In-Plane Lateral Performance of AAC Block Walls Reinforced with CFPR Sheets

Abstract

:1. Introduction and Background

2. Research Methodology

3. Performance of the AAC Blocks

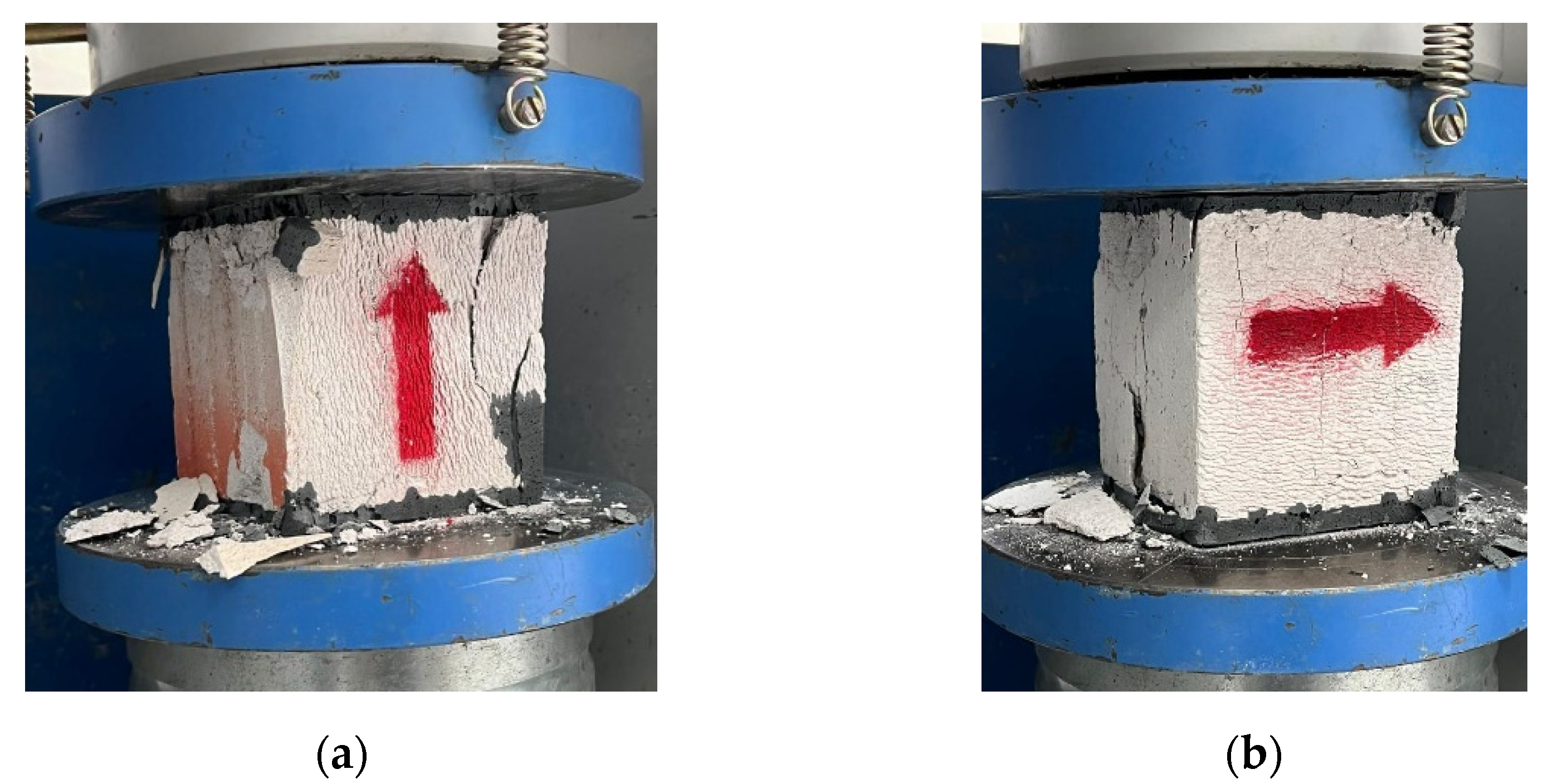

3.1. Compressive Strength

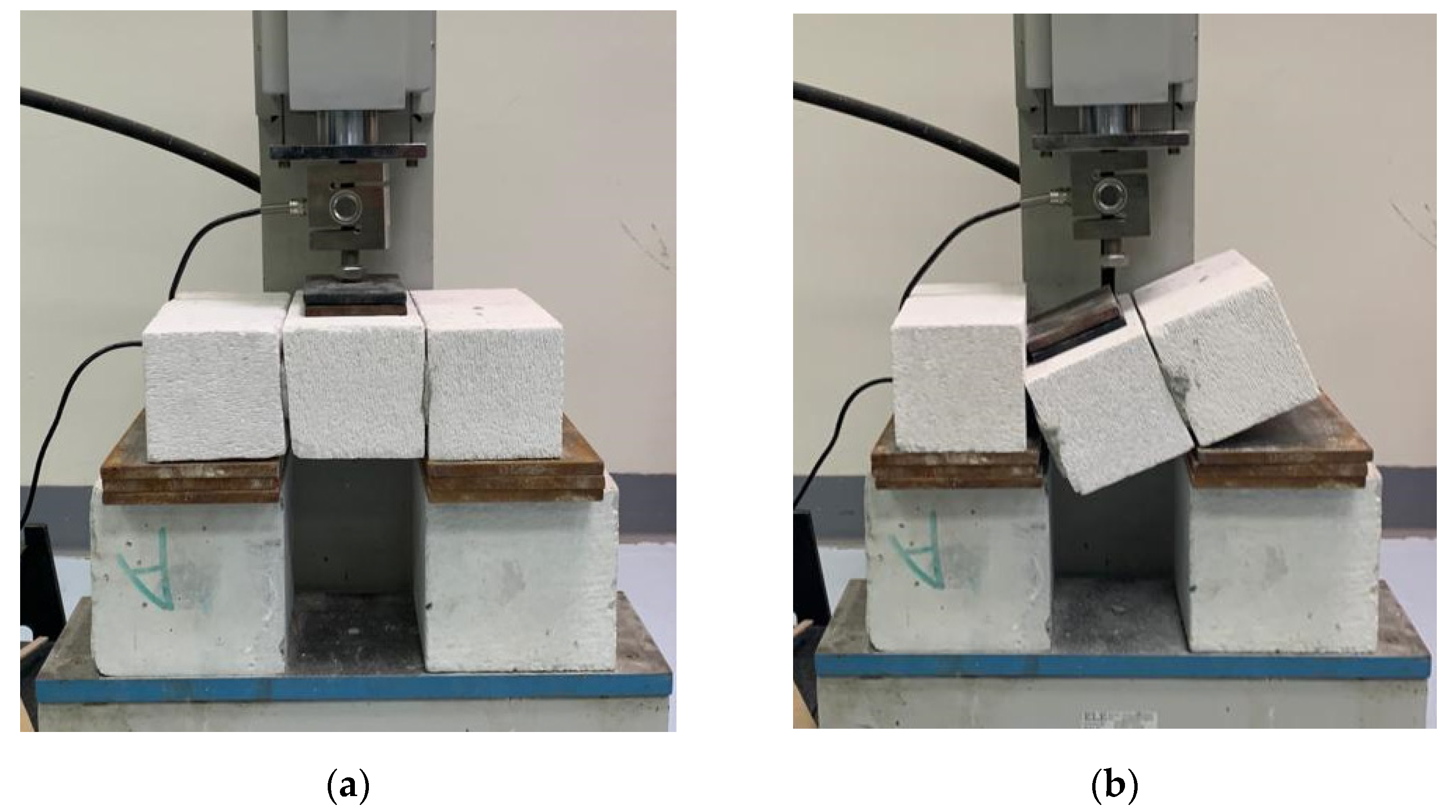

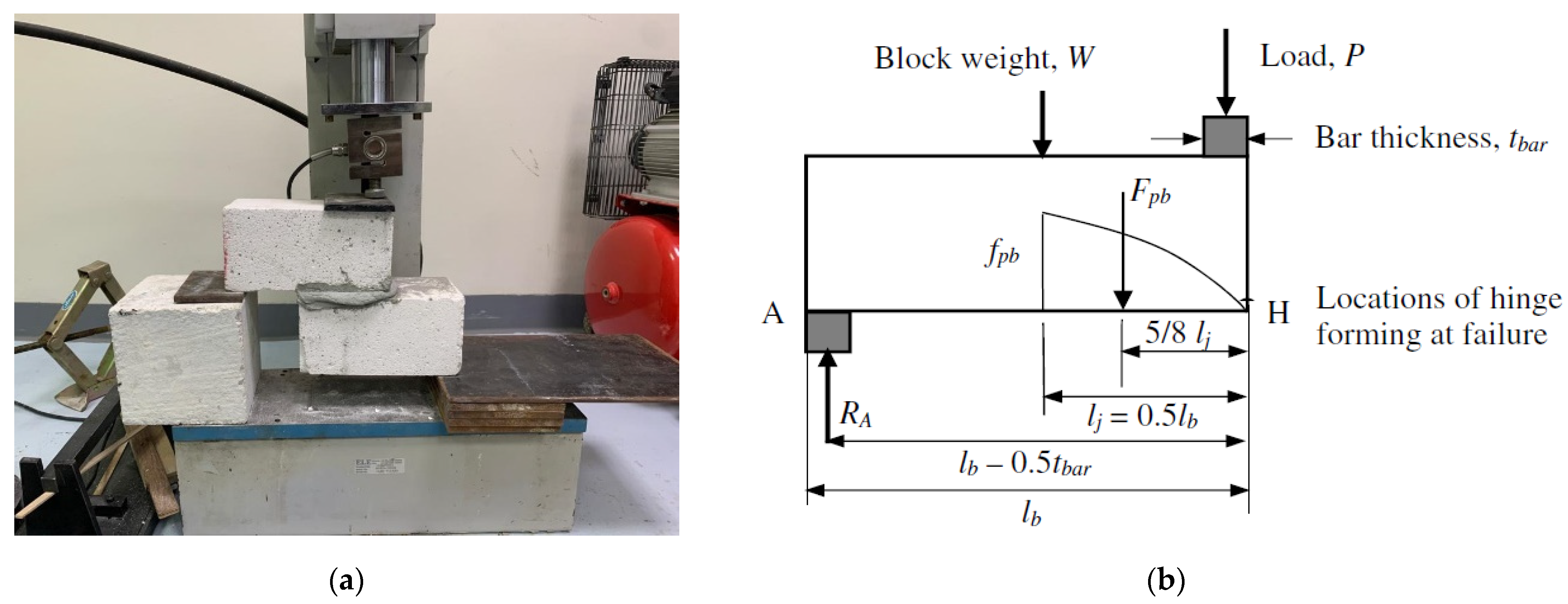

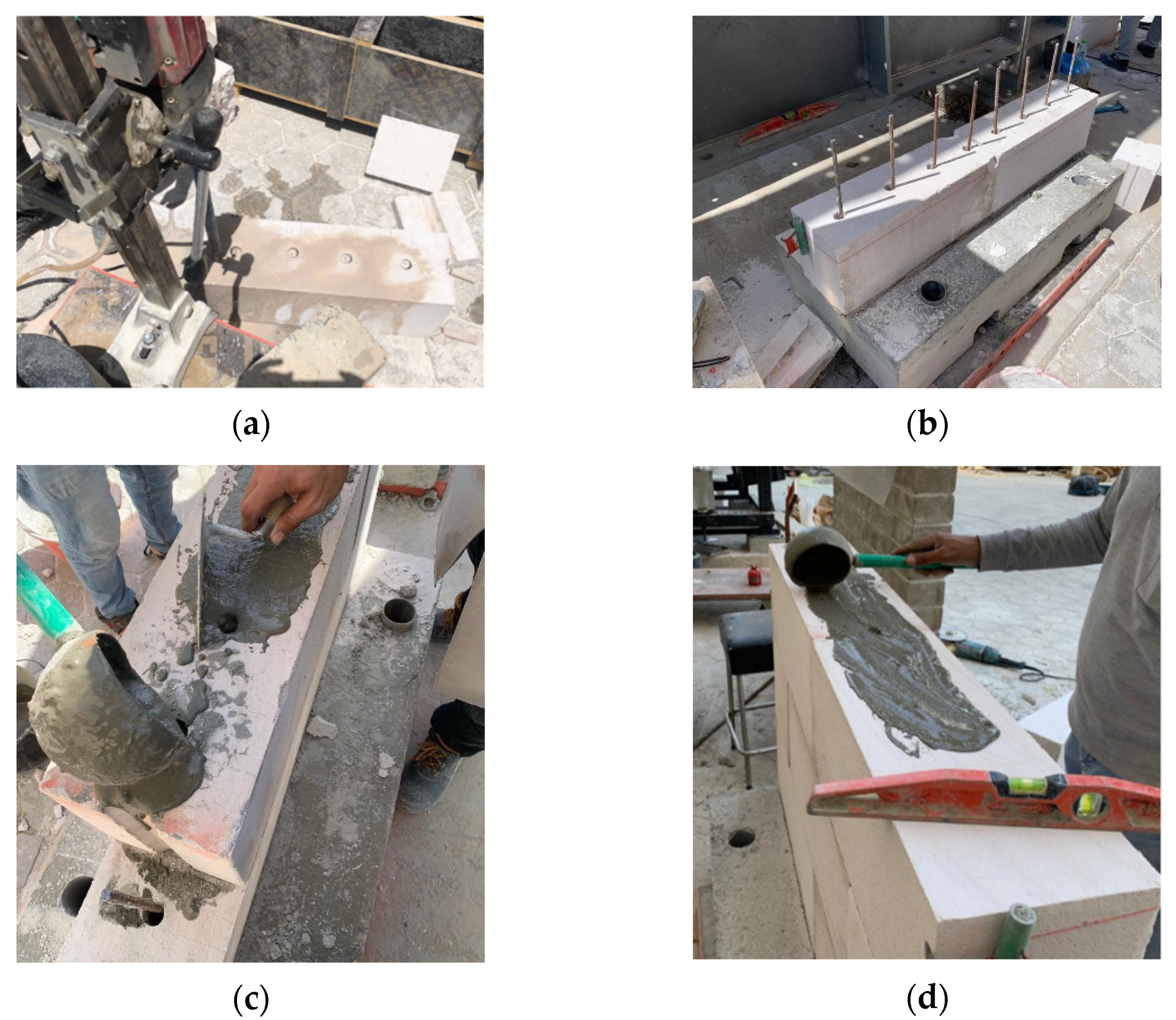

3.2. Shear Bond Strength

3.3. Mortar Testing

4. In-Plane Wall Performance

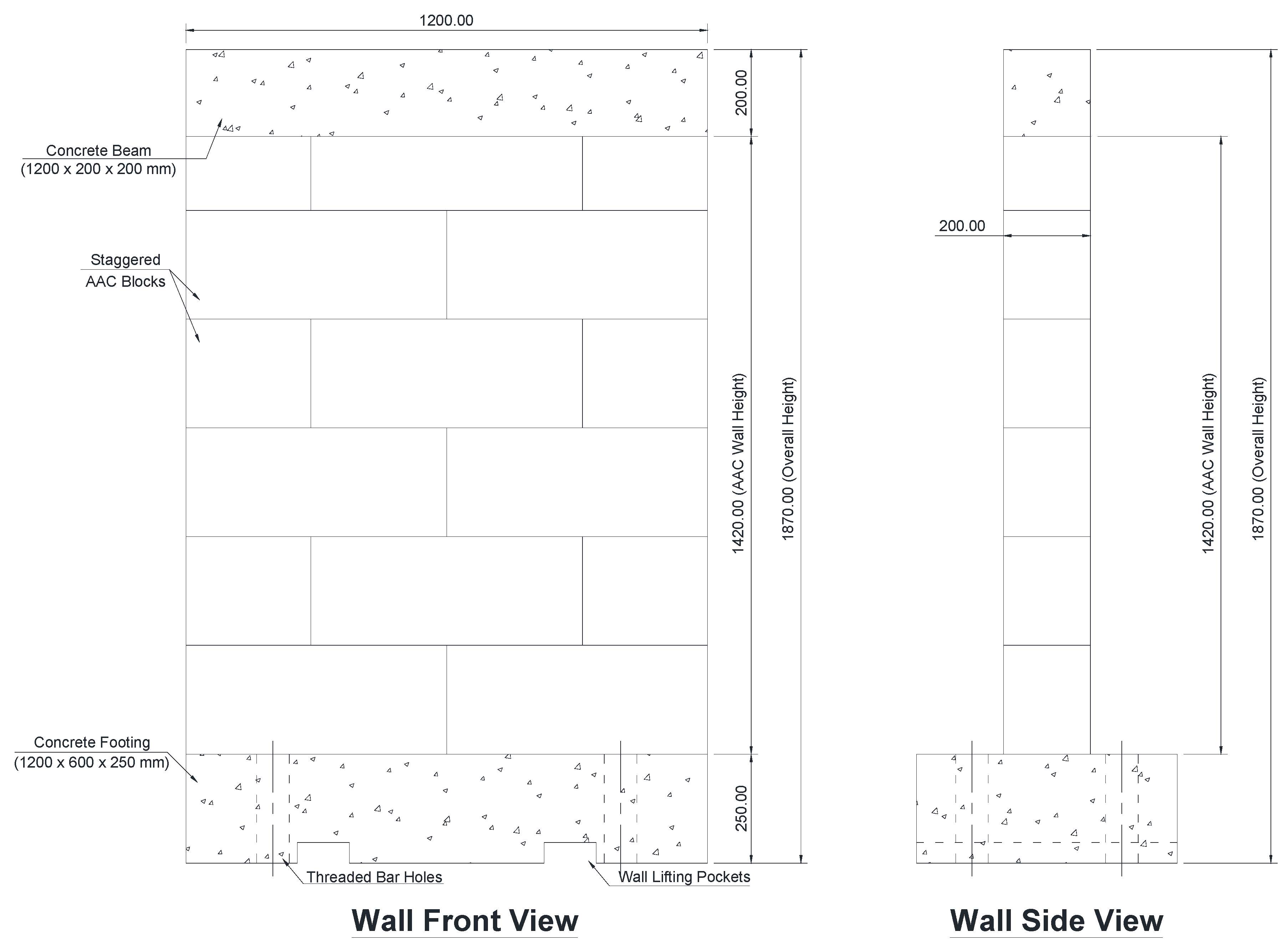

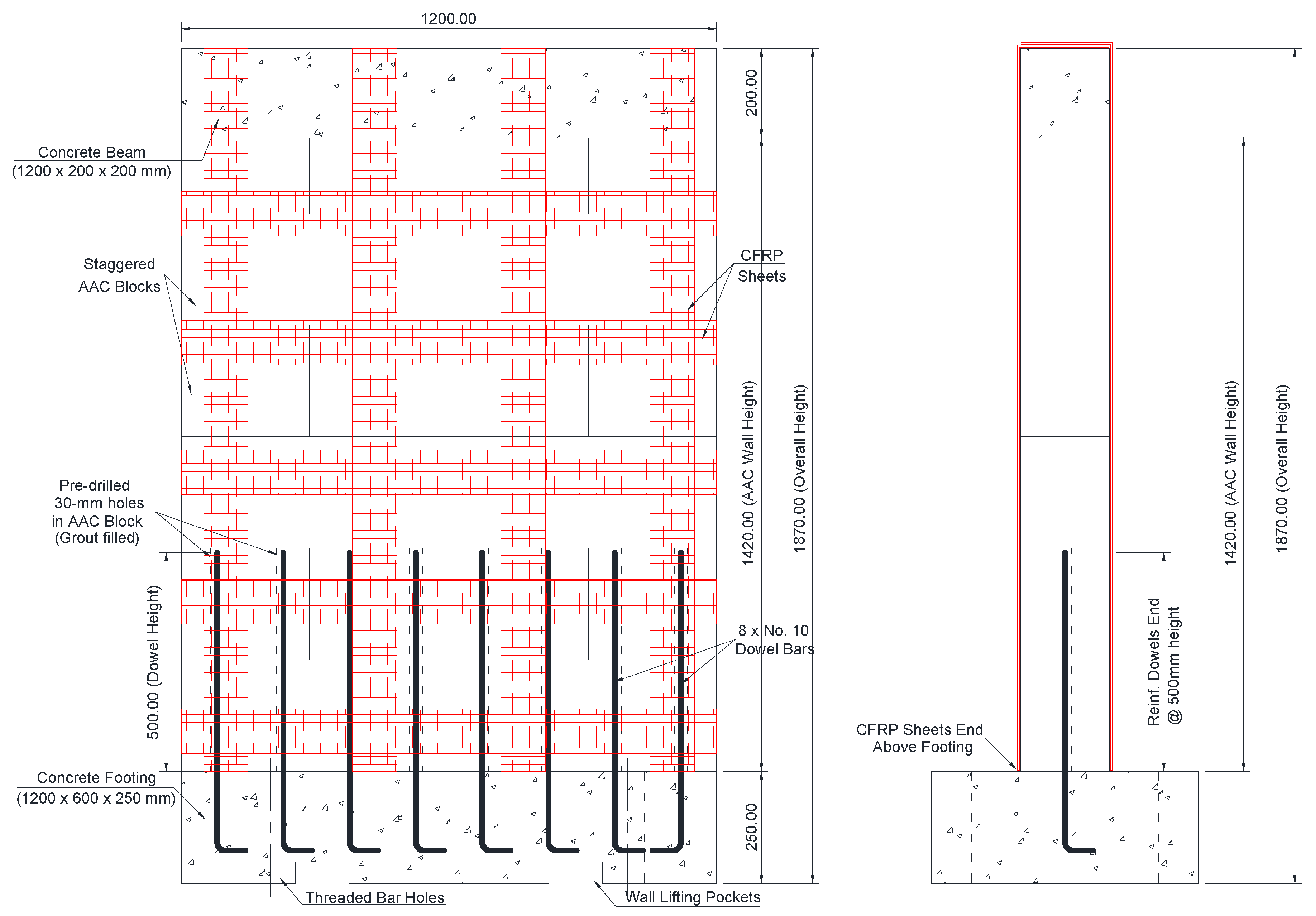

4.1. Wall Specimens

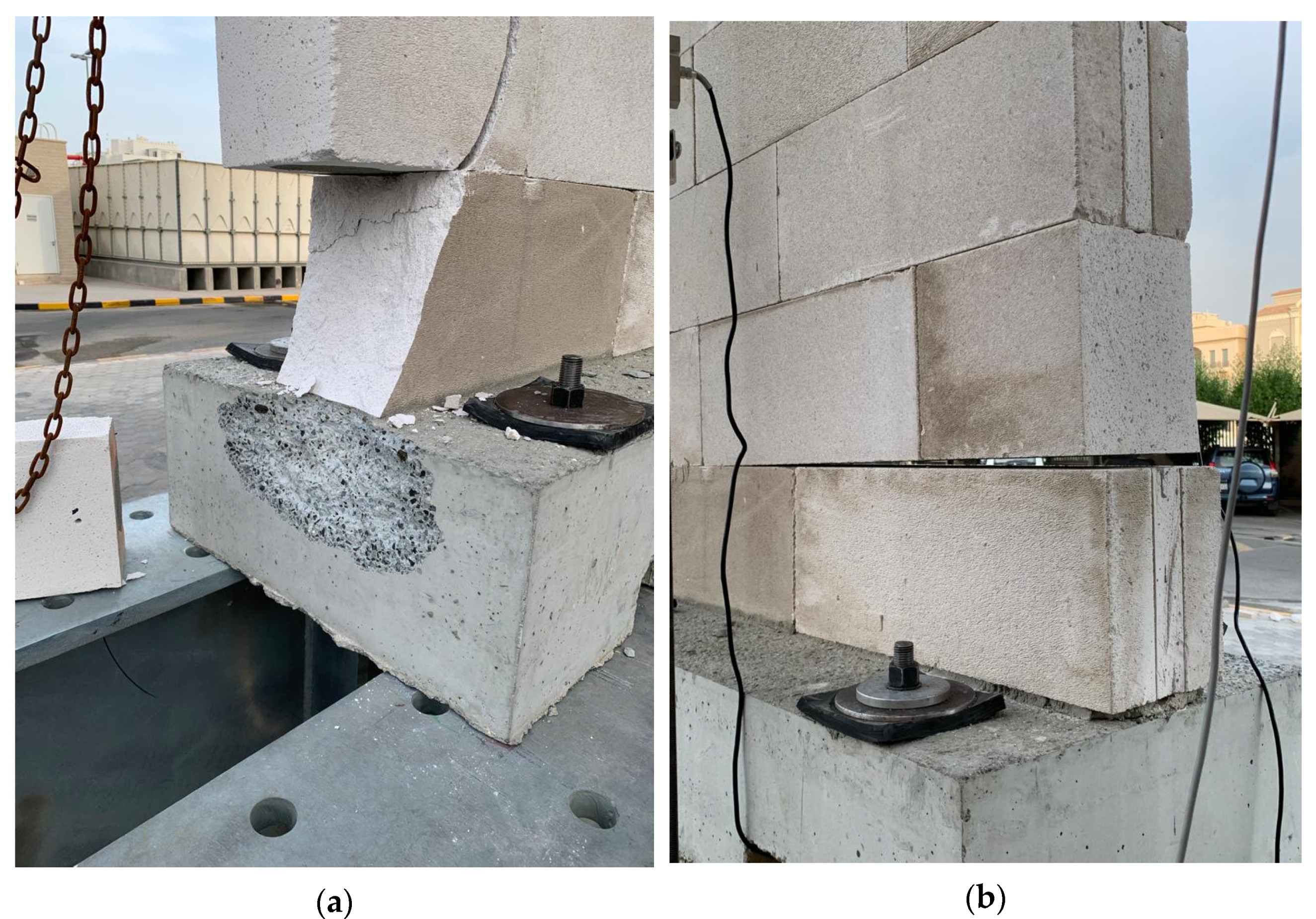

4.1.1. Unreinforced Wall

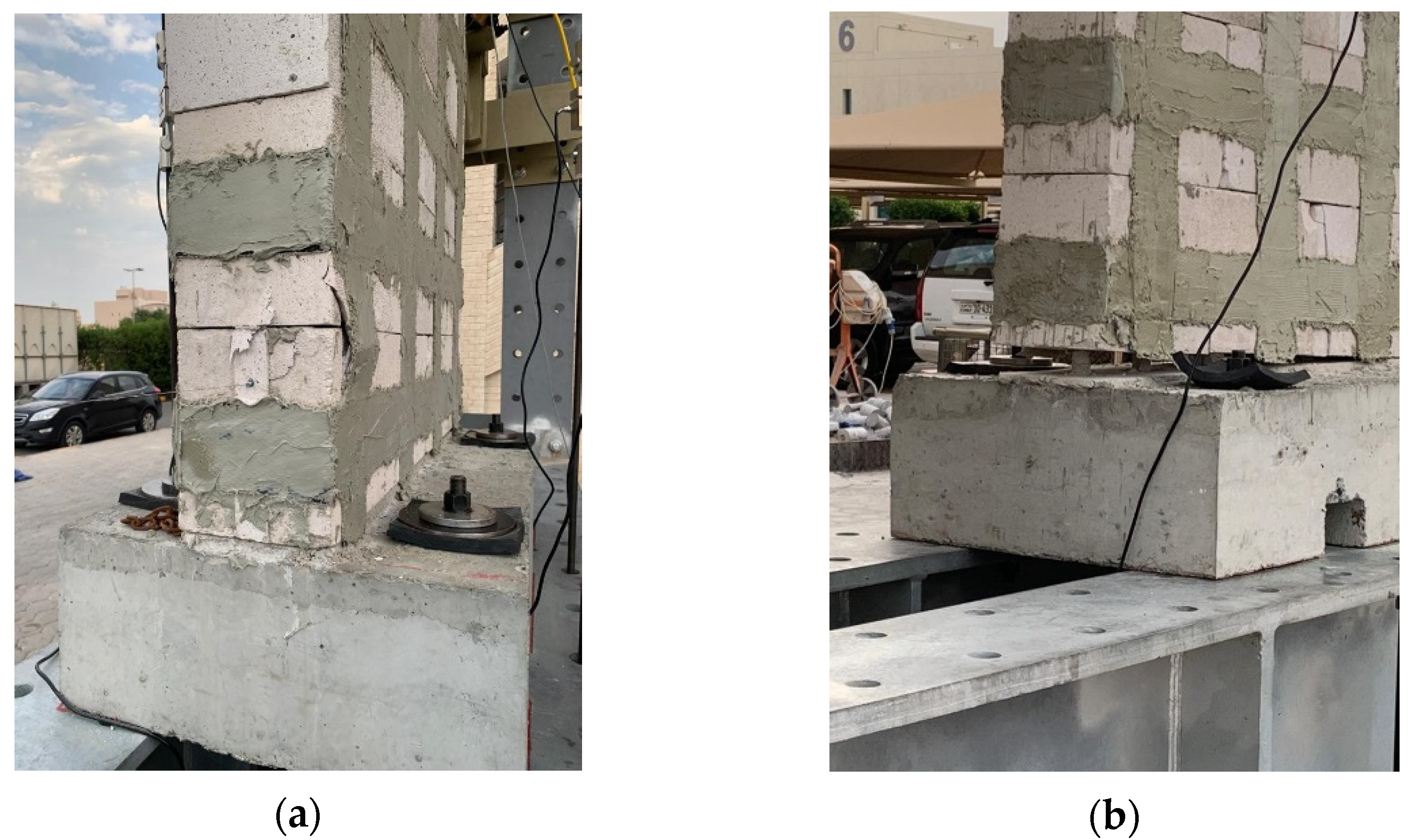

4.1.2. Reinforced Wall

4.2. Large-Scale Test Setup

4.3. In-Plane Lateral Performance of the Walls

5. Cost Analysis of the Used Method

- -

- Building floor heights are of 4.0 m in addition to 1.0 m height between the footings and the ground floor, and the total height of the loading bearing walls is 9.0 m.

- -

- The average cost of construction is USD 500 per square meter for medium finishing criteria, resulting in a total price of construction equal to USD 300,000 for this building. This value includes the structural, civil, and architectural work, and excludes the land and furniture cost.

- -

- In this scenario, four (two-meter wide) walls are reinforced with CFRPs (to the full height) to increase the lateral resistance by following the proposed methodology of this study (two walls in each direction for symmetry).

- -

- The price of each 100 m roll of the CFRPs was USD 200, including shipping, which results in a price of USD 2.0 per meter of the CFRPs (100-mm-wide sheets).

- -

- The external walls are assumed to have a thickness of 200.0 mm and, hence, a reinforcement ratio of 0.15% (similar to the study walls) requires 7 × 100-mm-wide sheets on each side vertically (total of 14 sheets per wall).

- -

- Similarly, to reach the same ratio in the horizontal direction, a total of ten 100-mm-wide sheets are required on each side (total of 20 sheets per wall).

- -

- By multiplying the lengths and the number of sheets, the total length of the required CFRP sheets per wall is 126.0 m.

- -

- The cost of the used epoxy resin bucket in this study was USD 40 and was sufficient to laminate 10.0 m length of the 100 mm wide sheets, which results in a price of USD 4.0/m.

- -

- Assuming the use of 11 No. 16 mm bars as dowels, with a length of 1.5 m per dowel, results in 106 kg of reinforcing bars for all four walls.

6. Conclusions

- Several performance tests were conducted on the used AAC blocks and grout in this research study. The tested AAC blocks, and the grout showed good structural performance, which confirmed the quality of the used materials before building the large-scale walls.

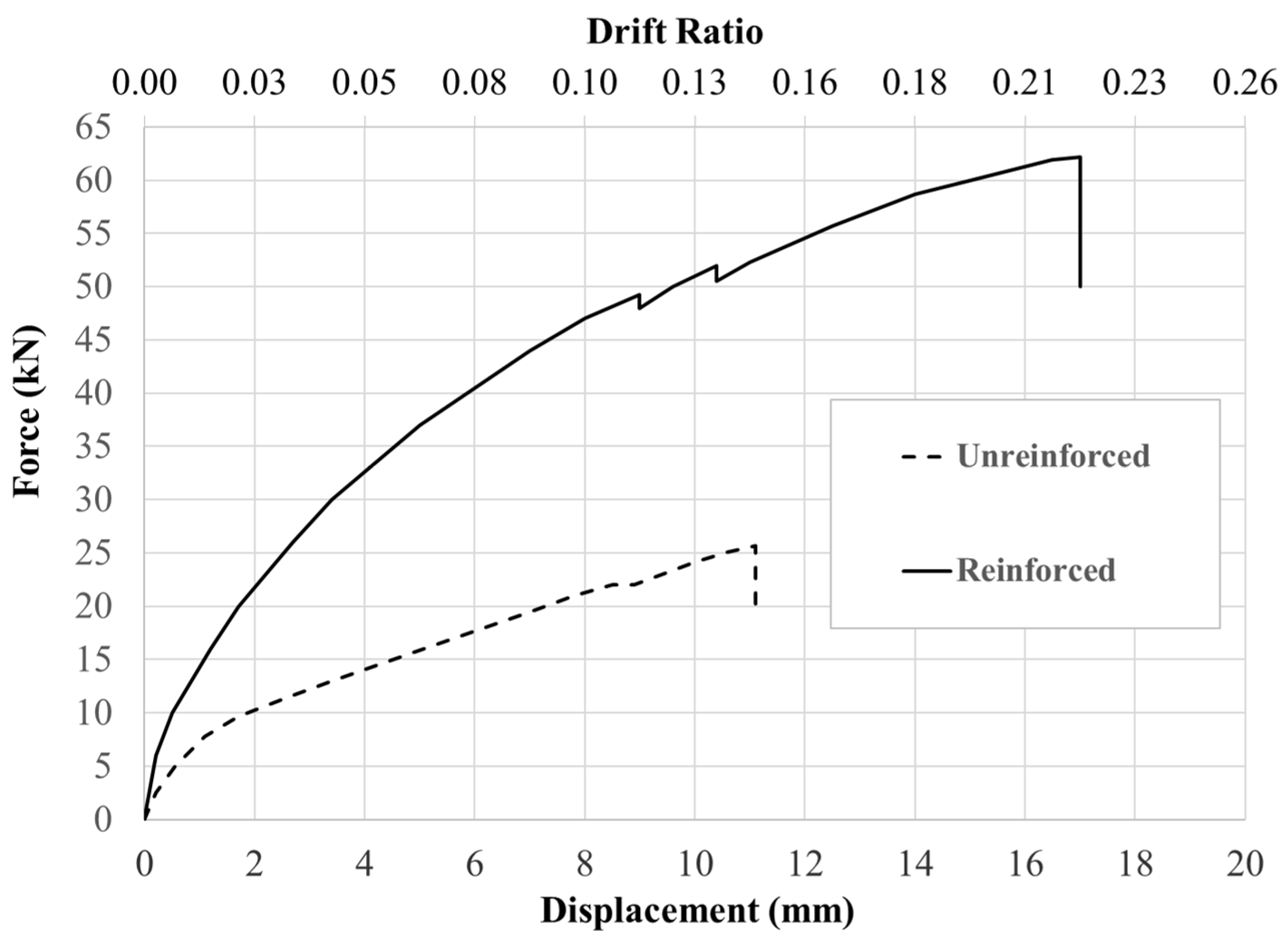

- Reinforcing the AAC wall with CFRPs significantly enhanced their in-plane lateral performance. The initial stiffness of the tested wall was increased from 12.5 kN/mm to 30.0 kN/mm with a 140% increase, the dissipated energy was increased from 181.09 kN.mm to 741.54 kN.mm with a 300% increase, and the ultimate lateral force increased from 25.7 kN to 62.2 kN with a 142% increase.

- The failure mode of the unreinforced AAC wall was dominated by sliding of the block rows, followed by uplifting and compressive shear failure at the compression side, resulting in a shear crack that extended through the whole wall. Alternatively, the reinforced wall experienced much less damage and its failure was dominated by slippage of the dowel bars, causing wall uplifting at the tension side, followed by localized compressive shear failure and buckling of the CFRP sheets on the compression side of the wall. No signs of global damage to the reinforced wall were observed.

- CFRP sheets also reduced the recorded residual displacements of the wall, which indicated reduced damage in post-lateral load application events.

- Cost analysis showed that the total added cost for reinforcing the AAC walls with CFRPs was less than 1.5% of the total construction cost of the building, which was insignificant compared to the added value to the lateral performance of the building.

7. Recommendations for Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Snow, C.A. A comprehensive Study of the Material Properties and Structural Behavior of AAC Products. Ph.D. Dissertation, University of Alabama at Birmingham, Birmingham, UK, 1999. [Google Scholar]

- Chen, Y.; Peng, M.; Zhang, Y.; Liu, Y. Mechanical properties of autoclaved aerated concrete with different densities. Adv. Civ. Eng. Mater. 2013, 2, 441–456. [Google Scholar] [CrossRef]

- The History of AAC. Available online: https://web.archive.org/web/20101204154720/http://www.hebel.co.nz:80/about/hebel%20history.php (accessed on 9 August 2019).

- Priestley, M.J.N.; Seible, F. Design of seismic retrofit measures for concrete and masonry structures. Constr. Build. Mater. 1995, 9, 365–377. [Google Scholar] [CrossRef]

- Bakis, C.E.; Bank, L.C.; Brown, V.; Cosenza, E.; Davalos, J.F.; Lesko, J.J.; Machida, A.; Rizkalla, S.H.; Triantafillou, T.C. Fiber-reinforced polymer composites for construction—State-of-the-art review. J. Compos. Constr. 2002, 6, 73–87. [Google Scholar] [CrossRef] [Green Version]

- Hollaway, L.C. A review of the present and future utilisation of FRP composites in the civil infrastructure with reference to their important in-service properties. Constr. Build. Mater. 2010, 24, 2419–2445. [Google Scholar] [CrossRef]

- Siddika, A.; Al Mamun, M.A.; Alyousef, R.; Amran, Y.M. Strengthening of reinforced concrete beams by using fiber-reinforced polymer composites: A review. J. Build. Eng. 2019, 25, 100798. [Google Scholar] [CrossRef]

- Phares, B.M.; Wipf, T.J.; Klaiber, F.W.; Abu-Hawash, A.; Lee, Y.S. Strengthening of steel girder bridges using FRP. In Proceedings of the 2003 Mid-Continent Transportation Research Symposium, Ames, IA, USA, 21–22 August 2003. [Google Scholar]

- Hutchinson, R.; Tadros, G.; Kroman, J.; Rizkalla, S. Use of externally bonded FRP systems for rehabilitation of bridges in Western Canada. ACI Spec. Publ. 2003, 215, 239–248. [Google Scholar]

- Klaiber, F.W.; Wipf, T.J.; Kempers, B.J. Repair of damaged prestressed concrete bridges using CFRP. In Proceedings of the 2003 Mid-Continent Transportation Research Symposium, Ames, IA, USA, 21–22 August 2003. [Google Scholar]

- Olofin, I.; Liu, R. The application of carbon fibre reinforced polymer (CFRP) cables in civil engineering structures. Int. J. Civ. Eng. 2015, 2, 1–5. [Google Scholar] [CrossRef]

- Zhai, K.; Fang, H.; Guo, C.; Ni, P.; Fu, B.; Wang, F.; Zhang, C. Strengthening of PCCP with broken wires using prestressed CFRP. Constr. Build. Mater. 2021, 267, 120903. [Google Scholar] [CrossRef]

- Valluzzi, M.R.; Tinazzi, D.; Modena, C. Shear behavior of masonry panels strengthened by FRP laminates. Constr. Build. Mater. 2002, 16, 409–416. [Google Scholar] [CrossRef]

- ElGawady, M.A.; Lestuzzi, P.; Badoux, M. Aseismic retrofitting of unreinforced masonry walls using FRP. Compos. Part B Eng. 2005, 37, 148–162. [Google Scholar] [CrossRef]

- Memari, A.M.; Grossenbacher, S.V.; Iulo, L.D. In-plane and out-of-plane load testing and evaluation of sustainable masonry walls. In Proceedings of the Architectural Engineering National Conference, Denver, CO, USA, 24–27 September 2008. [Google Scholar]

- Bland, D.W. In-Plane Cyclic Shear Performance of Interlocking Compressed Earth Block Walls. Master’s. Thesis, Faculty of California Polytechnic State University, San Luis Obispo, CA, USA, 2011. [Google Scholar]

- Qu, B.; Stirling, B.J.; Laursen, P.T.; Jansen, D.C.; Bland, D.W. Interlocking compressed earth block walls: In-plane structural response of flexure-dominated walls. In Proceedings of the 15th World Conference on Earthquake Engineering, IIAE, Lisbon, Portugal, 28 September 2012. [Google Scholar]

- Celano, T.; Argiento, L.U.; Ceroni, F.; Casapulla, C. Literature review of the in-plane behavior of masonry walls: Theoretical vs. experimental results. Materials 2021, 14, 3063. [Google Scholar] [CrossRef] [PubMed]

- Drysdale, R.G.; Essawy, A.S. Out-of-plane bending of concrete block wall. J. Struct. Eng. 1988, 114, 121–133. [Google Scholar] [CrossRef]

- Rodriguez, R.; Hamid, A.A.; Larralde, J. Flexural behavior of post-tensioned concrete masonry walls subjected to out-of-plane loads. Struct. J. 1998, 95, 61–70. [Google Scholar]

- Vaculik, J.; Griffith, M.C.; Hogarth, B.; Todd, J. Out-of-plane flexural response tests using dry-stack masonry. In Proceedings of the Australian Earthquake Society Conference, Mt Gambier, Australia, 5–7 November 2004. [Google Scholar]

- Valluzzi, M.R.; Da Porto, F.; Garbin, E.; Panizza, M. Out-of-plane behaviour of infill masonry panels strengthened with composite materials. Mater. Struct. 2014, 47, 2131–2145. [Google Scholar] [CrossRef]

- Laursen, P.T.; Herskedal, N.A.; Jansen, D.C.; Qu, B. Out-of-plane structural response of interlocking compressed earth block walls. Mater. Struct. 2015, 48, 321–336. [Google Scholar] [CrossRef]

- Saad, A.S.; Ahmed, T.A.; Yassin, M.H.; Radwan, A.I.; Ezzedine, A.I. Out-of-plane structural performance of compressed earth block walls subject to quasistatic loading. Adv. Civ. Eng. Mater. 2022, 11, 33–46. [Google Scholar] [CrossRef]

- Bui, T.T.; Limam, A. Out-of-plane behaviour of hollow concrete block masonry walls unstrengthened and strengthened with CFRP composite. Compos. Part B Eng. 2014, 67, 527–542. [Google Scholar] [CrossRef]

- Tomazevic, M. Seismic strengthening of brick masonry houses by CFRP strips: A shaking table study. In Proceedings of the 43rd CIB W23 Commission Meeting, Darmstadt, Germany, 13–15 September 1989; CIB Publication: Lisbon, Portugal, 2006. [Google Scholar]

- Santa Maria, H.; Alcaino, P.; Luders, C. Experimental response of masonry walls externally reinforced with carbon fiber fabrics. In Proceedings of the 8th US National Conference on Earthquake Engineering, San Francisco, CA, USA, 22 April 2006. [Google Scholar]

- Yalcin, C.; Kaya, O.; Sinangil, M. Seismic retrofitting of R/C columns having plain rebars using CFRP sheets for improved strength and ductility. Constr. Build. Mater. 2008, 22, 295–307. [Google Scholar] [CrossRef]

- Tafsirojjaman, T.; Fawzia, S.; Thambiratnam, D.; Zhao, X.L. Seismic strengthening of rigid steel frame with CFRP. Arch. Civ. Mech. Eng. 2019, 19, 334–347. [Google Scholar] [CrossRef]

- Markou, G. A new method of seismic retrofitting cost analysis and effectiveness for reinforced concrete structures. Eng. Struct. 2021, 246, 113083. [Google Scholar] [CrossRef]

- Zhou, S.C.; Demartino, C.; Xu, J.J.; Xiao, Y. Effectiveness of CFRP seismic-retrofit of circular RC bridge piers under vehicular lateral impact loading. Eng. Struct. 2021, 243, 112602. [Google Scholar] [CrossRef]

- Jacques, E.; Lloyd, A.; Imbeau, P.; Palermo, D.; Quek, J. GFRP-retrofitted reinforced concrete columns subjected to simulated blast loading. J. Struct. Eng. 2015, 141, 04015028. [Google Scholar] [CrossRef]

- Swesi, A.O.; Cotsovos, D.M.; Val, D.V. Effect of CFRP strengthening on response of RC columns to lateral static and impact loads. Compos. Struct. 2022, 287, 115356. [Google Scholar] [CrossRef]

- Jahami, A.; Temsah, Y.; Khatib, J. The efficiency of using CFRP as a strengthening technique for reinforced concrete beams subjected to blast loading. Int. J. Adv. Struct. Eng. 2019, 11, 411–420. [Google Scholar] [CrossRef] [Green Version]

- Jahami, A.; Temsah, Y.; Khatib, J.; Baalbaki, O.; Kenai, S. The behavior of CFRP strengthened RC beams subjected to blast loading. Mag. Civ. Eng. 2021, 3, 10309. [Google Scholar]

- Guerreiro, J.; Proença, J.; Ferreira, J.G.; Gago, A. Experimental characterization of in-plane behaviour of old masonry walls strengthened through the addition of CFRP reinforced render. Compos. Part B Eng. 2018, 148, 14–26. [Google Scholar] [CrossRef]

- Kubica, J.; Galman, I. Comparison of two ways of AAC block masonry strengthening using CFRP strips-diagonal compression test. Procedia Eng. 2017, 193, 42–49. [Google Scholar] [CrossRef]

- Uddin, N.; Fouad, F.; Vaidya, U.K.; Khotpal, A.; Serrano-Perez, J.C. Structural characterization of hybrid fiber reinforced polymer (FRP)-autoclave aerated concrete (AAC) panels. J. Reinf. Plast. Compos. 2006, 25, 981–999. [Google Scholar] [CrossRef]

- Kałuża, M. Analysis of in-plane deformation of walls made using AAC blocks strengthened by GFRP mesh. Procedia Eng. 2017, 193, 393–400. [Google Scholar] [CrossRef]

- ASTM C1693-21; Standard Specification for Autoclaved Aerated Concrete (AAC). ASTM International: West Conshohocken, PA, USA, 2022. Available online: www.astm.org (accessed on 7 July 2022).

- Bhosale, A.; Zade, N.P.; Davis, R.; Sarkar, P. Experimental investigation of autoclaved aerated concrete masonry. J. Mater. Civ. Eng. 2019, 31, 04019109. [Google Scholar] [CrossRef]

- ASTM C109/C109M-20; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). ASTM International: West Conshohocken, PA, USA, 2022. Available online: www.astm.org (accessed on 7 July 2022).

- Khalaf, F.M. New test for determination of masonry tensile bond strength. J. Mater. Civ. Eng. 2005, 17, 725–732. [Google Scholar] [CrossRef]

- BSI-BS 5628-1; Code of Practice for the Use of Masonry—Part 1: Structural Use of Unreinforced Masonry. British Standards Institution (BSI): London, UK, 1992.

- Australian Standards (AS 3700:2018); Masonry Structures. Standards Australia: Sydney, Australia, 2018. Available online: www.standards.org.au (accessed on 7 July 2022).

- ASTM C270-19; Standard Specification for Mortar for Unit Masonry. ASTM International: West Conshohocken, PA, USA, 2022. Available online: www.astm.org (accessed on 7 July 2022).

- ASTM C1072-19; Standard Test Methods for Measurement of Masonry Flexural Bond Strength. ASTM International: West Conshohocken, PA, USA, 2022. Available online: www.astm.org (accessed on 7 July 2022).

| Physical Test | Dry Compressive Strength | Wet Compressive Strength | |||

|---|---|---|---|---|---|

| Parallel to the Wall Loading | Perpendicular to the Wall Loading | Triplets | Parallel to the Wall Loading | Perpendicular to the Wall Loading | |

| Average Compressive Strength (MPa) | 4.85 | 2.83 | 3.41 | 4.08 | 2.31 |

| Standard Deviation (MPa) | 0.28 | 0.33 | 1.31 | 0.68 | 0.14 |

| Coefficient of variation | 5.1% | 11.6% | 38.4% | 16.7% | 6.3% |

| Half-Grouted Specimens | Fully Grouted Specimens | |

|---|---|---|

| Average Shear Bond Strength (MPa) | 0.202 | 0.373 |

| Standard Deviation (MPa) | 0.085 | 0.13 |

| Coefficient of Variation | 42.5% | 34.4% |

| 7 Days | 28 Days | |

|---|---|---|

| Mortar cubes compressive strength (MPa) | 4.33 | 5.05 |

| Standard deviation (MPa) | 0.22 | 0.46 |

| Coefficient of variation | 5.1% | 9.1% |

| Tensile Bond Strength fpb (MPa) | Total Tensile Bond Force Fpb (kN) | |

|---|---|---|

| 0.32 | 2.2 | |

| Standard deviation (kN) | 0.06 | 0.4 |

| Coefficient of variation | 18% | 18% |

| (1) | ||

| (2) | ||

| Unreinforced Wall | Reinforced Wall | |

|---|---|---|

| Initial Stiffness (kN/mm) | 12.5 | 30.0 |

| Dissipated Energy (kN.mm) | 181.09 | 741.54 |

| Ultimate Force (kN) | 25.7 | 62.2 |

| Displacement @ Failure (mm) | 11.1 | 17.0 |

| Unit Price | Cost per Wall | Total Cost | |

|---|---|---|---|

| Price of CFRP | 2.0 USD/m | USD 252 | USD 1008 |

| Price of Epoxy Resin | 4.0 USD/m | USD 504 | USD 2016 |

| Price of steel dowel bars | 600 USD/ton | USD 16 | USD 64 |

| Total material cost | USD 3088 | ||

| 10% Indirect costs | USD 308.8 | ||

| Installation Cost (30% of material cost) | USD 926.4 | ||

| Total Cost | USD 4324 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saad, A.S.; Ahmed, T.A.; Radwan, A.I. In-Plane Lateral Performance of AAC Block Walls Reinforced with CFPR Sheets. Buildings 2022, 12, 1680. https://doi.org/10.3390/buildings12101680

Saad AS, Ahmed TA, Radwan AI. In-Plane Lateral Performance of AAC Block Walls Reinforced with CFPR Sheets. Buildings. 2022; 12(10):1680. https://doi.org/10.3390/buildings12101680

Chicago/Turabian StyleSaad, Ahmad S., Taha A. Ahmed, and Ali I. Radwan. 2022. "In-Plane Lateral Performance of AAC Block Walls Reinforced with CFPR Sheets" Buildings 12, no. 10: 1680. https://doi.org/10.3390/buildings12101680

APA StyleSaad, A. S., Ahmed, T. A., & Radwan, A. I. (2022). In-Plane Lateral Performance of AAC Block Walls Reinforced with CFPR Sheets. Buildings, 12(10), 1680. https://doi.org/10.3390/buildings12101680