 1.74 |

| J3-4-S-1 | 156.80 | 301.20 | 190.50 | 282.70 | 1920.92 | 0.30 | 0.28 | 1.07 |

| J3-6-S-1 | 242.16 | 447.30 | 314.60 | 316.60 | 1847.13 | 0.30 | 0.21 | 1.41 |

| J3-8-S-1 | 278.10 | 468.10 | 316.70 | 336.90 | 1683.21 | 0.23 | 0.17 | 1.39 |

| J3-8-S-2 | 229.70 | 465.50 | 288.70 | 356.10 | 2026.56 | 0.24 | 0.19 | 1.31 |

| A/m2 | Type | H/mm | K1/kN/m | δ2/mm | μs | μd | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P1 | P2 | P3 | P4 | P1 | P2 | P3 | P4 | P1 | P2 | P3 | P4 | ||||

| 0.16 | 400 × 400 | 99 | 2033.81 | 128.76 | 181.82 | 227.27 | 265.22 | 0.35 | 0.33 | 0.31 | 0.29 | 0.20 | 0.19 | 0.18 | 0.17 |

| 0.2025 | 450 × 450 | 99 | 2491.42 | 129.48 | 182.52 | 227.72 | 265.15 | 0.34 | 0.32 | 0.30 | 0.28 | 0.19 | 0.18 | 0.17 | 0.16 |

| 114 | 2282.73 | 139.94 | 197.13 | 245.77 | 285.93 | 0.34 | 0.32 | 0.30 | 0.28 | 0.19 | 0.18 | 0.17 | 0.16 | ||

| 0.25 | 500 × 500 | 110 | 2850.27 | 134.44 | 189.04 | 235.17 | 272.92 | 0.33 | 0.31 | 0.29 | 0.27 | 0.17 | 0.16 | 0.15 | 0.14 |

| 130 | 2572.15 | 146.96 | 206.45 | 256.56 | 297.38 | 0.32 | 0.30 | 0.28 | 0.26 | 0.17 | 0.16 | 0.15 | 0.14 | ||

| A/m2 | Type | H/mm | K1/kN/m | δ2/mm | μs | μd | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P1 | P2 | P3 | P1 | P2 | P3 | P1 | P2 | P3 | ||||

| 0.16 | 400 × 400 | 99 | 1699.28 | 184.94 | 244.75 | 283.06 | 0.36 | 0.32 | 0.28 | 0.30 | 0.25 | 0.19 |

| 0.2025 | 450 × 450 | 99 | 2134.23 | 173.60 | 227.96 | 260.98 | 0.34 | 0.30 | 0.26 | 0.29 | 0.24 | 0.18 |

| 114 | 1777.31 | 205.71 | 270.11 | 309.20 | 0.34 | 0.30 | 0.26 | 0.29 | 0.24 | 0.18 | ||

| 0.25 | 500 × 500 | 110 | 2359.00 | 176.57 | 229.55 | 259.31 | 0.32 | 0.28 | 0.24 | 0.28 | 0.23 | 0.17 |

| 130 | 1883.36 | 217.17 | 282.30 | 318.85 | 0.32 | 0.28 | 0.24 | 0.28 | 0.23 | 0.17 | ||

| Earthquake | Year | Station | Magnitude | PGA-Horizontal (g) | Rjb (km) | Rrup (km) |

|---|---|---|---|---|---|---|

| “Northridge-01” | 1994 | “LA-Saturn St” | 6.69 | 0.467 | 21.17 | 27.01 |

| “Northridge-01” | 1994 | “LA-Centinela St” | 6.69 | 0.448 | 20.36 | 28.3 |

| “Northridge-01” | 1994 | “Beverly Hills-14145 Mulhol” | 6.69 | 0.443 | 9.44 | 17.15 |

| “Loma Prieta” | 1989 | “Gilroy Array #4” | 6.93 | 0.418 | 13.81 | 14.34 |

| “Loma Prieta” | 1989 | “Hollister-South & Pine” | 6.93 | 0.369 | 27.67 | 27.93 |

| “Superstition Hills-02” | 1987 | “El Centro Imp. Co. Cent” | 6.54 | 0.357 | 18.2 | 18.2 |

| “Whittier Narrows-01” | 1987 | “Tarzana-Cedar Hill” | 5.99 | 0.472 | 38.24 | 41.22 |

| Mechanical Properties of Bearing | Model 1 | Model 2 | Model 3 | Model 4 |

|---|---|---|---|---|

| K1 | 2033.81 kN/m | 1699.28 kN/m | 2033.81 kN/m | 1699.28 kN/m |

| δ2 | 128.76 mm | 184.94 mm | / | / |

| μs | 0.35 | 0.36 | 0.25 | 0.2 |

| μd | 0.20 | 0.30 | 0.25 | 0.2 |

| u1 | 62.93 mm | 112.98 mm | 78.67 mm | 75.32 mm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, B.; Wang, K.; Lu, G.; Qiu, W.; Yin, W. Experimental and Seismic Response Study of Laminated Rubber Bearings Considering Different Friction Interfaces. Buildings 2022, 12, 1526. https://doi.org/10.3390/buildings12101526

Zhang B, Wang K, Lu G, Qiu W, Yin W. Experimental and Seismic Response Study of Laminated Rubber Bearings Considering Different Friction Interfaces. Buildings. 2022; 12(10):1526. https://doi.org/10.3390/buildings12101526

Chicago/Turabian StyleZhang, Bingzhe, Kehai Wang, Guanya Lu, Wenhua Qiu, and Weitao Yin. 2022. "Experimental and Seismic Response Study of Laminated Rubber Bearings Considering Different Friction Interfaces" Buildings 12, no. 10: 1526. https://doi.org/10.3390/buildings12101526

APA StyleZhang, B., Wang, K., Lu, G., Qiu, W., & Yin, W. (2022). Experimental and Seismic Response Study of Laminated Rubber Bearings Considering Different Friction Interfaces. Buildings, 12(10), 1526. https://doi.org/10.3390/buildings12101526