Life Cycle Regional Economic Impacts of Bridge Repair Using Cross-Laminated Timber Floor Slabs: A Case Study in Akita Prefecture, Japan

Abstract

:1. Introduction

2. Materials and Methods

2.1. Target Bridge and Floor Slabs

2.2. Scope and Duration of Estimation

2.3. Creating an Extended Input–Output Table for Construction

2.4. Creating an Extended Input–Output Table for Maintenance and Disposal

2.5. Data Used

2.6. Commercial Margin and Domestic Freight Rate Treatment

2.7. Prefecture’s Self-Sufficiency Rate

2.8. Estimation of Economic Impacts

3. Results and Discussion

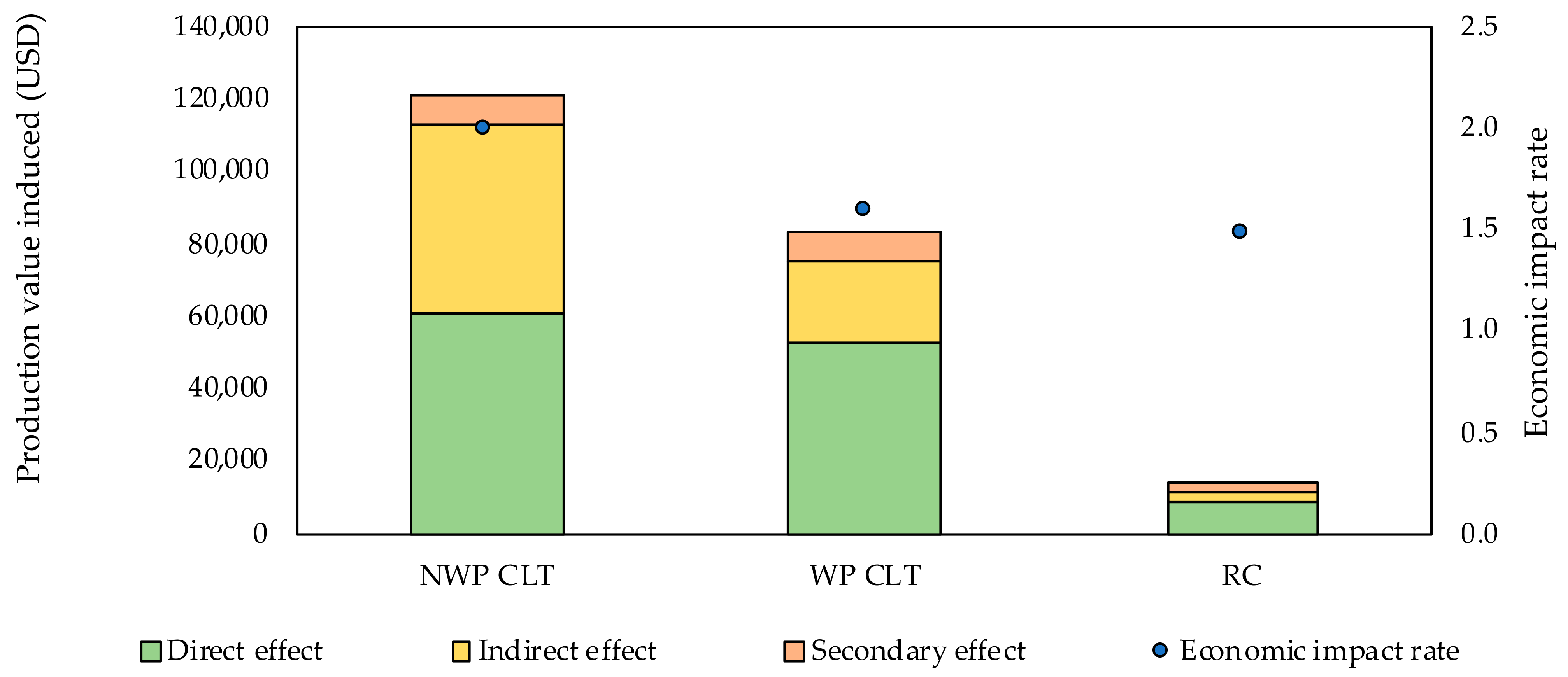

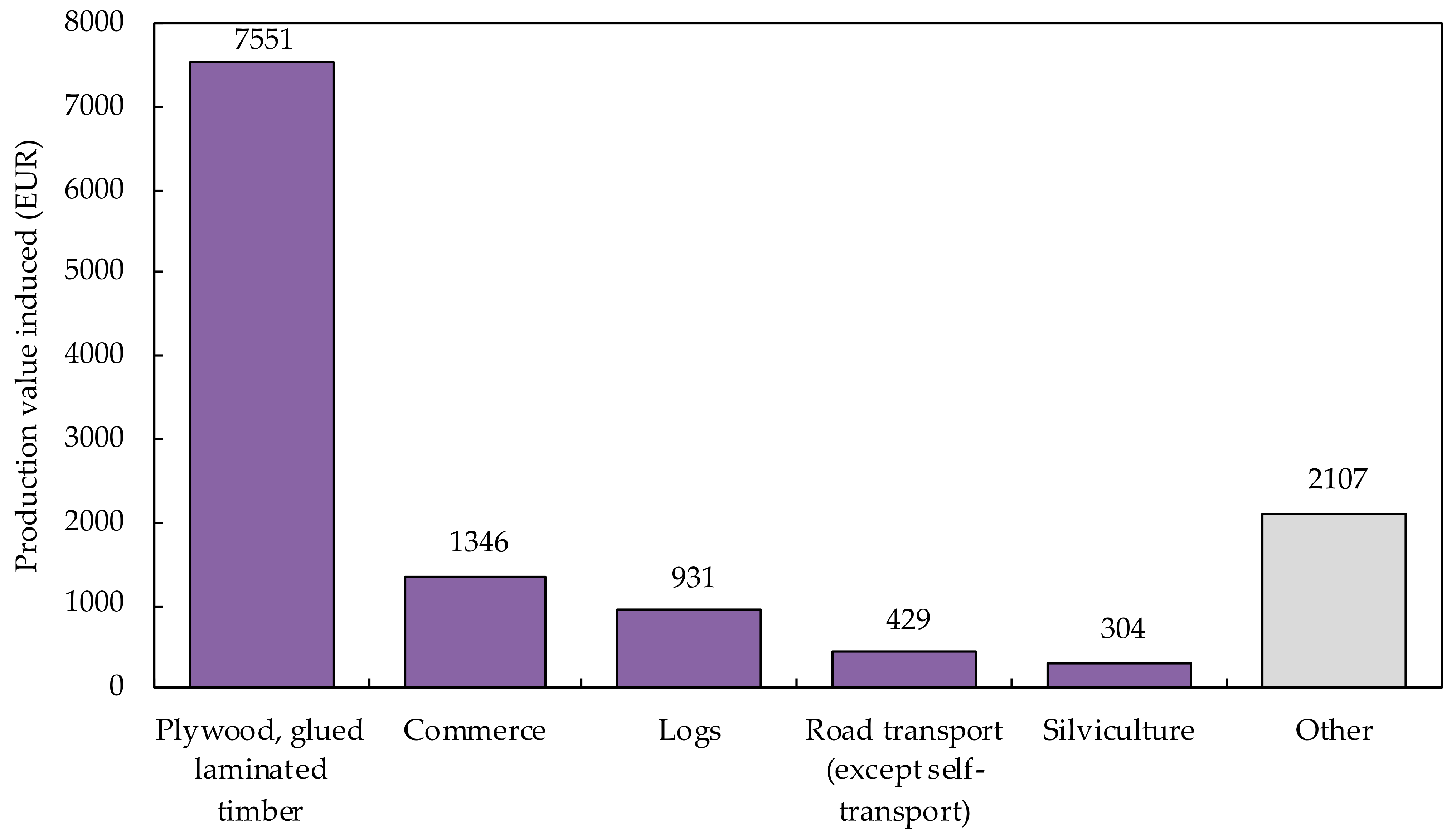

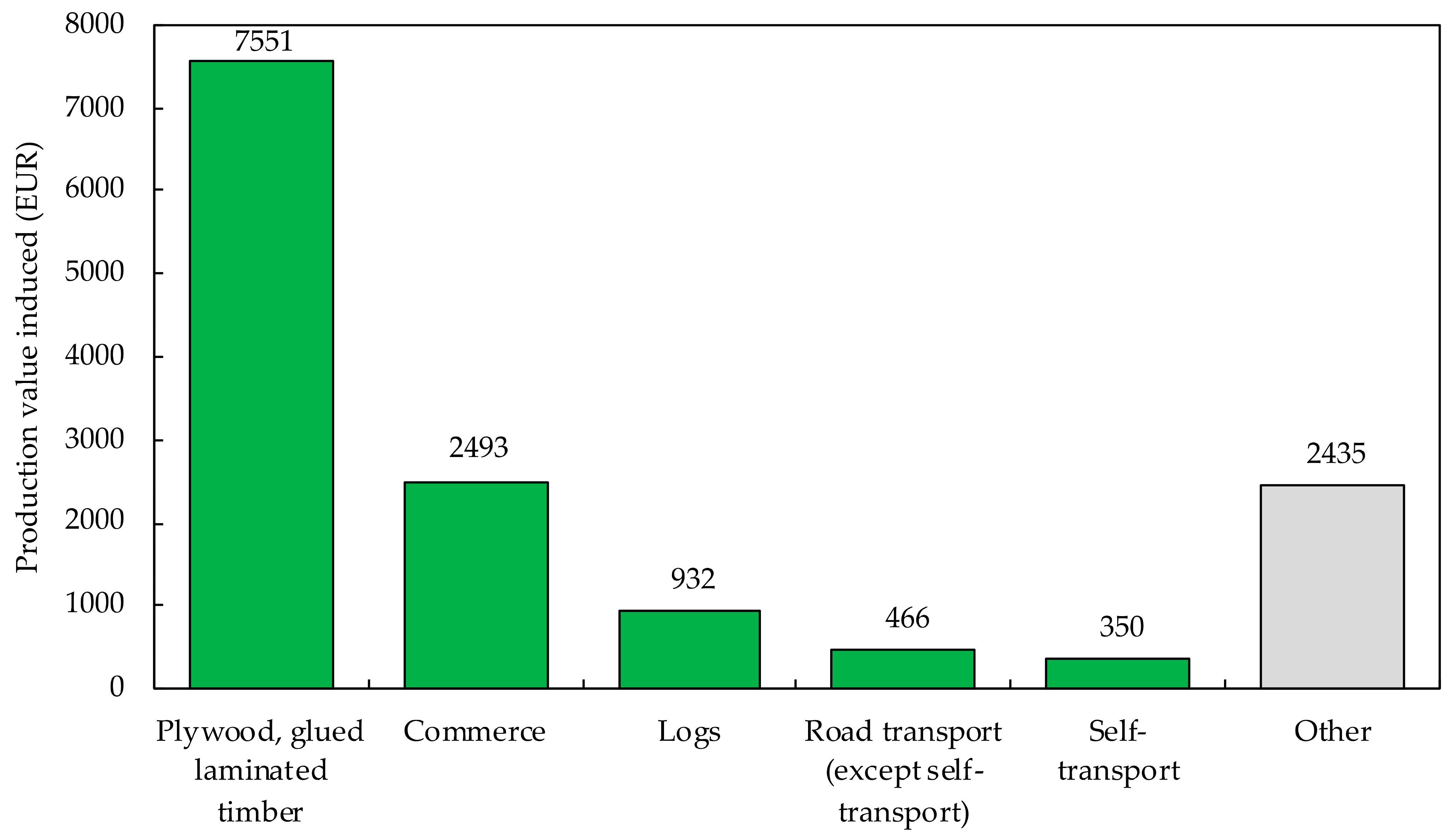

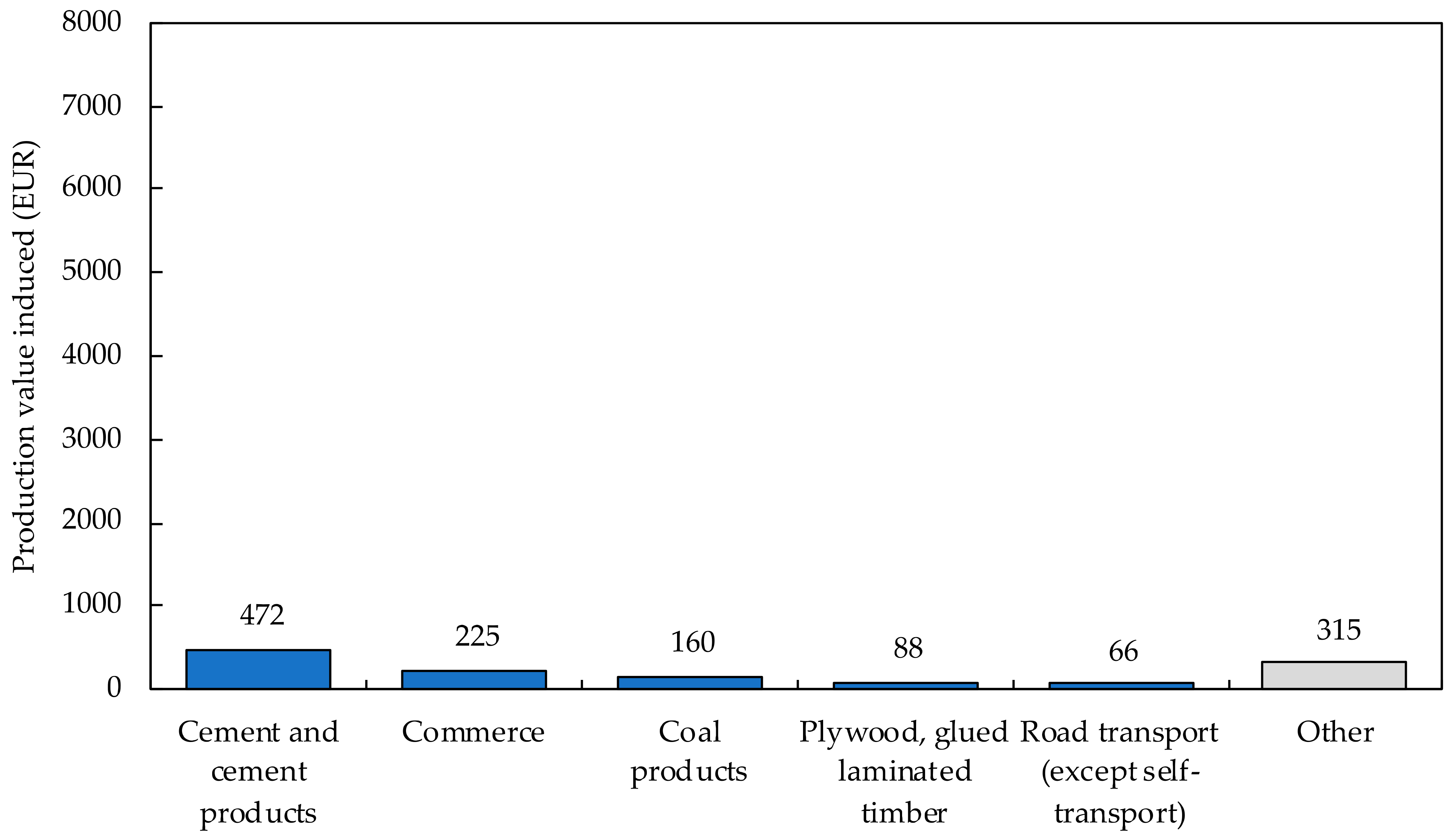

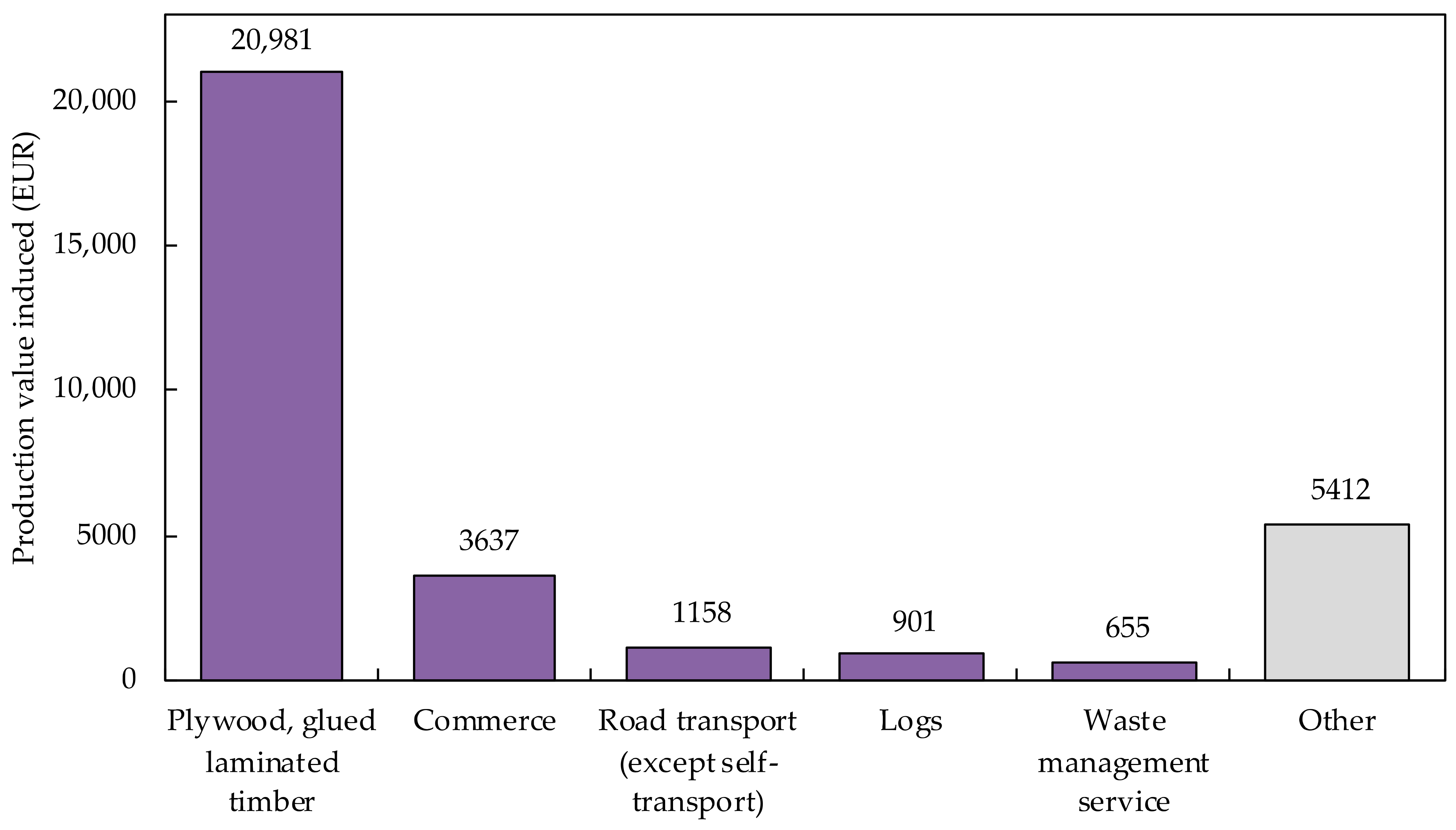

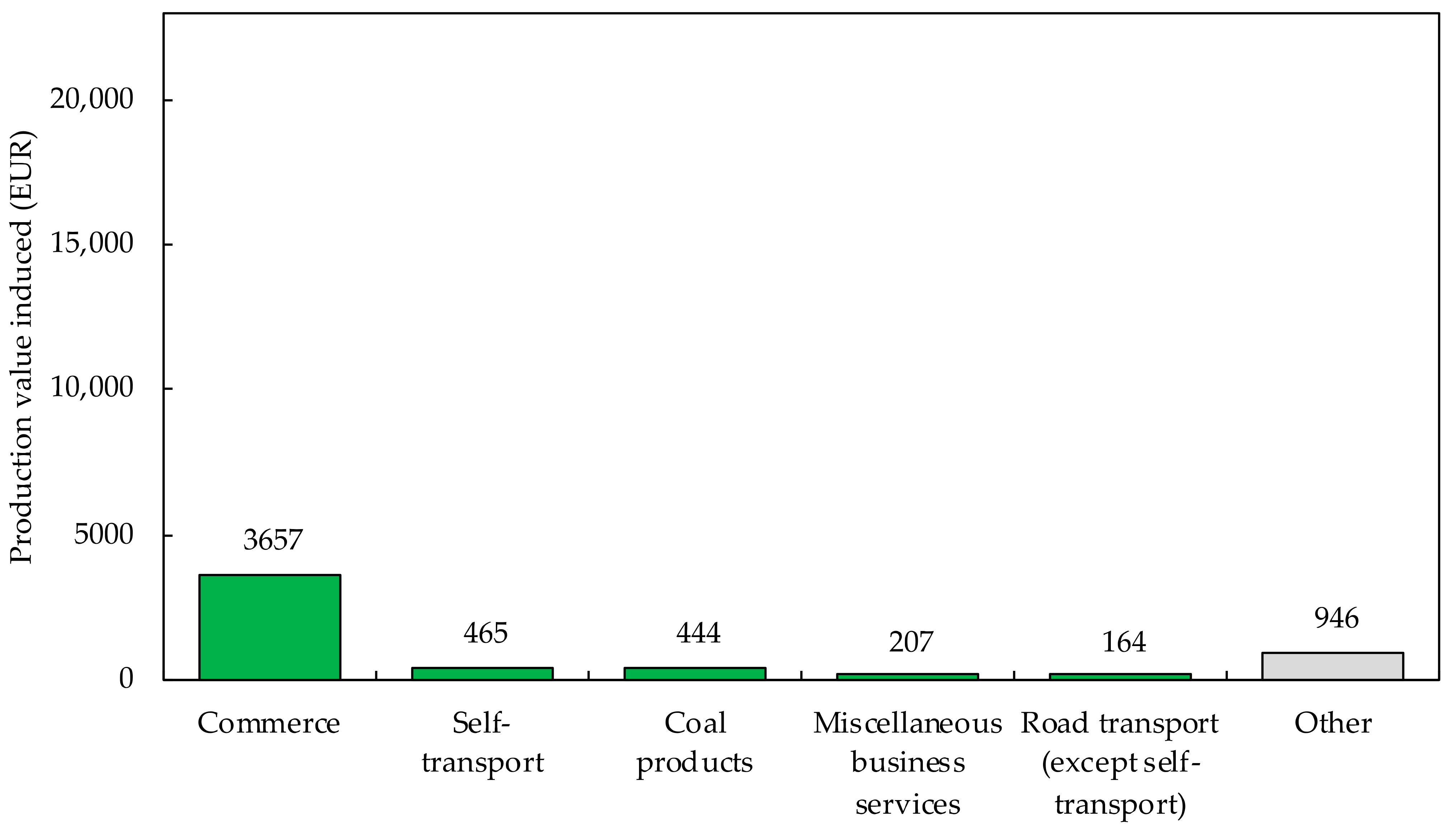

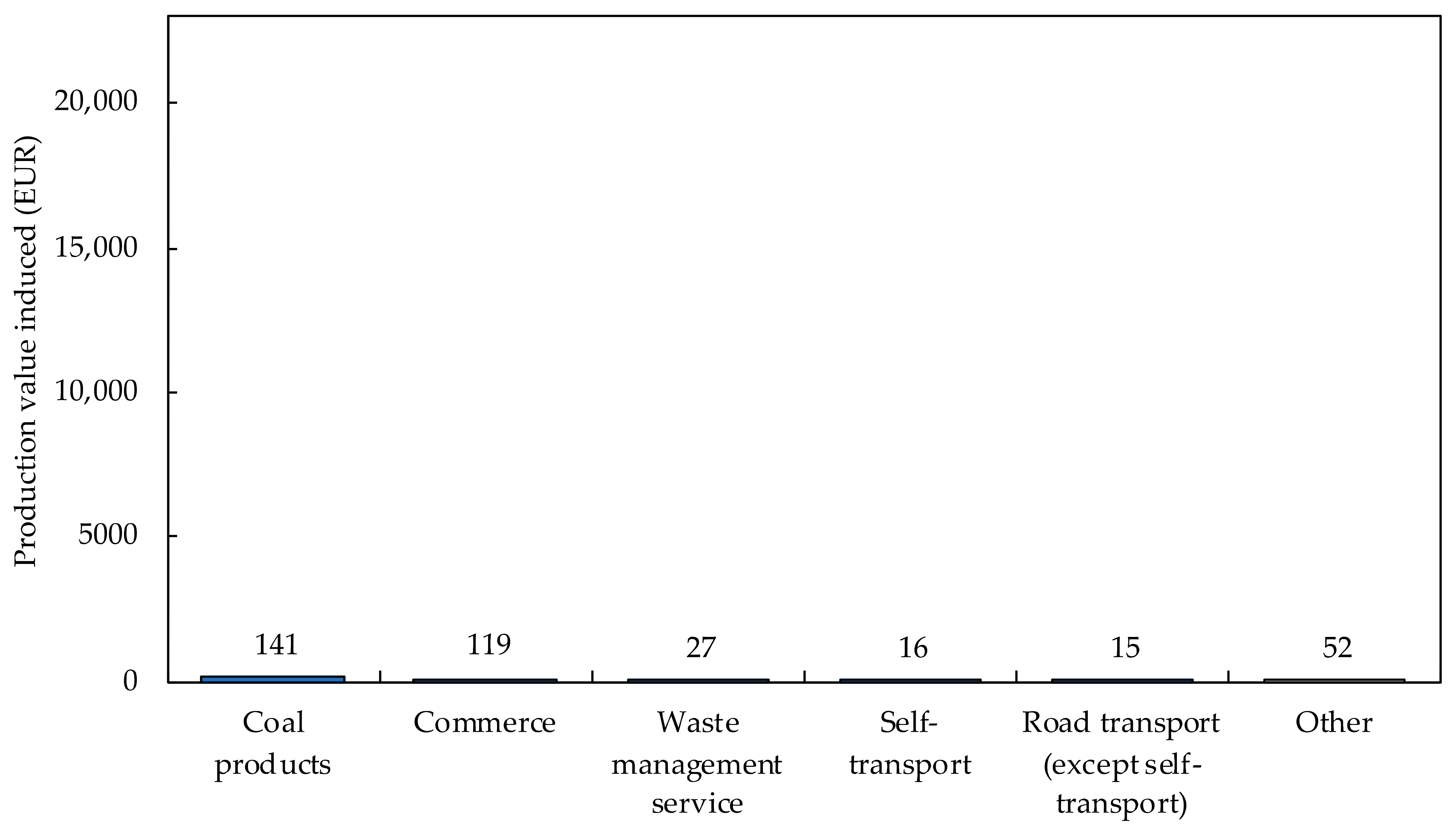

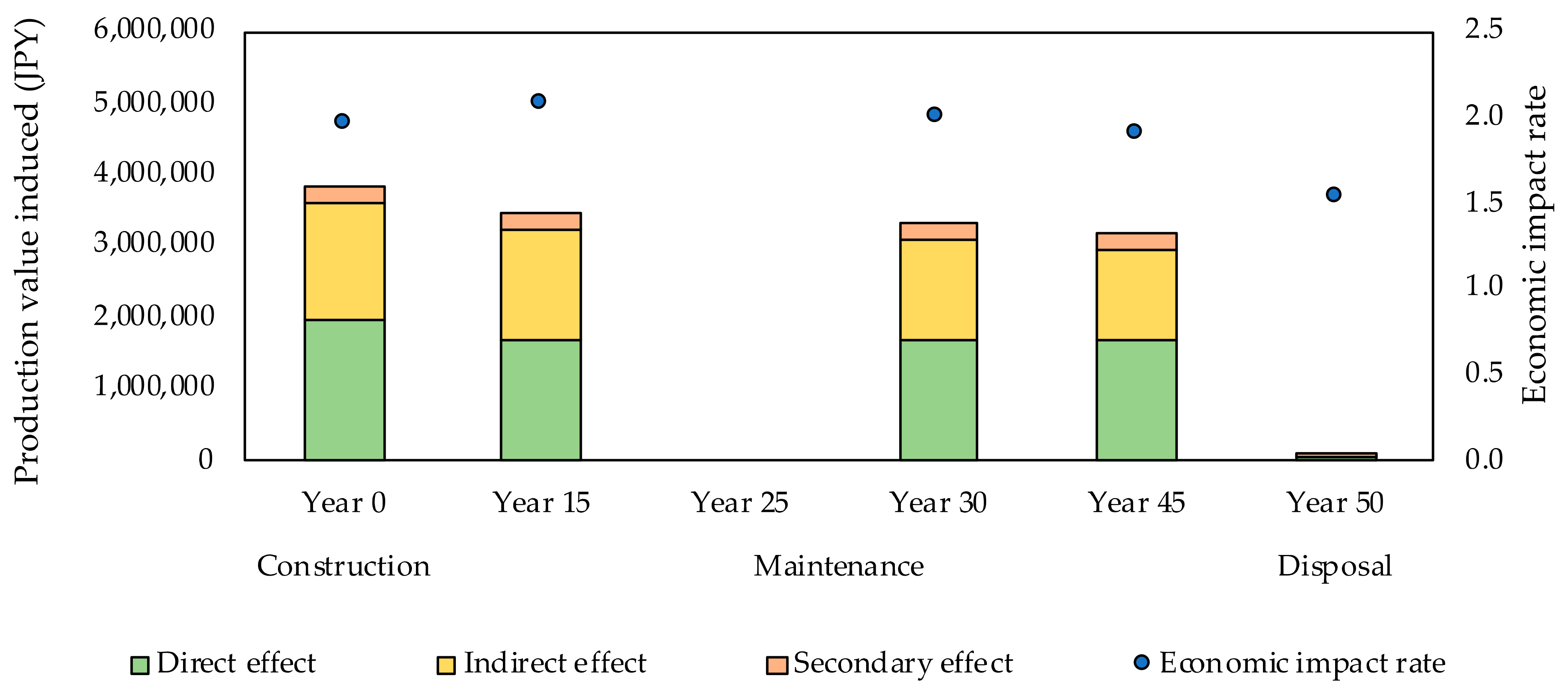

3.1. Regional Economic Impact

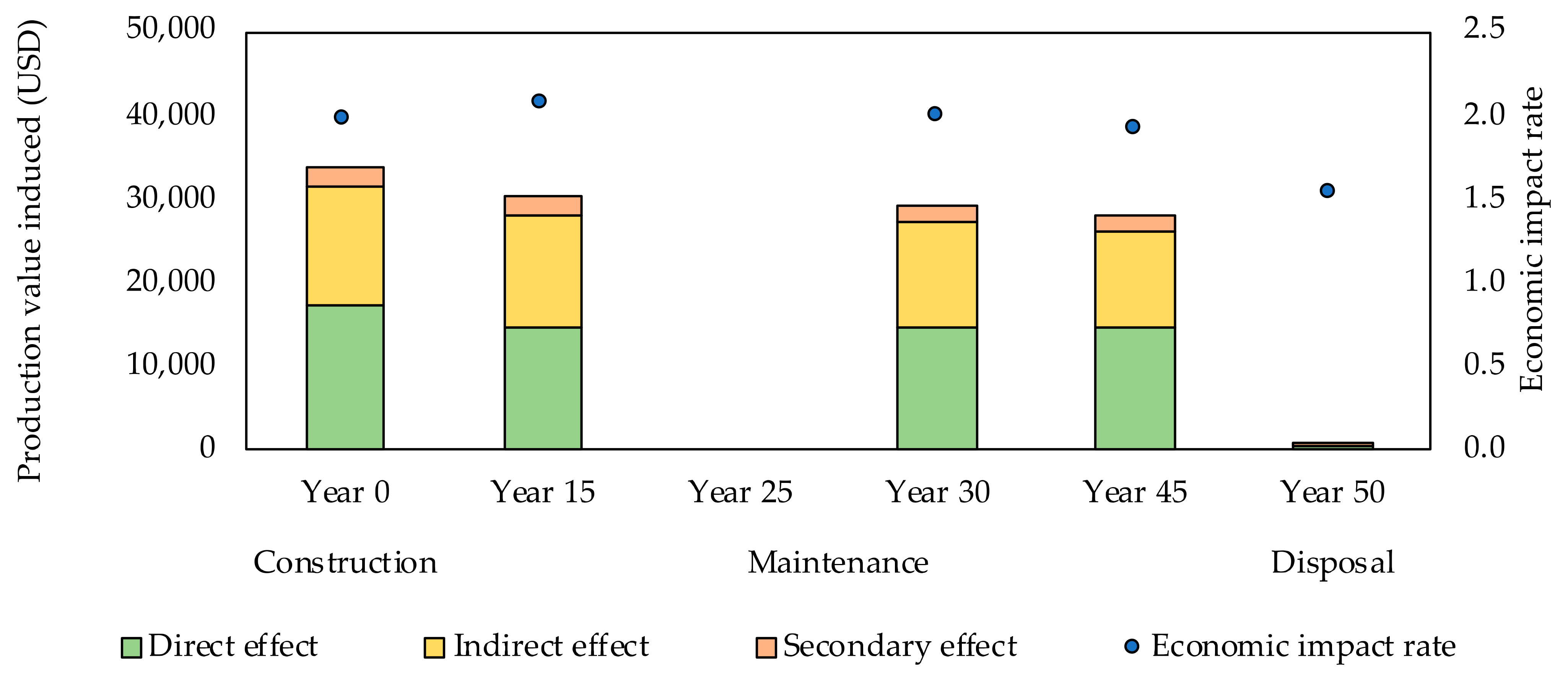

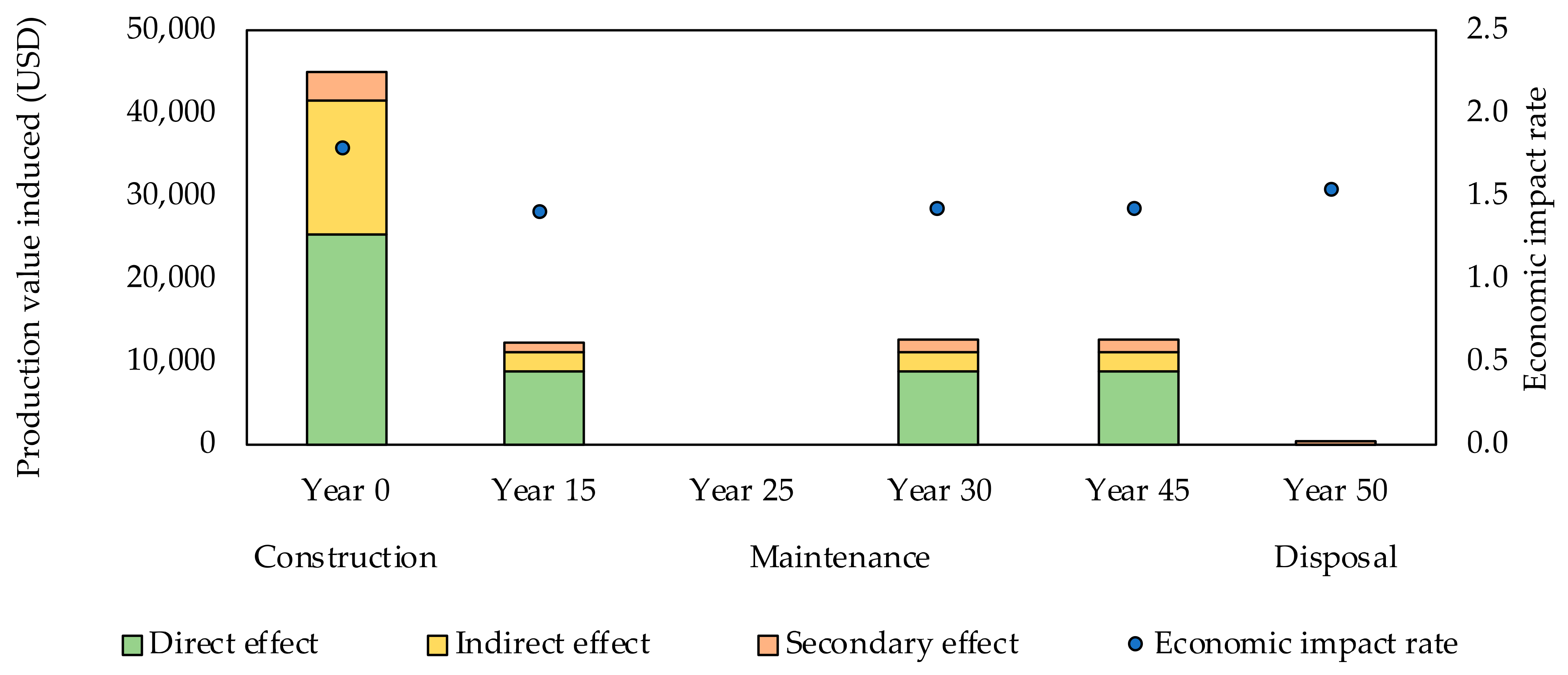

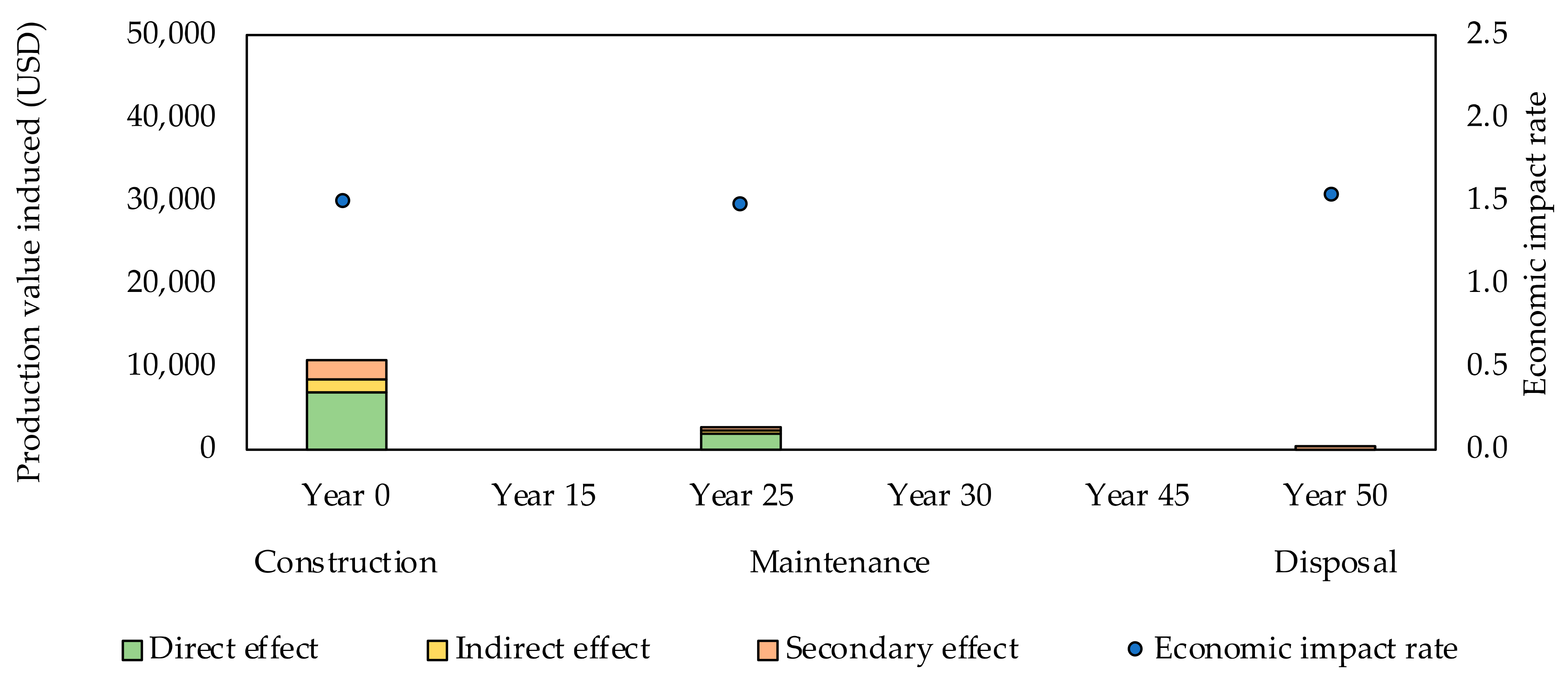

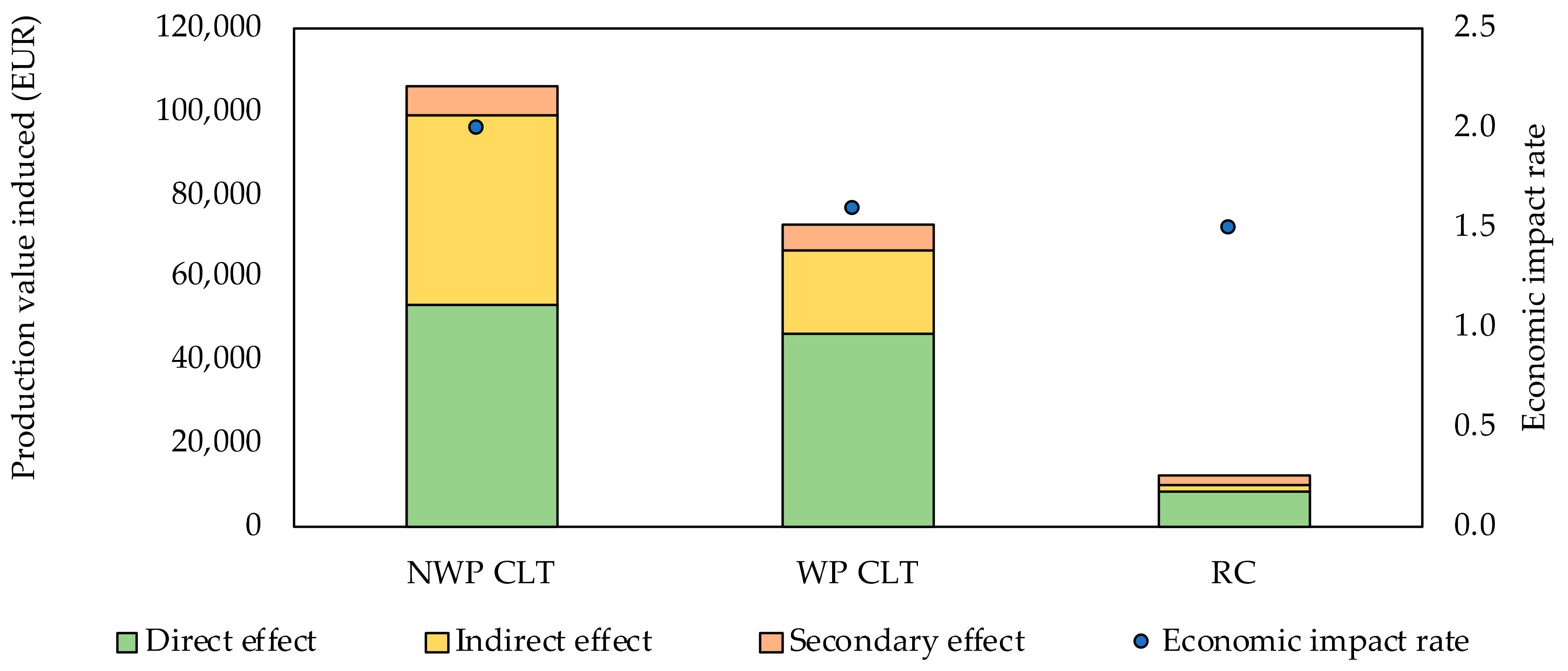

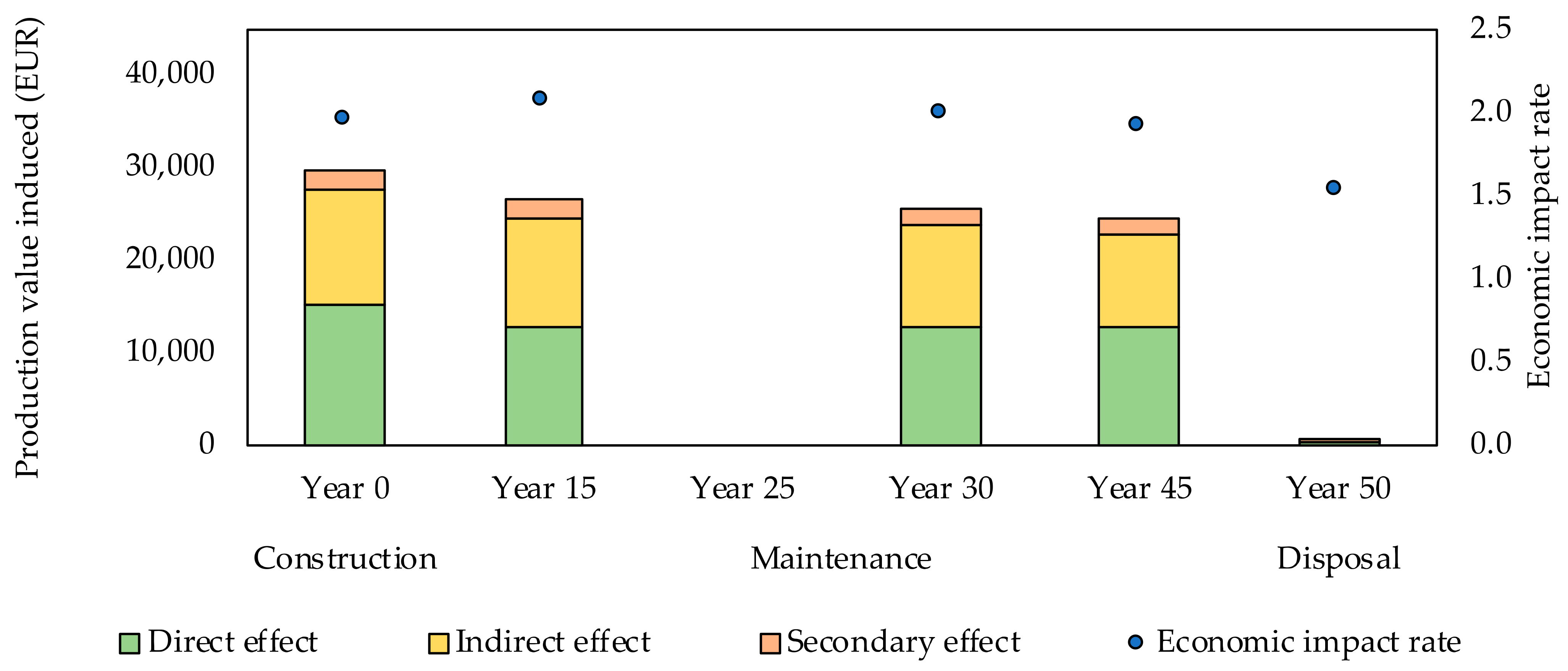

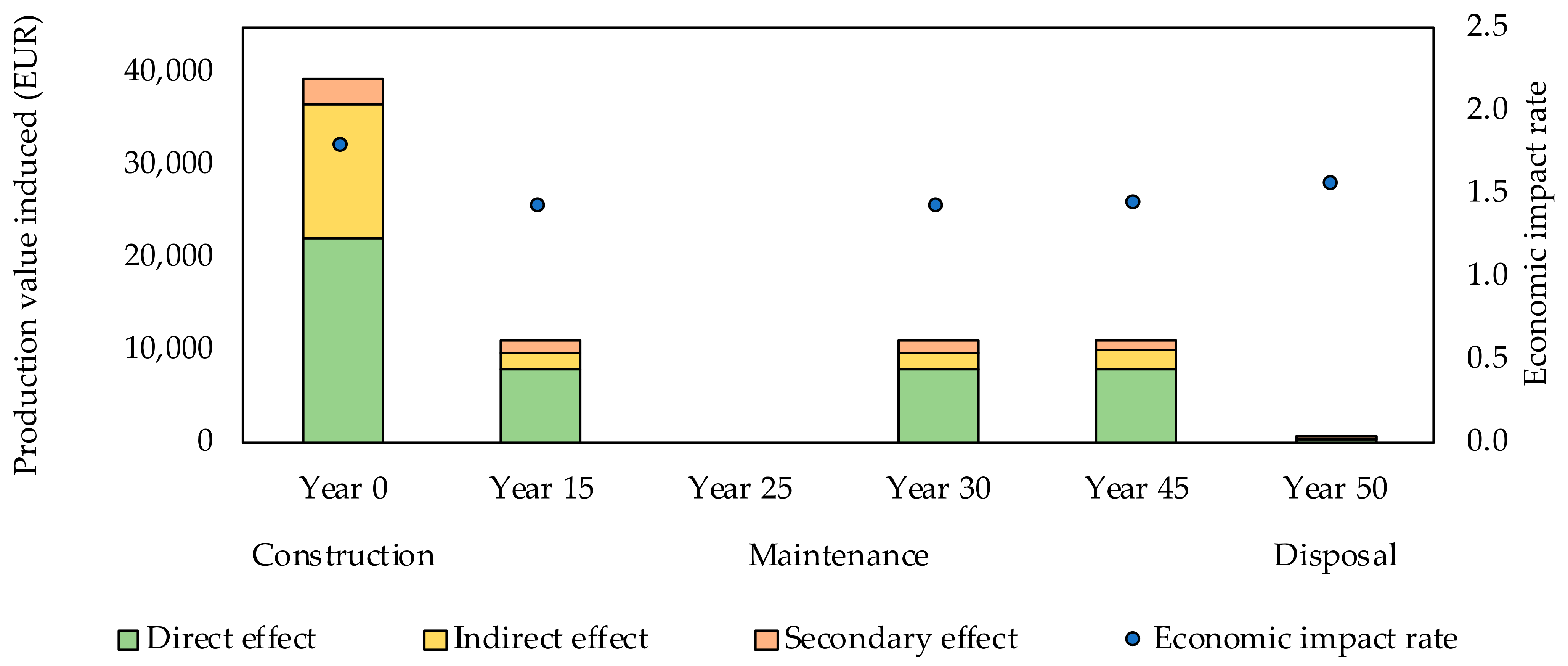

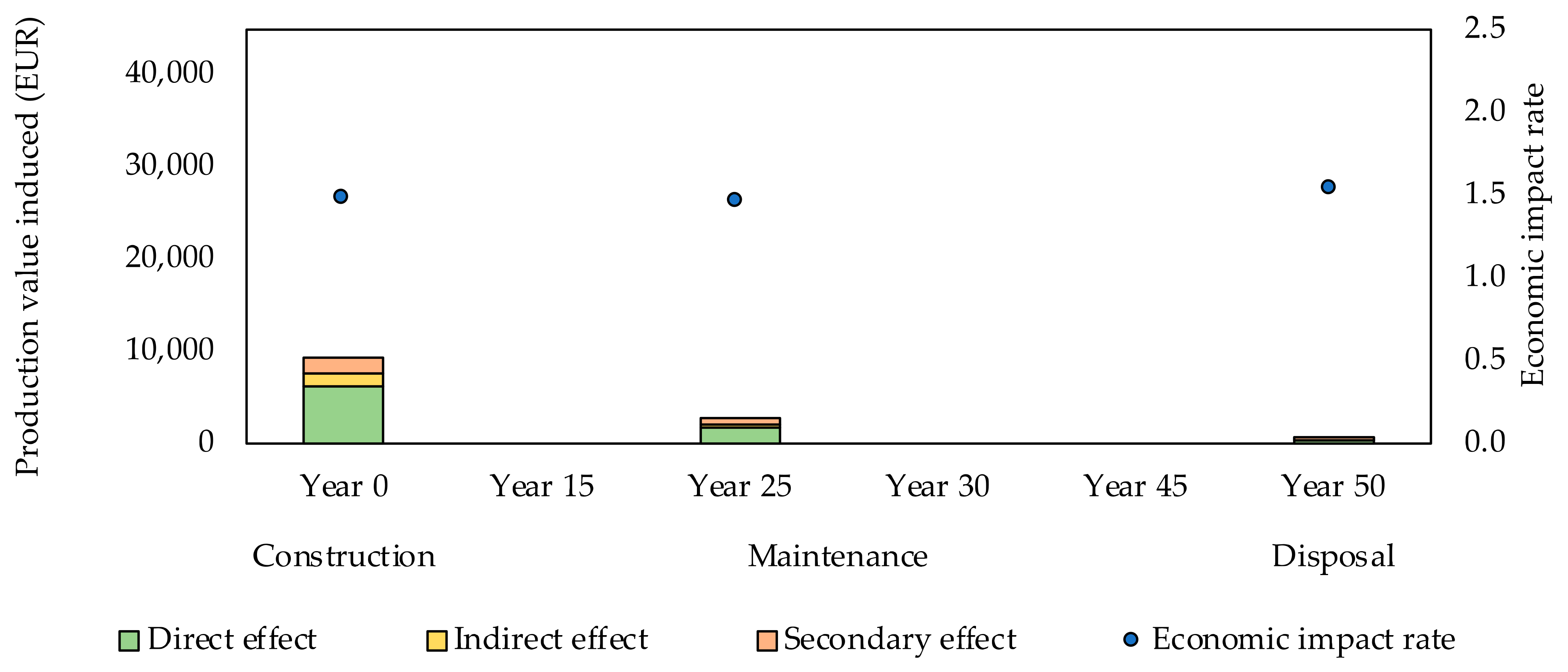

3.1.1. Regional Economic Impacts over the Life Cycle of the Three Floor Slabs

3.1.2. Net Regional Economic Impacts

3.2. Sensitivity Analysis

3.2.1. Effect of Different Maintenance Cycles

3.2.2. Effect of Changes in the Prefecture’s Self-Sufficiency Rate of CLT

3.3. Comparison with Previous Studies

4. Conclusions

- (1)

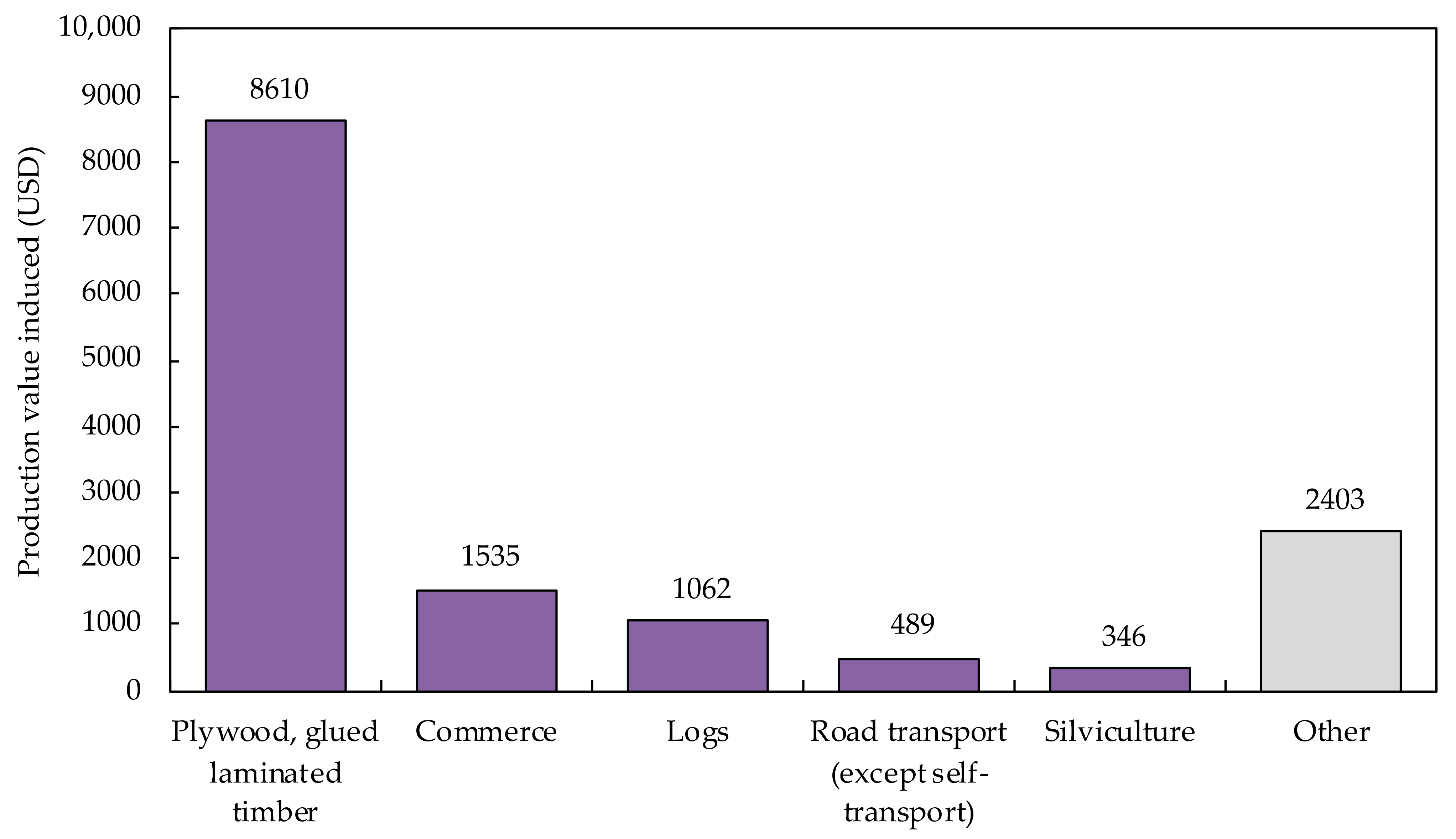

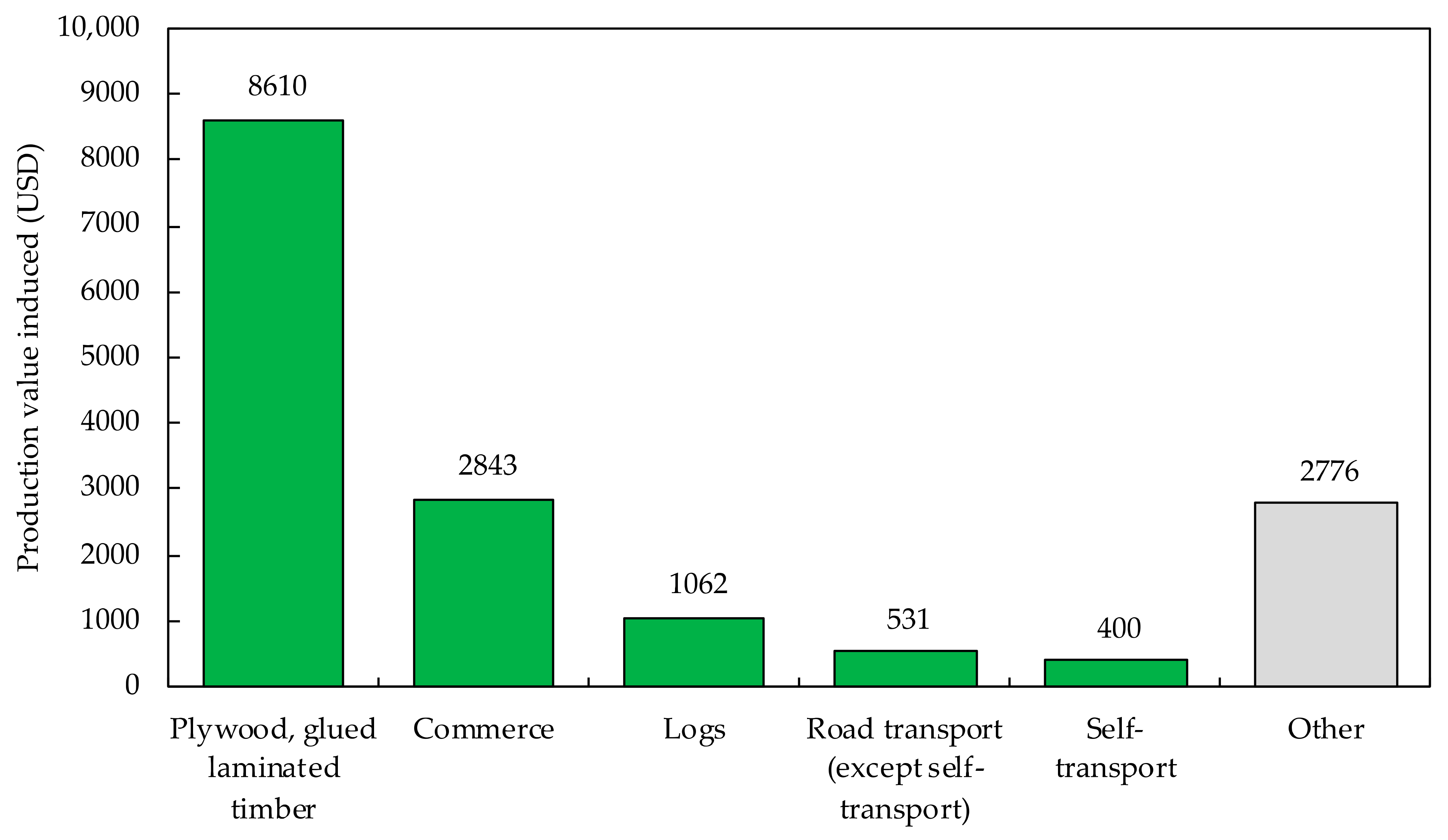

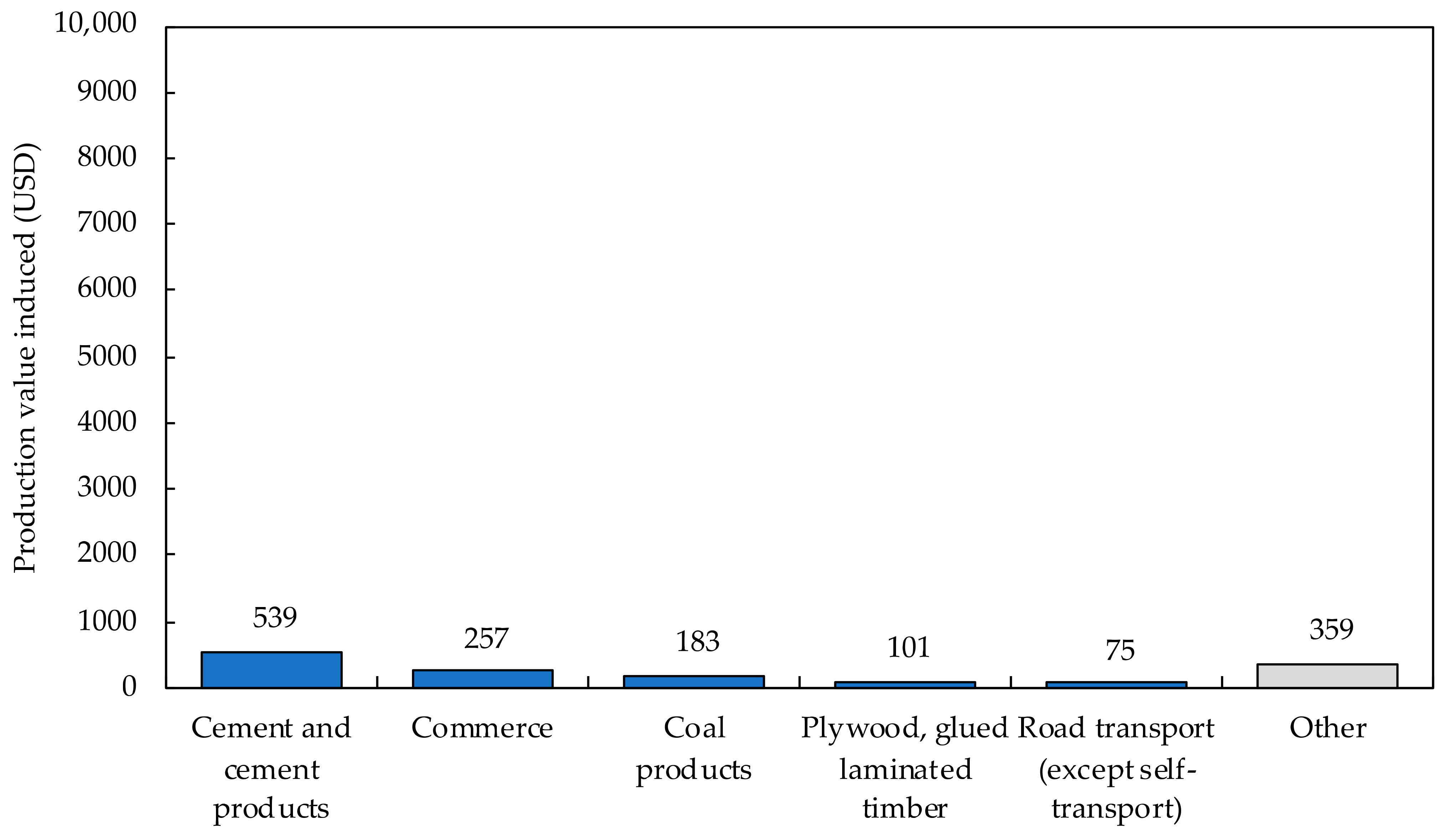

- The regional economic impact of floor slab construction was larger for CLT than for RC. The construction and maintenance costs of RC are lower than those of CLT. However, the use of CLT also has a greater economic impact on upstream industries, indicating that its use has a more positive impact on the regional economy.

- (2)

- The largest economic impact rate over the life cycle of the floor slabs was observed for NWP CLT. Compared to WP CLT, NWP CLT increases the demand for CLT production during maintenance. Since CLT is more expensive than waterproofing agents, the maintenance cost of NWP CLT is higher than that of WP CLT. However, an increase in the demand for CLT should have a positive economic impact on upstream industries, thus increasing the regional economic impact.

- (3)

- The net economic impact over the life cycle of the floor slabs was largest for NWP CLT. If NWP CLT replaces WP CLT or RC, net losses will occur in certain sectors. However, this is offset by the net benefits of NWP CLT in the plywood and glued laminated sector and logs sector. Therefore, replacement with NWP CLT has a net positive economic impact.

- (4)

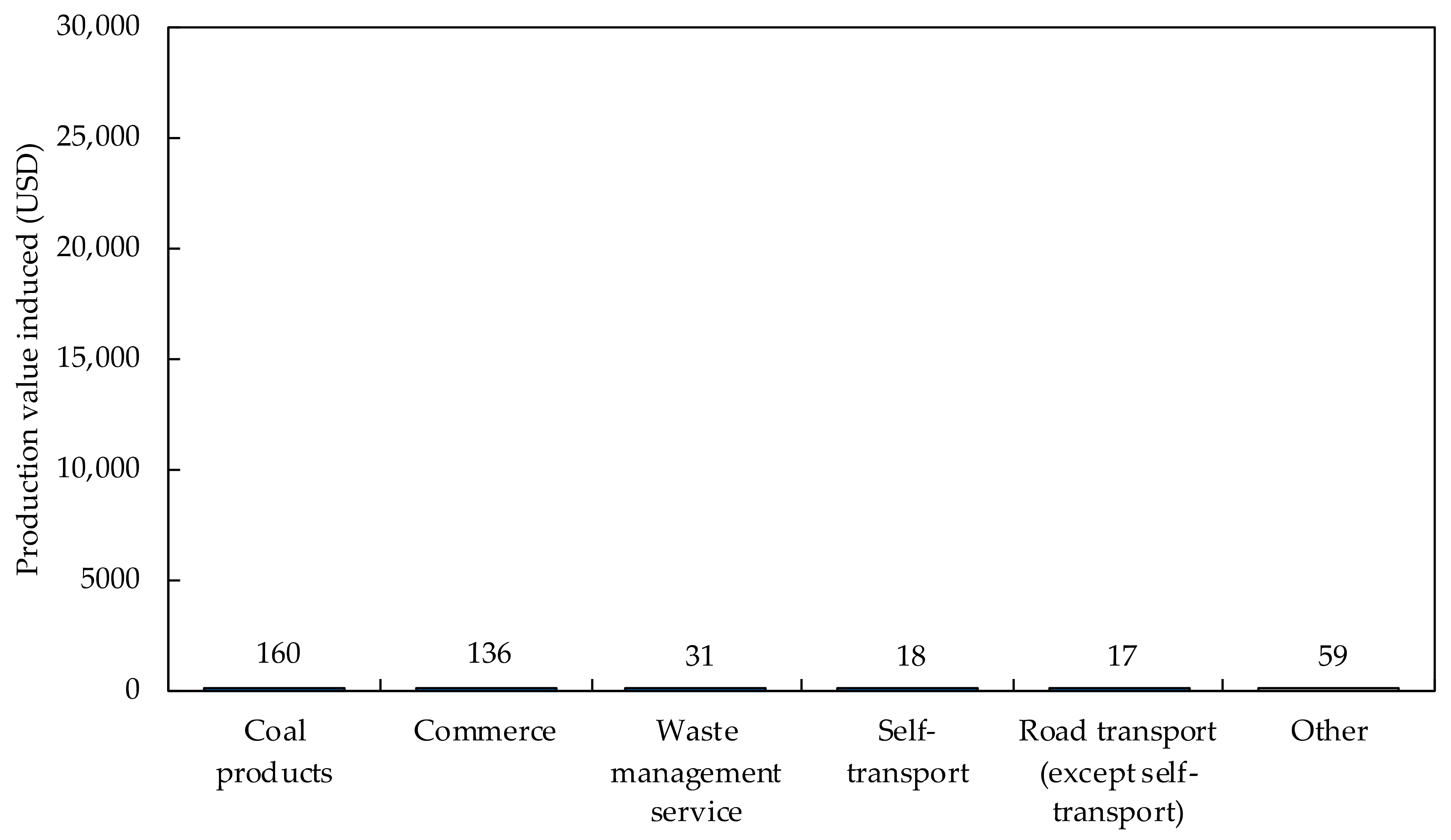

- The impact of the change in the maintenance period on the economic impact is small. However, a decrease in the prefecture’s self-sufficiency rate of CLT production may reverse the economic impact of NWP CLT and that of WP CLT and RC. In other words, to expect a great economic impact, it is important to have a large amount of CLT production in the prefecture when using CLT for floor slabs.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Net Benefit | Net Loss | ||

|---|---|---|---|

| Sector | USD | Sector | USD |

| Plywood, glued laminated timber | 23,925 | Commerce | −1329 |

| Road transport (except self-transport) | 1091 | Final chemical products (except medicaments) | −58 |

| Logs | 1027 | Special forest products | −0.016 |

| Activities not elsewhere classified | 686 | Synthetic resins | −0.009 |

| Waste management service | 634 | - | - |

| Net Benefit | Net Loss | ||

|---|---|---|---|

| Sector | USD | Sector | USD |

| Plywood, glued laminated timber | 32,435 | Cement and cement products | −537 |

| Commerce | 5292 | Miscellaneous mining industry | −2 |

| Logs | 2082 | Miscellaneous ceramic, stone, and clay products | −0.53 |

| Road transport (except self-transport) | 1717 | Miscellaneous iron or steel products | −0.020 |

| Activities not elsewhere classified | 1027 | - | - |

| Maintenance Period | Direct Effect (USD) (A) | Total Effect (USD) (B) | Economic Impact Rate (B/A) | Employment Effect (People) | |

|---|---|---|---|---|---|

| NWP CLT | Current (year 15, 30, 45) | 61,079 | 121,194 | 1.984 | 0.686 |

| +5 years (year 20, 40) | 46,509 | 92,170 | 1.982 | 0.554 | |

| −5 years (year 10, 20, 30, 40) | 75,649 | 151,759 | 2.006 | 0.886 | |

| WP CLT | Current (year 15, 30, 45) | 52,613 | 83,277 | 1.583 | 0.635 |

| +5 years (year 20, 40) | 43,624 | 70,645 | 1.619 | 0.564 | |

| −5 years (year 10, 20, 30, 40) | 61,602 | 95,781 | 1.555 | 0.737 | |

| RC | Current (year 25) | 9477 | 14,027 | 1.480 | 0.129 |

| +5 years (year 30) | 9477 | 14,027 | 1.480 | 0.123 | |

| −5 years (year 20, 40) | 11,536 | 17,052 | 1.478 | 0.139 |

Appendix B

| Net Benefit | Net Loss | ||

|---|---|---|---|

| Sector | EUR | Sector | EUR |

| Plywood, glued laminated timber | 20,980 | Commerce | −1166 |

| Road transport (except self-transport) | 956 | Final chemical products (except medicaments) | −51 |

| Logs | 901 | Special forest products | −0.014 |

| Activities not elsewhere classified | 602 | Synthetic resins | −0.0075 |

| Waste management service | 556 | - | - |

| Net Benefit | Net Loss | ||

|---|---|---|---|

| Sector | EUR | Sector | EUR |

| Plywood, glued laminated timber | 28,443 | Cement and cement products | −471 |

| Commerce | 4641 | Miscellaneous mining industry | −2 |

| Logs | 1826 | Miscellaneous ceramic, stone, and clay products | −0.47 |

| Road transport (except self-transport) | 1506 | Miscellaneous iron or steel products | −0.018 |

| Activities not elsewhere classified | 900 | - | - |

| Maintenance Period | Direct Effect (EUR) (A) | Total Effect (EUR) (B) | Economic Impact Rate (B/A) | Employment Effect (People) | |

|---|---|---|---|---|---|

| NWP CLT | Current (year 15, 30, 45) | 53,562 | 106,278 | 1.984 | 0.686 |

| +5 years (year 20, 40) | 40,785 | 80,826 | 1.982 | 0.554 | |

| −5 years (year 10, 20, 30, 40) | 66,339 | 133,081 | 2.006 | 0.886 | |

| WP CLT | Current (year 15, 30, 45) | 46,137 | 73,028 | 1.583 | 0.635 |

| +5 years (year 20, 40) | 38,255 | 61,950 | 1.619 | 0.564 | |

| −5 years (year 10, 20, 30, 40) | 54,020 | 83,992 | 1.555 | 0.737 | |

| RC | Current (year 25) | 8311 | 12,301 | 1.480 | 0.129 |

| +5 years (year 30) | 8311 | 12,300 | 1.480 | 0.123 | |

| −5 years (year 20, 40) | 10,117 | 14,953 | 1.478 | 0.139 |

References

- Ross, R.J. Wood Handbook: Wood as an Engineering Material; U.S. Dept. of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010.

- Intergovernmental Panel on Climate Change (IPCC) Climate Change 2014, Mitigation of Climate Change, Fifth Assessment Report; Cambridge University Press: New York, NY, USA, 2014.

- Food and Agriculture Organization of the United Nations (FAO) FAOSTAT. Available online: http://www.fao.org/faostat/en/#data/QC (accessed on 29 November 2021).

- Forestry Agency Annual Report on Forest and Forestry in Japan (Fiscal Year 2020); Forestry Agency: Tokyo, Japan, 2020.

- Ministry of Land, Infrastructure, Transport and Tourism White Paper on Land, Infrastructure, Transport and Tourism in Japan, 2016; Ministry of Land, Infrastructure, Transport and Tourism: Tokyo, Japan, 2016.

- Ministry of Land, Infrastructure, Transport and Tourism White Paper on Land, Infrastructure, Transport and Tourism in Japan, 2017; Ministry of Land, Infrastructure, Transport and Tourism: Tokyo, Japan, 2017.

- Ministry of Land, Infrastructure, Transport and Tourism White Paper on Land, Infrastructure, Transport and Tourism in Japan, 2018; Ministry of Land, Infrastructure, Transport and Tourism: Tokyo, Japan, 2018.

- Ministry of Land, Infrastructure, Transport and Tourism White Paper on Land, Infrastructure, Transport and Tourism in Japan, 2019; Ministry of Land, Infrastructure, Transport and Tourism: Tokyo, Japan, 2019.

- Ministry of Land, Infrastructure, Transport and Tourism White Paper on Land, Infrastructure, Transport and Tourism in Japan, 2020; Ministry of Land, Infrastructure, Transport and Tourism: Tokyo, Japan, 2020.

- Ministry of Land, Infrastructure, Transport and Tourism Annual Report on Road Maintenance in Japan (Fiscal Year 2020); Ministry of Land, Infrastructure, Transport and Tourism: Tokyo, Japan, 2020.

- Ministry of Internal Affairs and Communications List of Major Financial Indicators for Local Governments in FY2019. Available online: https://www.soumu.go.jp/iken/zaisei/R01_chiho.html (accessed on 19 August 2021).

- Daneshvar, H.; Niederwestberg, J.; Dickof, C.; Chui, Y.H. Structural Behaviour of Deep CLT Lintels Subjected to Concentric and Eccentric Loading. J. Build. Eng. 2021, 43, 103101. [Google Scholar] [CrossRef]

- Sandoli, A.; Calderoni, B. The rolling shear influence on the out-of-plane behavior of CLT panels: A comparative analysis. Buildings 2020, 10, 42. [Google Scholar] [CrossRef] [Green Version]

- Cherry, R.; Manalo, A.; Karunasena, W.; Stringer, G. Out-of-grade sawn pine: A state-of-the-art review on challenges and new opportunities in cross laminated timber (CLT). Constr. Build. Mater. 2019, 211, 858–868. [Google Scholar] [CrossRef]

- Haynes, M.; Coleri, E.; Estaji, M. Selection of the Most Effective Pavement Surfacing Strategy for the Glenwood Cross Laminated Timber Parking Garage. Constr. Build. Mater. 2019, 226, 162–172. [Google Scholar] [CrossRef]

- Pang, S.-J.; Jeong, G.Y. Effects of combinations of lamina grade and thickness, and span-to-depth ratios on bending properties of cross-laminated timber (CLT) floor. Constr. Build. Mater. 2019, 222, 142–151. [Google Scholar] [CrossRef]

- Goremikins, V.; Serdjuks, D.; Buka-Vaivade, K.; Pakrastins, L.; Vatin, N. Prediction of Behaviour of Prestressed Suspension Bridge with Timber Deck Panels. Balt. J. Road Bridge Eng. 2017, 12, 234–240. [Google Scholar] [CrossRef] [Green Version]

- Divekar, N. Introduction to New Material—Cross Laminated Timber. Int. J. Eng. Res. 2016, 5, 675–679. [Google Scholar] [CrossRef]

- Japan Cross Laminated Timber Association List of Domestic CLT Manufacturing Companies (Japan CLT Association Members, JAS Certified Factories). Available online: https://clta.jp/wp-content/uploads/2021/09/Jas-Approved-CLT-Factory20210610.pdf (accessed on 27 December 2021).

- Toyoda, A.; Sasaki, T.; Araki, S.; Ariyama, Y.; Gotou, H. Design and repairing of short span bridge using cross laminated timber slabs. J. Struct. Eng. 2019, 65, 799–806. [Google Scholar] [CrossRef]

- Hassan, O.A.B.; Öberg, F.; Gezelius, E. Cross-laminated timber flooring and concrete slab flooring: A comparative study of structural design, economic and environmental consequences. J. Build. Eng. 2019, 26, 100881. [Google Scholar] [CrossRef]

- Ahmed, S.; Arocho, I. Analysis of cost comparison and effects of change orders during construction: Study of a mass timber and a concrete building project. J. Build. Eng. 2021, 33, 101856. [Google Scholar] [CrossRef]

- Iwase, T.; Sasaki, T.; Araki, S.; Huzita, T.; Kayo, C. Environmental and economic evaluation of small-scale bridge repair using cross-laminated timber floor slabs. Sustainability 2020, 12, 3424. [Google Scholar] [CrossRef] [Green Version]

- Huzita, T.; Noda, R.; Kayo, C. Regional economic impacts from timber check dam construction—A comparison with concrete check dam construction. Forests 2020, 11, 1073. [Google Scholar] [CrossRef]

- Huzita, T.; Kayo, C. Regional economic impacts from timber check dam construction—A comparison with concrete check dam construction, Part II: The question of premium vouchers. Forests 2021, 12, 347. [Google Scholar] [CrossRef]

- Scouse, A.; Kelley, S.S.; Liang, S.; Bergman, R. Regional and net economic impacts of high-rise mass timber construction in Oregon. Sustain. Cities Soc. 2020, 61, 102154. [Google Scholar] [CrossRef]

- Sasaki, T.; Yamauchi, H.; Adachi, K.; Hayashi, T. Water Resistance Evaluation of CLT Treated with Wrapping. In Proceedings of the 34th Annual Meeting of the Japan Wood Protection Association, Tokyo, Japan, 22–24 April 2018. [Google Scholar]

- Akita Prefecture 2015 Akita Prefecture Input-Output Table. Available online: https://www.pref.akita.lg.jp/pages/archive/53289/ (accessed on 20 December 2021).

- Akita Prefecture 1990 Transactions Valued at Producers’ Prices for Akita Prefecture. Available online: https://www.pref.akita.lg.jp/uploads/public/archive_0000000854_00/H2sangyorenkan_1.seisanshakakaku-14.xls (accessed on 10 April 2021).

- Akita Prefecture 1995 Transactions Valued at Producers’ Prices for Akita Prefecture. Available online: https://www.pref.akita.lg.jp/uploads/public/archive_0000000854_00/H7sangyorenkan_1.bumon-14.xls (accessed on 10 April 2021).

- Akita Prefecture 2000 Transactions Valued at Producers’ Prices for Akita Prefecture. Available online: https://www.pref.akita.lg.jp/uploads/public/archive_0000000150_00/050012022200000000001.xls (accessed on 10 April 2021).

- Akita Prefecture 2005 Transactions Valued at Producers’ Prices for Akita Prefecture. Available online: https://www.pref.akita.lg.jp/uploads/public/archive_0000004356_00/torihiki-15.xls (accessed on 10 April 2021).

- Akita Prefecture 2011 Transactions Valued at Producers’ Prices for Akita Prefecture. Available online: https://www.pref.akita.lg.jp/uploads/public/archive_0000031259_00/%E5%8F%96%E5%BC%95%E5%9F%BA%E6%9C%AC%E8%A1%A8%E7%AD%89%EF%BC%88%EF%BC%91%EF%BC%95%E9%83%A8%E9%96%80%E5%88%86%E9%A1%9E%EF%BC%89.xls (accessed on 10 April 2021).

- Akita Prefecture 2015 Transactions Valued at Producers’ Prices for Akita Prefecture. Available online: https://www.pref.akita.lg.jp/uploads/public/archive_0000053289_00/27-1%E5%85%AC%E8%A1%A8%E7%94%A8%E3%83%87%E3%83%BC%E3%82%BF%EF%BC%8815%E9%83%A8%E9%96%80%E5%88%86%E9%A1%9E%EF%BC%89ok.xlsx (accessed on 10 April 2021).

- Terasaki, T. Non-survey method for constructing input-output tables and measuring errors: A case study of production ripple effects using the input-output table of Miyazu City. Kyoto Sangyo Univ. Econ. Rev. 2018, 5, 1–39. [Google Scholar]

- Maruyama, S. Estimation and verification of input coefficient by non-survey approach. Econ. Bus. Rev. 2009, 21, 1–7. [Google Scholar]

- Akita Prefecture 1995 Employees Engaged in Production Activities (by Occupation) for Akita Prefecture. Available online: https://www.pref.akita.lg.jp/uploads/public/archive_0000000854_00/H7sangyorenkan_4.koyo.xls (accessed on 10 April 2021).

- Akita Prefecture 2000 Employees Engaged in Production Activities (by Occupation) for Akita Prefecture. Available online: https://www.pref.akita.lg.jp/uploads/public/archive_0000000150_00/050012022200000000004.xls (accessed on 10 April 2021).

- Akita Prefecture 2005 Employees Engaged in Production Activities (by Occupation) for Akita Prefecture. Available online: https://www.pref.akita.lg.jp/uploads/public/archive_0000004356_00/koyou-15.xls (accessed on 10 April 2021).

- Akita Prefecture 2011 Employees Engaged in Production Activities (by Occupation) for Akita Prefecture. Available online: https://www.pref.akita.lg.jp/uploads/public/archive_0000031259_00/%E9%9B%87%E7%94%A8%E8%A1%A8%E7%AD%89%EF%BC%88%EF%BC%91%EF%BC%95%E9%83%A8%E9%96%80%E5%88%86%E9%A1%9E%EF%BC%89.xls (accessed on 10 April 2021).

- Akita Prefecture 2015 Employees Engaged in Production Activities (by Occupation) for Akita Prefecture. Available online: https://www.pref.akita.lg.jp/uploads/public/archive_0000031259_00/27-1%E5%85.xls (accessed on 10 April 2021).

- Ministry of Internal Affairs and Communications 2015 Input-Output Tables Explanatory Report; Ministry of Internal Affairs and Communications: Tokyo, Japan, 2020; pp. 147–358.

- Ministry of Internal Affairs and Communications Input-Output Tables for Japan 2015. Available online: https://www.e-stat.go.jp/en/stat-search/files?page=1&layout=datalist&toukei=00200603&tstat=000001130583 (accessed on 10 April 2021).

- Ministry of Health, Labour and Welfare Annual Health, Labour and Welfare Report 2020; Ministry of Health, Labour and Welfare: Tokyo, Japan, 2020; pp. 65–70.

| Net Benefit | Net Loss | ||

|---|---|---|---|

| Sector | JPY | Sector | JPY |

| Plywood, glued laminated timber | 2,727,449 | Commerce | −151,533 |

| Road transport (except self-transport) | 124,318 | Final chemical products (except medicaments) | −6607 |

| Logs | 117,093 | Special forest products | −2 |

| Activities not elsewhere classified | 78,253 | Synthetic resins | −1 |

| Waste management service | 72,241 | - | - |

| Net Benefit | Net Loss | ||

|---|---|---|---|

| Sector | JPY | Sector | JPY |

| Plywood, glued laminated timber | 3,697,592 | Cement and cement products | −61,196 |

| Commerce | 603,302 | Miscellaneous mining industry | −247 |

| Logs | 237,321 | Miscellaneous ceramic, stone, and clay products | −61 |

| Road transport (except self-transport) | 195,773 | Miscellaneous iron or steel products | −2 |

| Activities not elsewhere classified | 117,030 | - | - |

| Maintenance Period | Direct Effect (JPY) (A) | Total Effect (JPY) (B) | Economic Impact Rate (B/A) | Employment Effect (People) | |

|---|---|---|---|---|---|

| NWP CLT | Current (year 15, 30, 45) | 6,963,037 | 13,816,130 | 1.984 | 0.686 |

| +5 years (year 20, 40) | 5,302,043 | 10,507,375 | 1.982 | 0.554 | |

| −5 years (year 10, 20, 30, 40) | 8,624,031 | 17,300,543 | 2.006 | 0.886 | |

| WP CLT | Current (year 15, 30, 45) | 5,997,863 | 9,493,620 | 1.583 | 0.635 |

| +5 years (year 20, 40) | 4,973,103 | 8,053,529 | 1.619 | 0.564 | |

| −5 years (year 10, 20, 30, 40) | 7,022,622 | 10,918,999 | 1.555 | 0.737 | |

| RC | Current (year 25) | 1,080,400 | 1,599,126 | 1.480 | 0.129 |

| +5 years (year 30) | 1,080,400 | 1,599,046 | 1.480 | 0.123 | |

| −5 years (year 20, 40) | 1,315,150 | 1,943,886 | 1.478 | 0.139 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huzita, T.; Sasaki, T.; Araki, S.; Kayo, C. Life Cycle Regional Economic Impacts of Bridge Repair Using Cross-Laminated Timber Floor Slabs: A Case Study in Akita Prefecture, Japan. Buildings 2022, 12, 158. https://doi.org/10.3390/buildings12020158

Huzita T, Sasaki T, Araki S, Kayo C. Life Cycle Regional Economic Impacts of Bridge Repair Using Cross-Laminated Timber Floor Slabs: A Case Study in Akita Prefecture, Japan. Buildings. 2022; 12(2):158. https://doi.org/10.3390/buildings12020158

Chicago/Turabian StyleHuzita, Tomohumi, Takanobu Sasaki, Shogo Araki, and Chihiro Kayo. 2022. "Life Cycle Regional Economic Impacts of Bridge Repair Using Cross-Laminated Timber Floor Slabs: A Case Study in Akita Prefecture, Japan" Buildings 12, no. 2: 158. https://doi.org/10.3390/buildings12020158