Fiber-Type Influence on the Flexural Behavior of RC Two-Way Slabs with an Opening

Abstract

:1. Introduction

2. Materials and Experimental Work

2.1. Materials

2.1.1. Cement

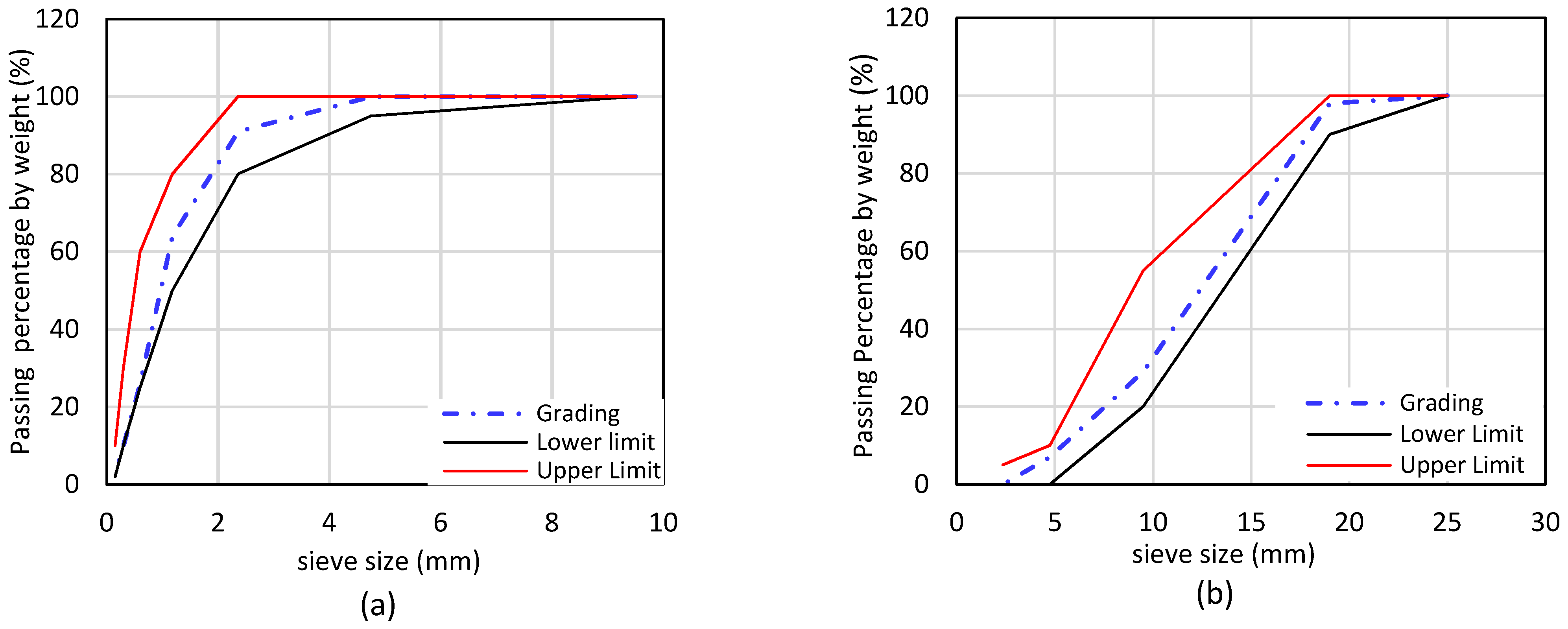

2.1.2. Aggregate

2.1.3. Fibers

2.1.4. Mix Proportion

2.2. Sample Preparation

2.2.1. Mechanical Properties

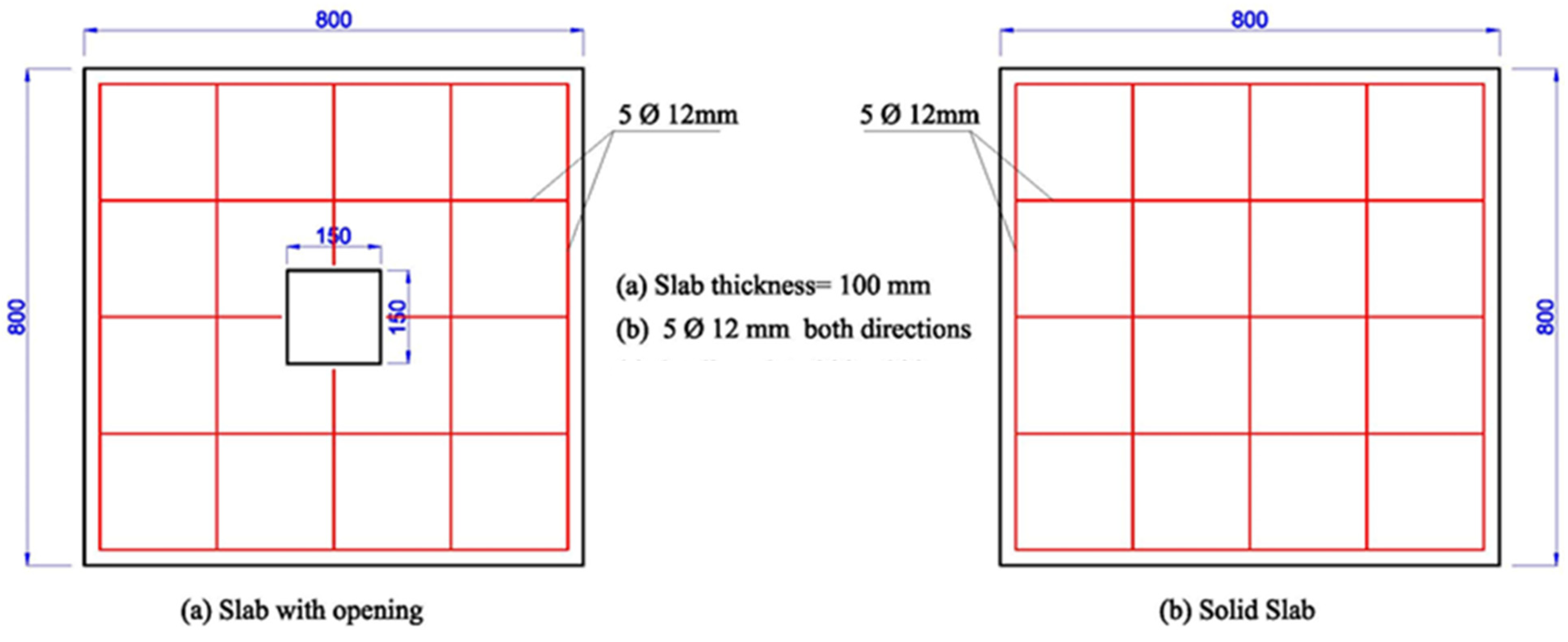

2.2.2. Two-Way Slab Details

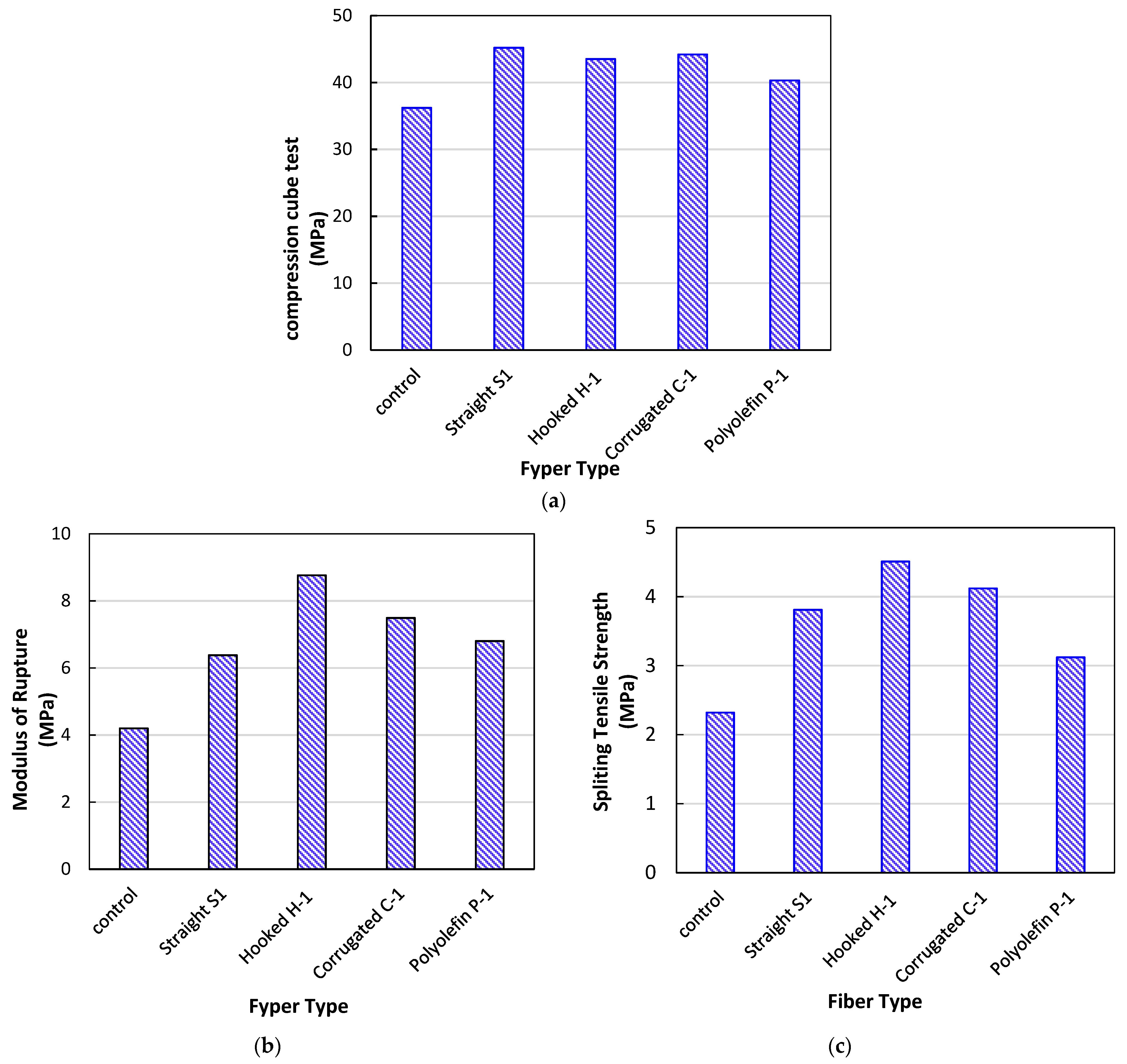

3. Mechanical Properties Results

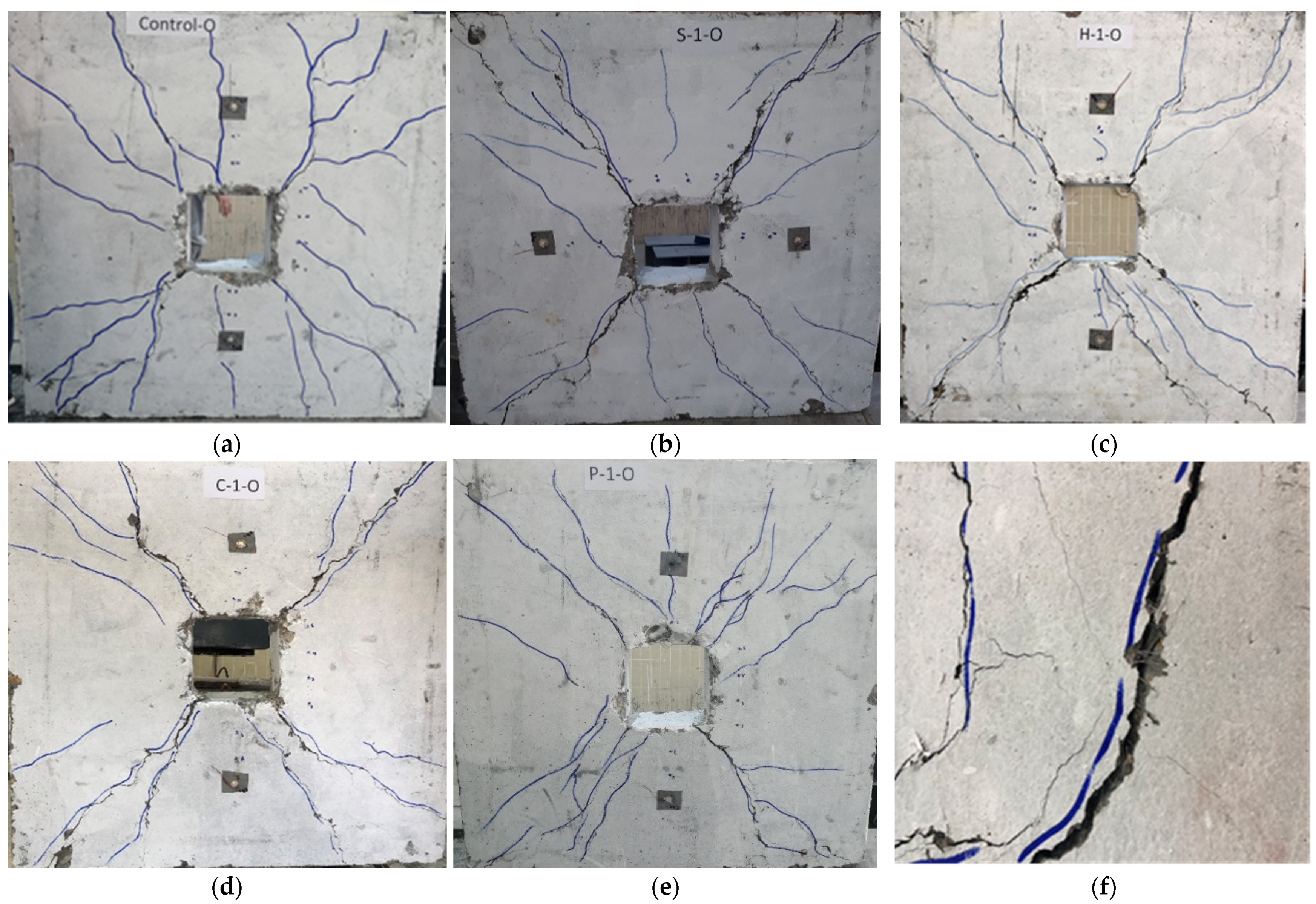

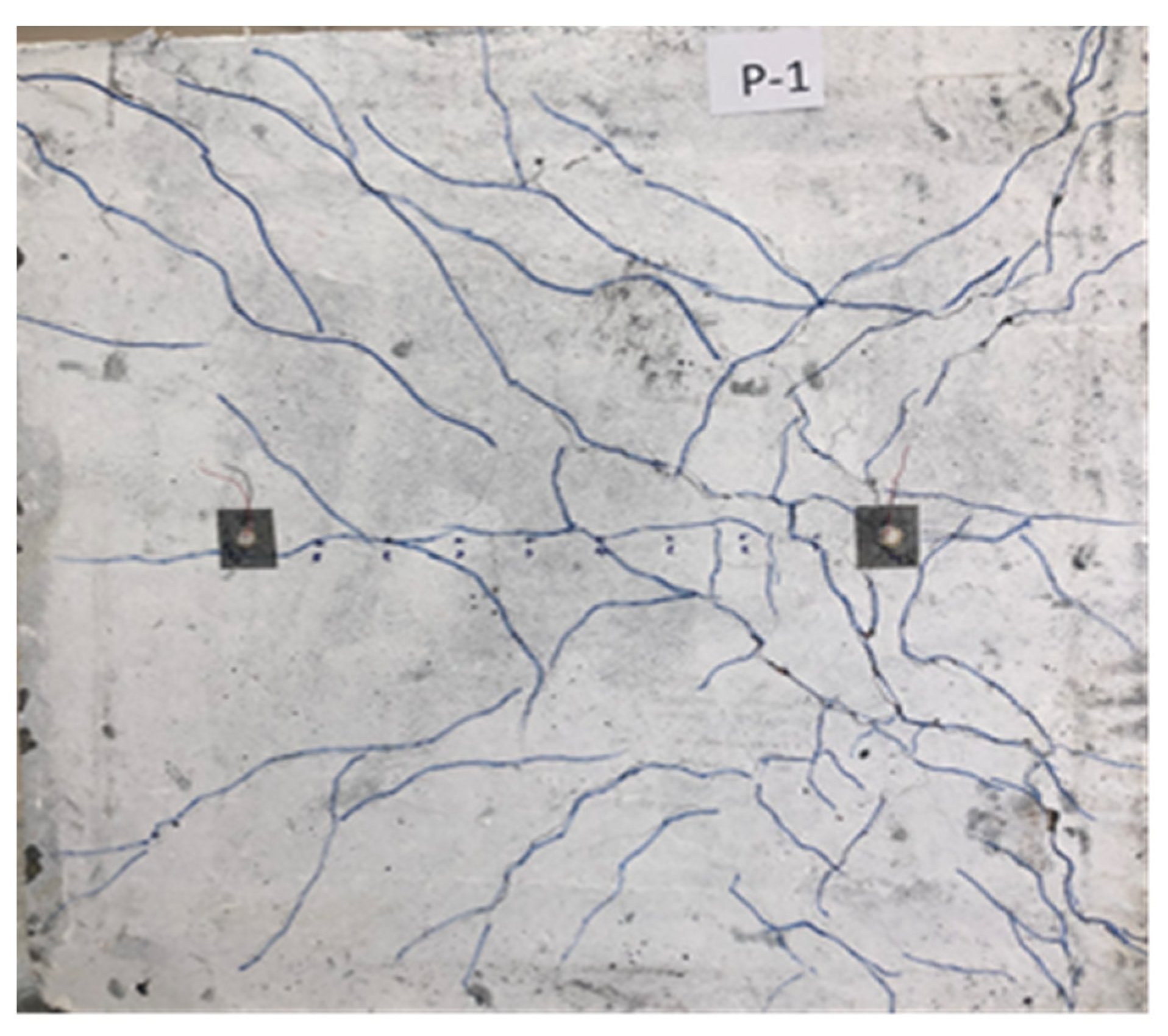

4. Failure Modes and Crack Patterns

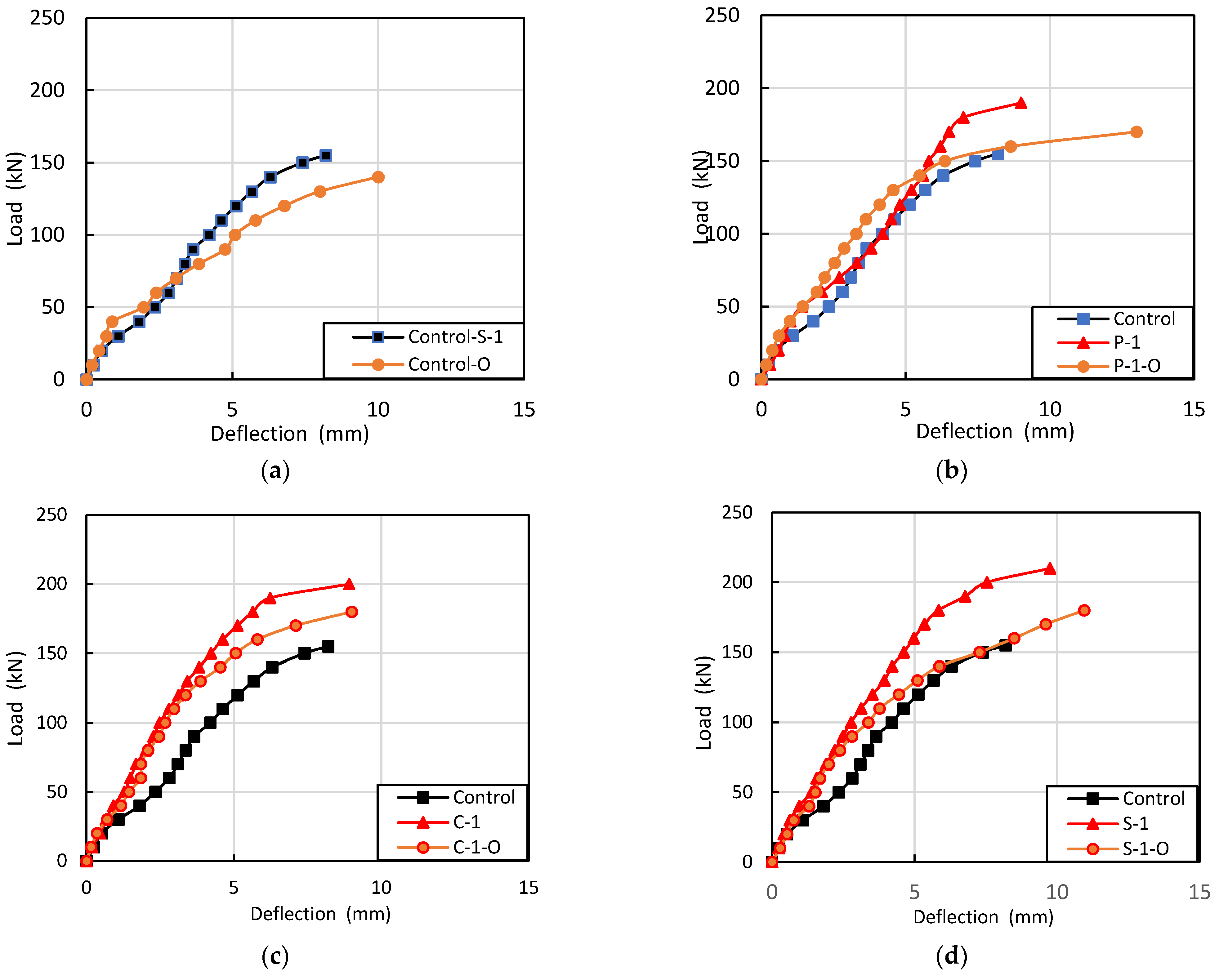

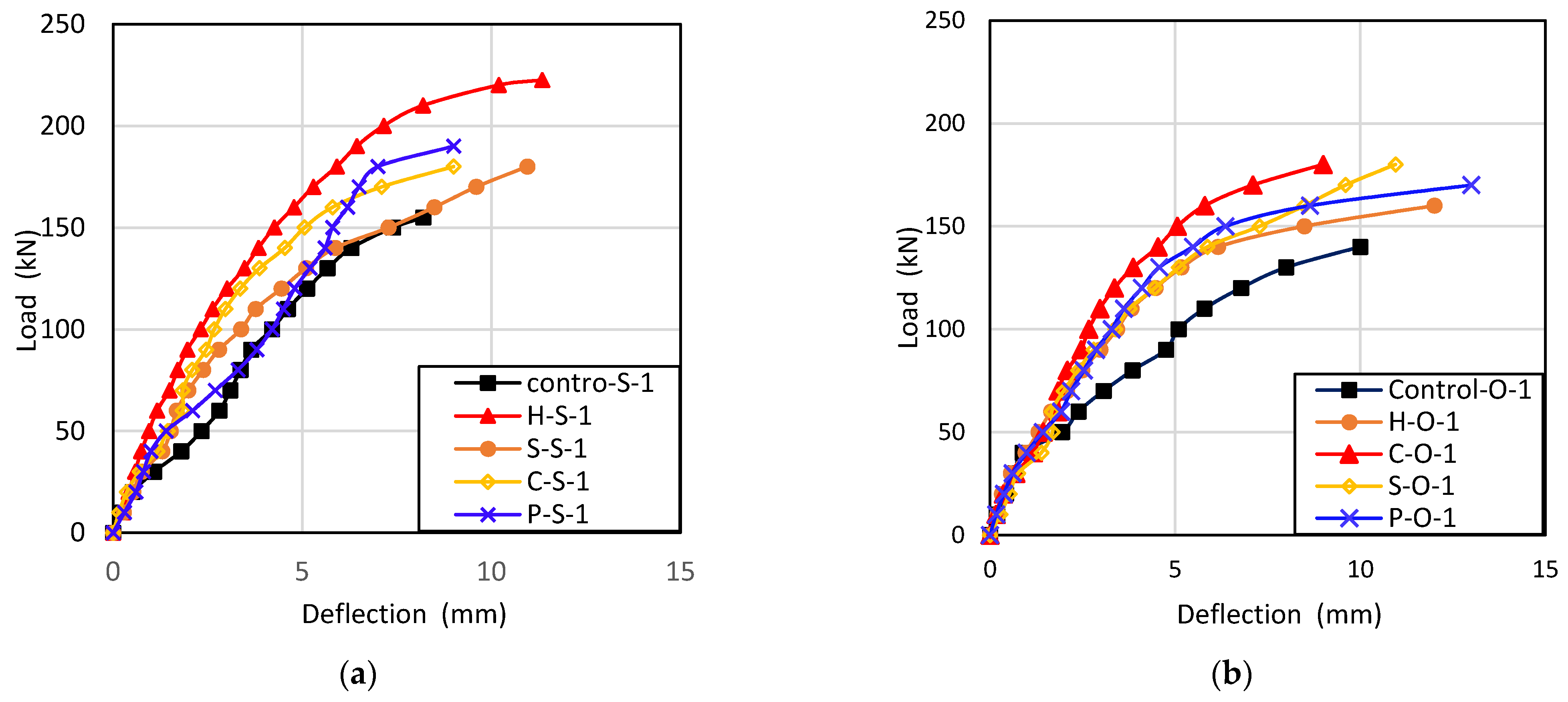

5. Load-Deflection Results

6. Conclusions

- The compressive strength of concrete modified with fibers showed that the specimen with steel fibers had improved compressive strength. The corrugated and hooked steel fibers showed higher improvement compared with other type of fibers. Polyolefin fiber slightly increased the compressive strength compared with control specimens. The addition of fiber had a slight improving effect on the compressive strength, varying between 11.3% to 24.8%.

- Splitting tensile strength test results suggest good enhancement for all specimens using different types of fiber in concrete mixes. Hooked and corrugated steel fiber showed the highest improvements (94% and 77%) compared with a control plain specimen. Polyolefin fiber showed less improvement than steel fiber.

- The hooked steel fiber gave the best performance of the fiber types in improving modulus of rupture, where the increase ratio was 109% compared with the control specimen, whereas the polyolefin fiber enhancement was around 62%. Generally, the improvement was superior in modulus of rupture.

- The effect of fiber shape with a constant dosage of steel fibers on the flexural behavior and tested mechanical properties shows that hook steel fiber produced the higher improvement.

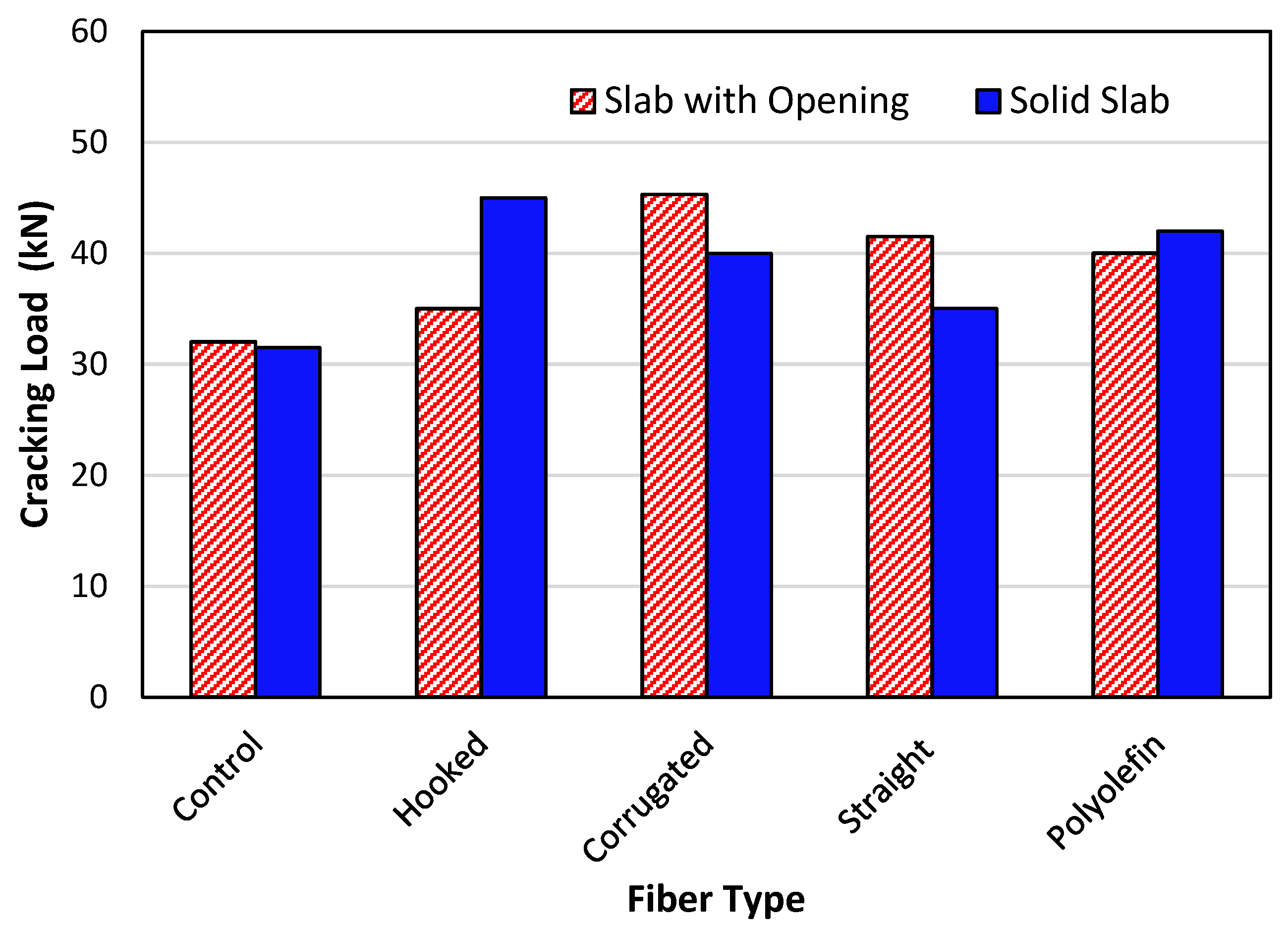

- It was concluded that the cracking load increased for all sample with fibers and the highest improvement occurred for combined reinforced concrete with hooked fiber (43%) for a solid slab compared with a reference slab. A moderate increment in cracking load was obtained by using polyolefin fiber (19%). It was noticed that the flexural behavior of two-way slabs with fibers appeared more ductile. Slabs with openings presented good improvements in cracking and ultimate load while developing larger deflections than the solid slabs.

- All the specimens failed in flexural mode due to the interaction of fibers with concrete and this combination reduced the weakness of flexural behavior, especially in slabs with an opening. Moreover, the enhancement in flexural behavior was good compared with control specimens due to improved ductility and delays in the progress of cracks.

- Generally, fibers increase the bond more efficiently between concrete matrix by friction and mechanical interaction, so it is preferable to use hooked or corrugated steel fibers for flexural improvement.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Marcos, G.; Alberti, A.E.; Jaime, C.G. Polyolefin Fibres for the Reinforcement of Concrete. In Alkenes; Book Chapter 6; InTech Open: London, UK, 2017. [Google Scholar] [CrossRef] [Green Version]

- Fall, D.; Shu, J.; Rempling, R.; Lundgren, K.; Zandi, K. Two-way slabs: Experimental investigation of load redistributions in steel fibre reinforced concrete. Eng. Struct. 2014, 80, 61–74. [Google Scholar] [CrossRef] [Green Version]

- Grzesiak, S.; Pahn, M.; Schultz-Cornelius, M.; Harenberg, S.; Hahn, C. Influence of Fiber Addition on the Properties of High-Performance Concrete. Materials 2021, 14, 3736. [Google Scholar] [CrossRef] [PubMed]

- Altun, F.; Haktanir, T.; Ari, K. Experimental investigation of steel fiber reinforced concrete box beams under bending. Mater. Struct. 2006, 47, 491–499. [Google Scholar] [CrossRef]

- Yang, D.; Zhang, B.; Liu, G. Experimental Study on Spall Resistance of Steel-Fiber Reinforced Concrete Slab Subjected to Explosion. Int. J. Concr. Struct. Mater. 2021, 15, 23. [Google Scholar] [CrossRef]

- Concrete Society. Concrete Industrial Ground Floors: A Guide to Their Design and Construction, Technical Report No.34, 3rd ed.; The Concrete Society: London, UK, 2003. [Google Scholar]

- Kosa, K.; Naaman, A.E. Corrosion of steel fiber reinforced concrete. Mater. J. 1990, 87, 27–37. [Google Scholar]

- Yin, S.; Tuladhar, R.; Shanks, R.A.; Collister, T.; Combe, M.; Jacob, M.; Tian, M.; Sivakugan, N. Fiber preparation and mechanical properties of recycled polypropylene for reinforcing concrete. J. Appl. Polym. Sci. 2015, 132, 41866. [Google Scholar] [CrossRef]

- Fraternali, F.; Ciancia, V.; Chechile, R.; Rizzano, G.; Feo, L.; Incarnato, L. Experimental study of the thermo-mechanical properties of recycled PET fiber-reinforced concrete. Compos. Struct. 2011, 93, 2368–2374. [Google Scholar] [CrossRef]

- Zamanzadeh, Z.; Lourenco, L.; Barros, J. Recycled steel fibre reinforced concrete failing in bending and in shear. Constr. Build. Mater. 2015, 85, 195–207. [Google Scholar] [CrossRef] [Green Version]

- Son, D.-H.; Bae, B.-I.; Lee, M.-S.; Lee, M.-S.; Choi, C.-S. Flexural Strength of Composite Deck Slab with Macro Synthetic Fiber Reinforced Concrete. Appl. Sci. 2021, 11, 1662. [Google Scholar] [CrossRef]

- Akhavan, A.; Shafaatian, S.; Rajabipour, F. Quantifying the effects of crack width, tortuosity, and roughness on water permeability of cracked mortars. Cem. Concr. Res. 2012, 42, 313–320. [Google Scholar] [CrossRef]

- Zhang, L.; Zhao, J.; Fan, C.; Wang, Z. Effect of Surface Shape and Content of Steel Fiber on Mechanical Properties of Concrete. Adv. Civ. Eng. 2020, 2020, 11. [Google Scholar] [CrossRef]

- Denisiewicz, A.; Socha, T. Influence of Steel and Polypropylene Fibers Addition on Selected Properties of Fine-Grained Concrete. Civ. Environ. Eng. Rep. 2018, 28, 138–148. [Google Scholar] [CrossRef] [Green Version]

- Lehner, P.; Horňáková, M. Effect of Amount of Fibre and Damage Level on Service Life of SFR Recycled Concrete in Aggressive Environment. Buildings 2021, 11, 489. [Google Scholar] [CrossRef]

- Huang, Q.; Hamed, E.; Gilbert, R.I. Behavior of Concrete Sandwich Panels under Eccentric Axial Compression—Testing and Finite Element Analysis. ACI Struct. J. 2020, 117, 235–247. [Google Scholar] [CrossRef]

- Ding, L.; He, W.; Wang, X.; Cheng, F.; Wu, Z. Flexural behavior of reinforced concrete slabs strengthened with BFRP grids and PCM. J. Cent. South Univ. 2020, 51, 1085–1096. [Google Scholar]

- ASTM C204; Standard Test Methods for Fineness of Hydraulic Cement by Air-Permeability Apparatus. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM C191; Standard Test Methods for Time of Setting of Hydraulic Cement by Vicat Needle. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C349; Standard Test Method for Compressive Strength of Hydraulic-Cement Mortars (Using Portions of Prisms Broken in Flexure). ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C33/86; Standard Specification for Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 1986.

- ASTM C 128-01; Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption. ASTM International: West Conshohocken, PA, USA, 2001.

- ASTM C494; Standard Specification for Chemical Admixtures for Concrete. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C192; Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C39/C39M; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM C496/C496M; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C78/C78M; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2018.

| Chemical Components of Cement | Main Components of Cement | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | Na2O | K2O | SO3 | Insoluble Residue | LOI | C3S | C2S | C3A | C4AF |

| 20.7 | 5.3 | 3.9 | 62.8 | 1.94 | 0.35 | 0.66 | 1.96 | 0.47 | 1.4 | 50.2 | 24.3 | 6.81 | 10.5 |

| Property | Standard | Test Method | Unit | Result |

|---|---|---|---|---|

| Fineness | ASTM C204 [18] | Mesh 170 | % | 6.4% |

| Blaine air permeability | (m2/kg) | 309 | ||

| Setting time | ASTM C191 [19] | Initial | minute | 135 |

| Final | minute | 260 | ||

| Compressive strength | ASTM-C349 [20] | 3 days | MPa | 19.2 MPa |

| 7 days | MPa | 26.3 MPa |

| Aggregate Type | Bulk Specific Gravity (SSD) | Apparent Specific Gravity | Dense Dry Density (kg/m3) | Loose Dry Density (kg/m3) | Sulphate Content (%) | Absorption (%) |

|---|---|---|---|---|---|---|

| Coarse Aggregate (gravel) | 2.46 | 2.50 | 1620 | 1468 | - | 0.89 |

| Fine Aggregate (sand) | 2.68 | 2.74 | 1871 | 1722 | 0.24 | 1.62 |

| Fiber Type | Shape | Length (mm) | Diameter (mm) | Aspect Ratio ** (mm) | Tensile Strength (MPa) |

|---|---|---|---|---|---|

| Straight steel fiber | Straight | 12 | 0.25 | 50 | 2850 |

| Hooked steel fiber | Hooked | 30 | 0.5 | 60 | >1000 |

| Corrugated steel fiber | Corrugated | 30 | 0.55 * | 55 | >700 |

| Polyolefin fiber | - | 60 | 0.84 * | 71 | 465 |

| Cement (kg) | Fine Aggregate (kg/m3) | Fine Aggregate (kg/m3) | Water (kg/m3) | Fiber (kg/m3) | Super Plasticizer (kg) |

|---|---|---|---|---|---|

| 370 | 740 | 1110 | 181 | 3.7 | 2.22 |

| Sample Type | Symbols | Compression Cylinder Test (MPa) | Modulus of Rupture (MPa) | Splitting Tensile Strength (MPa) |

|---|---|---|---|---|

| Without fiber (control) | control | 36.2 | 4.20 | 2.32 |

| Straight steel fiber 12 mm | S-1 | 45.2 | 6.38 | 3.81 |

| Hooked steel fiber 30 mm | H-1 | 43.5 | 8.76 | 4.51 |

| Corrugated steel fiber 30 mm | C-1 | 44.2 | 7.49 | 4.12 |

| Polyolefin fiber 60 mm | P-1 | 40.3 | 6.80 | 3.12 |

| Sample | Pcr (Soild) (kN) | Pcr (Opening) (kN) | Pcr (Solid)/Pcr (Control) (Ratio) | Pcr (Opening)/Pcr (Control) (Ratio) | Pcr (Solid)/Pcr (Opening) (Ratio) |

|---|---|---|---|---|---|

| Control | 31.5 | 32.0 | 1.00 | 1.00 | 0.98 |

| H1 | 45.0 | 35.0 | 1.43 | 1.10 | 1.29 |

| C1 | 40.0 | 45.5 | 1.27 | 1.42 | 1.14 |

| S1 | 35.0 | 41.5 | 1.11 | 1.17 | 1.19 |

| P1 | 42.0 | 40.0 | 1.33 | 1.25 | 0.95 |

| Sample | Ultimate Load (Solid) Pu (kN) | Ultimate Load (with Opening) Pu (kN) | Pu (Solid)/ Pu (Control) (Ratio) | Pu (Opening)/Pu (Control) (Ratio) | Pu (Solid)/ Pu (Opening) (Ratio) |

|---|---|---|---|---|---|

| Control | 160 | 140 | 1.00 | 1.00 | 1.14 |

| H1 | 223 | 161 | 1.39 | 1.15 | 1.39 |

| C1 | 180 | 179 | 1.125 | 1.28 | 1.00 |

| S1 | 181 | 161 | 1.13 | 1.15 | 1.12 |

| P1 | 191 | 170 | 1.19 | 1.21 | 1.12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hussain, H.K.; Abbas, A.M.; Ojaimi, M.F. Fiber-Type Influence on the Flexural Behavior of RC Two-Way Slabs with an Opening. Buildings 2022, 12, 279. https://doi.org/10.3390/buildings12030279

Hussain HK, Abbas AM, Ojaimi MF. Fiber-Type Influence on the Flexural Behavior of RC Two-Way Slabs with an Opening. Buildings. 2022; 12(3):279. https://doi.org/10.3390/buildings12030279

Chicago/Turabian StyleHussain, Haleem K., Abdulnasser M. Abbas, and Mohammed Farhan Ojaimi. 2022. "Fiber-Type Influence on the Flexural Behavior of RC Two-Way Slabs with an Opening" Buildings 12, no. 3: 279. https://doi.org/10.3390/buildings12030279