Study on New Prefabricated Reinforced Concrete Structure Technology Based on Fault-Tolerant Design

Abstract

:1. Introduction

2. Introduction of FTPC Structure

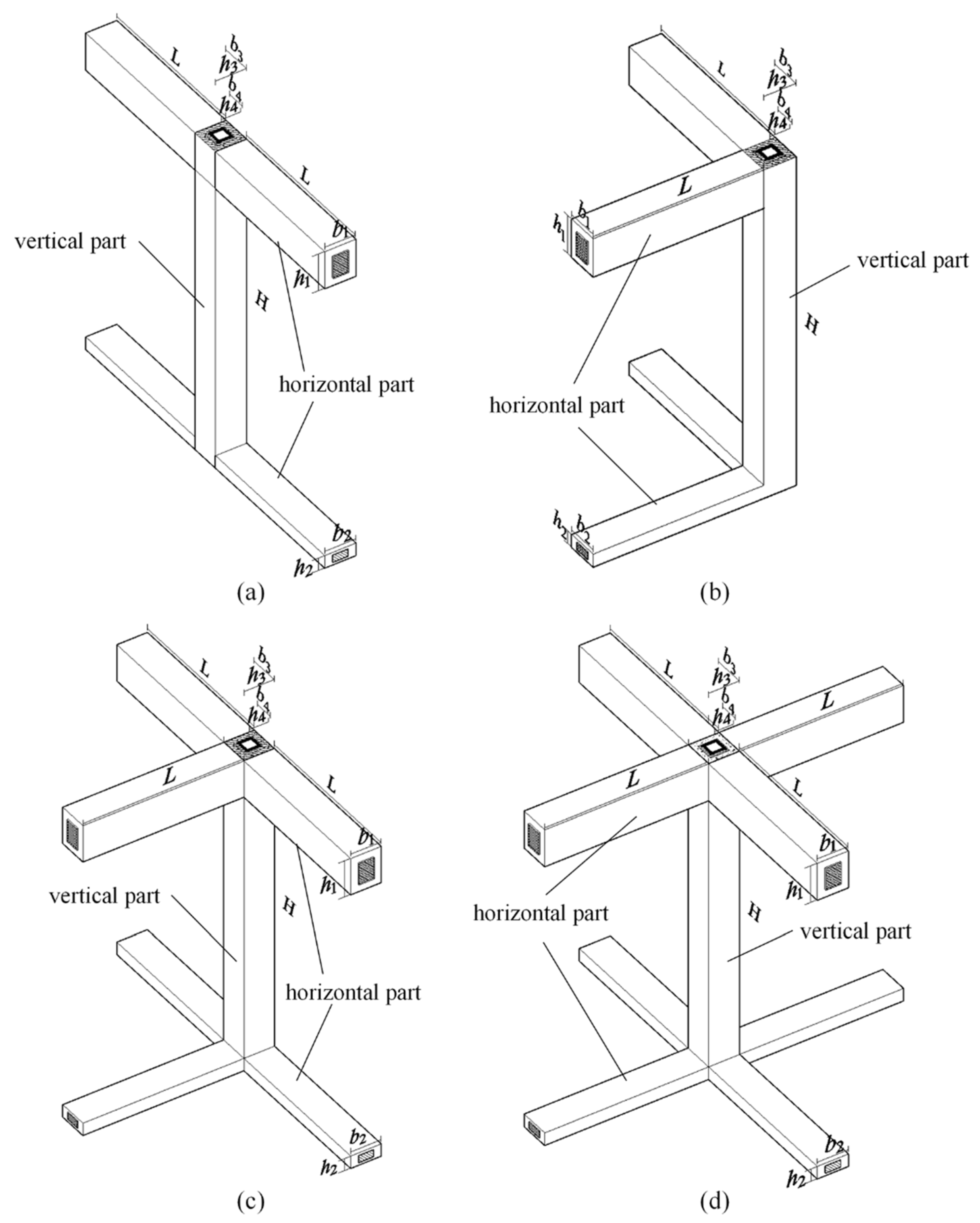

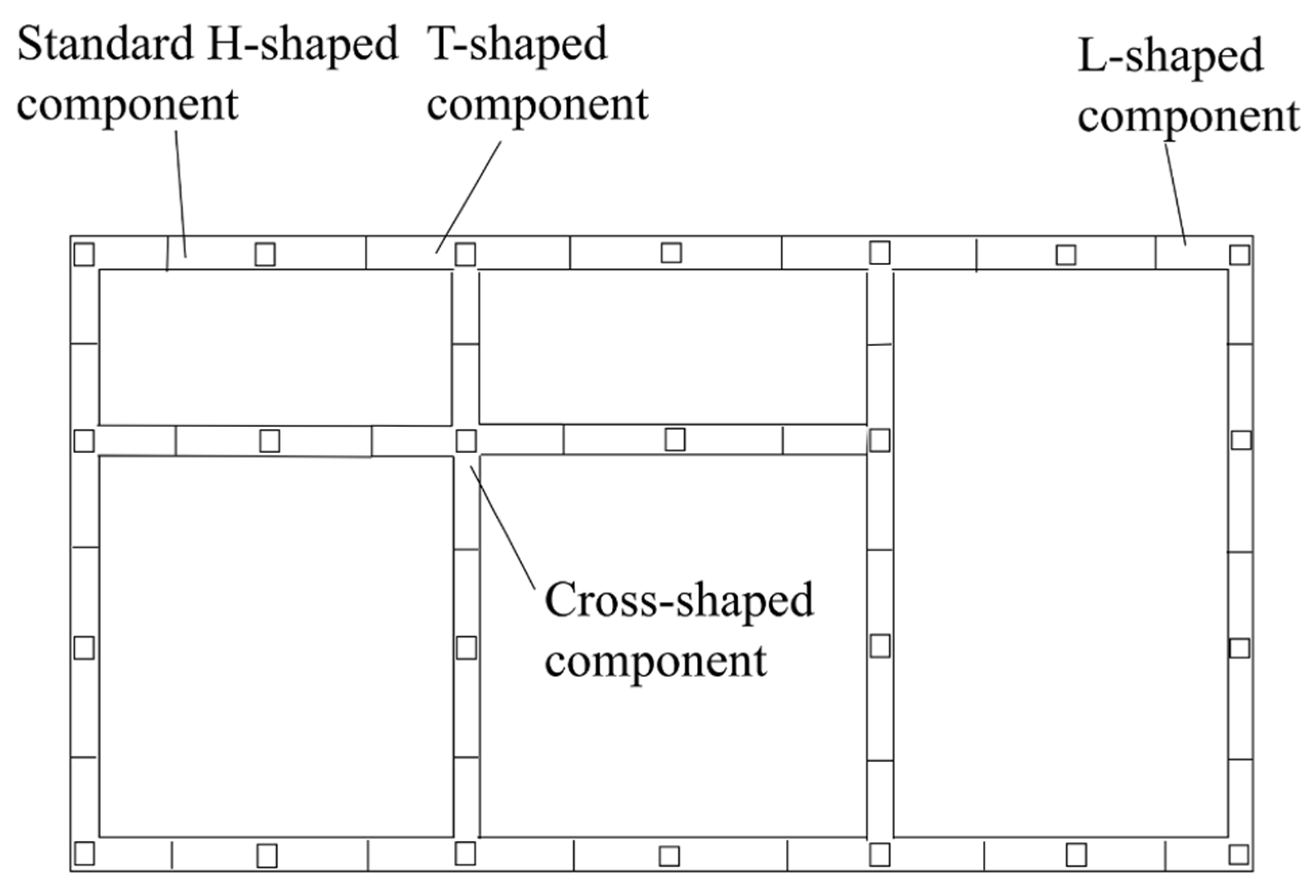

2.1. Division and Connection Mode of Basic Components

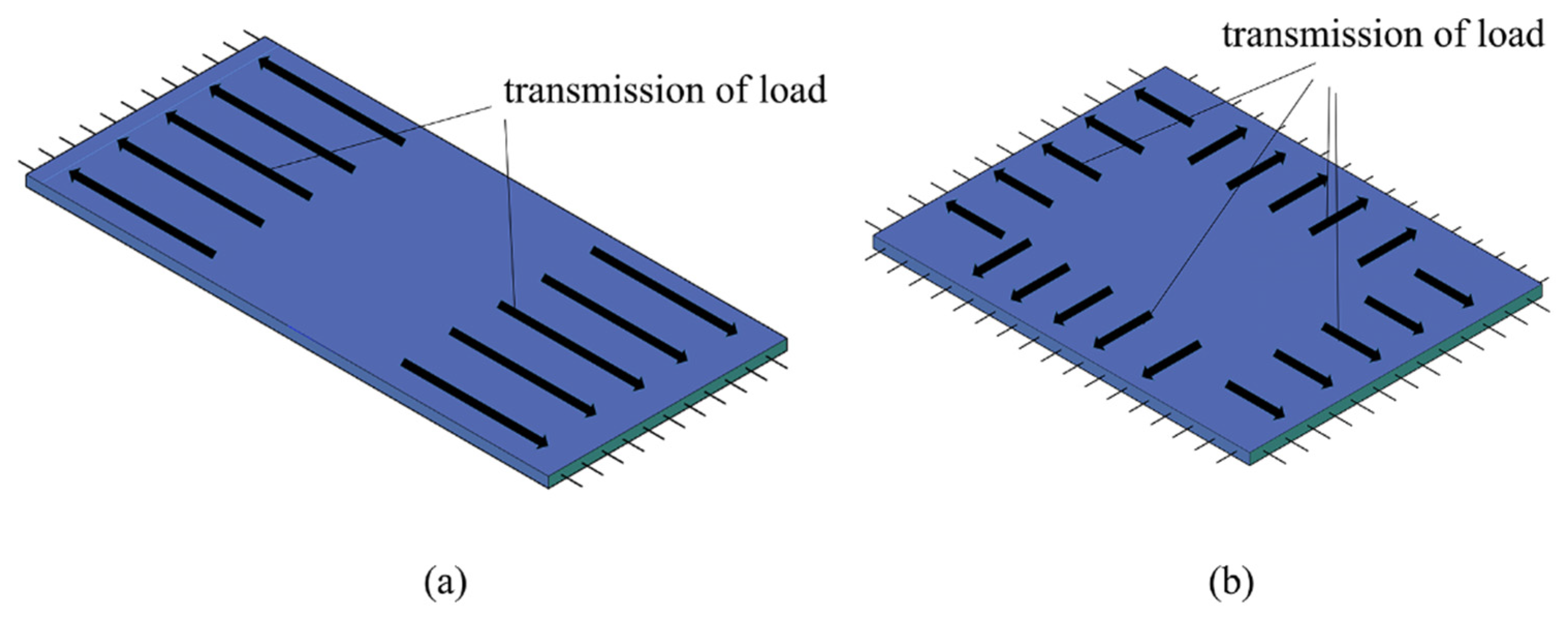

2.2. Features of FTPC Structure

- (1)

- The primary load-bearing components in this new form of prefabricated concrete structure are characterized by off-site prefabrication, which leads to excellent quality, high efficiency, and minimal pollution. Through the division and combination of four types of basic prefabricated cantilever components, it realizes the standardization of components while meeting the diverse demands of building types.

- (2)

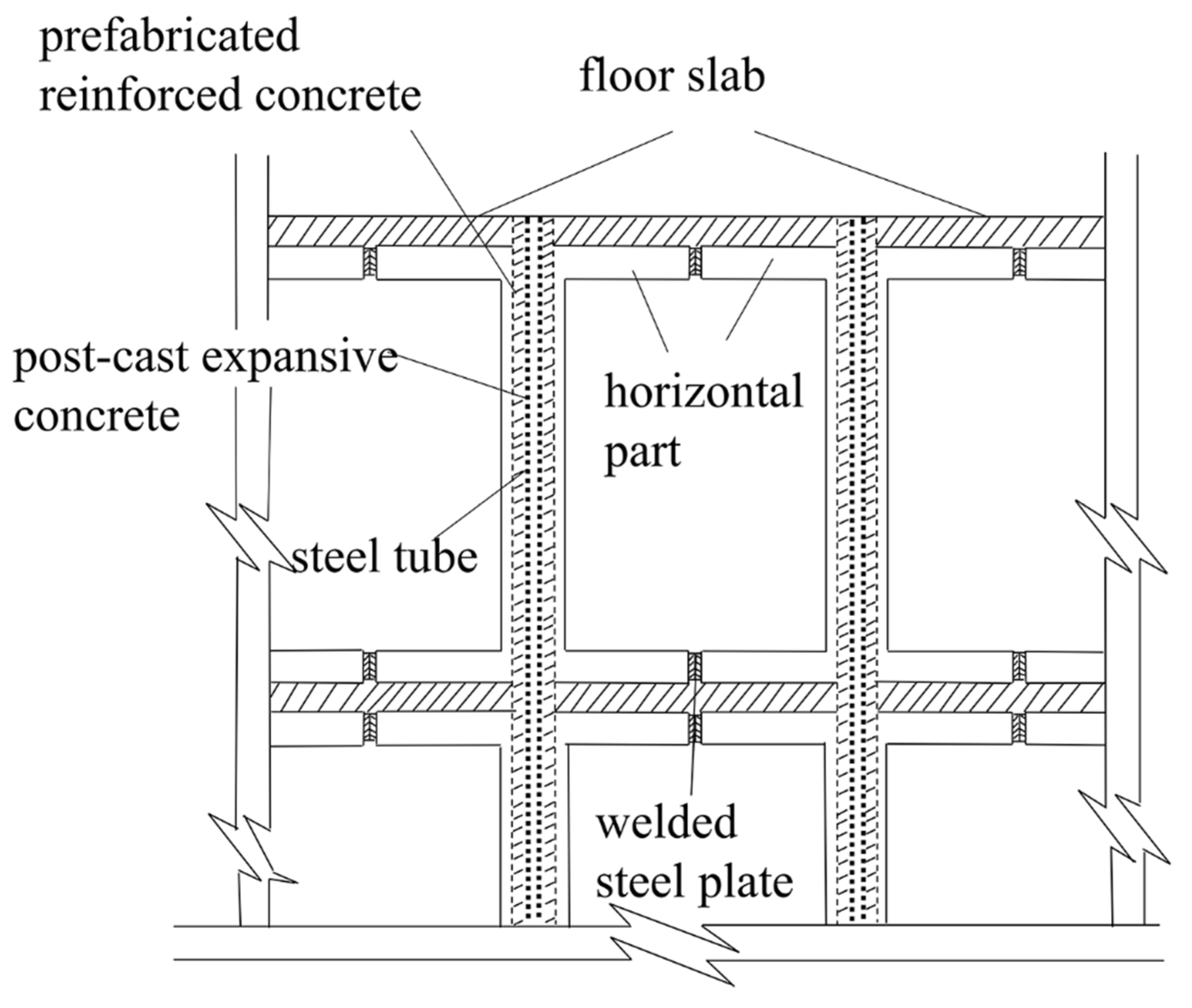

- The force transmission mechanism of an FTPC structure is clear, which provides convenience for design. The prefabricated cantilever components have a simple connection mode, which can facilitate construction. The workload of wet work is quite small, and the pouring of post-cast concrete does not require formwork. Each prefabricated component has a moderate volume, which leads to convenience for transportation and installation.

- (3)

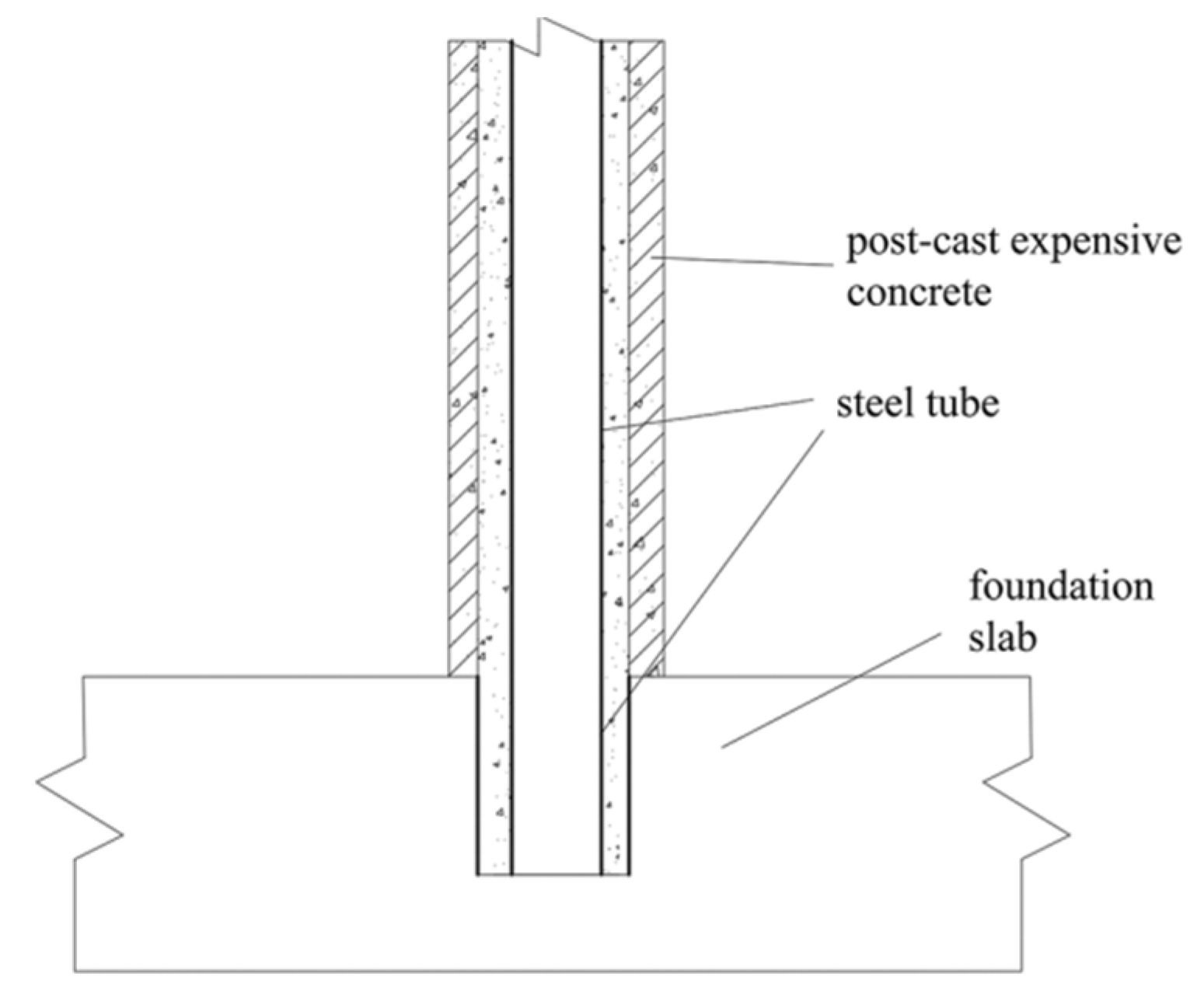

- Each prefabricated cantilever component is fixed by hollow steel tube and post-cast expansive concrete. Therefore, even if each prefabricated cantilever component is disconnected from an adjacent component on the same floor, which means that the welding of steel plates embedded at the outer end of the horizontal part is invalid, an FTPC structure will not become a mechanism, but rather is under a statically determinate state similar to a large tree with multiple layers of branches. The vertical part of the prefabricated cantilever component can be seen as the trunk, and the horizontal part can be seen as the branch. As a result, an FTPC structure has strong fault tolerance for on-site poor weld quality in the connection operation of the horizontal parts. Under normal circumstances, the welded joint can be regarded as a hinged joint because the tiny rotation under bending moment action is hard to avoid. If the poor weld quality makes the welded joint reach a disconnected state, an FTPC structure will not fail.

2.3. Key Design Points of an FTPC Structure

- (1)

- The location, type, and quantity of prefabricated cantilever components should be determined according to the specific situation of an actual engineering with the requirement that the number of component types should be minimized to achieve the maximum level of standardization.

- (2)

- In the initial stage of structural design, the type of floor slab and its force transmission mechanism should be determined first, and then the external size of each prefabricated cantilever component should be selected preliminarily. The type selection of reinforcement, concrete, and steel tube should then be carried out. The lightweight infill walls between the neighboring vertical parts of the prefabricated cantilever components are determined synchronously. The vertical load, wind load, and earthquake action can then be calculated according to GB 50009-2012 [27].

- (3)

- Based on the fault-tolerant characteristics of an FTPC structure, methods of random mathematics can be used to select some connection nodes of horizontal parts of adjacent prefabricated cantilever components as disconnected nodes to consider the actual poor weld quality. According to different node selection schemes, several corresponding analytical models for an FTPC structure can be established to take into account the internal force condition of the structure under different weld quality statuses. The internal force analysis results of multiple models provide a basis for further component optimization design, which can improve the robustness of the overall structure and ensure structural safety better.

- (4)

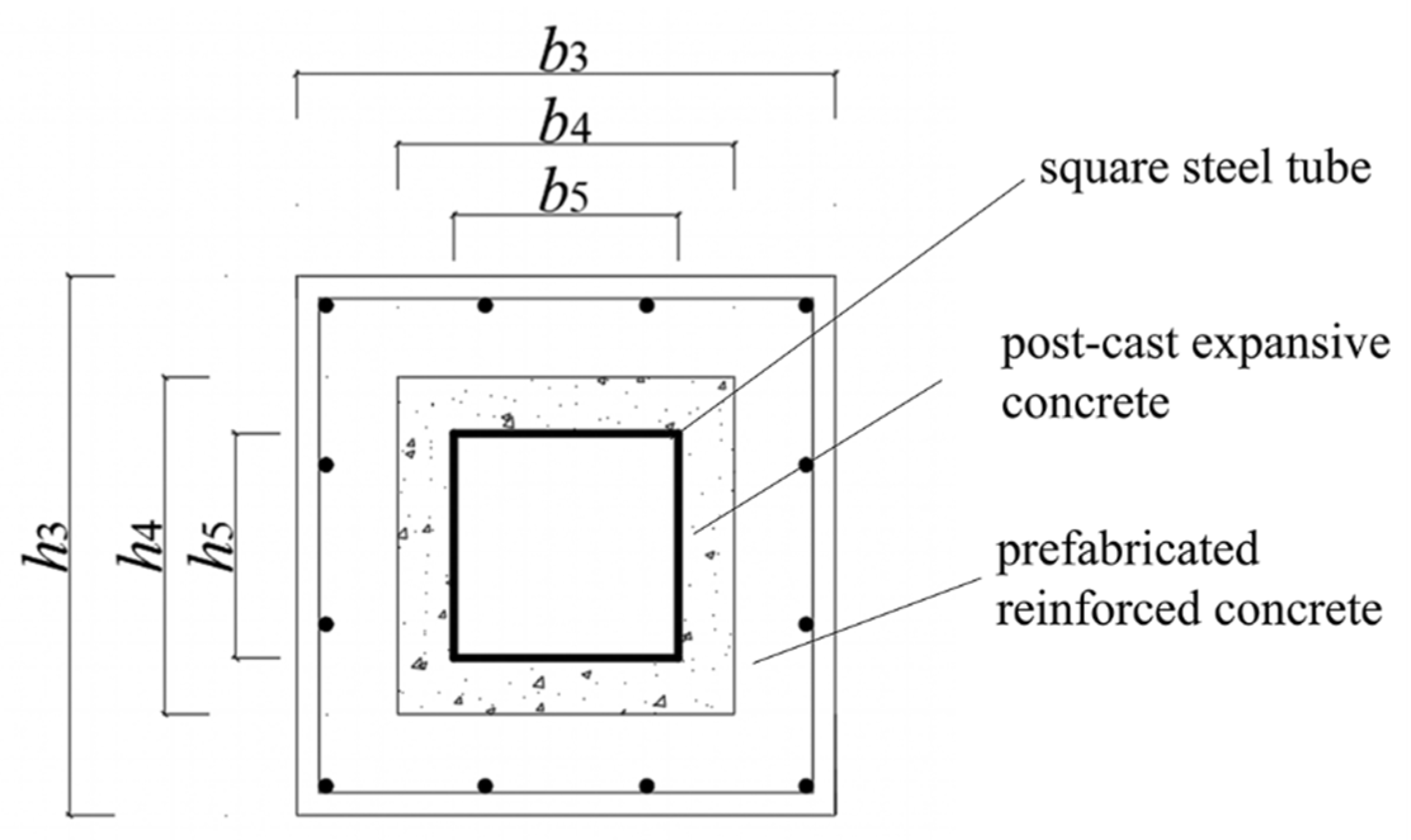

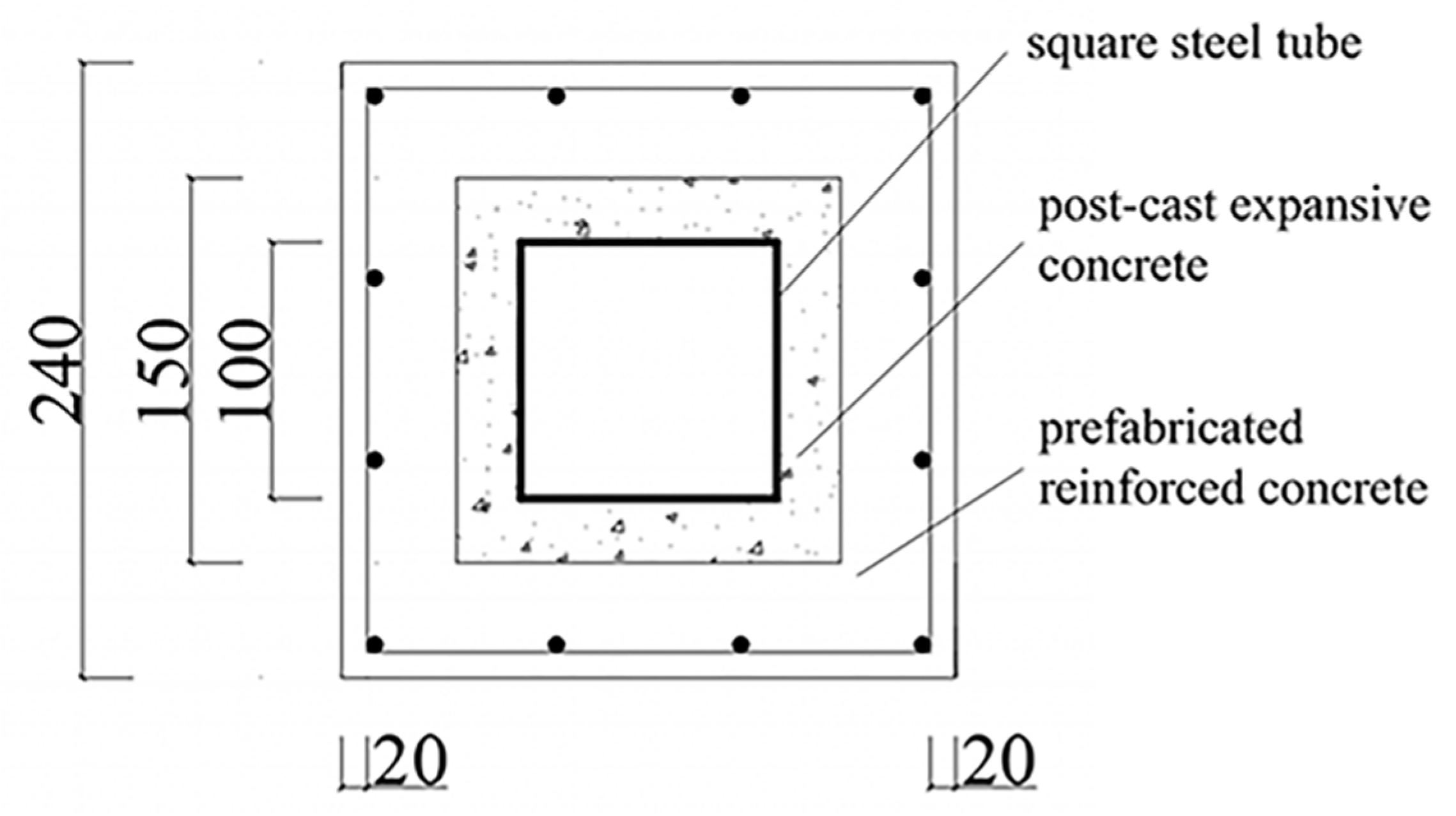

- The horizontal parts of the prefabricated cantilever components can be designed as ordinary reinforced concrete components, while the vertical parts should be designed as the steel–concrete composite components (section is shown as Figure 6).

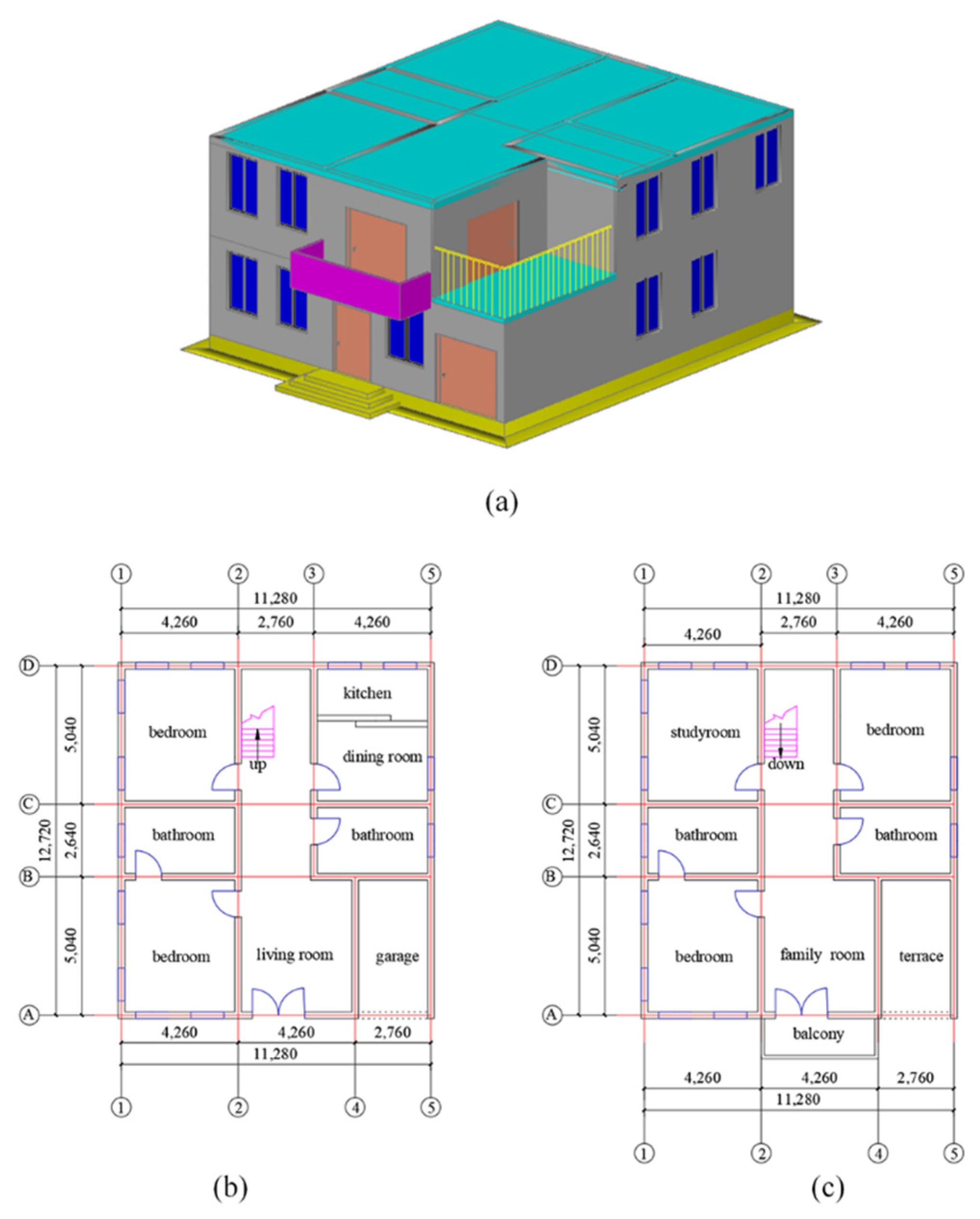

3. Example Analysis

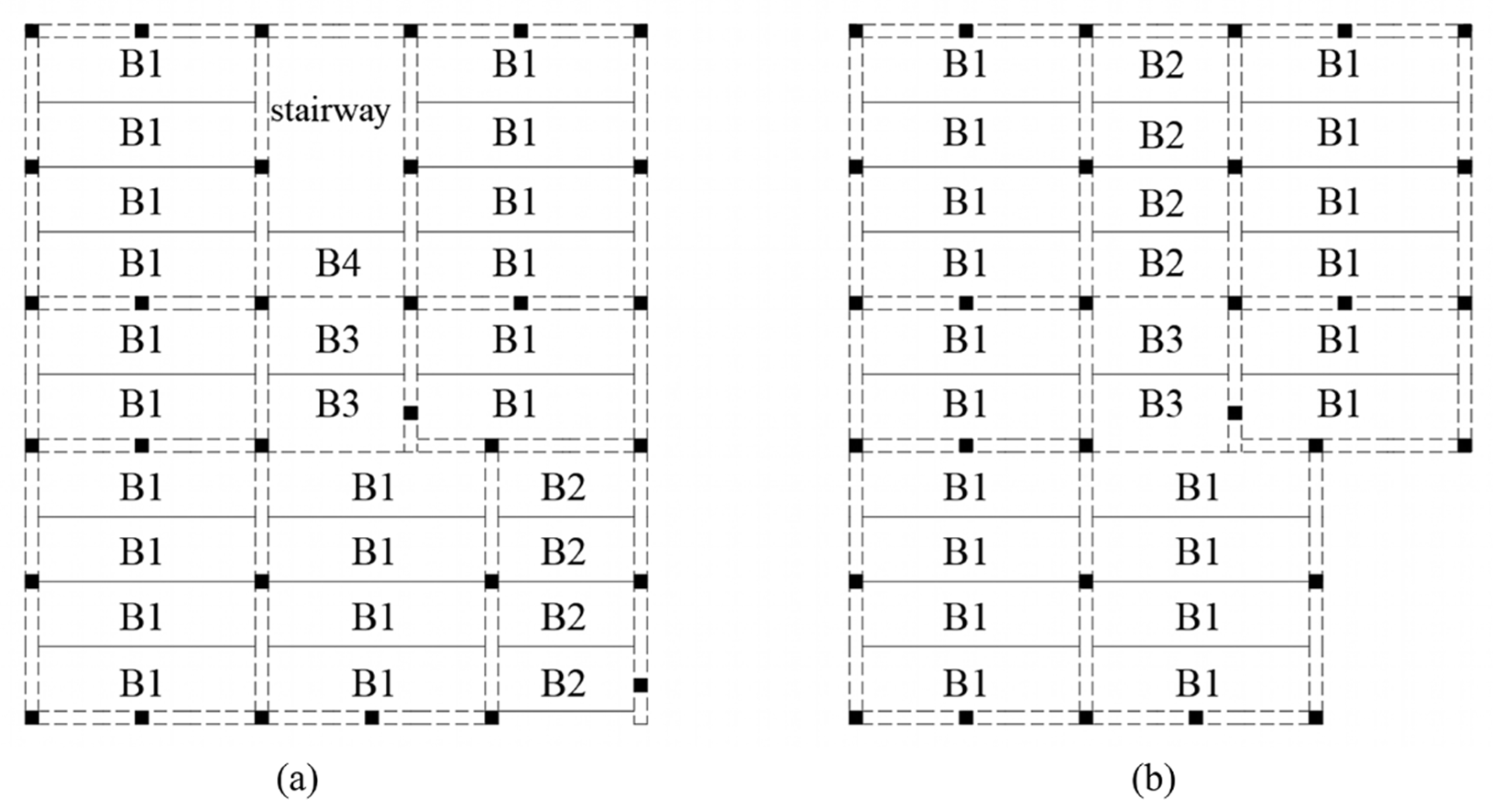

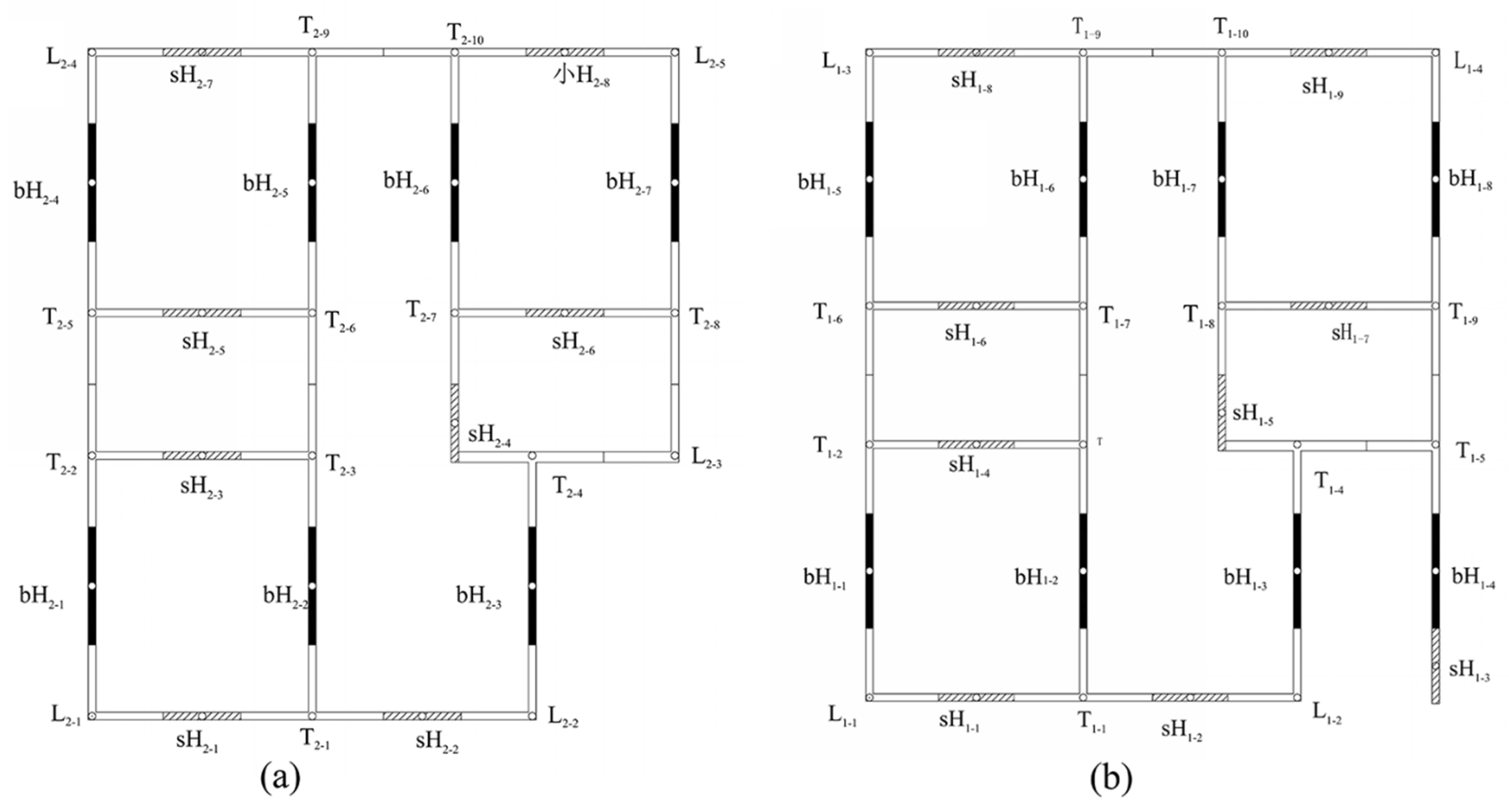

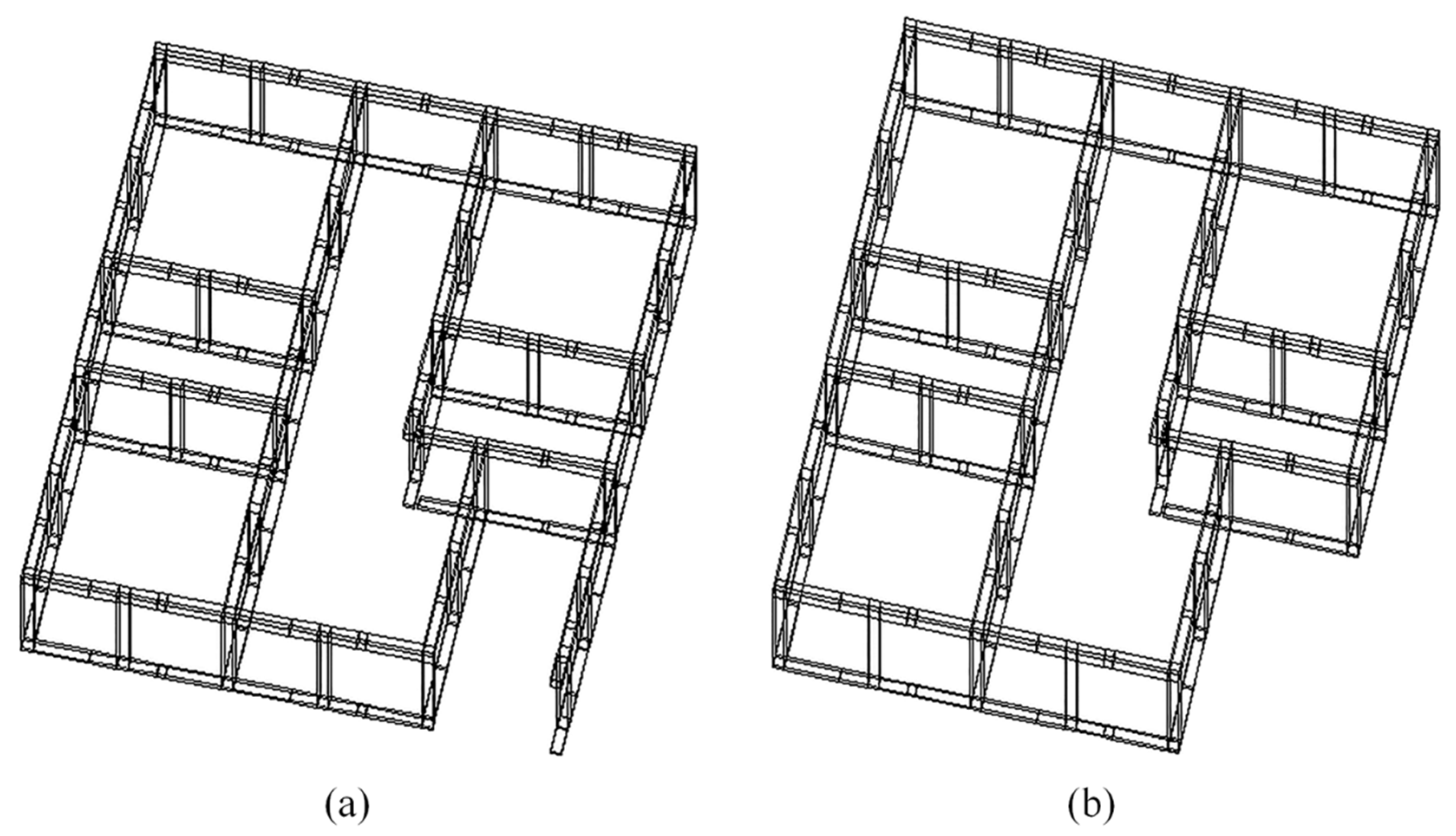

3.1. Type Selection and Design of Load-Bearing Components

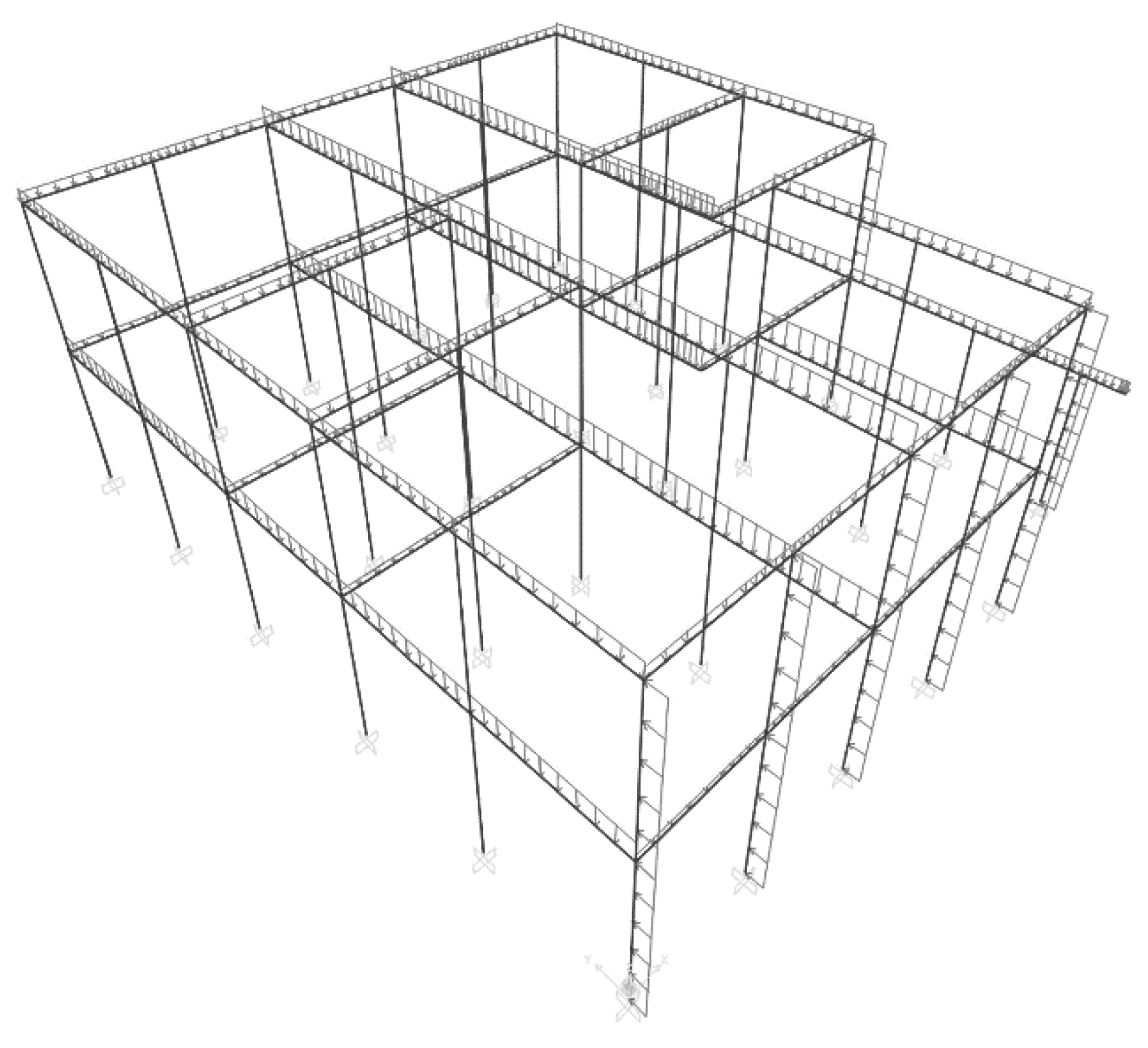

3.2. Analytical Model of the Overall Structure

3.3. Internal Force Analysis and Comparison of Each Model

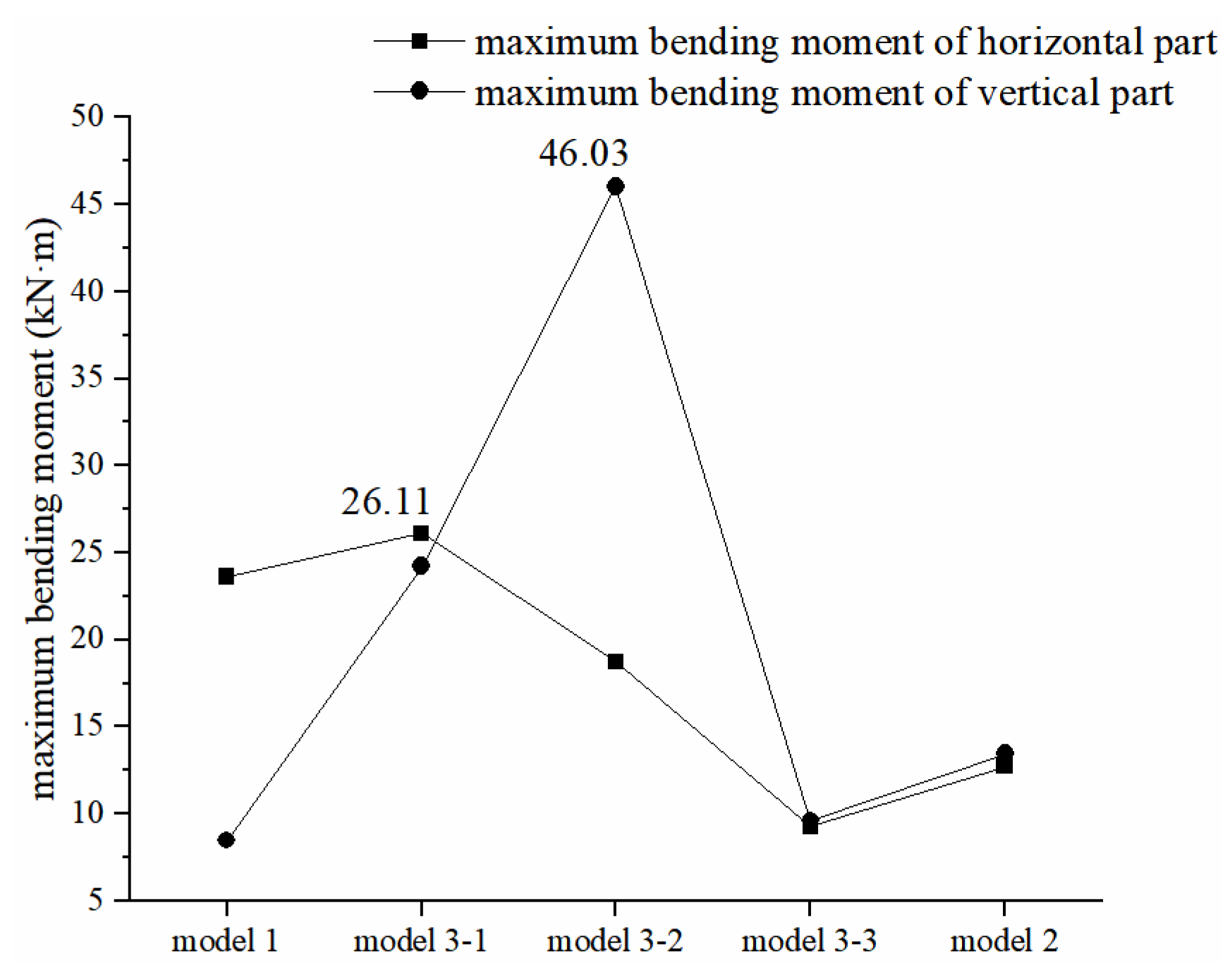

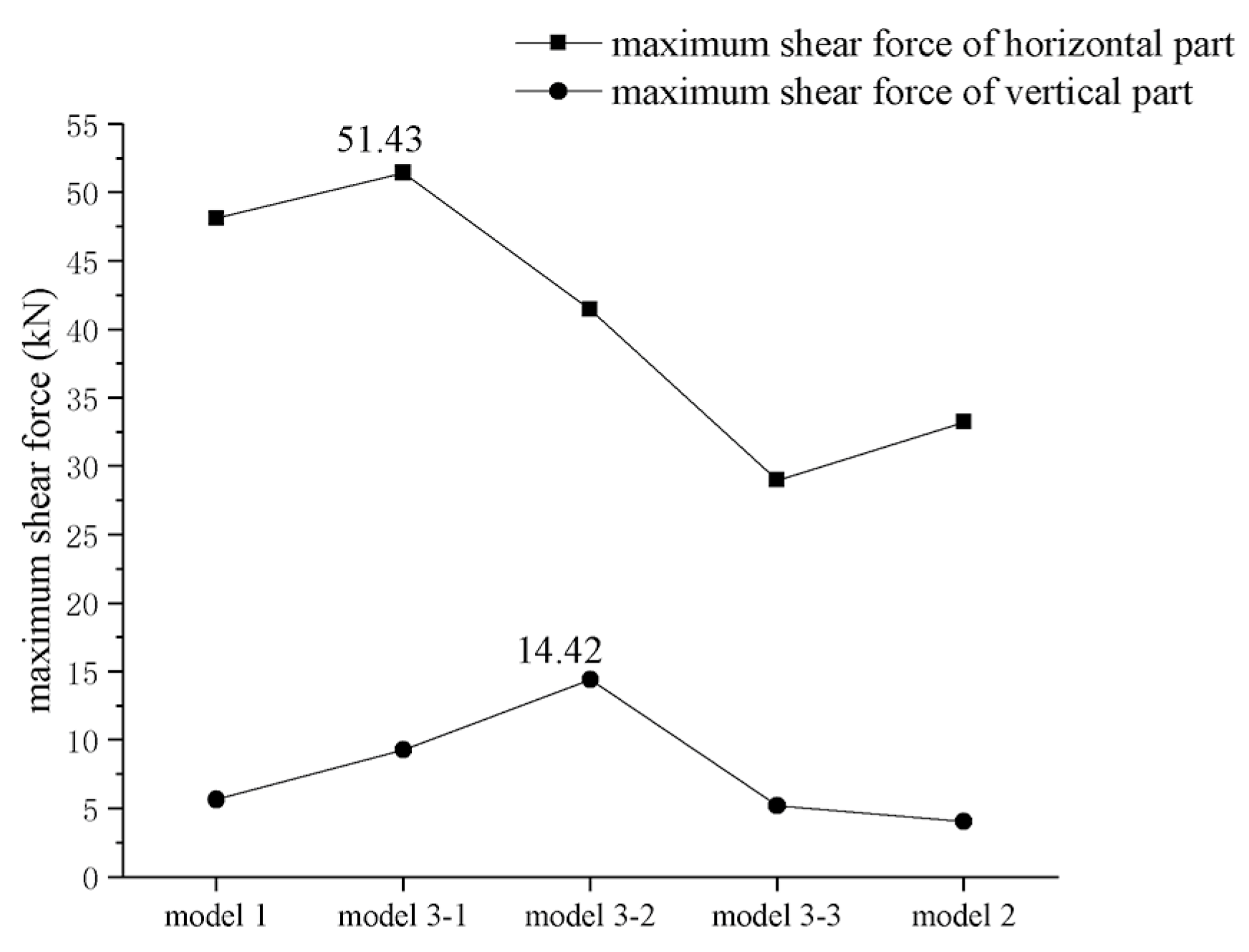

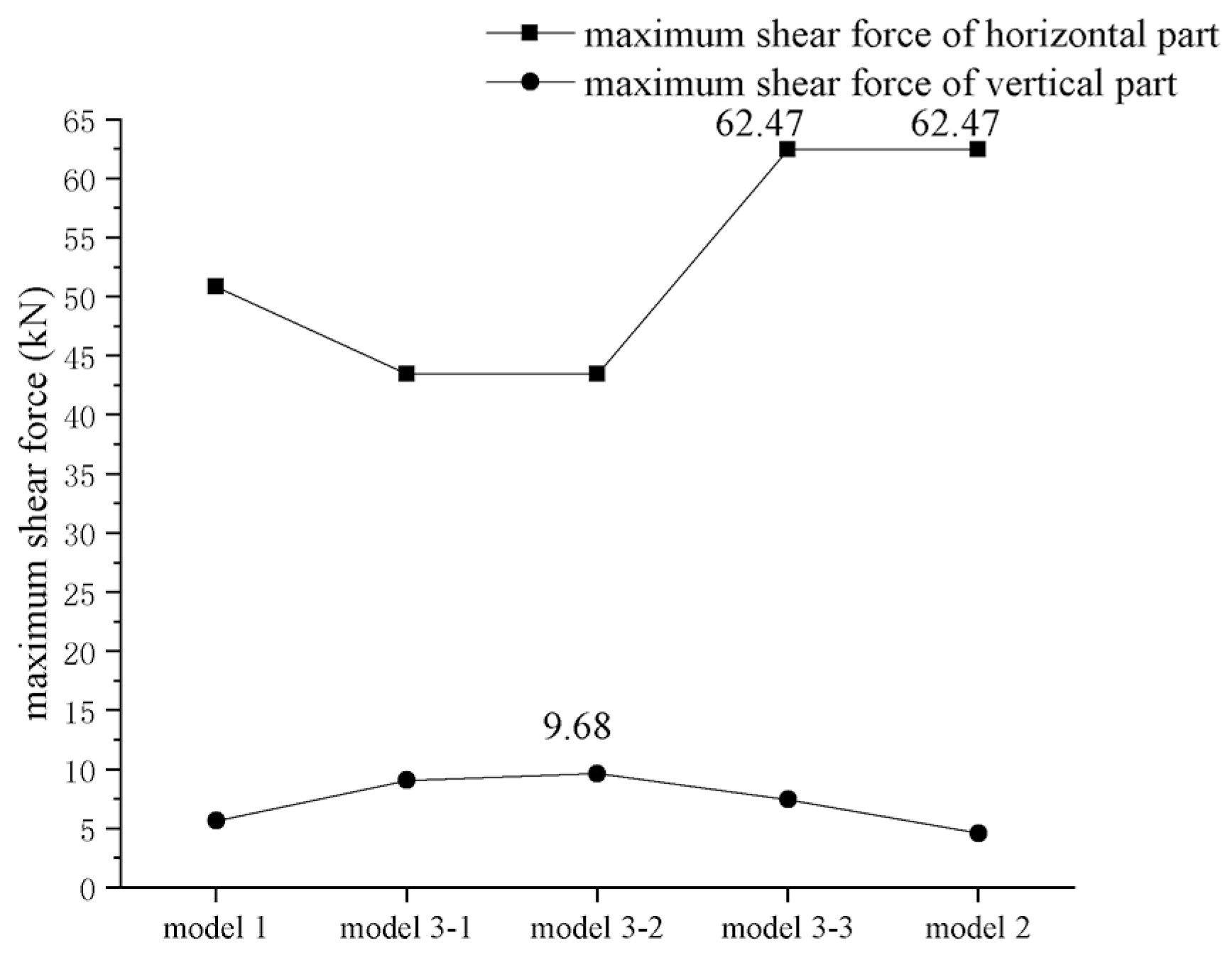

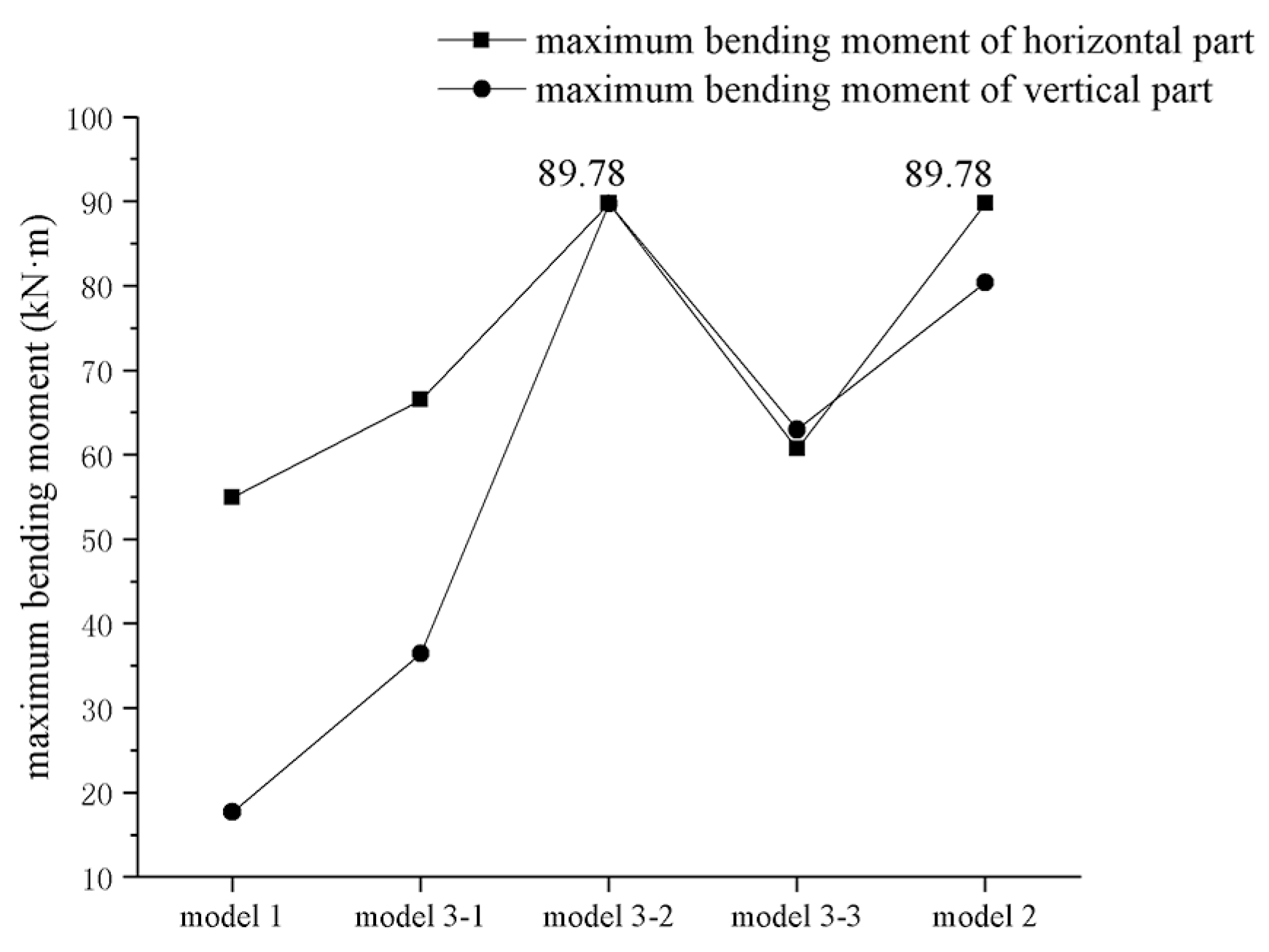

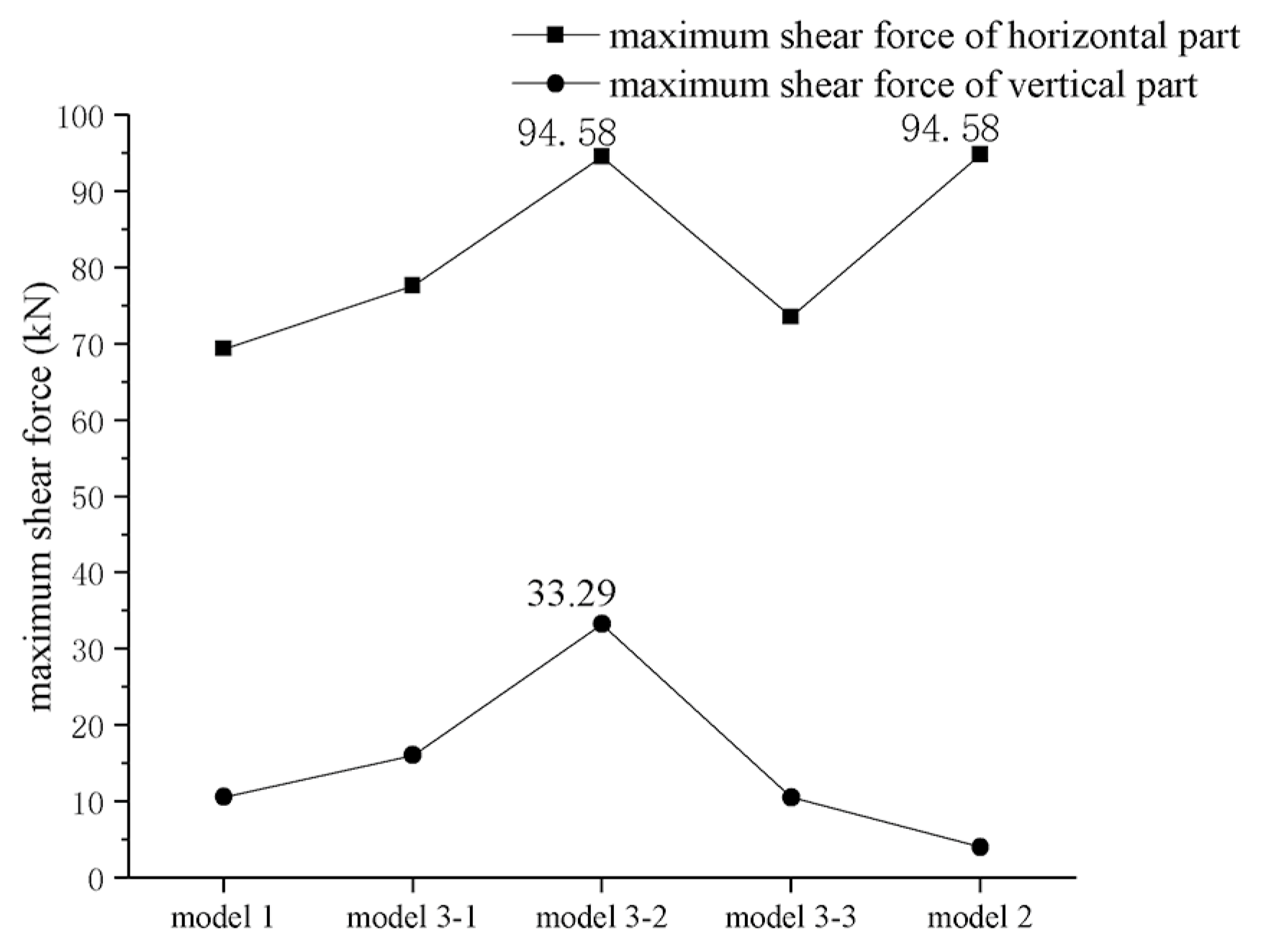

3.3.1. For the Whole Vertical Load-Bearing Unit

- (1)

- Upper horizontal part of each prefabricated cantilever component

- (2)

- Vertical part of each prefabricated cantilever component

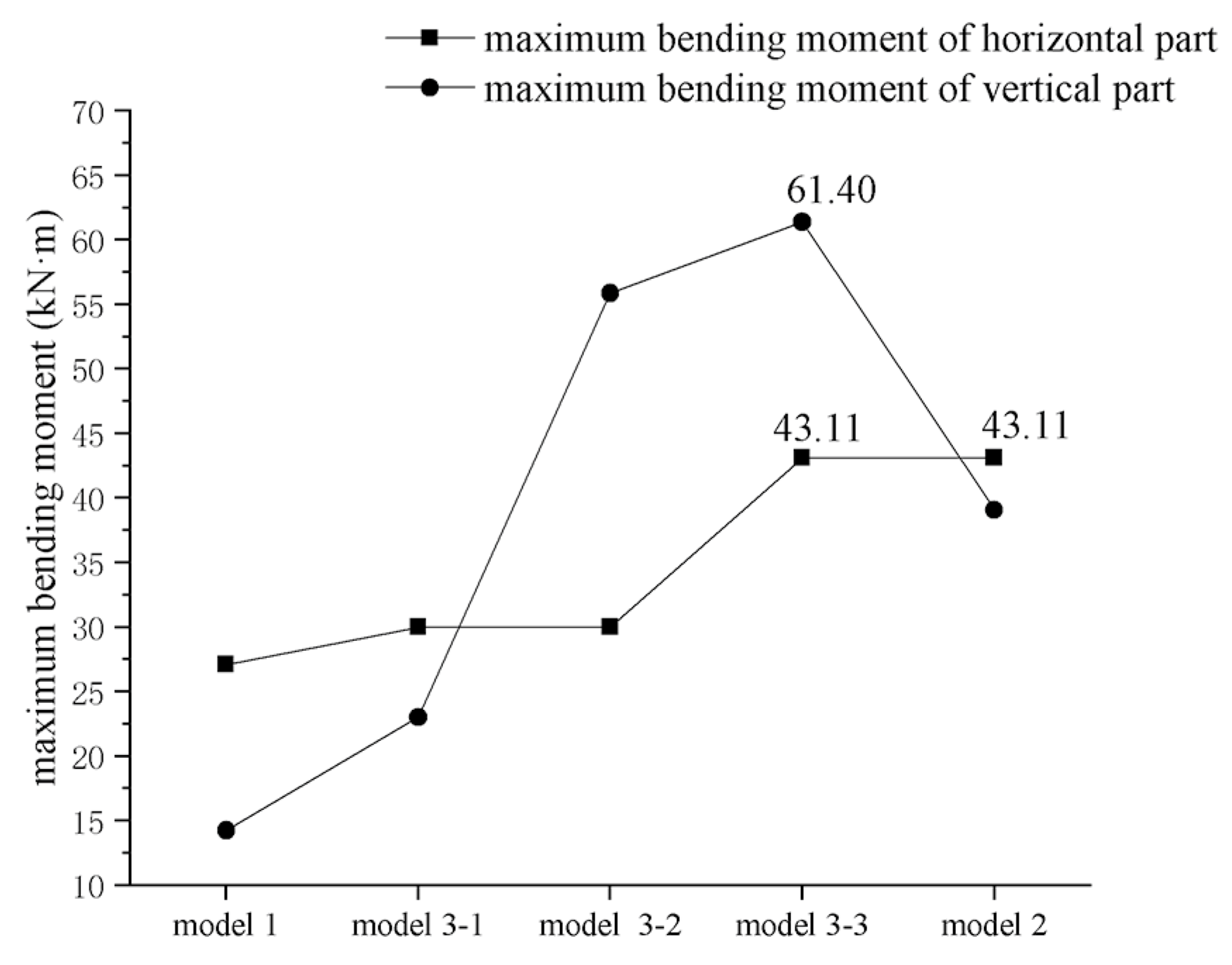

3.3.2. For Each Prefabricated Cantilever Component

- (1)

- sH-shaped components

- (2)

- bH-shaped components

- (3)

- L-shaped components

- (4)

- T-shaped components

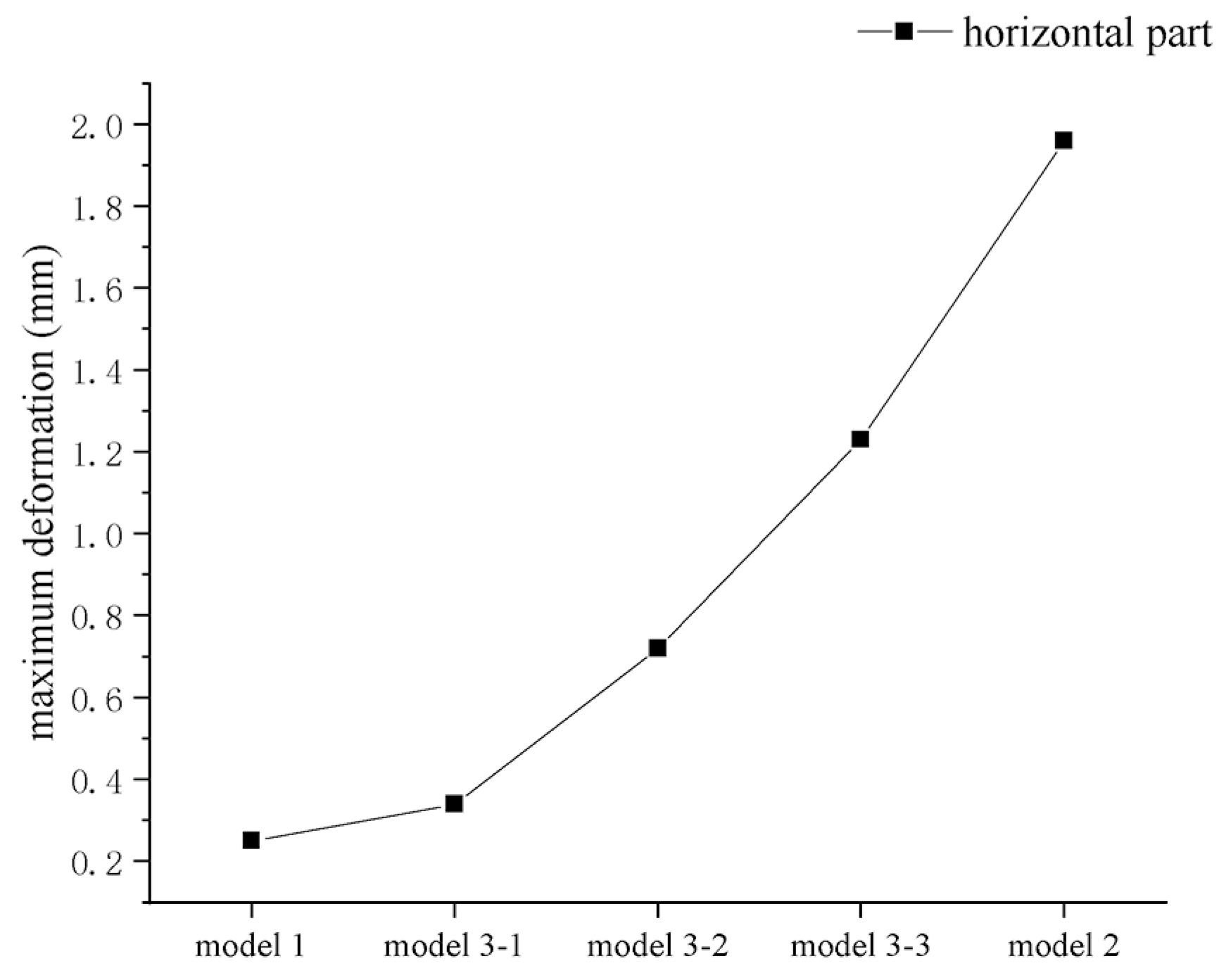

3.4. Analysis of Maximum Deformation of the Prefabricated Cantilever Components in Each Model

- (1)

- Maximum vertical displacement of the horizontal part

- (2)

- The maximum horizontal displacement of the vertical part (corresponding to the displacement angle between floors)

3.5. Note

4. Conclusions

- (1)

- Four types of prefabricated cantilever components serve as the vertical load-bearing unit of an FTPC structure. Through the different combinations of these four standard components, a variety of house types can be fully satisfied, leading to great promotion and application value.

- (2)

- The vertical connection method is more convenient than traditional wet methods while achieving an equivalent cast-in-place connection. Moreover, the characteristic of small force in the welded section reduces the quality requirement for welding.

- (3)

- The multimodel method based on the mathematical method considering the failure nodes is feasible. The fault-tolerant design can be realized by the multimodel analysis of the overall structure and the envelope design of the load-bearing parts. With five model structures, it has been verified that the safety of an FTPC structure meets the requirements.

- (4)

- The moderate volume of the prefabricated components leads to convenience for transportation and installation.

- (5)

- The vertical part of the cantilevered component under the combined loads needs further study about bearing capacity. The quantitative method of weld quality and its influence on the overall robustness of an FTPC structure can be considered more delicately in the future.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tavares, V.; Gregory, J.; Kirchain, R.; Freire, F. What is the potential for prefabricated buildings to decrease costs and contribute to meeting EU environmental targets? Build. Environ. 2021, 206, 108382. [Google Scholar] [CrossRef]

- Yrjl, J.; Bujnak, J. Shear tests on demountable precast column connections. Struct. Concr. 2021, 22, 2432–2442. [Google Scholar] [CrossRef]

- Ye, M.; Jiang, J.; Chen, H.M.; Zhou, H.Y.; Song, D.D. Seismic behavior of an innovative hybrid beam-column connection for precast concrete structures. Eng. Struct. 2021, 227, 111436. [Google Scholar] [CrossRef]

- Tong, C.; Wu, J.; Li, C.Y. A novel precast concrete beam-to-column connection with replaceable energy-dissipation connector: Experimental investigation and theoretical analysis. Bull. Earthq. Eng. 2021, 12, 4911–4943. [Google Scholar] [CrossRef]

- Huang, W.; Jiang, J.; Hu, G.X.; Zhang, J.R. Experimental study on the seismic performance of new precast concrete beam-column joints with replaceable connection. Structures 2022, 35, 856–872. [Google Scholar] [CrossRef]

- Chen, Y.; Shi, H.R.; Wang, C.L.; Wu, J.; Liao, Z.Q. Flexural mechanism and design method of novel precast concrete slabs with crossed bent-up rebar. Bull. Earthq. Eng. 2022, 50, 104216. [Google Scholar] [CrossRef]

- Wang, M.F.; Guo, S.Q.; Jing, F.; Zhang, Y.Q. Seismic performance of superimposed RC shear walls with concealed bracings using different horizontal connections. J. Build. Eng. 2022, 51, 104258. [Google Scholar] [CrossRef]

- Bei, C.; Yuan, C.; Looi, D.T.W. Experiment and numerical study of a new bolted steel plate horizontal joints for precast concrete shear wall structures. Structures 2021, 32, 760–777. [Google Scholar] [CrossRef]

- Naserpour, A.; Fathi, M. Numerical study of a multiple post-tensioned rocking wall-frame system for seismic resilient precast concrete buildings. Earthq. Eng. Eng. Vib. 2022, 21, 377–393. [Google Scholar] [CrossRef]

- Kurama, Y.C.; Sritharan, S.; Fleischman, R.B.; Restrepo, J.I.; Henry, R.S.; Cleland, N.M.; Ghosh, S.K.; Bonelli, P. Seismic-Resistant Precast Concrete Structures: State of the Art. J. Struct. Eng. 2018, 144, 03118001. [Google Scholar] [CrossRef] [Green Version]

- Lu, Y.J.; Wu, D.Y.; Peng, X.D.; Wang, S.L.; Wang, X.; Chen, W.; Wang, S.L. Study on the low cyclic loading test of a new reinforced tenon precast shear wall under different axial compression ratios. Adv. Struct. Eng. 2022, 4, 1631–1641. [Google Scholar] [CrossRef]

- Su, H.; Chen, W.; Wu, D.Y.; Wu, Q.; Wang, S.L.; Wang, W. Experimental study on seismic performance of new reinforced tenon joint precast shear walls. Adv. Struct. Eng. 2021, 24, 1631–1641. [Google Scholar] [CrossRef]

- Yang, Y.; Ding, X.; Liu, Y.; Deng, L.; Lv, F.; Zhao, S. Lateral Pressure Test of Vertical Joint Concrete and Formwork Optimization Design for Monolithic Precast Concrete Structure. Buildings 2022, 12, 261. [Google Scholar] [CrossRef]

- Li, J.B.; Fan, Q.Q.; Lu, Z.; Wang, Y. Experimental study on seismic performance of T-shaped partly precast reinforced concrete shear wall with grouting sleeves. Struct. Des. Tall Spec. Build. 2019, 28, e1632.1–e1632.13. [Google Scholar] [CrossRef]

- Fang, Z.; Fang, S.; Liu, F. Experimental and Numerical Study on the Shear Performance of Short Stud Shear Connectors in Steel–UHPC Composite Beams. Buildings 2022, 12, 418. [Google Scholar] [CrossRef]

- Ng, W.H.; Kong, S.Y.; Chua, Y.S.; Bai, Y. Tensile behaviour of innovative one-sided bolts in concrete-filled steel tubular connections. J. Constr. Steel Res. 2022, 191, 107165. [Google Scholar] [CrossRef]

- Guo, H.S.; Shi, P.F.; Qi, H.; Wu, B.; Pan, P.; Li, L.M.; Li, L.M.; Liu, K.; Wang, D.Y. Full-scale experimental study on post-tensioned prestressed precast frame structures. J. Build. Struct. 2021, 42, 119–132. (In Chinese) [Google Scholar] [CrossRef]

- Zhu, H.; He, Y.; Ji, D.; Tang, J.; Li, C. Experimental Research on the Mechanical Properties and Autogenous Shrinkage of Precast Members Joint Concrete. Buildings 2022, 12, 373. [Google Scholar] [CrossRef]

- Abusafaqa, F.R.; Samaaneh, M.A.; Dwaikat, M.B.M. Improving ductility behavior of sway-special exterior beam-column joint using ultra-high performance fiber-reinforced concrete. Structures 2022, 36, 979–996. [Google Scholar] [CrossRef]

- Liu, Y.L.; Zhu, S.T. Finite element analysis on the seismic behavior of side joint of Prefabricated Cage System in prefabricated concrete frame. Front. Struct. Civ. Eng. 2019, 13, 1095–1104. [Google Scholar] [CrossRef]

- Wang, X.; Li, L.Z.; Deng, B.Y.; Zhang, Z.; Jia, L. Experimental study on seismic behavior of prefabricated RC frame joints with T-shaped columns. Eng. Struct. 2021, 233, 111912. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, L.; Zhang, Q.; He, X.; Su, Y. Anchorage behavior of grouting sleeves under uniaxial and cyclic loading-A comparative study of the internal structure of sleeves. J. Build. Eng. 2022, 49, 104057. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, Z.; Cheng, X.; Li, Y.; Diao, M.; Sun, H. Experimental and numerical investigation of the progressive collapse of precast reinforced concrete frame substructures with wet connections. Eng. Struct. 2022, 256, 114010. [Google Scholar] [CrossRef]

- Guo, T.; Yang, J.; Wang, W.; Li, C. Experimental investigation on connection performance of fully-grouted sleeve connectors with various grouting defects. Constr. Build. Mater. 2022, 327, 126981. [Google Scholar] [CrossRef]

- Xu, L.H.; Wang, Q.L.; Yu, M.; Chi, Y.; Yang, B.; Liu, M.; Ye, J.Q. Experimental Study on Seismic Behavior of Cluster-Reinforced Precast Concrete Columns with Grouting-Anchor Connections. J. Earthq. Tsunami 2019, 13, 70–89. [Google Scholar] [CrossRef] [Green Version]

- Sayadi, A.A.; Rahman, A.B.A.; Jumaat, M.Z.B.; Alengaram, U.J.; Ahmad, S. The relationship between interlocking mechanism and bond strength in elastic and inelastic segment of splice sleeve. Constr. Build. Mater. 2014, 55, 227–237. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Development (MOHURD). GB 50009-2012 Load Code for the Design of Building Structures; China Architecture & Building Press: Beijing, China, 2012. (In Chinese)

- Wang, Y.L.; Zhao, H.K.; Liu, Q.L.; Li, G.N. Floor design method and example based on concrete composite slab reinforced by one-way truss bars. Eng. Constr. 2020, 52, 23–29. (In Chinese) [Google Scholar] [CrossRef]

- Wang, Y.L.; Zhao, H.K.; Liu, Q.L.; Li, G.N. Classification research on the section flexural stiffness setermination method of steel reinforced concrete columns. J. Chongqing Univ. Sci. Technol. (Nat. Sci. Ed.) 2020, 22, 97–101. (In Chinese) [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Development (MOHURD). JGJ 138-2016 Code for Design of Composites; China Architecture & Building Press: Beijing, China, 2016. (In Chinese)

- Qiu, G.X.; Eftekharian, A. Extropy information of maximum and minimum ranked set sampling with unequal samples. Commun. Stat.-Theory Methods 2021, 50, 2979–2995. [Google Scholar] [CrossRef]

- Takumi, S. Mann–Whitney test for two-phase stratified sampling. Stat 2021, 10, e321.1–e321.9. [Google Scholar] [CrossRef]

- Igwe, N.O.; Bassey, U.; Oyah, M.P. Comparative analysis of the efficiency of simple random sampling and stratified random sampling techniques using data from 2006 population Fig.s of the six south-south states of nigeria. Int. J. Adv. Res. (IJAR) 2020, 8, 1056–1064. [Google Scholar] [CrossRef] [Green Version]

- Ministry of Housing and Urban-Rural Development (MOHURD). GB 50010-2010 Code for Design of Concrete Structures; China Architecture & Building Press: Beijing, China, 2010. (In Chinese)

- Ministry of Housing and Urban-Rural Development (MOHURD). JGJ 3-2010 Technical Specification for Concrete Structures of Tall Building; China Architecture & Building Press: Beijing, China, 2010. (In Chinese)

| Type of Slab | Width (mm) | Clear Span Length (mm) | Thickness (mm) |

|---|---|---|---|

| B1 | 1200 | 4020 | 140 |

| B2 | 1200 | 2520 | 140 |

| B3 | 1440 | 2520 | 140 |

| B4 | 1100 | 2760 | 140 |

| Types of Components | Horizontal Part | Vertical Part | ||||

|---|---|---|---|---|---|---|

| Cantilever Length l (mm) | Upper Section Size (b1 × h1) (mm × mm) | Lower Section Size (b2 × h2) (mm × mm) | Outer Size (b3 × b3) (mm × mm) | Inner Size (b4 × h4) (mm × mm) | Height h (mm) | |

| sH-shaped component | 630 | 240 × 300 | 240 × 100 | 240 × 240 | 150 × 150 | 2850 |

| bH-shaped component | 1020 | 240 × 300 | 240 × 100 | 240 × 240 | 150 × 150 | 2850 |

| L-shaped component | 1260 | 240 × 300 | 240 × 100 | 240 × 240 | 150 × 150 | 2850 |

| T-shaped component | 1260 | 240 × 300 | 240 × 100 | 240 × 240 | 150 × 150 | 2850 |

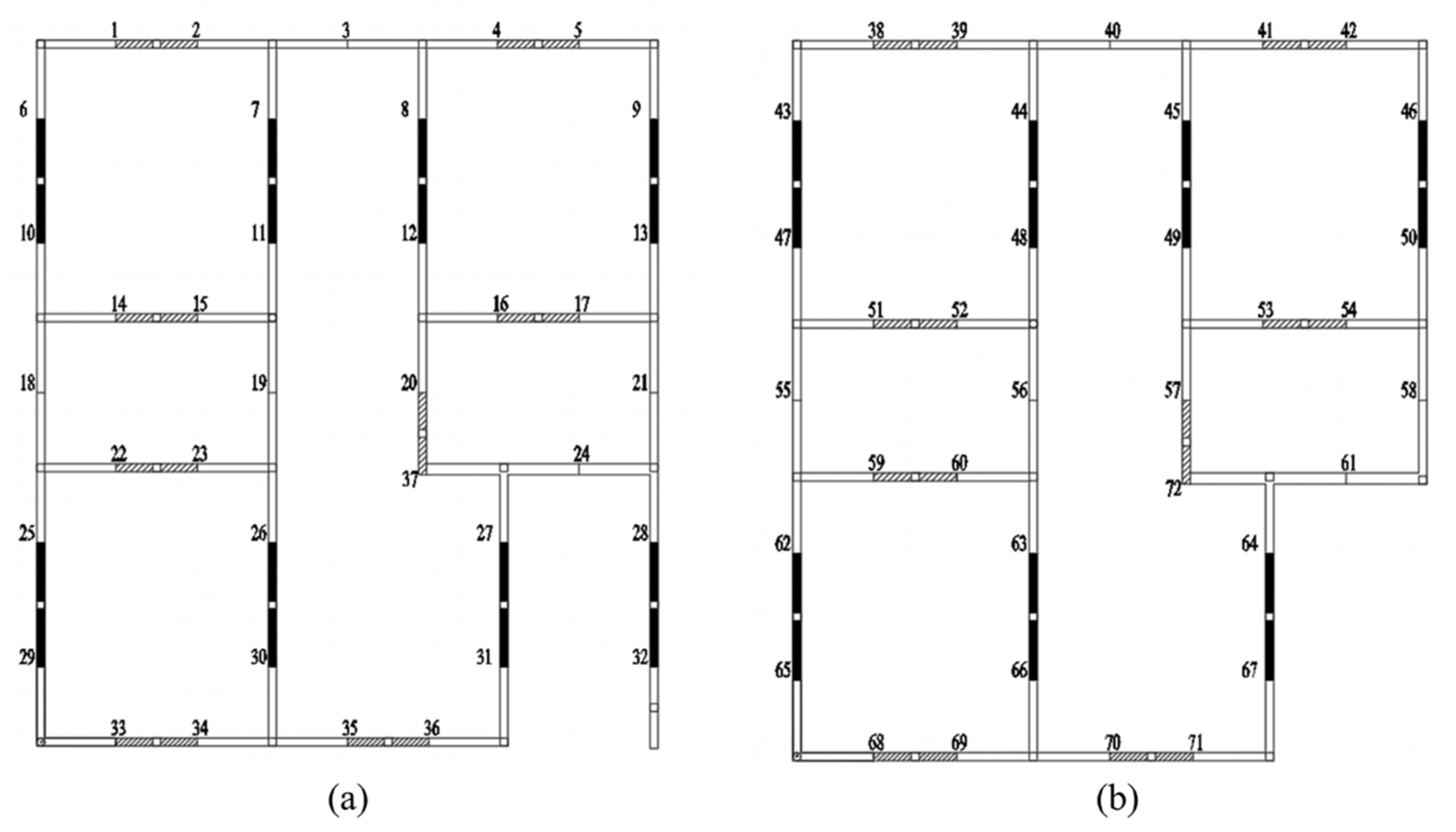

| Model Number | Total Quantity of Disconnected Nodes | Floor Number | Quantity of Disconnected Nodes Per Floor | Number of Disconnected Node | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3-1 | 18 | 1 | 9 | 7 | 9 | 15 | 25 | 26 | 27 | 30 | 32 | 37 |

| 2 | 9 | 38 | 41 | 51 | 55 | 58 | 60 | 64 | 66 | 67 | ||

| 3-2 | 36 | 1 | 18 | 1 | 3 | 4 | 6 | 9 | 11 | 12 | 14 | 18 |

| 22 | 25 | 26 | 29 | 30 | 32 | 33 | 34 | 36 | ||||

| 2 | 18 | 38 | 40 | 41 | 43 | 44 | 46 | 47 | 50 | 52 | ||

| 56 | 58 | 60 | 61 | 65 | 66 | 67 | 68 | 70 | ||||

| 3-3 | 54 | 1 | 28 | 1 | 2 | 4 | 5 | 7 | 8 | 12 | 13 | 15 |

| 16 | 17 | 18 | 19 | 21 | 22 | 23 | 24 | 26 | ||||

| 27 | 28 | 30 | 31 | 32 | 33 | 34 | 35 | 36 | ||||

| 37 | ||||||||||||

| 2 | 26 | 38 | 39 | 40 | 41 | 44 | 45 | 47 | 49 | 50 | ||

| 51 | 52 | 54 | 55 | 56 | 57 | 58 | 59 | 61 | ||||

| 62 | 63 | 64 | 65 | 67 | 69 | 71 | 72 | |||||

| Model Number | Maximum Interfloor Displacement Angle |

|---|---|

| 1 | 1/834 |

| 3-1 | 1/999 |

| 3-2 | 1/610 |

| 3-3 | 1/596 |

| 2 | 1/596 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Wang, Y.; Sheng, D.; Wang, Y. Study on New Prefabricated Reinforced Concrete Structure Technology Based on Fault-Tolerant Design. Buildings 2022, 12, 814. https://doi.org/10.3390/buildings12060814

Wang S, Wang Y, Sheng D, Wang Y. Study on New Prefabricated Reinforced Concrete Structure Technology Based on Fault-Tolerant Design. Buildings. 2022; 12(6):814. https://doi.org/10.3390/buildings12060814

Chicago/Turabian StyleWang, Shunyao, Yilin Wang, Dapeng Sheng, and Yu Wang. 2022. "Study on New Prefabricated Reinforced Concrete Structure Technology Based on Fault-Tolerant Design" Buildings 12, no. 6: 814. https://doi.org/10.3390/buildings12060814

APA StyleWang, S., Wang, Y., Sheng, D., & Wang, Y. (2022). Study on New Prefabricated Reinforced Concrete Structure Technology Based on Fault-Tolerant Design. Buildings, 12(6), 814. https://doi.org/10.3390/buildings12060814