Numerical Assessment of the Structural Damage of a Composite Lining Water Conveyance Tunnel Subjected to Reverse Fault Conditions

Abstract

:1. Introduction

2. Numerical Modeling

2.1. Brief Introduction to Composite Lining Structures

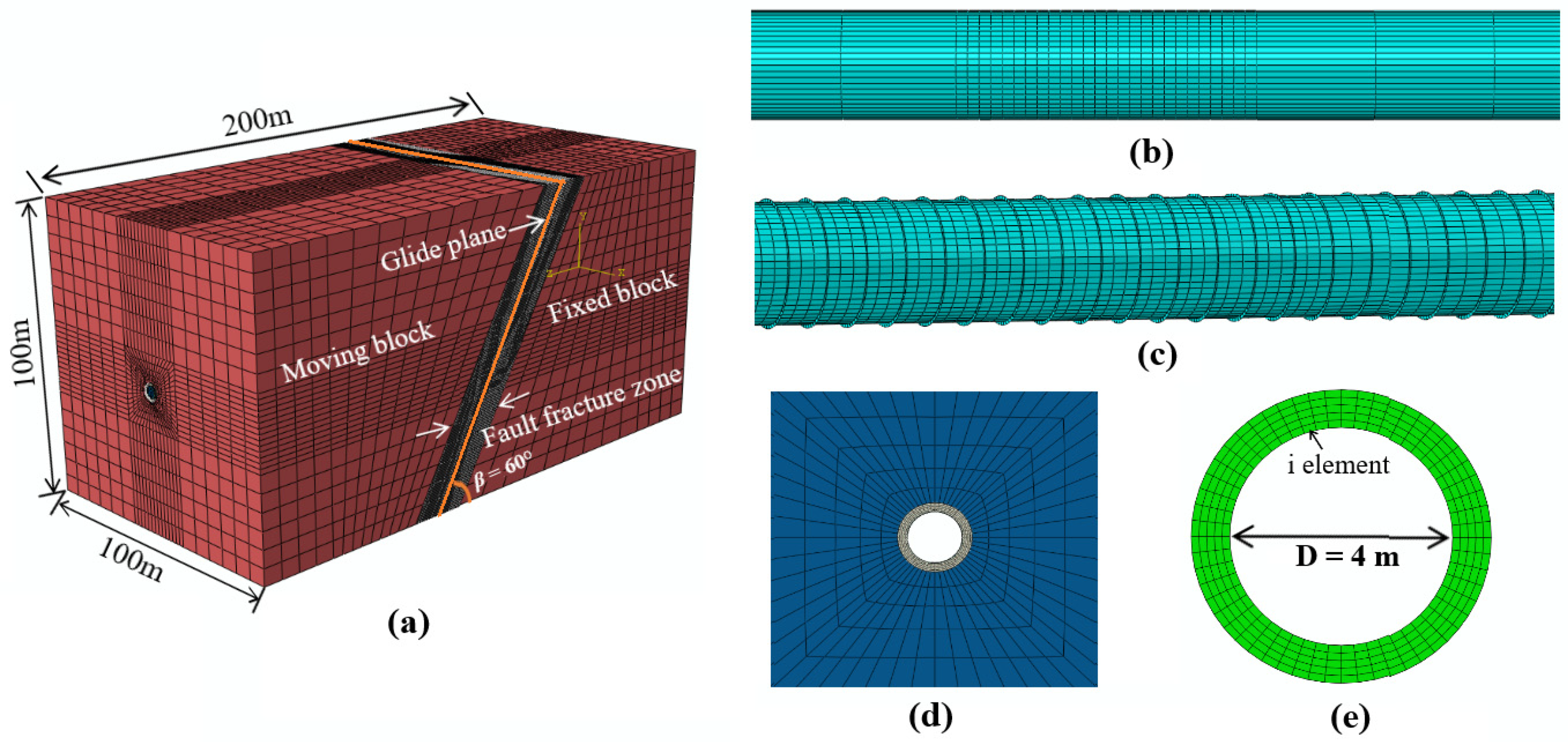

2.2. Numerical Modeling

2.3. Analysis Procedure and Boundary Conditions

3. Structural Damage Indicators

3.1. Overall Structural Damage Index of Concrete

3.2. Ultimate Strain of Steel Tube

- (1)

- Operable limit state (OL)

- (2)

- Pressure integrity limit state (PI)

- (3)

- Ultimate limit state (UL)

4. Numerical Case Studies

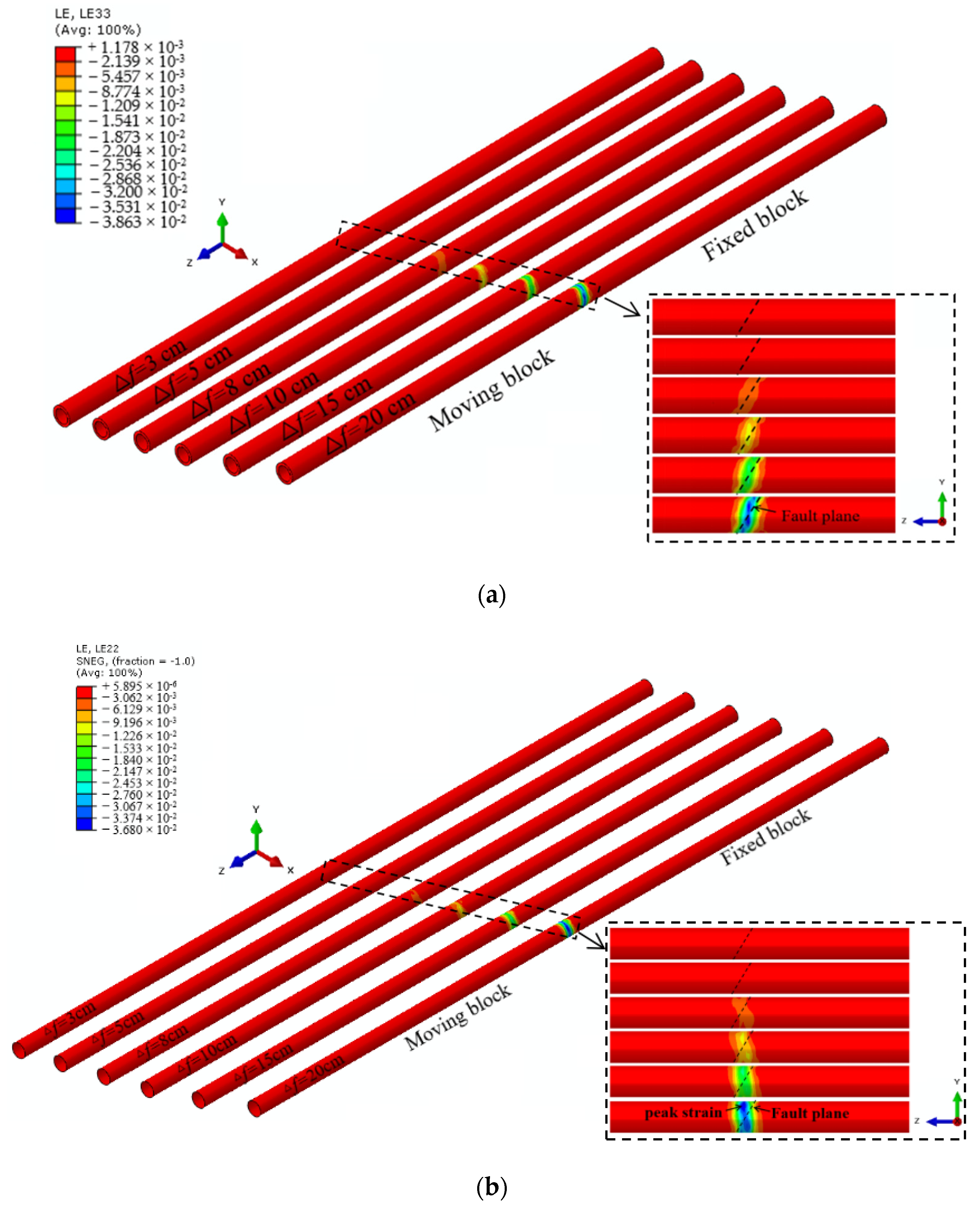

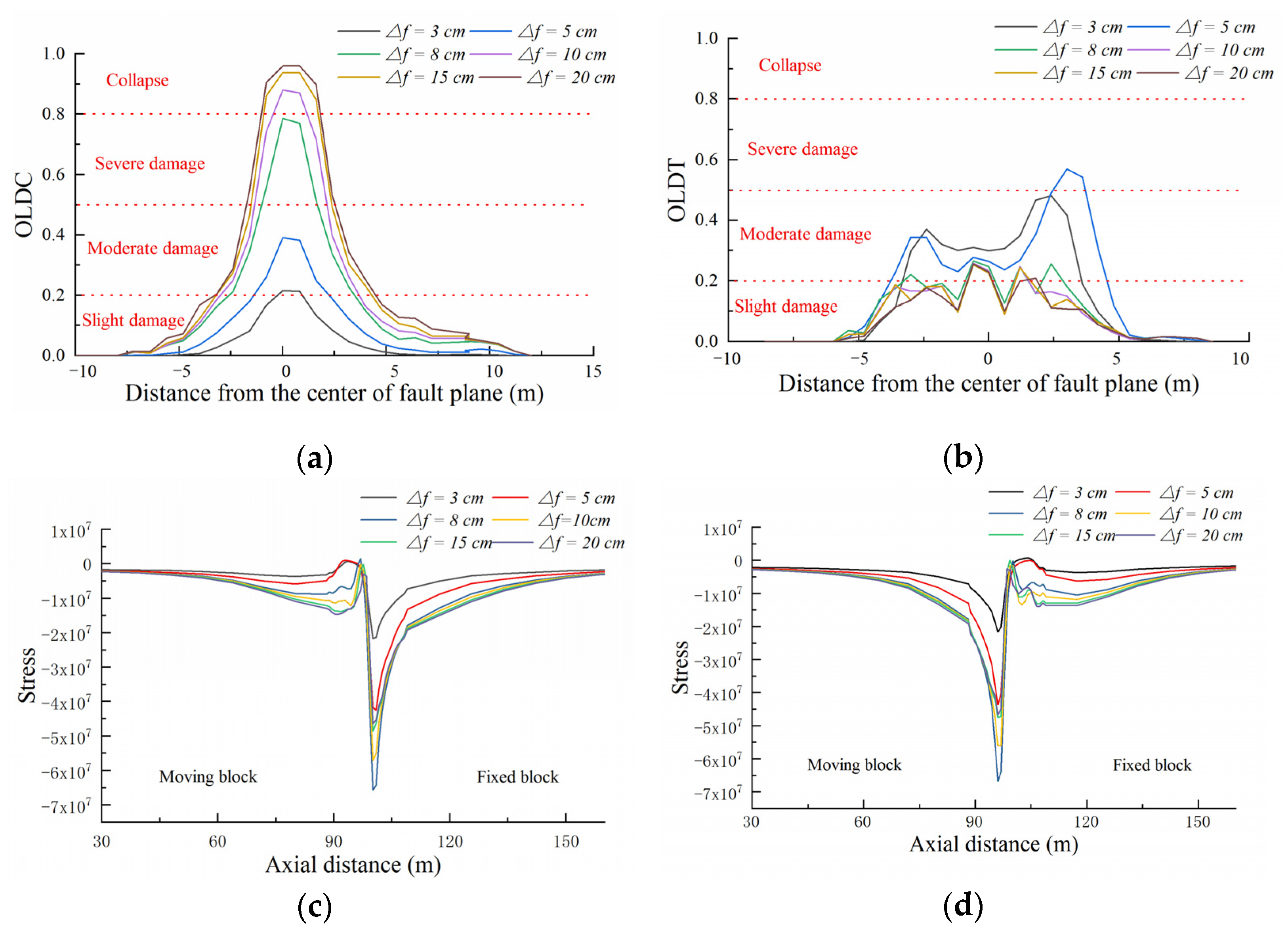

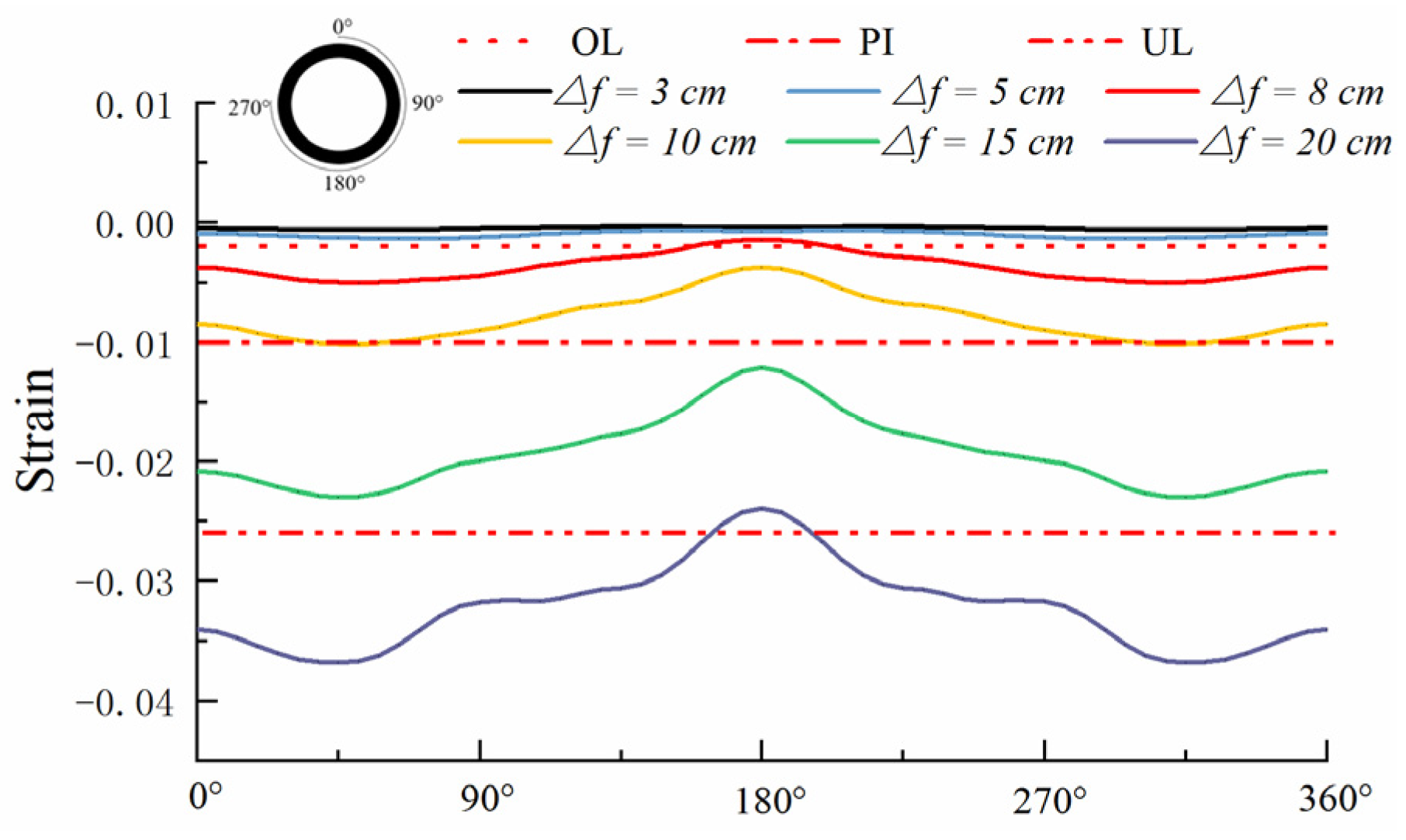

4.1. Effects of Fault Dislocation Displacement (Δf)

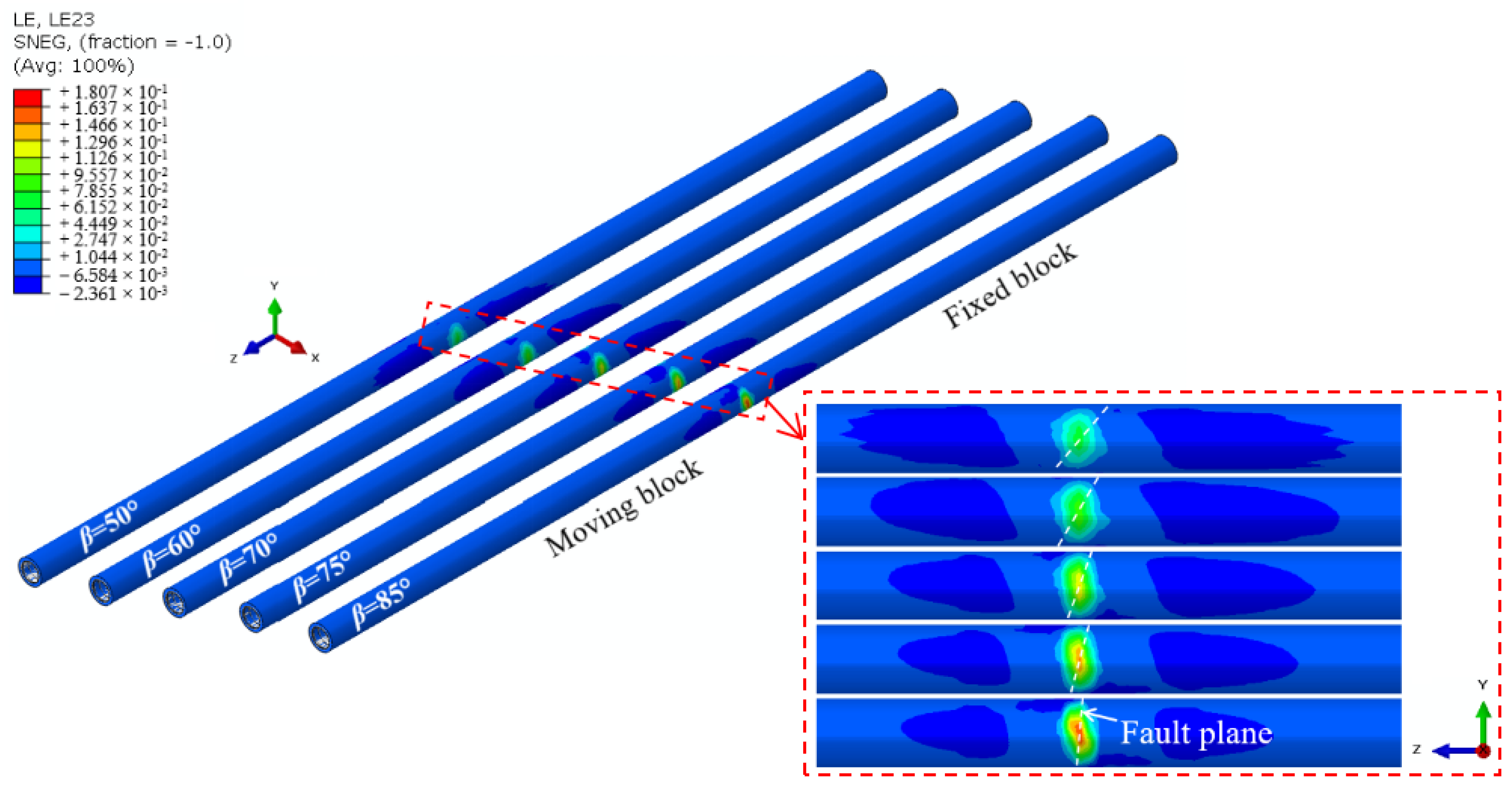

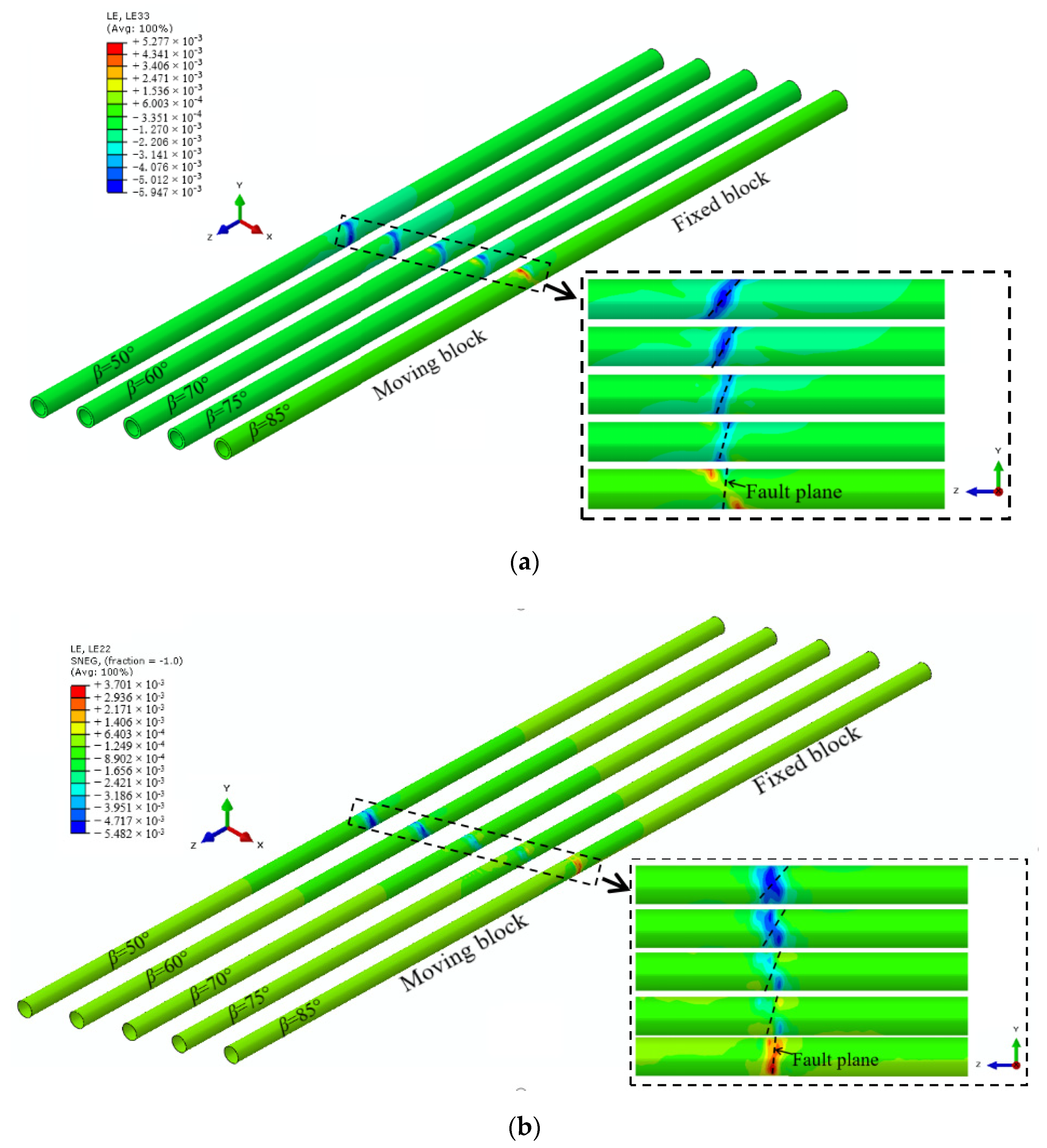

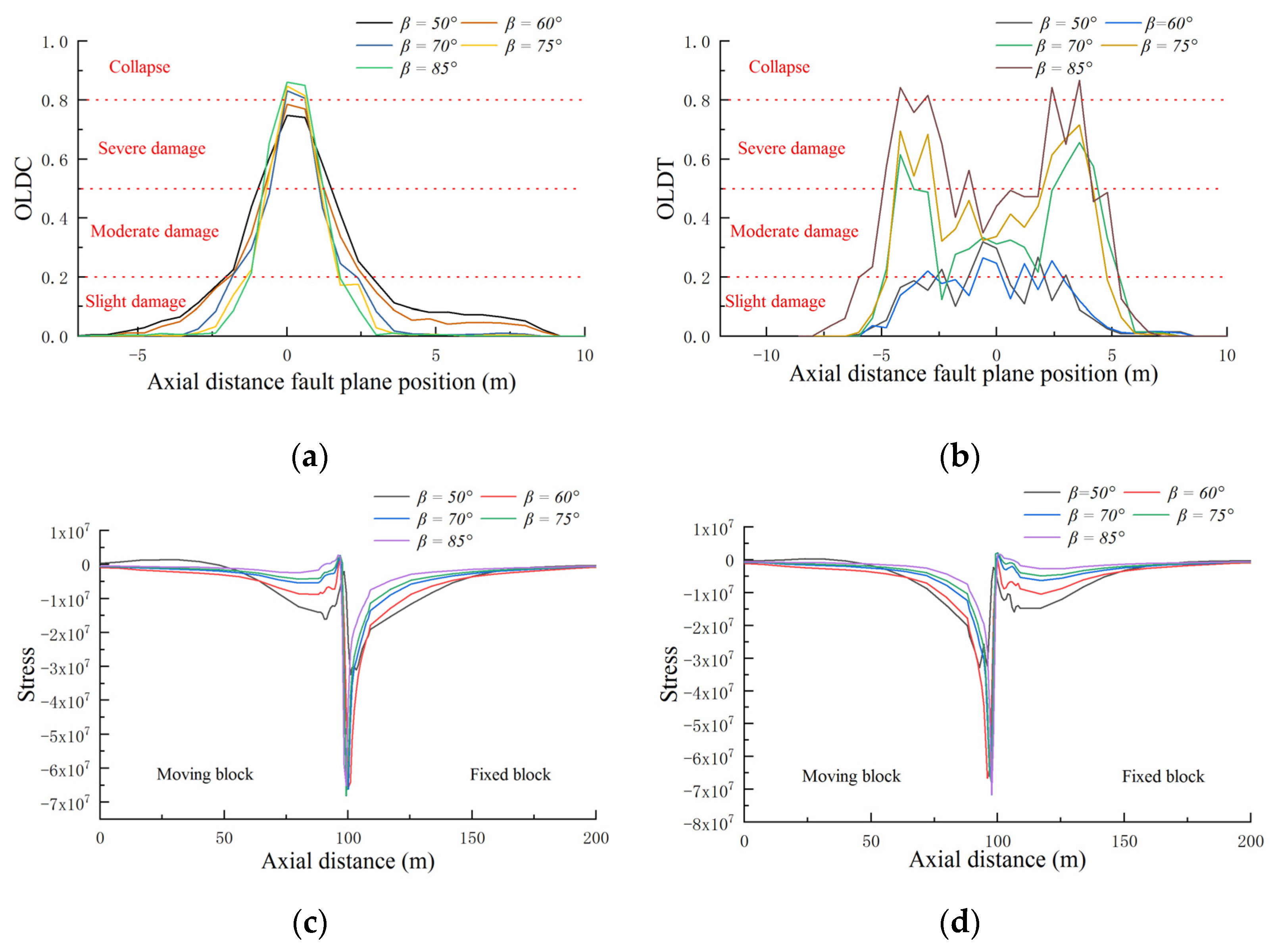

4.2. Effects of Fault Dip Angle (β)

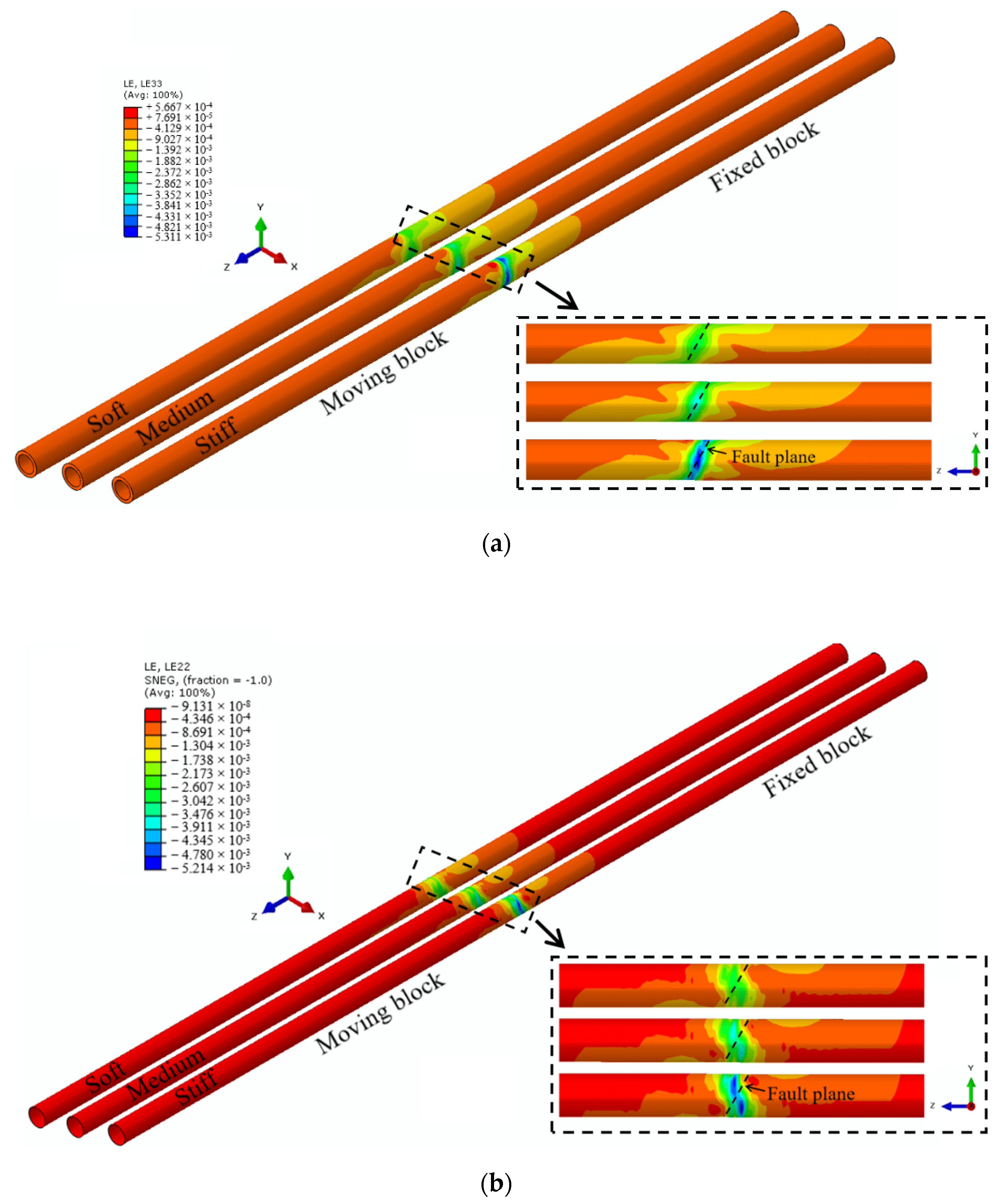

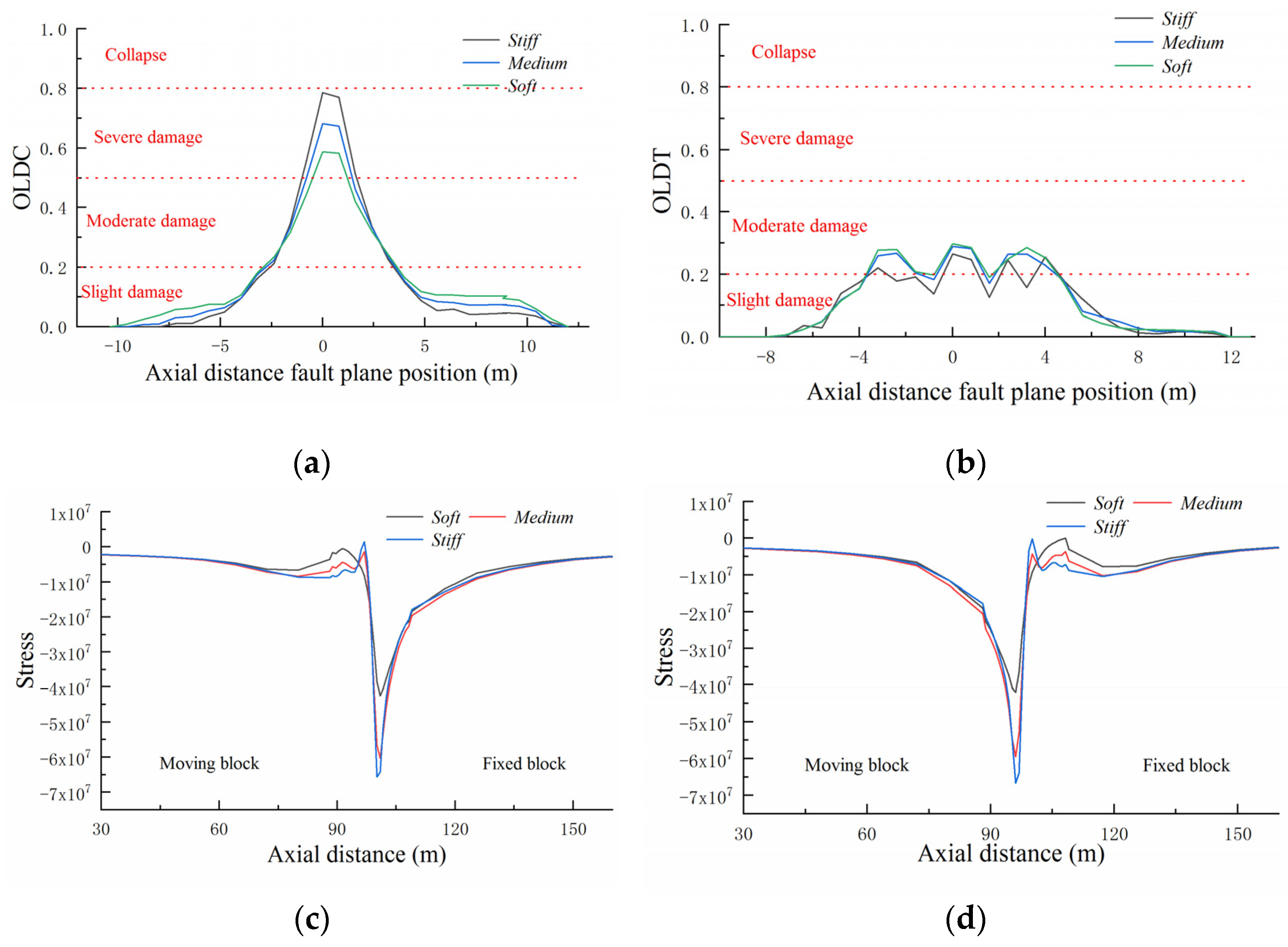

4.3. Effects of Mechanical Properties of Surrounding Rock Mass in the Fault Fracture Zone

5. Conclusions

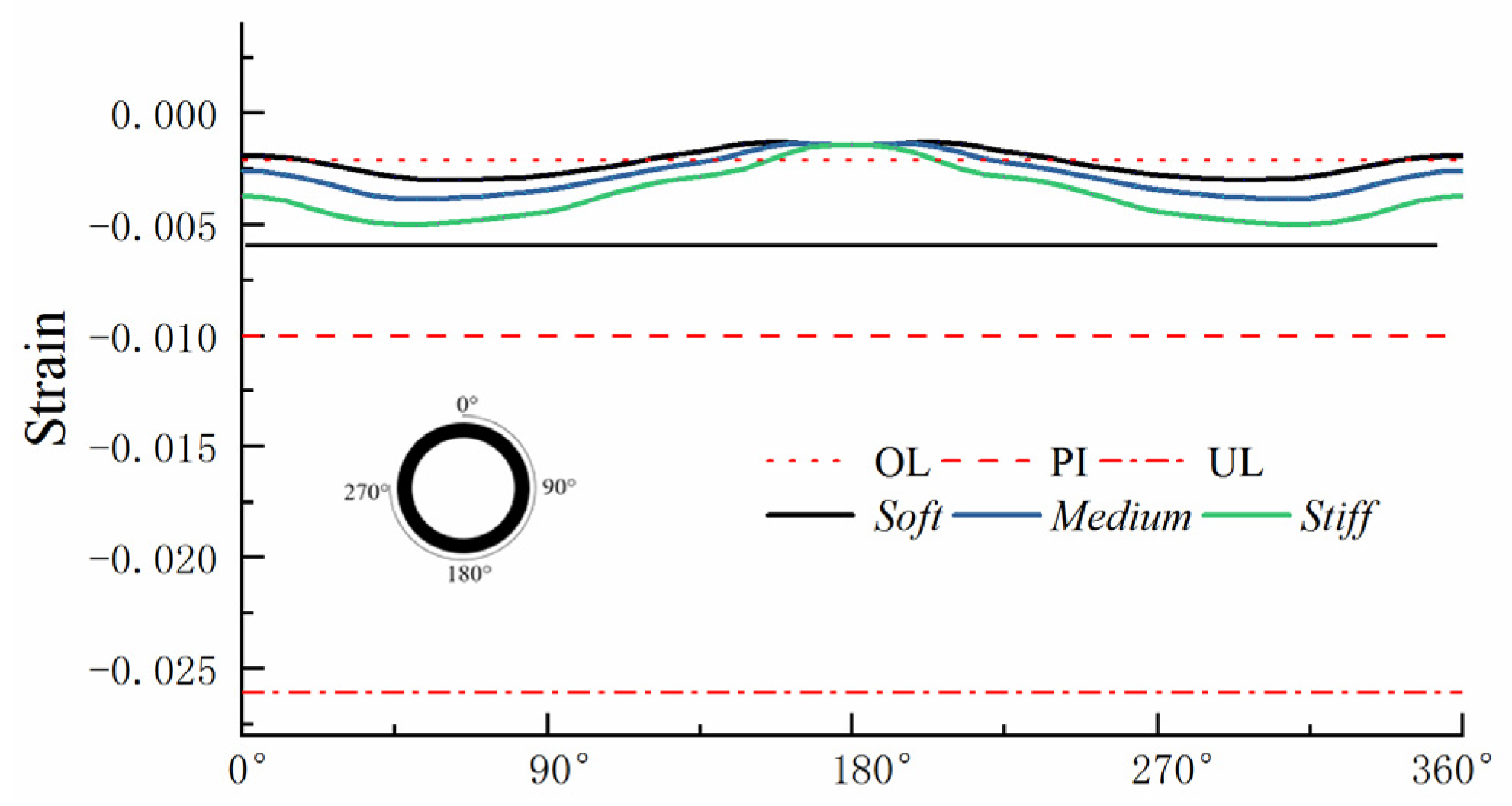

- Under reverse fault conditions, the composite lining structure is most severely damaged at the fault plane arch waist sidewall by the stresses of tension, compression, and shearing. Different from the failure forms of traditional water conveyance tunnels, the buckling failure of the steel tube lining under axial compressive strain is the dominant failure mode of the composite lining structure.

- Fault dislocation displacement is the main factor leading to the failure of composite lining water conveyance tunnels. When the dislocation displacement is small, the composite lining is mainly damaged by tensile and shear strains. With the increase in the dislocation displacement, the axial compressive stress increases significantly, thereby reducing the tensile damage of the concrete lining under fault dislocation; however, it increases the buckling deformation of the steel tube and aggravates the overall failure of the composite lining structure.

- As the fault dip angle increases, the composite lining water conveyance tunnel gradually changes from axial compression failure to combined bending and shear stress failure. Considering the damage degree and range of the composite lining, the structure is the safest when crossing the thrust fault fracture zone at β = 75°.

- The change in the surrounding rock properties of the fault fracture zone will not change the failure mode of the composite lining structure. However, the increase in rock stiffness in the fault fracture zone reduces the scope of damage while increasing the severity of structural damage to the composite lining.

6. Further Development

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kang, J.; Davidson, J. Structural effects of concrete lining for concrete-lined corrugated steel pipes. Struct. Infrastruct. Eng. 2013, 9, 130–140. [Google Scholar] [CrossRef]

- Yang, F.; Cao, S.; Qin, G. Performance of the Prestressed Composite Lining of a Tunnel: Case Study of the Yellow River Crossing Tunnel. Int. J. Civ. Eng. 2018, 16, 229–241. [Google Scholar] [CrossRef]

- Li, M.; Feng, X. Multisensor data fusion-based structural health monitoring for buried metallic pipelines under complicated stress states. J. Civ. Struct. Health Monit. 2022, 1–13. [Google Scholar] [CrossRef]

- Chen, J.; Feng, X.; Xiao, S. Leakage zone identifcation for water distribution networks based on the alarm levels of pressure sensors. J. Civ. Struct. Health Monit. 2022, 1–13. [Google Scholar] [CrossRef]

- Wang, W.; Wang, T.; Su, J.; Lin, C.; Seng, C.; Huang, T. Assessment of damage in mountain tunnels due to the Taiwan Chi-chi earthquake. Tunn. Undergr. Space Technol. 2001, 16, 133–150. [Google Scholar] [CrossRef]

- Yu, H.; Chen, J.; Bobet, A.; Yuan, Y. Damage observation and assessment of the Longxi tunnel during the Wenchuan earthquake. Tunn. Undergr. Space Technol. 2016, 54, 102–116. [Google Scholar] [CrossRef]

- Chen, Z.; Shi, C.; Li, T.; Yuan, Y. Damage characteristics and influence factors of mountain tunnels under strong earthquakes. Nat. Hazards 2012, 61, 387–401. [Google Scholar] [CrossRef]

- Lai, J.; He, S.; Qiu, J.; Chen, J.; Wang, L.; Wang, K.; Wang, J. Characteristics of seismic disasters and aseismic measures of tunnels in Wenchuan earthquake. Environ. Earth Sci. 2017, 76, 94. [Google Scholar] [CrossRef]

- Ong, D.E.L.; Choo, C.S. Back-analysis and finite element modeling of jacking forces in weathered rocks. Tunn. Undergr. Space Technol. 2016, 51, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Feng, X.; Zhao, L. Failure analysis of a buried large-diameter prestressed concrete cylinder pipeline subjected to strike-slip fault displacement. Tunn. Undergr. Space Technol. 2022, 121, 104334. [Google Scholar] [CrossRef]

- Zhai, K.; Fang, H.; Guo, C.; Fu, B.; Ni, P.; Ma, H.; He, H.; Wang, F. Mechanical properties of CFRP-strengthened prestressed concrete cylinder pipe based on multi-field coupling. Thin-Walled Struct. 2021, 162, 107629. [Google Scholar] [CrossRef]

- Lin, M.; Chung, C.; Jeng, F. Deformation of overburden soil induced by thrust fault slip. Eng. Geol. 2006, 88, 70–89. [Google Scholar] [CrossRef]

- Johansson, J.; Konagai, K. Fault induced permanent ground deformations—An experimental comparison of wet and dry soil and implications for buried structures. Soil Dyn. Earthq. Eng. 2006, 26, 45–53. [Google Scholar] [CrossRef]

- Bransby, M.; Davies, M.; El Nahas, A.; Nagaoka, S. Centrifuge modelling of reverse fault–foundation interaction. Bull. Earthq. Eng. 2008, 6, 607–628. [Google Scholar] [CrossRef]

- Baziar, M.; Nabizadeh, A.; Jung Lee, C.; Hung, W.Y. Centrifuge modeling of interaction between reverse faulting and tunnel. Soil Dyn. Earthq. Eng. 2014, 65, 151–164. [Google Scholar] [CrossRef]

- Tali, N.; Lashkaripour, G.; Hafezi Moghadas, N.; Ghalandarzadeh, A. Centrifuge modeling of reverse fault rupture propagation through single-layered and stratifified soil. Eng. Geol. 2019, 249, 273–289. [Google Scholar] [CrossRef]

- Jalali, H.; Rofooei, F.; Attari, N.; Samadian, M. Experimental and finite element study of the reverse faulting effects on buried continuous steel gas pipelines. Soil Dyn. Earthq. Eng. 2016, 86, 1–14. [Google Scholar] [CrossRef]

- Liu, X.; Li, X.; Sang, Y.; Lin, L. Experimental study on normal fault rupture propagation in loose strata and its impact on mountain tunnels. Tunn. Undergr. Space Technol. 2015, 49, 417–425. [Google Scholar] [CrossRef]

- Li, H.; Li, X.; Yang, Y.; Liu, Y.; Ma, M. Structural Stress Characteristics and Joint Deformation of Shield Tunnels Crossing Active Faults. Appl. Sci. 2022, 12, 3229. [Google Scholar] [CrossRef]

- Burridge, P.; Scott, R.; Hall, J. Centrifuge study of faulting effects on tunnel. J. Geotech. Eng. 1989, 115, 949–967. [Google Scholar] [CrossRef]

- Chang, Y.; Lee, C.; Huang, W.; Huang, W.J.; Lin, M.; Hung, W.; Lin, Y. Use of centrifuge experiments and discrete element analysis to model the reverse fault slip. Int. J. Civ. Eng. 2013, 11, 79–89. [Google Scholar]

- Kiani, M.; Akhlaghi, T.; Ghalandarzadeh, A. Experimental modeling of segmental shallow tunnels in alluvial affected by normal faults. Tunn. Undergr. Space Technol. 2016, 51, 108–119. [Google Scholar] [CrossRef]

- Sabagh, M.; Ghalandarzadeh, A. Centrifugal modeling of continuous shallow tunnels at active normal faults intersection. Transp. Geotech. 2020, 22, 100325. [Google Scholar] [CrossRef]

- Hu, B.; Fang, H.; Wang, F.; Zhai, K. Full-scale test and numerical simulation study on load-carrying capacity of prestressed concrete cylinder pipe (PCCP) with broken wires under internal water pressure. Eng. Fail. Anal. 2019, 104, 513–530. [Google Scholar] [CrossRef]

- Ni, P.; Moore, I.D.; Take, W.A. Numerical modeling of normal fault-pipeline interaction and comparison with centrifuge tests. Soil Dyn. Earthq. Eng. 2018, 105, 127–138. [Google Scholar] [CrossRef]

- Tohidifar, H.; Moosavi, M.; Jafari, M.K. Behavior of tunnels against the reverse faulting deformations using centrifuge test and numerical modelling. JSEE 2020, 2, 22–38. [Google Scholar]

- Russo, M.; Germani, G.; Amberg, W. Design and construction of large tunnel through active faults: A recent application. In Proceedings of the International Conference of Tunneling and Underground Space Use, Istanbul, Turkey, 16–18 October 2002. [Google Scholar]

- Yao, C.; He, C.; Takemura, J.; Feng, K.; Guo, D.; Huang, X. Active length of a continuous pipe or tunnel subjected to reverse faulting. Soil Dyn. Earthq. Eng. 2021, 148, 106825. [Google Scholar] [CrossRef]

- Monshizadeh Naeen, A.; Seyedi Hosseininia, E. Numerical Investigation on the Deformational Behavior of Continuous Buried Pipelines Under Reverse Faulting. Arab. J. Sci. Eng. 2020, 45, 8475–8490. [Google Scholar] [CrossRef]

- Baziar, M.; Nabizadeh, A.; Mehrabi, R.; Lee, C.; Hung, W. Evaluation of underground tunnel response to reverse fault rupture using numerical approach. Soil Dyn. Earthq. Eng. 2016, 83, 1–17. [Google Scholar] [CrossRef]

- Ghadimi Chermahini, A.; Tahghighi, H. Numerical finite element analysis of underground tunnel crossing an active reverse fault: A case study on the Sabzkouh segmental tunnel. Geomech. Geoeng. 2019, 14, 155–166. [Google Scholar] [CrossRef]

- Zhong, Z.; Wang, Z.; Zhao, M.; Du, X. Structural damage assessment of mountain tunnels in fault fracture zone subjected to multiple strike-slip fault movement. Tunn. Undergr. Space Technol. 2020, 104, 103527. [Google Scholar] [CrossRef]

- Gazetas, G.; Pecker, A.; Faccioli, E.; Paolucci, R.; Anastasopoulos, I. Preliminary design recommendations for dip-slip fault–foundation interaction. Bull. Earthq. Eng. 2008, 6, 677–687. [Google Scholar] [CrossRef]

- Sidoroff, F. Description of anisotropic damage application to elasticity. In Physical Non-Linearities in Structural Analysis; Springer: Berlin/Heidelberg, Germany, 1981; pp. 237–244. [Google Scholar]

- Zhao, Y.; Guo, E.; Liu, Z.; Gao, L. Damage analysis of urban metro tunnel under strike-slip fault. Rock Soil Mech. 2014, 35, 467–473. (In Chinese) [Google Scholar]

- ACI 318; Building Code Requirements for Structural Concrete: Commentary on Building Code Requirements for Structural Concrete. ACI Report; American Concrete Institute: Farmington Hills, MI, USA, 2019.

- Park, Y.; Ang, A.H.S. Mechanistic seismic damage model for reinforced concrete. Struct. Eng. 1985, 111, 722–739. [Google Scholar] [CrossRef]

- Bracci, J.; Reinhorn, A.; Mander, J.; Kunnath, S.K. Deterministic Model for Seismic Damage Evaluation of Reinforced Concrete Structures; NCEER-89-0033; National Center for Earthquake Engineering Research, State University of New York at Buffalo: Buffalo, NY, USA, 1989. [Google Scholar]

- Roufaiel, M.S.L.; Meyer, C. Reliability of concrete frames damaged by earthquakes. Struct. Eng. ASCE 1987, 113, 445–457. [Google Scholar] [CrossRef]

- Chen, Z.; Wei, J. Correlation between ground motion parameters and lining damage indices for mountain tunnels. Nat. Hazards 2013, 65, 1683–1702. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Z. Seismic damage classification and risk assessment of mountain tunnels with a validation for the 2008 Wenchuan earthquake. Soil Dyn. Earthq. Eng. 2013, 45, 45–55. [Google Scholar] [CrossRef]

- Federal Emergency Management Agency. Multi-Hazard Loss Estimation Methodology: Earthquake Model HAZUS-MH 2.1 User Manual; FEMA Mitigation Division: Washington, DC, USA, 2010. [Google Scholar]

- Liu, G.; Xiao, M.; Chen, J. Seismic performance assessment of tunnel structure based on incremental dynamic analysis. Adv. Eng. Sci. 2019, 51, 92–100. [Google Scholar]

- Shakib, H.; Jahangiri, V. Intensity measures for the assessment of the seismic response of buried steel pipelines. Bull. Earthq. Eng. 2016, 14, 1265–1284. [Google Scholar] [CrossRef]

- Jahangiri, V.; Shakib, H. Seismic risk assessment of buried steel gas pipelines under seismic wave propagation based on fragility analysis. Bull. Earthq. Eng. 2018, 16, 1571–1605. [Google Scholar] [CrossRef]

- Hashash, Y.M.A.; Hook, J.J.; Schmidt, B.; Yao, I.C. Seismic design and analysis of underground structures. Tunn. Undergr. Space Technol. 2001, 16, 247–293. [Google Scholar] [CrossRef]

- Ha, D.; Abdoun, T.H.; O’Rourke, M.J.; Symans, M.; O’Rourke, T.D.; Palmer, M.; Stewart, H. Earthquake faulting effects on buried pipelines-case history and centrifuge study. Earthq. Eng. 2010, 14, 646–669. [Google Scholar] [CrossRef]

- Ministry of Transport of the People’s Republic of China. JTG C20-2011: Code for Highway Engineering Geological Investigation; Communications Press: Beijing, China, 2011; p. 72. (In Chinese) [Google Scholar]

- Xing, Y.; Kulatilake, P.H.S.W.; Sandbak, L.A. Effect of rock mass and discontinuity mechanical properties and delayed rock supporting on tunnel stability in an underground mine. Eng. Geol. 2018, 238, 62–75. [Google Scholar] [CrossRef]

- Ministry of Transport of the People’s Republic of China. JTG/TD70-2010: Guidelines for Design of Highway Tunnel; Communications Press: Beijing, China, 2010. (In Chinese) [Google Scholar]

| Materials | Density (kg/m3) | Poisson’s Ratio | Elastic Modulus (GPa) | Cohesion (MPa) | Internal Friction Angle (°) |

|---|---|---|---|---|---|

| Rock mass | 2900 | 0.28 | 7.5 | 1.1 | 45 |

| Fault fracture zone | 2300 | 0.3 | 3.8 | 0.5 | 29 |

| Materials | Density (kg/m3) | Poisson’s Ratio | Elastic Modulus (GPa) | Ultimate Stress (MPa) | Compressive Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|---|---|---|---|

| Concrete | 2200 | 0.2 | 30 | - | 20.1 | 2.01 |

| Stiffened steel tubes | 7850 | 0.28 | 206 | 490 | 345 | 345 |

| Damage State | Overall Damage Index | Description of Damage States |

|---|---|---|

| Slight damage | 0~0.2 | Invisible cracks without need of repair; |

| Moderate damage | 0.2~0.5 | Microcracks develop into visible cracks with reduced bearing capacity; |

| Service break | 0.5~0.8 | Extensive cracking and local spalling; |

| collapse | 0.8~1 | Extensive spalling and loss of bearing capacity. |

| Damage State | Compressive Strain (εc) | Description of Damage States |

|---|---|---|

| No damage | εc ≤ 0.002 | Small plastic deformation occurs locally without need of repair; |

| Slight damage | 0.002 < εc ≤ 0.01 | Obvious plastic deformation occurs, but no leakage occurs; |

| Moderate damage | 0.01 < εc ≤ 0.026 | Severe plastic deformation occurs, there is a risk of leakage, and the tunnel operation needs to be interrupted for repair; |

| Severe damage | εc > 0.026 | Steel tube was damaged and there was a serious leak. |

| Surrounding Rock Classification | Density (kg/m−3) | Poisson’s Ratio | Elastic Modulus (GPa) | Cohesion (MPa) | Internal Frication Angle (°) |

|---|---|---|---|---|---|

| Soft | 2100 | 0.3 | 3.8 | 0.5 | 29 |

| Medium | 2300 | 0.3 | 5 | 0.7 | 37 |

| Stiff | 2900 | 0.28 | 7.5 | 1.1 | 45 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, X.; Feng, X. Numerical Assessment of the Structural Damage of a Composite Lining Water Conveyance Tunnel Subjected to Reverse Fault Conditions. Buildings 2022, 12, 1647. https://doi.org/10.3390/buildings12101647

Shi X, Feng X. Numerical Assessment of the Structural Damage of a Composite Lining Water Conveyance Tunnel Subjected to Reverse Fault Conditions. Buildings. 2022; 12(10):1647. https://doi.org/10.3390/buildings12101647

Chicago/Turabian StyleShi, Xinwei, and Xin Feng. 2022. "Numerical Assessment of the Structural Damage of a Composite Lining Water Conveyance Tunnel Subjected to Reverse Fault Conditions" Buildings 12, no. 10: 1647. https://doi.org/10.3390/buildings12101647

APA StyleShi, X., & Feng, X. (2022). Numerical Assessment of the Structural Damage of a Composite Lining Water Conveyance Tunnel Subjected to Reverse Fault Conditions. Buildings, 12(10), 1647. https://doi.org/10.3390/buildings12101647