1. Introduction

It is important to integrate renewable energy into the building sector to the greatest extent possible because it accounts for 30% of the global energy consumption. Furthermore, more than half of the energy used in buildings is for space and water heating, and buildings can require more than 500 kWh per square meter of floor space annually. Moreover, going forward, it will be challenging for energy infrastructures to keep up with, and continue to provide for, increasing urban energy densities [

1,

2,

3,

4,

5]. Trombe walls are a passive solar energy technology with high potential for reducing building energy loads because they are simple to build, easy to maintain, have very little operational costs, are highly efficient, and cost-effective. Indeed, it has been reported that a Trombe wall can reduce a building’s heating demands by 30% [

6,

7,

8]. The classic Trombe wall consists of an air channel situated between a thermal storage wall and a glazed window. Sunlight passes through the glazed window and heats up the storage wall, which, in turn, heats up the air in the channel. Building air moves from indoors to the channel through a vent at the bottom of the thermal storage wall and is heated as it moves up the channel. Heated air returns to the building through a vent at the top of the thermal storage wall. The vents can be closed to prevent overheating, which is not uncommon when Trombe walls are operating in hot weather under sunny conditions. The thermal storage wall is typically made of high thermal capacity materials, such as bricks, concrete, and stone. The surface of the wall is usually painted black to increase the absorption of solar radiation.

Researchers have investigated the benefits of using different materials for Trombe walls. For example, numerous studies have investigated the performance of Trombe walls wherein the thermal storage wall comprises a Phase Change Material (PCM) [

9]. PCMs can store solar thermal energy in the form of latent heat, which makes them a high-performance lightweight alternative to heavy Trombe walls. Sun et al. showed that indoor air temperature fluctuations during winter can be reduced by integrating paraffin-based PCMs with a phase temperature and latent heat of 19.45 °C, and 128.46 J/g, respectively [

10]. Furthermore, Li et al. numerically investigated a Trombe wall with a thermal storage wall made of encapsulated PCMs (with a melting temperature of 27.5 °C and latent heat of 127 kJ/kg). Simulations were performed to study the performance of Trombe walls with and without PCMs. The results showed that using the Trombe wall with PCMs allowed for ~20% increase in the indoor temperature at night, as compared to the case when the Trombe wall without PCMs was used [

11].

Trombe walls provide effective passive heating during the winter. However, they can also cause overheating during the summer months. Pittaluga performed a numerical analysis to study the performance of Trombe walls with an electrochromic glazing (EG). The transmittance of an EG can be reduced during summer months to prevent overheating. Numerical analysis revealed that the Trombe wall equipped with an EG provided an energy saving of about 17% [

12]. Another way to reduce overheating from Trombe walls during summer weather conditions is to use water as the thermal storage medium. Water has a high heat capacity and can store more thermal energy than other thermal storage walls on a per volume basis. The high heat capacity also keeps the temperature of the water Trombe wall lower than other Trombe walls, which can help reduce thermal losses to the surroundings. Additionally, the water can potentially be removed from the Trombe wall and used as a source of hot water for the building. The ability to remove hot water from the Trombe wall during summer months is especially attractive for preventing overheating during hot weather conditions. Furthermore, the transparent property of water can be utilized in making aesthetically pleasing designs when architecting buildings. Indeed, translucent materials of different colors have been integrated into water Trombe walls, giving them a vibrant appearance [

13]. Despite their unique combination of advantages, a limited amount of research has been done on water Trombe walls in comparison to other Trombe walls.

Weiliang et al. analyzed the thermal performance of a Trombe wall consisting of water as a thermal energy storage medium. A south-facing water Trombe wall prototype with a single-story house with floor area of 700 m

2 and shape coefficient 0.374 (which is the ratio of the external surface area and inner volume) was set up in North China for experimental analysis, and a simulation model was set up in TRNSYS. The outer layer of the Trombe wall was made of a steel plate. A total of 29 small modules of water (with dimensions of 1.1 m × 0.4 m × 2.5 m) were placed along the inner side of the wall. Numerical and experimental analyses were conducted and compared with the traditional Trombe wall. The results showed a reduction in energy consumption per year by 8.6% and the indoor thermal comfort evaluation index was improved by approximately 13%, as compared to the classic Trombe wall [

14]. Nayak did a numerical analysis of the thermal performance between a south-facing drum water wall and a water transwall. The drum wall consisted of metallic containers of water stacked upon each other. One surface of the wall was colored black and had glazing on it, but the other surface could be separated from the room by a concrete wall or insulating layer. The transwall consisted of water in containers that were made of parallel glass walls. Each wall had a semi-transparent material kept between the water column and the room, between the glazing and the water column, or in the water column itself. The results showed that the transwall met the daytime heating load more effectively than the drum wall, whereas the drum wall performed better in terms of load levelling and day–night performance [

15]. Turner et al. studied the performance of a water Trombe wall consisting of 7.6 cm diameter plastic tubes embedded into a studded wall. During the winter season, the system was charged for 6 h with hot ambient air and then passively discharged for 18 h. The results showed that the Trombe wall temperature remained approximately 2.6 °C higher, even after the discharging cycle completed, which helped in reducing the heating load of the house. Further, it was noted that during the summer season, water walls can be charged using cool ambient air at night to achieve thermal comfort during the daytime [

16]. Tiwari et al. did a comparative study of the total heat gain of different south facing Trombe walls, such as a glass wall, a water wall, an active air collector wall, and a transwall. Several design parameters were taken into consideration, such as the thickness of the water wall and transwall, and the flow rate of the air collector wall. The design parameters were varied for a heated room under winter weather conditions to conduct different experiments. The results showed that the performance of the water wall and the transwall were better for space heating during nighttime because of their greater thermal storage capacity. On the other hand, the glass wall and the air collector wall were efficient for space heating during sunshine hours. It was also observed that the air temperature of the room was higher during the extreme winter conditions in Srinagar, India, when a transwall was used in a non-conditioned passive solar house in comparison to when a water wall was used [

17]. Mohamad et al. designed a novel Trombe wall to reduce the heating and cooling loads in the winter and summer seasons, respectively. The Trombe wall consisted of a water tank that acted as a thermal energy storage medium and could also supply hot water if required. The proposed Trombe wall model could be used for space heating during day and night, and excess heat could be used for domestic hot water supply in the summer season. The excess heat could be extracted out of the building through vents or could be used for domestic water heating purposes to reduce the cooling load. Their numerical results showed that the proposed system was more efficient in charging and discharging thermal energy, as compared to a classical Trombe wall. The thermal storage efficiency of the proposed system reached ~80% [

18].

In this work we conducted experiments to investigate if water-based Trombe walls can be designed to provide multiple functions including the following: (1) to provide a passive source of heating, (2) to function as a window or tinted semi-transparent window, and (3) to provide heated water. Semi-transparent Trombe walls that can provide heated water for building applications have yet to be reported in the literature. We experimentally measured the thermal performance of a laboratory-scale Trombe wall prototype consisting of a tinted acrylic sheet integrated into a water storage wall. Specifically, a tinted acrylic sheet was integrated into the water wall, such that it was semi-transparent, which is desirable for the design of aesthetically pleasing Trombe walls. The Trombe wall design proposed in this work can provide passive heating throughout the year, and heated water during the summer months. Results from the experiments conducted in this work showed that the percentage of solar-simulated light energy incident onto the Trombe wall prototype for five hours, that was stored as thermal energy in the water, increased from 60.3% to 83.2% when tinted glass was inserted in the water storage wall. Furthermore, the temperature of the water at the top of the Trombe wall reached ~56 °C, which is suitable to be used as pre-heated water in building applications.

2. Materials and Methods

In previous work, we built a small Trombe wall prototype to study the effects of managing the airflow through Trombe wall vents on the amount of thermal energy stored in the thermal storage wall [

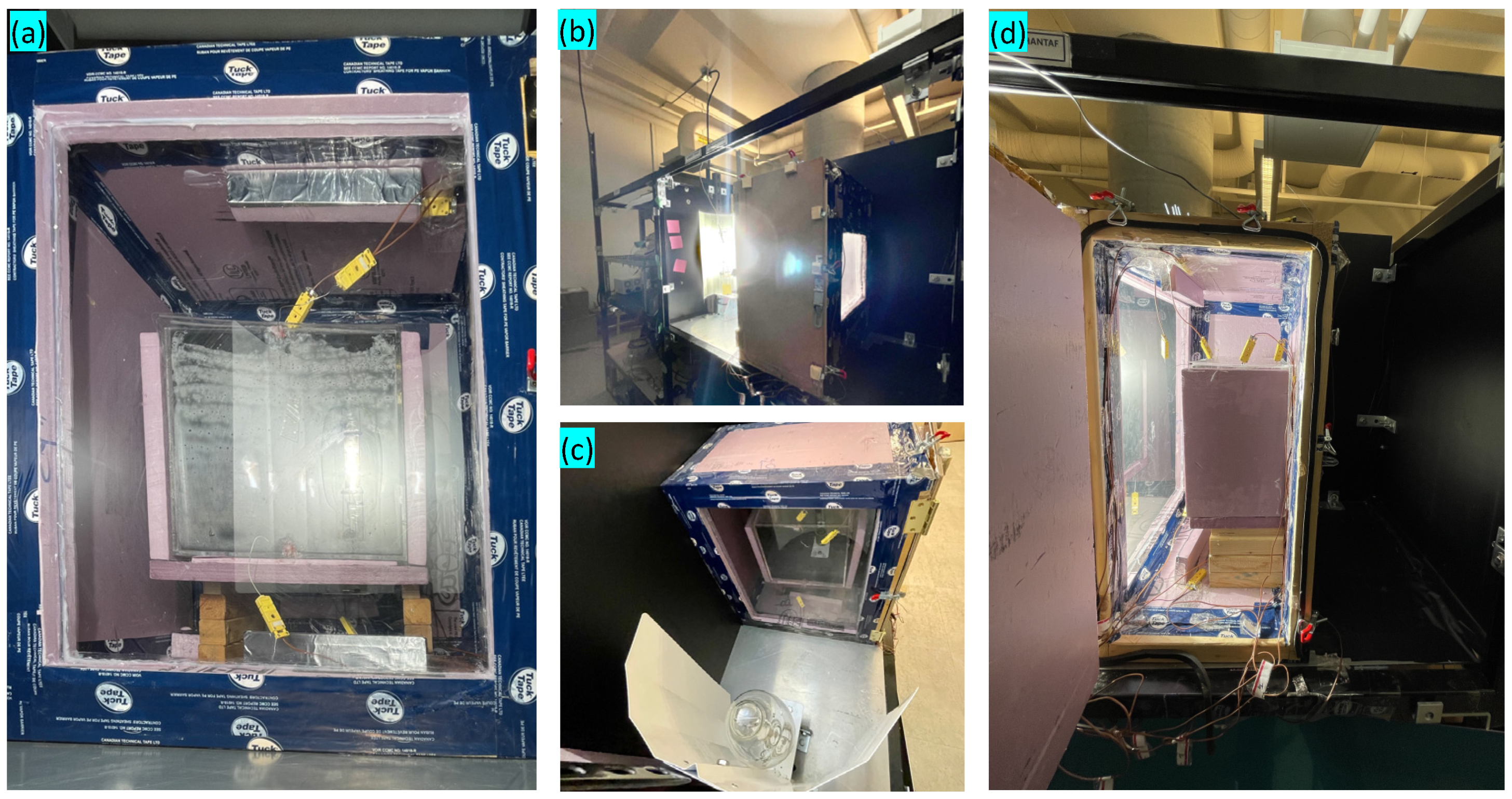

19]. In this work, we have modified this Trombe wall prototype, shown in

Figure 1, to experimentally investigate and compare the ability to store solar thermal energy in water storage walls with and without tinted glass. The Trombe wall prototype was built using 3.8 × 3.8 cm wooden frames because of their low thermal conductivity. The overall dimensions of the model frame were 58.4 × 38.1 × 66.0 cm. The frame wa insulated using 1.5-inch thick FOAMULAR extruded polystyrene insulation boards (which have a thermal conductivity of 0.029 W/m·K). Silicon sealant was used to assemble the prototype.

The front surface of the Trombe wall prototype was made from a 3 mm thick clear acrylic sheet that was tightly fitted in the insulation board frame and then sealed using silicon sealant at its edges. These seals were subsequently covered with sheathing tape. The reflectance (R) and transmittance (T) of this clear acrylic sheet was measured over the wavelength range extending from 300 nm to 1400 nm using a UV-VIS spectrophotometer (Shimadzu 2600i). The reflectance and transmittance of the clear acrylic sheet over the wavelength range from 1400 nm to 23 μm was measured using an FTIR spectrometer (VERTEX 70). The absorptance (A) of the clear acrylic sheet was determined using the reflectance and transmittance measurements and the equation A + R + T = 1. A 3 mm thick acrylic plexiglass sheet of dimensions 35 cm × 35 cm was integrated into the back side insulation of the prototype. This allowed light to pass through the Trombe wall prototype, as a desired feature of the water Trombe wall in this work was transparency or semi-transparency. The side of the Trombe wall prototype was designed as an insulated door to allow users to change the TES medium and adjust the position of the thermocouples. A 1000 W Hortilux Blue W Metal Halide bulb mounted vertically with a white reflector behind it was used to simulate solar radiation. This light source was 38 cm away from the front surface of the acrylic sheet. The Trombe wall consisted of a TES medium as water and the water was stored in a clear acrylic plexiglass container. The dimensions of the water container were 30 × 20 × 20 cm. Some experiments were run with a 5 mm thick tinted acrylic sheet (manufactured by Chemcast) integrated into the TES medium at the front of the water container. Similar to the clear acrylic sheet at the front of the Trombe wall prototype, the reflectance, transmittance and absorbance of the tinted acrylic sheet were determined using UV-VIS and FTIR measurements. The plexiglass container, with and without the tinted acrylic sheet, is shown in

Figure 2. In addition, experiments were run with either one or two 3 mm thick clear plexiglass sheets at the rear side of the Trombe wall prototype to investigate the effects of having better insulation at the “inside” of the Trombe wall (the air gap between the two clear sheets acted as an insulative layer). These clear plexiglass sheets at the rear side of the Trombe wall prototype were separated by 2.5 cm.

Eight type-K thermocouples were placed in different locations within the water thermal storage medium, as shown in

Figure 3. Thermocouples T

1 and T

7 were installed 2.5 cm away from the front (light-facing) side of the water storage medium at the top-center and bottom-center, respectively. Similarly, thermocouples T

2 and T

8 were installed close to the back side (2.5 cm away from the rear side at the center) at the top and bottom of the water container, respectively. Thermocouples T

3, T

4, and T

5 were mounted in the horizontal mid-plane of the water container at 2.5 cm, 7.5 cm, and 17.5 cm from the front of the container, respectively, and 15 cm from the top of the water storage medium. Thermocouple T

6 was mounted in the mid-plane of the container 2 cm from its right side (the side facing the door of the Trombe wall prototype, as shown in

Figure 1d) and 15 cm from the top. A Labjack data acquisition system (T7-Pro) was used to capture the readings from the thermocouples. Experiments were conducted to determine the temperature profiles over time for thermocouples T

1 through T

8 for four cases of different thermal storage medium configurations, as summarized in

Table 1.

Each experiment consisted of a charging period followed by a discharging period. The charging period was initiated by turning on the solar simulator lamp. The charging period lasted for 5 h and was completed by turning the lamp off. The temperature measurements were continued as the discharging phase proceeded with the lamp off. The total duration of each experiment was 24 h. The Trombe wall prototype door and vents were always closed for these experiments, which is the expected operating configuration for summer conditions.

The thermal storage efficiency of the Trombe wall prototype was estimated as the ratio of the thermal energy stored in the water-based storage medium at the end of the charging phase (when the light was switched off at the 5-h mark of the experiment) to the amount of light energy incident onto the plexiglass sheet at the front of the Trombe wall prototype. This thermal storage efficiency was expressed numerically in Equation (1):

where,

is the thermal energy stored in the water at the end of the charging phase and

is the total radiant energy incident onto the window of the Trombe wall prototype during the charging period. Equation (2) was used to estimate

:

where,

is the mass of the water in the storage medium,

is the specific heat of water, and

is the different between the average temperature of the water at the end and the beginning of the charging period. For Cases 2 and 4, wherein a tinted acrylic sheet was inserted into the water storage medium at its front face, the difference between the heat capacity of the acrylic in the water was not taken into consideration in the calculations (it was assumed the entire volume within the water container was occupied with water). This assumption was reasonable because the thickness of the tinted acrylic sheet was much less than that of the water storage medium (5 mm as compared to 20 cm). Furthermore,

was determined by first calculating the amount of thermal energy stored in the top and bottom halves of the water storage medium, and then summing the results together afterwards. The average temperature in top and bottom halves of the water storage medium were determined using Equations (3) and (4), respectively:

where

Ttop,

Tmiddle, and

Tbottom are the average measurements from the thermocouples located at the top, middle and bottom of the water storage medium, respectively.

Equation (5) was used to calculate

:

To calculate the average incident radiant energy from the solar-simulated light provided by the lamp, the plexiglass at the front of the Trombe wall prototype was considered to be divided into equal areas in a 3 × 3 mesh. The incident light intensity was then measured at the center of each of the nine areas in the mesh using a power meter (THORLABS, PM 100D), and the average of these measurements, which was 44.4 mW/cm2, was taken as the average incident radiation. The time used to calculate was five hours, which was the time during which the lamp was on during the charging phase. The area of the acrylic sheet at the front of the Trombe wall prototype (57.2 cm × 43.2 cm = 2468 cm2) was used as the area in Equation (5).

The power meter was also used to measure the amount of radiant energy that passed through the window at the rear side of the Trombe wall prototype. Furthermore, the error values on the thermal energy stored and the thermal efficiency, reported in

Table 2, were determined assuming the error on the thermocouple measurements was ±2.2 °C and the error on the power meter used to measure the light intensity was ±3% (these error values were in accordance with the technical specifications for the measuring devices used). The error on the other values used in the calculations (such as the area of the acrylic sheet, and the time the light was on) were much smaller in comparison and were assumed to be negligible.

4. Discussion

The highest thermal efficiency estimate in this work was 83.2% for Case 4 when the Trombe wall prototype had tinted glass in the thermal storage medium and two plexiglass sheets at its rear side. It was expected that the thermal efficiency of the Trombe wall could be increased by using a tinted acrylic sheet with a higher absorptance. However, increased absorptance would also reduce the amount of light entering the building. The absorptance of the Trombe wall could also be made to be adjustable to adapt to changing weather conditions throughout the year, such as when a higher absorptance is required during summer months to heat water and reduce the amount of sunlight entering and heating the building. This could be accomplished by making the tinted acrylic sheet removable or by using strips of tinted acrylic that could be rotated (similarly to vertical blinds) to control the portion of light entering the building. Alternatively, using electrochromic windows instead of tinted acrylic sheets is another potential method to control the trade-off between the amount of sunlight used for heating water or used for indoor lighting.

It could also be noted that the efficiencies of the Trombe wall for the four cases reported in this work, which ranged from 57.9 to 83.2%, were comparable to efficiencies reported in the literature. For example, Kara et al. reported an efficiency of 20–36% for a thermal storage wall comprised of PCMs [

21]. This efficiency was calculated as the ratio of the energy extracted from the PCM wall to the light energy incident onto the wall. Mohamad et al. defined the efficiency of a water-based Trombe wall as the ratio between the sum of the thermal energy absorbed by the water and the energy carried by the air divided by the amount of solar energy received by the system. Using this definition, the total efficiency was calculated to be greater than 80% for some cases [

18]. Zhang et al. calculated an efficiency of 73.5% for a Trombe wall with an aluminum plate absorber located within the air channel. This efficiency was defined as the amount of heat transferred to the air divided by the total radiant solar energy received by the Trombe wall [

22]. Hu et al. investigated a novel Trombe wall with blinds for shading and a water flowing channel that could be used to pre-heat water for building applications. The monthly average thermal efficiency was between 20% and 60% from April to September, and was 30% to 50% from December to March [

23].

The density of the water in the Trombe wall decreases as it is heated by the solar-simulated light, and the hotter water moves to the top of the thermal storage container. As shown in

Figure 4, the difference between the temperatures at the top and bottom of the water storage medium could be greater than 20 °C at the end of the charging period (e.g., for Cases 2 and 4). The capability of the water Trombe wall to move stored thermal energy to the top of the wall in the form of heated water allows for increased functionality that cannot be achieved using traditional Trombe wall materials. That is, the heated water at the top of the Trombe wall can be used for applications other than space heating, especially during the summer months. For example, it has been observed that dishwashers operate at temperatures as low as 38 °C, and comfortable temperatures for showering are between 37–40 °C. Furthermore, the recommended temperature in new washing machines for high efficiency is about 49 °C. Moreover, it is preferrable to store building water in hot water heaters at 60 °C or higher to minimize bacteria, although the water temperature at fixture outlets should be a maximum of 49 °C to prevent scalding injuries. Considering the inlet water temperature to building water tanks is typically less than 20 °C in the summer (and the temperature at the top of the Trombe wall prototype reached ~55 °C for the experiments reported in this work) the inlet water could be preheated in a water-based Trombe wall to help reduce water heating costs and energy consumption in buildings.