Optimization of Tuned Liquid Damper Including Different Liquids for Lateral Displacement Control of Single and Multi-Story Structures

Abstract

:1. Introduction

2. Materials and Methods

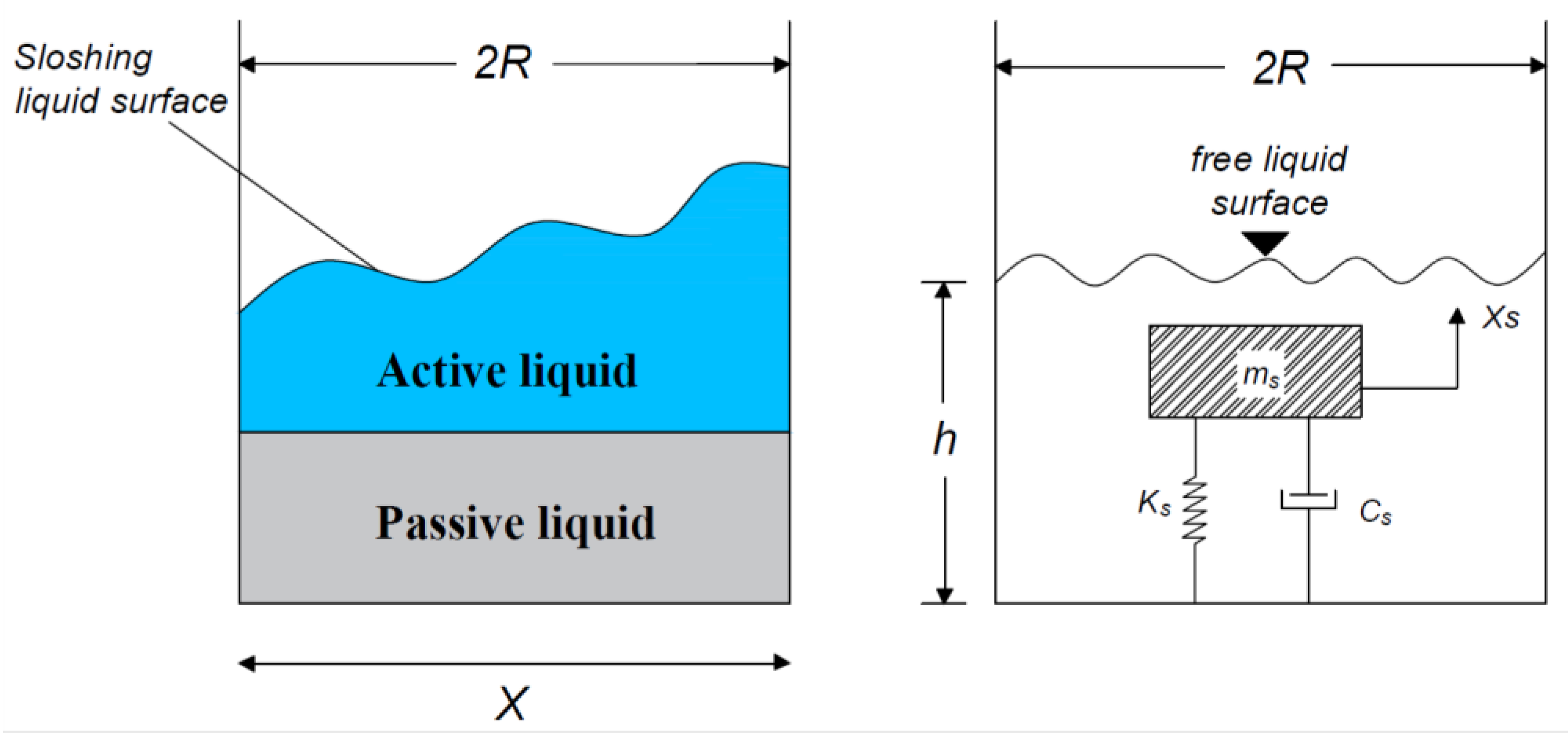

2.1. Design of TLDs and Equations of Motion

2.2. Harmony Search and Adaptive Harmony Search Algorithm

3. Numerical Examples

3.1. Single-Story Structure

3.2. Ten-Story Structure

3.3. Forty-Story Structure

4. Discussion

5. Conclusions

- -

- The ideal liquid for a single-story structure is acetone. According to the liquid analysis, it has been observed that choosing a TLD liquid with a smaller viscosity to be used for a single-story normal weight structure will increase the efficiency, while a less dense liquid with similar viscosity liquids will increase the performance.

- -

- It can be said that, in the ten-story structure design, since the structure mass increases compared to the single-story structure, the low viscosity required in the design is replaced by a more viscous liquid. It has been understood that the performance of the more viscous liquid increases with a slight increase in the mass, and in contrast to the single-story structure in the liquid with similar viscosity, the one with the higher density is more efficient. Increasing the structure mass a little bit brought the viscosity to the fore.

- -

- For the forty-story heavy structure, the optimum liquid was mercury, which is the densest. It is seen that continuing to increase the structure mass compared to the ten-story structure is related to density in terms of efficiency. Although a precise comparison of the viscosity cannot be made for heavy structures, it has been observed that a denser liquid should be preferred.

- -

- As a result of all the liquid analyses, it is understood that remarkable displacement and total acceleration decreases will be achieved with the optimization of the TLDs.

- -

- For vibration control, the best factor for the success of the method is to use the most realistic model in the dynamic analysis. In that case, soil–structure interactions (SSIs) can play an important role in the optimum design of control systems. In the last decade, the SSI effect has been considered in several studies related to tuned mass dampers [65,66,67,68,69]. As a future work, the SSI effect can be also considered in the optimization of TLDs.

- -

- In the design of structures, the variable loads are assumed as the standard values. In that case, the mass of structures is uncertain, and it may change the frequency content of the system. Due to that, the optimum parameters are affected, and the control systems may be not effective in that case. In the present study, the single-story structure cases were investigated for different mass values for the optimum TLD parameters that were found for the assumed mass. While the best performance was seen for acetone with 18.43% and 20.38% reduction of displacement and acceleration, respectively, the response reductions reduced to 18.27% and 19.17% for the 25% reduction of the mass. These reductions were small, and the optimum TLD was also effective for the mass increase, but the values for displacement and acceleration, respectively, reduced 9.91% and 13.02% due to the reduction of the mass ratio of the TLD and structure. In general, the TLD was proven as a robust system. In future works, a multi-objective approach that considers the response of several possible structure properties can be developed.

- -

- In structural control systems, it is important to test failure situations with experimental simulations [70]. This is also valid for TLDs, and it can be considered in future works.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbols and Abbreviations | Description |

| Three degrees of freedom | |

| Twelve degrees of freedom | |

| Forty-two degrees of freedom | |

| Adaptive harmony search algorithm | |

| Damping coefficient matrix | |

| Damping coefficient | |

| TLD damping coefficient | |

| Damping coefficient of sloshing liquid | |

| Quantification of Building Seismic Performance Factors | |

| Fret width | |

| Initial Fret Width | |

| Gravitational acceleration | |

| Liquid height in the TLD tank | |

| Harmony Memory Consideration Rate | |

| Initial Harmony Memory Consideration Rate | |

| Harmony memory size | |

| Harmony Search Algorithm | |

| Stiffness matrix | |

| Structure stiffness coefficient | |

| Sloshing liquid stiffness | |

| TLD stiffness | |

| Liquid column vibration absorbers | |

| Mass matrix | |

| Mass of structure | |

| Empty tank mass and passive liquid mass of TLD | |

| Magneto rheological | |

| Mass of sloshing liquid | |

| Total liquid mass | |

| maximum iteration number | |

| Multiple Tuned Liquid Column Damper | |

| Multiple tuned liquid column damper inerter | |

| Mass of TLD | |

| Tank radius of TLD | |

| Stroke capacity | |

| Second | |

| Iteration number | |

| Period of TLD | |

| Tuned liquid column ball damper | |

| Tuned liquid column ball spring damper | |

| Tuned liquid column damper | |

| Tuned liquid column damper inerter | |

| Tuned liquid damper | |

| Tuned mass damper | |

| Horizontal displacement of the structure relative to the ground | |

| Upper limit for design variable | |

| Lower limit for design variable | |

| nth Harmony | |

| New value in design | |

| Velocity of structure | |

| Acceleration of structure | |

| Acceleration of ground | |

| Damping rate of TLD | |

| Damping rate of sloshing liquid | |

| The damping ratio of the liquid according to the vibration mode in the tangential (m) and radial (n) directions | |

| Kinematic viscosity | |

| Density of liquid |

References

- Abramson, H.N. The Dynamic Behavior of Liquids in Moving Containers; NASA SP-106; NASA Special Publication: Washington, DC, USA, 1966; Volume 106. [Google Scholar]

- Ibrahim, R.A. Liquid Sloshing Dynamics: Theory and Applications; Cambridge University Press: Cambridge, UK, 2005; ISBN 0-521-83885-1. [Google Scholar]

- Sun, L.M.; Fujino, Y.; Pacheco, B.M.; Chaiseri, P. Modeling of tuned liquid damper (TLD). J. Wind. Eng. Ind. Aerodyn. 1992, 43, 1883–1894. [Google Scholar] [CrossRef]

- Yu, J.K.; Wakahara, T.; Reed, D.A. A non-linear numerical model of the tuned liquid damper. Earthq. Eng. Struct. Dyn. 1999, 28, 671–686. [Google Scholar] [CrossRef]

- Vickery, B.J.; Isyumov, N.; Davenport, A.G. The role of dumping, mass, and acceleration. J. Wind Eng. Ind. Aerodyn. 1983, 11, 285–294. [Google Scholar] [CrossRef]

- Rana, R.; Soong, T.T. Parametric study and simplified design of tuned mass dampers. Eng. Struct. 1998, 20, 193–204. [Google Scholar] [CrossRef]

- Wang, Q.; Tiwari, N.D.; Qiao, H.; Wang, Q. Inerter-based tuned liquid column damper for seismic vibration control of a single-degree-of-freedom structure. Int. J. Mech. Sci. 2020, 184, 105840. [Google Scholar] [CrossRef]

- Di Matteo, A.; Masnata, C.; Adam, C.; Pirrotta, A. Optimal design of tuned liquid column damper inerter for vibration control. Mech. Syst. Signal Process. 2022, 167, 108553. [Google Scholar] [CrossRef]

- Wang, Q.; Qiao, H.; De Domenico, D.; Zhu, Z.; Tang, Y. Seismic performance of optimal Multi-Tuned Liquid Column Damper-Inerter (MTLCDI) applied to adjacent high-rise buildings. Soil Dyn. Earthq. Eng. 2021, 143, 106653. [Google Scholar] [CrossRef]

- Chang, C.C.; Gu, M. Suppression of vortex-excited vibration of tall buildings using tuned liquid dampers. J. Wind. Eng. Ind. Aerodyn. 1999, 83, 225–237. [Google Scholar] [CrossRef]

- Casciati, F.; De Stefano, A.; Matta, E. Simulating a conical tuned liquid damper. Simul. Model. Pract. Theory 2003, 11, 353–370. [Google Scholar] [CrossRef]

- Zhang, Z. Numerical and experimental investigations of the sloshing modal properties of sloped-bottom tuned liquid dampers for structural vibration control. Eng. Struct. 2020, 204, 110042. [Google Scholar] [CrossRef]

- Cavalagli, N.; Agresta, A.; Biscarini, C.; Ubertini, F.; Ubertini, S. Enhanced energy dissipation through 3D printed bottom geometry in Tuned Sloshing Dampers. J. Fluids Struct. 2021, 106, 103377. [Google Scholar] [CrossRef]

- Fujino, Y.; Sun, L.; Pacheco, B.M.; Chaiseri, P. Tuned liquid damper (TLD) for suppressing horizontal motion of structures. J. Eng. Mech. 1992, 118, 2017–2030. [Google Scholar] [CrossRef] [Green Version]

- Balendra, T.; Wang, C.M.; Cheong, H.F. Effectiveness of tuned liquid column dampers for vibration control of towers. Eng. Struct. 1995, 17, 668–675. [Google Scholar] [CrossRef]

- Ocak, A.; Bekdaş, G.; Nigdeli, S.M. A metaheuristic-based optimum tuning approach for tuned liquid dampers for structures. Struct. Des. Tall Spec. Build. 2022, 31, e1907. [Google Scholar] [CrossRef]

- Tanveer, M.; Usman, M.; Khan, I.U.; Farooq, S.H.; Hanif, A. Material optimization of tuned liquid column ball damper (TLCBD) for the vibration control of multi-story structures using various liquid and ball densities. J. Build. Eng. 2020, 32, 101742. [Google Scholar] [CrossRef]

- Shah, M.U.; Usman, M.; Farooq, S.H.; Kim, I.H. Effect of Tuned Spring on Vibration Control Performance of Modified Liquid Column Ball Damper. Appl. Sci. 2022, 12, 318. [Google Scholar] [CrossRef]

- Hitchcock, P.A.; Kwok, K.C.S.; Watkins, R.D.; Samali, B. Characteristics of liquid column vibration absorbers (LCVA)—I. Eng. Struct. 1997, 19, 126–134. [Google Scholar] [CrossRef]

- Xin, Y.; Chen, G.; Lou, M. Seismic response control with density-variable tuned liquid dampers. Earthq. Eng. Eng. Vib. 2009, 8, 537–546. [Google Scholar] [CrossRef]

- Debbarma, R.; Chakraborty, S.; Ghosh, S.K. Optimum design of tuned liquid column dampers under stochastic earthquake load considering uncertain bounded system parameters. Int. J. Mech. Sci. 2010, 52, 1385–1393. [Google Scholar] [CrossRef]

- Das, S.; Choudhury, S. Seismic response control by tuned liquid dampers for low-rise RC frame buildings. Aust. J. Struct. Eng. 2017, 18, 135–145. [Google Scholar] [CrossRef]

- Sun, H.; Wang, X.; Chen, Z. Magnetorheological tuned liquid column damper (MR-TLCD) for semi-active control of structures under earthquake. J. Earthq. Eng. Eng. Vib. 2010, 30, 22–28. [Google Scholar]

- Cheng, C.W.; Lee, H.H.; Luo, Y.T. Experimental study of controllable MR-TLCD applied to the mitigation of structure vibration. Smart Struct. Syst. 2015, 15, 1481–1501. [Google Scholar] [CrossRef]

- Xin, C.; Aiqun, L.; Zhiqiang, Z. Optimum design of ring-shape TLD control for high-rise structure using multi-objective genetic algorithm. China Civ. Eng. J. 2014, 47, 73–81. [Google Scholar]

- Ab Talib, M.H.; Darus, I.Z.M. Fuzzy logic with firefly algorithm for semi-active suspension system using a magneto-rheological damper. In Proceedings of the 2014 IEEE Symposium on Industrial Electronics & Applications (ISIEA), Kota Kinabalu, Malaysia, 28 September–1 October 2014; pp. 142–147. [Google Scholar]

- Mohebbi, M.; Dabbagh, H.R.; Shakeri, K. Optimal design of multiple tuned liquid column dampers for seismic vibration control of MDOF structures. Period. Polytech. Civ. Eng. 2015, 59, 543–558. [Google Scholar] [CrossRef] [Green Version]

- Xin, C.; Ai-qun, L.I.; Qing-yang, X.U.; Zhi-Qiang, Z.H.A.N.G. Satisfaction optimum design of ring-shaped tld control for high-rise structure using genetic algorithm. Eng. Mech. 2016, 33, 77–84. [Google Scholar]

- Abubaker, S.; Nagan, S.; Nasar, T. Particle swarm optimized fuzzy control of structure with tuned liquid column damper. Glob. J. Pure Appl. Math. 2016, 12, 875–886. [Google Scholar]

- Ab Talib, M.H.; Mat Darus, I.Z. Intelligent fuzzy logic with firefly algorithm and particle swarm optimization for semi-active suspension system using a magneto-rheological damper. J. Vib. Control 2017, 23, 501–514. [Google Scholar] [CrossRef]

- Samiee, H.R. The hybrid passive control system of TLD and TMD for seismic response mitigation of Tall Buildings. J. Vibroeng. 2017, 19, 3648–3667. [Google Scholar] [CrossRef]

- Das, S.; Chakraborty, A. Optimal Design of MRTLCD for Semi-active Vibration Control of Building Structures Using Genetic Algorithm. In Advances in Rotor Dynamics, Control, and Structural Health Monitoring; Springer: Singapore, 2020; pp. 615–625. [Google Scholar]

- Geem, Z.W.; Kim, J.H.; Loganathan, G.V. A new heuristic optimization algorithm: Harmony search. Simulation 2001, 76, 60–68. [Google Scholar] [CrossRef]

- Nigdeli, S.M.; Bekdas, G.; Kim, S.; Geem, Z.W. A novel harmony search-based optimization of reinforced concrete biaxially loaded columns. Struct. Eng. Mech. Int. J. 2015, 54, 1097–1109. [Google Scholar] [CrossRef]

- Siddique, N.; Adeli, H. Applications of harmony search algorithms in engineering. Int. J. Artif. Intell. Tools 2015, 24, 1530002. [Google Scholar] [CrossRef]

- De Almeida, F.S. Optimization of laminated composite structures using a harmony search algorithm. Compos. Struct. 2019, 221, 110852. [Google Scholar] [CrossRef] [Green Version]

- Cakiroglu, C.; Bekdaş, G.; Kim, S.; Geem, Z.W. Optimization of Shear and Lateral–Torsional Buckling of Steel Plate Girders Using Meta-Heuristic Algorithms. Appl. Sci. 2020, 10, 3639. [Google Scholar] [CrossRef]

- Cakiroglu, C.; Islam, K.; Bekdaş, G.; Kim, S.; Geem, Z.W. Metaheuristic Optimization of Laminated Composite Plates with Cut-Outs. Coatings 2021, 11, 1235. [Google Scholar] [CrossRef]

- Kayabekir, A.E.; Bekdaş, G.; Nigdeli, S.M.; Geem, Z.W. Optimum design of PID controlled active tuned mass damper via modified harmony search. Appl. Sci. 2020, 10, 2976. [Google Scholar] [CrossRef]

- Ulusoy, S.; Bekdaş, G.; Nigdeli, S.M.; Kim, S.; Geem, Z.W. Performance of optimum tuned PID controller with different feedback strategies on active-controlled structures. Appl. Sci. 2021, 11, 1682. [Google Scholar] [CrossRef]

- Nigdeli, S.M.; Bekdaş, G. Optimum tuned mass damper design in the frequency domain for structures. KSCE J. Civ. Eng. 2017, 21, 912–922. [Google Scholar] [CrossRef]

- Jin, C.; Chung, W.C.; Kwon, D.S.; Kim, M. Optimization of tuned mass damper for seismic control of submerged floating tunnel. Eng. Struct. 2021, 241, 112460. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Zhang, L.J. Tuned mass damper system of high-rise intake towers optimized by the improved harmony search algorithm. Eng. Struct. 2017, 138, 270–282. [Google Scholar] [CrossRef]

- Den Hartog, J.P. Mechanical Vibrations, 3rd ed.; McGraw-Hill: New York, NY, USA, 1947; ISBN 978-1443725361. [Google Scholar]

- Warburton, G.B. Optimum absorber parameters for various combinations of response and excitation parameters. Earthq. Eng. Struct. Dyn. 1982, 10, 381–401. [Google Scholar] [CrossRef]

- Sadek, F.; Mohraz, B.; Taylor, A.W.; Chung, R.M. A method of estimating the parameters of tuned mass dampers for seismic application. Earthq. Eng. Struct. Dyn. 1997, 26, 617–635. [Google Scholar] [CrossRef]

- Leung, A.Y.T.; Zhang, H. Particle swarm optimization of tuned mass dampers. Eng. Struct. 2009, 31, 715–728. [Google Scholar] [CrossRef]

- Keshtegar, B.; Etedali, S. Nonlinear mathematical modeling and optimum design of tuned mass dampers using adaptive dynamic harmony search algorithm. Struct. Control Health Monit. 2018, 25, e2163. [Google Scholar] [CrossRef]

- Alkhadashi, A.; Mohammad, F.; Zubayr, R.O.; Klalib, H.A.; Balik, P. Multi-objective design optimization of steel-framed structures using three different methods. Int. J. Struct. Integr. 2021, 13, 92–111. [Google Scholar] [CrossRef]

- Toklu, Y.C.; Bekdaş, G.; Yücel, M.; Nigdeli, S.M.; Kayabekir, A.E.; Kim, S.; Geem, Z.W. Total Potential Optimization Using Metaheuristic Algorithms for Solving Nonlinear Plane Strain Systems. Appl. Sci. 2021, 11, 3220. [Google Scholar] [CrossRef]

- Keshtegar, B.; Nehdi, M.L.; Kolahchi, R.; Trung, N.T.; Bagheri, M. Novel hybrid machine learning model for predicting the shear strength of reinforced concrete shear walls. Eng. Comput. 2021, 1–12. [Google Scholar] [CrossRef]

- Peifeng, W.; Liqun, G.; Xiang, Z.; Dongli, Z. Application of adaptive harmony search algorithm in Structural engineering design. Chin. J. Sci. Instrum. 2012, 33, 1676–1680. [Google Scholar]

- Ocak, A.; Nigdeli, S.M.; Bekdaş, G.; Kim, S.; Geem, Z.W. Adaptive Harmony Search for Tuned Liquid Damper Optimization under Seismic Excitation. Appl. Sci. 2022, 12, 2645. [Google Scholar] [CrossRef]

- The MathWorks. Matlab R2018a; The MathWorks: Natick, MA, USA, 2018. [Google Scholar]

- FEMA P-695. Quantification of Building Seismic Performance Factors; FEMA: Washington, DC, USA, 2008. [Google Scholar]

- Sharma, V.; Arun, C.O.; Krishna, I.P. Development and validation of a simple two degree of freedom model for predicting maximum fundamental sloshing mode wave height in a cylindrical tank. J. Sound Vib. 2019, 461, 114906. [Google Scholar] [CrossRef]

- Bauer, H.F. Tables, and graphs of zeros of cross-product Bessel functions. Math. Comput. 1964, 18, 128. [Google Scholar]

- Mikishev, G.N.; Dorozhkin, N.Y. An experimental investigation of free oscillations of a liquid in containers. Izv. Akad. Nauk. SSSR Otd. Tekhnicheskikh Nauk. Mekhanika Mashinostroenie 1961, 4, 48–53. [Google Scholar]

- Lide, D.R. CRC Handbook of Chemistry and Physics; CRC Press: Boca Raton, FL, USA, 2004; Volume 85. [Google Scholar]

- Munson, R.B.; Young, D.F.; Okiishi, T.H. Fundamentals of Fluid Mechanics, 2nd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1995. [Google Scholar]

- Istanbul University. Available online: https://avesis.istanbul.edu.tr/resume/downloadfile/emine.kahraman?key=e3a09eb3-c53f-4e2f-a64a-32849279de25 (accessed on 3 March 2022).

- Atik, Z. Densities and excess molar volumes of binary and ternary mixtures of aqueous solutions of 2, 2, 2-trifluoroethanol with acetone and alcohols at the temperature of 298.15 K and Pressure of 101 kPa. J. Solut. Chem. 2004, 33, 1447–1466. [Google Scholar] [CrossRef]

- El-Hammamy, N.H.; El-Kholy, M.M.; Amira, M.F. Effect of the dielectric constant of the medium on conductance for acetylcholine halides and perchlorate in normal and branched alcohols. J. Indian Chem. Soc. 2008, 85, 1112. [Google Scholar]

- Singh, M.P.; Singh, S.; Moreschi, L.M. Tuned mass dampers for response control of torsional buildings. Earthq. Eng. Struct. D. 2002, 31, 749–769. [Google Scholar] [CrossRef]

- Liu, M.Y.; Chiang, W.L.; Hwang, J.H.; Chu, C.R. Wind-induced vibration of high-rise building with tuned mass damper including soil–structure interaction. J. Wind. Eng. Ind. Aerodyn. 2008, 96, 1092–1102. [Google Scholar] [CrossRef]

- Bekdaş, G.; Kayabekir, A.E.; Nigdeli, S.M.; Toklu, Y.C. Tranfer function amplitude minimization for structures with tuned mass dampers considering soil-structure interaction. Soil Dyn. Earthq. Eng. 2019, 116, 552–562. [Google Scholar] [CrossRef]

- Bekdaş, G.; Nigdeli, S.M. Metaheuristic based optimization of tuned mass dampers under earthquake excitation by considering soil-structure interaction. Soil Dyn. Earthq. Eng. 2017, 92, 443–461. [Google Scholar] [CrossRef]

- Liu, S.; Lu, Z.; Li, P.; Zhang, W.; Taciroglu, E. Effectiveness of particle tuned mass damper devices for pile-supported multi-story frames under seismic excitations. Struct. Control Health Monit. 2020, 27, e2627. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, S.; Shokrabadi, M.; Dehghanpoor, A.; Taciroglu, E. Nonlinear seismic fragility assessment of tall buildings equipped with tuned mass damper (TMD) and considering soil-structure interaction effects. Bull. Earthq. Eng. 2022, 1–15. [Google Scholar] [CrossRef]

- Guan, D.; Jing, X.; Shen, H.; Jing, L.; Gong, J. Test and simulation the failure characteristics of twin tube shock absorber. Mech. Syst. Signal Process. 2019, 122, 707–719. [Google Scholar] [CrossRef]

| Earthquake Number | Date | Earthquake Name | Component 1 | Component 2 |

|---|---|---|---|---|

| 1 | 1994 | Northridge | NORTHR/MUL009 | NORTHR/MUL279 |

| 2 | 1994 | Northridge | NORTHR/LOS000 | NORTHR/LA270 |

| 3 | 1999 | Duzce, Turkey | DUZCE/BOL0000 | DUZCE/BOL090 |

| 4 | 1999 | Hector Mine | HECTOR/HEC000 | HECTOR/HEC090 |

| 5 | 1979 | Imperial Valley | IMPVALL/H-DLT262 | IMPVALL/H-DLT352 |

| 6 | 1979 | Imperial Valley | IMPVALL/H-E11140 | IMPVALL/H-E11230 |

| 7 | 1995 | Kobe, Japan | KOBE/NIS000 | KOBE/NIS090 |

| 8 | 1995 | Kobe, Japan | KOBE/SHI000 | KOBE/SHI090 |

| 9 | 1999 | Kocaeli, Turkey | KOCAELI/DZC180 | KOCAELI/DZC270 |

| 10 | 1999 | Kocaeli, Turkey | KOCAELI/ARC000 | KOCAELI/ARC090 |

| 11 | 1992 | Landers | LANDERS/PLACE270 | LANDERS/YER360 |

| 12 | 1992 | Landers | LANDERS/CLW-LN | LANDERS/CLW-TR |

| 13 | 1989 | Loma Prieta | LOMAP/CAP000 | LOMAP/CAP090 |

| 14 | 1989 | Loma Prieta | LOMAP/G03000 | LOMAP/G03090 |

| 15 | 1990 | Manjil, Iran | MANJIL/ABBAR--L | MANJIL/ABBAR--T |

| 16 | 1987 | Superstition Hills | SUPERST/B-ICC000 | SUPERST/B-ICC090 |

| 17 | 1987 | Superstition Hills | SUPERST/B-POE270 | SUPERST/B-POE360 |

| 18 | 1992 | Cape Mendocino | CAPEMEND/RIO270 | CAPEMEND/RIO360 |

| 19 | 1999 | Chi-Chi, Taiwan | CHICHI/CHY101-E | CHICHI/CHY101-N |

| 20 | 1999 | Chi-Chi, Taiwan | CHICHI/TCU045-E | CHICHI/TCU045-N |

| 21 | 1971 | San Fernando | SFERN/PEL090 | SFERN/PEL180 |

| 22 | 1976 | Friuli, Italy | FRIULI/A-TMZ000 | FRIULI/A-TMZ270 |

| Liquid | Dynamic Viscosity (Pa·s) | Temperature (°C) | Kinematic Viscosity (m2/s) | Density (kg/m3) |

|---|---|---|---|---|

| Chloroform | 0.58 × 10−3 | 20 | 3.92 × 10−7 | 1480.3 |

| Acetone | 0.306 × 10−3 | 25 | 3.90 × 10−7 | 784.89 |

| Propanol | 1.945 × 10−3 | 25 | 2.43 × 10−6 | 799.60 |

| Mercury | 1.57 × 10−3 | 20 | 1.15 × 10−7 | 13,600 |

| Sea water | 1.20 × 10−3 | 15.6 | 1.17 × 10−6 | 1030 |

| Explanation | Design Parameter |

|---|---|

| TLD mass | 5% of the mass of the structure |

| Max Height | m |

| Minimum Height | 0.1 m |

| Max Radius | m |

| Minimum Radius | m |

| TLD Period | Structure Period |

| The ratio of height to radius | |

| Damping Ratio | 1~50% |

| Stroke capacity | (|Xd − X|)with TLD/(|X|)without TLD ≤ stmax |

| Population Number | 10 |

| İteration Number | 1000 |

| Fret Width initial | 0.05 |

| Harmony Memory Consideration Rate initial | 0.5 |

| Variables | Optimized Values | ||||

|---|---|---|---|---|---|

| TLD | |||||

| Chloroform | Acetone | Propanol | Mercury | Seawater | |

| (s) | 1.0188 | 0.9454 | 1.0613 | 0.9251 | 1.0829 |

| 0.1473 | 0.0810 | 0.2336 | 0.0637 | 0.2402 | |

| (m) | 0.2947 | 0.5418 | 0.2784 | 0.3225 | 0.2395 |

| (m) | 1.4482 | 2.2884 | 9.3378 | 0.1531 | 6.2101 |

| Liquid | Structure with TLD | Structure without TLD | ||

|---|---|---|---|---|

| Displacement (m) | Total Acceleration (m/s2) | Displacement (m) | Total Acceleration (m/s2) | |

| Acetone | 0.2343740 | 9.0757597 | 0.2873419 | 11.4077630 |

| Mercury | 0.2358324 | 9.3099176 | ||

| Chloroform | 0.2390329 | 9.3747324 | ||

| Water | 0.2446071 | 9.5648807 | ||

| Propanol | 0.2467634 | 9.6208562 | ||

| Seawater | 0.2472287 | 9.6666351 | ||

| Structure Mass (Ton) | Without TLD Structure | TLD–Acetone | With TLD–Mercury | With TLD–Chloroform | With TLD–Propanol | With TLD–Seawater | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Displacement (m) | Total Acceleration (m/s2) | Displacement (m) | Total Acceleration (m/s2) | Displacement (m) | Total Acceleration (m/s2) | Displacement (m) | Total Acceleration (m/s2) | Displacement (m) | Total Acceleration (m/s2) | Displacement (m) | Total Acceleration (m/s2) | |

| 75 | 0.2467190 | 13.0798250 | 0.2016451 | 10.5720449 | 0.2040501 | 10.8828848 | 0.2049643 | 10.8633207 | 0.2130885 | 11.1656552 | 0.2134193 | 11.2102898 |

| 80 | 0.2610085 | 12.9673247 | 0.2121752 | 10.4000571 | 0.2147651 | 10.7101163 | 0.2161374 | 10.7134861 | 0.2243689 | 11.0040281 | 0.2247637 | 11.0509856 |

| 85 | 0.2719087 | 12.7072278 | 0.2208049 | 10.1468190 | 0.2233240 | 10.4448977 | 0.2251804 | 10.4687604 | 0.2333662 | 10.7471630 | 0.2338051 | 10.7952535 |

| 90 | 0.2797414 | 12.3429855 | 0.2274021 | 9.8344712 | 0.2297169 | 10.1139567 | 0.2320593 | 10.1552950 | 0.2401109 | 10.4234478 | 0.2405728 | 10.4710945 |

| 95 | 0.2847697 | 11.9041599 | 0.2319002 | 9.4777271 | 0.2338087 | 9.7346701 | 0.2366186 | 9.7901571 | 0.2445091 | 10.0467491 | 0.2449773 | 10.0939986 |

| 100 | 0.2873419 | 11.4077630 | 0.2343740 | 9.0757597 | 0.2358324 | 9.3099176 | 0.2390329 | 9.3747324 | 0.2467634 | 9.6208562 | 0.2472287 | 9.6666351 |

| 105 | 0.2880210 | 10.8842557 | 0.2386721 | 8.6500651 | 0.2379030 | 8.8520454 | 0.2407919 | 8.9226726 | 0.2473454 | 9.1617944 | 0.2478043 | 9.2060348 |

| 110 | 0.2874282 | 10.3619123 | 0.2446614 | 8.4727027 | 0.2435005 | 8.5176305 | 0.2467701 | 8.6071533 | 0.2496793 | 8.7163183 | 0.2495807 | 8.7358429 |

| 115 | 0.2861626 | 9.8615057 | 0.2493544 | 8.2673290 | 0.2478725 | 8.2998641 | 0.2514130 | 8.3935198 | 0.2543800 | 8.5034826 | 0.2542933 | 8.5167682 |

| 120 | 0.2844103 | 9.3895882 | 0.2526405 | 8.0375150 | 0.2509446 | 8.0621324 | 0.2546598 | 8.1557408 | 0.2577386 | 8.2653892 | 0.2576823 | 8.2792175 |

| 125 | 0.2824851 | 8.9483986 | 0.2544804 | 7.7830968 | 0.2526808 | 7.8039051 | 0.2564466 | 7.8936965 | 0.2596475 | 8.0033980 | 0.2596366 | 8.0179645 |

| Variables | Optimized Values | ||||

|---|---|---|---|---|---|

| TLD | |||||

| Chloroform | Acetone | Propanol | Mercury | Seawater | |

| (s) | 1.0097 | 1.0301 | 0.9957 | 1.0201 | 0.9962 |

| 0.1843 | 0.2399 | 0.1839 | 0.2156 | 0.1841 | |

| (m) | 1.0416 | 0.9500 | 1.2055 | 0.3639 | 1.1087 |

| (m) | 0.7641 | 10 | 0.8985 | 4.4510 | 0.7556 |

| Liquid | Structure with TLD | Structure without TLD | ||

|---|---|---|---|---|

| Displacement (m) | Total Acceleration (m/s2) | Displacement (m) | Total Acceleration (m/s2) | |

| Propanol | 0.2971402 | 14.3139493 | 0.4101091 | 19.2833064 |

| Seawater | 0.2971696 | 14.3177283 | ||

| Chloroform | 0.2974617 | 14.4231051 | ||

| Mercury | 0.3017123 | 14.5490568 | ||

| Acetone | 0.3070783 | 14.6519753 | ||

| Variables | Optimized Values | ||||

|---|---|---|---|---|---|

| TLD | |||||

| Chloroform | Acetone | Propanol | Mercury | Seawater | |

| (s) | 5.3564 | 5.0104 | 4.9877 | 3.5626 | 5.7453 |

| 0.1575 | 0.3991 | 0.3974 | 0.2270 | 0.1923 | |

| (m) | 5.7016 | 8.3976 | 8.3731 | 4.1312 | 5.9943 |

| (m) | 7.3909 | 8.3196 | 8.0591 | 2.3684 | 7.6785 |

| Liquid | Structure with TLD | Structure without TLD | ||

|---|---|---|---|---|

| Displacement (m) | Total Acceleration (m/s2) | Displacement (m) | Total Acceleration (m/s2) | |

| Mercury | 1.4018155 | 5.1254171 | 1.9277898 | 6.1734370 |

| Chloroform | 1.4226523 | 5.2496230 | ||

| Seawater | 1.4570743 | 5.2789575 | ||

| Propanol | 1.5225798 | 5.3138740 | ||

| Acetone | 1.5234954 | 5.3147893 | ||

| Variable | Single-Story Structure | Kinematic Viscosity (m2/s) | Density (kg/m3) | |

|---|---|---|---|---|

| Displacement (%) | Total Acceleration (%) | |||

| Acetone | 18.43 | 20.44 | 3.90 × 10−7 | 784.89 |

| Mercury | 17.92 | 18.39 | 1.15 × 10−7 | 13600 |

| Chloroform | 16.81 | 17.82 | 3.92 × 10−7 | 1480.3 |

| Propanol | 14.12 | 15.66 | 2.43 × 10−6 | 799.60 |

| Sea water | 13.96 | 15.26 | 1.17 × 10−6 | 1030 |

| Variable | 10-Story Structure | Kinematic Viscosity (m2/s) | Density (kg/m3) | |

|---|---|---|---|---|

| Displacement (%) | Total Acceleration (%) | |||

| Propanol | 27.55 | 25.77 | 2.43 × 10−6 | 799.60 |

| Sea water | 27.54 | 25.75 | 1.17 × 10−6 | 1030 |

| Chloroform | 27.47 | 25.20 | 3.92 × 10−7 | 1480.3 |

| Mercury | 26.43 | 24.55 | 1.15 × 10−7 | 13600 |

| Acetone | 25.12 | 24.02 | 3.90 × 10−7 | 784.89 |

| Variable | 40-Story Structure | Kinematic Viscosity (m2/s) | Density (kg/m3) | |

|---|---|---|---|---|

| Displacement (%) | Total Acceleration (%) | |||

| Mercury | 27.28 | 16.98 | 1.15 × 10−7 | 13600 |

| Chloroform | 26.20 | 14.96 | 3.92 × 10−7 | 1480.3 |

| Sea water | 24.42 | 14.49 | 1.17 × 10−6 | 1030 |

| Propanol | 21.02 | 13.92 | 2.43 × 10−6 | 799.60 |

| Acetone | 20.97 | 13.91 | 3.90 × 10−7 | 784.89 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ocak, A.; Bekdaş, G.; Nigdeli, S.M.; Kim, S.; Geem, Z.W. Optimization of Tuned Liquid Damper Including Different Liquids for Lateral Displacement Control of Single and Multi-Story Structures. Buildings 2022, 12, 377. https://doi.org/10.3390/buildings12030377

Ocak A, Bekdaş G, Nigdeli SM, Kim S, Geem ZW. Optimization of Tuned Liquid Damper Including Different Liquids for Lateral Displacement Control of Single and Multi-Story Structures. Buildings. 2022; 12(3):377. https://doi.org/10.3390/buildings12030377

Chicago/Turabian StyleOcak, Ayla, Gebrail Bekdaş, Sinan Melih Nigdeli, Sanghun Kim, and Zong Woo Geem. 2022. "Optimization of Tuned Liquid Damper Including Different Liquids for Lateral Displacement Control of Single and Multi-Story Structures" Buildings 12, no. 3: 377. https://doi.org/10.3390/buildings12030377