Abstract

Risks hinder the role of prefabricated construction (PC) in promoting construction automation. Although existing research has focused on risk management (RM) in PC, the lack of a global perspective has affected the effectiveness of RM. Accordingly, this paper adopts a scientometric analysis to review the knowledge domain of RM in PC. A total of 144 articles were selected from the Scopus database for journal citation analysis, document co-citation analysis, and keyword co-occurrence analysis. The results show that since 2011, the annual publications show an overall upward trend. International Journal of Construction Management, Journal of Building Engineering, and Buildings have been cited more frequently recently. PC research, RM research, environmental sustainability research, and ergonomic research provide a solid foundation for the research on RM in PC. Existing studies are conducted from five knowledge themes, namely, Supply chain and industry, Decision and optimization, Safety and health, Environment and overheating, and Investment and cost. Further, current research content, future research needs, and RM strategies for PC practices are discussed. This study helps stimulate further promising research and enhance the effectiveness of RM in PC in practice.

1. Introduction

Prefabricated construction (PC) has provided a convenient platform for construction automation and attracted significant attention worldwide recently [1,2]. It is known as a modern construction method where prefabricated components can be produced in a controlled environment and assembled quickly on-site [3]. Compared with traditional cast-in-situ construction (TCC), PC demonstrates advantages in quality control [4], efficiency improvement [5], worker safety [6], and clean production [7]. Nevertheless, many risks hinder PC development, which has inspired research on risk management (RM) [8]. For example, the technical complexity of PC incubates defect design risk, which causes a great quality disaster [9], and requires more time and expense to make up [10]. To manage defect design risk, a multi-agent-based simulation model and BIM-based prototype system have been established, making it possible to test and choose the most optimized strategies for design change [11,12]. The overturning of heavy equipment and the fall of unfixed prefabricated components incur safety risks during the hoisting process [13]. Hussein and Zayed [14] proposed an effective control system to maintain the stability of a crane and eliminate the swinging of the components. Moreover, existing literature has identified and assessed critical risks (e.g., high costs, poor supply chain performance) that limit PC development [15,16]. Corresponding RM methods have been proposed. However, the diversity of risks and RM approaches has led to a fragmented research of RM in PC, hindering the reader’s comprehensive understanding of this field [17]. As research gaps are not revealed, homogeneous and redundant research in this field may be increasing. This further hinders the validity and comprehensiveness of RM in practice and is detrimental to the development of PC [8]. Hence, a holistic review of the current research on RM in PC is needed. From a scholarly perspective, the review of RM in PC can provide a global picture of the knowledge domain and suggest innovative directions for future research. In practice, such a review can provide references to optimize the RM practice, thereby promoting the development of PC.

Some review studies were conducted. For example, Wuni, Shen, and Mahmud [8] conducted a systematic review of 39 empirical studies and determined the critical risks that affect PC development. Wuni and Shen [17] made important contributions to the salient research topics and critical risk events of PC. Nonetheless, these studies focused on summarizing the risk of PC without reviewing the content of RM. There are also some studies reviewing the health and safety risk of construction workers [18], stakeholder-oriented risks [19], construction risks [20,21], project risks in Yemen [22], RM techniques of projects [23,24], and so on. However, these studies conflate TCC with PC, whose business model and construction logic are very different from TCC’s. Therefore, although the above studies provide research insights, they are not universal and valuable in facilitating the effectiveness of RM in PC [8]. Furthermore, although the qualitative analysis adopted by the above reviews provides in-depth discussion, it may magnify the effects of the authors’ subjectivity. As a quantitative review method, the scientometric analysis performs well in exploring and visualizing knowledge domains objectively and accurately [25]. Given that the research of RM in PC involves a variety of journals, topics, etc., the scientometric analysis is applicable to the knowledge exploration of this field [1].

Given the above, this study aims to concentrate on the existing literature on RM in PC and explore the overall knowledge domain in this field. Based on summarizing the current research contents, proposing future research needs and RM strategies are also the objectives of this study. As the first scientometric review of RM in PC, this study helps contribute to the insight, integration, and improvement of the knowledge system, as well as provide researchers with directions for further innovation in a scholarly way. In practice, the results of this study can provide practitioners with a reference for RM, thus alleviating the limitations of PC development. The remaining sections of this article are structured as follows. Section 2 describes the research methodology. Section 3 provides the results of the scientometric analysis, which is extended by the in-depth qualitative study in Section 4. Section 5 further discusses the knowledge status, research needs, and RM strategies. Finally, Section 6 concludes this review.

2. Methodology

2.1. Data Collection and Processing

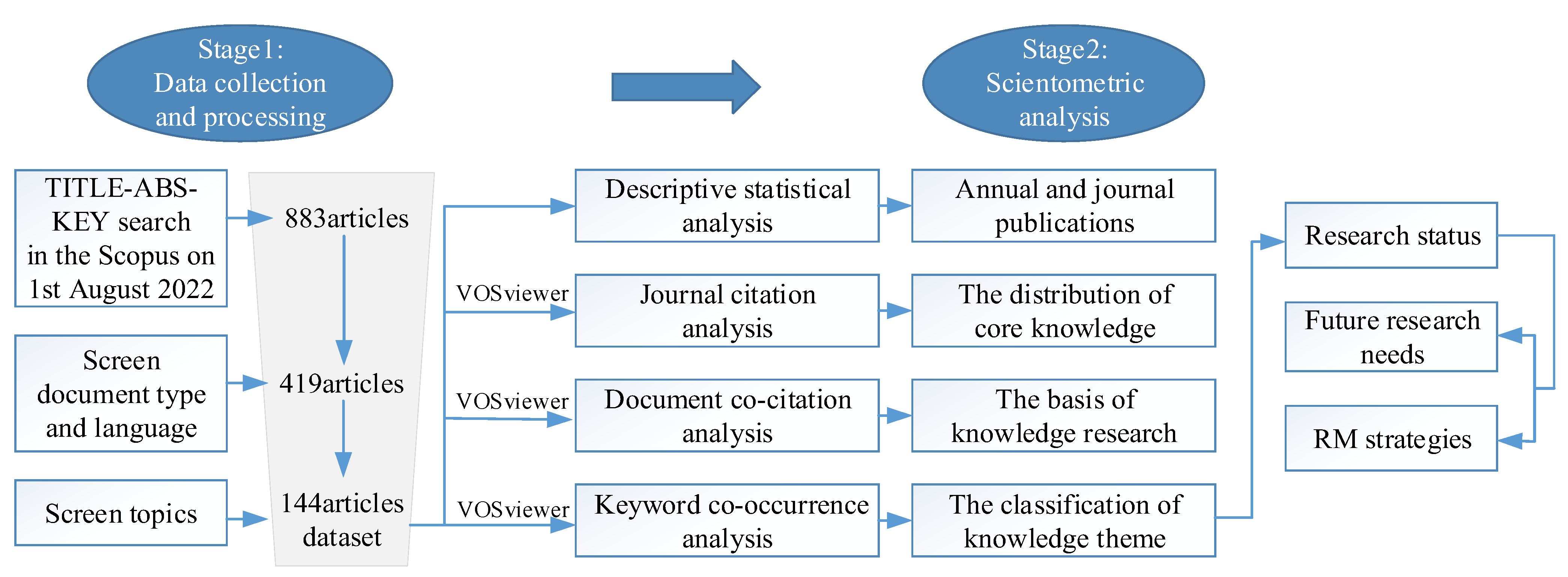

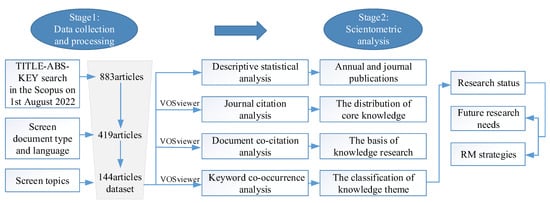

The methodological process is shown in Figure 1. Collecting bibliometric data (including information such as authors, title, source title, abstract, keywords, references, etc.) is the first step in a scientometric review. In the initial data collection phase, this study combined two databases, Web of Science (WoS) and Scopus, which are often used in scientometric reviews [1,26]. Subsequently, it was found that for RM in PC, the Scopus database covers a broader range than WoS. In this way, to maintain consistency of data for subsequent scientometric analysis, the Scopus database was used in this study to obtain bibliometric data. Given that PC has multiple forms of expression in different countries and situations, in order not to miss any available article, this study constructed an overall retrieval code in the Scopus as follows: TITLE-ABS-KEY ((prefabrication) OR (“prefabricated building”) OR (“prefabricated housing”) OR (“prefabricated construction”) OR (“precast concrete”) OR (“precast fabrication”) OR (“off*site construction”) OR (“off*site manufactur*”) OR (“off*site production”) OR (“modular construction”) OR (“modular building”) OR (“industriali?ed construction”) OR (“industriali?ed building*”) OR (“industriali?ed housing”) OR (“modern method* of construction”) OR (“modular integrated construction”) OR (“construction Industrialization”)) AND TITLE-ABS-KEY (risk), where “TITLE-ABS-KEY” means to retrieve all the publications whose titles, abstracts, or keywords contain the above text. “*” and “?” are wildcards used for a fuzzy search. “*” can only replace one letter and “?” can replace any letter. The date range criterion was set to all years to the present, to provide as much insight as possible. Herein, on 1st August 2022, a total of 883 articles were collected in the initial record.

Figure 1.

The methodological process.

The TITLE-ABS-KEY search model ensures that relevant literature is collected. However, it also increases the likelihood of collecting useless and irrelevant articles. Hence, this study further processed the initial records to ensure the accuracy of the data. First, as suggested by other reviews [26,27], conference papers were excluded, given that conference articles provide less information than peer-reviewed articles. The language was limited to English. In this way, 419 articles were identified. Given the focus of this study on the management issues of PC risks, articles that are not relevant to RM in PC (e.g., structural seismic, chemistry, and materials) were excluded by reviewing all abstracts or full texts. Finally, 144 articles were determined as the dataset for this review.

2.2. Scientometric Analysis Methods

The scientometric analysis includes a variety of analysis methods. Among them, journal citation analysis, document co-citation analysis, and keyword co-occurrence analysis are sufficient to reveal the core knowledge and are adopted by scientometric reviews commonly [28,29]. Various software can be used to perform the above analysis. Compared to other software, VOSviewer is adopted by a large number of existing reviews for its efficient computational power and readable graphical presentation [30,31]. Accordingly, VOSviewer was used in this study. The explanation and execution process of the above analysis are as follows:

- Journal citation analysis. It visualizes the journals to which the cited articles in the dataset belong [32]. This analysis enables the presentation of influential journals in the research field, and the strength of mutual citations between these journals [31]. Specifically, the bibliographic data of the 144 articles were exported from the Scopus database and then input into VOSviewer. The journal citation network was created by setting the minimum number of cited articles in a journal to 3. The threshold selection was based on existing research experience and multiple experiments to generate the optimal network [1,33].

- Document co-citation analysis. If two papers appear in the references of the third citing article at the same time, the two papers constitute a co-citation relationship. By visualizing the network of co-citation papers, document co-citation analysis shows the basis and structure of the knowledge domain [26]. The above information can help the reader to generate a quick and in-depth understanding of the research area [34]. In this study, the document co-citation network was created by setting the minimum number of citations to 3 in VOSviewer.

- Keyword co-occurrence analysis. This analysis shows the keyword network by counting the frequency (i.e., link strength) of any two keywords occurring in an article simultaneously [26]. The higher the link strength between keywords, the more likely they are to appear in the same cluster. Since the keywords represent the main content and research boundary of the article, when keywords appear in a cluster, they often reflect the same knowledge theme. In this way, different knowledge themes can be classified based on different keyword clusters [35]. By setting the minimum number of keyword occurrences as 5 in VOSviewer, the network was created. The results of the above scientometric analyses are shown in Section 3.

After visualizing the classification of knowledge themes, Luo et al. [36] and Jin et al. [37] further summarized the main research content of each knowledge theme, inferring and displaying a reliable and robust knowledge body. This study also used this method to summarize the current research in Section 4.

3. Results

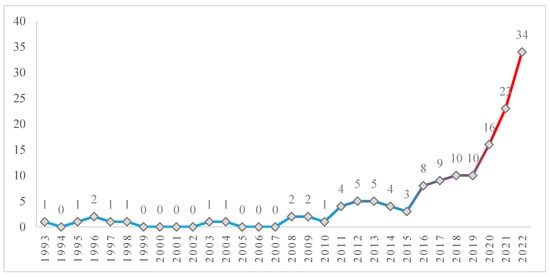

3.1. Wave of Research on RM in PC

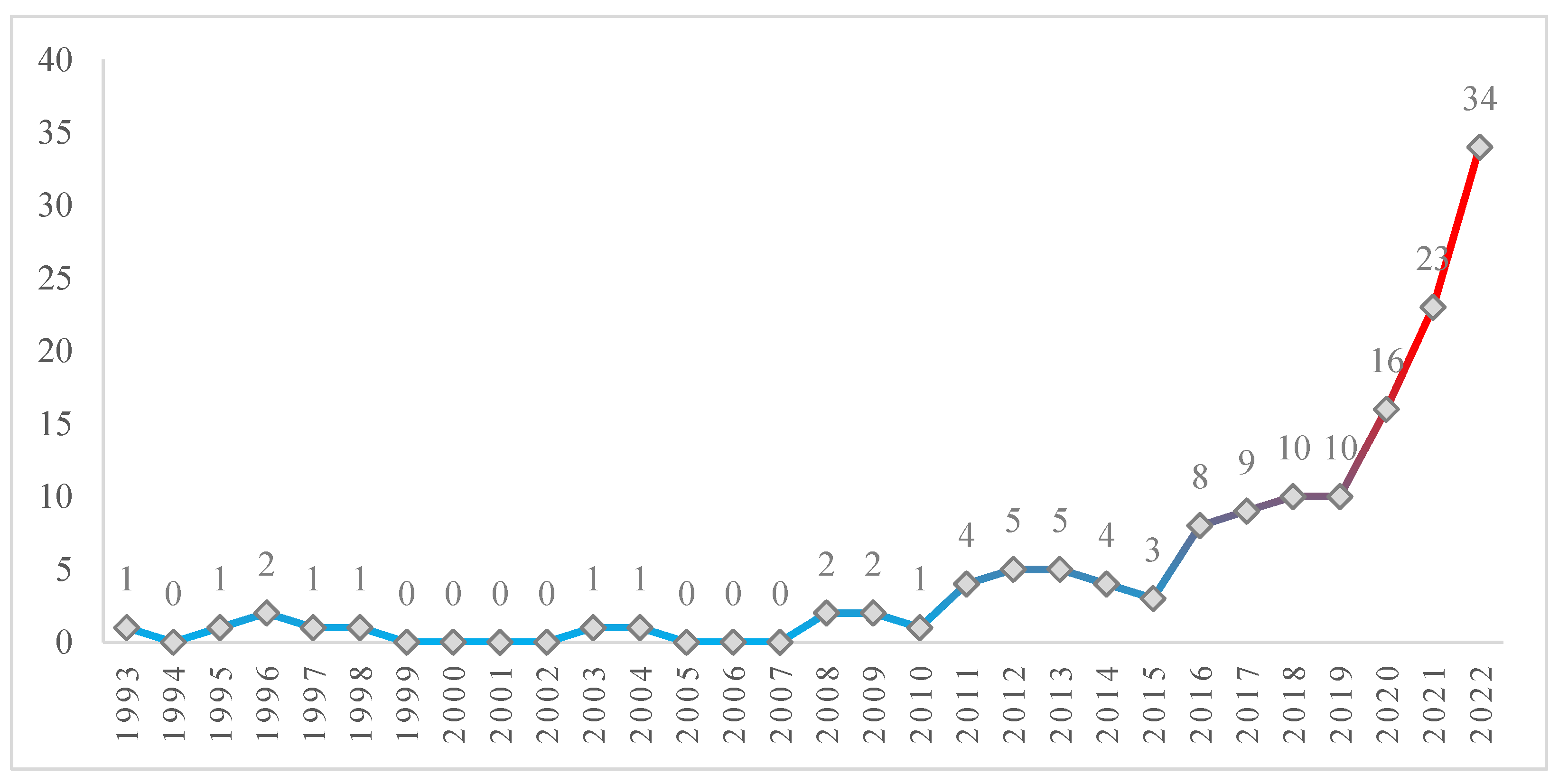

Figure 2 presents the annual publications of RM in PC. The first article in this field was published in 1993, which proposed a decision-making framework of PC considering project risk [38]. Before 2011, studies on RM in PC were sporadic. Since then, the publications have started to show an upward trend. The publications have increased rapidly since 2019, reaching the maximum number of 34 in 2022 (up to 1st August). Consequently, it is inferred that the research on RM in PC will continue to increase in the future. Based on the statistical data retrieved from the Scopus database, it can be seen that the publication of PC studies increased approximately 2.47 times from 2011 to 2022, while the publication of RM in PC studies increased approximately 8.5 times during this period. This highlights the strong interest in the study of RM in PC, despite the dramatic increase in the total number of all topic publications in recent years. The rapid growth of publications on RM in PC may be influenced by the critical need to manage the risks that threaten the realization of PC advantages, as PC is gradually recognized and adopted [39].

Figure 2.

Annual trend of publications of RM in PC.

3.2. The Distribution of Core Knowledge

Both journal publication volume and journal citation network can show the knowledge distribution of RM in PC. The former reflects the fit of the journal to the research field, while the latter reflects the relationship and influence of journals in this field.

Table 1 shows 18 journals that published no fewer than 2 articles in this field. The publications of these journals only account for 58% of all the publications, showing a fragmented distribution of the existing knowledge. The topics of these journals cover construction engineering (e.g., Journal of Construction Engineering and Management), sustainable development (e.g., Journal of Cleaner Production and Sustainability), and ergonomics (e.g., Applied Ergonomics). This highlights the concern of RM in PC for environmental sustainability and worker health. Furthermore, the high recognition of journals in Table 1 indicates that RM in PC has received strong interest from the research field.

Table 1.

Journals with no fewer than 2 publications of RM in PC.

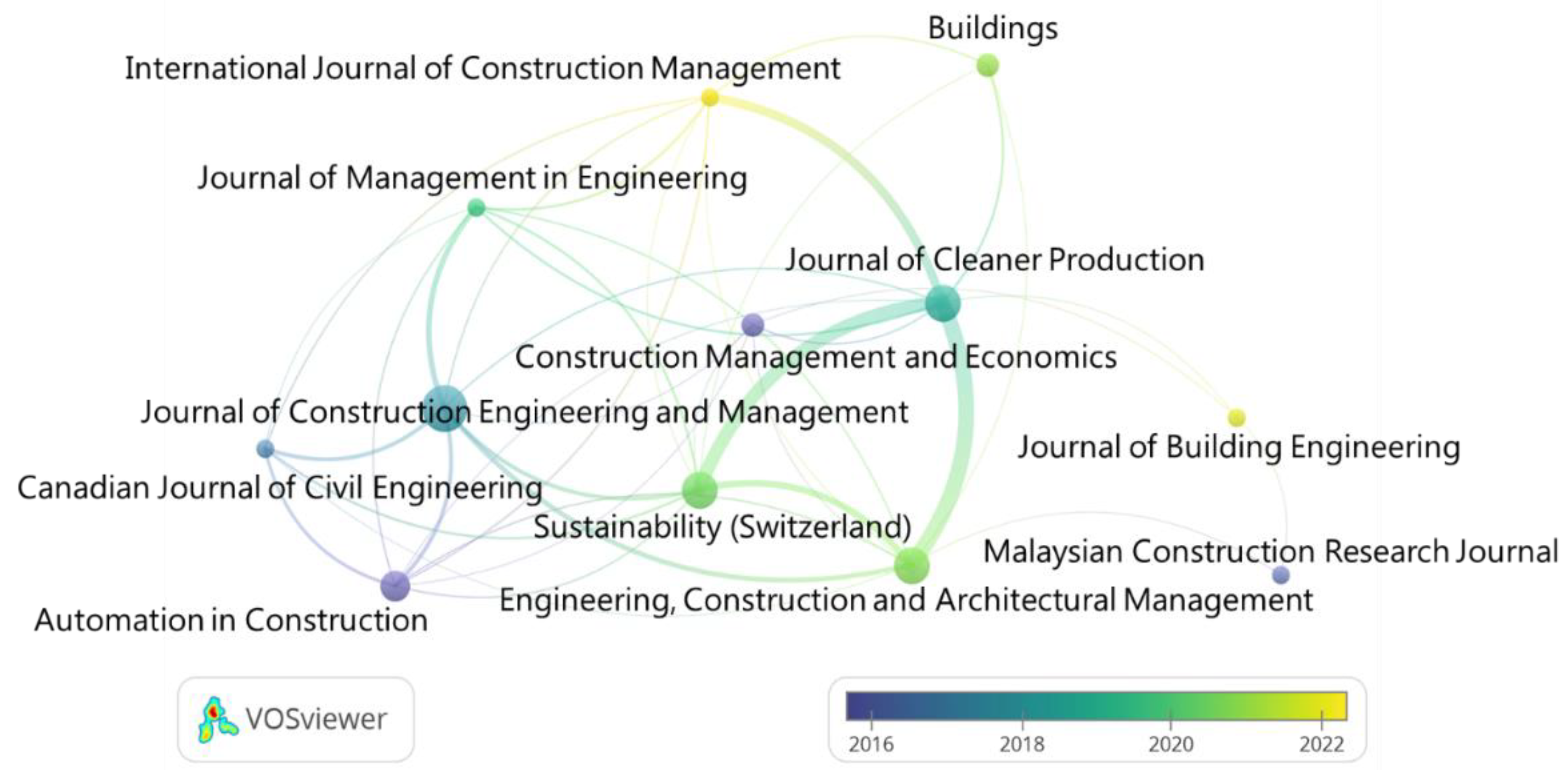

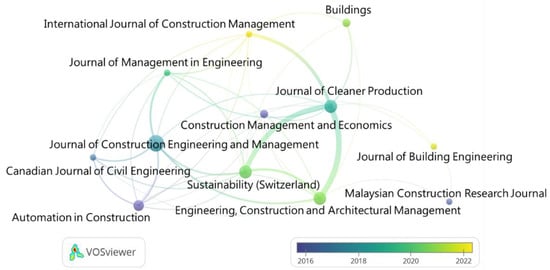

Figure 3 visualizes the journal citation network and the average publication year of cited articles in these journals. The size of the nodes indicates the number of cited articles in the journals. The thickness of the lines implies the link strength of mutual citations between these journals. In Table 2, Articles shows the number of cited articles published by the journal. Citations show the total number of citations to the journal. Average citation is equal to Citation divided by Articles. Total link strength shows the strength of mutual citations between journals. Avg. pub. year shows the average publication year of cited articles in journals.

Figure 3.

Journal citation network.

Table 2.

Journals with no fewer than 3 cited articles of RM in PC.

Journal of Construction Engineering and Management has the highest number of publications and the most cited articles in this field. This indicates that it plays a pivotal role in the diffusion of knowledge. Journal of Cleaner Production (572 total citations, 47.67 average citations), Journal of Construction Engineering and Management (493 total citations, 25.95 average citations), Automation in Construction (325 total citations, 40.63 average citations), and Journal of Management Engineering (155 total citations, 51.67 average citations) receive high citations and average citations. This highlights the influence of the above journals in this field. Journal of Cleaner Production, Engineering, Construction and Architectural Management, and Sustainability (Switzerland) have a high total link strength, indicating that they are certain homogeneous and active in terms of publishing articles on RM in PC. Although the above analyses were able to expose influential journals, it was argued that the average publication year of cited articles in these journals could not be disregarded [31]. Otherwise, journals with outstanding contributions in recent years would be buried, as older articles have more time to be cited than more recent ones [33]. Avg. pub. year calculated by VOSviewer provides a reference for this. As illustrated in Table 2, International Journal of Construction Management, Journal of Building Engineering, and Buildings have been cited more frequently in recent years and can provide an up-to-date research base.

3.3. The Basis of Knowledge Research

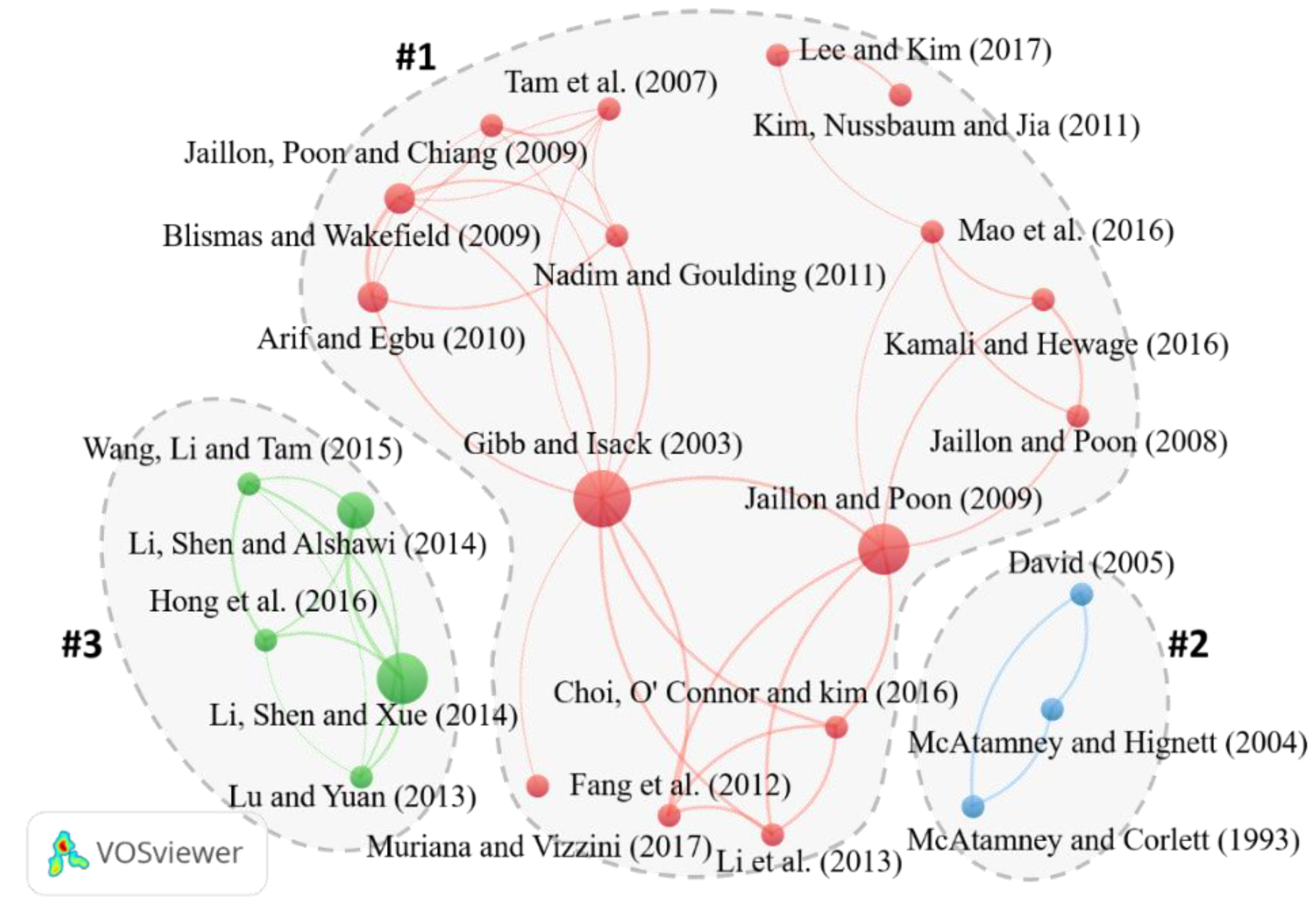

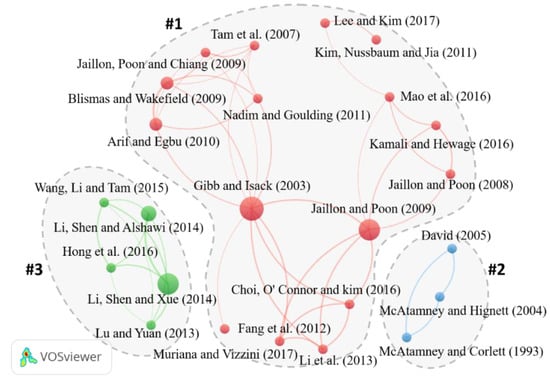

The document co-citation network is shown in Figure 4. The node size represents the number of citations of the paper. The thickness of the lines indicates the total link strength between papers. The clusters of different colors distinguish the tightness between these papers. Details are shown in Table 3, where Total Link Strength and Citation reflect the influence of these papers.

Figure 4.

Document co-citation network.

Table 3.

Highly co-citation papers.

According to Figure 4, Cluster 1 contains the most nodes and links than other clusters. As the papers in Cluster 1 are related to PC or RM, it can be inferred that PC research and RM research are well integrated and cited as the knowledge basis of RM in PC. Cluster 2 provides a knowledge base of worker ergonomic risks, reflecting consideration of social sustainability in this field [56,58,62]. The papers in Cluster 2 were published early, indicating that these papers are classic literature in the field of ergonomics. It may also indicate that the study of RM in PC has not yet drawn enough theory and ideas from recent ergonomic research. Cluster 3 contains a review paper and four research papers. The review paper highlights the sustainable performance of PC [41]. The topics of the four research papers are waste reduction [44,48,52] and life-cycle energy of PC [47]. These papers provide a theoretical basis for studying the risks of achieving the environmental sustainability of PC. In Figure 4, these three clusters are disjointed. The research argues that such isolated and homogeneous clusters occur when authors do not cite studies outside the cluster [1,63]. This suggests that researchers are not fully benefiting from the outcomes of other research areas. Hence, due to considerations of research enrichment and innovation, as well as the urgency of achieving sustainability in the construction industry [36,50], integrating these three clusters to achieve PC sustainability may be a promising research direction.

Some of the papers in Table 3 study RM in PC, and they are also the articles in the dataset of this study [59]. Reading these papers helps to reinforce the key knowledge base of RM in PC. However, some papers in Table 3 are not related to PC. For example, David [56] proposed classic ergonomic methods for assessing the health risk of workers. Even though this paper is not aimed at PC scenarios, it has become a reference method for studying the health risk of PC workers [64]. These papers, related to RM rather than PC, may provide innovative and effective solutions for managing the risk of PC. Some papers in Table 3 are not related to RM but are connected to PC. For instance, the paper with the highest total link strength and citations divided PC into four categories, namely modular building, volumetric pre-assembly, non-volumetric pre-assembly, and component manufacture/subassembly [40]. Then this paper has been widely recognized and cited by subsequent studies in the dataset to introduce PC clearly [1,6,65]. Reading these papers, which are related to PC but not RM, is advantageous to enhance the understanding of PC and inspire the research direction of RM in PC.

3.4. The Classification of Knowledge Theme

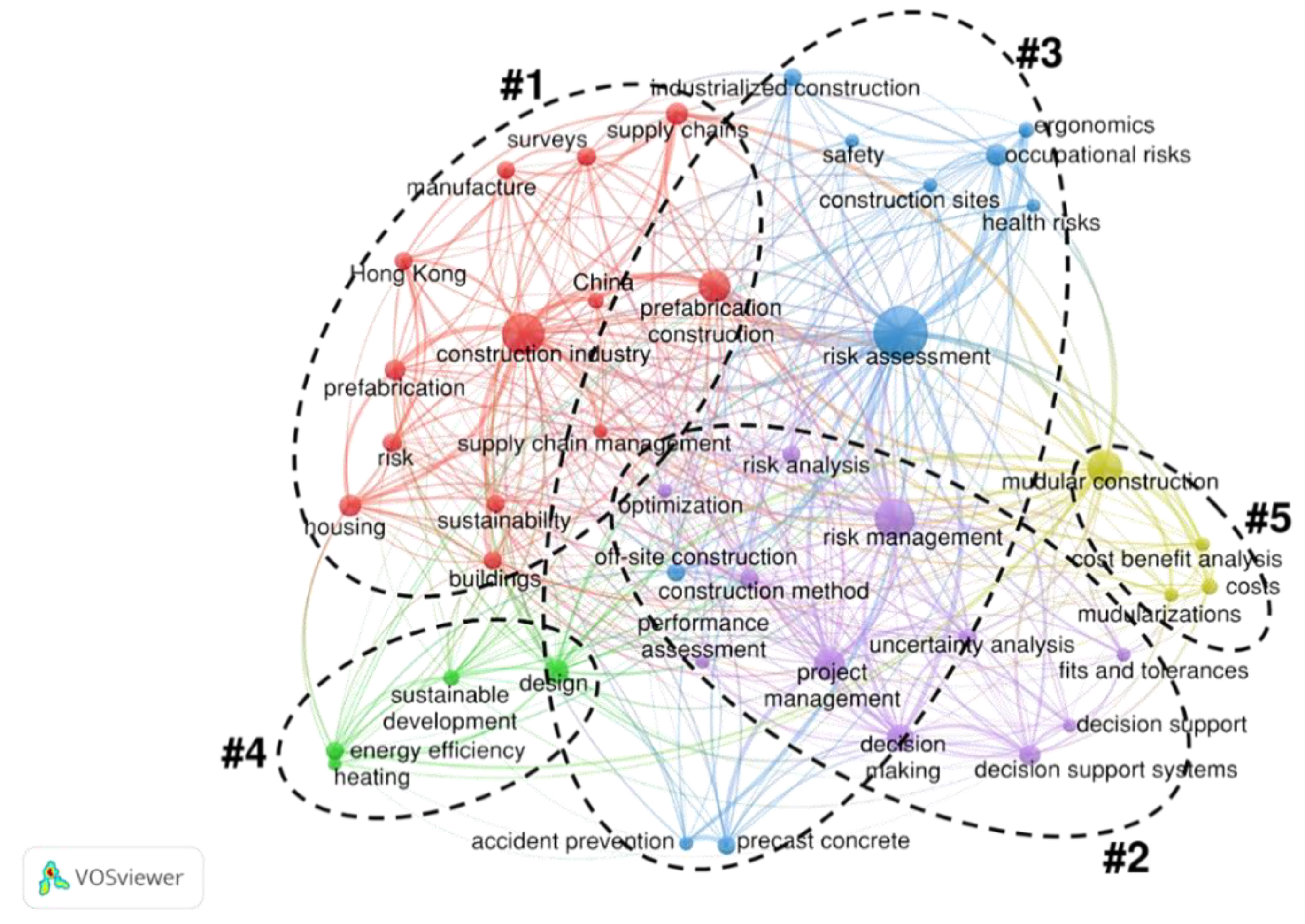

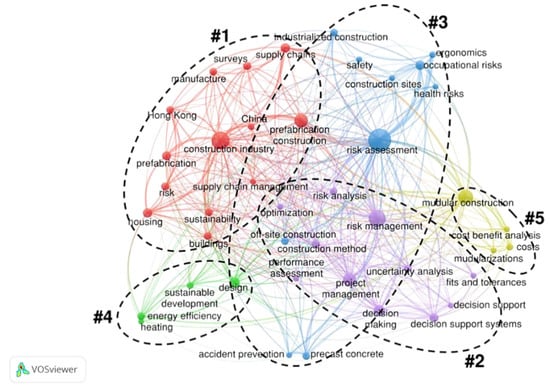

The keyword co-occurrence network is shown in Figure 5. In fact, some keywords in Figure 5 are not directly related to RM or PC in the literal sense. Nevertheless, this study believes that they do reflect the research boundaries, subjects, or content of RM in PC, which is why the original authors of these 144 articles chose these words as the keywords. In this case, this study did not artificially exclude any keywords in Figure 5, to help provide more information and classify knowledge themes more accurately. Knowledge themes can be classified according to the color of the keyword nodes in Figure 5. The naming of the knowledge themes is based on the common feature represented by the keywords within the cluster and the main content of articles where these keywords are located. The detailed naming explanation and research findings are as follows:

Figure 5.

Keyword co-occurrence network.

In Cluster 1, Supply chains and Supply chain management are critical factors in maintaining the development of the prefabrication industry [66]. Keywords such as China, Hong Kong, Housing, Buildings, and Construction industry all reflect the characteristics of the macro industry. Manufacture and Sustainability are the goals that PC is committed to achieving at the industry level [39,67]. Survey is often used to find out the situation and mechanism of PC applications at the macro industry level. In summary, all the above keywords support the naming of Cluster 1 as Supply chain and industry. China, Hong Kong, Prefabricated construction, Prefabrication, and Risk appear in this cluster, indicating that mainland China and Hong Kong attach importance to RM in PC.

In Cluster 2, according to Decision making, Decision supports, Decision support systems, Fits and tolerances (the optimization object that attracted attention in recent years), and Optimization, Cluster 2 is named Decision and optimization. Other keywords in this cluster are also related to decision-making and optimization. Before establishing decision-making and optimization models, Risk analysis and Uncertainty analysis is necessary. Once these models are established, it is necessary to evaluate their performance before applying them to real cases. Accordingly, Performance assessment support Cluster 2 is named Decision and optimization. Since project management can provide valuable decisions and optimization methods for RM in PC, it is justified that Project management and Risk management appear together in this cluster. For example, under the practice of stakeholder management in project management, RM decisions that are conducive to overall project performance can be made by coordinating stakeholder interests and goals [19].

Health risks, Occupational risks, Safety, Accident prevention, and Ergonomics are the strong support for naming Cluster 3 as Safety and Health. Ergonomics, as a subject that studies the interaction between people and the work environment, focuses on the physical health and psychological comfort of workers [58]. Its appearance indicates that providing a safe and decent environment for workers has received the attention from existing research. Construction sites are locations where safety and health risks are elevated. Accident prevention and Risk assessment are the focus of attention in safety and health risk research [68,69]. The presence of these keywords in this cluster also supports the naming of this theme as Safety and Health.

Backtracking the keywords in Cluster 4 to their articles, it is found that these articles discuss the environment and overheating risk of PC. In this way, this cluster is named Environment and overheating. Given that Design appears in this cluster, it can be inferred that articles have studied how to manage these risks from the design phase. Studies have confirmed that managing the generation, transfer, and reuse of waste in the design stage of PC can effectively alleviate the amplified impact of waste [52]. Sustainable development appears in this cluster, highlighting the role of managing environmental risks in promoting the sustainable development of PC. Sustainability that is similar to sustainable development, appears in Cluster 1 rather than this cluster. The reason for this is that sustainability is one of the goals of the PC industry and it makes more sense to appear in Cluster 1.

Based on the main content of the articles where the keywords in Cluster 5 are located, Cluster 5 is named Investment and cost. The size of the nodes in this cluster is small, indicating that only a few articles study RM in PC from the cost perspective. However, cost is the main issue restricting the development of PC [53,70], so it can be inferred that this theme calls for more research. Only one method, Cost-benefit analysis, is shown in this cluster. Therefore, a promising research opportunity may be to apply more methods to manage the investment and cost risks of PC. Moreover, Cluster 4 and Cluster 5 have the fewest keywords compared to other clusters. This suggests that the existing literature has paid relatively little attention to these risks.

4. Summary of Current Research

4.1. Knowledge Theme 1: Supply Chain and Industry

Many studies in this theme have widely identified and assessed critical risks of PC at the industry level. The evaluated critical risks include high initial and total cost [16], defect design [71], poor supply chain performance [72], complex construction management [42], unwarranted technology level [73], unskilled labor [74], stubborn socio-cultural climate [75], and volatile regulation [8]. Subsequently, corresponding strategies were proposed, such as improving the specification standard system, selecting the appropriate precast rate, and promoting whole-decoration residence industrialization [76].

According to the scientometric analysis, the supply chain risks (SCRs) are prominent in this theme. Due to (1) a longer chain caused by two or more workplaces; (2) more and earlier design work due to prefabrication lead time; and (3) higher requirements for accuracy, PC faces more SCRs than TCC [10]. As SCRs affect the integration, productivity, and efficiency of PC significantly [77], researchers have managed SCRs from the following three perspectives. Firstly, strengthening supply chain integration is confirmed as an effective measure to reduce SCRs according to the results of the game-theoretic analysis and the numerical simulation [78,79]. Then, lean thinking and knowledge management were introduced as the integration strategies to turn the SCRs into potential opportunities [77,80,81]. Secondly, optimizing the design of the supply chain is also a feasible strategy [29,82]. Afterward, risk-averse logistics configuration and hybrid intelligent vehicle systems were re-designed to reduce associated tension [83,84]. The last and emerging research is supply chain resilience, which is defined as the adaptive capability of the supply chain to prepare for unexpected events, respond to disruptions, and recover from them [85]. Research has confirmed that a more resilient supply chain can deal with SCRs effectively [86]. The vulnerabilities and capabilities of construction companies that affect supply chain resilience were also revealed [87,88]. For instance, the production and assembly construction of components have a significant impact on the resilience of the supply chain, while information and partnership factors moderate this influence process [89].

Researchers also explored the risks that affect the sustainability of PC. For example, Yunus and Yang [90] found poor coordination among stakeholders and improper construction plans affected the generation and disposal of waste, hindering the environmental sustainability of PC. Osobajo et al. [91] emphasized that researchers should focus on social issues of PC, such as the condition of workers. Khoshnava et al. [92] explored obstacles and drivers in steering PC towards the agenda of green and sustainability, revealing that cost hindered the sustainability performance of PC.

4.2. Knowledge Theme 2: Decision and Optimization

Effective decision-making can help manage PC risks. When deciding whether to adopt PC in the early stages of project execution, Murtaza, Fisher, and Skibniewski [38] proposed a computerized knowledge system that considered project risks to assist decision-making. Abdul Nabi and El-adaway [93] developed a risk-based method to assess the impact of PC adoption on the cost performance of construction projects, providing improved practices for decision-making, project team alignment, and RM. Then, for bidding, an information system was developed to reduce the risk of decision errors [94]. During the subsequent construction phase of PC, the fuzzy TOPSIS method [95,96], multi-agent-based simulation model [11], and BIM [84] were used for supplier selection, design change decision, and maintenance plan formulation, respectively, to reduce corresponding risks.

Optimization is also a powerful channel to manage PC risks. There are iterative and coupling tasks in PC projects, which cause a certain probability of rework [97]. In such a scenario, it is a challenge to optimize schedule performance and realize the advantages of PC in reducing construction time [98]. To address this issue, Shen, Li, Cao, and Zhang [97] developed a model for optimizing coupling tasks, using design structure matrix (DSM) and genetic algorithm (GA). The results of the case study show that the model can reduce the impacts of rework risk on time by 82.24%. To optimize schedule performance, Li et al. [99] developed a radio frequency identification device (RFID)-enabled BIM platform, which integrates various stakeholders, information/data flow, and construction processes. Fits and tolerances are popular optimization objects in recent years. In tradition, trial and error strategies and standardized tolerance values were used for managing the accumulating effects of dimensional and geometric variability in PC, usually leading to the rework risk [17]. To fill this gap, comprehensive tolerance strategies have been used for minimizing both fabrication costs and project risks [100]. For example, Monte Carlo tolerance simulation was used for tolerance analysis [101]. Bayesian inference theory was used for evaluating the unique relationships among tolerance-related risks [102]. The probability-impact risk model was employed for dynamic assessment and proactive management [65]. These studies have played a positive role in optimizing dimensional and geometric variability to reduce rework risks.

When carrying out RM through decision-making and optimization methods, uncertainty analysis is often involved [103]. For instance, to express uncertainty, fuzzy set theory and the analytic hierarchy process (AHP) method were applied [42]. Multi-attribute utility theory [104], Media richness theory [105], Bayesian theory [102], discrete event simulation experiments [106], and cloud model [107] were also used for uncertainty analysis to support decision-making and optimization. Obviously, uncertainty analysis has injected valuable content into RM in PC. It can be further inferred that uncertainty analysis, decision-making, and optimization methods will be inseparable in future research.

4.3. Knowledge Theme 3: Safety and Health

As PC transfers construction activities to the more controlled off-site and has fewer high-altitude operations, it is considered to be more effective in managing safety risks than TCC [6,108]. However, the overturning of heavy equipment and the fall of unfixed PC components still incur safety accidents during the hoisting process [13]. Hussein and Zayed [14] argued that cranes are the centerpiece of construction equipment. This study also proposed that it is crucial to design an effective control system to maintain the stability of the crane and eliminate the swinging of the prefabricated components. Mohandes, et al. [109] developed a Crane Safety Index to improve the occupational safety of PC workers. BIM and digital twin were combined to build a PC monitoring system to visualize the time-varying data information and mine the coupling safety risk [110,111]. Similar to TCC, unsafe behavior of workers (e.g., the improper wearing of protective equipment) and the lack of a safety management system elevate safety risks [107]. Therefore, workers’ safety training is crucial for managing safety risks. Traditional safety training methods include video training, on-site training, and lecture presentations. As these approaches can be either costly or unengaging [112], Goulding et al. [113] proposed a VR interactive training environment prototype. The case study proved that this method improved workers’ safety awareness and could be cost-effective. Additionally, Kim et al. [114] argued that most research on PC safety management has focused on on-site safety, but those potentially hazardous tasks (e.g., handling and transporting heavy materials) in component factories should not be overlooked. In this regard, this study proposed safety management guidelines for PC plants. The guidance suggests that the key safety management point is the proximity of workers to dynamic risk factors (e.g., moving equipment or vehicles, moving loads), so vision-based real-time localization and proximity detection between objects should be applied to this scenario.

As for the health risk of PC, all the existing literature is based on ergonomics. Despite the widespread use of automated equipment in PC projects, workers are often exposed to repetitive motion and awkward body postures [68]. Such ergonomic risk factors are the primary causes of work-related musculoskeletal disorders (e.g., injuries and disorders of muscles, tendons, and nerves) [115]. To deal with this problem, REBA and RULA have been used for identifying and assessing workers’ body postures [64,116]. As they can only be used for assessing a single body posture manually, VR and motion capture technology are combined to provide more automatic and accurate ergonomic evaluation results recently, urging workers to reduce inappropriate postures and improve workplace design [68,117].

4.4. Knowledge Theme 4: Environment and Overheating

The case study found that construction waste could be reduced by 84.7% with the adoption of PC [55]. However, this study only considered the situation at the construction site. According to Lu and Yuan [52], the production and transportation of prefabricated components also increase the risk of waste generation. On the one hand, transferring the waste from the construction site to other construction phases is irresponsible and detrimental to the cooperation of stakeholders. On the other hand, only reducing waste at the construction site hinders the PC’s sustainable development. Future research should consider the generation and reuse of construction waste of all the construction stages from the whole life cycle perspective.

Overheating of buildings is mainly caused by the building’s limited ability to reject and dissipate unwanted heat [118]. Due to past climatic conditions, air conditioning is not used in most of Europe. Since the heat wave intensified in 2010, European scholars, especially British scholars, have carried out the research on overheating risk of buildings. For example, through simulation analysis, Rodrigues et al. [119] found that despite mitigation strategies developed at the design stage, PC still faces the overheating risk, which will aggravate in future scenarios. Monitored data from Bradford Royal Infirmary also supported this view [120]. To solve this issue, through experimental testing, Rodrigues, Sougkakis, and Gillott [118] found that the application of high-density fiberboard and phase change materials could regulate the internal temperature. Simulations also showed that with adequate solar shading, reinforced natural ventilation [121], and climate-adaptive design [122], overheating risk of PC could be mitigated greatly. In short, the result reveals that PC itself does not have an excellent mitigation effect on overheating risk, but the construction logic of PC provides a platform to apply more mitigation measures from the design stage. This is more beneficial and suitable for the management of the overheating risk compared to TCC.

4.5. Knowledge Theme 5: Investment and Cost

Compared with TCC, PC faces more initial investment risk and incremental cost risk [123]. For example, when investing in a production line for prefabricated components, an initial one-time cost and fund recovery period arouse the concern and hesitation of factories [124]. After that, the contractor needs to pay the factory a deposit in advance [125]. These situations have brought high investment and financing risks to PC practitioners [126]. Moreover, the evolutionary game analysis revealed that PC is exposed to incremental cost risk [127]. The study believes that design defects and immaturity of PC technology amplify this risk [128]. The results of the failure mode and effects analysis (FMEA) show that defects in the design phase incur more incremental costs than defects in other stages of PC [59].

To manage these risks, researchers have put forward many targeted strategies. For investment and financing risks, according to the empirical results of the structural equation modelling, financial institutions should provide more consumer loan channels for small and medium-sized enterprises. The enterprises should analyze the fund-raising channels and choose the most appropriate way carefully to reduce the financing cost [124]. Usually, the investment risk comes mainly from the immaturity of the PC market, which is beyond a company’s own control and assumption [59]. In this way, government intervention is crucial. For incremental cost risk, the research shows that the suitability of the design for modularization, timely design freeze, and early design changes were sufficient to achieve cost success, that is, to manage the incremental cost risk [5,128]. Simulation results of the system dynamics showed that improved technical efficiency could reduce this risk [129]. In this way, cooperation, innovation, and breakthroughs in PC technology are essential [128]. In addition, research has shown that the complete prefabrication contract that clarifies the rights and responsibilities of both participate was an effective way to manage incremental cost risk [125,130]. Similarly, through the analysis of the commercial and legal provisions, case study analysis, and comparative analysis, Assaad et al. [131] provided a lot of guidance for PC, including offer acceptance, requirements for a written contract, risk of loss, contract breach, and warranties.

5. Discussion

By summarizing the above research status, it is found that there is significant room for further exploration of RM in PC. In Cluster 1, many studies have extensively identified and evaluated key risks in PC, such as high initial costs and defective designs. Corresponding RM strategies were subsequently proposed. However, most articles did not evaluate the effect of eliminating key risks [76]. In this way, the effectiveness of the strategies proposed in these articles is not convincing enough. Hence, it is necessary and promising to confirm the effectiveness of these RM strategies through simulation analysis and case studies. In addition, these studies are based on an individual country or regional contexts. Risks of PC in different countries and scenarios are still worth comparing to provide an international perspective. The applicability of the proposed strategies in different countries and regions also needs to be further explored. Moreover, as some studies have highlighted the risks to PC sustainability from environmental, social, and economic dimensions [90,91,92], more research is needed to integrate the above three dimensions to help promote PC sustainability from a holistic perspective [132].

In Cluster 2, existing decision-making methods are applied to supplier selection, design change decisions, and maintenance plan development to reduce corresponding risks [11,84,95]. More actual scenarios still require decision-making, such as the combination of prefabricated components, the intervention of sustainable construction, etc. Moreover, limited to previous computing capacity, the decision-making and optimization models simplify the complex scenarios more or less. Now with the innovation of intelligent algorithms, future research can add more factors (e.g., psychological factors of stakeholders) in the models to get closer to the real scenario and obtain more scientific results for RM in PC [133,134].

In Cluster 3, although many methods have been proposed to manage the safety risks of PC, the large-scale application of these methods to form a safety culture and climate is still a challenge. The barriers to application deserve further exploration in future studies [113]. Multiple digital tools are also worthy of further exploration in this theme. For example, based on 3S (remote sensing, RS; geography information systems, GIS; global positioning systems, GPS) and RFID technology, the real-time location and early warning system can be established [37]. Existing studies have assessed health risks by recruiting participants based on ergonomics in a laboratory setting using technologies such as VR and motion capture [68,116]. Although the sample size of participants is sufficient to support the feasibility of the study, a more robust statistical result could have been provided if the data set had been extended. Besides, the physical workload and mental state of the participants may be different in the laboratory than in the actual PC construction site. This suggests that the impact of the cognitive and affective state on the health risk should be measured [68].

In Cluster 4, future research should manage the generation and reuse of waste in PC from the whole life cycle perspective to avoid risk transfer. The treatment of this risk can refer to the research results related to the circular economy [52]. Moreover, this review found no papers that study the overheating risk of PC published in 2021 and 2022, suggesting that this topic has not received much attention from recent studies. However, the high temperatures of 2022 break the historical extremes of many countries (e.g., China), endangering people’s lives and economic ecology. This situation is still likely to continue to worsen as the climate warms. Therefore, exploring how to take advantage of PC to mitigate the overheating risk remains a promising research direction.

In Cluster 5, managing investment risk requires the intervention of the state. However, specific recommendations for policy makers are lacking and it is unclear how to coordinate between policy makers, firms, and financial institutions. According to Yuan et al. [135] and Dou et al. [136], specific measures can be developed in detail through tripartite evolutionary game analysis. Existing research has provided much guidance on the allocation of responsibility for prefabricated contracts in the hope of reducing incremental cost risk [131]. Nevertheless, the adaptability and adjustment of the prefabricated contract in different countries and regions need to be further explored.

In addition, as smart construction is integrated with construction industrialization, emerging fields such as digital twin and blockchain will inject new development sources for PC [137]. Nonetheless, the application of these digital-driven technologies can also spawn trade secrets and data breaches, as well as raise ethical risks, which need to be attended to in future research and practice.

Because of the difference in the construction process and business model between PC and TCC, the risks they face and their focus on RM are different. One example is the safety risk of crane overturning during PC hoisting process [14]. Nonetheless, the content of RM in PC also belongs to the classic processes of RM, which include risk identification, analysis, assessment, and treatment [23,24]. Hence, after categorizing the 144 articles into the RM processes, the findings were further discussed. It should be noted that the 144 articles in the dataset may involve several processes of RM, so the sum of the number of articles involving these four processes is not equal to 144.

- Risk identification: There are 38 articles involved in risk identification of PC. The most commonly used method is to establish a checklist through brainstorming, literature review, expert interviews, questionnaire surveys, and field investigations [71,79,138]. Furthermore, FMEA and thematic analysis are also used for risk identification in a small number of studies [59,88]. Using these methods, studies have extensively identified the risk of PC. Both PC and TCC are exposed to risks such as material price fluctuations, material supply delays, severe weather, and policy changes. PC’s proprietary risks include dimensional deviations of components, damage to components, and collisions of components with workers.

- Risk analysis: There are 30 articles involved in risk analysis of PC. Most of the articles adopt simulation techniques to determine the influence of risks. For example, multi-agent simulation was used for measuring the improvement of project performance by RM strategies in design changes [11]. System dynamics was used for analyzing the impact of the risk on the PC schedule [139]. Monte Carlo simulation was used for predicting the accumulation of tolerances and dimensional variability [101]. Probability-impact risk model was used for showing the relative importance of risk events [65,69]. Nonetheless, the impact of various risks on project objectives such as cost, quality, and sustainability has not been analyzed fully and comprehensively. This is not conducive to revealing the severity of the risk or to raising practitioners’ concerns about managing PC risk.

- Risk assessment: In total, 39 articles are involved in risk assessment of PC. There are many techniques used for it, such as statistical tests [16], meta-network analysis [15], social network analysis [79], principal component analysis [140], fuzzy AHP [141], and so on. This study has summarized the critical risks of PC in Section 4.1. In general, the critical risks are affirmed, and the applied methods are prosperous.

- Risk treatment: 60 articles in the dataset study risk treatment. Among them, three articles discussed risk aversion [83,142,143], four articles discussed risk transfer [52,69,144,145], and no article discussed risk retention for PC. The remaining articles belong to the category of risk reduction. As the most responsible method in risk treatment, risk reduction is worthy of study. Nevertheless, as risk reduction in practice is not so accessible, the suitability of other risk treatment methods in different contexts may be worth discussing. For instance, when the probability of the risk occurring is low and the consequences of the risk are acceptable, the risk retention approach is feasible.

After proposing future research directions in terms of both knowledge themes and classical processes of RM, this research further proposes RM strategies. It is hoped that this will promote RM practice and thus alleviate the limitations of PC development.

In Cluster 1, existing literature suggested that managing SCRs is of great importance to the development of PC industry [10]. Existing studies have confirmed that enhancing supply chain integration, optimizing supply chain design, and developing supply chain resilience are effective measures to reduce SCRs in PC. The specific practice suggestions are as follows. Conduct regular communication with supply chain members and develop contractual documents that clearly define the roles and responsibilities of members to reduce interest conflicts and promote supply chain integration [77]. Optimize PC’s supply chain by building long-term relationships with dedicated small, local suppliers to facilitate the formation of value-driven lean purchasing [81]. Use information markers for components and establish an information-sharing platform to improve the risk resistance of the supply chain [89].

In Cluster 2, practitioners should draw on decision models from existing literature to help reduce the impact of risks on PC performance in selecting suppliers, combining components, etc. [95,96]. Schedule risk influences the realization of PC’s efficiency advantage [98]. Lean thinking can be used to manage this risk significantly. Specifically, it is essential to identify value-generating activities in the production, transportation, and warehousing processes and streamline those activities (e.g., secondary handling of components) that do not generate value to improve efficiency [146]. Moreover, comprehensive tolerance strategies (e.g., including all dimensional and geometric tolerances for outsourced components in the production plan so that workers are aware of acceptable geometric and dimensional variables) that have been proposed in recent years should be adopted to optimize the accumulating effect of dimensional and geometric variability in PC [65]. This can compensate for the error that arise in traditional designs.

In Cluster 3, according to existing studies, crane overturning is an important factor in causing safety accidents in PC [14]. The use of an effective control system to maintain the stability of the crane and minimize the oscillation of the prefabricated components is the most effective means in dealing with the safety risk of PC. Widespread application of safety warning systems based on BIM, RFID, 3S, etc. also contributes to the safety of workers [110,111]. At the same time, it is necessary to raise workers’ safety awareness and reduce their unsafe behaviors (e.g., the improper wearing of protective equipment) through VR training and lecture presentations [113]. Worker health is a concern for the long-term development of the construction industry. Practitioners can use REBA, RULA, and VR to identify and assess the health risks of workers in PC factories and construction sites [68,117]. Then, urge workers to reduce inappropriate posture and improve workplace design to ensure the health of workers.

In Cluster 4, PC stakeholders should be involved in the design phase in advance to consider waste generation and reuse from the perspective of the whole life cycle [52]. This can avoid the transfer of waste. As the climate deteriorates, the risk of overheating in buildings cannot be underestimated. For PC, existing research confirms that conducting climate-adaptive design and adding mitigation measures (e.g., high-density fibreboard, phase change materials) are effective measures [118].

In Cluster 5, for investment risk, effective measures confirmed by the existing literature include strengthening the role of state action (e.g., establishing industrial bases to achieve economies of scale) and introducing preferential and incentive strategies (e.g., providing more access to low-interest loans) [124]. Incremental cost risk is an important factor affecting PC adoption [59]. Improving the design, regulating market behavior, clarifying commercial legal provisions, and defining stakeholder rights and responsibilities in contracts are all strategies that have a significant influence on the incremental cost risk of PC [129,131].

6. Conclusions

RM in PC has attracted increasing attention worldwide because of the profound impact of risks on PC performance. This study adopted the scientometric analysis to explore the knowledge domain of RM in PC. A total of 144 peer-reviewed articles were selected from the Scopus database as the dataset for this review. Through annual publication statistics, journal citation analysis, document co-citation analysis, and keyword co-occurrence analysis, key highlights are as follows:

- Since 2011, publications concerning RM in PC have gradually increased. It is inferred that the research in this domain will continue to grow in the future.

- Journal of Construction Engineering and Management has the highest number of publications and the most cited articles in this field. International Journal of Construction Management, Journal of Building Engineering, and Buildings have been cited more frequently in recent years and can provide an up-to-date research base.

- PC research, RM research, environmental sustainability research, and ergonomic research form a solid foundation for the research on RM in PC.

- Existing studies are conducted from five knowledge themes, namely, Supply chain and industry, Decision and optimization, Safety and health, Environment and overheating, and Investment and cost. These themes are related to each other and reflect their apparent boundaries.

After that, this study revealed the research status according to the classification of knowledge themes. Future research directions are proposed in terms of both knowledge themes and classical processes of RM. Finally, RM strategies for PC practice are provided. In this way, this review provides both theoretical and practical implications. In terms of theoretical implications, as the first review to study RM in PC using the scientometric analysis, this study makes up for the lack of core knowledge distribution, knowledge research base, and knowledge theme classification in existing reviews. By integrating the fragmented knowledge and proposing future research directions, this study may stimulate researchers to make further innovative efforts in this area. In terms of practical implications, the results of this study provide practitioners with a clear and holistic picture of the knowledge domain in this field. This may improve their perception of the need for RM in PC. The RM strategies proposed in this study may be conducive to optimizing RM practices in PC, thus facilitating the development of PC. Nevertheless, there remain some limitations. For example, RM strategies proposed in this study are largely made based on anecdotal evidence rather than rigorous data. As a result, the effectiveness of these strategies in different scenarios needs to be compared and tested in future research and practice.

Author Contributions

Conceptualization, T.L. and L.L.; methodology, T.L. and Z.L.; software, T.L.; validation, Z.L., L.L. and P.J.; formal analysis, L.L.; investigation, T.L. and P.J.; resources, Z.L.; data curation, T.L.; writing—original draft preparation, T.L.; writing—review and editing, L.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China, grant number 72071027, the Natural Science Foundation of Shandong Province, grant number ZR2021QG046, and the China Postdoctoral Science Foundation, grant number 2022M712047.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors appreciate the financial support of the National Natural Science Foundation of China, grant number (72071027), the Natural Science Foundation of Shandong Province, grant number (ZR2021QG046), and the China Postdoctoral Science Foundation, grant number (2022M712047).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hosseini, M.R.; Martek, I.; Zavadskas, E.K.; Aibinu, A.A.; Arashpour, M.; Chileshe, N. Critical evaluation of off-site construction research: A Scientometric analysis. Autom. Constr. 2018, 87, 235–247. [Google Scholar] [CrossRef]

- Li, L.; Li, Z.; Li, X.; Wu, G. A review of global lean construction during the past two decades: Analysis and visualization. Eng. Constr. Arch. Manag. 2019, 26, 1192–1216. [Google Scholar] [CrossRef]

- Li, L.; Li, Z.; Wu, G.; Li, X. Critical Success Factors for Project Planning and Control in Prefabrication Housing Production: A China Study. Sustainability 2018, 10, 836. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C. The evolution of prefabricated residential building systems in Hong Kong: A review of the public and the private sector. Autom. Constr. 2009, 18, 239–248. [Google Scholar] [CrossRef]

- Choi, J.O.; O’Connor, J.T.; Kim, T.W. Recipes for Cost and Schedule Successes in Industrial Modular Projects: Qualitative Comparative Analysis. J. Constr. Eng. Manag. 2016, 142, 04016055. [Google Scholar] [CrossRef]

- Ahn, S.; Crouch, L.; Kim, T.W.; Rameezdeen, R. Comparison of worker safety risks between onsite and offsite construction methods: A site management perspective. J. Constr. Eng. Manag. 2020, 146, 05020010. [Google Scholar] [CrossRef]

- Li, L.; Li, Z.; Li, X.; Zhang, S.; Luo, X. A new framework of industrialized construction in China: Towards on-site industrialization. J. Clean. Prod. 2020, 244, 118469. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q.P.; Mahmud, A.T. Critical risk factors in the application of modular integrated construction: A systematic review. Int. J. Constr. Manag. 2019, 22, 133–147. [Google Scholar] [CrossRef]

- Arditi, D.; Ergin, U.; Günhan, S. Factors Affecting the Use of Precast Concrete Systems. J. Archit. Eng. 2000, 6, 79–86. [Google Scholar] [CrossRef]

- Koskela, L. Is structural change the primary solution to the problems of construction? Build. Res. Inf. 2003, 31, 85–96. [Google Scholar] [CrossRef]

- Du, J.; Jing, H.; Castro-Lacouture, D.; Sugumaran, V. Multi-agent simulation for managing design changes in prefabricated construction projects. Eng. Constr. Arch. Manag. 2019, 27, 270–295. [Google Scholar] [CrossRef]

- Bin Ismail, Z.-A. Hybrid intelligent vehicle system for managing construction supply chain in precast concrete building construction projects. World J. Eng. 2021, 18, 538–546. [Google Scholar] [CrossRef]

- Jeong, G.; Kim, H.; Lee, H.-S.; Park, M.; Hyun, H. Analysis of safety risk factors of modular construction to identify accident trends. J. Asian Arch. Build. Eng. 2021, 21, 1040–1052. [Google Scholar] [CrossRef]

- Hussein, M.; Zayed, T. Crane operations and planning in modular integrated construction: Mixed review of literature. Autom. Constr. 2021, 122, 103466. [Google Scholar] [CrossRef]

- Wang, T.; Gao, S.; Li, X.; Ning, X. A meta-network-based risk evaluation and control method for industrialized building construction projects. J. Clean. Prod. 2018, 205, 552–564. [Google Scholar] [CrossRef]

- Zhang, W.; Lee, M.W.; Jaillon, L.; Poon, C.-S. The hindrance to using prefabrication in Hong Kong’s building industry. J. Clean. Prod. 2018, 204, 70–81. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q. Barriers to the adoption of modular integrated construction: Systematic review and meta-analysis, integrated conceptual framework, and strategies. J. Clean. Prod. 2020, 249, 119347. [Google Scholar] [CrossRef]

- Sousa, V.; Almeida, N.M.; Dias, L.A. Risk-based management of occupational safety and health in the construction industry—Part 1: Background knowledge. Saf. Sci. 2014, 66, 75–86. [Google Scholar] [CrossRef]

- Xia, N.; Zou, P.X.; Griffin, M.A.; Wang, X.; Zhong, R. Towards integrating construction risk management and stakeholder management: A systematic literature review and future research agendas. Int. J. Proj. Manag. 2018, 36, 701–715. [Google Scholar] [CrossRef]

- Edwards, P.J.; Bowen, P.A. Risk and risk management in construction: A review and future directions for research. Eng. Constr. Archit. Manag. 1998, 5, 339–349. [Google Scholar] [CrossRef]

- Siraj, N.B.; Fayek, A.R. Risk Identification and Common Risks in Construction: Literature Review and Content Analysis. J. Constr. Eng. Manag. 2019, 145, 03119004. [Google Scholar] [CrossRef]

- Kassem, M.A.; Khoiry, M.A.; Hamzah, N. Theoretical review on critical risk factors in oil and gas construction projects in Yemen. Eng. Constr. Arch. Manag. 2021, 28, 934–968. [Google Scholar] [CrossRef]

- Ahmed, A.; Kayis, B.; Amornsawadwatana, S. A review of techniques for risk management in projects. Benchmarking Int. J. 2007, 14, 22–36. [Google Scholar] [CrossRef]

- Mills, A. A systematic approach to risk management for construction. Struct. Surv. 2001, 19, 245–252. [Google Scholar] [CrossRef]

- Hood, W.; Wilson, C. The literature of bibliometrics, scientometrics, and informetrics. Scientometrics 2001, 52, 291–314. [Google Scholar] [CrossRef]

- Martinez, P.; Al-Hussein, M.; Ahmad, R. A scientometric analysis and critical review of computer vision applications for construction. Autom. Constr. 2019, 107, 102947. [Google Scholar] [CrossRef]

- Zhao, X. A scientometric review of global BIM research: Analysis and visualization. Autom. Constr. 2017, 80, 37–47. [Google Scholar] [CrossRef]

- Jin, R.; Zou, Y.; Gidado, K.; Ashton, P.; Painting, N. Scientometric analysis of BIM-based research in construction engineering and management. Eng. Constr. Arch. Manag. 2019, 26, 1750–1776. [Google Scholar] [CrossRef]

- Luo, L.; Jin, X.; Shen, G.Q.; Wang, Y.; Liang, X.; Li, X.; Li, C.Z. Supply Chain Management for Prefabricated Building Projects in Hong Kong. J. Manag. Eng. 2020, 36, 05020001. [Google Scholar] [CrossRef]

- Ghosh, A.; Edwards, D.J.; Hosseini, M.R. Patterns and trends in Internet of Things (IoT) research: Future applications in the construction industry. Eng. Constr. Arch. Manag. 2021, 28, 457–481. [Google Scholar] [CrossRef]

- Jin, R.; Gao, S.; Cheshmehzangi, A.; Aboagye-Nimo, E. A holistic review of off-site construction literature published between 2008 and 2018. J. Clean. Prod. 2018, 202, 1202–1219. [Google Scholar] [CrossRef]

- Araújo, A.G.; Pereira Carneiro, A.M.; Palha, R.P. Sustainable construction management: A systematic review of the literature with meta-analysis. J. Clean. Prod. 2020, 256, 120350. [Google Scholar] [CrossRef]

- Zhang, S.; Li, Z.; Li, T.; Yuan, M. A Holistic Literature Review of Building Information Modeling for Prefabricated Construction. J. Civ. Eng. Manag. 2021, 27, 485–499. [Google Scholar] [CrossRef]

- Zhong, B.; Wu, H.; Li, H.; Sepasgozar, S.; Luo, H.; He, L. A scientometric analysis and critical review of construction related ontology research. Autom. Constr. 2019, 101, 17–31. [Google Scholar] [CrossRef]

- Su, H.-N.; Lee, P.-C. Mapping knowledge structure by keyword co-occurrence: A first look at journal papers in Technology Foresight. Scientometrics 2010, 85, 65–79. [Google Scholar] [CrossRef]

- Luo, T.; Xue, X.; Tan, Y.; Wang, Y.; Zhang, Y. Exploring a body of knowledge for promoting the sustainable transition to prefabricated construction. Eng. Constr. Arch. Manag. 2021, 28, 2637–2666. [Google Scholar] [CrossRef]

- Jin, R.; Zou, P.X.; Piroozfar, P.; Wood, H.; Yang, Y.; Yan, L.; Han, Y. A science mapping approach based review of construction safety research. Saf. Sci. 2019, 113, 285–297. [Google Scholar] [CrossRef]

- Murtaza, M.B.; Fisher, D.J.; Skibniewski, M.J. Knowledge-Based Approach to Modular Construction Decision Support. J. Constr. Eng. Manag. 1993, 119, 115–130. [Google Scholar] [CrossRef]

- Li, L.; Luan, H.; Yin, X.; Dou, Y.; Yuan, M.; Li, Z. Understanding Sustainability in Off-Site Construction Management: State of the Art and Future Directions. J. Constr. Eng. Manag. 2022, 148, 03122008. [Google Scholar] [CrossRef]

- Gibb, A.G.; Isack, F. Re-engineering through pre-assembly: Client expectations and drivers. Build. Res. Inf. 2003, 31, 146–160. [Google Scholar] [CrossRef]

- Li, Z.; Shen, G.Q.; Xue, X. Critical review of the research on the management of prefabricated construction. Habitat Int. 2014, 43, 240–249. [Google Scholar] [CrossRef]

- Li, H.; Al-Hussein, M.; Lei, Z.; Ajweh, Z. Risk identification and assessment of modular construction utilizing fuzzy analytic hierarchy process (AHP) and simulation. Can. J. Civ. Eng. 2013, 40, 1184–1195. [Google Scholar] [CrossRef]

- Muriana, C.; Vizzini, G. Project risk management: A deterministic quantitative technique for assessment and mitigation. Int. J. Proj. Manag. 2017, 35, 320–340. [Google Scholar] [CrossRef]

- Li, Z.; Shen, G.Q.; Alshawi, M. Measuring the impact of prefabrication on construction waste reduction: An empirical study in China. Resour. Conserv. Recycl. 2014, 91, 27–39. [Google Scholar] [CrossRef]

- Arif, M.; Egbu, C. Making a case for offsite construction in China. Eng. Constr. Arch. Manag. 2010, 17, 536–548. [Google Scholar] [CrossRef]

- Blismas, N.; Wakefield, R. Drivers, constraints and the future of offsite manufacture in Australia. Constr. Innov. 2009, 9, 72–83. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Mao, C.; Li, Z.; Li, K. Life-cycle energy analysis of prefabricated building components: An input–output-based hybrid model. J. Clean. Prod. 2016, 112, 2198–2207. [Google Scholar] [CrossRef]

- Wang, J.; Li, Z.; Tam, V.W. Identifying best design strategies for construction waste minimization. J. Clean. Prod. 2015, 92, 237–247. [Google Scholar] [CrossRef]

- Nadim, W.; Goulding, J.S. Offsite production: A model for building down barriers: A European construction industry perspective. Eng. Constr. Archit. Manag. 2011, 18, 82–101. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S. Sustainable construction aspects of using prefabrication in dense urban environment: A Hong Kong case study. Constr. Manag. Econ. 2008, 26, 953–966. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K. Life cycle performance of modular buildings: A critical review. Renew. Sustain. Energy Rev. 2016, 62, 1171–1183. [Google Scholar] [CrossRef]

- Lu, W.; Yuan, H. Investigating waste reduction potential in the upstream processes of offshore prefabrication construction. Renew. Sustain. Energy Rev. 2013, 28, 804–811. [Google Scholar] [CrossRef]

- Mao, C.; Xie, F.; Hou, L.; Wu, P.; Wang, J.; Wang, X. Cost analysis for sustainable off-site construction based on a multiple-case study in China. Habitat Int. 2016, 57, 215–222. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S.; Chiang, Y.H. Quantifying the waste reduction potential of using prefabrication in building construction in Hong Kong. Waste Manag. 2009, 29, 309–320. [Google Scholar] [CrossRef] [PubMed]

- Tam, V.W.; Tam, C.; Zeng, S.; Ng, W.C. Towards adoption of prefabrication in construction. Build. Environ. 2007, 42, 3642–3654. [Google Scholar] [CrossRef]

- David, G.C. Ergonomic methods for assessing exposure to risk factors for work-related musculoskeletal disorders. Occup. Med. 2005, 55, 190–199. [Google Scholar] [CrossRef]

- McAtamney, L.; Hignett, S. Rapid entire body assessment. In Handbook of Human Factors and Ergonomics Methods; CRC Press: Boca Raton, FL, USA, 2004; pp. 97–108. [Google Scholar]

- McAtamney, L.; Corlett, E.N. RULA: A survey method for the investigation of work-related upper limb disorders. Appl. Ergon. 1993, 24, 91–99. [Google Scholar] [CrossRef]

- Lee, J.-S.; Kim, Y.-S. Analysis of cost-increasing risk factors in modular construction in Korea using FMEA. KSCE J. Civ. Eng. 2017, 21, 1999–2010. [Google Scholar] [CrossRef]

- Kim, S.; Nussbaum, M.A.; Jia, B. Low back injury risks during construction with prefabricated (panelised) walls: Effects of task and design factors. Ergonomics 2011, 54, 60–71. [Google Scholar] [CrossRef]

- Fang, C.; Marle, F.; Zio, E.; Bocquet, J.-C. Network theory-based analysis of risk interactions in large engineering projects. Reliab. Eng. Syst. Saf. 2012, 106, 1–10. [Google Scholar] [CrossRef]

- Hignett, S.; McAtamney, L. Rapid Entire Body Assessment (REBA). Appl. Ergon. 2000, 31, 201–205. [Google Scholar] [CrossRef]

- Hicks, D. The difficulty of achieving full coverage of international social science literature and the bibliometric consequences. Scientometrics 1999, 44, 193–215. [Google Scholar] [CrossRef]

- Li, X.; Han, S.; Gül, M.; Al-Hussein, M. Automated post-3D visualization ergonomic analysis system for rapid workplace design in modular construction. Autom. Constr. 2019, 98, 160–174. [Google Scholar] [CrossRef]

- Enshassi, M.S.A.; Walbridge, S.; West, J.S.; Haas, C.T. Dynamic and Proactive Risk-Based Methodology for Managing Excessive Geometric Variability Issues in Modular Construction Projects Using Bayesian Theory. J. Constr. Eng. Manag. 2020, 146, 04019096. [Google Scholar] [CrossRef]

- Goh, C.S.; Chong, H.-Y.; Jack, L.; Faris, A.F.M. Revisiting triple bottom line within the context of sustainable construction: A systematic review. J. Clean. Prod. 2020, 252, 119884. [Google Scholar] [CrossRef]

- Ma, S.; Li, Z.; Li, L.; Yuan, M. Coupling coordination degree spatiotemporal characteristics and driving factors between new urbanization and construction industry: Evidence from China. Eng. Constr. Arch. Manag. 2022. [Google Scholar] [CrossRef]

- Barkokebas, R.D.; Al-Hussein, M.; Li, X. VR–MOCAP-Enabled Ergonomic Risk Assessment of Workstation Prototypes in Offsite Construction. J. Constr. Eng. Manag. 2022, 148, 04022064. [Google Scholar] [CrossRef]

- Dabirian, S.; Han, S.H.; Lee, J. Stochastic-based noise exposure assessment in modular and off-site construction. J. Clean. Prod. 2020, 244, 118758. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Li, Z.; Zhang, B.; Zhang, W. Barriers to promoting prefabricated construction in China: A cost–benefit analysis. J. Clean. Prod. 2018, 172, 649–660. [Google Scholar] [CrossRef]

- Wang, Z.-L.; Shen, H.-C.; Zuo, J. Risks in Prefabricated Buildings in China: Importance-Performance Analysis Approach. Sustainability 2019, 11, 3450. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q.; Saka, A.B. Computing the severities of critical onsite assembly risk factors for modular integrated construction projects. Eng. Constr. Arch. Manag. 2022. [Google Scholar] [CrossRef]

- Luo, L.-Z.; Mao, C.; Shen, L.-Y.; Li, Z.-D. Risk factors affecting practitioners’ attitudes toward the implementation of an industrialized building system: A case study from China. Eng. Constr. Archit. Manag. 2015, 22, 622–643. [Google Scholar] [CrossRef]

- Park, M.; Ingawale-Verma, Y.; Kim, W.; Ham, Y. Construction policymaking: With an example of Singaporean government’s policy to diffuse prefabrication to private sector. KSCE J. Civ. Eng. 2011, 15, 771–779. [Google Scholar] [CrossRef]

- Pan, W.; Gibb, A.G.F.; Dainty, A.R.J. Strategies for Integrating the Use of Off-Site Production Technologies in House Building. J. Constr. Eng. Manag. 2012, 138, 1331–1340. [Google Scholar] [CrossRef]

- Yuan, M.; Li, Z.; Li, X.; Luo, X. Managing stakeholder-associated risks and their interactions in the life cycle of prefabricated building projects: A social network analysis approach. J. Clean. Prod. 2021, 323, 129102. [Google Scholar] [CrossRef]

- Othman, M.Z.; Nawi, M.N.M.; Nifa, F.A.A.; Yaakob, M.; Rofie, K.; Zan, Z.M.; Pozin, M.A.A. A strategy towards team integration practice for improving the design and construction process in the Malaysian industrialized building system projects. Int. Rev. Manag. Mark. 2016, 6, 226–229. [Google Scholar]

- Han, Y.; Skibniewski, M.J.; Wang, L. A Market Equilibrium Supply Chain Model for Supporting Self-Manufacturing or Outsourcing Decisions in Prefabricated Construction. Sustainability 2017, 9, 2069. [Google Scholar] [CrossRef]

- Luo, L.; Shen, G.Q.; Xu, G.; Liu, Y.; Wang, Y. Stakeholder-Associated Supply Chain Risks and Their Interactions in a Prefabricated Building Project in Hong Kong. J. Manag. Eng. 2019, 35, 05018015. [Google Scholar] [CrossRef]

- Goh, E.; Loosemore, M. The impacts of industrialization on construction subcontractors: A resource based view. Constr. Manag. Econ. 2017, 35, 288–304. [Google Scholar] [CrossRef]

- Bildsten, L.; Björnfot, A.; Sandberg, E. Value-driven purchasing of kitchen cabinets in industrialised housing. J. Financial Manag. Prop. Constr. 2011, 16, 73–83. [Google Scholar] [CrossRef]

- Chiu, M.-C.; Okudan, G. An investigation on the impact of product modularity level on supply chain performance metrics: An industrial case study. J. Intell. Manuf. 2014, 25, 129–145. [Google Scholar] [CrossRef]

- Hsu, P.-Y.; Aurisicchio, M.; Angeloudis, P. Risk-averse supply chain for modular construction projects. Autom. Constr. 2019, 106, 102898. [Google Scholar] [CrossRef]

- Ismail, Z.-A. How BIM systems affect maintaining IBS building. Facilities 2021, 39, 196–214. [Google Scholar] [CrossRef]

- Ponomarov, S.Y.; Holcomb, M.C. Understanding the concept of supply chain resilience. Int. J. Logist. Manag. 2009, 20, 124–143. [Google Scholar] [CrossRef]

- Ekanayake, E.M.A.C.; Shen, G.Q.; Kumaraswamy, M.; Owusu, E.K. Critical supply chain vulnerabilities affecting supply chain resilience of industrialized construction in Hong Kong. Eng. Constr. Arch. Manag. 2021, 28, 3041–3059. [Google Scholar] [CrossRef]

- Ekanayake, E.M.A.C.; Shen, G.Q.P.; Kumaraswamy, M.M. Identifying supply chain capabilities of construction firms in industrialized construction. Prod. Plan. Control 2021, 32, 303–321. [Google Scholar] [CrossRef]

- Ekanayake, E.M.A.C.; Shen, G.Q.P.; Kumaraswamy, M.M.; Owusu, E.K. Identifying supply chain vulnerabilities in industrialized construction: An overview. Int. J. Constr. Manag. 2020, 22, 1464–1477. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, Y.; Ji, B. Influencing Factors of Resilience of PBSC Based on Empirical Analysis. Buildings 2021, 11, 467. [Google Scholar] [CrossRef]

- Yunus, R.; Yang, J. Improving ecological performance of industrialized building systems in Malaysia. Constr. Manag. Econ. 2014, 32, 183–195. [Google Scholar] [CrossRef]

- Osobajo, O.A.; Oke, A.; Omotayo, T.; Obi, L.I. A systematic review of circular economy research in the construction industry. Smart Sustain. Built Environ. 2022, 11, 39–64. [Google Scholar] [CrossRef]

- Khoshnava, S.M.; Rostami, R.; Ismail, M.; Lamit, H. Obstacles and Drivers in Steering IBS towards Green and Sustainability. Res. J. Appl. Sci. Eng. Technol. 2014, 8, 1639–1647. [Google Scholar] [CrossRef]

- Nabi, M.A.; El-Adaway, I.H. Risk-Based Approach to Predict the Cost Performance of Modularization in Construction Projects. J. Constr. Eng. Manag. 2021, 147, 04021133. [Google Scholar] [CrossRef]

- Dawood, N. A strategy of knowledge elicitation for developing an integrated bidding/production management expert system for the precast industry. Adv. Eng. Softw. 1996, 25, 225–234. [Google Scholar] [CrossRef]

- Omar, M.F.; Nursal, A.T.; Nawi, M.N.M. Vendor selection in Industrialised Building System (IBS) with TOPSIS under fuzzy environment. Malays. Constr. Res. J. (MCRJ) 2018, 3, 163–177. [Google Scholar]

- Cai, J.; Li, Z.; Dou, Y.; Teng, Y.; Yuan, M. Contractor selection for green buildings based on the fuzzy Kano model and TOPSIS: A developer satisfaction perspective. Eng. Constr. Arch. Manag. 2022. [Google Scholar] [CrossRef]

- Shen, K.; Li, X.; Cao, X.; Zhang, Z. Prefabricated Construction Process Optimization Based on Rework Risk. J. Constr. Eng. Manag. 2022, 148, 04022031. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, W.; Arashpour, M.; Yang, Z.; Shao, C.; Li, C. Predicting delays in prefabricated projects: SD-BP neural network to define effects of risk disruption. Eng. Constr. Arch. Manag. 2021, 29, 1753–1776. [Google Scholar] [CrossRef]

- Li, C.Z.; Zhong, R.Y.; Xue, F.; Xu, G.; Chen, K.; Huang, G.G.; Shen, G.Q. Integrating RFID and BIM technologies for mitigating risks and improving schedule performance of prefabricated house construction. J. Clean. Prod. 2017, 165, 1048–1062. [Google Scholar] [CrossRef]

- Shahtaheri, Y.; Rausch, C.; West, J.; Haas, C.; Nahangi, M. Managing risk in modular construction using dimensional and geometric tolerance strategies. Autom. Constr. 2017, 83, 303–315. [Google Scholar] [CrossRef]

- Rausch, C.; Nahangi, M.; Haas, C.; Liang, W. Monte Carlo simulation for tolerance analysis in prefabrication and offsite construction. Autom. Constr. 2019, 103, 300–314. [Google Scholar] [CrossRef]

- Enshassi, M.S.A.; Walbridge, S.; West, J.S.; Haas, C.T. Probabilistic Risk Management Framework for Tolerance-Related Issues in Modularized Projects: Local and Global Perspectives. ASCE-ASME J. Risk Uncertain. Eng. Syst. Part A Civ. Eng. 2020, 6, 04019022. [Google Scholar] [CrossRef]

- Arashpour, M.; Abbasi, B.; Arashpour, M.; Hosseini, M.R.; Yang, R. Integrated management of on-site, coordination and off-site uncertainty: Theorizing risk analysis within a hybrid project setting. Int. J. Proj. Manag. 2017, 35, 647–655. [Google Scholar] [CrossRef]

- Chen, Y.; Okudan, G.E.; Riley, D.R. Decision support for construction method selection in concrete buildings: Prefabrication adoption and optimization. Autom. Constr. 2010, 19, 665–675. [Google Scholar] [CrossRef]

- Levander, E.; Engström, S.; Sardén, Y.; Stehn, L. Construction clients’ ability to manage uncertainty and equivocality. Constr. Manag. Econ. 2011, 29, 753–764. [Google Scholar] [CrossRef]

- Arashpour, M.; Wakefield, R.; Lee, E.; Chan, R.; Hosseini, M.R. Analysis of interacting uncertainties in on-site and off-site activities: Implications for hybrid construction. Int. J. Proj. Manag. 2016, 34, 1393–1402. [Google Scholar] [CrossRef]

- Liu, J.; Gong, E.; Wang, D.; Teng, Y. Cloud Model-Based Safety Performance Evaluation of Prefabricated Building Project in China. Wirel. Pers. Commun. 2018, 102, 3021–3039. [Google Scholar] [CrossRef]

- Pan, W.; Gibb, A.G.; Dainty, A.R. Leading UK housebuilders’ utilization of offsite construction methods. Build. Res. Inf. 2008, 36, 56–67. [Google Scholar] [CrossRef]

- Mohandes, S.R.; Abdelmageed, S.; Hem, S.; Yoo, J.S.; Abhayajeewa, T.; Zayed, T. Occupational Health and Safety in Modular Integrated Construction projects: The case of crane operations. J. Clean. Prod. 2022, 342, 130950. [Google Scholar] [CrossRef]

- Liu, Z.; Meng, X.; Xing, Z.; Jiang, A. Digital Twin-Based Safety Risk Coupling of Prefabricated Building Hoisting. Sensors 2021, 21, 3583. [Google Scholar] [CrossRef]

- Chatzimichailidou, M.; Ma, Y. Using BIM in the safety risk management of modular construction. Saf. Sci. 2022, 154, 105852. [Google Scholar] [CrossRef]

- Joshi, S.; Hamilton, M.; Warren, R.; Faucett, D.; Tian, W.; Wang, Y.; Ma, J. Implementing Virtual Reality technology for safety training in the precast/ prestressed concrete industry. Appl. Ergon. 2021, 90, 103286. [Google Scholar] [CrossRef] [PubMed]

- Goulding, J.; Nadim, W.; Petridis, P.; Alshawi, M. Construction industry offsite production: A virtual reality interactive training environment prototype. Adv. Eng. Inform. 2012, 26, 103–116. [Google Scholar] [CrossRef]

- Kim, S.; Hwang, S.; Son, J. Safety Management Guidelines for Precast Concrete Production Plants Using Importance-Performance Analysis. J. Constr. Eng. Manag. 2022, 148, 04022038. [Google Scholar] [CrossRef]

- Golabchi, A.; Han, S.; Seo, J.; Han, S.; Lee, S.; Al-Hussein, M. An Automated Biomechanical Simulation Approach to Ergonomic Job Analysis for Workplace Design. J. Constr. Eng. Manag. 2015, 141, 04015020. [Google Scholar] [CrossRef]

- Wang, J.; Han, S.; Li, X. 3D fuzzy ergonomic analysis for rapid workplace design and modification in construction. Autom. Constr. 2021, 123, 103521. [Google Scholar] [CrossRef]

- Barkokebas, R.D.; Li, X. Use of Virtual Reality to Assess the Ergonomic Risk of Industrialized Construction Tasks. J. Constr. Eng. Manag. 2021, 147, 04020183. [Google Scholar] [CrossRef]