Renovation of Modernist Architecture Study Based on Selected Cases

Abstract

:1. Introduction

2. Materials and Methods

- architectural:

- ○

- preservation of the modernist character of a building,

- ○

- importance of a building to culture,

- ○

- functionality,

- ○

- aesthetics,

- ○

- high quality;

- sustainable:

- ○

- reducing energy use,

- ○

- affordable,

- ○

- and material availability (local products).

- ○

- A housing block section by Nankiera Square [18], original design (1969): Włodzimierz Czerechowski, Ryszard Natusiewicz, Anna and Jerzy Tarnawski; renovation design (2015): Agnieszka Hałas, Grzegorz Kaczmarowski, Marta Mnich, and Łukasz Wojciechowski.

- ○

- The complex of the residential towers with the commercial pavilion at Grunwaldzki Square [19,20], original design: Jadwiga Grabowska-Hawrylak, Krzysztof Sasiadek (1968–1978), renovation design (2012): Mnich, Marek Lamber, Natalia Rowińska, Łukasz Wojciechowski, Agnieszka Hałas, Hubert Rozewicz, consultants: Jadwiga Grabowska-Hawrylak, Andreas Wolf.

- ○

- The restaurant pavilion by the Centennial Hall (UNESCO heritage object) [21], original design (1913): Max Berg; renovation and extension design: Agnieszka Chrzanowska, Marta Mnich, Łukasz Wojciechowski, Wojtek Chrzanowski, in collaboration with Andrzej Chrzanowski, Juliusz Erdman, Grzegorz Kaczmarowski, Danuta Katarasińska, Agata Kurto, Natalia Rowińska, Sebastian Stanisławski.

- ○

- location,

- ○

- authors of original project and refurbishment,

- ○

- history,

- ○

- renovation assumptions,

- ○

- remodeling solutions,

- ○

- calculations of energy savings.

- W—unit: Watt;

- m—unit: meter;

- K—unit: Kelvin;

- U—thermal transmittance ;

- —total thermal resistance ;

- —is the internal surface resistance ;

- —are the design thermal resistance of each layer ;

- —is a total number of the designed layers;

- —is the external surface resistance ;

- d—thickness of the layer ;

- —the design thermal conductivity of material [W/mK];

3. Results

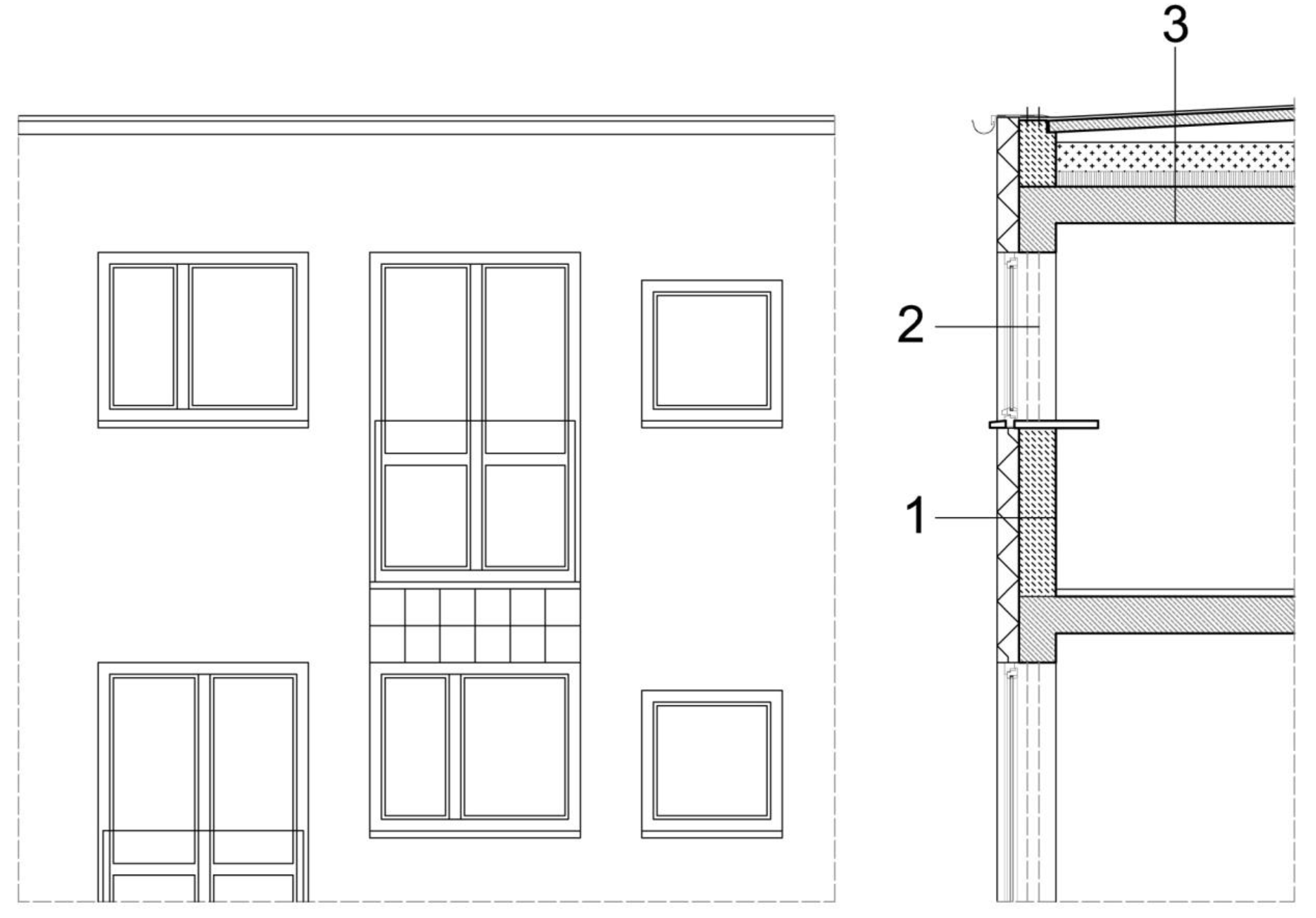

3.1. The Block-of-Flats by Nankiera Square-Completed

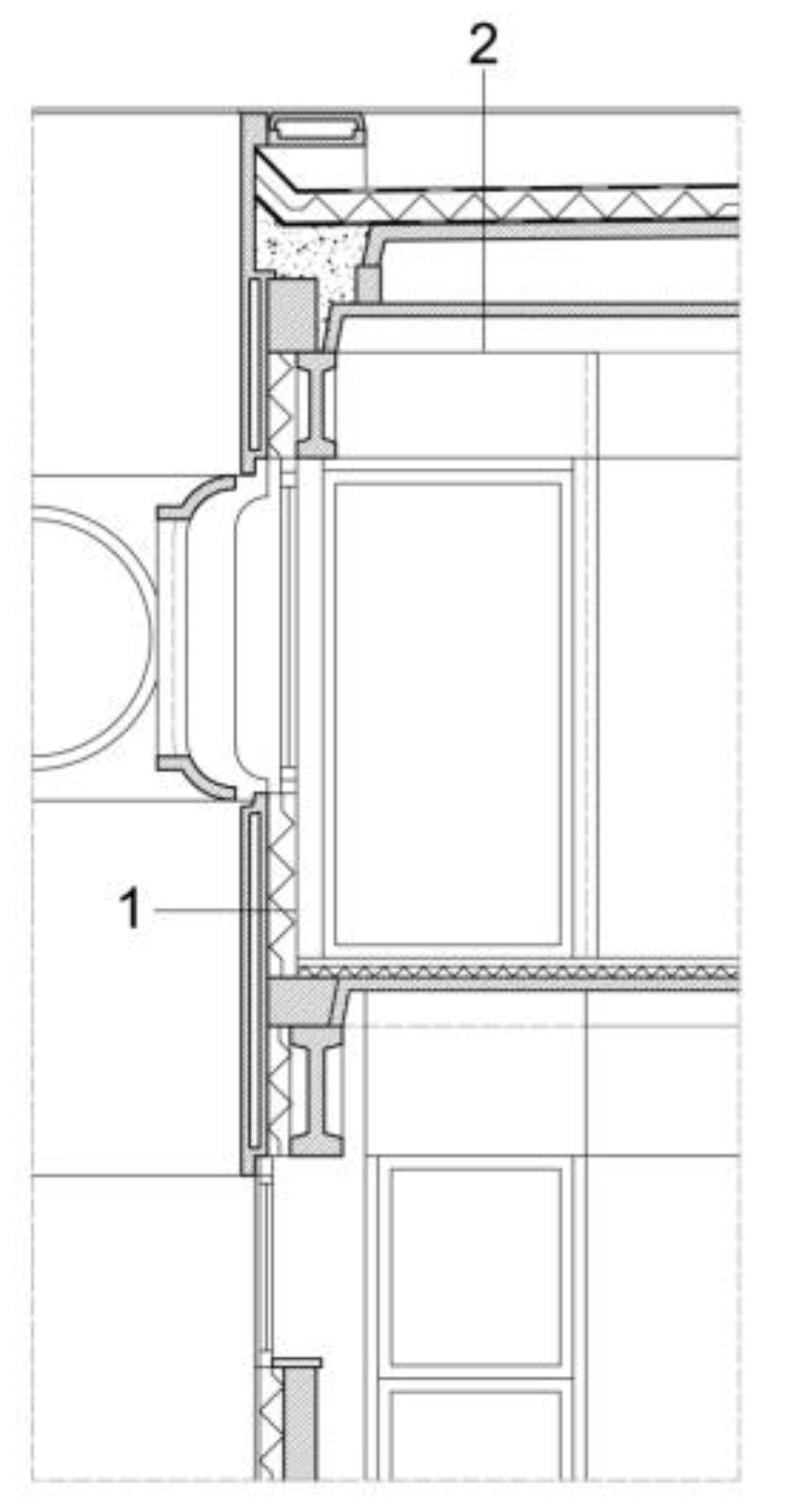

3.2. The Façades of Residential Buildings at Grunwaldzki Square–Project, Completed

3.3. The Commercial Pavillon by Grunwaldzki Square–Project, Not Completed

3.4. Renovation and Extension of the Restaurant Pavilion in the Centennial Hall Complex–Completed

- decorative structural pillars,

- a central lobby with oval skylight,

- a horizontally composed facade across the Centennial Hall.

4. Discussion

- external walls—61.53%

- roof—88.2%.

- Bilka [23] conducted the external energy audit for the initial and design phases. It concerned modification of possible building compartments, ventilation, change of form of heating, etc. The Author [23] analyzed different variants and selected the best one for the investor and the design studio. Based on this document, the shape factor A/V was (and is) 0.47. Improvements of mentioned parameters influenced calculated thermal power of the heating system, which initially was 46.66 [kW], and after designed refurbishment achieves 17.52 [kW]. The annual heat demand index to heat the building (without taking into account the efficient heating system and heating interruptions) was 224.54 [kWh/(m2 year)] and is 74.57 [kWh/(m2 year)], [23]. The Author shows other savings from decreasing heat transfer coefficients for windows—avg. 37%, doors and gates—34.6%, the slab over a passage—91.6%. We expect these parameters once all the construction works are finished according to the recommendations. Data from our calculations and external audits show substantial improvement in building energy performance. At the same time, due to the preservation of the initial structure and adding heat isolation and new coatings, the cost is low. The heat transfer coefficients, through construction partitions, were reduced by a range of 34.6% to 91.6% (dependent on the element).

- The calculated thermal power of the heating system was reduced by a range of 26.6–62.4% (dependent on the case study).

- The annual heat demand index to heat the building (without taking into account the efficient heating system and heating interruptions) reduced by a range of 33.4–66.8% (dependent on the case study).

- external walls—46.15%;

- roof—88.2%.

- external walls—63.78%;

- roof—20%.

- external walls—73.91%;

- Roof was re-designed.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Urbanik, J.; Tomaszewicz, A. Flat Roof—Advantage or Disadvantage of Modern Movement Buildings. In Proceedings of the SAHC2014—9th International Conference on Structural Analysis of Historical Constructions, Mexico City, Mexico, 14–17 October 2014; Peña, F., Chávez, M., Eds.; 2014. Available online: https://www.researchgate.net/publication/343294962_Flat_Roof_-_Advantage_or_Disadvantage_of_Modern_Movement_Buildings (accessed on 8 September 2021).

- Mulfarth, R.C.K.; Gonçalves, J.C.S.; Michalski, R.L.X.N.; Shimomura, A.R.P.; e Souza, B.N.; Cunha, G.R.M.; Marcondes-Cavaleri, M.P.; Monroy, M.A.G. The environmental response of office buildings from the Brazilian bioclimatic modernism in São Paulo: The case study of Complexo Conjunto Nacional—CCN (1962). Sol. Energy 2021, 220, 617–634. [Google Scholar] [CrossRef]

- Kahraman, A.D. Relationship of modernism, postmodernism and reflections of it on education. Procedia Soc. Behav. Sci. 2015, 174, 3991–3996. [Google Scholar] [CrossRef] [Green Version]

- Springer, F. Źle Urodzone (in English Language: Badly Borne); Karakter: Cracov, Poland, 2017. [Google Scholar]

- Gabiś, A. Całe Morze Budowania. Wrocławska architektura 1956–1970 (in English Language: The Whole Sea of Buiding. The Architecture of Wroclaw 1956–1970); Museum of Architecture in Wroclaw: Wroclaw, Poland, 2018. [Google Scholar]

- Elser, O.; Kurz, P.; Schmal, P. SOS Brutalism. A Global Survey; Park Books: Zürich, Switzerland, 2018. [Google Scholar]

- Giuliani, M.V.; Bucchignani, V. Preservation through change: Renovating modern architecture. J. Archit. Plan. Res. 2000, 17, 34–46. [Google Scholar]

- Mika, P. The nature of the technology in which the basic executive component is the precasted element. In Proceedings of the 4th International Multidisciplinary Scientific Conference on Social Sciences and Arts SGEM 2017, Albena, Bulgaria, 24–30 August 2017; Volume 17, pp. 823–830. [Google Scholar] [CrossRef]

- Pikas, E.; Seppänen, O.; Koskela, L.; Peltokorpi, A. Challenges in Industrialized Renovation of Apartment Buildings. In Proceedings of the 29th Annual Conference of the International Group for Lean Construction (IGLC29), Lima, Peru, 14–17 July 2021; Alarcon, L.F., González, V.A., Eds.; pp. 985–994. [Google Scholar] [CrossRef]

- European Commission. A European Green Deal. 2021. Available online: https://ec.europa.eu/info/strategy/priorities-2019-2024/european-green-deal_en (accessed on 8 September 2021).

- European Comission. Renovation Wave. 2021. Available online: https://ec.europa.eu/energy/topics/energy-efficiency/energy-efficient-buildings/renovation-wave_en (accessed on 8 September 2021).

- European Commission. New European Bauhaus: Commission Launches Design Phase. 2021. Available online: https://ec.europa.eu/commission/presscorner/detail/en/IP_21_111 (accessed on 8 September 2021).

- Sonnleithner, M. New Opportunities for Increasing the Renovation Rate of Buildings. Archit. Pap. Fac. Archit. Des. STU 2021, 26, 2–9. [Google Scholar] [CrossRef]

- Peters, T. Architectural Interventions For Social Sustainability: The Renovation Of Modern Housing. In Proceedings of the Regenerative and Resilient Urban Environment, Sustainable Built Environment, Toronto, ON, Canada, 19–20 September 2016; Available online: https://www.researchgate.net/publication/308702873_Architectural_Interventions_For_Social_Sustainability_The_Renovation_Of_Modern_Housing (accessed on 21 September 2021).

- Boza-Kiss, B.; Bertoldi, P.; Nives, D.V.; Economidou, M. One-stop shops for residential building energy renovation in the EU. In Analysis & Policy Recommendations; JRC Science for Policy Report [JRC125380]; Publications Office of the European Union: Luxembourg, 2021. [Google Scholar] [CrossRef]

- Sugár, V.; Talamon, A.; Horkai, A.; Kita, M. Energy saving retrofit in a heritage district: The case of the Budapest. J. Build. Eng. 2020, 27, 100982. [Google Scholar] [CrossRef]

- Nowogońska, B.; Mielczarek, M. Renovation Management Method in Neglected Buildings. Sustainability 2021, 13, 929. [Google Scholar] [CrossRef]

- Mnich, M.; Hałas, A.; Kaczmarowski, G.; Wojciechowski, Ł.; (Wrocław, Poland). Renovation and Reconstruction of a Residential and Service Building Nankiera 14, Wrocław. Personal communication, 2015. [Google Scholar]

- Mnich, M.; Wojciechowski, Ł.; Hałas, A.; Rowińska, N.; Wolf, A.; (Wrocław, Poland). The Concept of Revalorization of a Residential and Service Complex Plac Grunwaldzki, Wrocław. Personal communication, 2012. [Google Scholar]

- Mnich, M.; Wojciechowski, Ł.; Różycki, H.; (Wrocław, Poland). Renovation and Reconstruction of the Office and Commercial Building with the Conversion of the Basement into an Office and Training Function and Land Development Plac Grunwaldzki, Wrocław. Personal communication, 2020. [Google Scholar]

- Mnich, M.; Wojciechowski, Ł.; Chrzanowska, A.; Chrzanowski, W.; Chrzanowski, A.; (Wrocław, Poland). Establishment of the Regional Center for Business Tourism, ul. Wystawowa 1, Wrocław. Personal communication, 2008. [Google Scholar]

- Climate-data.org. Climate Wrocław (Poland). 2021. Available online: https://en.climate-data.org/europe/poland/lower-silesian-voivodeship/wroc%C5%82aw-4531/ (accessed on 21 September 2021).

- Bilka, P.; (Wrocław, Poland). Pracownia Projektowa (transl. from Polish Language: The Design Studio) BILAN Paweł Bilka: The Energy Audit for Nankiera 14 Building in Wroclaw. Personal communication, 2015. [Google Scholar]

- Żurawski, J.; (Wrocław, Poland). The Energy Audit for Thermal Modernization Enterprise for Implementation at the Basis of Act at 11 November 2008. Personal communication, 2012. [Google Scholar]

- Ordinance Minister of Infrastructure of April 12, 2002 on the Technical Conditions to Be Met by Buildings and Their Location, Journal of Laws 2019.1065, i.e of 2019.06.07, Based on Article. 7 sec. 2 point 1 of the Act of July 7, 1994—Construction Law (Journal of Laws of 2018, item 1202, as Amended); Valid at the Date of the Project. Available online: https://www.gov.pl/web/infrastruktura/warunki-techniczne2 (accessed on 14 October 2021).

- PN-EN ISO 6946:2017 Building Components and Building Elements—Thermal Resistance and Thermal Transmittance—Calculation Methods, European Standard, Available by: Polish Normalisation Committee (Polski Komitet Normalizacyjny). Available online: https://sklep.pkn.pl/pn-en-iso-6946-2017-10e.html (accessed on 15 January 2022).

- Lylykangas, K. Shape Factor as an Indicator of Heating Energy Demand, 15. Internationales Holzbau-Forum 09. 2009. Available online: https://www.forum-holzbau.com/pdf/ihf09_Lylykangas.pdf (accessed on 10 November 2021).

- Wolf, A. Post-war Modernism 2.0 von VROA-Architekten Wrocław. I. Sonntag (Hr. sgb); Sächsische Akademie der Künste: Dresden, Germany, 2014; pp. 202–207. [Google Scholar]

- Duda, M. Patchwork. Architektura Jadwigi Grabowskiej-Hawrylak (Patchwork, The Architecture of Jadwiga Grabowska-Hawrylak); Museum of Architecture in Wroclaw: Wrocław, Poland, 2016. [Google Scholar]

| No | Name of the Layer | The Thickness of the Layer [cm] | The Design Thermal Conductivity of a Material | |

|---|---|---|---|---|

| The existing external wall (before the mal modernisation) | ||||

| 1 | The external plaster | 2.0 | 0.82 | 0.39 |

| 2 | The existing brick ‘zeranska’/aerated concrete blocks (porous concrete blocks possible) | 24.0 | 0.105 | |

| 3 | The internal plaster | 1.5 | 0.70 | |

| The designed external wall | ||||

| 1 | The silicone plaster | 1.5 | 0.7 | 0.15 |

| 2 | The EPS polystyrene | 15.0 | 0.038 | |

| 3 | The aerated concrete blocks | 24.0 | 0.105 | |

| 4 | The internal plaster | 1.5 | 0.7 | |

| 5 | The silicone plaster | 1.5 | 0.7 | |

| The existing roof slab | ||||

| 1 | 2× roofing felt (bituminous felt and tar paper) | - | - | 0.34 |

| 2 | The levelling layer | 2.0 | 1.4 | |

| 4 | The slag concrete slabs in decline | 8.0 | 1.70 | |

| 5 | The ventilation gap | 5.0–30.0 | 0.16 1 | |

| 6 | The prefabricated channel slabs | 24.0 | 0.18 | |

| 7 | The internal plaster | 1.5 | 1.70 | |

| The designed roof slab | ||||

| 1 | 2× roofing felt (bituminous felt and tar paper) | - | - | 0.04 |

| 2 | The levelling layer | 2.0 | 1.4 | |

| 4 | The slag concrete slabs in decline (existing) | 8.0 | 1.70 | |

| 5 | The ventilation gap (existing) | 10.0 | 0.15 | |

| 6 | The mineral wool granules injected into the ventilation gap | 20.0 | 0.038 | |

| 7 | The prefabricated channel slabs (existing) | 24.0 | 0.18 | |

| 8 | The internal plaster | 1.5 | 1.70 | |

| No | Name of the Layer | The Thickness of the Layer [cm] | The Design Thermal Conductivity of a Material | |

|---|---|---|---|---|

| The existing external wall (between windows) | ||||

| 1 | The clinker tile | 2.0 | 0.67 | 0.39 |

| 2 | The ventilation gap | 2.0 | 0.00 | |

| 3 | The aerated concrete blocks | 24.0 | 0.105 | |

| 4 | The internal plaster | 1.5 | 0.7 | |

| The designed external wall (between windows) | ||||

| 0.21 | ||||

| 1 | The silicone plaster | 1.5 | 0.7 | |

| 2 | The mineral wool | 8.0 | 0.035 | |

| 3 | The aerated concrete blocks | 24.0 | 0.105 | |

| 4 | The internal plaster | 1.5 | 0.7 | |

| The existing roof slab | ||||

| 1 | 2× roofing felt (bituminous felt and tar paper) | - | - | 0.34 |

| 2 | The levelling layer | 2.0 | 1.4 | |

| 3 | The slag concrete slabs in decline | 8.0 | 1.70 | |

| 4 | The ventilation gap | 5.0–30.0 | 0.16 | |

| 5 | The prefabricated channel slabs | 24.0 | 0.18 | |

| 6 | The internal plaster | 1.5 | 1.7 | |

| The designed roof slab | ||||

| 1 | 2× roofing felt (bituminous felt and tar paper) | - | - | 0.04 |

| 2 | The levelling layer | 2.0 | 1.4 | |

| 3 | The slag concrete slabs in decline | 8.0 | 1.70 | |

| 4 | The ventilation gap | 10 | 0.15 | |

| 5 | The mineral wool granules injected into the ventilation gap | 20.0 | 0.038 | |

| 6 | The prefabricated channel slabs | 24.0 | 0.18 | |

| 7 | The internal plaster | 1.5 | 1.70 | |

| No | Name of the Layer | The Thickness of the Layer [cm] | The Design Thermal Conductivity of a Material | |

|---|---|---|---|---|

| The existing prefabricated walls | ||||

| 1 | The reinforced concrete prefabricates with an internal void of 5.0 cm | 15.0 (5 + 5 + 5) | 1.7 + 0.11 + 1.7 | 1.38 |

| The designed walls (decorative) | ||||

| 1 | The reinforced concrete prefabricates with an internal void of 5.0 cm–cleaning, fulfilling subsidence | 15.0 | 1.7 + 0.11 + 1.7 | 0.5 |

| 2 | The internal isolation of Multipor type boards | 5.0 | 0.040 | |

| 3 | The Heradesign type boards in natural color on a wooden grid | 2.5 | - | |

| The existing roof slab | ||||

| 1 | 3× jute felt paper (waterproof insulation) | - | - | 0.045 |

| 2 | The cement screed | 1.0 | 1.4 | |

| 3 | The sloped roof panels (channelled, reinforced concrete) | 25.0 | 0.18 | |

| 4 | The ventilation gap | 5.0–30.0 | 0.16 | |

| 5 | The slag wool | 6.0 | 0.045 | |

| 6 | The structural ceiling (reinforced concrete beams and trough slabs, reinforced concrete) | 30.0 | 1.7 | |

| The designed roof slab | ||||

| 1 | The EPDM film | - | - | |

| 2 | The Styrodur | 20.0 | 0.035 | |

| 3 | The vapor-permeable foil | - | - | |

| 4 | The cement screed | 1.0 | 1.4 | |

| 5 | The sloped roof panels (channelled, reinforced concrete) | 25.0 | 0.18 | 0.036 |

| 6 | The ventilation gap | 5.0–30.0 | ||

| 7 | The slag wool | 6.0 | 0.045 | |

| 8 | The structural ceiling (reinforced concrete beams and trough slabs, reinforced concrete) | 30.0 | 1.7 | |

| No | Name of the Layer | The Thickness of the Layer [cm] | The Design Thermal Conductivity of a Material | |

|---|---|---|---|---|

| The existing external wall | ||||

| 1 | The external plaster | 2.0 | 1.70 | |

| 2 | The full brick wall | 32.0 | 0.77 | 1.38 |

| 3 | The internal plaster | 1.5 | 1.70 | |

| The designed external wall | ||||

| 1 | The thin-layer plaster | 0.3 | 1.70 | |

| 2 | The external cement-lime plaster | 2.0 | 1.70 | |

| 3 | The masonry brick wall | 32.0 | 0.77 | |

| 4 | The dimpled foil | - | - | 0.36 |

| 5 | The ventilation gap | 2.0 | - | |

| 6 | The mineral wool | 8.0 | 0.038 | |

| 7 | The vapour barrier foil | - | - | |

| The existing roof slab | ||||

| 1 | The existing wooden structure–for dismantling | - | - | - |

| The designed roof slab | ||||

| 1 | The SBS modified tar paper | - | - | 0.04 |

| 2 | The underlay felt paper | - | - | |

| 3 | The hardboard of mineral wool–for inclination | 5.0–20.0 (avg. 12.5) | 0.038 | |

| 4 | The hardboard of mineral wool | 18.0 | 0.038 | |

| 5 | The vapor barrier | - | - | |

| 6 | The trapezoidal sheet T55x18 0.75cm | - | - | |

| 7 | The steel structure | 30.0 | - | |

| 8 | The fittings gap | 112 | - | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jablonska, J.; Wojciechowski, L. Renovation of Modernist Architecture Study Based on Selected Cases. Buildings 2022, 12, 195. https://doi.org/10.3390/buildings12020195

Jablonska J, Wojciechowski L. Renovation of Modernist Architecture Study Based on Selected Cases. Buildings. 2022; 12(2):195. https://doi.org/10.3390/buildings12020195

Chicago/Turabian StyleJablonska, Joanna, and Lukasz Wojciechowski. 2022. "Renovation of Modernist Architecture Study Based on Selected Cases" Buildings 12, no. 2: 195. https://doi.org/10.3390/buildings12020195

APA StyleJablonska, J., & Wojciechowski, L. (2022). Renovation of Modernist Architecture Study Based on Selected Cases. Buildings, 12(2), 195. https://doi.org/10.3390/buildings12020195