Partial Substitution of Binding Material by Bentonite Clay (BC) in Concrete: A Review

Abstract

:1. Introduction

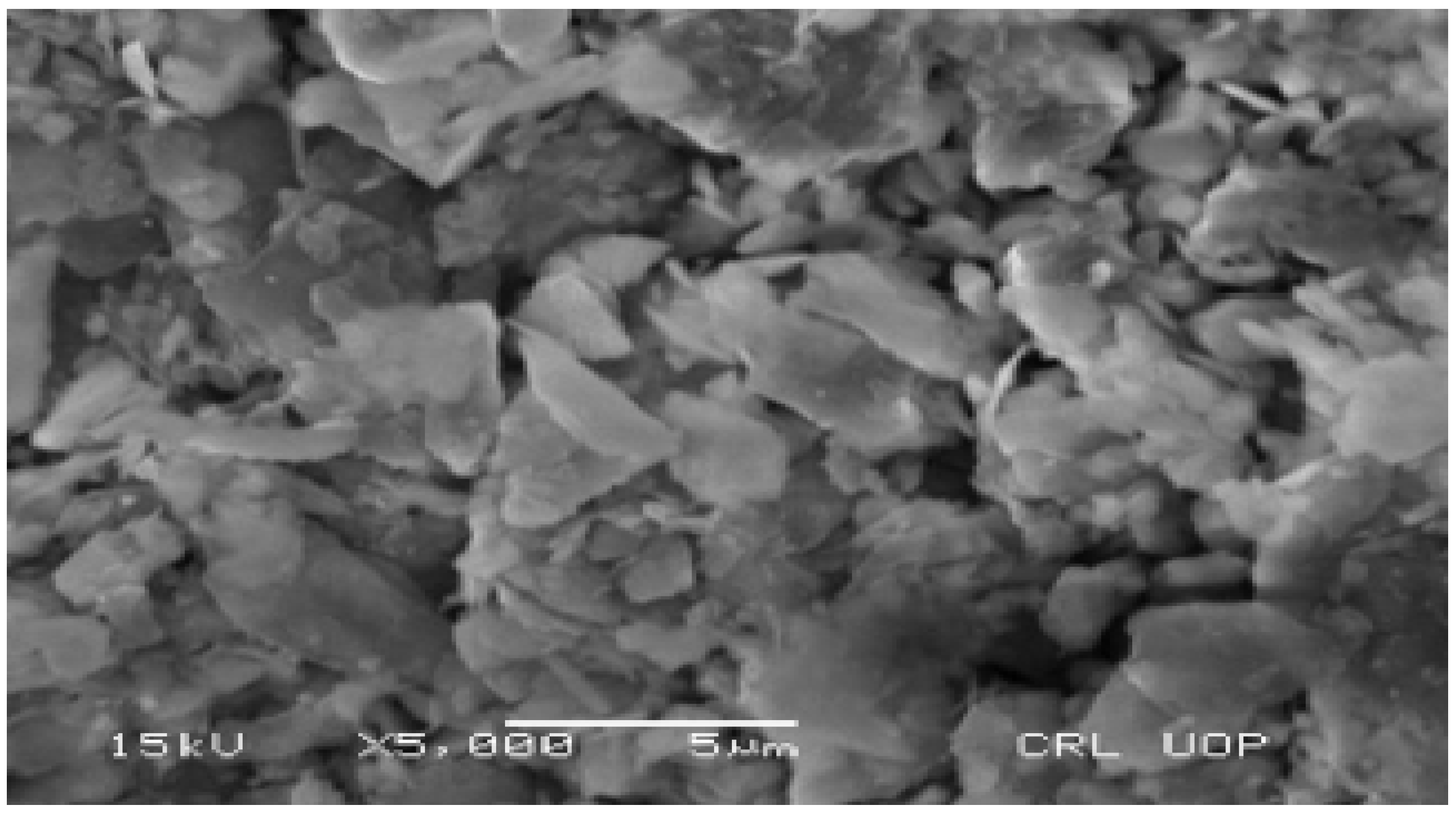

2. Physical Properties

3. Chemical Composition of Bentonite Clay

4. Fresh Properties

Workability and Fresh Density

5. Mechanical Properties

5.1. Compressive Strength

5.2. Split Tensile Strength

5.3. Flexure Strength

Load Deflection Curve and Ductility Ratio

6. Durability

6.1. Water Absorption (WA)

6.2. Acid Resistance

6.3. Dry Shrinkage

7. Conclusions

- Physical properties of bentonite clay show that the particle nature of bentonite clay is a rough and larger surface area than cement which negatively impacts the flowability of concrete.

- The chemical compounds of bentonite clay shows that it has the creditability to be utilized as a cement substitute.

- The flowability of concrete decreased with bentonite clay due to the larger surface area of bentonite clay which needed additional mortar to cover them and thus workability of concrete decreased.

- The fresh density was also noted to reduce with bentonite clay. The reduction in the fresh density is due to the lower specific gravity of bentonite clay as compared to cement.

- A reduction in mechanical performance was noted with bentonite clay. However, the decrease in strength was not significantly but approximately equal to the control. In contrast, some studies claim that strength was improved with bentonite clay due to pozzolanic reaction and micro filling voids, but more research is required in this regard.

- The load-deflection curve shows that the ductility of concrete is considerably improved with bentonite clay.

- Increased acid resistance and decreased dry shrinkage were observed with the substitution of bentonite clay instead of cement but still less studies are available on acid resistance and dry properties of concrete with substations of bentonite clay.

8. Future Perspective/Scope of BC

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sankh, A.C.; Biradar, P.M.; Naghathan, S.J.; Ishwargol, M.B. Recent Trends in Replacement of Natural Sand with Different Alternatives. In Proceedings of the International Conference on Advances in Engineering and Technology, Singapore, 29–30 March 2014; pp. 59–66. [Google Scholar]

- Svintsov, A.P.; Shchesnyak, E.L.; Galishnikova, V.V.; Fediuk, R.S.; Stashevskaya, N.A. Effect of Nano-Modified Additives on Properties of Concrete Mixtures during Winter Season. Constr. Build. Mater. 2020, 237, 117527. [Google Scholar] [CrossRef]

- Fediuk, R. Reducing Permeability of Fiber Concrete Using Composite Binders. Spec. Top. Rev. Porous Media Int. J. 2018, 9, 79–89. [Google Scholar] [CrossRef]

- Isler, J.W. Assessment of Concrete Masonry Units Containing Aggregate Replacements of Waste Glass and Rubber Tire Particles; University of Colorado at Denver: Denver, CO, USA, 2012; ISBN 1267297336. [Google Scholar]

- Taskin, A.; Fediuk, R.; Grebenyuk, I.; Elkin, O.; Kholodov, A. Effective Cement Binders on Fly and Slag Waste from Heat Power Industry of the Primorsky Krai, Russian Federation. Int. J. Sci. Technol. Res. 2020, 9, 3509–3512. [Google Scholar]

- Nassar, R.-U.-D.; Soroushian, P. Green and Durable Mortar Produced with Milled Waste Glass. Mag. Concr. Res. 2012, 64, 605–615. [Google Scholar] [CrossRef]

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global Strategies and Potentials to Curb CO2 Emissions in Cement Industry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Oh, D.-Y.; Noguchi, T.; Kitagaki, R.; Park, W.-J. CO2 Emission Reduction by Reuse of Building Material Waste in the Japanese Cement Industry. Renew. Sustain. Energy Rev. 2014, 38, 796–810. [Google Scholar] [CrossRef]

- Agency, I.E.; Agency, I.E. Tracking Industrial Energy Efficiency and CO2 Emissions; OECD: Paris, France, 2007; ISBN 9789264030169. [Google Scholar]

- Berriel, S.S.; Favier, A.; Domínguez, E.R.; Machado, I.R.S.; Heierli, U.; Scrivener, K.; Hernández, F.M.; Habert, G. Assessing the Environmental and Economic Potential of Limestone Calcined Clay Cement in Cuba. J. Clean. Prod. 2016, 124, 361–369. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S. Properties of Self-Compacting Concrete Prepared with Coarse and Fine Recycled Concrete Aggregates. Cem. Concr. Compos. 2009, 31, 622–627. [Google Scholar] [CrossRef]

- Si, R.; Dai, Q.; Guo, S.; Wang, J. Mechanical Property, Nanopore Structure and Drying Shrinkage of Metakaolin-Based Geopolymer with Waste Glass Powder. J. Clean. Prod. 2020, 242, 118502. [Google Scholar] [CrossRef]

- Mirza, J.; Riaz, M.; Naseer, A.; Rehman, F.; Khan, A.N.; Ali, Q. Pakistani Bentonite in Mortars and Concrete as Low Cost Construction Material. Appl. Clay Sci. 2009, 45, 220–226. [Google Scholar] [CrossRef]

- Smith, R.A.; Kersey, J.R.; Griffiths, P.J. The Construction Industry Mass Balance: Resource Use, Wastes and Emissions. Construction 2002, 4, 680. [Google Scholar]

- Jiang, Y.; Ling, T.-C.; Mo, K.H.; Shi, C. A Critical Review of Waste Glass Powder—Multiple Roles of Utilization in Cement-Based Materials and Construction Products. J. Environ. Manag. 2019, 242, 440–449. [Google Scholar] [CrossRef] [PubMed]

- Anwar, A. The Influence of Waste Glass Powder as a Pozzolanic Material in Concrete. Int. J. Civ. Eng. Technol. 2016, 7, 131–148. [Google Scholar]

- Zhang, T.; Yang, Y.-L.; Liu, S.-Y. Application of Biomass by-Product Lignin Stabilized Soils as Sustainable Geomaterials: A Review. Sci. Total Environ. 2020, 728, 138830. [Google Scholar] [CrossRef]

- Park, S.B.; Lee, B.C.; Kim, J.H. Studies on Mechanical Properties of Concrete Containing Waste Glass Aggregate. Cem. Concr. Res. 2004, 34, 2181–2189. [Google Scholar] [CrossRef]

- Rahma, A.; El Naber, N.; Issa Ismail, S. Effect of Glass Powder on the Compression Strength and the Workability of Concrete. Cogent Eng. 2017, 4, 1373415. [Google Scholar] [CrossRef]

- Somasri, M.; Kumar, B.N. Graphene Oxide as Nano Material in High Strength Self-Compacting Concrete. Mater. Today Proc. 2021, 43, 2280–2289. [Google Scholar] [CrossRef]

- Siddique, R.; Singh, G.; Singh, M. Recycle Option for Metallurgical by-Product (Spent Foundry Sand) in Green Concrete for Sustainable Construction. J. Clean. Prod. 2018, 172, 1111–1120. [Google Scholar] [CrossRef]

- Idir, R.; Cyr, M.; Tagnit-Hamou, A. Use of Waste Glass As Powder and Aggregate in Cement-Based Materials. In Proceedings of the SBEIDCO-1st International Conference on Sustainable Built Environment Infrastructures in Developing Countries, Oran, Algeria, 12–14 October 2009; pp. 109–116. [Google Scholar]

- Kumar, R.; Goel, P.; Mathur, R. Suitability of Concrete Reinforced with Synthetic Fiber for the Construction of Pavements. In Proceedings of the 3rd International Conference on Sustainable Construction Materials and Technologies, Kyoto, Japan, 18–21 August 2013; pp. 18–22. [Google Scholar]

- Amin, S.K.; Allam, M.E.; Garas, G.L.; Ezz, H. A Study of the Chemical Effect of Marble and Granite Slurry on Green Mortar Compressive Strength. Bull. Natl. Res. Cent. 2020, 44, 19. [Google Scholar] [CrossRef] [Green Version]

- Jani, Y.; Hogland, W. Waste Glass in the Production of Cement and Concrete—A Review. J. Environ. Chem. Eng. 2014, 2, 1767–1775. [Google Scholar] [CrossRef]

- Humphreys, D. Long-Run Availability of Mineral Commodities. Miner. Econ. 2013, 26, 1–11. [Google Scholar] [CrossRef]

- Müller, N.; Harnisch, J. How to Turn Around the Trend of Cement Related Emissions in the Developing World; WWF: Gland, Switzerland, 2008. [Google Scholar]

- Imbabi, M.S.; Carrigan, C.; McKenna, S. Trends and Developments in Green Cement and Concrete Technology. Int. J. Sustain. Built Environ. 2012, 1, 194–216. [Google Scholar] [CrossRef] [Green Version]

- McEwan, A.E. From Cottages to ‘Skyscrapers’: The Architecture of AE & ES Luttrell in Tasmania and New Zealand. Master’s Thesis, University of Canterbury, Christchurch, New Zealand, 1988. [Google Scholar]

- Okeke, K.L.; Adedeji, A.A. A Review on the Properties of Concrete Incorporated with Waste Glass as a Substitute for Cement. Epistem. Sci. Eng. Technol. 2016, 5, 396–407. [Google Scholar]

- Idir, R.; Cyr, M.; Tagnit-Hamou, A. Use of Fine Glass as ASR Inhibitor in Glass Aggregate Mortars. Constr. Build. Mater. 2010, 24, 1309–1312. [Google Scholar] [CrossRef]

- Rashad, A.M. Recycled Waste Glass as Fine Aggregate Replacement in Cementitious Materials Based on Portland Cement. Constr. Build. Mater. 2014, 72, 340–357. [Google Scholar] [CrossRef]

- Pusch, R. Bentonite Clay: Environmental Properties and Applications; CRC Press: Boca Raton, FL, USA, 2015; ISBN 148224344X. [Google Scholar]

- Arslan, M.; Abdioğlu, E.; Kadir, S. Mineralogy, Geochemistry, and Origin of Bentonite in Upper Cretaceous Pyroclastic Units of the Tirebolu Area, Giresun, Northeast Turkey. Clays Clay Miner. 2010, 58, 120–141. [Google Scholar] [CrossRef]

- Ahmad, J.; Tufail, R.F.; Aslam, F.; Mosavi, A.; Alyousef, R.; Faisal Javed, M.; Zaid, O.; Khan Niazi, M.S. A Step towards Sustainable Self-Compacting Concrete by Using Partial Substitution of Wheat Straw Ash and Bentonite Clay Instead of Cement. Sustainability 2021, 13, 824. [Google Scholar] [CrossRef]

- Fernandez, R.; Martirena, F.; Scrivener, K.L. The Origin of the Pozzolanic Activity of Calcined Clay Minerals: A Comparison between Kaolinite, Illite and Montmorillonite. Cem. Concr. Res. 2011, 41, 113–122. [Google Scholar] [CrossRef]

- Andrade, C.; Martínez-Serrano, A.; Sanjuán, M.Á.; Tenorio Ríos, J.A. Reduced Carbonation, Sulfate and Chloride Ingress Due to the Substitution of Cement by 10% Non-Precalcined Bentonite. Materials 2021, 14, 1300. [Google Scholar] [CrossRef]

- Ramezanianpour, A.A.; Pourkhorshidi, A.R. Durability of Concretes Containing Supplementary Cementing Materials under Hot and Aggressive Environment. Spec. Publ. 2004, 221, 633–646. [Google Scholar]

- Reddy, G.V.K.; Rao, V.R.; Reddy, M.A.K. Experimental Investigation of Strength Parameters of Cement and Concrete by Partial Replacement of Cement with Indian Calcium Bentonite. Int. J. Civ. Eng. Technol. 2017, 8, 512–518. [Google Scholar]

- Wei, J.; Gencturk, B. Hydration of Ternary Portland Cement Blends Containing Metakaolin and Sodium Bentonite. Cem. Concr. Res. 2019, 123, 105772. [Google Scholar] [CrossRef]

- Ashraf, M.; Iqbal, M.F.; Rauf, M.; Ashraf, M.U.; Ulhaq, A.; Muhammad, H.; Liu, Q. Developing a Sustainable Concrete Incorporating Bentonite Clay and Silica Fume: Mechanical and Durability Performance. J. Clean. Prod. 2022, 337, 130315. [Google Scholar] [CrossRef]

- Khandelwal, S.; Rhee, K.Y. Evaluation of Pozzolanic Activity, Heterogeneous Nucleation, and Microstructure of Cement Composites with Modified Bentonite Clays. Constr. Build. Mater. 2022, 323, 126617. [Google Scholar] [CrossRef]

- Reddy, M.A.K.; Rao, V.R.; Chaitanya, K.N.; Khed, V.C. Optimization of Bentocrete Parameters Using Response Surface Methodology (RSM). AIMS Mater. Sci. 2021, 8, 221–247. [Google Scholar] [CrossRef]

- Memon, S.A.; Arsalan, R.; Khan, S.; Lo, T.Y. Utilization of Pakistani Bentonite as Partial Replacement of Cement in Concrete. Constr. Build. Mater. 2012, 30, 237–242. [Google Scholar] [CrossRef]

- Khushnood, R.A.; Rizwan, S.A.; Memon, S.A.; Tulliani, J.-M.; Ferro, G.A. Experimental Investigation on Use of Wheat Straw Ash and Bentonite in Self-Compacting Cementitious System. Adv. Mater. Sci. Eng. 2014, 2014, 832508. [Google Scholar] [CrossRef] [Green Version]

- Ahmad, J.; Martínez-García, R.; De-Prado-Gil, J.; Irshad, K.; El-Shorbagy, M.A.; Fediuk, R.; Vatin, N.I. Concrete with Partial Substitution of Waste Glass and Recycled Concrete Aggregate. Materials 2022, 15, 430. [Google Scholar] [CrossRef]

- ASTM D6868; Specification for Biodegradable Plastics Used as Coatings on Paper and Other Compostable Substrates. ASTM International: West Conshohocken, PA, USA, 2017.

- Akbar, J.; Alam, B.; Ashraf, M.; Afzal, S.; Ahmad, A.; Shahzada, K. Evaluating the Effect of Bentonite on Strength and Durability of High Performance Concrete. Int. J. Adv. Struct. Geotech. Eng. 2013, 2, 1–5. [Google Scholar]

- Vijay, C.; Reddy, M.A.K. Optimization of Bentonite Modified Cement Mortar Parameters at Elevated Temperatures Using RSM. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1197, p. 12040. [Google Scholar]

- Shabab, M.E.; Shahzada, K.; Gencturk, B.; Ashraf, M.; Fahad, M. Synergistic Effect of Fly Ash and Bentonite as Partial Replacement of Cement in Mass Concrete. KSCE J. Civ. Eng. 2016, 20, 1987–1995. [Google Scholar] [CrossRef]

- Mousavi, S.S.; Dehestani, M.; Mousavi, S.M. Bond Strength and Development Length of Glass Fiber-Reinforced Polymer Bar in Unconfined Self-Consolidating Concrete. J. Reinf. Plast. Compos. 2016, 35, 924–941. [Google Scholar] [CrossRef]

- Ahmad, J.; Zaid, O.; Shahzaib, M.; Abdullah, M.U.; Ullah, A.; Ullah, R. Mechanical Properties of Sustainable Concrete Modified by Adding Marble Slurry as Cement Substitution. AIMS Mater. Sci. 2021, 8, 343–358. [Google Scholar] [CrossRef]

- Waqas, R.M.; Butt, F.; Danish, A.; Alqurashi, M.; Mosaberpanah, M.A.; Masood, B.; Hussein, E.E. Influence of Bentonite on Mechanical and Durability Properties of High-Calcium Fly Ash Geopolymer Concrete with Natural and Recycled Aggregates. Materials 2021, 14, 7790. [Google Scholar] [CrossRef] [PubMed]

- Fadaie, M.A.; Nekooei, M.; Javadi, P. Effect of Dry and Saturated Bentonite on Plastic Concrete. KSCE J. Civ. Eng. 2019, 23, 3431–3442. [Google Scholar] [CrossRef]

- Ahmad, J.; Aslam, F.; Martinez-Garcia, R.; De-Prado-Gil, J.; Qaidi, S.M.A.; Brahmia, A. Effects of Waste Glass and Waste Marble on Mechanical and Durability Performance of Concrete. Sci. Rep. 2021, 11, 21525. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, S.; Barbhuiya, S.A.; Elahi, A.; Iqbal, J. Effect of Pakistani Bentonite on Properties of Mortar and Concrete. Clay Miner. 2011, 46, 85–92. [Google Scholar] [CrossRef]

- Ahmad, J.; Aslam, F.; Martinez-Garcia, R.; El Ouni, M.H.; Khedher, K.M. Performance of Sustainable Self-Compacting Fiber Reinforced Concrete with Substitution of Marble Waste (MW) and Coconut Fibers (CFs). Sci. Rep. 2021, 11, 23184. [Google Scholar] [CrossRef]

- Chandrakanth, M.; Rao, N.P.C.; Rao, K.S. Experimental Studies on Concrete with Bentonite as Mineral Admixture. GRD J. 2016, 1, 7–10. [Google Scholar]

- Taklymi, S.M.Q.; Rezaifar, O.; Gholhaki, M. Investigating the Properties of Bentonite and Kaolin Modified Concrete as a Partial Substitute to Cement. SN Appl. Sci. 2020, 2, 2023. [Google Scholar] [CrossRef]

- Ashish, P.; Srinivasarao, C. Influence of Bentonite as Partial Replacement of Cement in Basalt Fiber Concrete. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1185, p. 12015. [Google Scholar]

- Sumitha, Y.; Abraham, R. Experimental Study on Bentonite Clay Powder with Silica Fume and GGBS as Partial Replacement of Cement in M40 Grade Concrete. Int. J. Eng. Res. Technol. 2016, 5. [Google Scholar] [CrossRef]

- Liu, M.; Hu, Y.; Lai, Z.; Yan, T.; He, X.; Wu, J.; Lu, Z.; Lv, S. Influence of Various Bentonites on the Mechanical Properties and Impermeability of Cement Mortars. Constr. Build. Mater. 2020, 241, 118015. [Google Scholar] [CrossRef]

- Kumar, B.P.; Rao, V.R.; Reddy, M.A.K. Effect on Strength Properties of Concrete by Partial Replacement of Cement with Calcium Bentonite and Fly Ash. Technology 2017, 8, 450–455. [Google Scholar]

- Khaliq, S.U.L.; Jamil, I.; Ullah, H. Evaluating Permeability and Mechanical Properties of Waste Marble Dust Mix Concrete and Bentonite Mix Concrete. In Proceedings of the International Structural Engineering and Construction, Brisbane, Australia, 3–5 December 2018. [Google Scholar] [CrossRef]

- Adeboje, A.O.; Kupolati, W.K.; Sadiku, E.R.; Ndambuki, J.M.; Kambole, C. Experimental Investigation of Modified Bentonite Clay-Crumb Rubber Concrete. Constr. Build. Mater. 2020, 233, 117187. [Google Scholar] [CrossRef]

- Shannag, M.J. High Strength Concrete Containing Natural Pozzolan and Silica Fume. Cem. Concr. Compos. 2000, 22, 399–406. [Google Scholar] [CrossRef]

- Rawal, P. Development of Durable Concrete from Pulverized Fly Ash and Pozzolan Derived from Agricultural Wastes. Master’s Thesis, Asian Institute of Technology, Bangkok, Thailand, 2003. [Google Scholar]

- Fediuk, R.; Pak, A.; Kuzmin, D. Fine-Grained Concrete of Composite Binder. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; Volume 262, p. 12025. [Google Scholar]

- Bheel, N.; Abbasi, S.A.; Awoyera, P.; Olalusi, O.B.; Sohu, S.; Rondon, C.; Echeverría, A.M. Fresh and Hardened Properties of Concrete Incorporating Binary Blend of Metakaolin and Ground Granulated Blast Furnace Slag as Supplementary Cementitious Material. Adv. Civ. Eng. 2020, 2020, 8851030. [Google Scholar] [CrossRef]

- Ahmad, J.; Zaid, O.; Siddique, M.S.; Aslam, F.; Alabduljabbar, H.; Khedher, K.M. Mechanical and Durability Characteristics of Sustainable Coconut Fibers Reinforced Concrete with Incorporation of Marble Powder. Mater. Res. Express 2021, 8, 075505. [Google Scholar] [CrossRef]

- Afzal, S.; Shahzada, K.; Fahad, M.; Saeed, S.; Ashraf, M. Assessment of Early-Age Autogenous Shrinkage Strains in Concrete Using Bentonite Clay as Internal Curing Technique. Constr. Build. Mater. 2014, 66, 403–409. [Google Scholar] [CrossRef]

| Property Name | Achyutha et al. [43] | Memom et al. [44] | Rao et al. [45] |

|---|---|---|---|

| Specific Gravity | 3.12 | 2.79 | 2.82 |

| Particle Size (µm) | - | 4.32 | 4.75 |

| Blains Fineness (cm2/g) | 1730 | 4800 | 4800 |

| Chemical Name | Akbar et al. [48] | Vijay et al. [49] | Shabab et al. [50] |

|---|---|---|---|

| SiO2 | 49.63 | 51.11 | 52.1 |

| Al2O3 | 21.11 | 16.38 | 13.4 |

| Fe2O3 | 3.23 | 7.65 | 7.5 |

| MgO | 12.56 | 7.57 | 2.64 |

| CaO | 3.59 | 7.12 | 12.0 |

| K2O | 2.091 | 1.34 | 2.64 |

| Na2O | 0.449 | 0.29 | - |

| TiO2 | 0.498 | 1.29 | - |

| P2O5 | 0.119 | 0.29 | - |

| LOI | - | 6.75 | 8.61 |

| Beam Type | Deflection at Ultimate Point | Deflection at Yield Point | Ductility Ratio * |

|---|---|---|---|

| Control Beam | 37.00 | 4.87 | 7.61 |

| 25% Bentonite Clay | 56.83 | 5.66 | 10.05 |

| Authors | Remarks | Bentonite Clay (%) | Tensile Strength (MPa) | Compression Strength (MPa) | Flexure Strength (MPa) |

|---|---|---|---|---|---|

| Ahmad et al. [35] | 14 days, 28 days | 14 days, 28 days | - | ||

| BC-5% | 2.6, 3.5 | 20, 30 | |||

| BC-10% | 2.7, 3.6 | 21, 32 | |||

| BC-15% | 3, 4 | 24, 34 | |||

| BC-20% | 2.6, 3.2 | 17, 26 | |||

| Sumitha et al. [61] | Silica Fume 10% | 7 days, 28 days | 7 days, 28 days | 7 days, 28 days | |

| 0% | 2.4, 3.3 | 38, 48 | 6, 8 | ||

| 5% | 2.5, 3.3 | 28, 42 | 5, 7 | ||

| 10% | 1.6, 2 | 25, 42 | 4.5, 5.5 | ||

| 15% | 1.4, 1.8 | 22, 35 | 3, 4.2 | ||

| Liu et al. [62] | - | - | 28 days | 28 days | |

| Ca-bent = 0%, | 11, | 2.7, | |||

| 2%, 4%, 6%, | 12, 12.2, 14, | 2.8, 3, 3.5, | |||

| 8%, 10% | 15, 16 | 3.4, 3.7 | |||

| Na-bent = 0%, | 11 | 2.7, | |||

| 2%, 4%, 6% | 13, 14, 17, | 2.8, 3, 3.5, 3, | |||

| 8%, 10% | 17, 18 | 6, 3.7 | |||

| Mg-bent = 0%, | 11, | 2.7, | |||

| 2%, 4%, 6%, | 12, 13, 14, | 3.5, 3.4, 3.6, | |||

| 8%, 10%. | 16, 17 | 3.7, 4 | |||

| Akbar et al. [48] | Plasticizer (%) 1.5 | 0%, 20% | - | 7 days | - |

| 25, 30 | |||||

| 14 days | |||||

| 32, 40 | |||||

| 28 days | |||||

| 20, 22 | |||||

| 56 days | |||||

| 24, 32 | |||||

| Rao et al. [45] | - | - | 7 days, 28 days | 7 days, 28 days | |

| Control | 55, 65 | 16, 18 | |||

| 10% WSA | 52, 68 | 15, 19 | |||

| 10% BC (H) | 50, 60 | 14, 16 | |||

| 10% BC (R) | 45, 50 | 10, 12 | |||

| Kumar et al. [63] | Fly Ash | 7 days, 28 days | 7 days, 28 days | - | |

| 0% | 0% | 1.9, 2.3 | 45, 90 | ||

| 5% | 5% | 1.4, 2 | 25, 50 | ||

| 7.5% | 7.5% | 1.6, 2 | 40, 70 | ||

| 12.5% | 12.5% | 1.5, 1.5 | 30, 60 | ||

| 15% | 15% | 1.3, 1.3 | 40, 65 | ||

| Chandrakanth et al. [58] | 7 days, 28 days | 7 days, 28 days | 7 days, 28 days | ||

| 0% | 2.5, 3.5 | 21.33, 25.77 | 12.5, 20 | ||

| 5% | 2.96, 3.8 | 22.66, 26.67 | 17.5, 25 | ||

| 10% | 2.8, 3.67 | 22.22, 25.77 | 15, 20 | ||

| 15% | 2.65, 3.49 | 21.72, 25.10 | 13.75, 17 | ||

| 20% | 2.5, 3.25 | 21.33, 24.44 | 12.5, 15 | ||

| Mirza et al. [13] | - | 7 days, 28 days | - | ||

| 0% | 16, 23 | ||||

| 20% | 15, 19 | ||||

| 25% | 15, 19 | ||||

| 30% | 14, 16 | ||||

| 40% | 13, 14 | ||||

| 50% | 8, 10 | ||||

| 100% | 4, 2 | ||||

| Khaliq et al. [64] | 28 days | 28 days | - | ||

| 0% | 2.1 | 23.44 | |||

| 5% | 2.0 | 22.4 | |||

| 10% | 2.2 | 22 | |||

| 15% | 2.1 | 17.2 | |||

| 20% | 2.0 | 13.7 | |||

| Adeboje et al. [65] | Rubber | 28 days | 28 days | - | |

| 0 | 0 | 1.9 | 27 | ||

| 0.75 | 0.25 | 1.7 | 25 | ||

| 0.50 | 0.50 | 1.8 | 26 | ||

| 0.25 | 0.75 | 1.7 | 25 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad, J.; Kontoleon, K.J.; Al-Mulali, M.Z.; Shaik, S.; Hechmi El Ouni, M.; El-Shorbagy, M.A. Partial Substitution of Binding Material by Bentonite Clay (BC) in Concrete: A Review. Buildings 2022, 12, 634. https://doi.org/10.3390/buildings12050634

Ahmad J, Kontoleon KJ, Al-Mulali MZ, Shaik S, Hechmi El Ouni M, El-Shorbagy MA. Partial Substitution of Binding Material by Bentonite Clay (BC) in Concrete: A Review. Buildings. 2022; 12(5):634. https://doi.org/10.3390/buildings12050634

Chicago/Turabian StyleAhmad, Jawad, Karolos J. Kontoleon, Mohammed Zuhear Al-Mulali, Saboor Shaik, Mohamed Hechmi El Ouni, and Mohammed A. El-Shorbagy. 2022. "Partial Substitution of Binding Material by Bentonite Clay (BC) in Concrete: A Review" Buildings 12, no. 5: 634. https://doi.org/10.3390/buildings12050634

APA StyleAhmad, J., Kontoleon, K. J., Al-Mulali, M. Z., Shaik, S., Hechmi El Ouni, M., & El-Shorbagy, M. A. (2022). Partial Substitution of Binding Material by Bentonite Clay (BC) in Concrete: A Review. Buildings, 12(5), 634. https://doi.org/10.3390/buildings12050634