Strength Performance of Different Mortars Doped Using Olive Stones as Lightweight Aggregate

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.1.1. Cement

2.1.2. Fine Aggregate

2.1.3. Olive Stone (GOS)

2.1.4. Potable Water

2.1.5. Release Agent

2.2. Mixed Design

2.3. Mixing and Casting Process

2.4. Testing Procedures

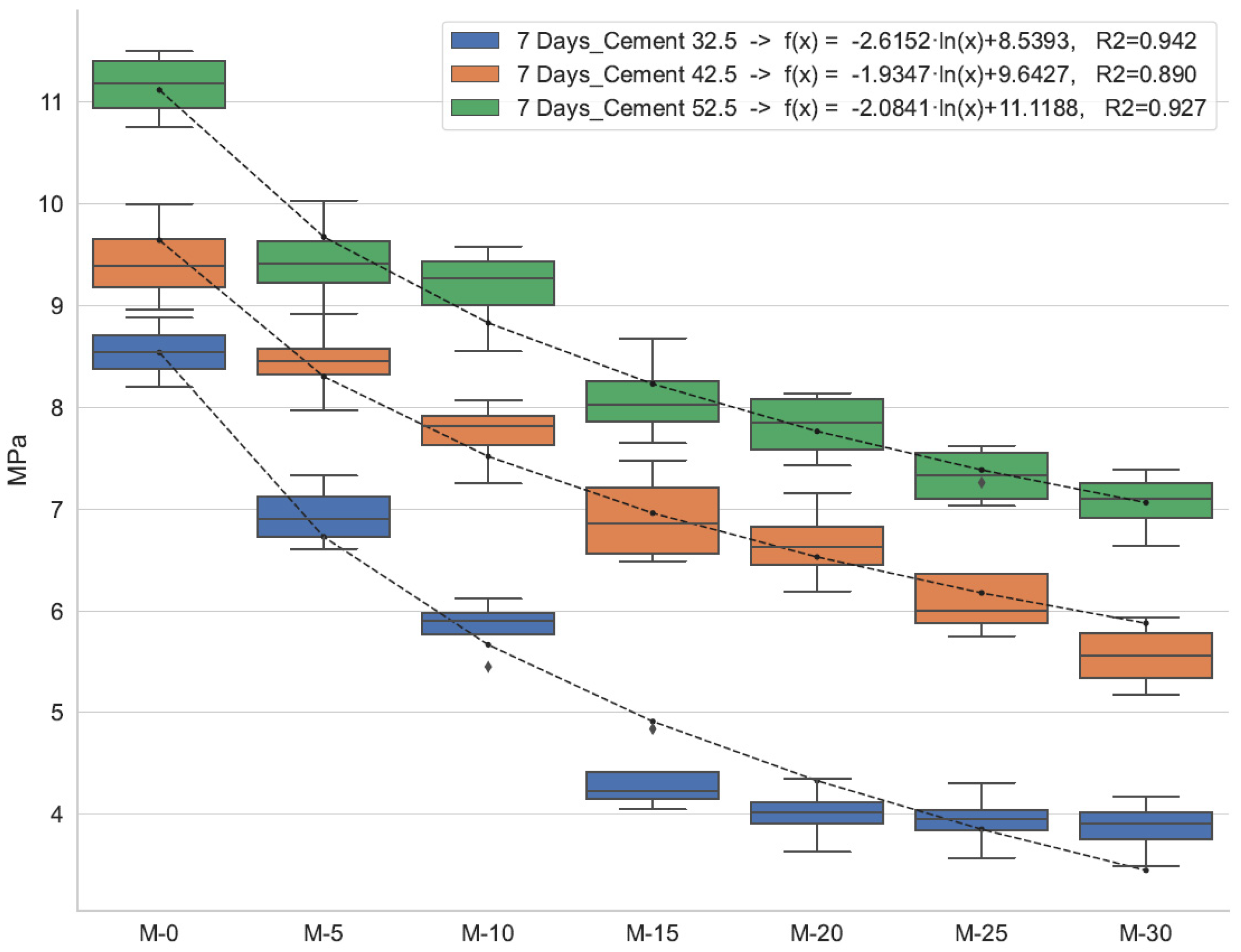

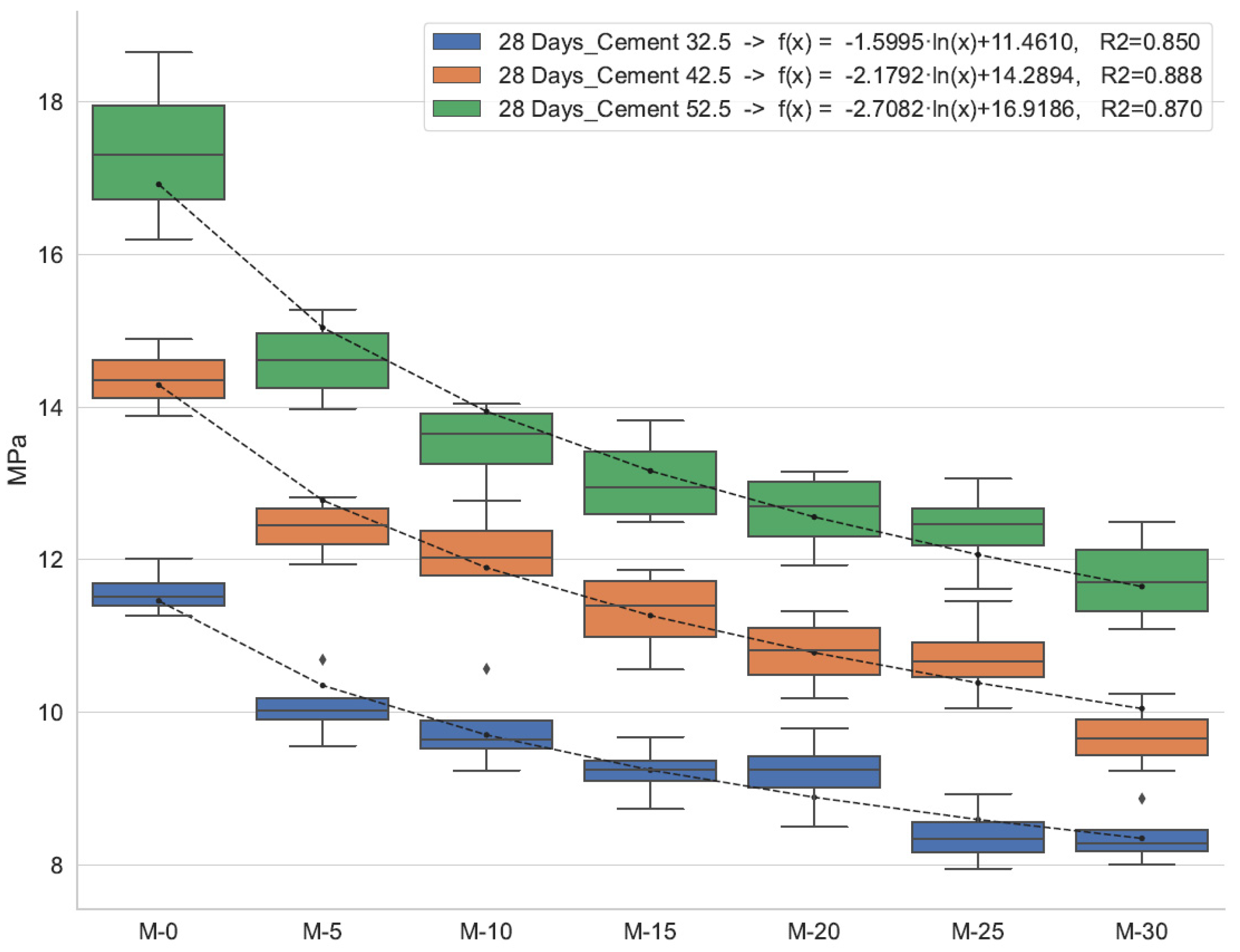

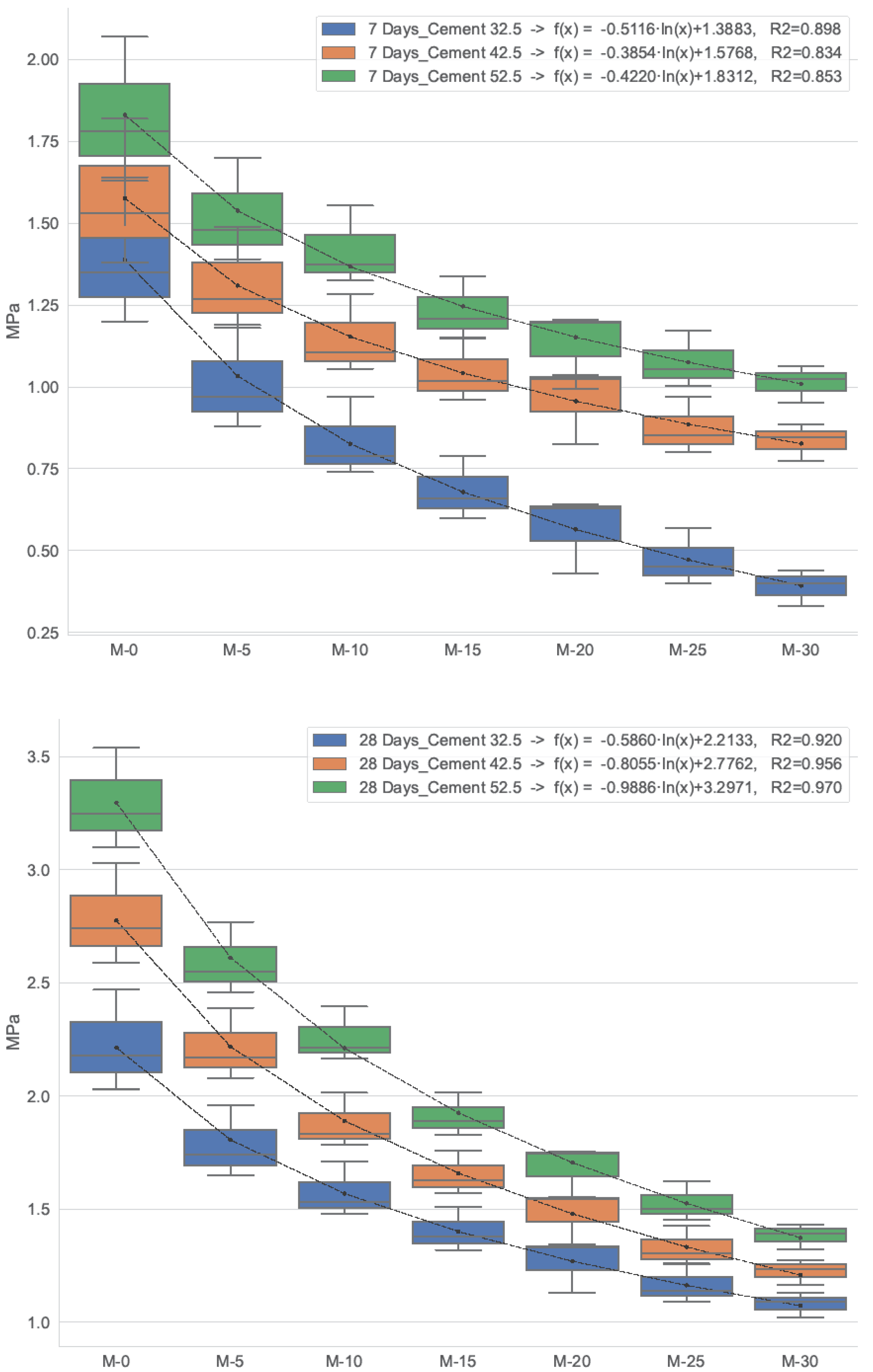

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Boufi, S. Biocomposites from olive-stone flour. In Lignocellulosic Fibre and Biomass-Based Composite Materials; Elsevier: Amsterdam, The Netherlands, 2017; pp. 387–408. [Google Scholar]

- Cuevas, M.; Sánchez, S.; García, J.F. Thermochemical and biochemical conversion of olive stones. In Agricultural Wastes: Char-acteristics, Types and Management; Nova Science Publishers: Hauppauge, NY, USA, 2015; pp. 61–85. [Google Scholar]

- Fokaides, P.A. Energy recovery alternatives of the olive oil industry byproducts. In European Biomass Conference and Exhibition Proceedings; ETA Florence Revewable Energies: Florence, Italy, 2018; Volume 2018, no. 26thEUBCE; pp. 83–87. [Google Scholar]

- Alshuiael, S.M.; Al-Ghouti, M.A. Multivariate analysis for FTIR in understanding treatment of used cooking oil using activated carbon prepared from olive stone. PLoS ONE 2020, 15, e0232997. [Google Scholar] [CrossRef] [PubMed]

- Ghouma, I.; Jeguirim, M.; Dorge, S.; Limousy, L.; Ghimbeu, C.M.; Ouederni, A. Activated carbon prepared by physical activa-tion of olive stones for the removal of NO2 at ambient temperature. Comptes Rendus Chim. 2015, 18, 63–74. [Google Scholar] [CrossRef]

- Corral Bobadilla, M.; Lostado Lorza, R.; Somovilla Gómez, F.; Escribano García, R. Adsorptive of Nickel in Wastewater by Olive Stone Waste: Optimization through Multi-Response Surface Methodology Using Desirability Functions. Water 2020, 12, 1320. [Google Scholar] [CrossRef]

- Martín-Lara, M.A.; Blázquez, G.; Trujillo, M.C.; Pérez, A.; Calero, M. New treatment of real electroplating wastewater containing heavy metal ions by adsorption onto olive stone. J. Clean. Prod. 2014, 81, 120–129. [Google Scholar] [CrossRef]

- La Rubia-García, M.D.; Yebra-Rodríguez, Á.; Eliche-Quesada, D.; Corpas-Iglesias, F.A.; López-Galindo, A. Assessment of olive mill solid residue (pomace) as an additive in lightweight brick production. Constr. Build. Mater. 2012, 36, 495–500. [Google Scholar] [CrossRef]

- Eliche-Quesada, D.; Felipe-Sesé, M.A.; Infantes-Molina, A. Evaluation of fly and bottom ash of different biomass combustion as raw materials in clay-based ceramics. In Ceramic Materials: Synthesis, Performance and Applications; Nova Science Publishers, Inc.: Hauppauge, NY, USA, 2017; pp. 1–32. [Google Scholar]

- Quaranta, N.E.; Caligaris, M.G.; Unsen, M.A.; López, H.A.; Pelozo, G.G.; Cristóbal, A.A. Residual biomass of the agricultural industry as pore forming material in ceramics. In Municipal and Industrial Waste: Sources, Management Practices and Future Challenges; Nova Science Publishers, Inc.: Hauppauge, NY, USA, 2018; pp. 249–264. [Google Scholar]

- Arezki, S.; Chelouah, N.; Tahakourt, A. The effect of the addition of ground olive stones on the physical and mechanical proper-ties of clay bricks. Mater. Construcción 2016, 66, e082. [Google Scholar] [CrossRef] [Green Version]

- Djadouf, S.; Chelouah, N.; Tahakourt, A. Influence de la distribution en taille (broyat de noyaux d’olive) sur les propriétés de la brique. Matériaux Tech. 2019, 107, 403. [Google Scholar] [CrossRef]

- Bories, C.; Aouba, L.; Vedrenne, E.; Vilarem, G. Fired clay bricks using agricultural biomass wastes: Study and characterization. Constr. Build. Mater. 2015, 91, 158–163. [Google Scholar] [CrossRef] [Green Version]

- Serrano, S.; Barreneche, C.; Cabeza, L.F. Use of by-products as additives in adobe bricks: Mechanical properties characterisation. Constr. Build. Mater. 2016, 108, 105–111. [Google Scholar] [CrossRef] [Green Version]

- Djadouf, S.; Chelouah, N.; Tahakourt, A. The influence of the addition of ground olive stone on the thermo-mechanical behavior of compressed earth blocks. Matériaux Tech. 2020, 108, 203. [Google Scholar] [CrossRef]

- Sodupe-Ortega, E.; Fraile-Garcia, E.; Ferreiro-Cabello, J.; Sanz-Garcia, A. Evaluation of crumb rubber as aggregate for auto-mated manufacturing of rubberized long hollow blocks and bricks. Constr. Build. Mater. 2016, 106, 305–316. [Google Scholar] [CrossRef] [Green Version]

- Adelusi, E.; Ajala, O.; Afolabi, R.; Olaoye, K. Strength and dimensional stability of cement-bonded wood waste-sand bricks. J. For. Sci. 2021, 67, 545–552. [Google Scholar] [CrossRef]

- El-Nadoury, W.W. Production of sustainable concrete using sawdust. Mag. Civ. Eng. 2021, 105, 66–74. [Google Scholar] [CrossRef]

- Hasan, M.; Saidi, T.; Afifuddin, M. Mechanical properties and absorption of lightweight concrete using lightweight aggre-gate from diatomaceous earth. Constr. Build. Mater. 2021, 277, 122324. [Google Scholar] [CrossRef]

- Manjunatha, M.; Seth, D.; Balaji, K.V.G.D.; Chilukoti, S. Influence of PVC waste powder and silica fume on strength and microstructure prop-erties of concrete: An experimental study. Case Stud. Constr. Mater. 2021, 15, e00610. [Google Scholar] [CrossRef]

- De Moraes Pinheiro, S.M.; Font, A.; Soriano, L.; Tashima, M.M.; Monzó, J.; Borrachero, M.V.; Payá, J. Olive-stone biomass ash (OBA): An alternative alkaline source for the blast furnace slag activation. Constr. Build. Mater. 2018, 178, 327–338. [Google Scholar] [CrossRef] [Green Version]

- Font, A.; Soriano, L.; de Moraes Pinheiro, S.M.; Tashima, M.M.; Monzó, J.; Borrachero, M.V.; Payá, J. Design and properties of 100% waste-based ternary alkali-activated mortars: Blast furnace slag, olive-stone bio-mass ash and rice husk ash. J. Clean. Prod. 2020, 243, 118568. [Google Scholar] [CrossRef]

- Font, A.; Soriano, L.; Moraes, J.; Tashima, M.; Monzó, J.; Borrachero, M.; Payá, J. A 100% waste-based alkali-activated material by using olive-stone biomass ash (OBA) and blast furnace slag (BFS). Mater. Lett. 2017, 203, 46–49. [Google Scholar] [CrossRef] [Green Version]

- Cuenca, J.; Rodríguez, J.; Martín-Morales, M.; Sánchez-Roldán, Z.; Zamorano, M. Effects of olive residue biomass fly ash as filler in self-compacting concrete. Constr. Build. Mater. 2013, 40, 702–709. [Google Scholar] [CrossRef]

- Font, A.; Soriano, L.; Tashima, M.M.; Monzó, J.; Borrachero, M.V.; Payá, J. One-part eco-cellular concrete for the precast industry: Functional features and life cycle assessment. J. Clean. Prod. 2020, 269, 122203. [Google Scholar] [CrossRef]

- Brasileiro, G.A.M.; Vieira, J.A.R.; Barreto, L.S. Use of coir pith particles in composites with Portland cement. J. Environ. Manag. 2013, 131, 228–238. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; He, T.; Zhou, Y.; Tang, S.; Tan, J.; Liu, Z.; Su, J. The influence of fiber type and length on the cracking resistance, durability and pore structure of face slab con-crete. Constr. Build. Mater. 2021, 282, 122706. [Google Scholar] [CrossRef]

- Wang, L.; Guo, F.; Yang, H.; Wang, Y.A.N.; Tang, S. Comparison of fly ash, PVA fiber, MGO and shrinkage-reducing admix-ture on the frost resistance of face slab concrete via pore structural and fractal analysis. Fractals 2021, 29, 1–18. [Google Scholar] [CrossRef]

- Del Río Merino, M.; Rodríguez, J.G.; Martínez, F.F.; Astorqui, J.S.C. Viability of using olive stones as lightweight aggregate in construction mortars. Rev. Constr. 2017, 16, 431–438. [Google Scholar] [CrossRef] [Green Version]

- MAbdulkarem, A.; Rasool, D.A.; Nabhan, B.J. Utilization of olive and pumice stones to improve the thermal properties of cement mortar. Int. J. Nanoelectron. Mater. 2020, 13, 181–188. [Google Scholar]

- Barreca, F.; Fichera, C.R. Use of olive stone as an additive in cement lime mortar to improve thermal insulation. Energy Build. 2013, 62, 507–513. [Google Scholar] [CrossRef]

- AEN/CTN 146-ÁRIDOS, UNE-EN 933-1; Tests for Geometrical Properties of Aggregates—Part 1: Determination of Particle Size Distribution—Sieving Method. AENOR: Madrid, Spain, 2012.

- AEN/CTN 83, EN 12350-2; Testing Fresh Concrete—Part 2: Slump-Test. AENOR: Madrid, Spain, 2020.

- CTN 83-HORMIGÓN, UNE-EN 12390-2; Testing Hardened Concrete—Part 2: Making and Curing Specimens for Strength Tests. AENOR: Madrid, Spain, 2020.

- CTN 83-HORMIGÓN. UNE-EN 12390-3; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. AENOR: Madrid, Spain, 2020.

- CTN 83-HORMIGÓN. UNE-EN 12390-5; Testing Hardened Concrete—Part 5: Flexural Strength of Test Specimens. AENOR: Madrid, Spain, 2020.

| CEM II/B-M (V-L) 32.5 R | CEM II/B-M (V-S-LL) 42.5 R | CEM I 52.5 R | |||||

|---|---|---|---|---|---|---|---|

| Regulation | Standard | Regulation | Standard | Regulation | Standard | ||

| Components | Clinker (%) | 65–79 | 70 | 65–79 | 76 | 95–100 | 95 |

| Limestone (L) (%) | 21–35 | 14 | 21–35 | 8 | - | 5 | |

| Pozzolana (P) (%) | - | - | - | - | - | - | |

| Fly ash (V) (%) | 21–35 | 16 | 21–35 | 8 | - | - | |

| Steel slag (S) (%) | - | - | 21–35 | 8 | - | - | |

| Setting regulator, gypsum (%) | - | 4 | - | 2 | - | 5 | |

| Chemical | Chemical sulfur trioxide (SO3) (%) | 3.5 max. | 2.6 | 4 max. | 3.1 | 4 max. | 2.9 |

| Chlorides (Cl−) (%) | 0.1 max. | 0.01 | 0.1 max. | 0.03 | 0.1 max. | 0.01 | |

| Loss on ignition (%) | - | - | - | - | 5 max. | 2.6 | |

| Insoluble residue (%) | - | - | - | - | 5 max. | 0.6 | |

| Physical | Blaine specific surface (cm2/g) | - | 4000 | - | 3682 | - | 4800 |

| Le Chatelier expansion (mm) | 10 max. | 0 | 10 max. | 1 | 10 max. | 1 | |

| Setting start time (min) | 75 | 195 | 60 | 200 | 45 | 110 | |

| Final setting time (min) | - | 250 | - | 270 | - | 155 | |

| Mechanical | Compression day 1 (MPa) | - | 13 | - | 17 | - | 27 |

| Compression day 2 (MPa) | - | 20 | - | 28 | - | 42 | |

| Compression day 7 (MPa) | - | 34 | - | 42 | - | 50 | |

| Compression day 28 (MPa) | 32.5–52.5 | 45 | 42.5–62.5 | 55 | 52.5 | 63 | |

| Chemical composition | C (%) | 50.2 |

| O (%) | 45.2 | |

| H (%) | 7.02 | |

| N (%) | 0.47 | |

| S (%) | 0.04 | |

| By component | Lignin (%) | 32.1 |

| Hemicellulose (%) | 34.8 | |

| Cellulose (%) | 26.9 | |

| Soluble (%) | 5.4 | |

| Ash (%) | 0.8 |

| Mixture Name | GOS (%) | Cement (kg) | Fine Aggregate (kg) | GOS (kg) |

|---|---|---|---|---|

| M-0 | 0 | 8 | 40 | 0 |

| M-5 | 5 | 8 | 38 | 0.71 |

| M-10 | 10 | 8 | 36 | 1.42 |

| M-15 | 15 | 8 | 34 | 2.10 |

| M-20 | 20 | 8 | 32 | 2.83 |

| M-25 | 25 | 8 | 30 | 3.54 |

| M-30 | 30 | 8 | 28 | 4.30 |

| M-50 | 50 | 8 | 20 | 7.08 |

| M-100 | 100 | 8 | 0 | 14.20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferreiro-Cabello, J.; Fraile-Garcia, E.; Pernia-Espinoza, A.; Martinez-de-Pison, F.J. Strength Performance of Different Mortars Doped Using Olive Stones as Lightweight Aggregate. Buildings 2022, 12, 1668. https://doi.org/10.3390/buildings12101668

Ferreiro-Cabello J, Fraile-Garcia E, Pernia-Espinoza A, Martinez-de-Pison FJ. Strength Performance of Different Mortars Doped Using Olive Stones as Lightweight Aggregate. Buildings. 2022; 12(10):1668. https://doi.org/10.3390/buildings12101668

Chicago/Turabian StyleFerreiro-Cabello, Javier, Esteban Fraile-Garcia, Alpha Pernia-Espinoza, and Francisco Javier Martinez-de-Pison. 2022. "Strength Performance of Different Mortars Doped Using Olive Stones as Lightweight Aggregate" Buildings 12, no. 10: 1668. https://doi.org/10.3390/buildings12101668

APA StyleFerreiro-Cabello, J., Fraile-Garcia, E., Pernia-Espinoza, A., & Martinez-de-Pison, F. J. (2022). Strength Performance of Different Mortars Doped Using Olive Stones as Lightweight Aggregate. Buildings, 12(10), 1668. https://doi.org/10.3390/buildings12101668