Web Crippling Behaviour of Cold-Formed Carbon Steel, Stainless Steel, and Aluminium Lipped Channel Sections with Web Openings

Abstract

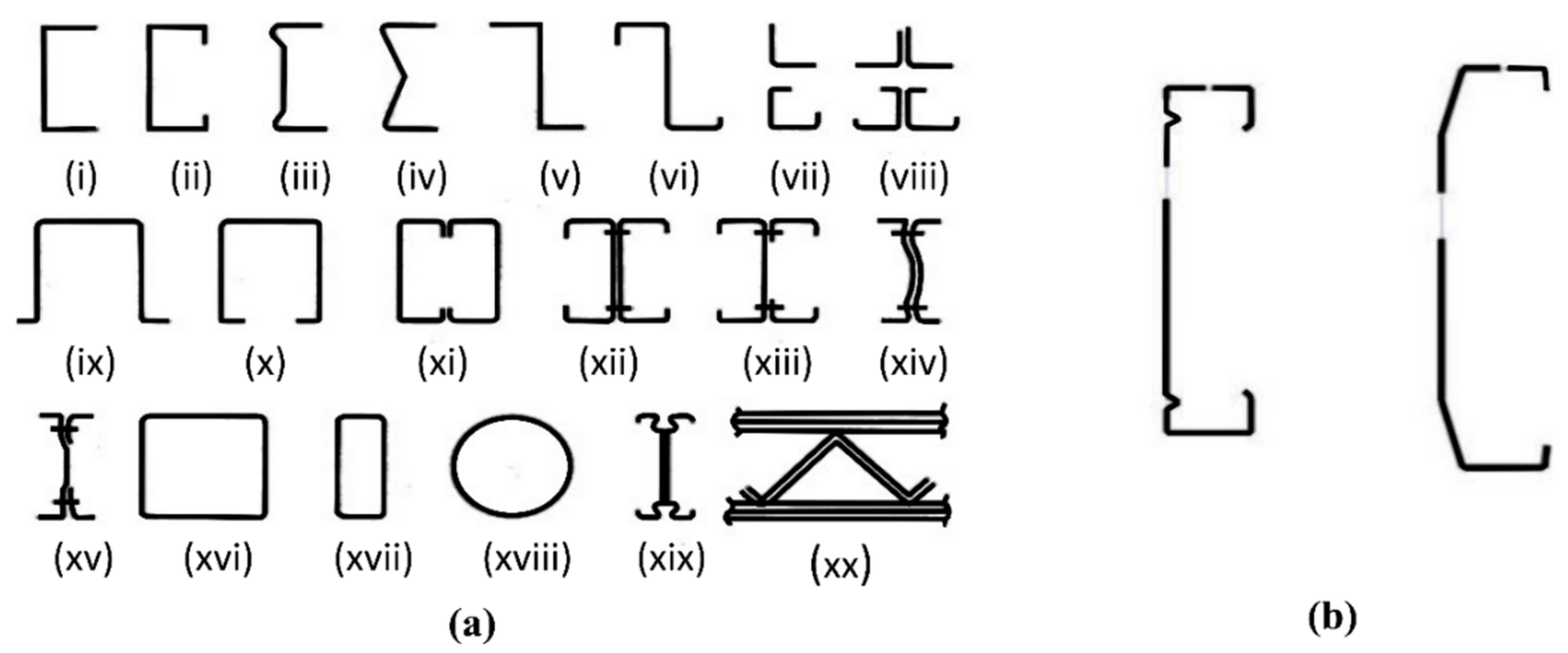

1. Introduction

2. Different Approaches for Studying Web Crippling Behaviour

2.1. Theoretical Investigations

2.2. Experimental Investigations

2.3. Numerical Investigations

3. Web Crippling Studies on Lipped CF Channel Sections with Web Perforations

3.1. CF Steel Sections

3.2. CF Stainless Steel Sections

3.3. CF Aluminum Sections

| Without Web Opening | ||||

|---|---|---|---|---|

| Loading/Support Condition | Carbon Steel | Stainless Steel | Aluminium | |

| ETF | Unfastened | Winter and Pian [26] * Hetrakul and Yu [27] * Young and Hancock [31] * Keerthan et al. [32] * Steau et al. [34] * Gatheeshgar et al. [41] *# Thirunavukkarasu et al. [42] *# McIntosh et al. [76] # Gunalan and Mahendran [87] * Sundararajah et al. [13,37,38,88] *# | Li and Young [63] *# Zhou and Young [68,69,70,71] ¤# McIntosh et al. [76] # | Alsanat et al. [20] *# McIntosh et al. [76] # Young and Zhou [80] #¤ Zhou and Young [79,89] *# Chen et al. [82] *# Alsanat et al. [83] *# Alsanat et al. [90] # |

| Fastened | Steau et al. [36] * | - | Alsanat et al. [52] *# Alsanat et al. [84] *# Alsanat et al. [85] *# | |

| ITF | Unfastened | Winter and Pian [26] * Hetrakul and Yu [27] * Young and Hancock [31] * Keerthan et al. [32] * Steau et al. [34] * Gatheeshgar et al. [40] *# McIntosh et al. [77] # Gunalan and Mahendran [87] * Sundararajah et al. [13,37,38,88] *# | Li and Young [63] *# Zhou and Young [68,69,70,71] ¤# McIntosh et al. [77] # | Alsanat et al. [20] *# McIntosh et al. [77] # Young and Zhou [80] #¤ Zhou and Young [79,89] *# Chen et al. [82] *# Alsanat et al. [83] *# Alsanat et al. [90] # |

| Fastened | Steau et al. [36] * | - | Alsanat et al. [52] *# Alsanat et al. [84] *# Alsanat et al. [85] *# | |

| EOF | Unfastened | Winter and Pian [26] * Hetrakul and Yu [27] * Young and Hancock [31] * Keerthan et al. [32] * Steau et al. [35] * Sundararajah et al. [39,91] *# | Li and Young [63] *# Zhou and Young [68,69,70,71] ¤# Bock et al. [92] # | Chen et al. [82] *# Alsanat et al. [93] *# |

| Fastened | Bhakta et al. [17] * Cain et al. [28] * Gerges and Schuster [29] * Steau et al. [35] * Sundararajah et al. [39,91] *# | - | - | |

| IOF | Unfastened | Winter and Pian [26] * Hetrakul and Yu [27] * Young and Hancock [31] * Keerthan et al. [32] * Steau et al. [35] * Sundararajah et al. [91] *# | Li and Young [63] *# Talja and Salmi [66] * Gardner et al. [67] *# Zhou and Young [68,69,70,71] ¤# | Chen et al. [82] *# Alsanat et al. [93] *# |

| Fastened | Bhakta et al. [17] * Cain et al. [28] * Gerges and Schuster [29] * Steau et al. [35] * Sundararajah et al. [91] *# | - | - | |

| With Web Openings | ||||

| Loading/Support Condition | Carbon Steel | Stainless Steel | Aluminium | |

| ETF | Unfastened | Uzzaman et al. [19,58,59] *# | Yousefi et al. [8] *# Fareed et al. [75] # | Zhou and Young [81] *# Alsanat et al. [86] * |

| Fastened | Uzzaman et al. [19,58,59] *# | Yousefi et al. [8] *# Yousefi et al. [64] *# | Alsanat et al. [86] * | |

| ITF | Unfastened | Davis [55] *¤ Uzzaman et al. [7,58,59] *# | Yousefi et al. [74] *# Fareed et al. [75] # | Zhou and Young [81] *# |

| Fastened | Uzzaman et al. [7,58,59] *# | - | - | |

| EOF | Unfastened | LaBoube et al. [5] * Langan et al. [56] * Lian et al. [6,57] *# Gatheeshgar et al. [94] # | Yousefi et al. [73] *# | - |

| Fastened | Lian et al. [6,57] *# | Yousefi et al. [73] *# | - | |

| IOF | Unfastened | LaBoube et al. [5] * Sivakumaran and Zielonka [12] * Sivakumaran [30] * Langan et al. [56] * Lian et al. [6,57] *# Fang et al. [62] # Gatheeshgar et al. [95] # | Yousefi et al. [72] *# Yousefi et al. [96] # | - |

| Fastened | Lian et al. [60,61] #,*# Fang et al. [62] # | Yousefi et al. [72] *# Yousefi et al. [96] # | - | |

4. Current Design Guidelines

5. Numerical Model

5.1. Element Type and Mesh Control

5.2. Material Properties

5.3. Contact Behaviour, Boundary Conditions and Loading

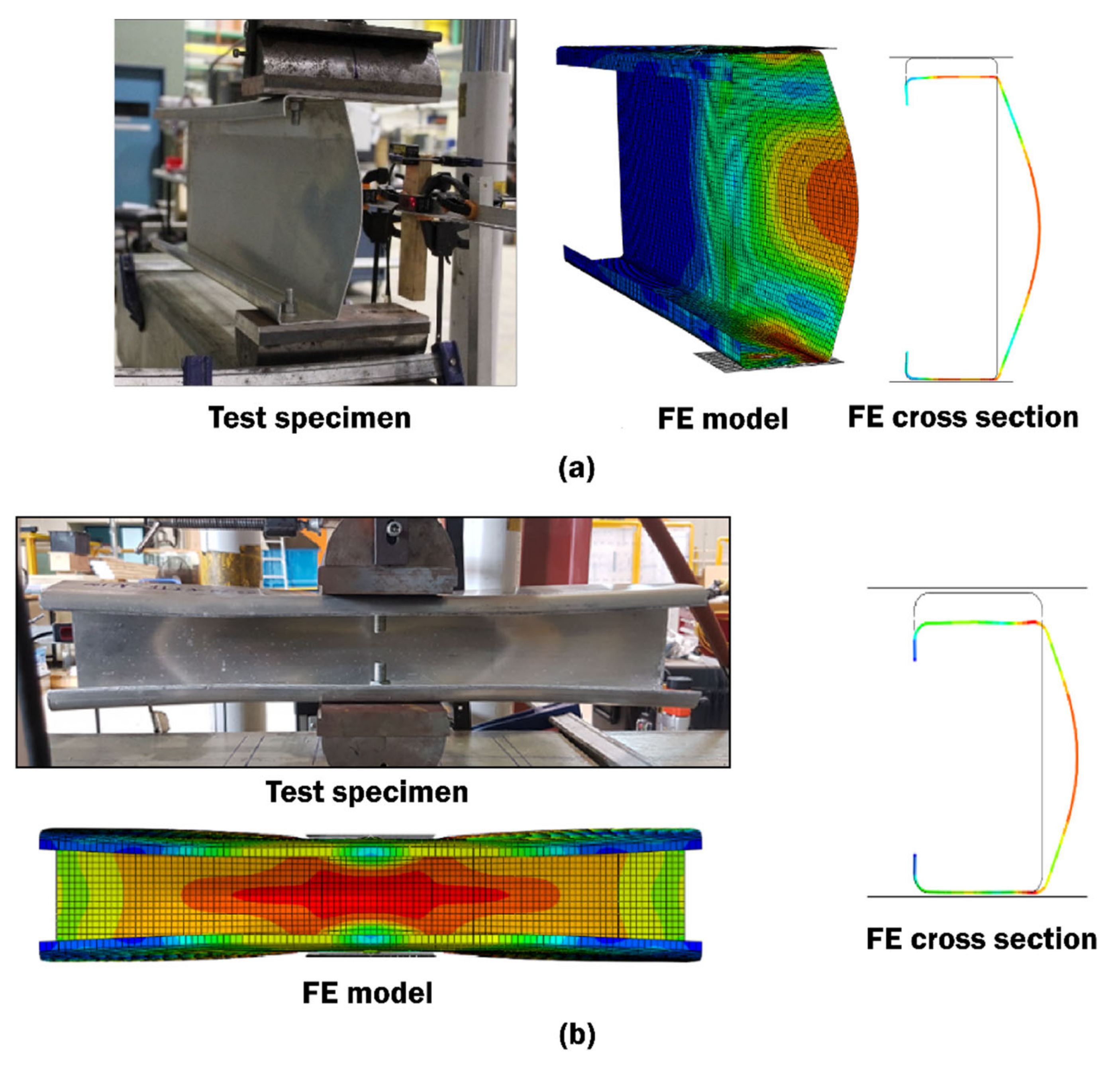

5.4. Model Validation

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ma, W.; Becque, J.; Hajirasouliha, I.; Ye, J. Cross-sectional optimization of cold-formed steel channels to Eurocode 3. Eng. Struct. 2015, 101, 641–651. [Google Scholar] [CrossRef]

- Macdonald, M.; Heiyantuduwa, M.A.; Rhodes, J. Recent developments in the design of cold-formed steel members and structures. Thin-Walled Struct. 2008, 46, 1047–1053. [Google Scholar] [CrossRef]

- Wang, L.; Young, B. Design of cold-formed steel channels with stiffened webs subjected to bending. Thin-Walled Struct. 2014, 85, 81–92. [Google Scholar] [CrossRef]

- Ye, J.; Hajirasouliha, I.; Becque, J.; Eslami, A. Optimum design of cold-formed steel beams using Particle Swarm Optimisation method. J. Constr. Steel Res. 2016, 122, 80–93. [Google Scholar] [CrossRef]

- LaBoube, R.A.; Yu, W.W.; Deshmukh, S.U.; Uphoff, C.A. Crippling Capacity of Web Elements with Openings. J. Struct. Eng. 1999, 125, 137–141. [Google Scholar] [CrossRef]

- Lian, Y.; Uzzaman, A.; Lim, J.B.; Abdelal, G.; Nash, D.; Young, B. Effect of web holes on web crippling strength of cold-formed steel channel sections under end-one-flange loading condition—Part I: Tests and finite element analysis. Thin-Walled Struct. 2016, 107, 443–452. [Google Scholar] [CrossRef]

- Uzzaman, A.; Lim, J.B.; Nash, D.; Rhodes, J.; Young, B. Web crippling behaviour of cold-formed steel channel sections with offset web holes subjected to interior-two-flange loading. Thin-Walled Struct. 2012, 50, 76–86. [Google Scholar] [CrossRef]

- Yousefi, A.M.; Uzzaman, A.; Lim, J.B.P.; Clifton, G.C.; Young, B. Web crippling strength of cold-formed stainless-steel lipped channels with web perforations under end-two-flange loading. Adv. Struct. Eng. 2017, 20, 1845–1863. [Google Scholar] [CrossRef]

- Yu, W.; LaBoube, R.A.; Chen, H. Cold-Formed Steel Design, 5th ed.; Wiley: Hoboken, NJ, USA, 2020; ISBN 9781119487395. [Google Scholar]

- Ye, J.; Hajirasouliha, I.; Becque, J.; Pilakoutas, K. Development of more efficient cold-formed steel channel sections in bending. Thin-Walled Struct. 2016, 101, 1–13. [Google Scholar] [CrossRef]

- Beshara, B.; Schuster, R.M. Web Crippling Data and Calibrations of Cold Formed Steel Members; American Iron and Steel Institute: Washington, DC, USA, 2000. [Google Scholar]

- Sivakumaran, K.S.; Zielonka, K.M. Web Crippling Strength of Thin-Walled Steel Members with Web Opening. Thin-Walled Struct. 1989, 8, 295–319. [Google Scholar] [CrossRef]

- Sundararajah, L.; Mahendran, M.; Poologanathan, K. Experimental Studies of Lipped Channel Beams Subject to Web Crippling under Two-Flange Load Cases. J. Struct. Eng. 2016, 142, 4016058. [Google Scholar] [CrossRef]

- AISI S909-17; Test Standard for Determining the Web Crippling Strength of Cold-Formed Steel Flexural Members, 2017 Edition. American Iron and Steel Institute: Washington, DC, USA, 2018.

- Sundararajah, L. Web Crippling Studies of Cold-Formed Steel Channel Beams. Ph.D. Thesis, Queensland University of Technology, Brisbane, Australia, 2017. [Google Scholar]

- Janarthanan, B.; Sundararajah, L.; Mahendran, M.; Keerthan, P.; Gunalan, S. Web crippling behaviour and design of cold-formed steel sections. Thin-Walled Struct. 2019, 140, 387–403. [Google Scholar] [CrossRef]

- Bhakta, B.H.; LaBoube, R.A.; Yu, W. The Effect of Flange Restraint on Web Crippling Strength; Center for Cold-Formed Steel Structures Library: Rolla, MO, USA, 1992. [Google Scholar]

- Rhodes, J.; Nash, D. An investigation of web crushing behaviour in thin-walled beams. Thin-Walled Struct. 1998, 32, 207–230. [Google Scholar] [CrossRef]

- Uzzaman, A.; Lim, J.B.; Nash, D.; Rhodes, J.; Young, B. Effect of offset web holes on web crippling strength of cold-formed steel channel sections under end-two-flange loading condition. Thin-Walled Struct. 2013, 65, 34–48. [Google Scholar] [CrossRef]

- Alsanat, H.; Gunalan, S.; Guan, H.; Keerthan, P.; Bull, J. Experimental study of aluminium lipped channel sections subjected to web crippling under two flange load cases. Thin-Walled Struct. 2019, 141, 460–476. [Google Scholar] [CrossRef]

- Macdonald, M.; Heiyantuduwa, M.A.; Harrison, D.K.; Bailey, R.; Rhodes, J. (Eds.) Literature Review of Web Crippling Behaviour. In Proceedings of the 2nd Scottish Conference on Postgraduate Research on the Built Environment, Glasgow, UK, 16–17 November 2005. [Google Scholar]

- Timoshenko, S.P.; Gere, J.M. Theory of Elastic Stability; Courier Corporation: Mineola, NY, USA, 2009; ISBN 0486472078. [Google Scholar]

- Zetlin, L. (Ed.) Elastic Instability of Flat Plates Subjected to Partial Edge Loads, 9th ed.; American Society of Civil Engineers: New York, NY, USA, 1955. [Google Scholar]

- Khan, M.Z.; Walker, A.C. Buckling of Plates Subjected to Localized Edge Loading; The Structural Engineer: London, UK, 1972. [Google Scholar]

- Poologanathan, K.; Mahendran, M. Web crippling tests of hollow flange channel beams: ETF and ITF load cases. In Proceedings of the Australasian Structural Engineering Conference, Auckland, New Zealand, 9–11 July 2015. [Google Scholar]

- Winter, G.; Pian, R. Crushing Strength of Thin Steel Webs; Cornell University: Ithaca, NY, USA, 1946. [Google Scholar]

- Hetrakul, N.; Yu, W.W. Structural Behaviour of Beam Webs Subjected to Web Crippling and a Combination of Web Crippling and Bending; Final Report, Civil Engineering Study 78-4; University of Missouri-Rolla: Rolla, Mo, USA, 1978. [Google Scholar]

- Cain, D.E.; LaBoube, R.A.; Yu, W. The Effect of Flange Restraint on Web Crippling Strength of Cold-Formed Steel Z- and I-Sections; Missouri University of Science and Technology: Rolla, Mo, USA, 1995. [Google Scholar]

- Gerges, R.R.; Schuster, R.M. (Eds.) Web Crippling of Single Web Cold Formed Steel Members Subjected to End One-Flange Loading. In Proceedings of the International Specialty Conference on Cold-Formed Steel Structures, St. Louis, MO, USA, 15–16 October 1998. [Google Scholar]

- Sivakumaran, K.S. (Ed.) Some Studies on Cold-formed Steel Sections with Web Openings. In Proceedings of the International Speciality Conference on Cold-Formed Steel Structures, St. Louis, MO, USA, 8–9 November 1988. [Google Scholar]

- Young, B.; Hancock, G. Design of Cold-Formed Channels Subjected to Web Crippling. J. Struct. Eng. 2001, 127, 1137–1144. [Google Scholar] [CrossRef]

- Keerthan, P.; Mahendran, M.; Steau, E. Experimental study of web crippling behaviour of hollow flange channel beams under two flange load cases. Thin-Walled Struct. 2014, 85, 207–219. [Google Scholar] [CrossRef]

- Keerthan, P.; Mahendran, M. Experimental study on web crippling strength of hollow flange channels under end-one-flange and interior-one-flange load cases. Adv. Struct. Eng. 2016, 19, 966–981. [Google Scholar] [CrossRef]

- Steau, E.; Mahendran, M.; Keerthan, P. Web crippling tests of Rivet Fastened Rectangular Hollow Flange Channel Beams under Two Flange Load Cases. Thin-Walled Struct. 2015, 95, 262–275. [Google Scholar] [CrossRef]

- Steau, E.; Keerthan, P.; Mahendran, M. Web crippling capacities of rivet fastened rectangular hollow flange channel beams under one flange load cases. Steel Constr. 2016, 9, 222–239. [Google Scholar] [CrossRef]

- Steau, E.; Keerthan, P.; Mahendran, M. Web crippling study of rivet fastened rectangular hollow flange channel beams with flanges fastened to supports. Adv. Struct. Eng. 2017, 20, 1059–1073. [Google Scholar] [CrossRef]

- Sundararajah, L.; Mahendran, M.; Poologanathan, K. (Eds.) Web Crippling Capacity of Cold-formed Channel Sections with and without Longitudinal Web Stiffeners Subject to Two Flange Load Cases. In Proceedings of the International Conference on Coupled Instabilities in Metal Structures, Baltimore, MD, USA, 7–8 November 2016. [Google Scholar]

- Sundararajah, L.; Mahendran, M.; Keerthan, P. Web crippling studies of SupaCee sections under two flange load cases. Eng. Struct. 2017, 153, 582–597. [Google Scholar] [CrossRef]

- Sundararajah, L.; Mahendran, M.; Poologanathan, K. Design of SupaCee Sections Subject to Web Crippling under One-Flange Load Cases. J. Struct. Eng. 2018, 144, 4018222. [Google Scholar] [CrossRef]

- Gatheeshgar, P.; Poologanathan, K.; Gunalan, S.; Nagaratnam, B.; Tsavdaridis, K.D.; Ye, J. Structural behaviour of optimized cold-formed steel beams. Steel Constr. 2020, 13, 294–304. [Google Scholar] [CrossRef]

- Gatheeshgar, P.; Poologanathan, K.; Gunalan, S.; Shyha, I.; Tsavdaridis, K.D.; Corradi, M. Optimal design of cold-formed steel lipped channel beams: Combined bending, shear, and web crippling. Structures 2020, 28, 825–836. [Google Scholar] [CrossRef]

- Thirunavukkarasu, K.; Kanthasamy, E.; Gatheeshgar, P.; Poologanathan, K.; Das, S.; Todhunter, S.; Suntharalingam, T. Web crippling design of modular construction optimised beams under ETF loading. J. Build. Eng. 2021, 43, 103072. [Google Scholar] [CrossRef]

- Natário, P.; Silvestre, N.; Camotim, D. Web crippling failure using quasi-static FE models. Thin-Walled Struct. 2014, 84, 34–49. [Google Scholar] [CrossRef]

- Sivakumaran, K.S. Analysis for web crippling behaviour of cold-formed steel members. Comput. Struct. 1989, 32, 707–719. [Google Scholar] [CrossRef]

- ADINA R&D, Inc. ADINA-A Finite Element Program for Automatic Dynamic Incremental Nonlinear Analysis; ADINA R&D, Inc.: Watertown, MA, USA, 1984. [Google Scholar]

- Dassault Systemes Simulia Corp. ABAQUS/CAE; Dassault Systemes Simulia Corp.: Providence, RI, USA, 2014. [Google Scholar]

- DeSalvo, G.J.; Swanson, J.A. ANSYS Engineering Analysis System User’s Manual; Swanson Analysis Systems: Houston, PA, USA, 1985. [Google Scholar]

- Janarthanan, B.; Mahendran, M.; Gunalan, S. Numerical modelling of web crippling failures in cold-formed steel unlipped channel sections. J. Constr. Steel Res. 2019, 158, 486–501. [Google Scholar] [CrossRef]

- Kaitila, O. Web crippling of thin-walled cold formed steel cassettes. J. Constr. Steel Res. 2007, 63, 766–778. [Google Scholar] [CrossRef]

- Macdonald, M.; Heiyantuduwa, M.A. A design rule for web crippling of cold-formed steel lipped channel beams based on nonlinear FEA. Thin-Walled Struct. 2012, 53, 123–130. [Google Scholar] [CrossRef]

- Macdonald, M.; Heiyantuduwa Don, M.A.; KoteŁko, M.; Rhodes, J. Web crippling behaviour of thin-walled lipped channel beams. Thin-Walled Struct. 2011, 49, 682–690. [Google Scholar] [CrossRef]

- Alsanat, H.; Gunalan, S.; Poologanathan, K.; Guan, H.; Tsavdaridis, K.D. Numerical investigation of web crippling in fastened aluminium lipped channel sections under two-flange loading conditions. Structures 2020, 23, 351–365. [Google Scholar] [CrossRef]

- Macdonald, M.; Rhodes, J.; Heiyantuduwa, M.A. (Eds.) Finite Element Analysis of Web Crippling Behaviour of Cold-formed Steel. In Proceedings of the International Specialty Conference on Cold-Formed Steel Structures, Orlando, FL, USA, 26–27 October 2006. [Google Scholar]

- Hancock, G. Cold-formed steel structures. J. Constr. Steel Res. 2003, 59, 473–487. [Google Scholar] [CrossRef]

- Davis, C.S. The Structural Behaviour of Cold-Formed Steel Members with Perforated Elements. Ph.D. Thesis, University of Missouri-Rolla, Rolla, MO, USA, 1972. [Google Scholar]

- Langan, J.E.; LaBoube, R.A.; Yu, W. Structural Behavior of Perforated Web Elements of Cold-Formed Steel Flexural Members Subjected to Web Crippling and a Combination of Web Crippling and Bending; Center for Cold-Formed Steel Structures Library: Rolla, MO, USA, 1994. [Google Scholar]

- Lian, Y.; Uzzaman, A.; Lim, J.B.; Abdelal, G.; Nash, D.; Young, B. Effect of web holes on web crippling strength of cold-formed steel channel sections under end-one-flange loading condition-Part II: Parametric study and proposed design equations. Thin-Walled Struct. 2016, 107, 489–501. [Google Scholar] [CrossRef]

- Uzzaman, A.; Lim, J.B.; Nash, D.; Rhodes, J.; Young, B. Cold-formed steel sections with web openings subjected to web crippling under two-flange loading conditions—Part I: Tests and finite element analysis. Thin-Walled Struct. 2012, 56, 38–48. [Google Scholar] [CrossRef]

- Uzzaman, A.; Lim, J.B.; Nash, D.; Rhodes, J.; Young, B. Cold-formed steel sections with web openings subjected to web crippling under two-flange loading conditions—Part II: Parametric study and proposed design equations. Thin-Walled Struct. 2012, 56, 79–87. [Google Scholar] [CrossRef]

- Lian, Y.; Uzzaman, A.; Lim, J.B.; Abdelal, G.; Nash, D.; Young, B. Web crippling behaviour of cold-formed steel channel sections with web holes subjected to interior-one-flange loading condition—Part II: Parametric study and proposed design equations. Thin-Walled Struct. 2017, 114, 92–106. [Google Scholar] [CrossRef]

- Lian, Y.; Uzzaman, A.; Lim, J.B.; Abdelal, G.; Nash, D.; Young, B. Web crippling behaviour of cold-formed steel channel sections with web holes subjected to interior-one-flange loading condition—Part I: Experimental and numerical investigation. Thin-Walled Struct. 2017, 111, 103–112. [Google Scholar] [CrossRef]

- Fang, Z.; Roy, K.; Liang, H.; Poologanathan, K.; Ghosh, K.; Mohamed, A.; Lim, J. Numerical Simulation and Design Recommendations for Web Crippling Strength of Cold-Formed Steel Channels with Web Holes under Interior-One-Flange Loading at Elevated Temperatures. Buildings 2021, 11, 666. [Google Scholar] [CrossRef]

- Li, H.-T.; Young, B. Web crippling of cold-formed ferritic stainless steel square and rectangular hollow sections. Eng. Struct. 2018, 176, 968–980. [Google Scholar] [CrossRef]

- Yousefi, A.M.; Lim, J.B.P.; Clifton, G.C. (Eds.) Web Crippling Design of Cold-formed Ferritic Stainless Steel Unlipped Channels with Web Holes and with Fastened Flanges Under End-two-flange loading Condition—Part I: Experimental Tests and Numerical Validation. In Proceedings of the Fifth International Experts Seminar on Stainless Steel in Structures, London, UK, 18–19 September 2017. [Google Scholar]

- Korvink, S.A.; van den Berg, G.J.; van der Merwe, P. Web Crippling of Stainless Steel Cold-formed Beams. J. Constr. Steel Res. 1995, 34, 225–248. [Google Scholar] [CrossRef]

- Talja, A.; Salmi, P. Design of Stainless Steel RHS Beams, Columns and Beam-Columns; VTT Technical Research Centre of Finland: Espoo, Finland, 1995. [Google Scholar]

- Gardner, L.; Taljab, A.; Baddooc, N.R. Structural design of high strength austenitic stainless steel. Thin-Walled Struct. 2006, 44, 517–528. [Google Scholar] [CrossRef]

- Zhou, F.; Young, B. Yield line mechanism analysis on web crippling of cold-formed stainless steel tubular sections under two-flange loading. Eng. Struct. 2006, 28, 880–892. [Google Scholar] [CrossRef]

- Zhou, F.; Young, B. Cold-Formed High-Strength Stainless Steel Tubular Sections Subjected to Web Crippling. J. Struct. Eng. 2007, 133, 368–377. [Google Scholar] [CrossRef]

- Zhou, F.; Young, B. Web crippling of cold-formed stainless steel tubular sections. Adv. Struct. Eng. 2008, 11, 679–691. [Google Scholar] [CrossRef]

- Zhou, F.; Young, B. Web crippling behaviour of cold-formed duplex stainless steel tubular sections at elevated temperatures. Eng. Struct. 2013, 57, 51–62. [Google Scholar] [CrossRef]

- Yousefi, A.M.; Lim, J.B.; Uzzaman, A.; Lian, Y.; Clifton, G.C.; Young, B. Web crippling strength of cold-formed stainless steel lipped channel-sections with web openings subjected to interior-one-flange loading condition. Steel Compos. Struct. 2016, 21, 629–659. [Google Scholar] [CrossRef][Green Version]

- Yousefi, A.M.; Lim, J.B.P.; Uzzaman, A.; Lian, Y.; Clifton, G.C.; Young, B. Design of cold-formed stainless steel lipped channel sections with web openings subjected to web crippling under end-one-flange loading condition. Adv. Struct. Eng. 2017, 20, 1024–1045. [Google Scholar] [CrossRef]

- Yousefi, A.M.; Uzzaman, A.; Lim, J.B.; Clifton, G.C.; Young, B. Numerical investigation of web crippling strength in cold-formed stainless steel lipped channels with web openings subjected to interior-two-flange loading condition. Steel Compos. Struct. 2017, 23, 363–383. [Google Scholar] [CrossRef]

- Fareed, I.; Somadasa, W.; Poologanathan, K.; Gunalan, S.; Beatini, V.; Sivabalan, S. (Eds.) Web Crippling Behaviour of Cold-formed Stainless Steel Beams with Non-Circular Web Opening. In Proceedings of the 14th Nordic Steel Construction Conference, Copenhagen, Denmark, 18–20 September 2019. [Google Scholar]

- McIntosh, A.; Gatheeshgar, P.; Poologanathan, K.; Gunalan, S.; Navaratnam, S.; Higgins, C. Web crippling of cold-formed carbon steel, stainless steel, and aluminium channels: Investigation and design. J. Constr. Steel Res. 2021, 179, 106538. [Google Scholar] [CrossRef]

- McIntosh, A.; Gatheeshgar, P.; Gunalan, S.; Kanthasamy, E.; Keerthan, P.; Corradi, M.; Higgins, C. Unified approach for the web crippling design of cold-formed channels: Carbon steel, stainless steel and aluminium. J. Build. Eng. 2022, 51, 104134. [Google Scholar] [CrossRef]

- Georgantzia, E.; Gkantou, M.; Kamaris, G.S. Aluminium alloys as structural material: A review of research. Eng. Struct. 2021, 227, 111372. [Google Scholar] [CrossRef]

- Zhou, F.; Young, B. Aluminum tubular sections subjected to web crippling—Part I. Thin-Walled Struct. 2008, 46, 339–351. [Google Scholar] [CrossRef]

- Young, B.; Zhou, F. Aluminum tubular sections subjected to web crippling—Part II: Proposed design equations. Thin-Walled Struct. 2008, 46, 352–361. [Google Scholar] [CrossRef]

- Zhou, F.; Young, B. Web crippling of aluminium tubes with perforated webs. Eng. Struct. 2010, 32, 1397–1410. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, X.; Wang, C. Aluminum tubular sections subjected to web crippling. Thin-Walled Struct. 2015, 90, 49–60. [Google Scholar] [CrossRef]

- Alsanat, H.; Gunalan, S.; Guan, H. (Eds.) Web crippling behaviour and design of aluminium lipped channel sections under two flange load cases. In Proceedings of the Eighth International Conference on Thin-Walled Structures, Lisbon, Portugal, 24–27 July 2018. [Google Scholar]

- Alsanat, H.; Gunalan, S.; Poologanathan, K.; Guan, H.; Baniotopoulos, C. Fastened Aluminum-Lipped Channel Sections Subjected to Web Crippling under Two-Flange Loading Conditions: Experimental Study. J. Struct. Eng. 2020, 146, 4020023. [Google Scholar] [CrossRef]

- Alsanat, H.; Gunalan, S.; Poologanathan, K.; Hong, G.; Charalampos, B. (Eds.) Web Crippling Behaviour of Fastened Aluminium Lipped Channel Sections. In Proceedings of the 9th International Conference on Steel and Aluminium Structures, Bradford, UK, 3–5 July 2019. [Google Scholar]

- Alsanat, H.; Gunalan, S.; Keerthan, P. Web Crippling Investigations of Aluminium Lipped Channel Sections with Web holes-End-Two-Flnage Loading Conditions. J. Civ. Eng. Int. Discip. 2021, 2, 17–22. [Google Scholar]

- Gunalan, S.; Mahendran, M. Web Crippling Tests of Cold-formed Steel Channels under Two Flange Load Cases. J. Constr. Steel Res. 2015, 110, 1–15. [Google Scholar] [CrossRef]

- Sundararajah, L.; Mahendran, M.; Keerthan, P. New design rules for lipped channel beams subject to web crippling under two-flange load cases. Thin-Walled Struct. 2017, 119, 421–437. [Google Scholar] [CrossRef]

- Zhou, F.; Young, B. Aluminium alloy channels subjected to web crippling. Adv. Struct. Eng. 2019, 22, 1617–1630. [Google Scholar] [CrossRef]

- Alsanat, H.; Gunalan, S.; Keerthan, P.; Guan, H.; Tsavdaridis, K.D. Web crippling behaviour and design of aluminium lipped channel sections under two flange loading conditions. Thin-Walled Struct. 2019, 144, 106265. [Google Scholar] [CrossRef]

- Sundararajah, L.; Mahendran, M.; Keerthan, P. Web crippling experiments of high strength lipped channel beams under one-flange loading. J. Constr. Steel Res. 2017, 138, 851–866. [Google Scholar] [CrossRef]

- Bock, M.; Arrayago, I.; Real, E.; Mirambell, E. Study of web crippling in ferritic stainless steel cold formed sections. Thin-Walled Struct. 2013, 69, 29–44. [Google Scholar] [CrossRef]

- Alsanat, H.; Gunalan, S.; Poologanathan, K.; Guan, H. Web crippling investigations of aluminium lipped channel sections under one-flange loading conditions. Thin-Walled Struct. 2021, 166, 108025. [Google Scholar] [CrossRef]

- Gatheeshgar, P.; Alsanat, H.; Poologanathan, K.; Gunalan, S.; Degtyareva, N.; Wanniarachchi, S.; Fareed, I. Web crippling of slotted perforated Cold-Formed Steel channels under EOF load case: Simulation and design. J. Build. Eng. 2021, 44, 103306. [Google Scholar] [CrossRef]

- Gatheeshgar, P.; Alsanat, H.; Poologanathan, K.; Gunalan, S.; Degtyareva, N.; Hajirasouliha, I. Web crippling behaviour of slotted perforated cold-formed steel channels: IOF load case. J. Constr. Steel Res. 2022, 188, 106974. [Google Scholar] [CrossRef]

- Yousefi, A.M.; Lim, J.B.P.; Uzzaman, A.; Lian, Y.; Clifton, G.C.; Young, B. (Eds.) Web Crippling Strength of Cold-Formed Duplex Stainless Steel Lipped-Channel Sections with Web Openings Subjected to Interior-One-Flange Loading. In Proceedings of the International Specialty Conference on Cold-Formed Steel Structures, Baltimore, MD, USA, 9–10 November 2016. [Google Scholar]

- AISI S100-16; North American Specification for the Design of Cold-Formed Steel Structural Members (Reaffirmed 2020) with Supplement 2. American Iron and Steel Institute: Washington, DC, USA, 2016.

- AS/NZS 4600; Cold Formed Steel Strucutures. Standards Australia/Standards New Zealand: Wellington, New Zealand, 2018.

- SEI/ASCE8-02; Specification for the Design of Cold-Formed Stainless Steel Structural Members. American Society of Civil Engineers: Reston, VA, USA, 2002.

- AS/NZS 4673; Cold-Formed Stainless Steel Structures. Standards Australia/Standards New Zealand: Wellington, New Zealand, 2001.

- AS/NZS 1664.1; Aluminium Structures-Part 1: Limit State Design. Standards Australia/Standards New Zealand: Wellington, New Zealand, 1997.

- EN 1993-1-3; Eurocode 3: Design of Steel Structures-Part 1–3: General Rules-Supplementary Rules for Cold-Formed Members and Sheeting. European Committee for Standardisation: Brussels, Belgium, 2006.

- EN 1993-1-4; Eurocode 3: Design of Steel Structures-Part 1–4: General Rules-Supplementary Rules for Stainless Steels. European Committee for Standardisation: Brussels, Belgium, 2007.

- EN 1999-1-4; Eurocode 9: Design of Aluminium Structures-Part 1–4: Cold-Formed Structural Sheeting. European Committee for Standardisation: Brussels, Belgium, 2011.

- Choy, M.Y.; Jia, X.F.; Yuan, X.; Zhou, J.; Wang, H.S.; Yu, C. (Eds.) Direct Strength Method for Web Crippling of Cold-Formed Steel C- and Z- Sections Subjected to Two-Flange Loading. In Proceedings of the Annual Stability Conference, Toronto, ON, Canada, 25–28 March 2014. [Google Scholar]

- Duarte, A.P.C.; Silvestre, N. A new slenderness-based approach for the web crippling design of plain channel steel beams. Int. J. Steel Struct. 2013, 13, 421–434. [Google Scholar] [CrossRef]

- Qiao, Z.; Li, C.; Zhong, W. (Eds.) Direct Strength Method for Web Crippling of Lipped Channel Sections with Flanges Restrained under ETF and ITF Loadings. In Proceedings of the Cold-Formed Steel Research Consortium Colloquium, 20–22 October 2020. Available online: https://jscholarship.library.jhu.edu/handle/1774.2/63146 (accessed on 10 September 2022).

- Dara, M.; Yu, C. Direct Strength Method for Web Crippling of Cold-formed Steel C- and Z sections Subjected to One-flange Loading. J. Steel Struct. Constr. 2015, 1, 1. [Google Scholar] [CrossRef]

- Heurkens, R.; Hofmeyer, H.; Mahendran, M.; Snijder, H.H. Direct strength method for web crippling—Lipped channels under EOF and IOF loading. Thin-Walled Struct. 2018, 123, 126–141. [Google Scholar] [CrossRef]

| Design Guideline | Material | Summary |

|---|---|---|

| AISI S100-16 [97] | Steel |

|

| AS/NZS 4600 [98] | Steel |

|

| EN1993-1-3 [102] | Steel |

|

| SEI/ASCE 8-02 [99] and AS/NZS 4673 [100] | Stainless steel |

|

| EN1993-1-4 [103] | Stainless steel |

|

| AS/NZS 1664 [101] | Aluminium |

|

| EN1999-1-4 [104] | Aluminium |

|

| Loading Condition | Support Condition | Carbon Steel | Stainless Steel | Aluminium |

|---|---|---|---|---|

| ETF | Unfastened | Duarte and Silvestre [106]—Unlipped Channel Sections (UCSs) without web openings Choy et al. [105]—C and Z channel sections without web openings Keerthan et al. [32]—Hollow flange channel sections without web openings Gunalan and Mahendran [87]— UCSs without web openings Janarthanan et al. [16]—C and SupaCee sections without web openings Qiao et al. [107]—LCSs without web openings | Li and Young [63]—SHSs and RHSs without web openings | Alsanat et al. [90]—LCSs without web openings |

| Fastened | Janarthanan et al. [16]—C and SupaCee sections without web openings | - | Alsanat et al. [52]—LCSs without web openings | |

| ITF | Unfastened | Duarte and Silvestre [106]—UCSs without web openings Choy et al. [105]—C and Z channel sections without web openings Keerthan et al. [32]—Hollow flange channel sections without web openings Gunalan and Mahendran [87]— UCSs without web openings Janarthanan et al. [16]—C and SupaCee sections without web openings Qiao et al. [107]—LCSs without web openings | Li and Young [63]—SHSs and RHSs without web openings | Alsanat et al. [90]—LCSs without web openings |

| Fastened | Janarthanan et al. [16]—C and SupaCee sections without web openings | - | Alsanat et al. [52]—LCSs without web openings | |

| EOF | Unfastened | Duarte and Silvestre [106]—UCSs without web openings Dara and Yu [108]—C and Z sections without web openings Keerthan and Mahendran [33]—Hollow flange channel sections without web openings Sundararajah et al. [91]—LCSs without web openings Heurkens et al. [109]—LCSs without web openings Janarthanan et al. [16]—C and SupaCee sections without web openings | Li and Young [63]—SHSs and RHSs without web openings | - |

| Fastened | Dara and Yu [108]—C and Z sections without web openings Janarthanan et al. [16]—C and SupaCee sections without web openings | - | - | |

| IOF | Unfastened | Duarte and Silvestre [106]—UCSs without web openings Dara and Yu [108]—C and Z sections without web openings Keerthan and Mahendran [33]—Hollow flange channel sections without web openings Sundararajah et al. [91]—LCSs without web openings Heurkens et al. [109]—LCSs without web openings Janarthanan et al. [16]—C and SupaCee sections without web openings | Li and Young [63]—SHSs and RHSs without web openings | - |

| Fastened | Dara and Yu [108]—C and Z sections without web openings Janarthanan et al. [16]—C and SupaCee sections without web openings | - | - |

| Specimen | Lipped Channel Dimension (mm) | Bearing Length (mm) | Yield Strength (Mpa) | Experimental Web Crippling Strength (kN) | Web Crippling Strength from FEM (kN) | Exp/FEM | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Depth of the Web | Flange Width | Lip Width | Web Thickness | Corner Radius | Opening Diameter | Length | ||||||

| 142x60x13-t1.3N90A0.2FR | 142.2 | 58.6 | 15.90 | 1.23 | 4.8 | 27.9 | 337.5 | 90 | 455 | 1.98 | 1.97 | 1.01 |

| 142x60x13-t1.3N90A0.4FR | 142.2 | 59.5 | 16.30 | 1.25 | 4.8 | 55.8 | 337.5 | 90 | 455 | 1.62 | 1.73 | 0.94 |

| 142x60x13-t1.3N90A0.6FR | 142.2 | 59.5 | 16.30 | 1.25 | 4.8 | 83.6 | 337.5 | 90 | 455 | 1.32 | 1.44 | 0.92 |

| 142x60x13-t1.3N120A0.2FR | 141.8 | 58.9 | 15.60 | 1.24 | 4.8 | 27.9 | 350 | 120 | 455 | 1.95 | 2.2 | 0.89 |

| 142x60x13-t1.3N120A0.4FR | 141.3 | 58.8 | 16.30 | 1.24 | 4.8 | 55.7 | 350 | 120 | 455 | 1.78 | 1.88 | 0.95 |

| 172x65x13-t1.3N120A0.4FR | 172.3 | 63.6 | 15.50 | 1.27 | 5 | 67.6 | 400 | 120 | 534 | 1.7 | 1.74 | 0.98 |

| 172x65x13-t1.3N120A0.6FR | 172.6 | 64.3 | 15.30 | 1.28 | 5 | 101.6 | 400 | 120 | 534 | 1.36 | 1.46 | 0.93 |

| 202x65x13-t1.4N120A0.4FR | 202.4 | 64.2 | 16.50 | 1.45 | 5 | 79.5 | 425 | 120 | 513 | 1.88 | 1.99 | 0.94 |

| 262x65x13-t1.6N120A0.4FR | 262.8 | 63.4 | 14.70 | 1.55 | 5.5 | 103.4 | 525 | 120 | 525 | 1.77 | 1.86 | 0.95 |

| 262x65x13-t1.6N150A0.4FR | 262.8 | 63.4 | 14.70 | 1.55 | 5.5 | 103.4 | 550 | 150 | 525 | 2.04 | 1.98 | 1.03 |

| Mean value | 0.95 | |||||||||||

| COV | 0.04 | |||||||||||

| Specimen | Lipped Channel Dimension (mm) | Bearing Length (mm) | Yield/Ultimate Strength (Mpa) | Experimental Web Crippling Strength (kN) | Web Crippling Strength from FEM (kN) | Exp/FEM | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Depth of the Web | Flange Width | Lip Width | Web Thickness | Corner Radius | Opening Diameter | Length | ||||||

| 142x60x13-t1.3N90A0.2FR | 142.2 | 58.6 | 15.90 | 1.23 | 4.8 | 27.9 | 337.5 | 90 | 455/532 | 1.98 | 2.01 | 0.99 |

| 142x60x13-t1.3N90A0.4FR | 142.2 | 59.5 | 16.30 | 1.25 | 4.8 | 55.8 | 337.5 | 90 | 455/532 | 1.62 | 1.67 | 0.97 |

| 142x60x13-t1.3N120A0.2FR | 141.8 | 58.9 | 15.60 | 1.24 | 4.8 | 27.9 | 350 | 120 | 455/532 | 1.95 | 2.01 | 0.97 |

| 172x65x13-t1.3N120A0.4FR | 172.3 | 63.6 | 15.50 | 1.27 | 5 | 67.6 | 400 | 120 | 534/566 | 1.7 | 1.69 | 1.01 |

| 202x65x13-t1.4N120A0.2FR | 202.4 | 64.3 | 16.30 | 1.45 | 5 | 39.8 | 425 | 120 | 513/552 | 2.41 | 2.51 | 0.96 |

| 202x65x13-t1.4N120A0.4FR | 202.4 | 64.2 | 16.50 | 1.45 | 5 | 79.5 | 425 | 120 | 513/552 | 1.88 | 2.05 | 0.92 |

| Mean value | 0.97 | |||||||||||

| COV | 0.03 | |||||||||||

| Specimen | Lipped Channel Dimension (mm) | Bearing Length (mm) | Yield Strength (Mpa) | Experimental Web Crippling Strength (kN) | Web Crippling Strength from FEM (kN) | Exp/FEM | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Depth of the Web | Flange Width | Lip Width | Web Thickness | Corner radius | Opening Diameter | Length | ||||||

| U-ETF-250-3-A0.2(a) | 252.4 | 76.7 | 24.90 | 2.94 | 4.8 | 47.384 | 716 | 100 | 210 | 4.8 | 4.7 | 1.02 |

| U-ETF-250-3-A0.2(b) | 252.3 | 76.9 | 23.70 | 2.94 | 5 | 47.284 | 714 | 100 | 210 | 4.7 | 4.63 | 1.02 |

| U-ETF-250-3-A0.5 | 253.5 | 77.2 | 23.60 | 2.97 | 4.8 | 118.98 | 715 | 100 | 206 | 3.9 | 3.6 | 1.08 |

| U-ETF-250-3-A0.8(a) | 254 | 77.7 | 25.60 | 2.94 | 4.8 | 190.816 | 714 | 100 | 206 | 3 | 2.94 | 1.02 |

| U-ETF-250-3-A0.8(b) | 262.1 | 76.2 | 22.70 | 2.44 | 4.8 | 198.096 | 715 | 100 | 206 | 3.1 | 2.6 | 1.19 |

| Mean value | 1.06 | |||||||||||

| COV | 0.06 | |||||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Weerasinghe, H.; Konthesingha, C.; Nanayakkara, A.; Poologanathan, K.; Perampalam, G.; Kanthasamy, E. Web Crippling Behaviour of Cold-Formed Carbon Steel, Stainless Steel, and Aluminium Lipped Channel Sections with Web Openings. Buildings 2022, 12, 1820. https://doi.org/10.3390/buildings12111820

Weerasinghe H, Konthesingha C, Nanayakkara A, Poologanathan K, Perampalam G, Kanthasamy E. Web Crippling Behaviour of Cold-Formed Carbon Steel, Stainless Steel, and Aluminium Lipped Channel Sections with Web Openings. Buildings. 2022; 12(11):1820. https://doi.org/10.3390/buildings12111820

Chicago/Turabian StyleWeerasinghe, Hasini, Chaminda Konthesingha, Anura Nanayakkara, Keerthan Poologanathan, Gatheeshgar Perampalam, and Elilarasi Kanthasamy. 2022. "Web Crippling Behaviour of Cold-Formed Carbon Steel, Stainless Steel, and Aluminium Lipped Channel Sections with Web Openings" Buildings 12, no. 11: 1820. https://doi.org/10.3390/buildings12111820

APA StyleWeerasinghe, H., Konthesingha, C., Nanayakkara, A., Poologanathan, K., Perampalam, G., & Kanthasamy, E. (2022). Web Crippling Behaviour of Cold-Formed Carbon Steel, Stainless Steel, and Aluminium Lipped Channel Sections with Web Openings. Buildings, 12(11), 1820. https://doi.org/10.3390/buildings12111820