An Experimental Study of the Hysteresis Model of the Kanchuang Frame Used in Chinese Traditional Timber Buildings of the Qing Dynasty

Abstract

1. Introduction

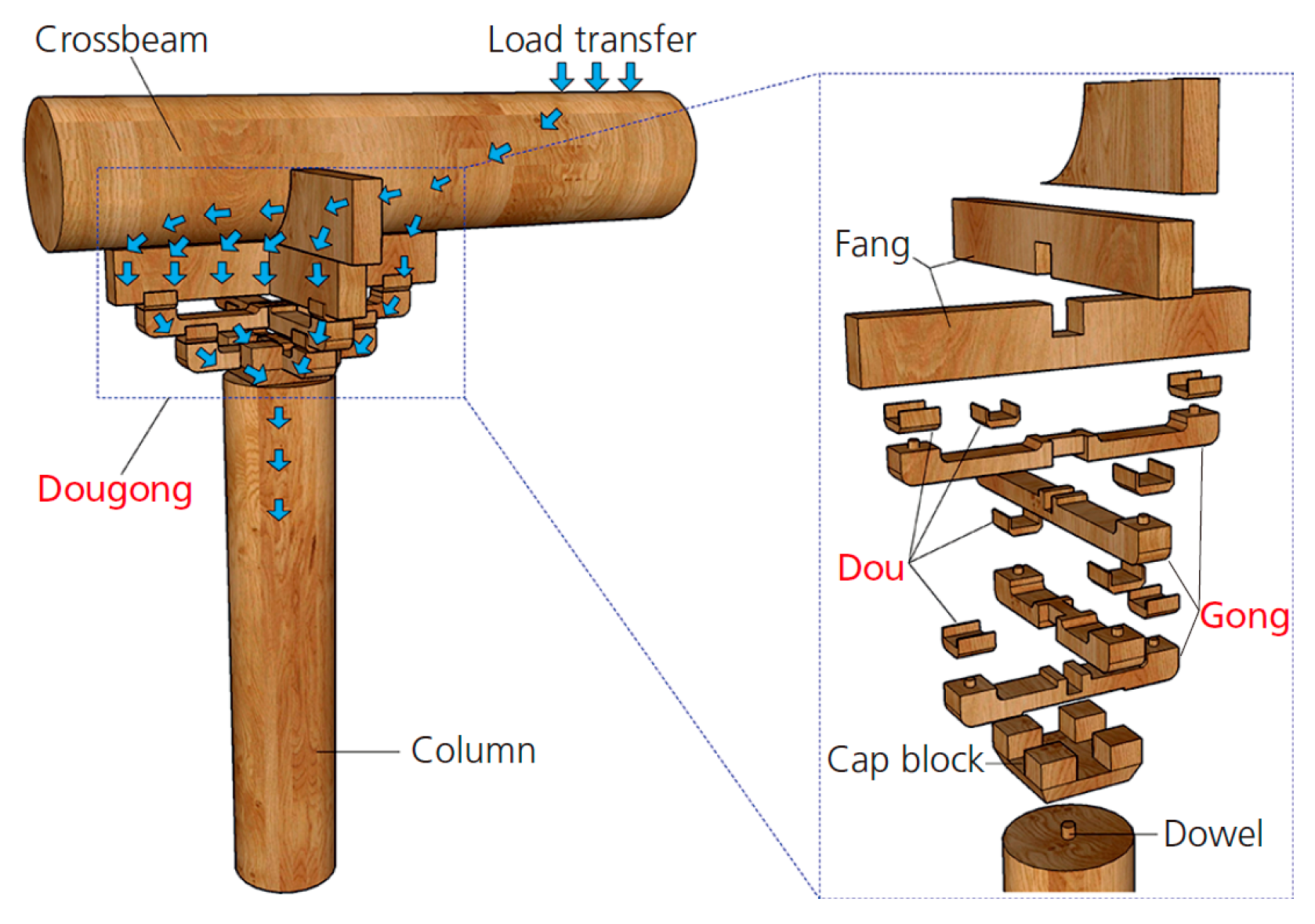

1.1. History and Research of Chinese Traditional Structures

1.2. Research on Timber Frames with Infill Walls

1.3. Research and Application of the Restoring Force Model

2. Experimental Studies

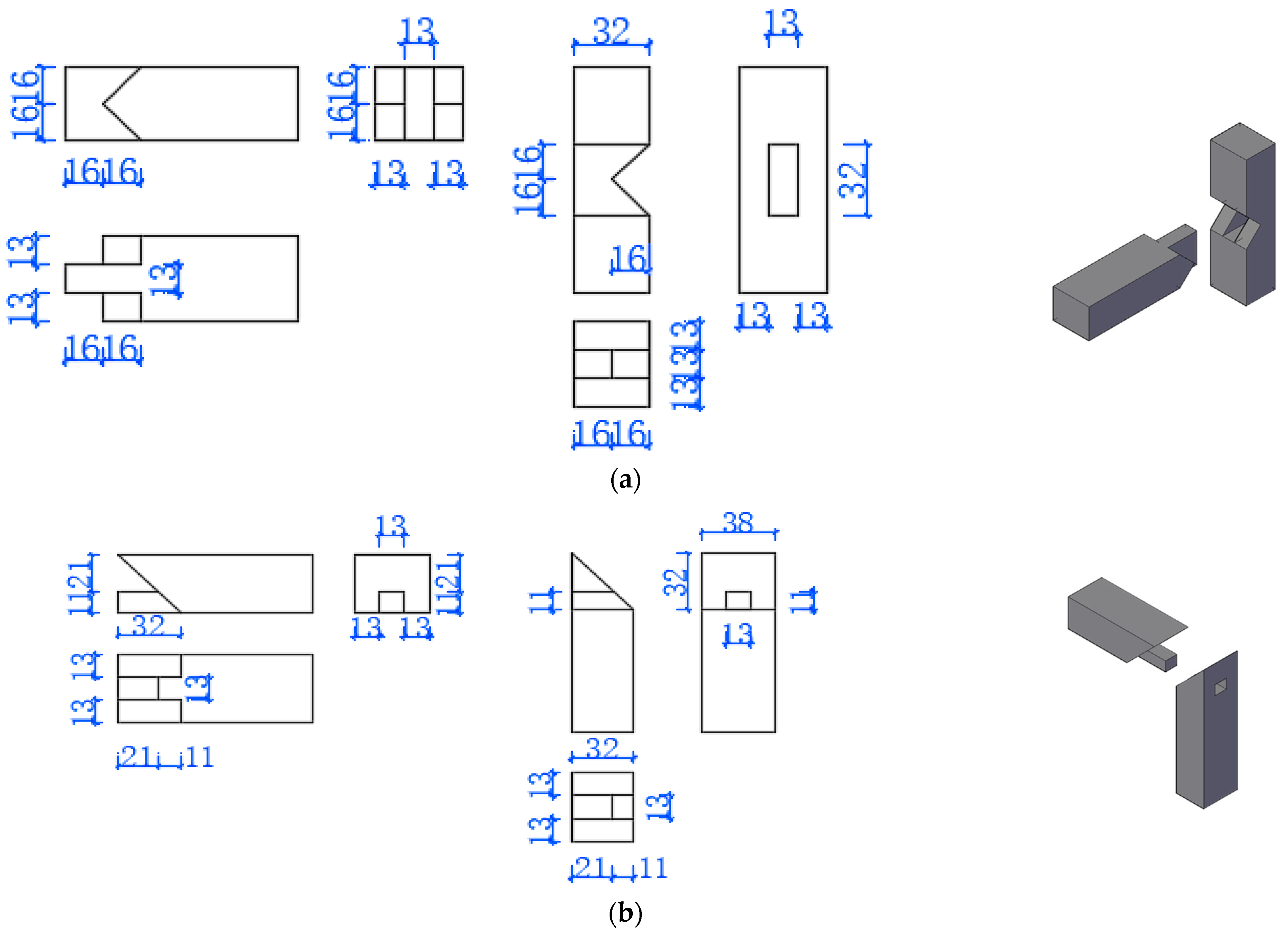

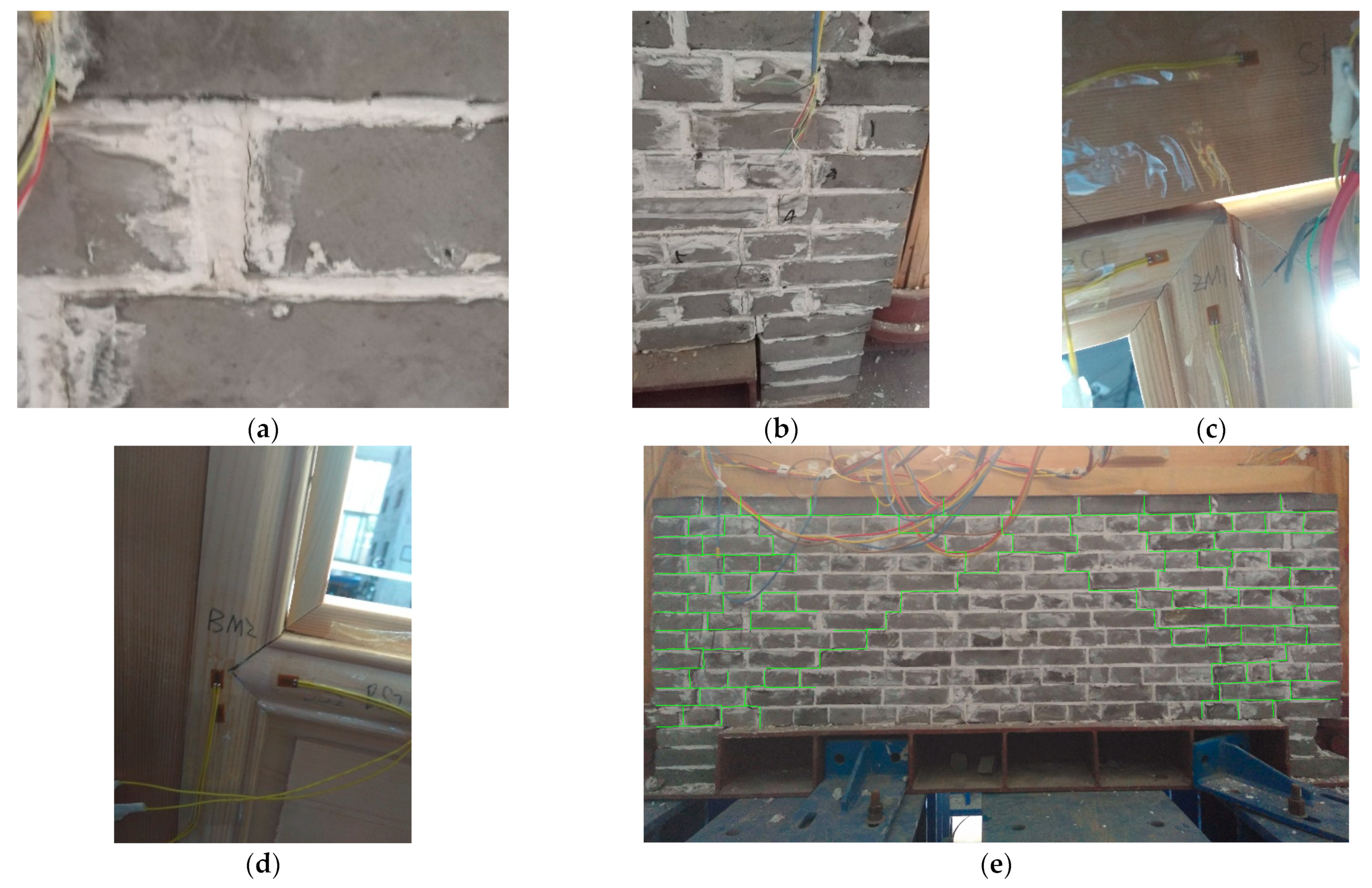

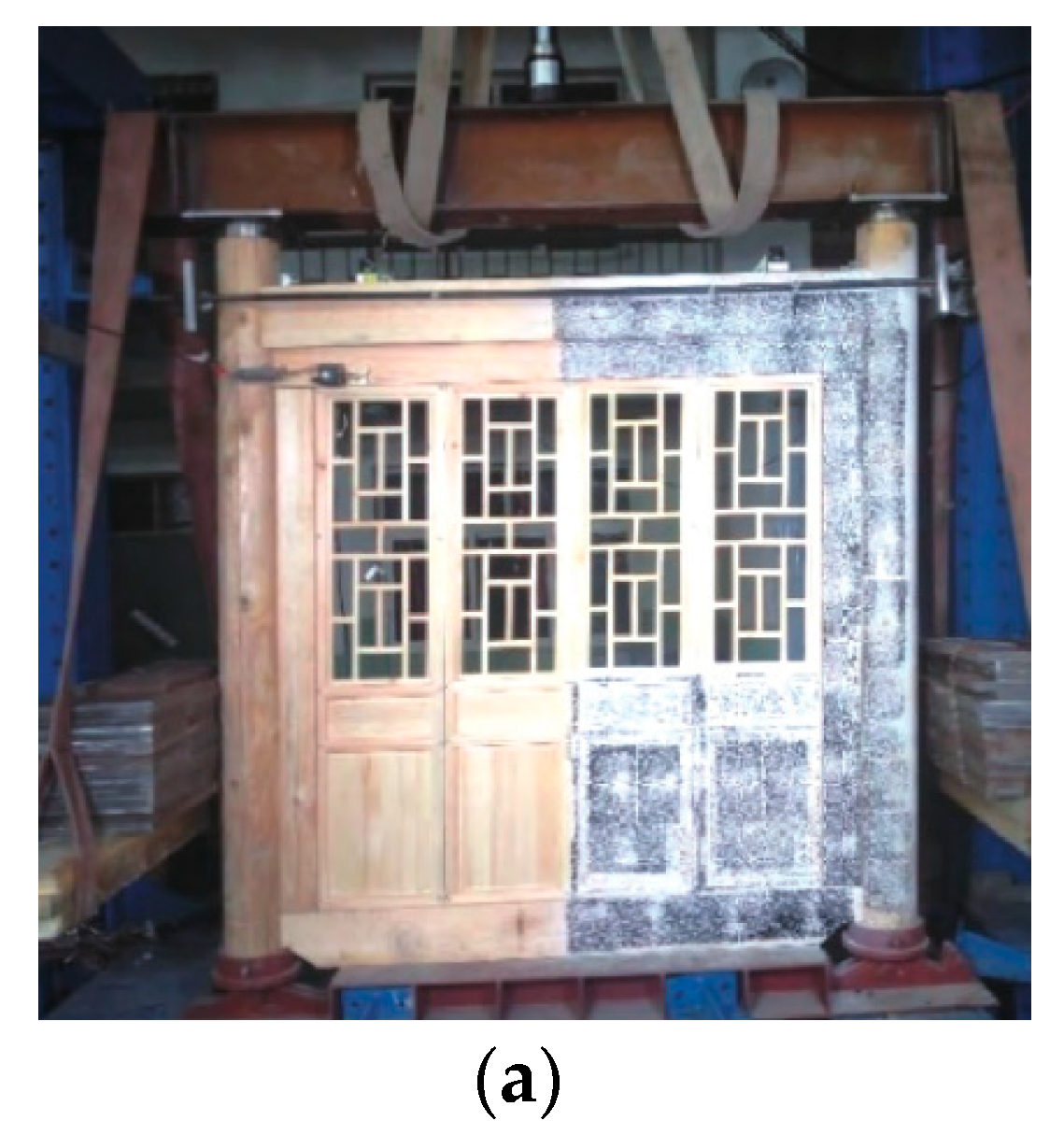

2.1. Specimen Fabrication

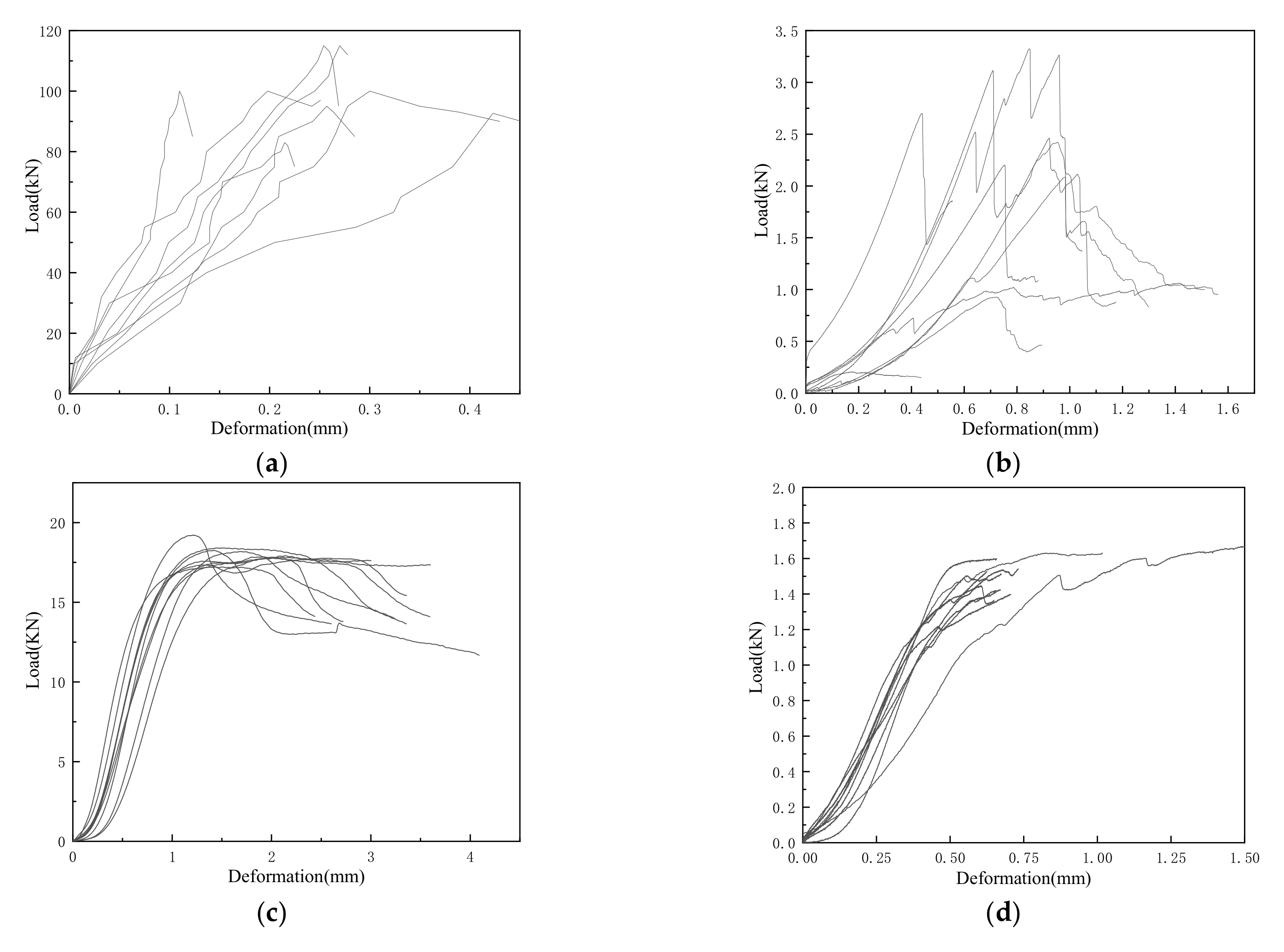

2.2. Material Properties

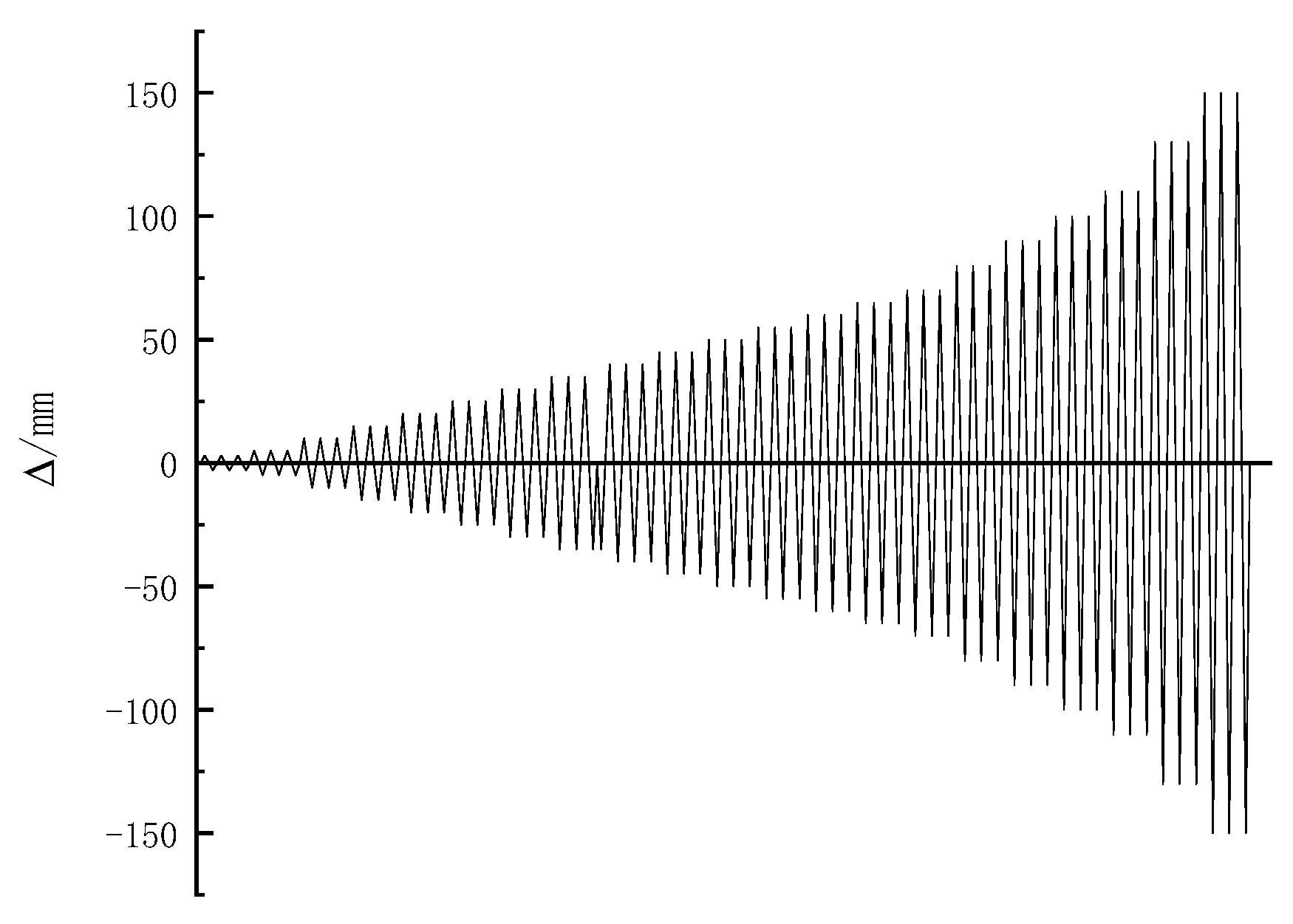

2.3. Testing and Measuring Schemes

2.4. General Observation

3. Analysis of the Characteristic Curves

- (1)

- Although the frame is symmetrical theoretically, in practice, the frame is not exactly symmetrical. The timber frame of ancient timber buildings is not symmetrical, as the specimens were handmade by the timber building restoration people. There are different sizes of small gaps between the components, especially between the mortise and tenon.

- (2)

- The cracks and damage of the components did not appear in an exactly symmetrical way, and the curves are unsymmetrical in different loading directions.

- (3)

- The horizontal cyclic loads were applied using a hydraulic actuator. The actuator was positioned at one side of the frame. It wasn’t positioned in the middle of the frame, which also made the curves unsymmetrical.

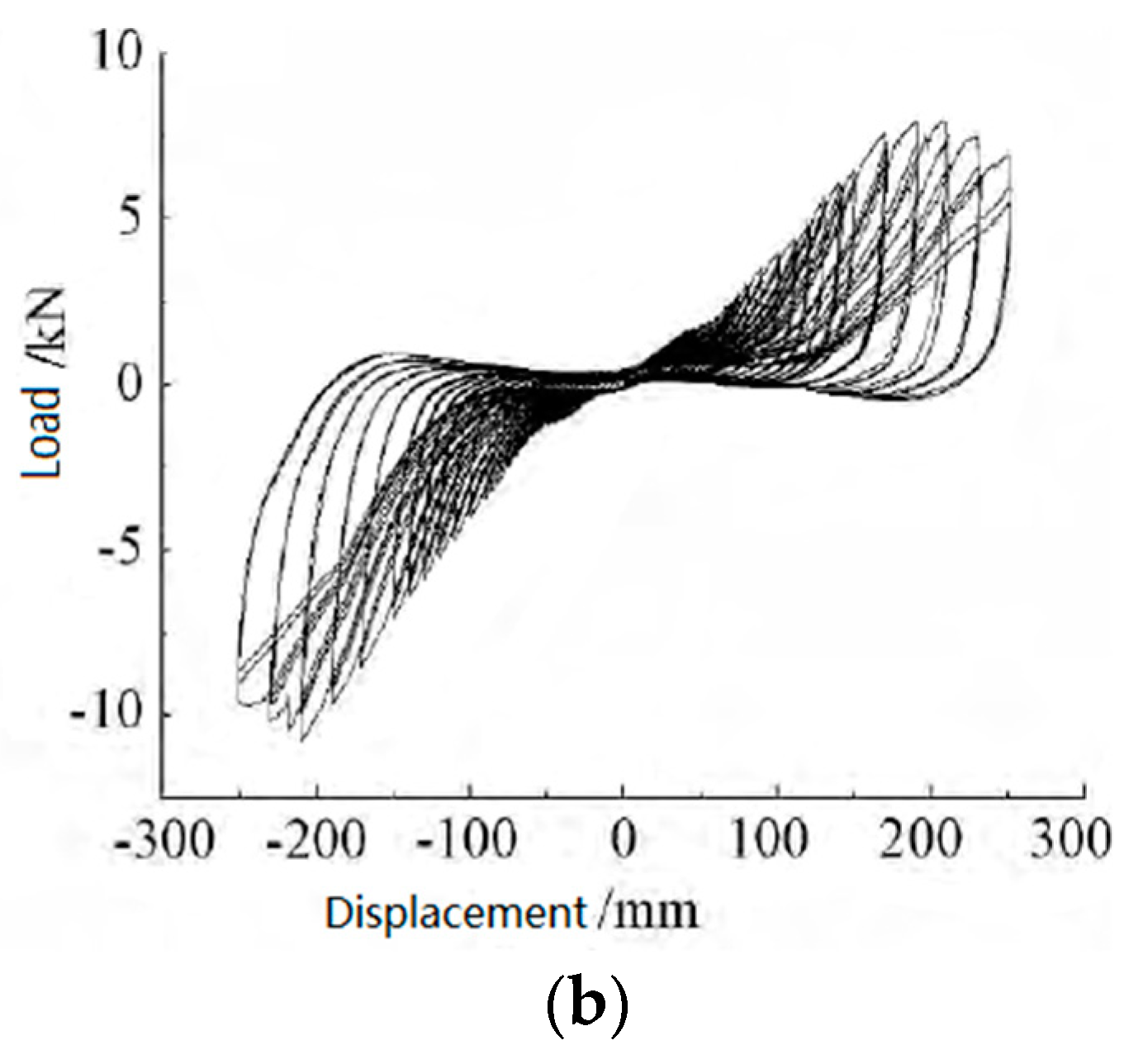

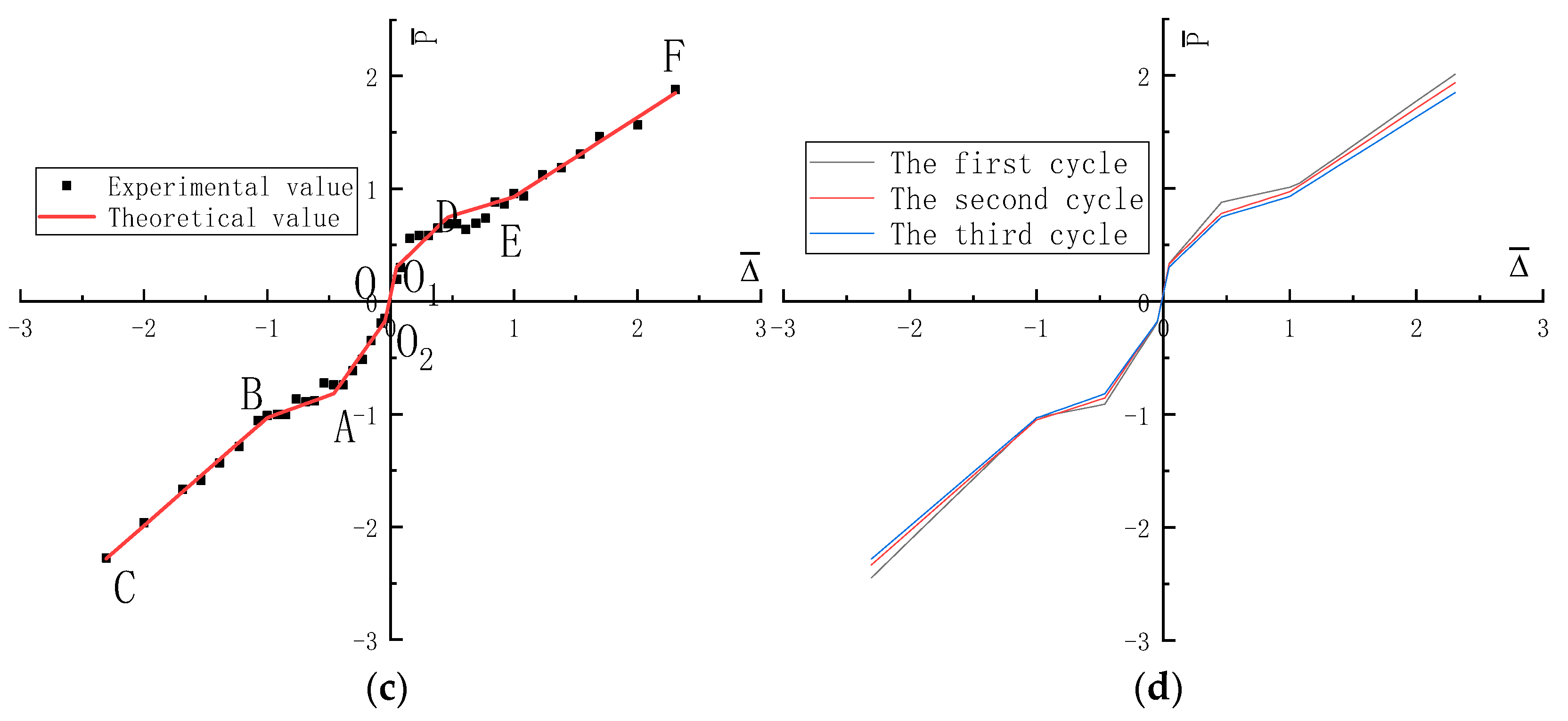

3.1. Load–Displacement Hysteretic Curve

3.2. Load–Displacement Envelope Curve

- (1)

- In different displacement cycles, the strength of first cycle was found to be stronger than the second and third cycles. The strength degradation was caused by the crack development and the plastic cumulative deformation of the wood components.

- (2)

- Both the positive and negative curves followed the same trend up to 25 mm (the drift angle was 1/64) displacement. Before the 25 mm (the drift angle was 1/64) cycles, no obvious damage occurred in the timber components and no penetrating cracks formed on the masonry wall. The whole frame was still in the elastic stage.

- (3)

- During the 30–65 mm (drift angle during 3/160 and 13/320) cycles, strength degradation began in both the left (negative) and right (positive) loading directions while the load was increasing. This happened because of the failure of the masonry wall, and the tenons were pulled out of the mortises. The penetrating cracks began to appear in the masonry wall, and the crannies became larger as the loading displacement increased. The gaps between mortise and tenon joints of the frame and wood windows increased as loading displacement increased. In the 65 mm (the drift angle was 13/320) cycles, the left and right side of the masonry wall began to collapse. During the loading process, the cracks on the right side (the positive direction) of the masonry wall grew faster than those on the left side (the negative direction) (see Figure 11e). Therefore, the strength degradation of the frame in the positive loading was weaker than that in the negative direction. The whole frame entered the elastoplastic deformation stage.

- (4)

- After the 65 mm (the drift angle was 13/320) cycles, the stiffness increased in both the right (positive) and left (negative) directions. The stiffness was stronger than that of the 30–65 mm (the drift angle during 3/160 and 13/320) cycles but weaker than that before the 30 mm (the drift angle was 3/160) cycles. This is because the masonry wall failed after the 65 mm (the drift angle was 13/320) cycles, and the components of the timber frames were compressed with each other. The structure reached a new elastic–plastic stage characterized by the increase of the stiffness and the residual deformation of the timber components.

4. Hysteresis Model

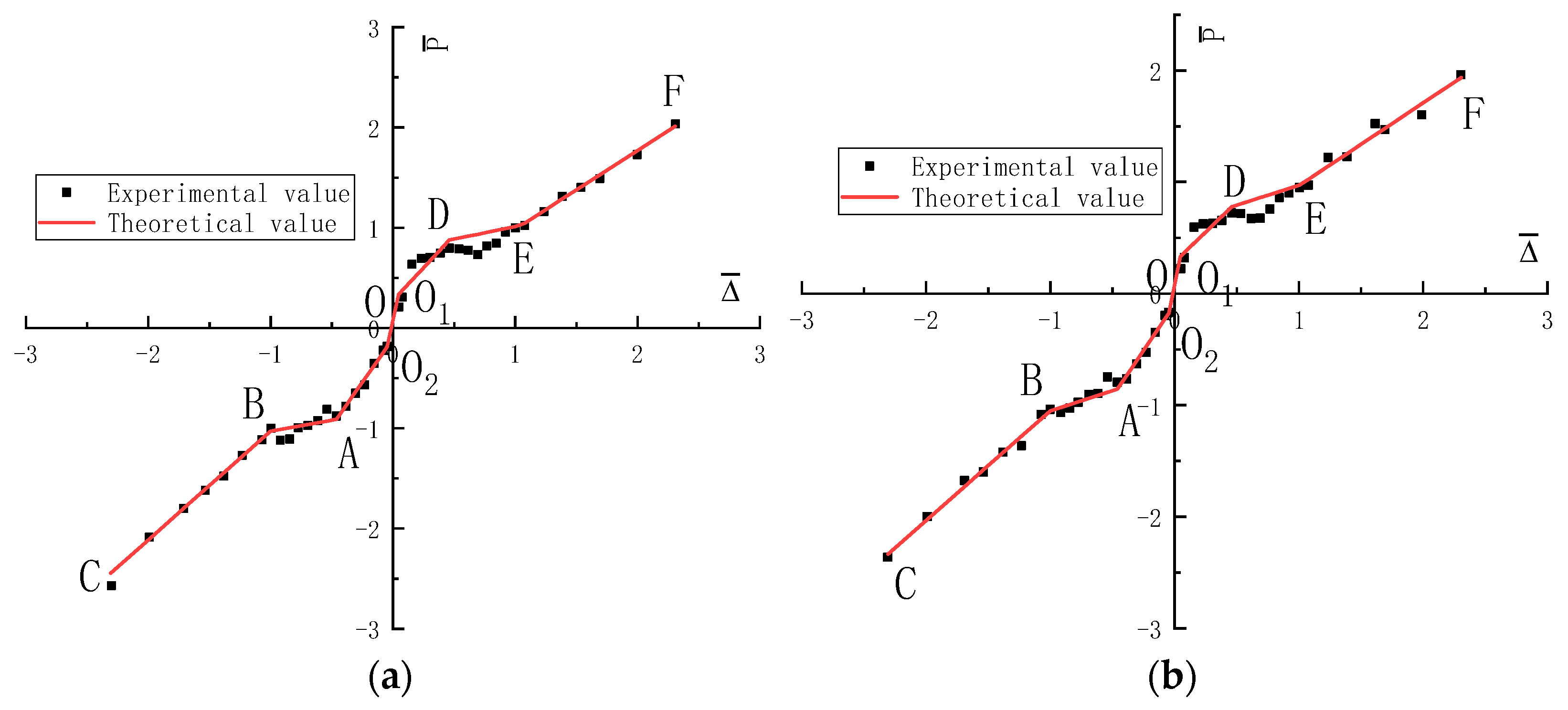

4.1. Envelope Curve

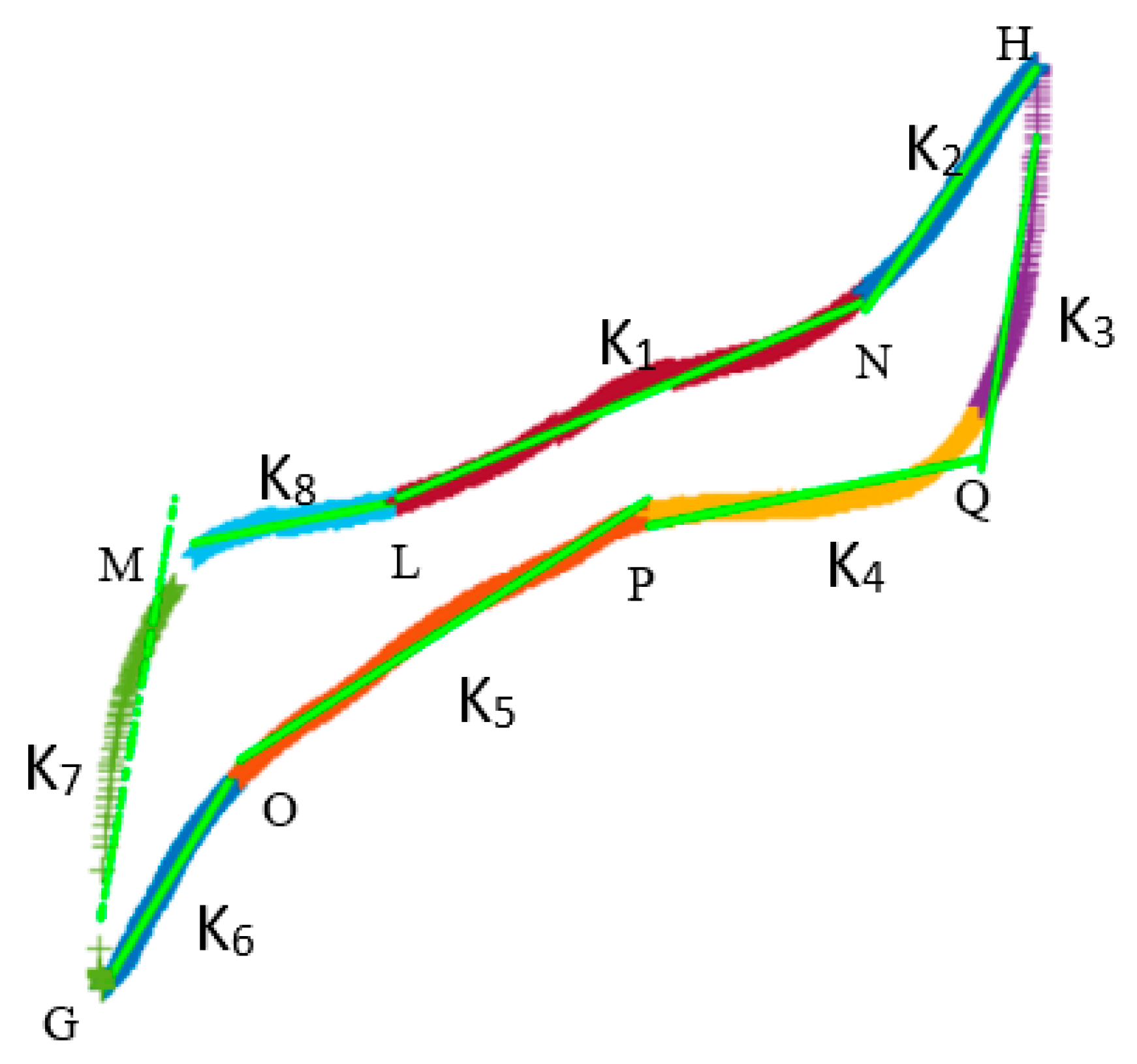

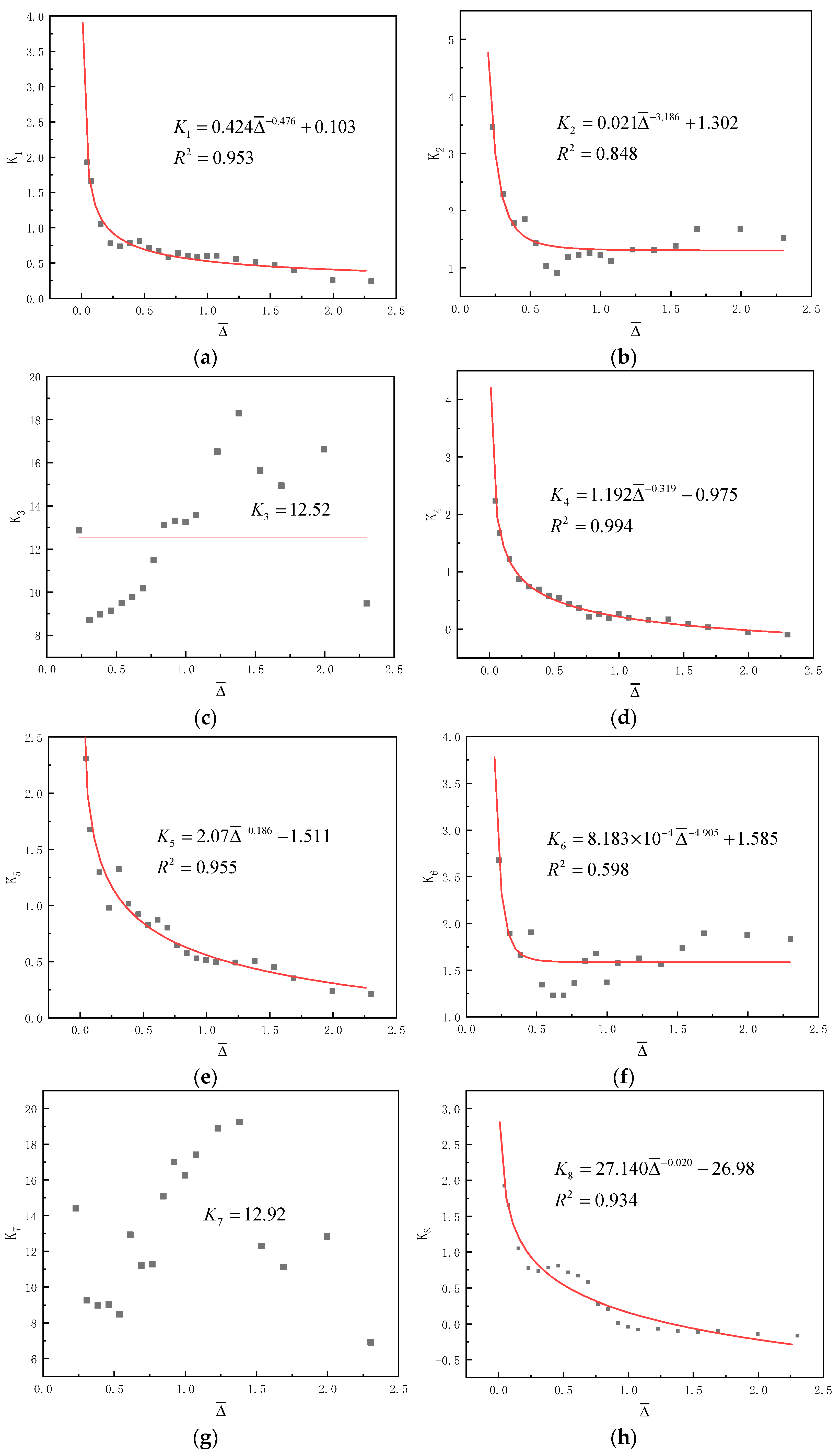

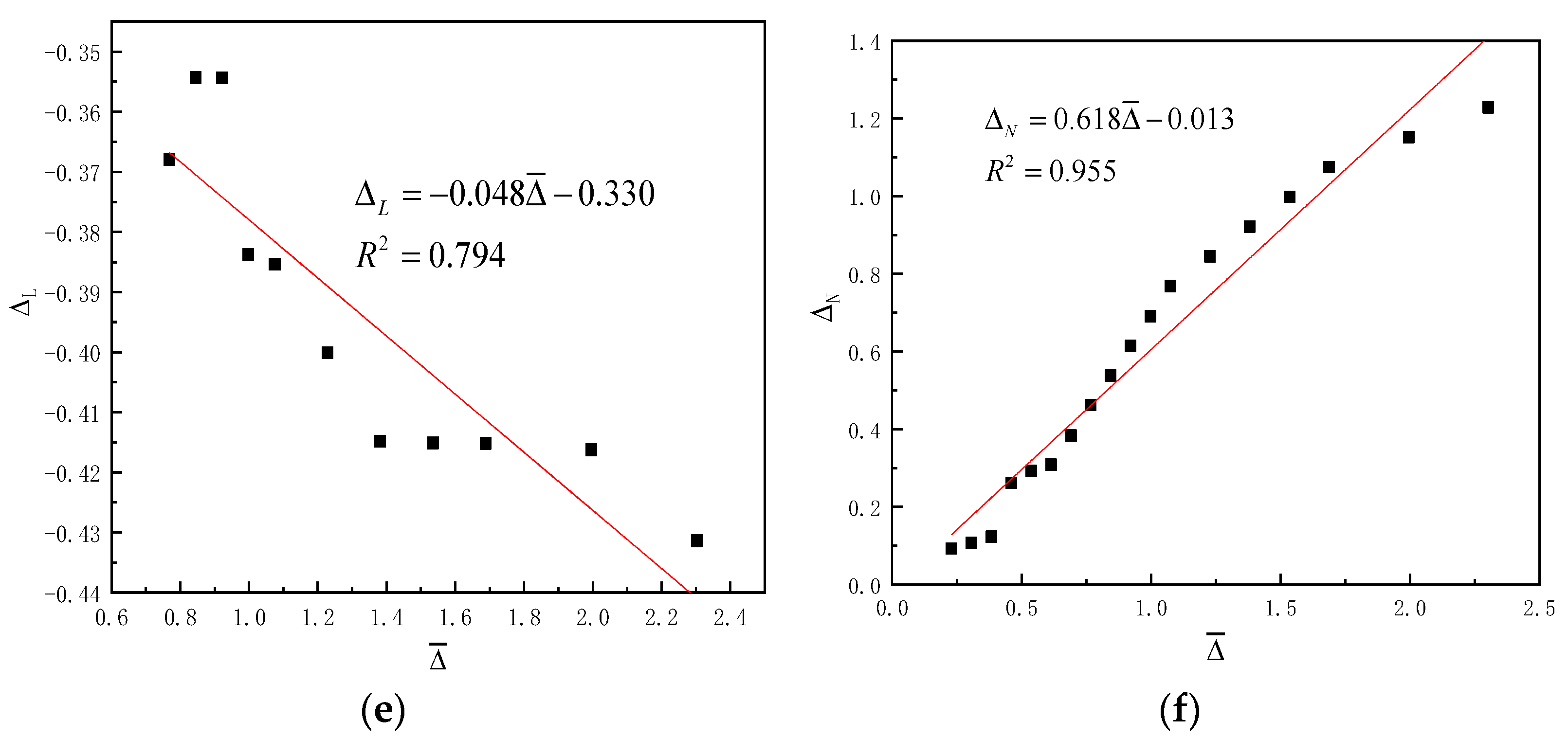

4.2. Stiffness of the Hysteretic Loops

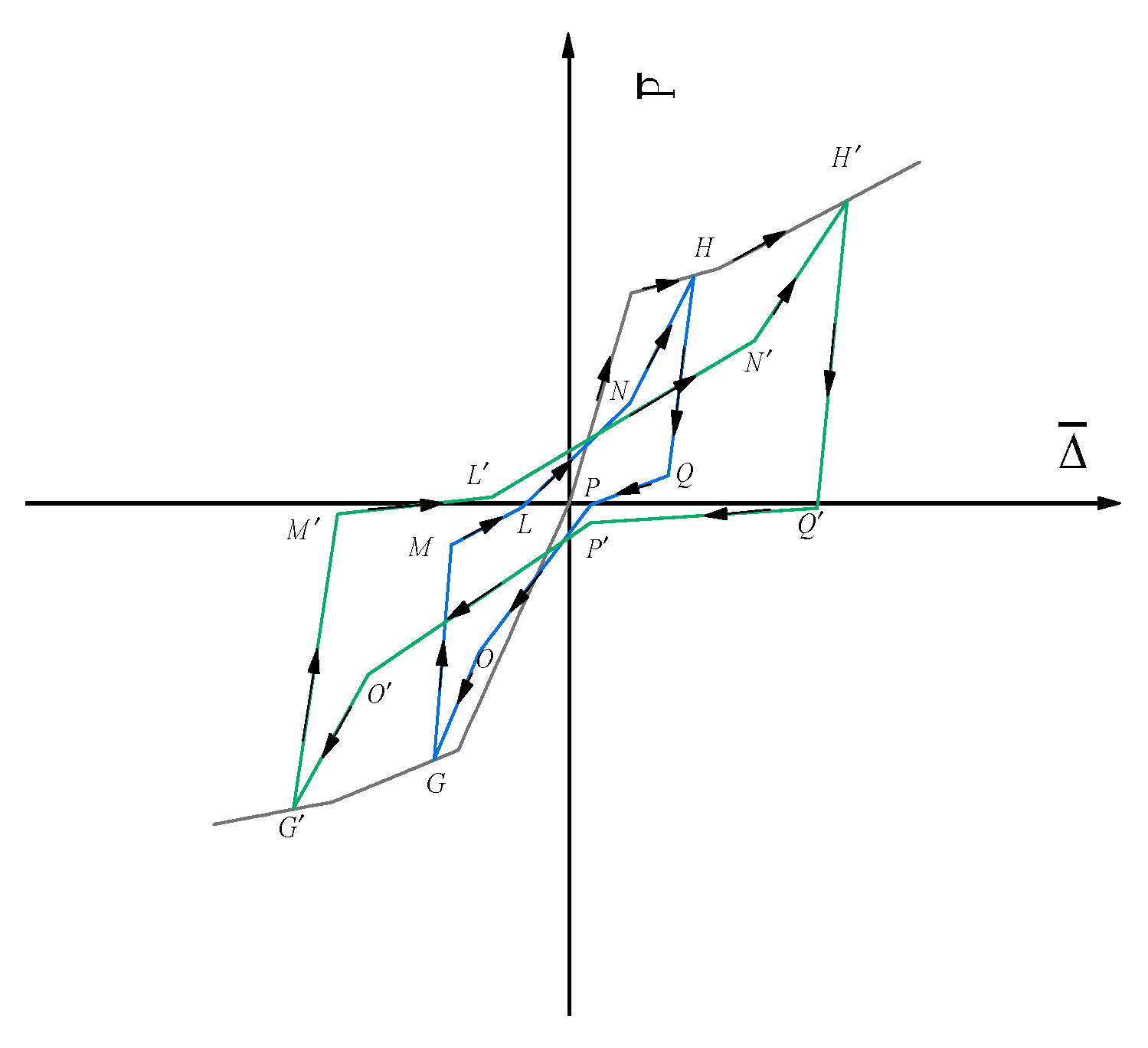

4.3. Hysteretic Rule

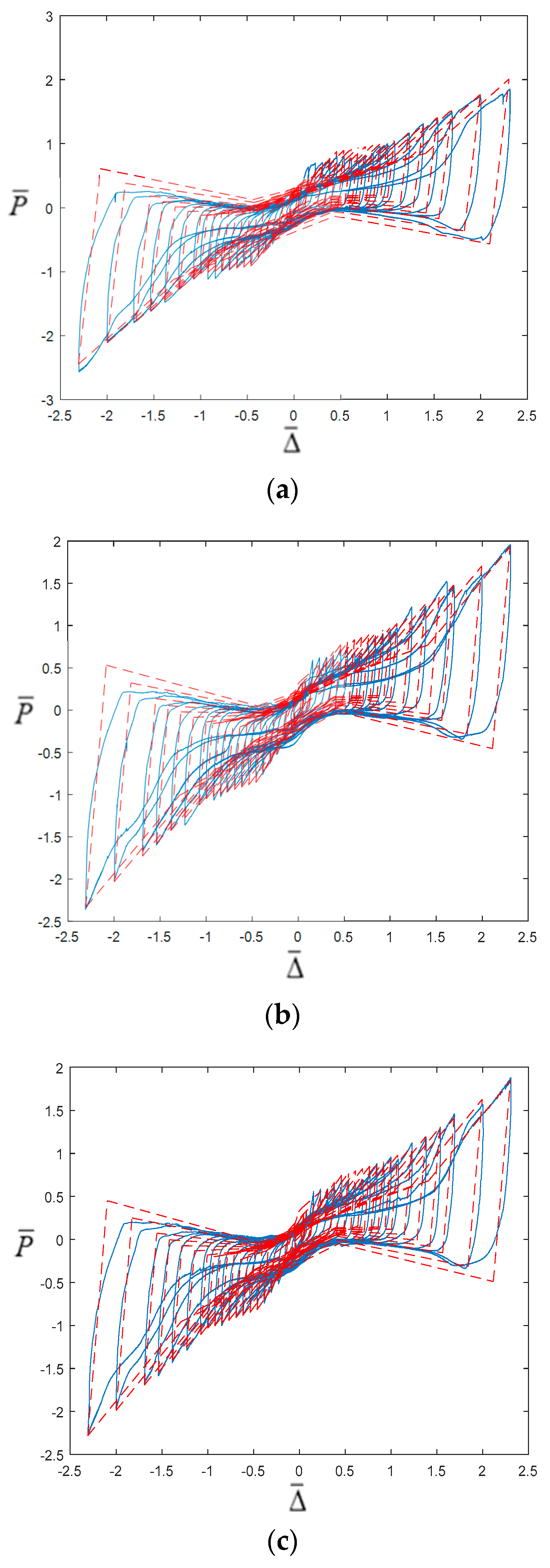

5. Comparison of the Hysteretic Curves between the Analysis and Test

6. Conclusions

- (1)

- The test results show that the loading process can be divided into three stages. At the elastic stage, no apparent damage was found through observation except for slight cracks on the wall. During the elastoplastic stage, the cracks on the wall became longer, wider and deeper as the loading displacement increased, and the gaps between the mortises and tenons steadily increased as the loading displacement increased. During the final new elastoplastic stage, the stiffness of the whole structure increased after the masonry wall collapsed. Brittle shear failure was observed in the masonry infill wall. At the end of the test, the masonry wall collapsed, but the timber frames did not fall apart. Slight cracks also appeared on the surface of the Lingtiao.

- (2)

- The pinching effect was observed from the hysteretic loops of the Kanchuang frame, indicating an occurrence of a slip between the timber components. The bearing capacity and stiffness of the frame were decreased but not lost, showing that the timber frame has good bearing and deformation capacities.

- (3)

- A dimensionless hysteretic model for the Kanchuang frame was established based on test results and numerical analysis. This model simulates the experimental curves’ strength degradation, stiffness degradation and pinching effect. The calculation results were consistent with the experimental results. They provide references for dynamic analyses of the traditional timber structure under dynamic loads.

- (4)

- This study provided a useful reference for the seismic evaluation and preservation of cultural heritage. This study also conducted dynamic analyses of the traditional timber structure under dynamic loads. However, in this study, the experimental and analytical studies were carried out on a scaled specimen, not a full-scaled one. Thus, further studies will be conducted to investigate whether this hysteretic model could apply to other frames of different dimensions. Moreover, the seismic and hysteretic behaviours of more timber frames with different types of infilled walls from ancient timber buildings will be studied.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, Q.; Yan, W.M.; Yang, X.S.; Bao, J.J. Damage of ancient Chinese architecture caused by the Wenchuan earthquake. Sci. Conserv. Archaeol. 2010, 22, 37–45. [Google Scholar]

- Fang, D.P.; Iwasaki, S.; Yu, M.H.; Shen, Q.P.; Miyamoto, Y.; Hikosaka, H. Ancient Chinese timber architecture I: An experimental study. J. Struct. Eng. 2001, 127, 1348–1357. [Google Scholar] [CrossRef]

- Xie, Q.; Zhang, L.; Wang, L.; Zhou, W.; Zhou, T. Lateral performance of traditional Chinese timber frames: Experiments and analytical model. Eng. Struct. 2019, 186, 446–455. [Google Scholar] [CrossRef]

- Li, J. Yingzao Fashi Construction Method; Royal Press: Kaifeng, China, 1103; (In Ancient Chinese). [Google Scholar]

- Liang, S.C. A Pictorial History of Chinese Architecture: A Study of the Development of Its Structural System and the Evolution of Its Types; MIT Press: Cambridge, MA, USA, 1984. [Google Scholar]

- Eckelman, C.A.; Uysal, M.; Haviarova, E. Statistical lower tolerance limits for rectangular mortise and tenon joints. BioResources 2016, 11, 7162–7171. [Google Scholar] [CrossRef][Green Version]

- Likos, E.; Haviarova, E.; Eckelman, C.A.; Erdil, Y.Z.; Ozcifci, A. Effect of tenon geometry, grain orientation, and shoulder on bending moment capacity and moment rotation characteristics of mortise and tenon joints. Wood Fiber Sci. 2012, 44, 462–469. [Google Scholar]

- Huan, J.H.; Ma, D.H.; Guo, X.D.; Xu, S. Experimental study of aseismic behaviors of flexural tenon joint, through tenon joint and dovetail joint reinforced with flat steel devices. J. Beijing Univ. Technol. 2019, 45, 763–771. [Google Scholar]

- Chen, C.; Qiu, H.; Lu, Y. Flexural behaviour of timber dovetail mortise–tenon joints. Constr. Build. Mater. 2016, 112, 366–377. [Google Scholar] [CrossRef]

- Zhong, J.; Wang, L.; Li, Y.; Zhou, M. Solving the mystery of China’s thousand-year-old wooden pagoda. Civ. Eng. 2017, 170, 169–173. [Google Scholar] [CrossRef]

- Chen, Z.; Zhu, E.; Lam, F.; Pan, J. Structural performance of Dou-Gong brackets of Yingxian Wood Pagoda under vertical load—An experimental study. Eng. Struct. 2014, 80, 274–288. [Google Scholar] [CrossRef]

- Wu, Y.; Song, X.; Ventura, C.; Lam, F. Modeling hysteretic behavior of lateral load-resisting elements in traditional Chinese timber structures. J. Struct. Eng. 2020, 146, 04020062. [Google Scholar] [CrossRef]

- Meng, X.-J.; Li, T.-Y.; Yang, Q.-S. Lateral structural performance of column frame layer and dou-gong layer in a timber structure. KSCE J. Civ. Eng. 2018, 23, 666–677. [Google Scholar] [CrossRef]

- Kaori, F. Dynamic performance of bracket complexes used in traditional timber structures in Japan. Proc. Jpn. Acad. 2019, 95, 568–580. [Google Scholar]

- Tsuwa, I.; Koshihara, M.; Fujita, K.; Isao, K. A study on the size effect of bracket complexes used in traditional timber structures on the vibration characteristics. In Proceedings of the 10th World Conference on Timber Engineering, Miyazaki, Japan, 2–5 June 2008. [Google Scholar]

- Cui, Z.H.; Wang, J.; Yang, Q.S. Study on the structural performance of the hall-style wooden frame and bracket complexes in Tang Dynasty. In Proceedings of the 10th World Conference on Timber Engineering, Miyazaki, Japan, 2–5 June 2008. [Google Scholar]

- Yeo, S.Y.; Chung, Y.L.; Huang, Y.C.; Yeh, Y.H.; Hsu, M.F. Seismic behaviour of Taiwanese timber complex brackets subjected to out-of-plane loading. J. Proc. Inst. Civ. Eng.-Eng. Hist. Herit. 2020, 174, 15–31. [Google Scholar] [CrossRef]

- Xie, W.; Wang, T.H.; Chang, W.S. Static behaviour of a two-tiered Dou-Gong system reinforced by super-elastic alloy. J. Proc. Inst. Civ. Eng.-Eng. Hist. Herit. 2019, 172, 164–173. [Google Scholar] [CrossRef]

- Huan, J.H.; Ma, D.H.; Wang, W. Vulnerability analysis of ancient timber architecture by considering the correlation of different failure modes. Math. Probl. Eng. 2018, 2018, 5163472. [Google Scholar] [CrossRef]

- Huan, J.H.; Ma, D.H.; Wang, W.; Guo, X.D.; Wang, Z.Y.; Wu, L.C. Evaluation model of structural entropy weight-matter element extension for ancient timber architecture safety state. Adv. Struct. Eng. 2020, 23, 1087–1097. [Google Scholar] [CrossRef]

- Huan, J.H.; Ma, D.H.; Wang, W.; Wang, Z. Safety State evaluation method based on attribute recognition model for ancient timber buildings. Adv. Civ. Eng. 2019, 2019, 3612535. [Google Scholar] [CrossRef]

- Xie, Q.; Wang, L.; Zhang, L.; Hu, W.; Zhou, T. Seismic behaviour of a traditional timber structure: Shaking table tests, energy dissipation mechanism and damage assessment model. Bull. Earthq. Eng. 2019, 17, 1689–1714. [Google Scholar] [CrossRef]

- Vieux-Champagne, F.; Sieffert, Y.; Grange, S.; Polastri, A.; Ceccotti, A.; Daudeville, L. Experimental analysis of seismic resistance of timber-framed structures with stones and earth infill. Eng. Struct. 2014, 69, 102–165. [Google Scholar] [CrossRef]

- Vieux-Champagne, F.; Sieffert, Y.; Grange, S.; Nko’Ol, C.B.; Bertrand, E.; Duccini, J.C.; Faye, C.; Daudeville, L. Experimental analysis of a shake table test of timber-framed structures with stones and earth infill. Earthq. Spectra 2017, 33, 1075–1100. [Google Scholar] [CrossRef]

- Ali, Q.; Schacher, T.; Ashraf, M.; Naeem, A.; Ahmad, N.; Umar, M. In-Plane Behavior of the Dhajji Walls (Wooden Braced Frame with Stone Infill). Earthq. Spectra 2012, 28, 835–858. [Google Scholar] [CrossRef]

- Poletti, E.; Vasconcelos, G. Seismic behaviour of traditional timber frame walls: Experimental results on unreinforced walls. Bull. Earthq. Eng. 2015, 13, 885–916. [Google Scholar] [CrossRef]

- Dutu, A.; Yamazaki, Y.; Sakata, H. Shear spring model proposed for seismic evaluation of a timber framed masonry infilled wall. Eng. Struct. 2018, 167, 671–682. [Google Scholar] [CrossRef]

- Dutu, A.; Sakata, H.; Yamazaki, Y.; Shindo, T. In-plane behavior of timber frames with masonry infills under static cyclic loading. J. Struct. Eng. 2016, 142, 04015140. [Google Scholar] [CrossRef]

- Guo, X.D.; Wu, L.C.; Xu, Q.F.; Huan, J.H. Research on drift angle on wooden frame with partition board based on value recognition. Ind. Constr. 2021, 51, 113–120. [Google Scholar]

- Xie, Q.; Wang, L.; Li, S.; Zhang, L.; Hu, W. Influence of wood infill walls on the seismic performance of Chinese traditional timber structure by shaking table tests. Bull. Earthq. Eng. 2020, 18, 5009–5029. [Google Scholar] [CrossRef]

- Chang, W.S.; Komatsu, K.; Hsu, M.F.; Chen, W.J. On mechanical behavior of traditional timber shear wall in Taiwan I: Background and theory derivation. J. Wood Sci. 2007, 53, 17–23. [Google Scholar] [CrossRef]

- Chang, W.S.; Hsu, M.F.; Komatsu, K. A new proposal to reinforce planked timber shear walls. J. Wood Sci. 2011, 57, 493–500. [Google Scholar] [CrossRef]

- Chang, W.S.; Hsu, M.F.; Komatsu, K.; Chen, W.J. On mechanical behavior of traditional timber shear wall in Taiwan II: Simplified calculation and experimental verification. J. Wood Sci. 2007, 53, 24–30. [Google Scholar] [CrossRef]

- Zhang, D.; Tao, Z.; Zhang, G.G.; Li, J.C. Experimental study on restoring force model for outer shell beam-column joints of steel structure. J. Eng. Sci. Technol. Rev. 2017, 10, 203–212. [Google Scholar] [CrossRef]

- Zhang, P.; Sun, R.; Deng, Y.; Li, Z.Z. Resilience model of steel-reinforced concrete tension columns. J. Disaster Prev. Mitig. Eng. 2021, 41, 549–557. [Google Scholar]

- Wu, L.W.; Chen, H.B.; Guo, X.Y.; Guo, J.J.; Wang, S. Study on hysteretic and restoring force model of precast T-shaped joint with concrete-filled steel tubular column. J. Build. Struct. 2021, 42 (Suppl. S2), 117–124. [Google Scholar]

- Kline, S.J. Similitude and Approximation Theory; Mc Graw-Hill: New York, NY, USA, 1965. [Google Scholar]

- Chen, Z.Y.; Zhu, E.C.; Pan, J.L.; Wu, G.F. Energy dissipation performance of typical beam-column joints in Yingxian Wood Pagoda: Experimental study. J. Perform. Constr. Facil. 2015, 30, 04015028. [Google Scholar] [CrossRef]

- JGJ/T 70-200; Standard for Test Method of Performance on Building Mortar. China Architecture and Building Press: Beijing, China, 2009.

- GB/T 2542; Test Method of Wall Bricks. China Architecture and Building Press: Beijing, China, 2012.

- GB/T 50129-2011; Standard for Test Method of Basic Mechanics Properties of Masonry. China Architecture and Building Press: Beijing, China, 2011.

- GB 1927-1943; Physical and Mechanical Methods of Wood: –91. China Standards Press: Beijing, China, 1992.

- Liu, D.K. Roof loads of Chinese timber buildings (first volume). Tradit. Chin. Archit. Gard. 2001, 3, 58–64. [Google Scholar]

- Liu, D.K. Roof loads of Chinese timber buildings (second volume). Tradit. Chin. Archit. Gard. 2001, 4, 56–63. [Google Scholar]

- Chen, J.Y.; Shi, X.W.; Niu, Q.F.; Wei, J.W.; Li, T.Y.; Zhao, Y.X. Analysis of similar CaiFen modular system based on the weight of the roof of Song dynasty. J. Civ. Archit. Environ. Eng. 2016, 38, 27–33. [Google Scholar]

- Zhou, Y.; Lv, X.L. Method and Technology for Shaking Table Model Test of Building Structures; Science Press: Beijing, China, 2016. [Google Scholar]

- Sabnis, G.M.; Harris, H.G. Structural Modeling and Experimental Techniques; Prentice-Hall: Englewood Cliffs, NJ, USA, 1983. [Google Scholar]

- ISO/FDIS 21581; Timber Structures—Static and Cyclic Lateral Load Test Methods for Shear Walls. China Standards Press: Beijing, China, 2010.

- Huan, J.H.; Guo, X.D.; Ma, D.H.; Guan, Z.Z. Seismic performance and damage evaluation of Kanchuang frame of ancient architecture. J. Civ. Environ. Eng. 2022, 44, 129–137. [Google Scholar]

| Length | Area | Displacement | Elastic Modulus | Force | Drift Angle | Moment | Density | Mass |

|---|---|---|---|---|---|---|---|---|

| 1/2 | 1/4 | 1/2 | 1 | 1/4 | 1 | 1/8 | 2 | 1/4 |

| Compressive Strength | Shear Strength of Masonry | Young’s Modulus of Masonry | ||

|---|---|---|---|---|

| Mortar | Brick | Masonry | ||

| 2.0 | 9.3 | 3.4 | 0.041 | 1259 |

| Density | Moisture Content | Parallel to Grain (MPa) | Perpendicular to Grain (MPa) | ||||

|---|---|---|---|---|---|---|---|

| Compressive Strength | Elastic Modulus | Compressive Strength (T) | Elastic Modulus (T) | Compressive Strength (R) | Elastic Modulus (R) | ||

| 0.369 g/m3 | 10.09% | 46.21 | 8907 | 3.39 | 771 | 5.49 | 1620 |

| Points | O2 | A | B | C | O1 | D | E | F | |

|---|---|---|---|---|---|---|---|---|---|

| The first cycle | −0.046 | −0.464 | −0.998 | −2.301 | 0.046 | 0.462 | 1.002 | 2.311 | |

| −0.187 | −0.913 | −1.007 | −2.511 | 0.334 | 0.878 | 1.011 | 1.906 | ||

| The second cycle | −0.046 | −0.461 | −1.001 | −2.309 | 0.046 | 0.459 | 1.005 | 2.304 | |

| −0.173 | −0.856 | −1.051 | −2.337 | 0.332 | 0.778 | 0.972 | 1.933 | ||

| The third cycle | −0.046 | −0.461 | −1.001 | −2.309 | 0.046 | 0.459 | 1.005 | 2.304 | |

| −0.176 | −0.856 | −1.051 | −2.337 | 0.303 | 0.778 | 0.972 | 1.933 | ||

| Line | Regression Equations | ||

|---|---|---|---|

| The First Cycle | The Second Cycle | The Third Cycle | |

| OA | |||

| AB | |||

| BC | |||

| OD | |||

| DE | |||

| EF | |||

| Feature Segment | Loading Elastic Stage 1 | Loading Strengthen Stage 1 | Rapid Unloading Stage 1 | Unloading Elastic Stage 1 | Loading Elastic Stage 2 | Loading Strengthen Stage 2 | Rapid Unloading Stage 2 | Unloading Elastic Stage 2 |

|---|---|---|---|---|---|---|---|---|

| Represent parameter |

| Feature Segment | Fitting Equations |

|---|---|

| Loading elastic stage 1 | |

| Loading strengthen stage 1 | |

| Rapid unloading stage 1 | |

| Unloading elastic stage 1 | |

| Loading elastic stage 2 | |

| Loading strengthen stage 2 | |

| Rapid unloading stage 2 | |

| Unloading elastic stage 2 |

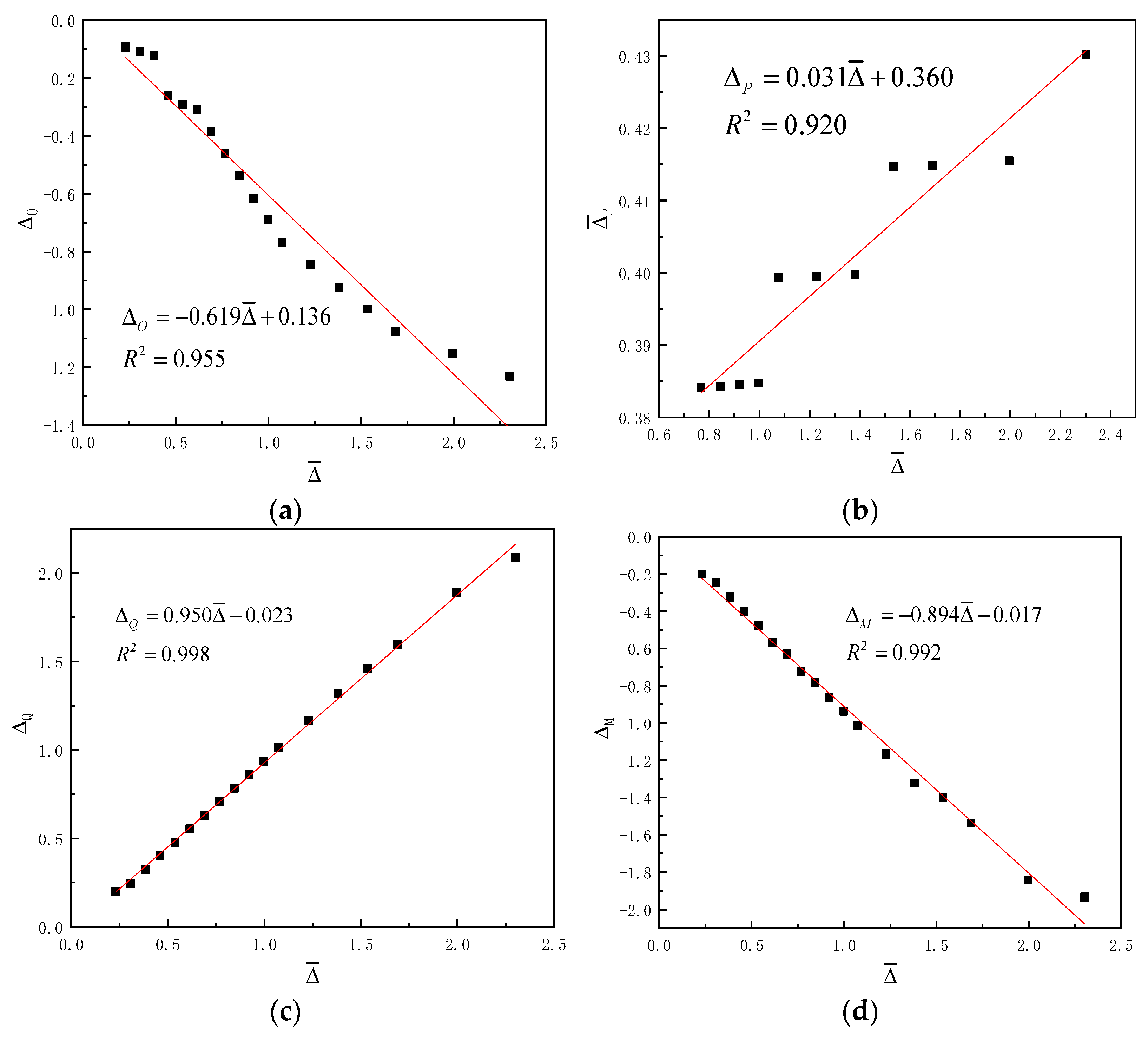

| Points | Fitting Equations |

|---|---|

| O | |

| P | |

| Q | |

| M | |

| L | |

| N |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huan, J.; Guo, X.; Guan, Z.; Yan, T.; Chu, T.; Sun, Z. An Experimental Study of the Hysteresis Model of the Kanchuang Frame Used in Chinese Traditional Timber Buildings of the Qing Dynasty. Buildings 2022, 12, 887. https://doi.org/10.3390/buildings12070887

Huan J, Guo X, Guan Z, Yan T, Chu T, Sun Z. An Experimental Study of the Hysteresis Model of the Kanchuang Frame Used in Chinese Traditional Timber Buildings of the Qing Dynasty. Buildings. 2022; 12(7):887. https://doi.org/10.3390/buildings12070887

Chicago/Turabian StyleHuan, Junhong, Xiaodong Guo, Zhongzheng Guan, Teliang Yan, Tianyang Chu, and Zemeng Sun. 2022. "An Experimental Study of the Hysteresis Model of the Kanchuang Frame Used in Chinese Traditional Timber Buildings of the Qing Dynasty" Buildings 12, no. 7: 887. https://doi.org/10.3390/buildings12070887

APA StyleHuan, J., Guo, X., Guan, Z., Yan, T., Chu, T., & Sun, Z. (2022). An Experimental Study of the Hysteresis Model of the Kanchuang Frame Used in Chinese Traditional Timber Buildings of the Qing Dynasty. Buildings, 12(7), 887. https://doi.org/10.3390/buildings12070887