Experimental Investigation of Seismic Performance of a Hybrid Beam–Column Connection in a Precast Concrete Frame

Abstract

:1. Introduction

2. Experimental Process

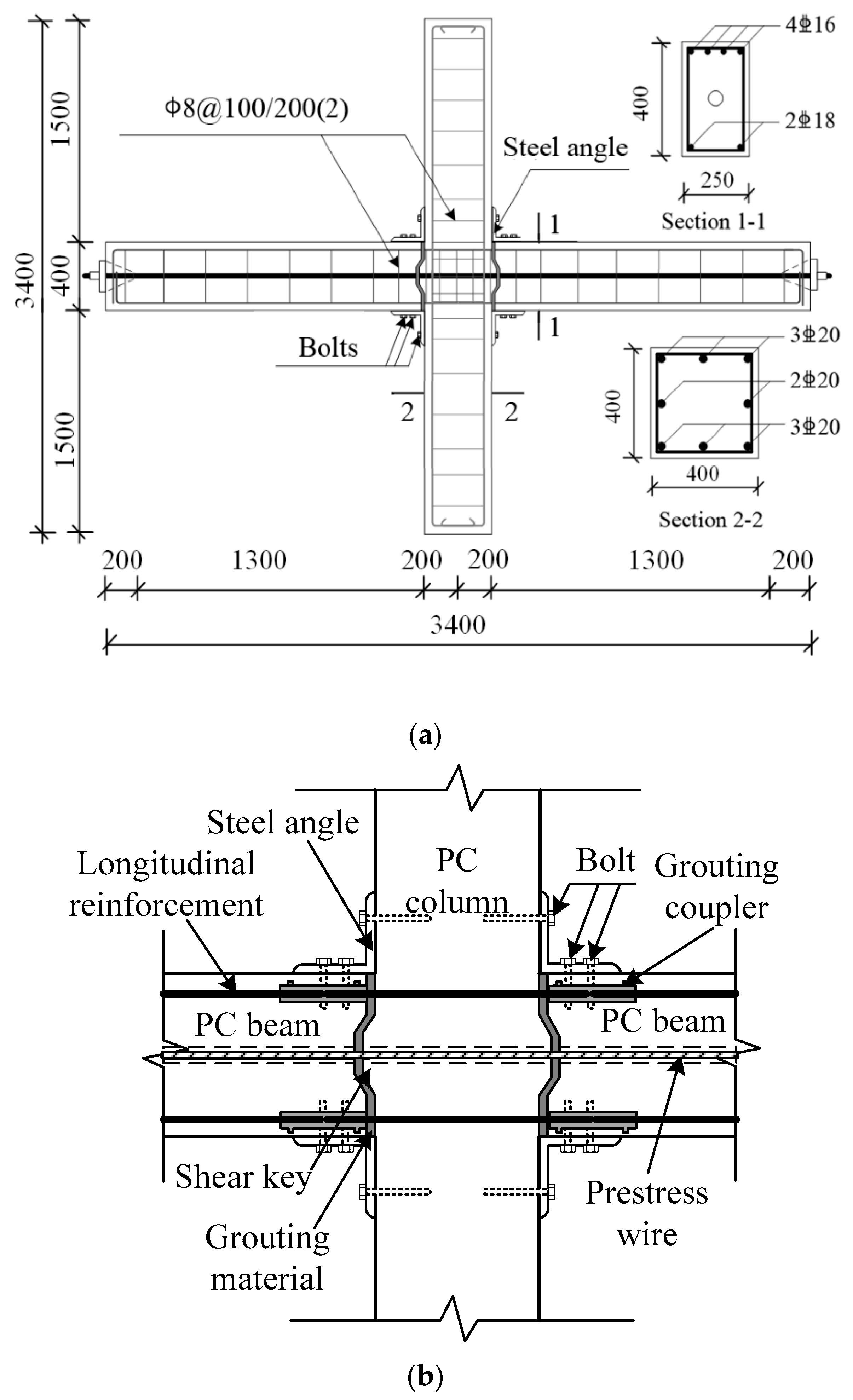

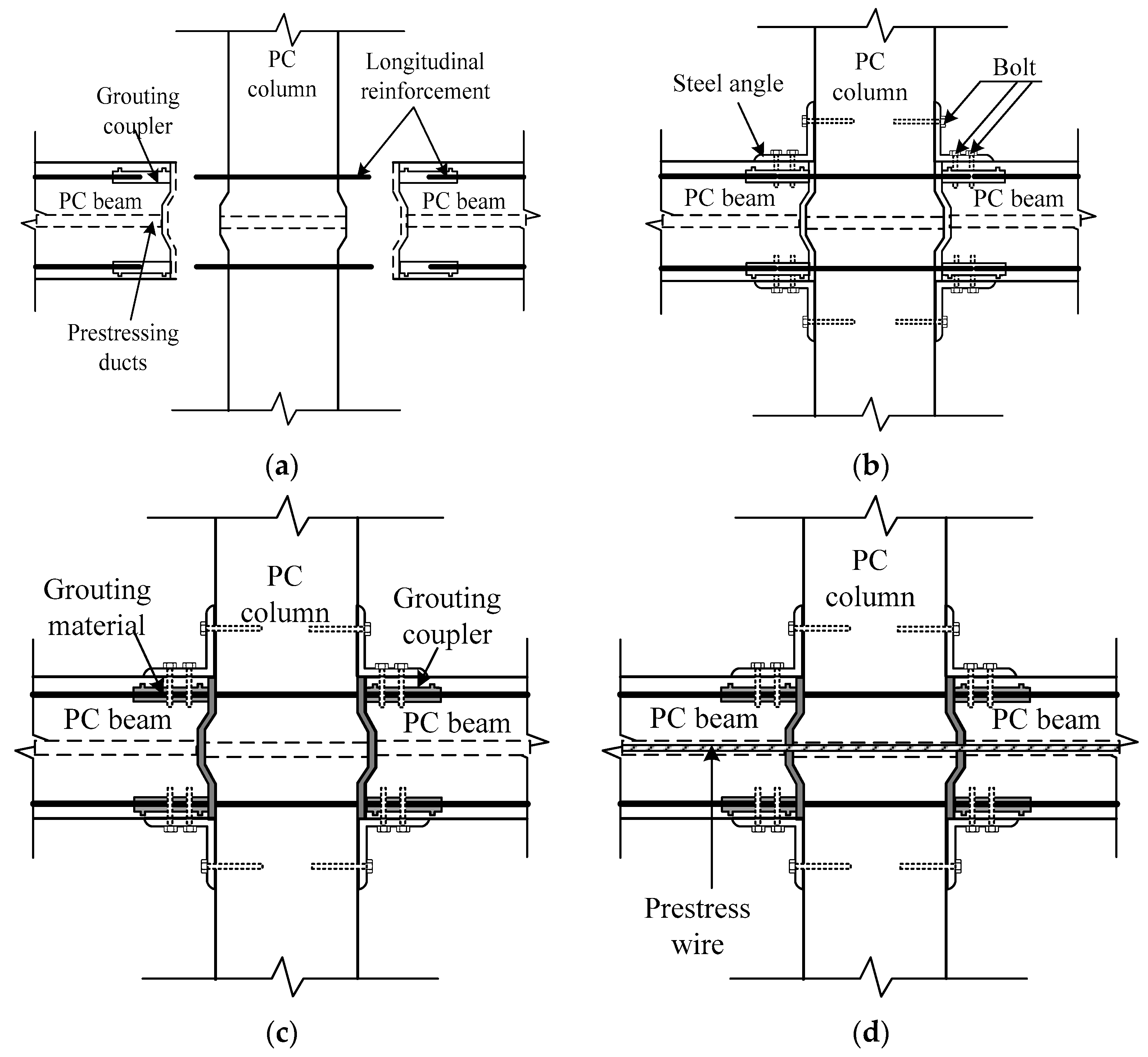

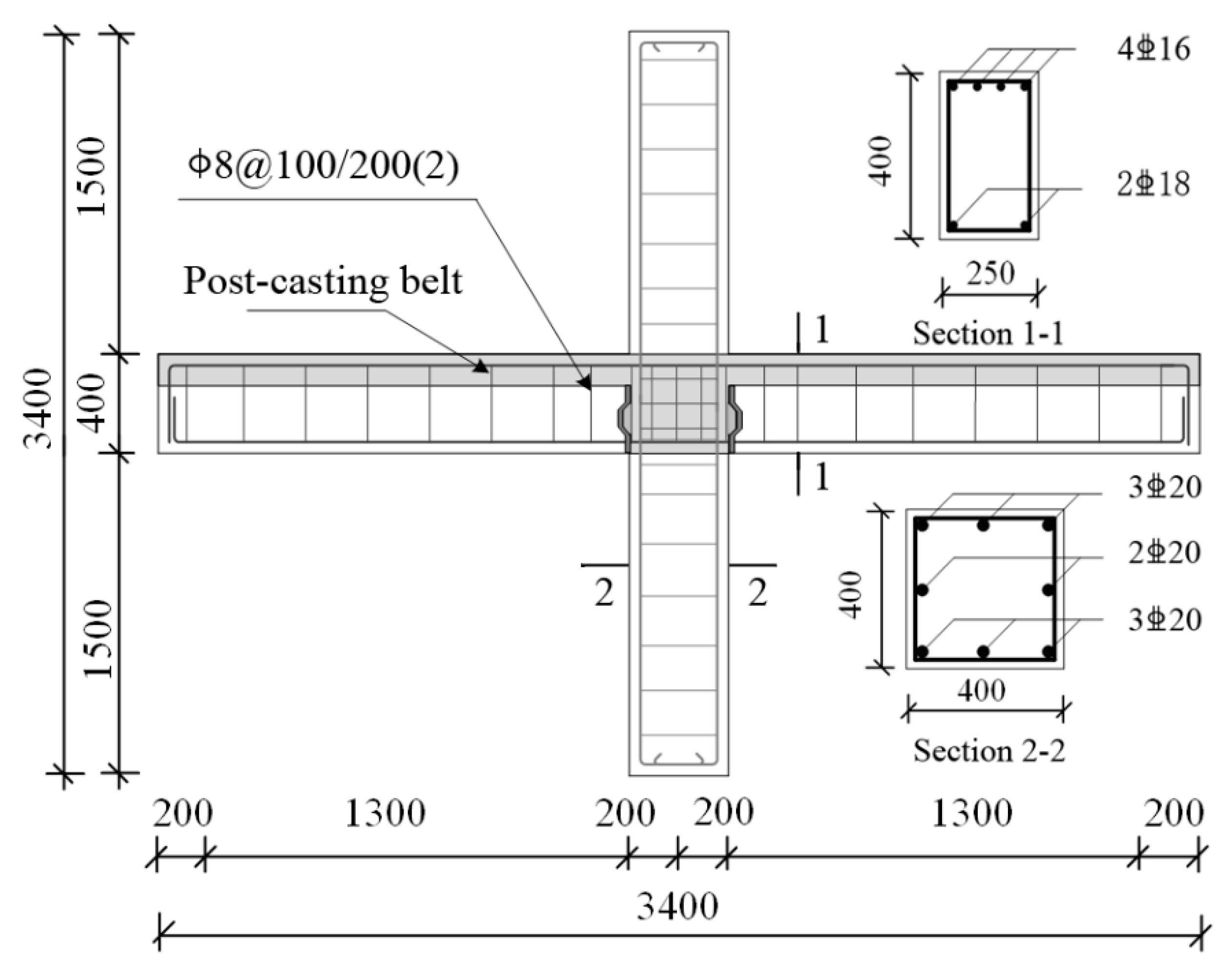

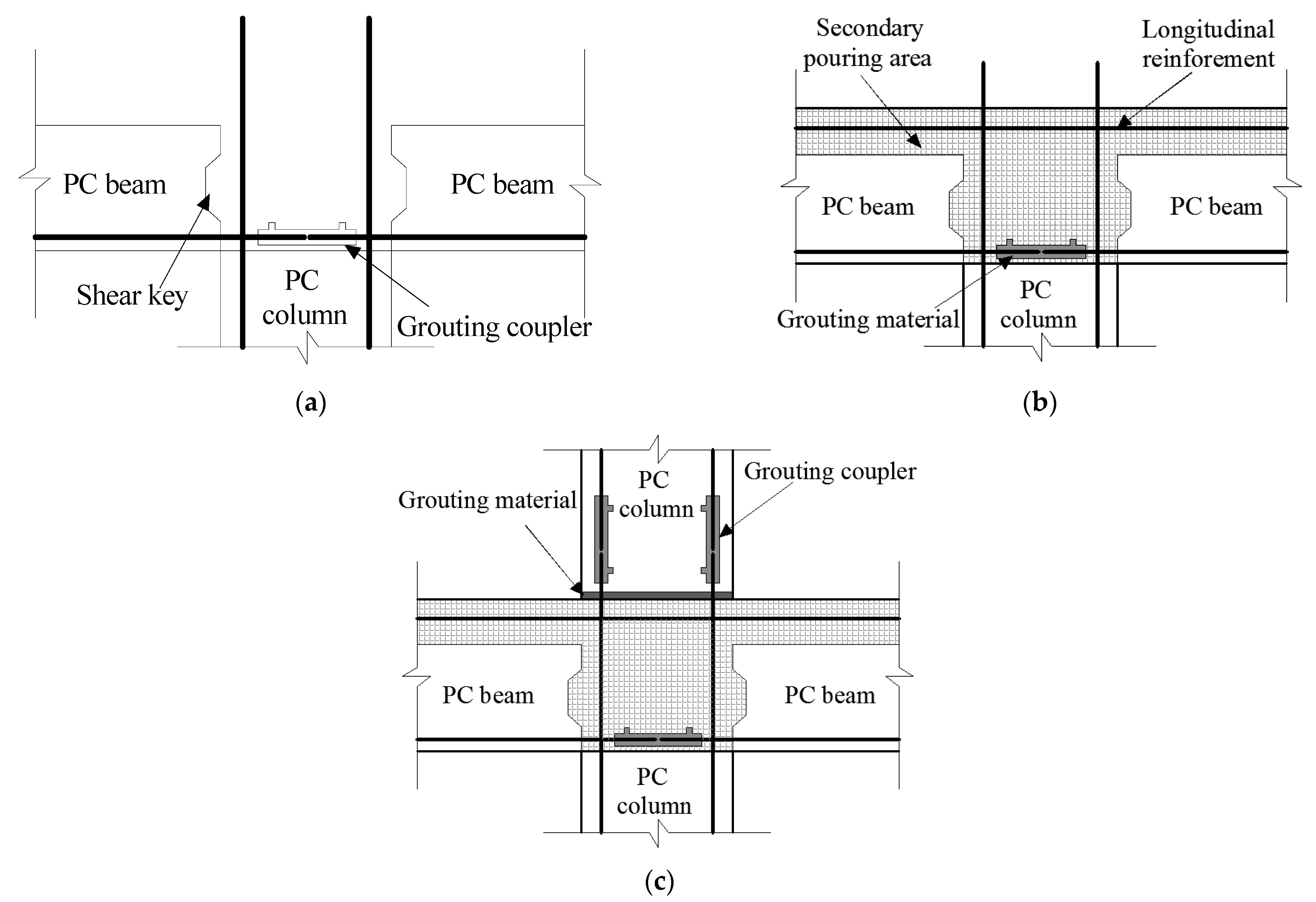

2.1. Conceptual Design of Hybrid Connection

2.2. Material Properties

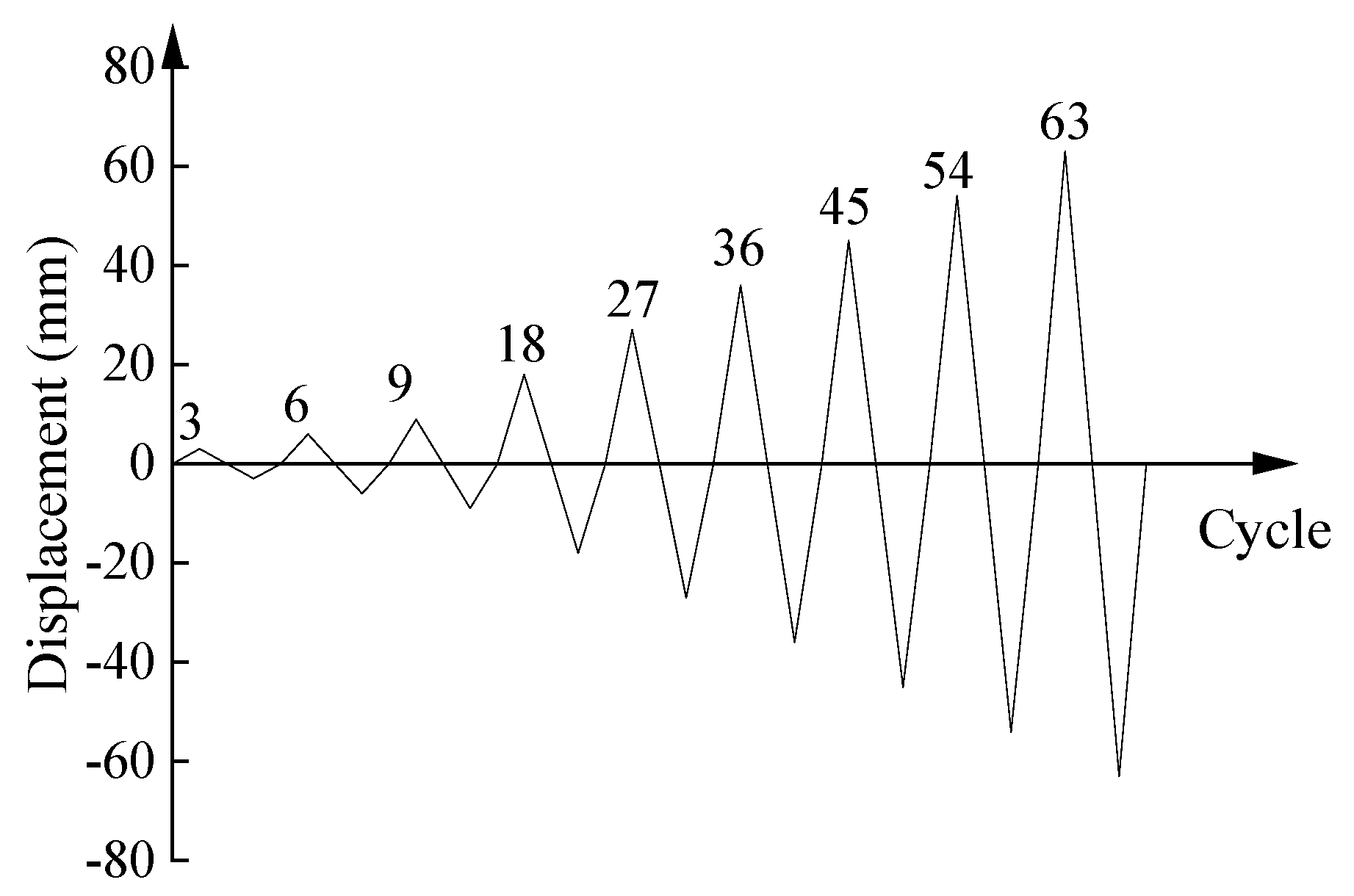

2.3. Test Setup and Loading Program

3. Experimental Results

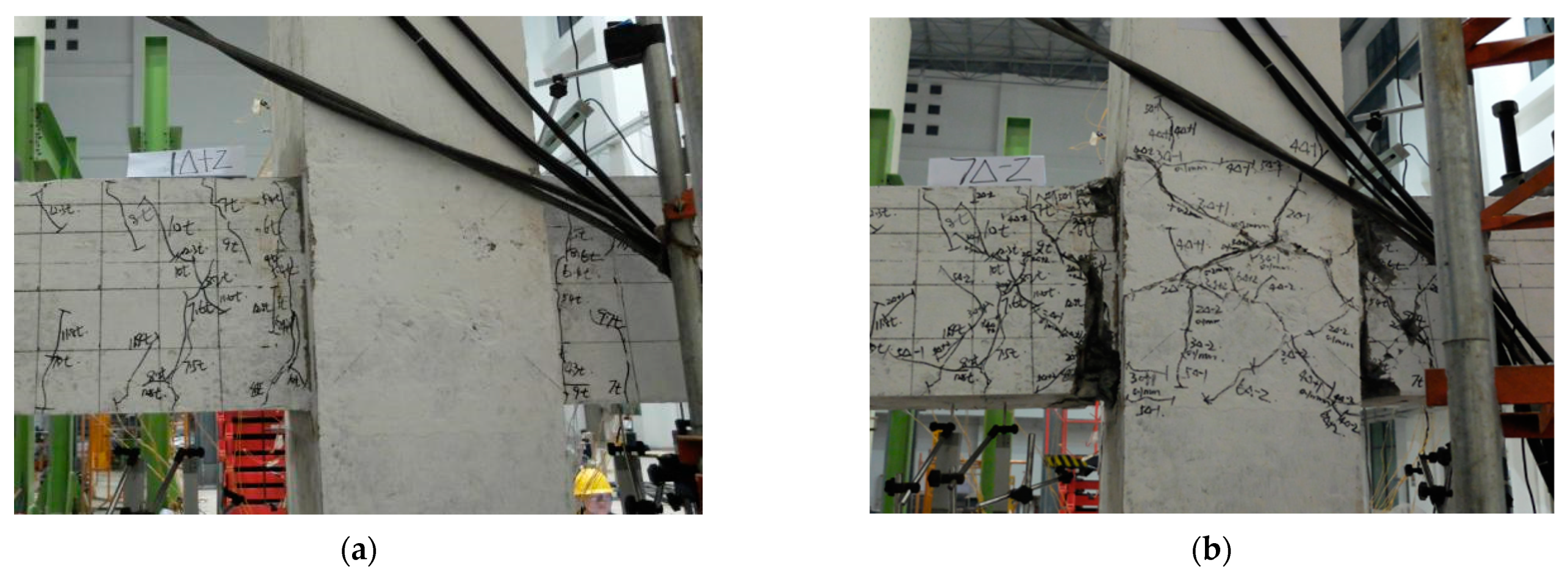

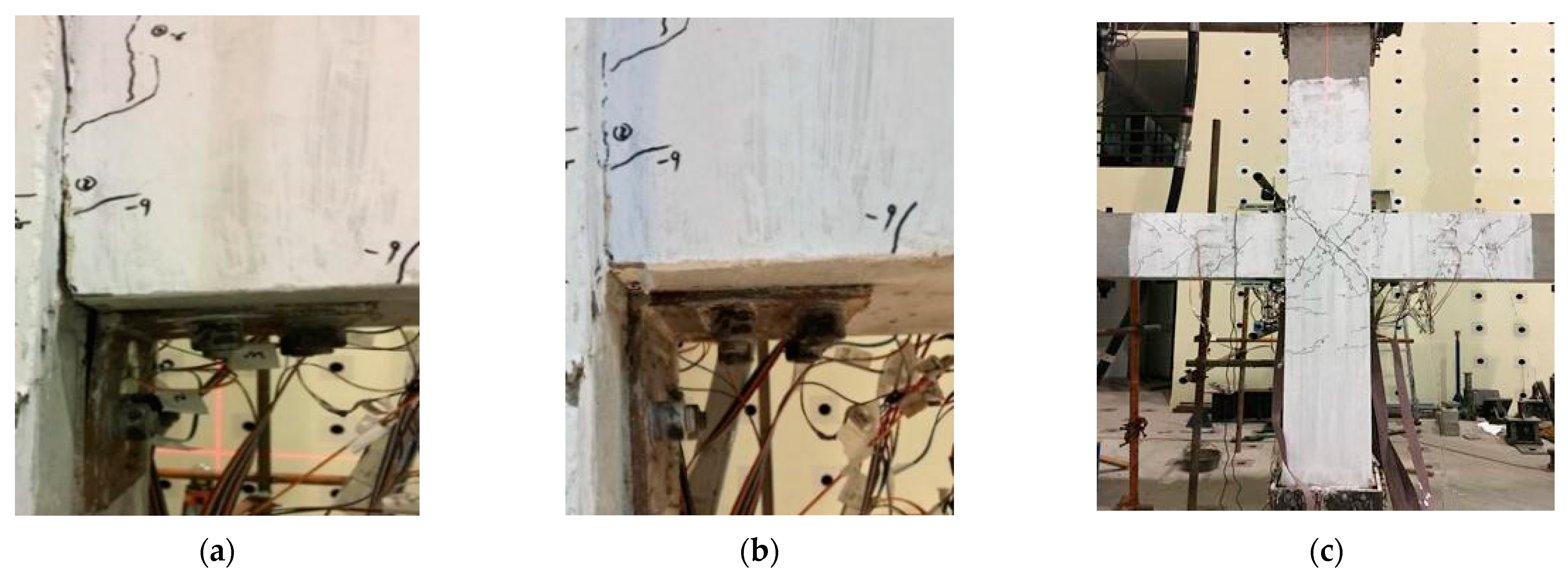

3.1. Crack Pattern and Failure Mode

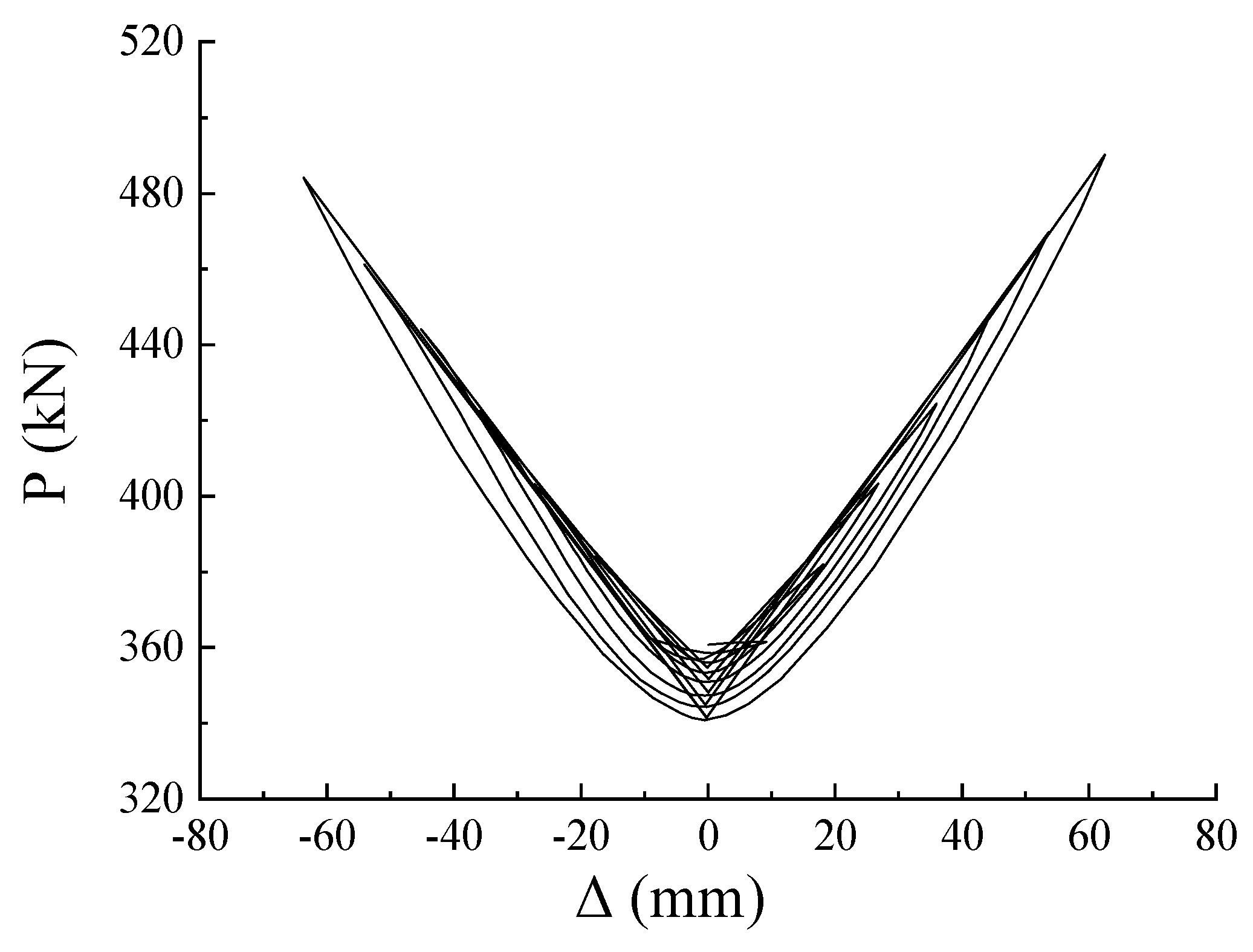

3.2. Hysteresis Curve

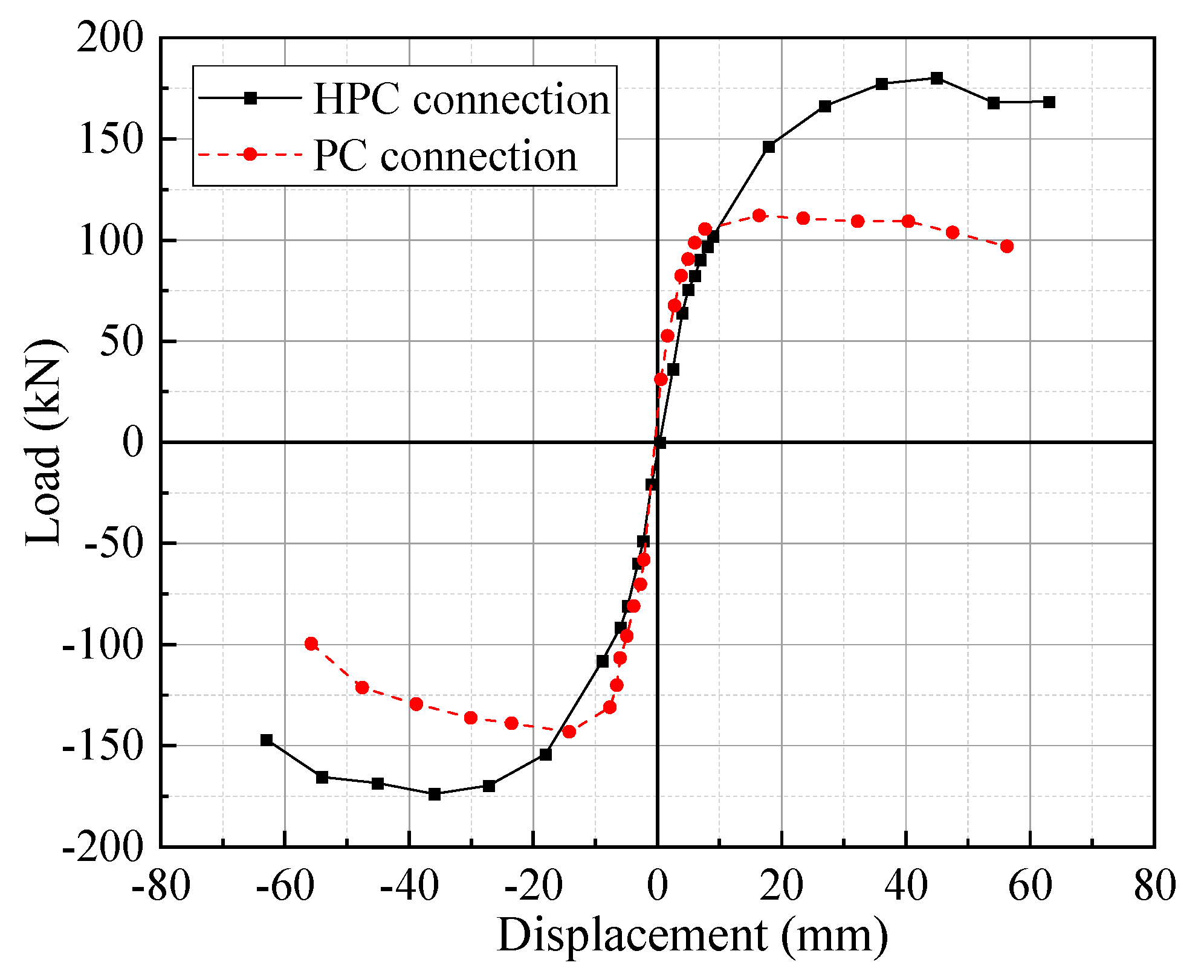

3.3. Envelope Curve

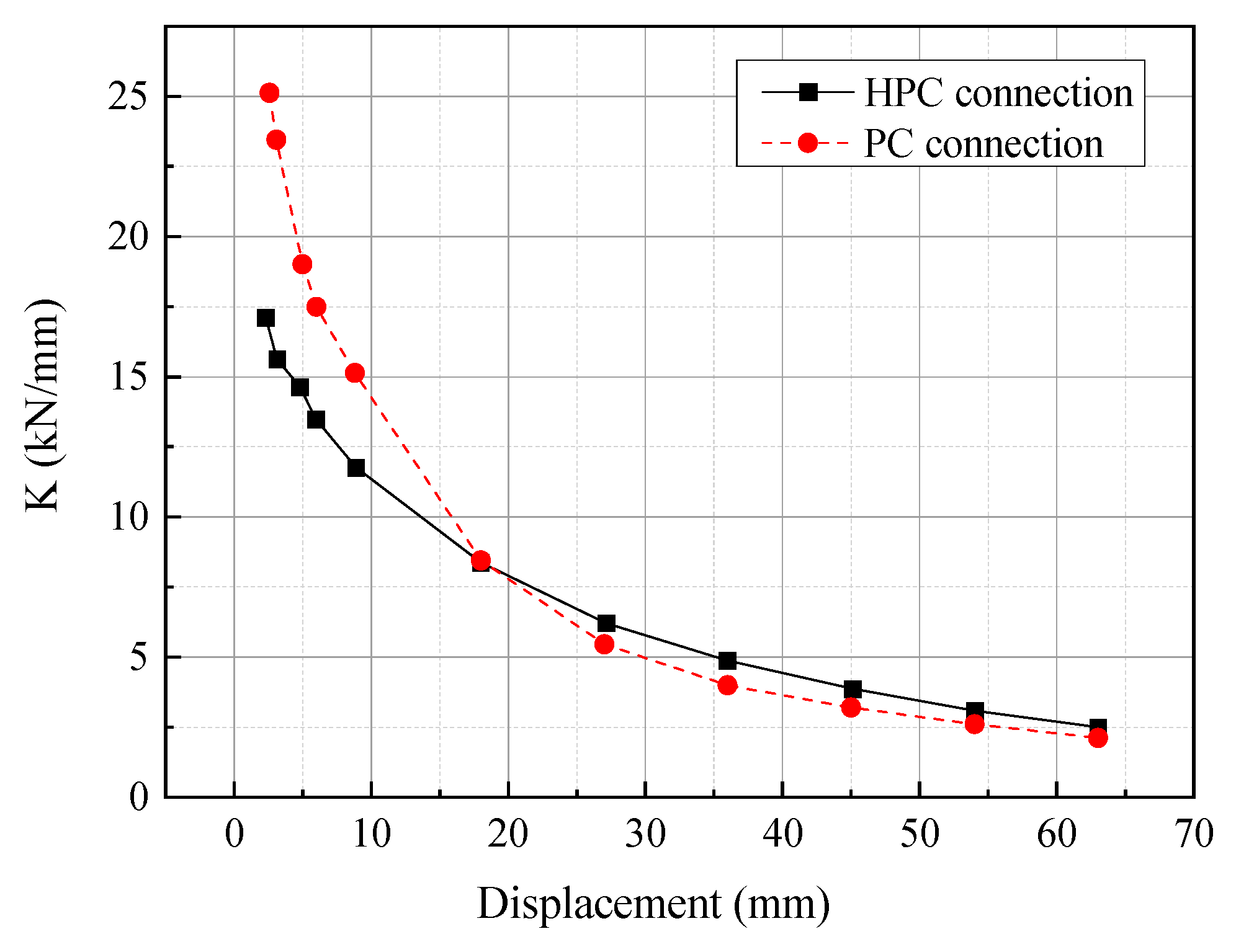

3.4. Ductility and Stiffness Degradation

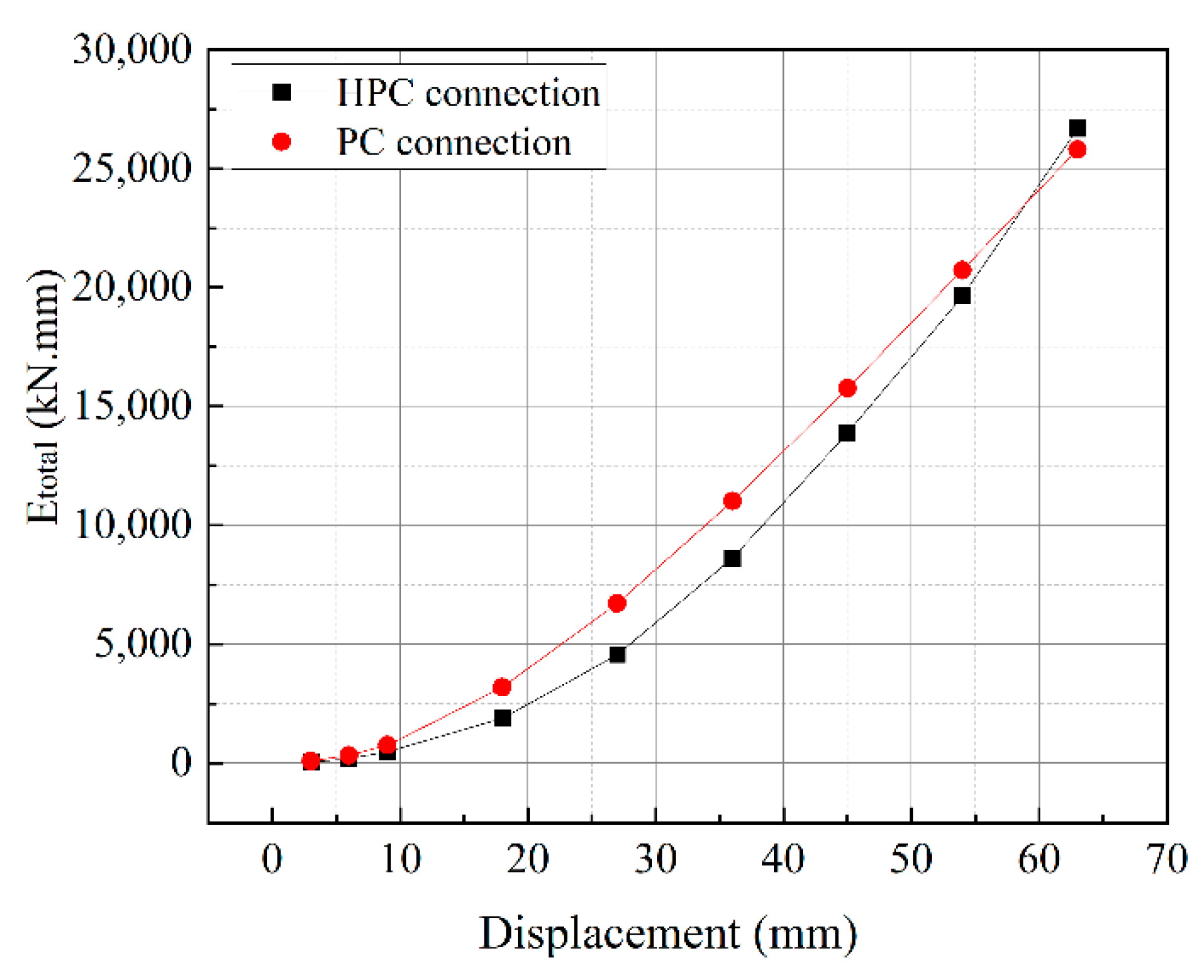

3.5. Energy Dissipation Capacity

4. Discussion

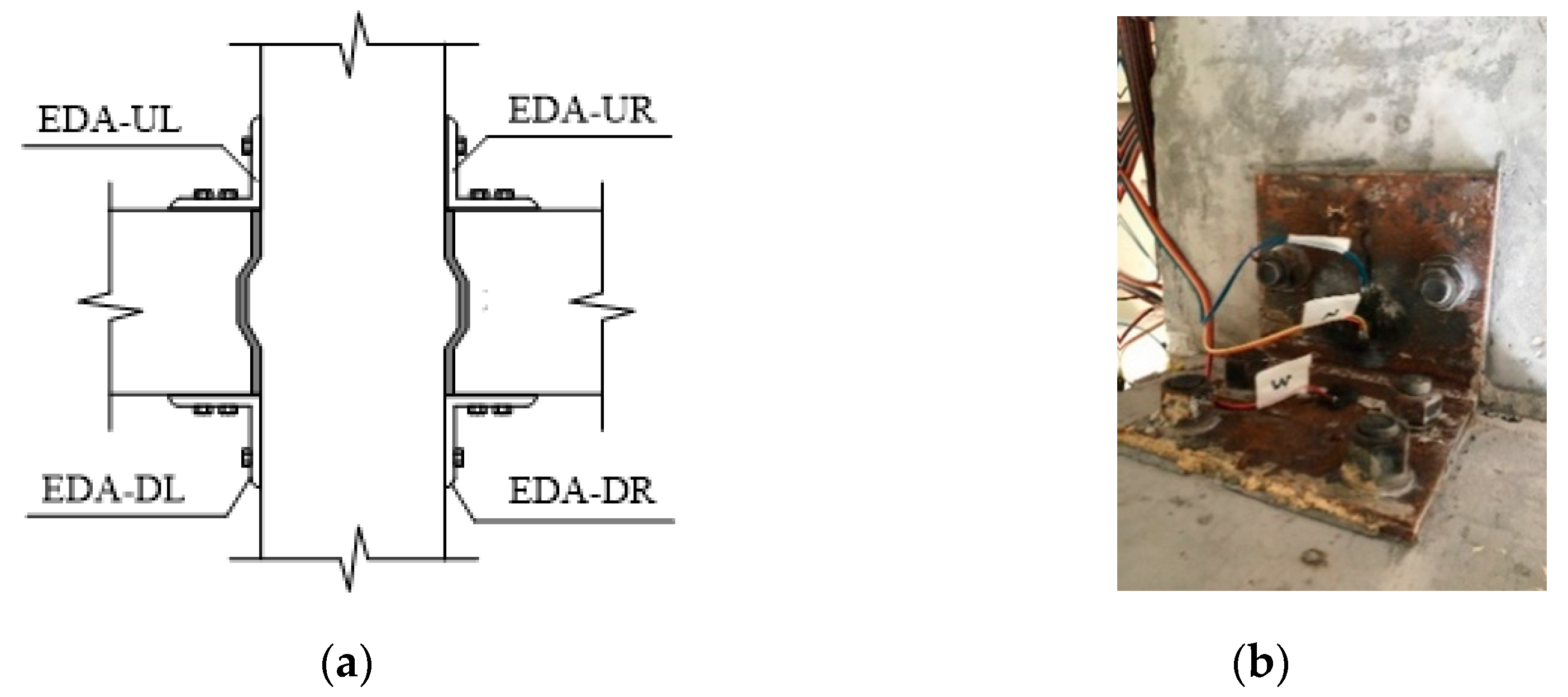

4.1. Energy Dissipation of Steel Angles

4.2. Variation in Prestressing Force

4.3. Deformation Capacity

4.4. Applied Element Method Simulation

5. Conclusions

- The proposed HPC connection exhibited lower cracking development, stiffness degradation, and residual displacement owing to prestressing strands, while the prestressing force remained elastic.

- The strength and energy dissipation capacity of the HPC connection increased rapidly, and both were larger than those of the PC connection (up to 52% and 10%, respectively) during the post-yielding stage. It was demonstrated that the steel angles played a critical role in improving the seismic performance of the connections.

- The grouting technique could efficiently realize the continuation of beam reinforcement with the minimum of cast in situ work. Thus, the proposed HPC connection has great potential for deployment in seismic regions, demonstrating excellent seismic performance and efficient construction techniques.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Polat, G. Prefabricated concrete systems in developing vs. industrialized countries. Civil Eng. Manage. 2010, 16, 85–94. [Google Scholar] [CrossRef]

- Deng, E.F.; Lian, J.Y.; Liu, Z.; Zhang, G.C.; Wang, S.B.; Cao, D.B. Compressive behavior of a fully prefabricated liftable connection for modular steel construction. Buildings 2022, 12, 649. [Google Scholar] [CrossRef]

- Yan, X.Y.; Wang, S.G.; Huang, C.Y.; Hong, C. Experimental study of a new precast prestressed concrete joint. Appl. Sci. 2018, 10, 1871. [Google Scholar] [CrossRef]

- Lacey, A.W.; Chen, W.; Hao, H.; Bi, K. Review of bolted inter-module connections in modular steel buildings. J. Build. Eng. 2019, 23, 207–219. [Google Scholar] [CrossRef]

- Nadeem, G.; Safiee, N.A.; Bakar, N.A.; Karim, I.A.; Nasir, N.A.M. Connection design in modular steel construction: A review. Structures 2021, 33, 3239–3256. [Google Scholar] [CrossRef]

- Campbell, R.D.; Griffin, M.J.; Bragagnolo, L.J.; Yanev, P.I. The 7 December 1988 Armenia Earthquake Effects on Selected Power, Industrial and Commercial Facilities; IAEA: Vienna, Austria, 1996. [Google Scholar]

- Marzo, A.; Marghella, G.; Indirli, M. The Emilia-Romagna earthquake: Damages to precast/prestressed reinforced concrete factories. Ing. Sismica 2012, 29, 132–147. [Google Scholar]

- Negro, P.; Bournas, D.A.; Molina, F.J. Pseudodynamic tests on a full-scale 3-storey prefabricated concrete building: Global response. Eng. Struct. 2013, 57, 594–608. [Google Scholar] [CrossRef]

- Mohammed, K.; Jameel, M.; Ibrahim, Z.; Tan, C.G. Performance of a ductile hybrid post-tensioned beam-to-column connection for precast concrete frames under seismic loads: A review. Appl. Sci. 2021, 11, 7497. [Google Scholar] [CrossRef]

- Rodríguez, M.E.; Torres-Matos, M. Seismic behavior of a type of welded prefabricated concrete beam-column connection. PCI J. 2013, 358, 81–94. [Google Scholar] [CrossRef]

- Deng, K.L.; Peng, P.; Lam, A.; Pan, Z.H.; Ye, L.P. Test and simulation of full-scale self-centering beam-to-column connection. Earthq. Eng. Eng. Vib. 2013, 4, 98–106. [Google Scholar] [CrossRef]

- Lago, B.D.; Negro, P.; Lago, A.D. Seismic design and performance of dry-assembled precast structures with adaptable joints. Soil Dyn. Earthq. Eng. 2018, 106, 182–195. [Google Scholar] [CrossRef]

- Guerrero, H.; Rodriguez, V.; Escobar, J.A.; Alcocer, S.M.; Bennetts, F.; Suarez, M. Experimental tests of precast reinforced concrete beam-column connections. Soil Dyn. Earthq. Eng. 2019, 125, 105743. [Google Scholar] [CrossRef]

- Ding, K.; Ye, Y.; Ma, W. Seismic performance of prefabricated concrete beam-column joint based on the bolt connection. Eng. Struct. 2021, 232, 111884. [Google Scholar] [CrossRef]

- Li, B.; Kulkarni, S.A.; Leong, C.L. Seismic performance of precast hybrid-steel concrete connections. J. Earthq. Eng. 2009, 13, 667–689. [Google Scholar] [CrossRef]

- Cavaco, E.; Pacheco, I.; Camara, J. Detailing of concrete-to-concrete interfaces for improved ductility. Eng. Struct. 2018, 156, 210–223. [Google Scholar] [CrossRef]

- Choi, H.K.; Choi, Y.C.; Choi, C.S. Development and testing of precast concrete beam-to-column connections. Eng. Struct. 2013, 56, 1820–1835. [Google Scholar] [CrossRef]

- Parastesh, H.; Hajirasouliha, I.; Ramezani, R. A new ductile moment-resisting connection for precast concrete frames in seismic regions: An experimental investigation. Eng. Struct. 2014, 70, 144–157. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Q.; Feng, J.; Zhang, Z. Experimental study on shear resistance of precast RC shear walls with novel bundled connections. J. Earthq. Tsunami 2019, 13, 1940002. [Google Scholar] [CrossRef]

- Ma, W.C. Behavior of Aged Reinforced Concrete Columns under High Sustained Concentric and Eccentric Loads; University of Nevada: Las Vegas, NV, USA, 2021. [Google Scholar]

- Ma, W.C. Simulate Initiation and Formation of Cracks and Potholes; Northeastern University: Boston, MA, USA, 2016. [Google Scholar]

- Esmaeili, J.; Ahooghalandary, N. Introducing an easy-install prefabricated concrete beam-to-column connection strengthened by steel box and peripheral plates. Eng. Struct. 2020, 205, 110006. [Google Scholar] [CrossRef]

- Dhanapal, J.; Ghaednia, H.; Das, S.; Velocci, J. Structural performance of state-of-the-art VectorBloc modular connector under axial loads. Eng. Struct. 2019, 183, 496–509. [Google Scholar] [CrossRef]

- Lima, J.M.; Bezerra, L.M.; Bonilla, J.; Barbosa, W.C.S. Study of the behavior and resistance of right-angle truss shear connector for composite steel concrete beams. Eng. Struct. 2022, 253, 113778. [Google Scholar] [CrossRef]

- Senturk, M.; Pul, S.; Ilki, A.; Hajirasouliha, I. Development of a monolithic-like prefabricated beam-column moment connection: Experimental and analytical investigation. Eng. Struct. 2020, 205, 110057. [Google Scholar] [CrossRef]

- Moghadasi, M.; Marsono, A.K.; Mohammadyan-Yasouj, S.E. A study on rotational behaviour of a new industrialised building system connection. Steel Compos. Struct. 2017, 25, 245–255. [Google Scholar]

- Song, B.X.; Xu, W.Z.; Du, D.S.; Wang, S.G.; Li, W.W.; Zhang, Y.L. Seismic design of hybrid unbonded post-tensioned prefabricated concrete joints based on bearing capacity and energy dissipation capacity. Adv. Struct. Eng. 2021, 24, 1724–1738. [Google Scholar] [CrossRef]

- Wang, J.H. Cyclic behaviors of reinforced concrete beam-column joints with debonded reinforcements and beam failure: Experiment and analysis. Bull. Earthq. Eng. 2021, 19, 101–133. [Google Scholar] [CrossRef]

- Huang, L.J.; Zhou, Z.; Huang, X.G.; Wang, Y.W. Variable friction damped self-centering precast concrete beam-column connections with hidden corbels: Experimental investigation and theoretical analysis. Eng. Struct. 2020, 206, 110150. [Google Scholar] [CrossRef]

- Huang, W.; Hu, G.; Miao, X.; Fan, Z. Seismic performance analysis of a novel demountable precast concrete beam-column connection with multi-slit devices. J. Build. Eng. 2021, 44, 102663. [Google Scholar] [CrossRef]

- Li, Y.; Geng, F.; Ding, Y.; Wang, L. Influence of mild steel damper design parameters on energy dissipation performance of low-damage self-centering precast concrete frame connections. Soil Dyn. Earthq. Eng. 2021, 144, 106696. [Google Scholar] [CrossRef]

- Gioiella, L.; Tubaldi, E.; Gara, F.; Dezi, L.; Dall’Asta, A. Modal properties and seismic behaviour of buildings equipped with external dissipative pinned rocking braced frames. Eng. Struct. 2018, 172, 807–819. [Google Scholar] [CrossRef]

- Zhou, X.; Ke, K.; Yam, M.C.; Zhao, Q.; Huang, Y.; Di, J. Shape memory alloy plates: Cyclic tension-release performance, seismic applications in beam-to-column connections and a structural seismic demand perspective. Thin-Walled Struct. 2021, 167, 108158. [Google Scholar] [CrossRef]

- Wang, W.; Chan, T.M.; Shao, H.L. Seismic performance of beam-column joints with SMA tendons strengthened by steel angles. J. Constr. Steel Res. 2015, 109, 61–71. [Google Scholar] [CrossRef]

- Jiang, R.; Su, X. Comparative study on empirical plastic hinge length formulas. Ind. Construct. 2008, 38, 425–430. [Google Scholar]

- Eom, T.S.; Cho, S.R.; Lim, J.J. Behavior of end plate connection for steel angles. Eng. Struct. 2022, 252, 113714. [Google Scholar] [CrossRef]

- Hwang, J.H.; Choi, S.H.; Lee, D.H.; Kim, K.S.; Kwon, O.S. Seismic behavior of post-tensioned precast concrete beam-column connections. Mag. Concrete Res. 2021, 73, 433–447. [Google Scholar] [CrossRef]

- Xin, G.T.; Xu, W.B.; Wang, J.; Yan, X.Y.; Chen, Y.J.; Yan, W.M.; Li, J.G. Seismic performance of fabricated concrete piers with grouted sleeve joints and bearing-capacity estimation method. Structures 2021, 33, 169–186. [Google Scholar] [CrossRef]

- Kwan, W.P.; Billington, S.L. Unbonded posttensioned concrete bridge piers. I: Monotonic and cyclic analyses. J. Bridge Eng. 2003, 8, 92–101. [Google Scholar] [CrossRef]

- Kwan, W.P.; Billington, S.L. Unbonded posttensioned concrete bridge piers. II: Seismic analyses. J. Bridge Eng. 2003, 8, 102–111. [Google Scholar] [CrossRef]

- Meguro, K.; Tagel-Din, H. Applied element method for structural analysis: Theory and application for linear mateirals. J. Struct. Eng. 2000, 17, 21–35. [Google Scholar] [CrossRef]

- Sediek, O.A.; El-Tawil, S.; McCormick, J. Seismic Debris Field for Collapsed RC Moment Resisting Frame Buildings. J. Struct. Eng. 2021, 147, 04021045. [Google Scholar] [CrossRef]

- Fathalla, E.; Salem, H. Parametric Study on Seismic Rehabilitation of Masonry Buildings Using FRP Based upon 3D Non-Linear Dynamic Analysis. Buildings 2018, 8, 124. [Google Scholar] [CrossRef]

| Diameter (mm) | 8 | 18 | 20 | Φ s 15.2 |

|---|---|---|---|---|

| Area (mm2) | 50.2 | 254.3 | 314 | 139 |

| Yield strength (MPa) | 310 | 402 | 403 | 1720 |

| Ultimate strength (MPa) | 404 | 540 | 530 | 1912 |

| Elastic modulus (MPa) | 2.01 × 105 | 2.11 × 105 | 1.99 × 105 | 1.95 × 105 |

| Specimen | Load Cycle Direction | Δy | Δu | μ | |

|---|---|---|---|---|---|

| HPC connection | + | 8.5 | 56.2 | 6.61 | 6.20 |

| − | −9.5 | −55.1 | 5.80 | ||

| PC connection | + | 5.8 | 33.7 | 5.81 | 5.02 |

| − | −6.7 | −28.5 | 4.23 |

| Δ (mm) | EDA-U (kN·mm) | E0 (kN·mm) | PP (%) | ||

|---|---|---|---|---|---|

| +Δ | −Δ | Total | |||

| 3 | 1.18 | 0.95 | 2.13 | 37.63 | 5.7 |

| 6 | 9.12 | 8.87 | 17.99 | 142.48 | 12.6 |

| 9 | 28.66 | 26.53 | 55.19 | 294.63 | 18.7 |

| 18 | 181.15 | 179.89 | 361.04 | 1411.11 | 25.6 |

| 27 | 333.58 | 278.88 | 612.46 | 2679.8 | 22.9 |

| 36 | 985.95 | 927.31 | 1913.26 | 4052.54 | 47.2 |

| 45 | 1626.52 | 1889.08 | 3515.60 | 5263.25 | 66.8 |

| 54 | 2362.64 | 2451.58 | 4814.22 | 5766.37 | 83.5 |

| 63 | 2831.15 | 3104.83 | 5935.98 | 7047.28 | 84.2 |

| Δ (mm) | Δrd (mm) | Δmax (mm) | θrd (%) | θmax (%) | Δrd/Δmax | θrd/θmax |

|---|---|---|---|---|---|---|

| 3 | 0.5 | 3.2 | 0.04 | 0.53 | 0.16 | 0.083 |

| 6 | 1.1 | 6.3 | 0.10 | 1. 07 | 0.17 | 0.097 |

| 9 | 1.8 | 9.5 | 0.17 | 1.60 | 0.18 | 0.106 |

| 18 | 3.3 | 17.9 | 0.31 | 2.13 | 0.18 | 0.144 |

| 27 | 4.2 | 27.8 | 0.39 | 2.67 | 0.15 | 0.148 |

| 36 | 7.3 | 36.4 | 0.48 | 3.20 | 0.20 | 0.150 |

| 45 | 9.5 | 45.5 | 0.56 | 3.66 | 0.21 | 0.153 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, W.; Xie, Y.; Guo, X.; Li, D. Experimental Investigation of Seismic Performance of a Hybrid Beam–Column Connection in a Precast Concrete Frame. Buildings 2022, 12, 801. https://doi.org/10.3390/buildings12060801

Chen W, Xie Y, Guo X, Li D. Experimental Investigation of Seismic Performance of a Hybrid Beam–Column Connection in a Precast Concrete Frame. Buildings. 2022; 12(6):801. https://doi.org/10.3390/buildings12060801

Chicago/Turabian StyleChen, Weihong, Yujun Xie, Xiaohui Guo, and Dong Li. 2022. "Experimental Investigation of Seismic Performance of a Hybrid Beam–Column Connection in a Precast Concrete Frame" Buildings 12, no. 6: 801. https://doi.org/10.3390/buildings12060801

APA StyleChen, W., Xie, Y., Guo, X., & Li, D. (2022). Experimental Investigation of Seismic Performance of a Hybrid Beam–Column Connection in a Precast Concrete Frame. Buildings, 12(6), 801. https://doi.org/10.3390/buildings12060801