Abstract

As one of the biggest energy consumers, buildings are the focus of the energy conservation market, and the building envelope, which has the highest impact on heating and cooling loads, is one of the main targets in retrofit projects. Several materials, systems, methods, and simulation tools are used in these projects, and it is critical to understand the impact of these methods in different locations, their frequency of use, and the effectiveness of market-ready new solutions. In that context, it is necessary to review the energy conservation measures (ECMs) that are suitable for residential building envelope retrofitting, and that are commercially available or under research and development. This paper provides an overview of these ECMs. A literature review was conducted on different building envelope ECMs, including traditional and innovative energy retrofit methods, such as aerogel and phase change materials on opaque and transparent components of existing buildings. Results show that the most effective retrofit projects include bundles of ECMs, and the traditional ECMs can be as effective as more innovative solutions in terms of energy saving. Moreover, computer energy models were created for a typical residential building in the US for cold and warm climate zones to determine the impact of different retrofit approaches based on a sensitivity analysis. Results show that envelope ECMs have higher energy saving potentials in cold climate zones, of up to around 30%, and reducing the air infiltration has the highest impact in both cold and warm climate zones in a typical small residential building.

1. Introduction

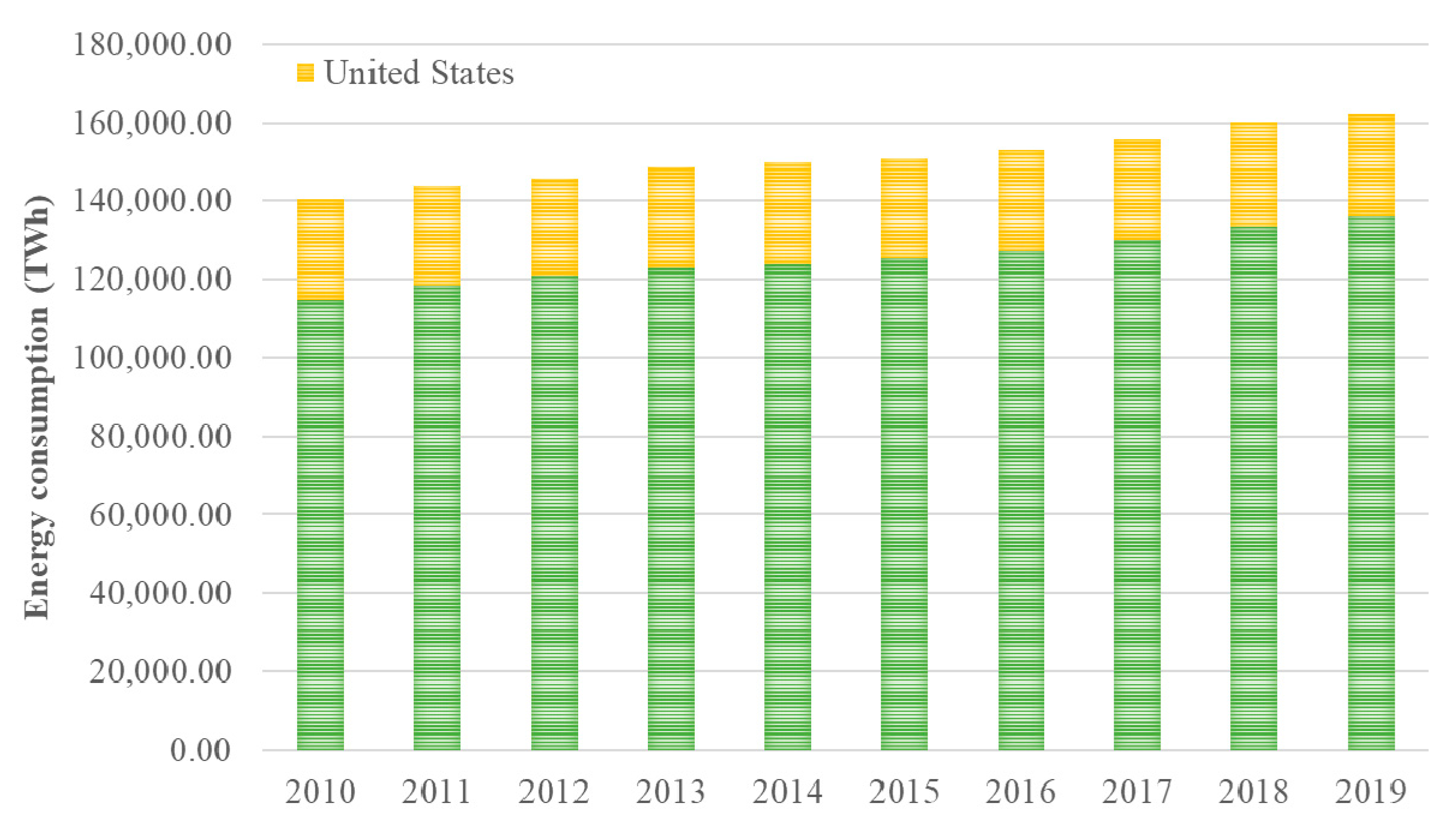

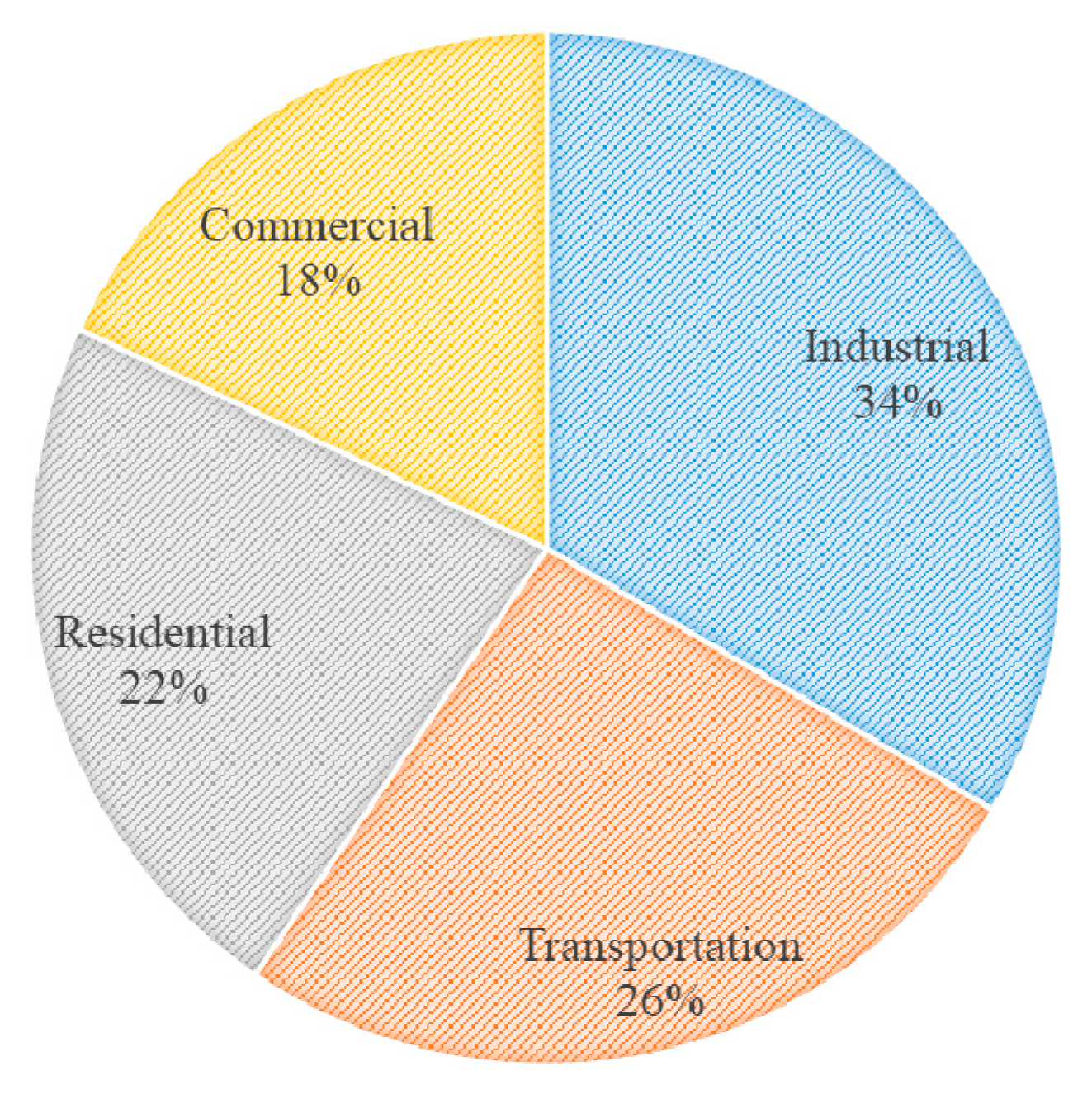

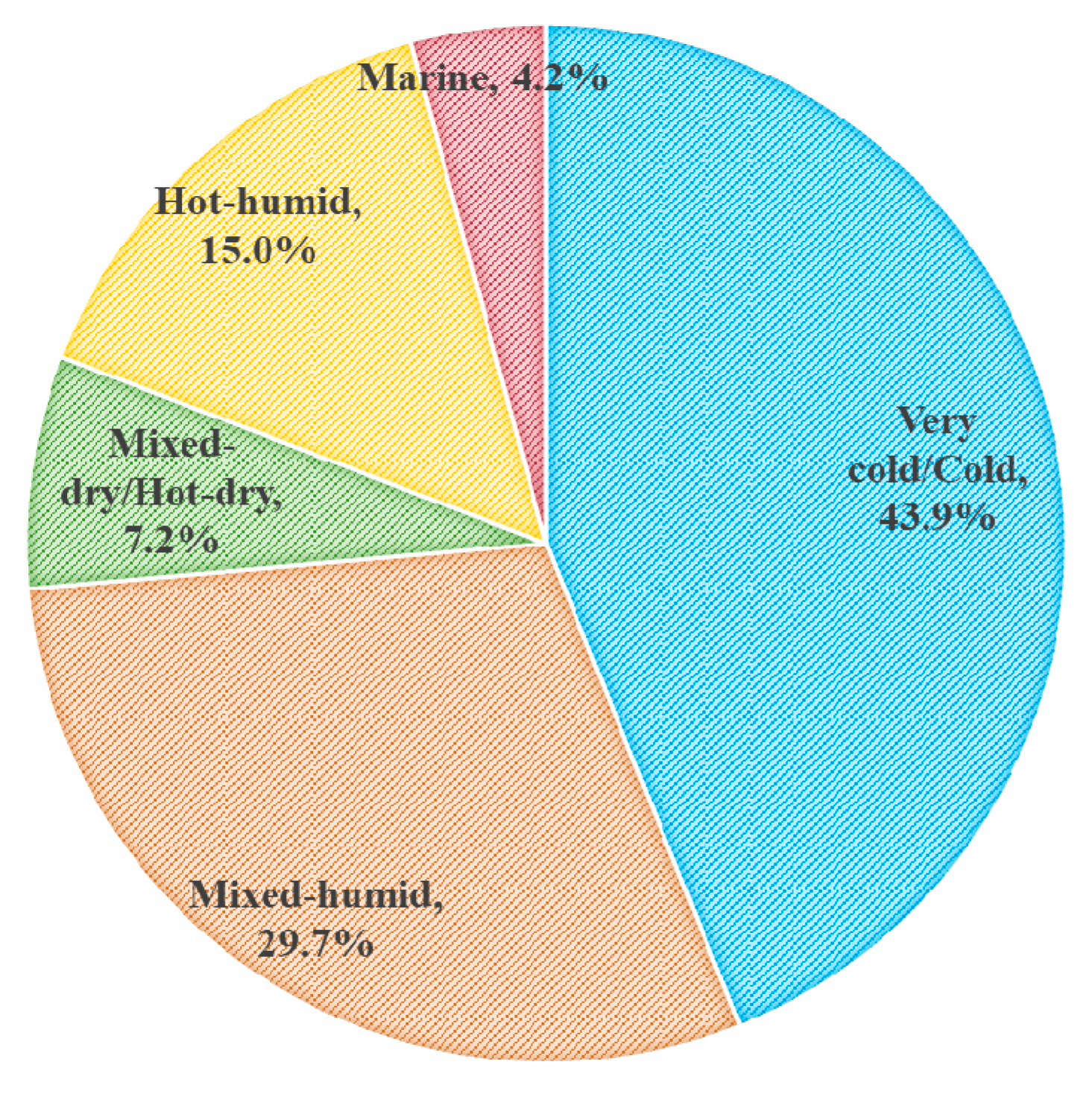

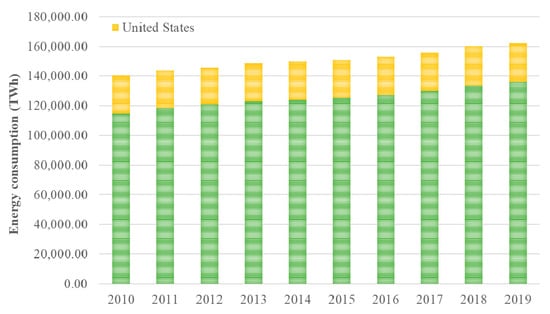

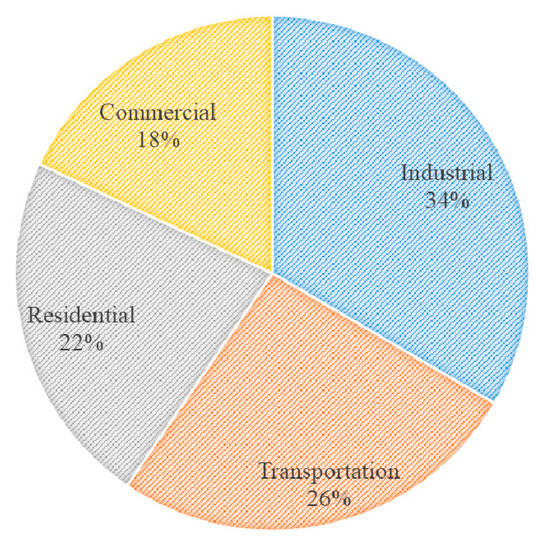

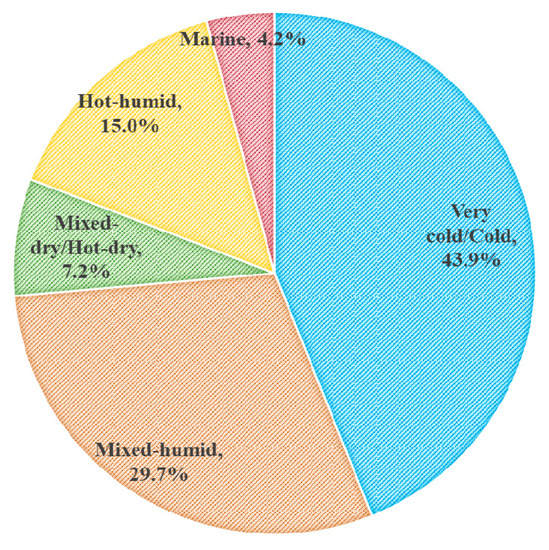

Growing world energy use has raised concerns about supply, exhaustion of resources, and environmental impacts. Residential and commercial sectors were responsible for about 40% of total energy consumption in the USA in 2015 [1]. Reducing even a small amount of this energy can lead to desirable environmental effects and financial benefits. The energy consumed in buildings can be reduced by using more energy-efficient appliances and reducing the energy loss, particularly through the building envelope. In 2013, U.S. primary energy use was about 17% of the world’s total energy consumption (Figure 1) [1]. In addition, residential and commercial sectors (Figure 2) accounted for almost 40% of the total energy consumption in the US in 2015 [1]; this proportion is between 20–40% in developed countries [2]. Residential and commercial sectors account for approximately 22% and 18% of total energy consumption, respectively. In addition to the more comprehensive reports, such as the Annual Energy Outlook (AEO), the Energy Information Administrative publishes more detailed reports on residential buildings, including Residential Energy Consumption Survey (RECS). Based on the 2015 report data, air conditioning, domestic hot water, and refrigerators consumed about 45% of the electricity in the residential sector. About 68% of the natural gas in the residential sector is used for space heating. Energy consumption due to space conditioning varies depending on climate zones and the age of buildings. In 2015, the energy consumption of residential buildings in the very cold/cold climate zone was about 45% (Figure 3) [3]. Residential buildings constructed before 1940 use about 54% of their energy for space conditioning, whereas this consumption is about 43% for houses built from 2000 to 2009 [3], indicating the importance of retrofitting the building envelope.

Figure 1.

World’s primary energy use vs. the US (adopted from [4]).

Figure 2.

US energy use by end-use sectors in 2020 (Total = 26,651.88 TWh).

Figure 3.

Site energy use in households in the US for different climate zones in 2015.

As there is growing interest in retrofitting existing buildings for more energy efficiency, this paper, as an extension to a previously published work by the authors [5], focuses on reviewing different energy retrofit methods that are already deemed and shown to be effective or are still under development and not available in the market. It is critical to understand the impact of these methods in different locations, their frequency of use, and the effectiveness of market-ready new solutions. In that context, it is necessary to review the energy conservation measures (ECMs) that are suitable for residential building envelope retrofitting, and that are commercially available or still under research and development. There is also a need to go beyond other similar studies, which do not perform a sensitivity analysis to compare these ECMs in different climate zones, and only focus on commercially available methods or are performed in limited climate zones. Therefore, the objectives of this paper are defined as follows: (1) to review the literature on commercially available and emerging building envelope energy retrofit materials and methods; (2) to identify the energy savings of different envelope ECMs in various locations globally; and (3) to generate knowledge based on computer simulation and a literature review about the impact of different ECMs on small residential buildings. The following research questions were proposed to address these objectives: (1) What are the main research areas related to building envelope energy retrofitting? (2) To what extent is energy use intensity reduced in buildings undergoing energy retrofit projects? And (3) What is the energy saving in residential buildings in cold and warm climate zones and under different envelope ECMs for typical residential buildings in the U.S.?

To address the third objective, a sensitivity analysis was performed on different residential building envelope ECMs in a benchmark house using the Beopt software program [6]. Different energy retrofit methods were considered in the study reported here, including adding exterior insulation and improving walls and roofs, using a cool roof, and improving windows’ U-Factor and Solar heat gain coefficient (SHGC). Energy analysis results show that the methods studied in this paper can potentially contribute to a reduction in energy use of approximately 30% in the benchmark house.

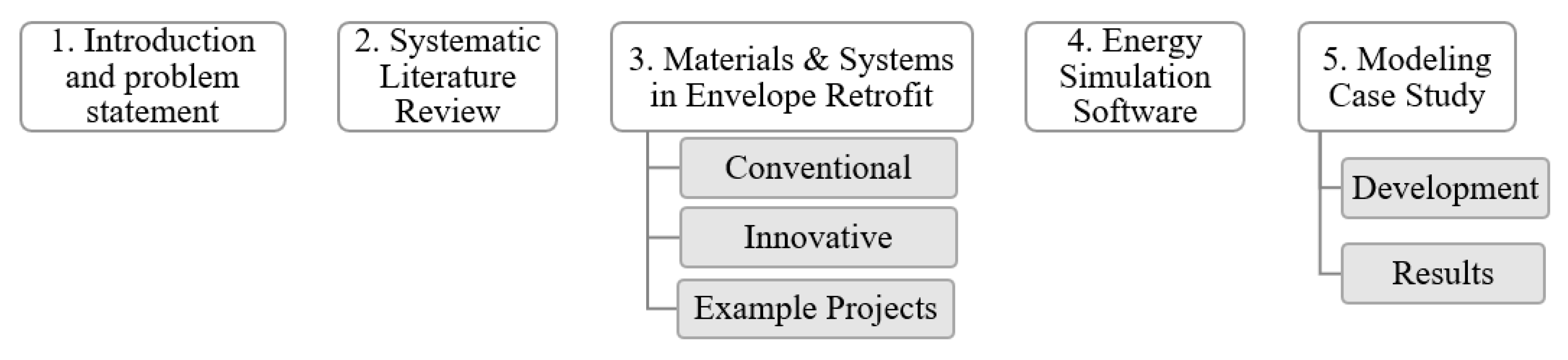

A snapshot overview of this article is shown in Figure 4, which shows the main content, and is comprised of the following sections: (1) the introduction and problem statement; (2) a comprehensive literature review; (3) a review of materials and systems that can be used in a building energy retrofit, and example projects to quantify the impact of different ECMs individually or as a bundle in buildings with different attributes in different climate zones; (4) a review of building energy simulation tools to show example applications and their typical use; and (5) a residential building energy model case study to help stakeholders determine the sensitivity of a residential building against different building envelope ECMs in different climate zones. The result of this study is expected to help overcome the challenges and obstacles that slow the implementation of energy-saving projects, such as information and technical issues identified by researchers [7].

Figure 4.

The paper’s overview.

2. Systematic Literature Review on Worldwide Building Envelope Energy Retrofit

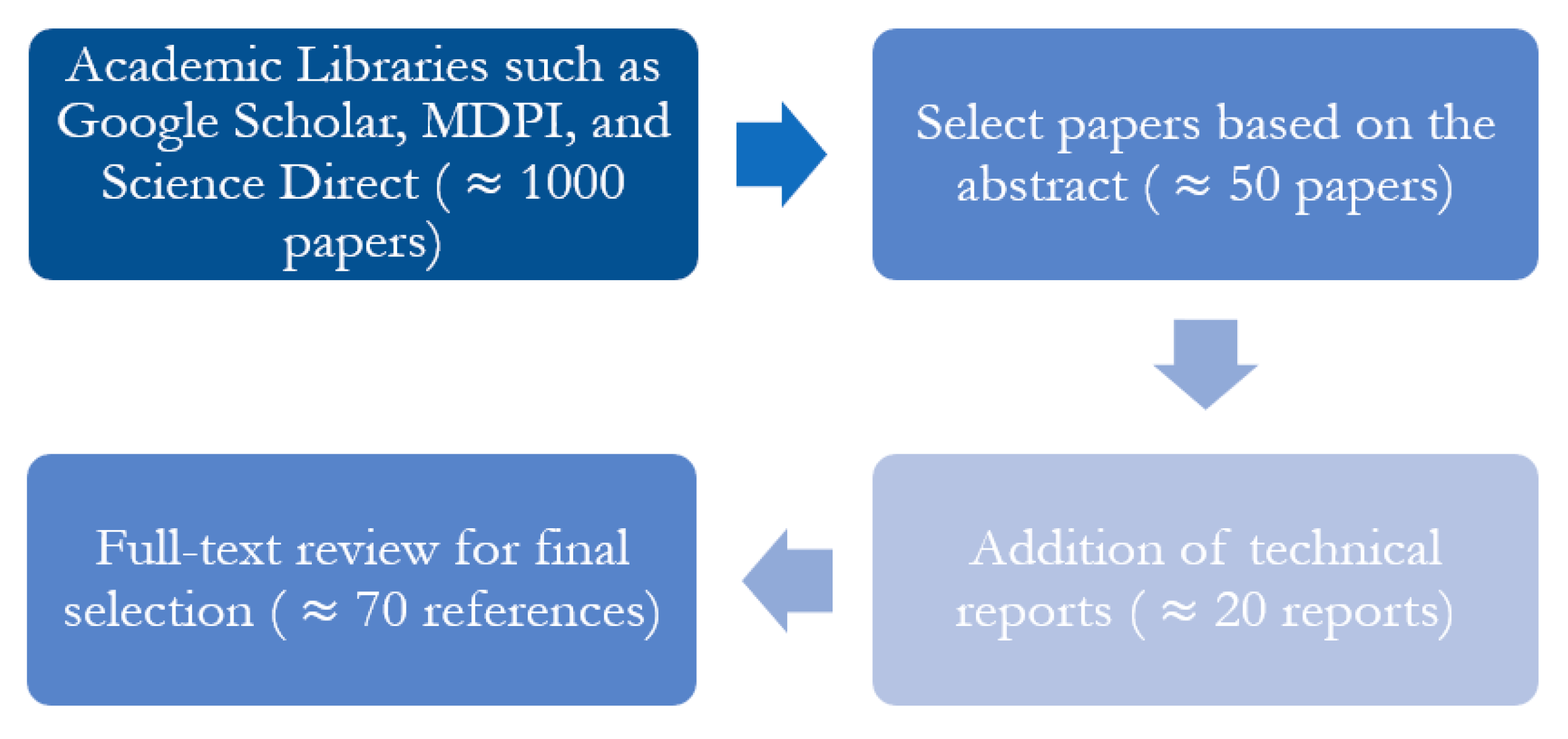

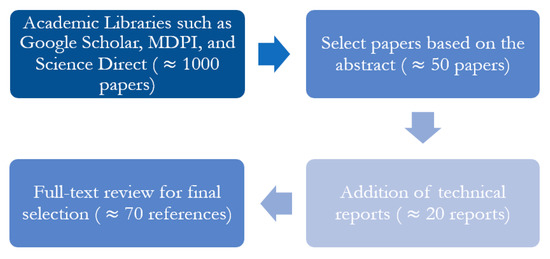

A systematic literature review was performed as a preliminary analysis to select the final articles for more in-depth analysis for case studies. The steps in this literature review includes: (1) mass review of articles’ abstracts based on relevant keywords; (2) identifying papers using more specific keywords and narrowing them down based on their abstract; (3) adding additional references not necessarily listed in archived publications, e.g., “unpublished” technical reports; and (4) examining the full texts for the final selection. This process is summarized in the flow diagram depicted in Figure 5.

Figure 5.

The selection process for papers.

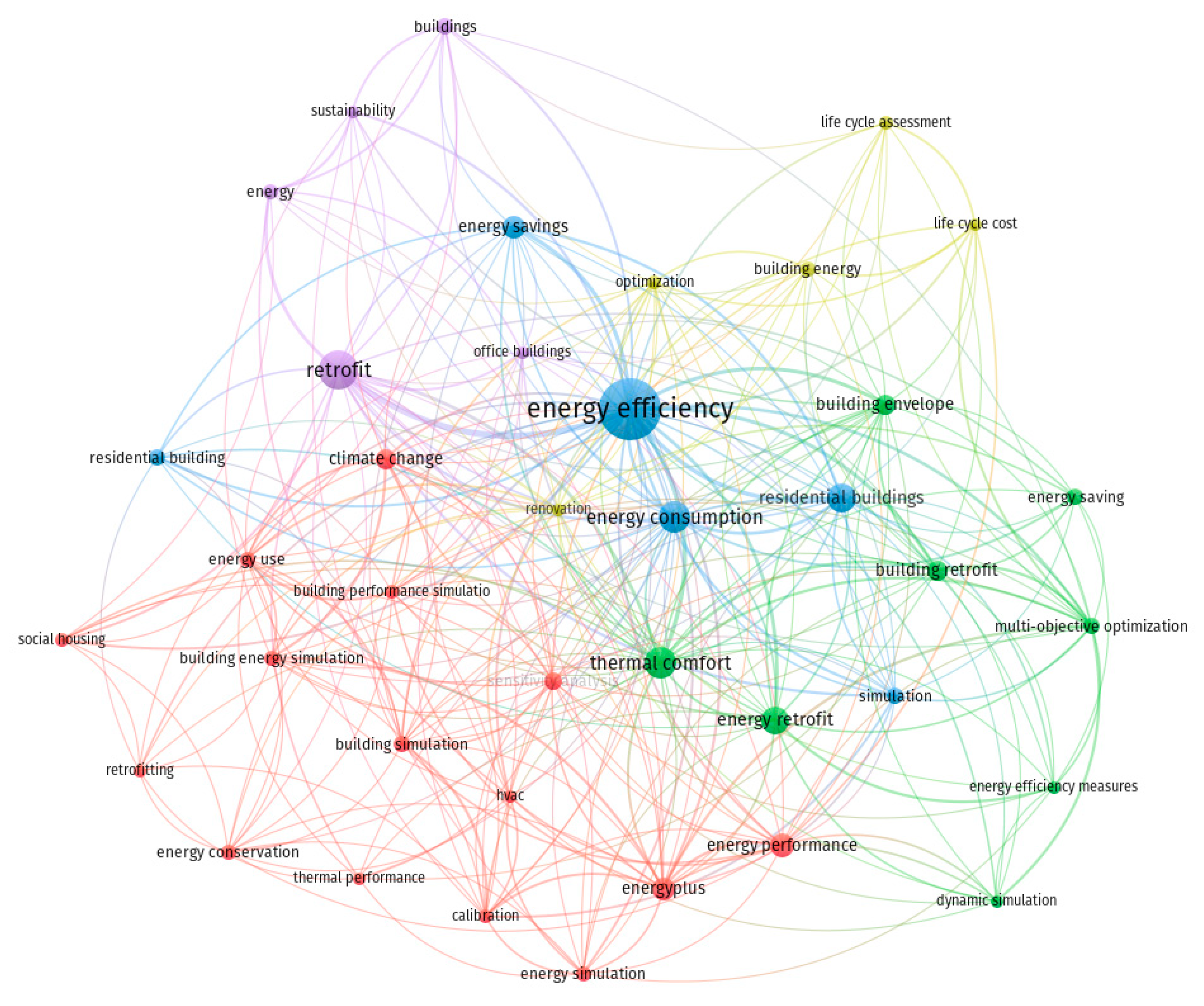

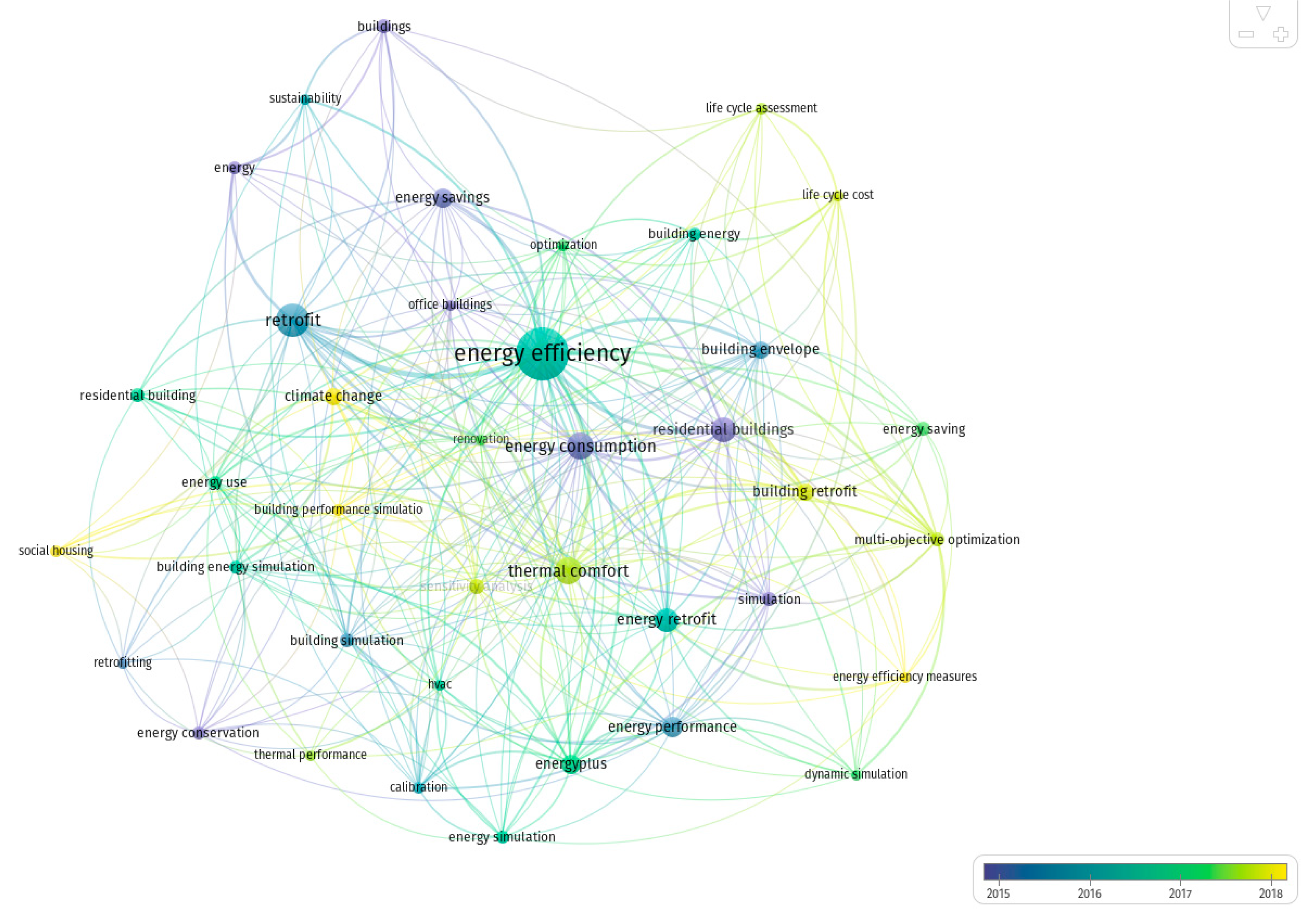

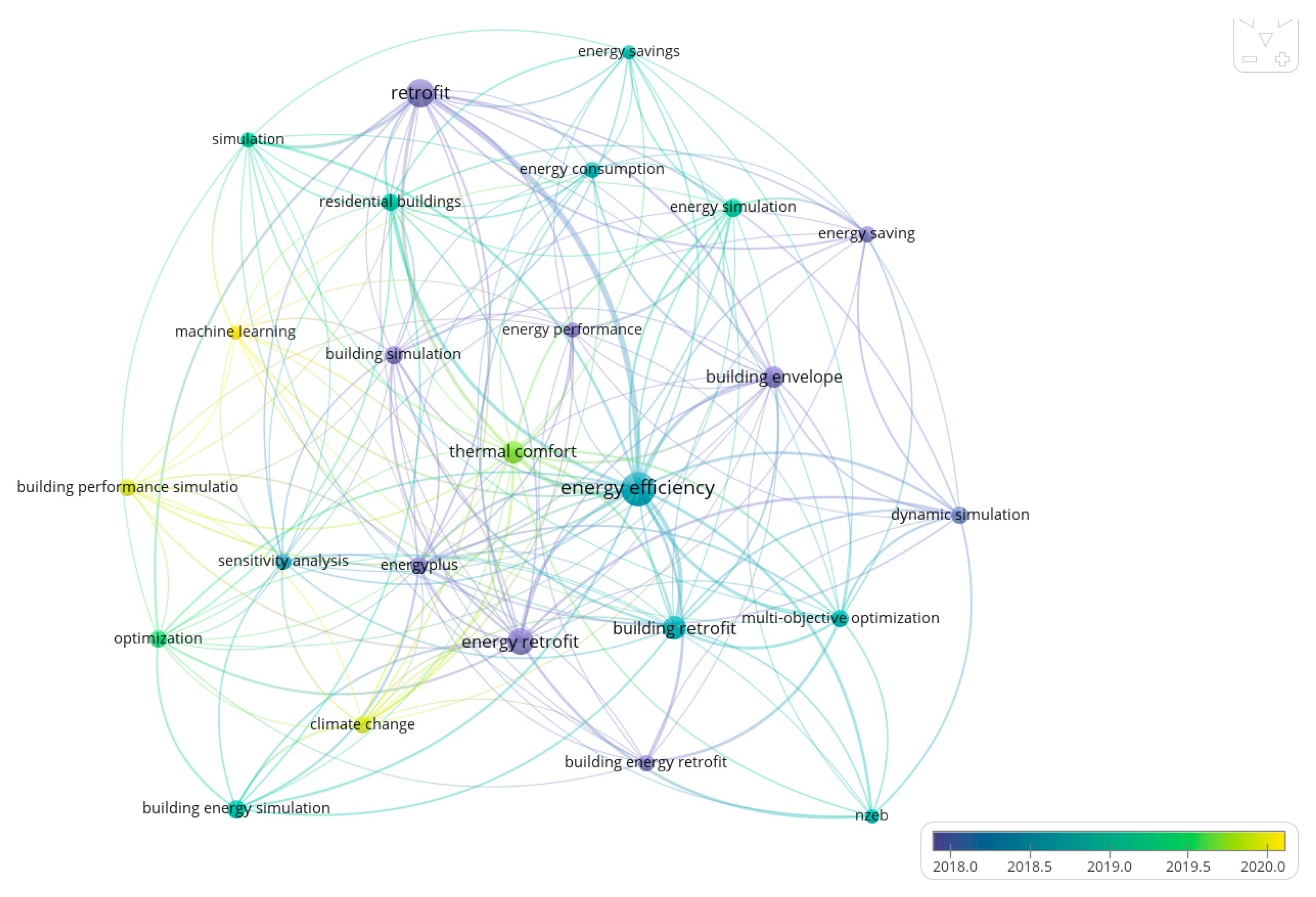

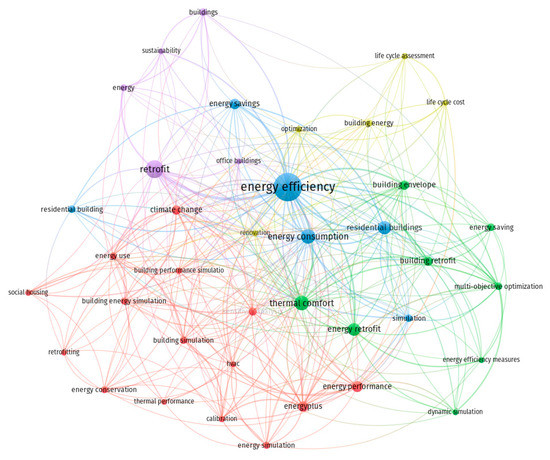

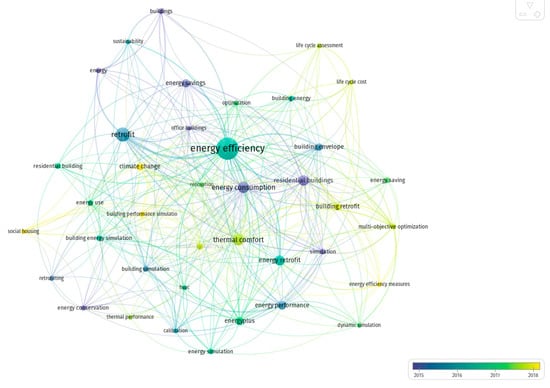

A comprehensive literature review was performed on 1000 articles’ abstracts to collect and study the most used keywords in papers related to “building envelope energy retrofit”. Figure 6 shows the top 39 keywords in the abstracts of these articles associated with building energy retrofit with a repetition higher than 15 times. It can be observed that the top keywords and areas in such articles include (1) energy efficiency, (2) energy retrofit, (3) thermal comfort, (4) energy consumption, (5) residential buildings, and (6) energy performance, indicating the most studied topics. Isolating the papers published after 2018 (Figure 7) shows that some of the most studied keywords shift to newer topics such as (1) climate change, (2) building performance simulation, (3) social housing, (4) energy efficiency measures, and (5) multi-objective optimization.

Figure 6.

Areas covered by the articles related to building envelope energy retrofit.

Figure 7.

Articles related to building envelope energy retrofit based on the publication year.

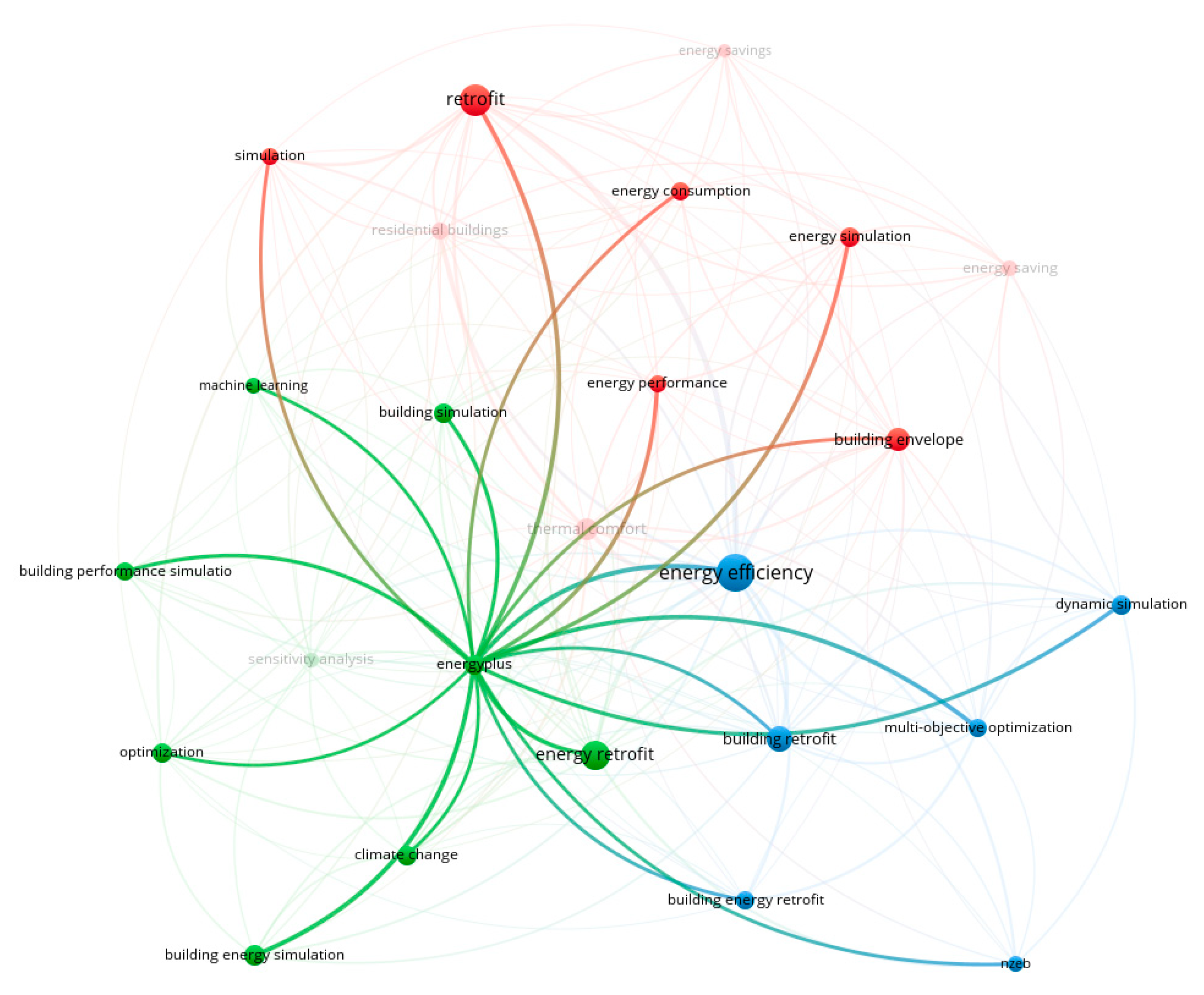

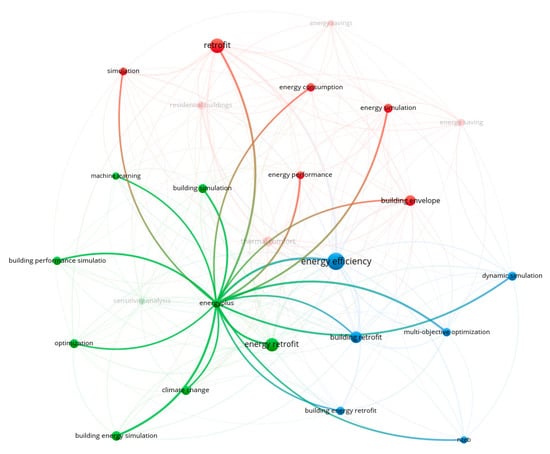

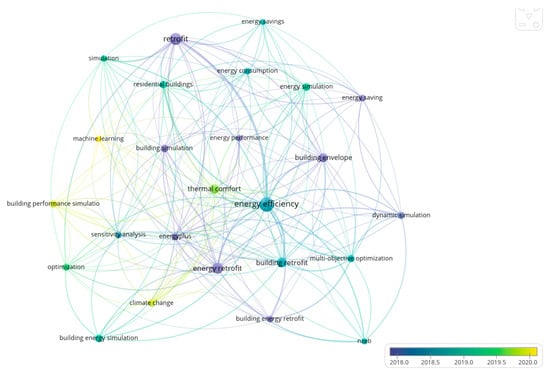

An additional contribution and area of focus in this paper is a sensitivity analysis based on computer simulation, as discussed in Section 5. Therefore, the comprehensive literature review was modified to select simulation-based research studies. Over 1000 papers were reviewed to isolate 25 keywords with at least 25 occurrences, shown in Figure 8. It can be observed that keywords such as EnergyPlus, sensitivity analysis, machine learning, optimization, and dynamic simulation are among the topics with the most interest. In this study, we used an EnergyPlus-based tool (i.e., Beopt) to perform the computer simulations discussed in more detail in Section 5. As depicted in Figure 8, EnergyPlus is one of the most used tools for energy simulation in building energy retrofit studies. The publication dates for these papers are mostly after 2018, and topics such as machine learning are used in more recent publications (Figure 9). As the research interests show diverse simulation tools and methods, a more comprehensive study is needed to review and compare different modeling techniques (e.g., physics-based models vs. data-driven strategies) in building envelope energy retrofits.

Figure 8.

Articles related to building energy simulation in building envelope retrofit projects and their relationship with EnergyPlus.

Figure 9.

The publication years for energy simulation-based articles.

This comprehensive literature review helped the authors select more relevant keywords for specific papers used in the following sections, and may be used by other researchers to determine future research topics related to building envelope retrofit. These papers do not have to be limited to certain types of buildings (e.g., residential buildings), as some retrofit methods and materials used in commercial buildings can be adopted in the residential sector.

3. Materials and Systems in Envelope Energy Retrofit

Academic articles and technical reports were selected based on the keywords identified in the literature review and their abstract. This section performs a more in-depth analysis on certain materials, methods, and systems related to building envelope energy retrofit. These energy retrofit measures can be applied to building envelope systems and areas such as walls, roofs, windows, floors, façades, and air leakage, and they are applicable in the residential buildings sector [8] as the dominant sector in energy-saving research studies [9]. Three heat gain/loss mechanisms influence building envelope energy retrofit: conduction, convection, and radiation. Most retrofit methods applicable to transparent or translucent components were developed to deal with radiation by limiting the radiative heat transfers, for example, by applying window films over the existing glass. To improve airtightness, however, heat transfer through convection should be limited. Although convection and air infiltration can significantly impact energy loss, most methods of envelope energy retrofit tend to limit energy loss through conduction. The basis for such retrofit methods is the application of insulation materials with low thermal conductivity or high thermal inertia (i.e., heat capacity measured by specific heat). Thermal inertia slows the changes in temperature by absorbing the thermal energy for later release, whereas thermal insulation slows the heat transfer without storing the thermal energy [2]. Table 1 shows examples of different heat control measures based on different materials and methods. The retrofit material and systems reviewed in this paper are categorized into conventional and innovative technologies discussed in the following sections.

Table 1.

Different heat control mechanisms in building envelope retrofit measures.

3.1. Conventional Retrofit Measures

Conventional insulation materials such as fiberglass, polyurethane, rockwool, and cellulose can be used for the energy retrofit of a building envelope. These materials can be produced and used in different forms such as sprayed-in-place, batts, rolls, loose-fill, and rigid board, as summarized in Table 2. The thermal conductivity of these materials ranges between 0.030 and 0.054 W/m·K [10] (summarized in Table 3). In addition to the thermal resistance of conventional insulation materials, other properties such as density, fire resistance, service temperature, vapor resistive properties, durability, potential health, and the composition of these materials (e.g., organic, inorganic, or combined) have also been of interest [10,11,12].

Table 2.

Conventional forms of insulation material (adopted from [10]).

Table 3.

Conventional types of insulation material (adopted from [10]).

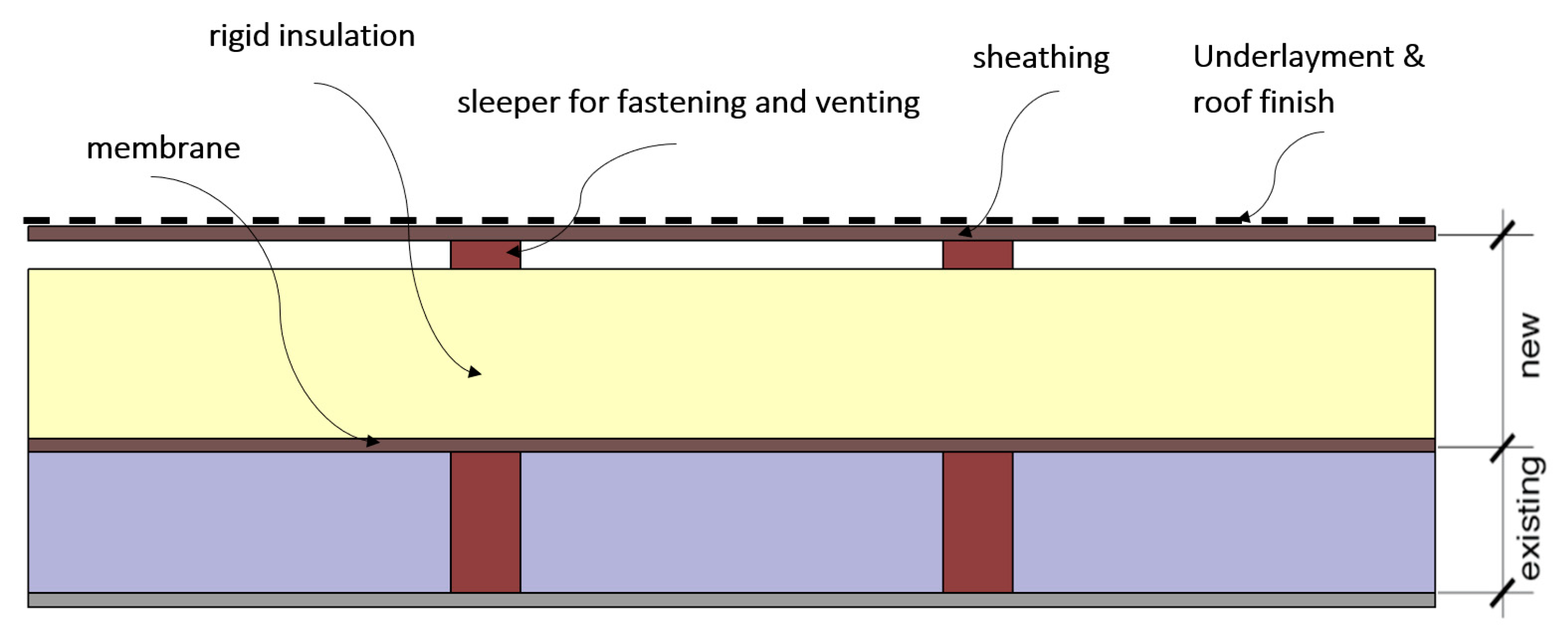

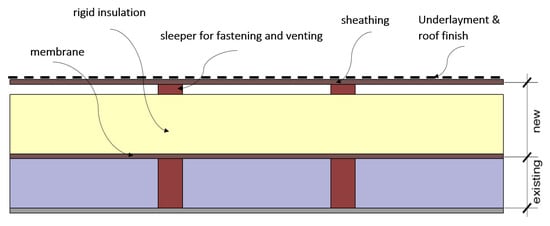

The retrofit system’s construction and installation will vary depending on the material used for the retrofit and its form. One of the most commonly used envelope energy retrofit methods is adding insulation to the exterior walls, which requires a rigid form of insulation material to be attached to the existing sheathing using fasteners [13]. Exterior thermal & moisture management system (ETMMS) (Figure 10) is an example of such an application. This system incorporates another membrane installed adjacent to the insulation material to control the air, water, or vapor [14].

Figure 10.

Exterior thermal & moisture management system (ETMMS) details for roof overcoat (adopted from [14]).

When selecting a suitable material or ECM, it should be noted that, depending on the building type, one of the ECMs may be more desirable than the other options. For example, commercial buildings with a high window-to-wall ratio may be more focused on improving the glazing systems’ thermal properties, reducing the heating and cooling loads by up to about 28% [15]. In contrast, residential buildings do not benefit from glazing improvement as much.

Other than energy-saving potential, the energy associated with the life cycle of the materials used in retrofit construction can also be an essential factor in the decision-making process [16,17,18,19,20,21]. Beccali et al. [16] discuss the Life cycle assessment (LCA) of a few conventional retrofit materials for single-family homes by considering different material’s life stages such as manufacturing embodied energy, operation energy, and demolition energy. The retrofitting options considered by Beccali et al. [16] include installing Expanded polystyrene (EPS) on exterior walls, adding rock wool over the roof, adding a layer of Extruded polystyrene (XPS) over the ground floor, installing Photovoltaic (PV) panels, or replacing the boiler. Their study shows that, unlike more environmentally friendly retrofit materials, such as reed, that reduce manufacturing energy and emissions, the materials with higher embodied energy lead to lower operational energy [16,18]. A similar study [13] looked at the life cycle impacts of 21 different scenarios of energy retrofit under the Mediterranean climate in Portugal for an attic space and discussed three different frame materials: wood, light steel, and lightweight concrete, with three different insulation materials, namely, rock wool, XPS, and polyurethane foam. In most cases, polyurethane foam had the lowest life-cycle impact. In contrast, rock wool had the lowest primary energy impact in the construction phase, and the operation phase accounted for 40–70% of the life cycle impacts [19].

As shown in Table 1, an energy retrofit can also be focused on controlling the radiations. Reducing or increasing the solar heat gain through building envelope surfaces is used in approaches specific to roofs, one being a “cool roof,” which reflects the sunlight and is more beneficial in warm climates [22]. The difference in temperature before and after applying a light color on the roof could be up to 24 °C [23]. The combination of the green roof and cool roof concepts using the Helichrysum Italicum plant has shown that it can reflect about 44% of the solar radiation, about 4% more than a typical concrete roof [24]. Reflective tiles can also be used to reduce solar heat gain. To measure the performance of such materials, the Solar Reflectance Index (SRI) with extreme values of 0 and 100, respectively, for a standard black and white surface can be used. As an example of the use of the SRI to evaluate the performance of a particular clay tile, Boarin et al. [25] report on the application of an innovative reflective clay tile with about 15% higher reflectance compared to conventional tiles and an SRI value of 67 used in a GBC Historical Building for roof and external pavement that led to a decrease in energy consumption [25].

Based on Department of Energy (DOE) guidelines, the most common approaches that improve the thermal performance of opaque and transparent building envelope components are summarized in Table 4 [26,27,28,29].

Table 4.

Building envelope energy retrofit methods reviewed in Department of Energy (DOE) guides (adopted from [26,27,28,29]).

3.2. New Retrofit Measures

This section mentions some existing technologies suitable for energy retrofitting but focuses more on emerging technologies. The envelope retrofit measures in this category include new innovative materials, further use of existing materials for retrofit purposes, or adding new systems that consist of current technologies employed innovatively. These can consist of common materials such as natural hydraulic lime, Portland cement, expanded perlite, granulated corncob, or granulated wheat straw as a vegetal-based thermal plaster with a conductivity of 0.086–0.115 W/m·K [17]. Other more innovative and emerging materials that can play an essential role in new retrofit measures include PCM and aerogel, which are discussed in more detail next.

3.2.1. Phase Change Material (PCM)

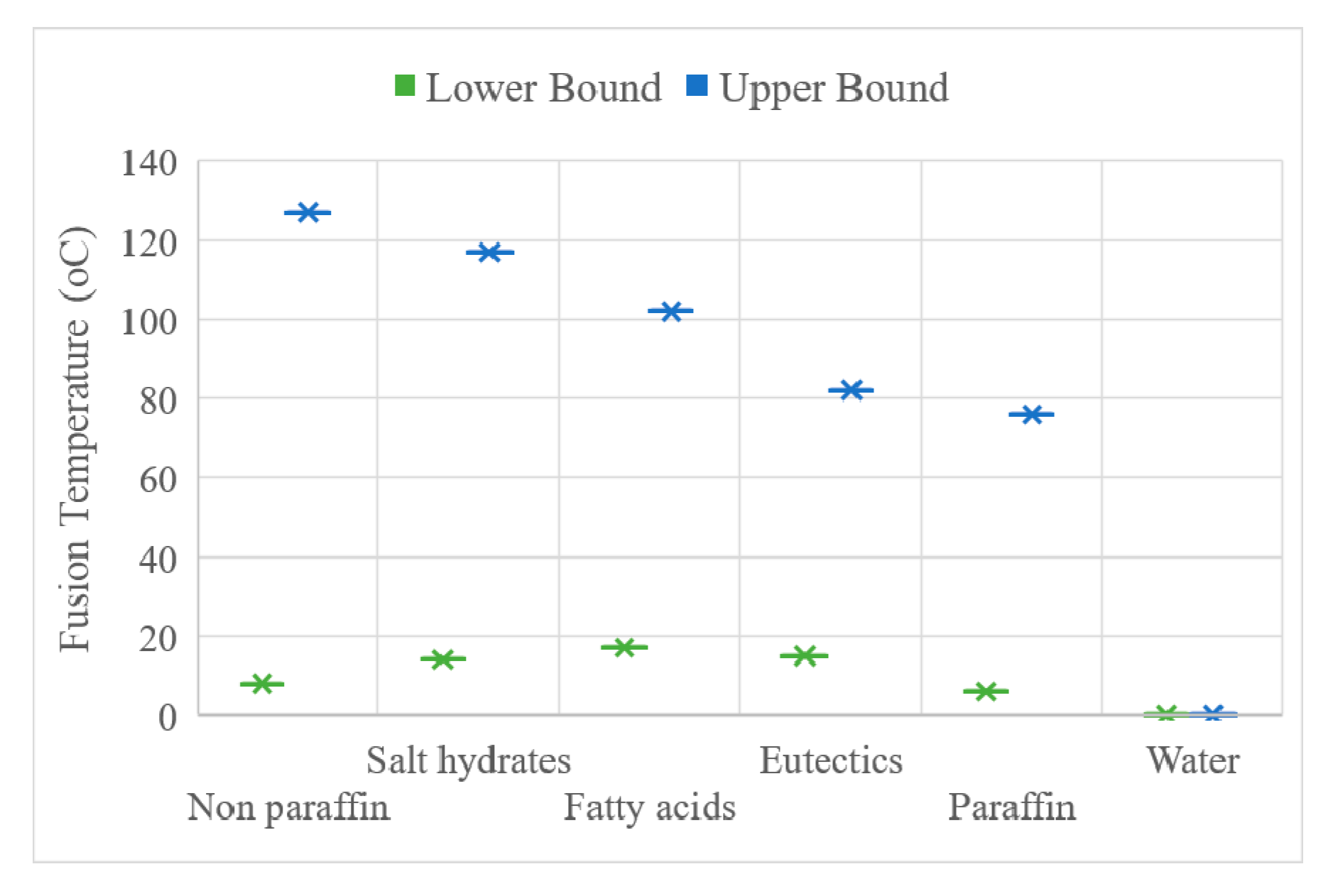

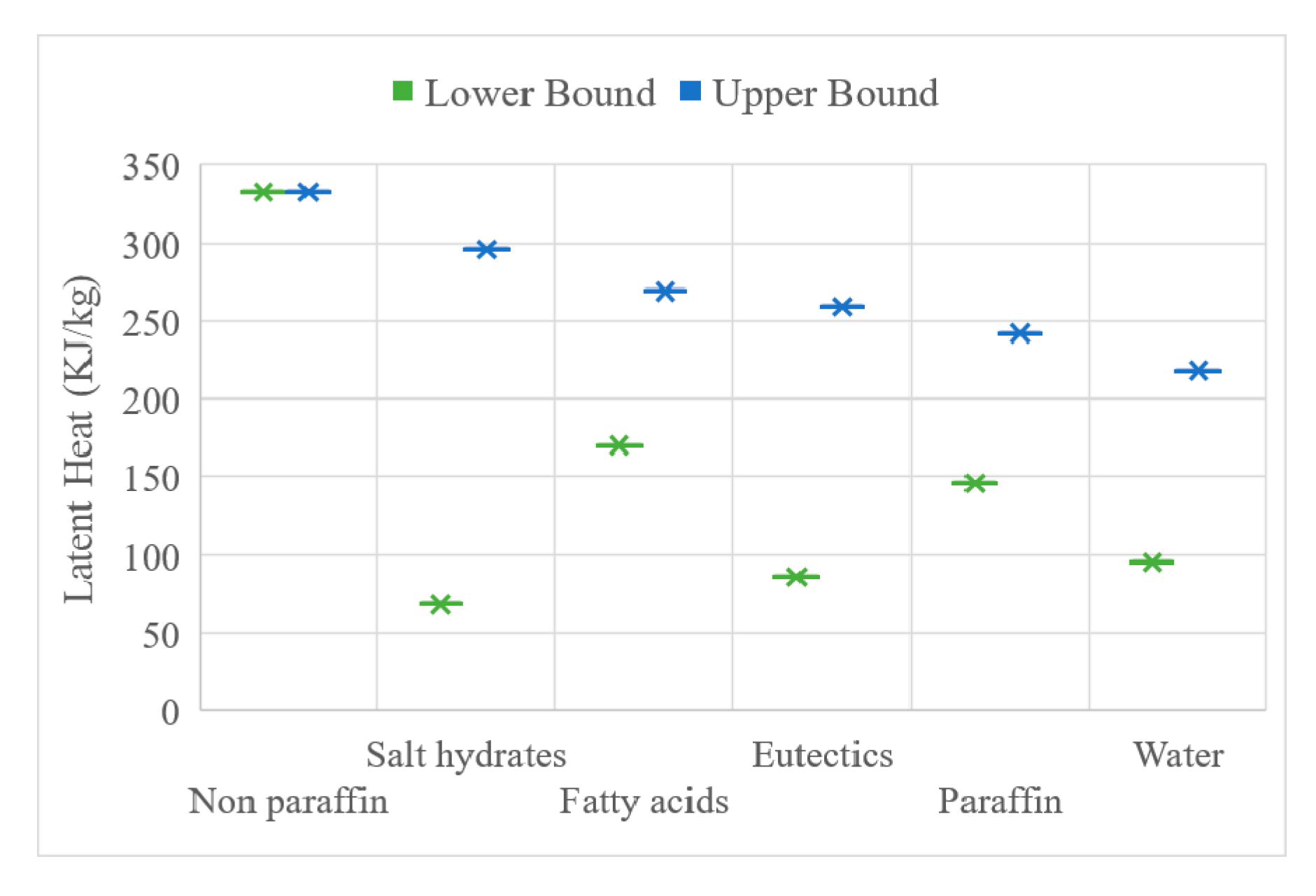

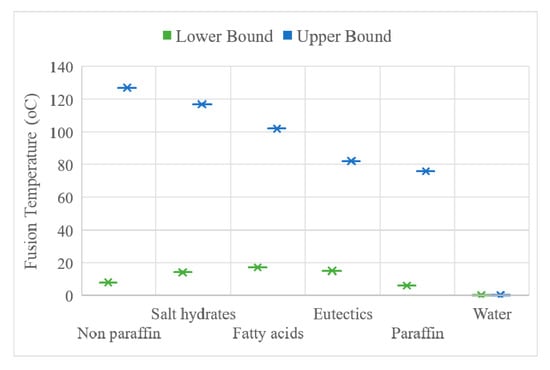

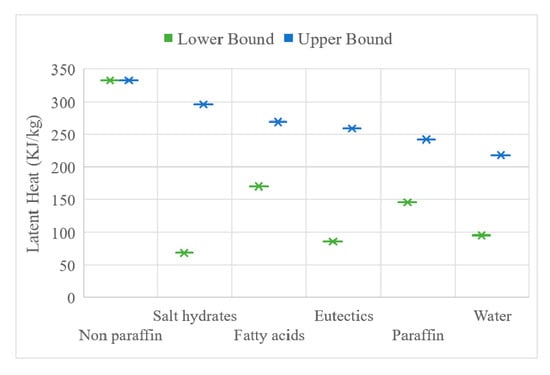

As shown in Table 1, PCMs are materials with high thermal inertia and are activated when the temperature reaches a certain level, typically between 23 and 26 °C, whereby the PCM undergoes a phase transition by absorbing heat. Phase transition could be solid to solid, liquid, or gas, or liquid to gas. The opposite phase transition, i.e., the release of heat by the PCM, occurs when the ambient temperature reaches the set point at night. These materials can be used in walls, floors, and ceilings with an operating temperature range of 20 to 35 °C [30]. Commonly used PCMs with different latent heat and fusion points include paraffin, non-paraffin, fatty acid, salt hydrates, and eutectics, as presented in Figure 11 and Figure 12 (reproduced from [30]). There are lower and upper bounds for these materials’ latent heat and fusion point. Figure 11 compares these materials with water, and it can be seen that the lower and upper bounds of fusion temperature range between 6–17 °C and 75–127 °C, respectively. The same comparison is shown in Figure 12 for latent heat, and the lower and upper bounds are between 70–170 kJ/kg and 220–300 kJ/kg, respectively, compared to water, which has 333 kJ/kg of latent heat.

Figure 11.

Fusion temperature for different phase change material (PCM) types (adopted from [30]).

Figure 12.

Latent heat for different types of PCM (adopted from [30]).

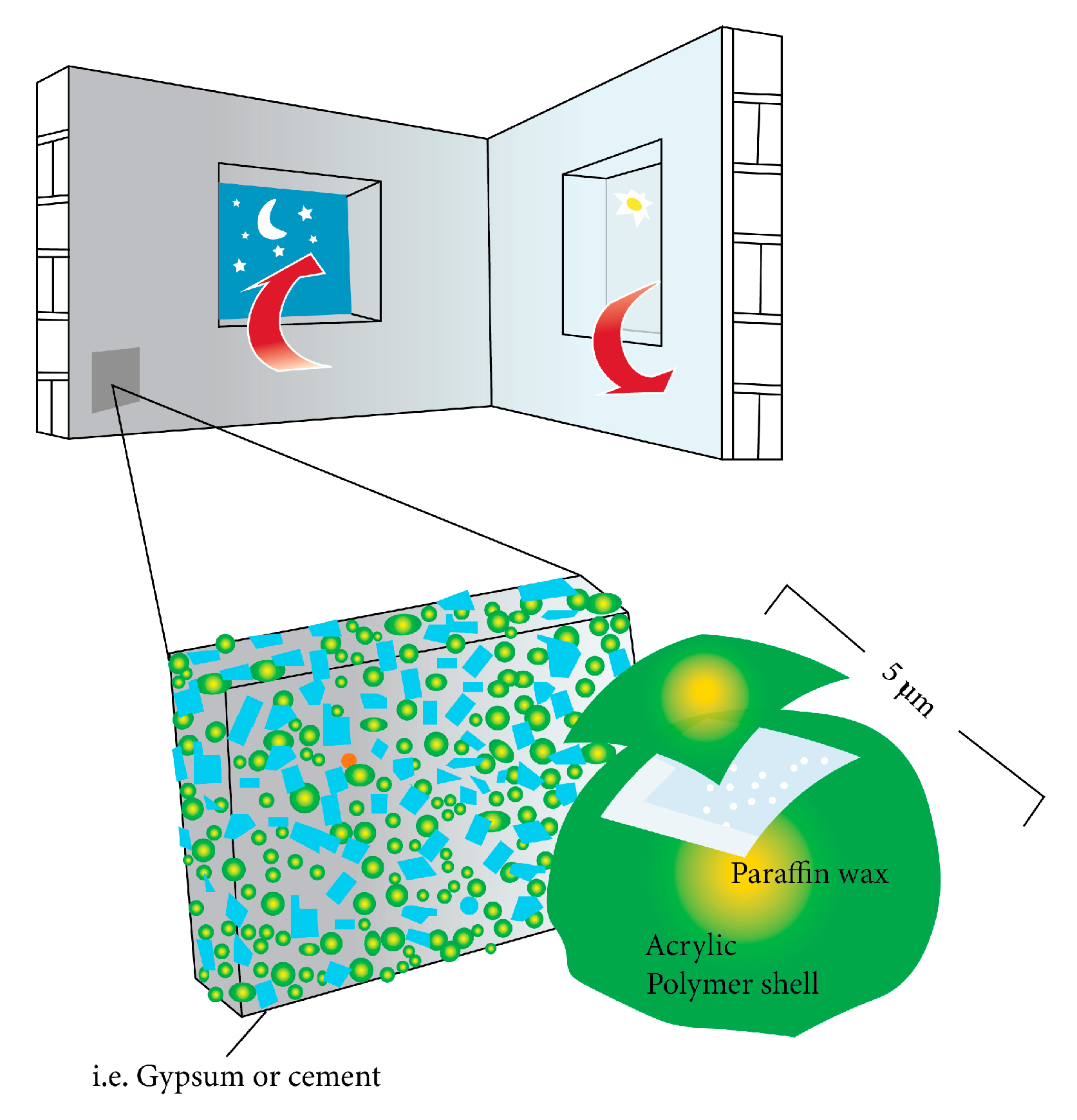

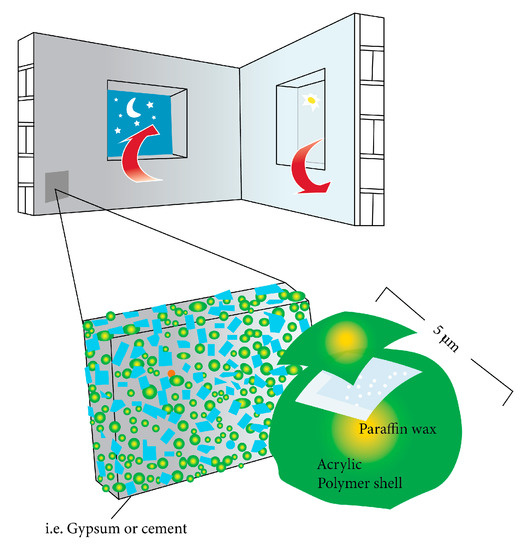

PCMs can be used in different forms, such as micro- and macro-encapsulation. Micro-capsules are less than 1 mm in diameter, making them easier to place within polymer films. Macro-capsules, however, can be larger tubes, spheres, or panels containing PCM. The capsule form allows these PCMs to be mixed with more common building products including plaster, screed, concrete, gypsum, acrylic paints, and wood products such as Medium-density fiberboard (MDF) and OSB, as shown in Figure 13. Salt hydrate PCM can also be placed inside an insulating glazing system that allows most light wavelengths to pass through, enhancing thermal performance [30]. There are also examples of the application of microcapsules embedded in common construction materials, such as wallboard, that includes PCM. Most researchers suggest the use of the PCM as a wall component, while some studies have demonstrated a reduction in energy use of up to 40% depending on the building orientation and height [31].

Figure 13.

PCM capsules inside construction materials (adopted from [32]).

Other researchers also studied the energy-saving potentials and applications of PCM. For example, plasters containing PCM with a melting point of 32 °C were applied on the wall’s exterior face. Combining this method and replacing deficient windows with low-e windows and new roof insulation materials resulted in a reduction in energy consumption of 38% [33]. Applying two layers of PCM plaster with different melting points makes it possible for individual layers to be activated in either summer or winter [33].

PCM shows better performance in an environment with higher fluctuations in temperature. Transportable houses are typically subjected to such a condition. Marin et al. [34] studied the effect of PCM integrated with gypsum boards in these types of buildings. The thermal conductivity, latent heat capacity, and peak melting temperature were 0.23 W/m·K, 200 kJ/m2, and 25 °C, respectively. EnergyPlus was used to study the effect of the PCM gypsum board in different climate zones, and the results showed that it can reduce the energy demand from 1% to 36%, depending on the climate zone [34].

3.2.2. Aerogel

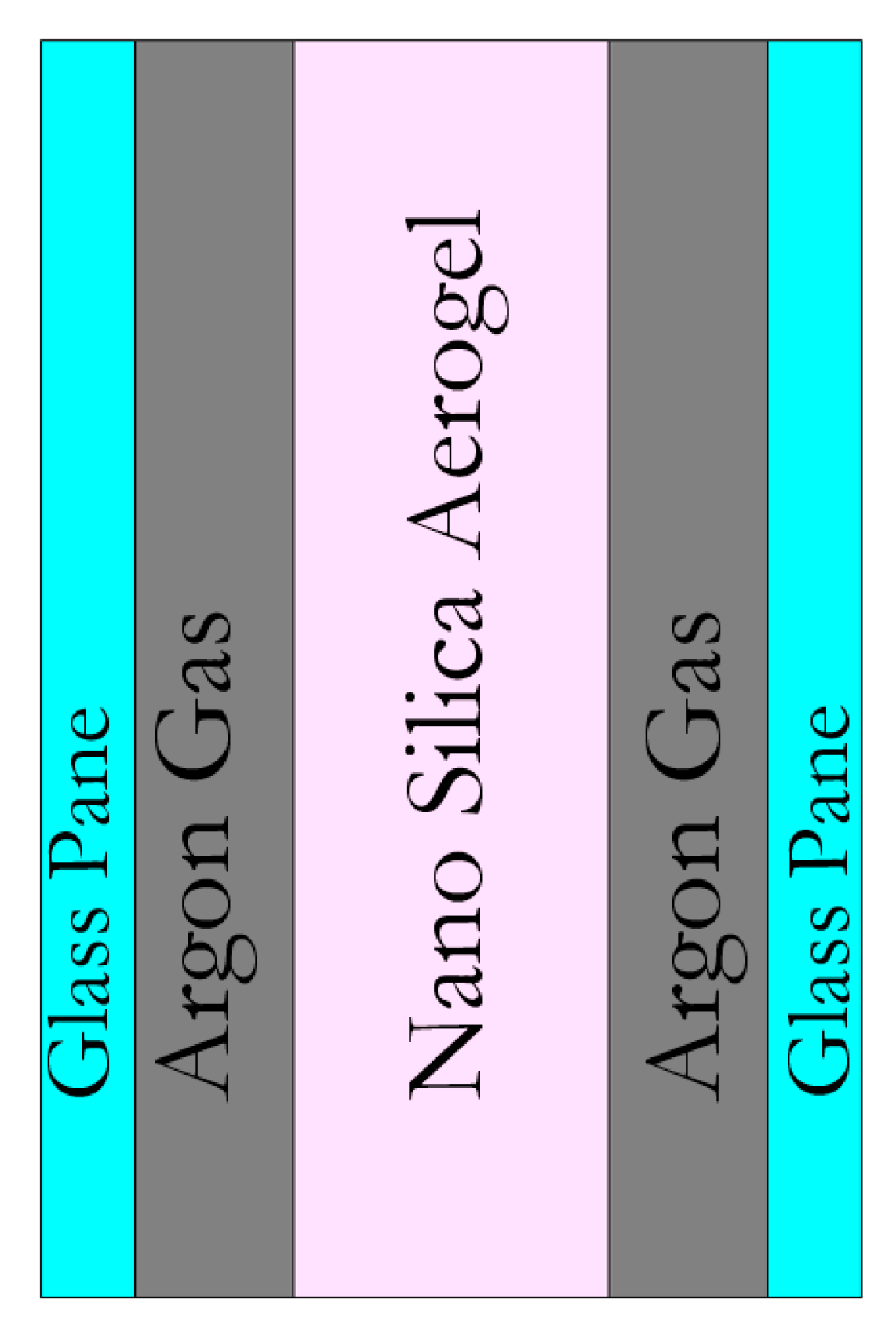

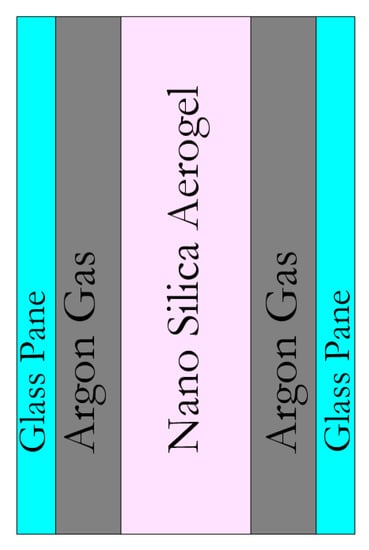

Materials on the size scale of between 1 and 100 nanometers are made via nanotechnology that can be used for insulation applications. Aerogel is an example of such a material obtained from different base materials such as silicon, aluminum, chromium, tin, or carbon. However, the most used material is silica-based [30]. The thermal conductivity of such a material made of silica at 25 °C can be about 0.016–0.03 W/m·K, which shows better thermal resistance compared with common insulation materials such as Polyisocyanurate foam (0.023 W/m·K), EPS (0.037–0.038 W/m·K), and XPS (0.030–0.032 W/m·K). Thermal properties are not the only advantage of aerogel, as their sound insulation and vapor resistance properties can also be higher than conventional insulation materials used in walls mentioned above [30].

Aerogel can be used in different forms, such as rolls, semi-rigid panels, and pre-coupled gypsum boards, especially when there are limitations in the thickness of insulation materials that may need to be added for retrofit purposes to existing walls, roofs, floors, or glazing systems (Figure 14) [35]. An example of limitations in the thickness of the insulation material is a case study project conducted in the UK to refurbish sea containers for residential use. Due to the limited interior space, a minimum thickness of the insulation material was much more desirable [36]. Polyester, glass, and carbon are more common as fiber reinforcement, and the blankets can be installed on walls, façades, ceilings, framings, and floors [37]. Aerogel is also beneficial when a translucent or, in some cases, a transparent insulation material is desirable and integrated with the glazing system. Berardi [38] studied the effect of varying the thickness and percentage of aerogel covering the window combined with the glazing system. It was observed that it could lead to a decrease in heating and cooling loads of about 80%. The THERM software package was used to evaluate the R-value of the window system, while EnergyPlus was used to assess the energy performance of the modeled building [38]. These materials are still about 8–10 times more expensive than common insulation materials [30]. As an example, the application of aerogel in a retrofit case study project of an old building in Germany is discussed by Filate [39], where aerogel (with the conductivity of 16 mW/m·K) is used in external walls with a total U-Factor of 0.26 W/(m2·K) and in flooring panels that consist of aerogel boards covered by rigid Magnesium Silicate with a total heat transfer coefficient of 0.42 W/(m2·K).

Figure 14.

An example of the application of aerogel in a glazing system (adopted from [35]).

Aerogel can also be used in opaque components. Fenoglio et al. [40] studied the application of aerogel as an additive in plasters or fillers in hollow construction units such as bricks. The aerogel used in their study has conductivity and specific heat of 0.027 W/m·K and 998 kJ/kgK, respectively. Their results showed a 4.5-cm thick aerogel layer could reduce the thermal conductivity of the wall from 1 to 0.42 W/m2·K, which is a reduction of about 60%.

3.2.3. Integrated Systems

The combined systems can innovatively include both conventional and new materials as appropriate. Many new products are used in the modular retrofit system, providing ease and speed of installation. Precast elements are the critical part of modular solutions for retrofit construction, with the added benefit of using building science guidelines and understanding, such as implementing moisture control provisions in the wall system before installation. An example of such precast elements in energy retrofitting is the Single-channel glazed photovoltaic thermal module (SGPVTM), which has a ventilation channel underneath it to ensure it does not heat up, as heat can decrease the efficiency of the PV panels [41]. Precast elements can also be beneficial in terms of installation costs because the total retrofit cost, as expected, is a function of the materials used in the system, the installation method, and the location. There are research programs such as the Envelope Approach that aim to improve sustainability and energy efficiency in existing multi-story, multi-owner residential buildings, and are devoted to finding innovative and preferably modular solutions, such as prefabricated shapeable retrofitting panel systems that include (1) a single layer of XPS with surface finishing, and (2) a composite EPS panel coated on both sides with Textile reinforced mortar (TRM) [42,43]. Such products show a trend toward prefabricated multi-layer products that combine the thermal and structural benefits of multiple materials, and ease construction (Figure 15) and save time and cost.

Figure 15.

Installation of a prefabricated insulated element (i.e., EPS sandwiched between two layers of TRM) in a retrofit project in Italy (adopted from [43]).

The energy retrofit design for exterior walls can also benefit from combined systems, such as External thermal insulation composite system (ETICS), which is an insulation board attached to the existing layer covered with a final finish having different insulation materials such as stone wool, EPS, and dense glass wool [44,45]. An apartment built in 1983 in a social housing compound in southern Italy used this system. Because the roof area was insufficient to install PV panels, a combined system approach, including the Building-integrated PV (BIPV) system and ETICS, was used. The insulation material in this ETICS was stone wool. The energy performance of the building was studied using DesignBuilder, which showed that heat loss through walls was reduced by 85% [46].

Some of these integrated systems are intended for use in retrofitting façade systems, such as Multi-functional energy-efficient façade system (MEEFS), Advanced Passive Solar Collector & Ventilation Unit Technical Unit (APSC&VU TU), and Advanced Solar Protection & Energy Absorption Technological Unit (ASP&EA TU), or for use in a façade system with a transparent photovoltaic coating (TPC) [46]. Some of these systems work based on the thermal storage and phase change material concepts [47,48]. Other façade systems, such as Active Solar Thermal Façades (ASTFs), can function as building envelope and solar collector components, with their primary functions being solar absorption and heat gain by the thermal absorber, and heat transfer through convection, conduction, and radiation [49]. Another type of innovative system for a façade energy retrofit is a double-skin façade, where the second (exterior) layer is an additional glazing surface over the existing (interior) transparent façade. The space between these two layers acts as an insulation layer heated by solar radiation and can be ventilated if over-heated. To control and optimize the solar heat gain in a double-skin façade, researchers have studied the effect of installing shading devices in the cavity of this system [50].

To summarize the different materials and systems mentioned in this review paper, brief information on all systems is tabulated in Table 5, which provides a useful snapshot of the technologies discussed. In addition to the systems that are focused on the façade of the building, such as the dynamic façade or double skin façade, most of the more innovative methods still consist of conventional materials that are used as precast components and modular structures, which are a combination of different layers, including an insulation layer made of traditional materials or more innovative materials, such as PCM or aerogel.

Table 5.

Summary of the energy retrofit methods used in the building envelope.

3.3. Example Retrofit Projects

Building energy retrofitting can target a limited number of components in mechanical systems, lighting, or the envelope; however, for what is referred to as “deep energy retrofit”, which leads to higher energy-saving levels, the retrofit design needs to target multiple areas and suggest significant changes. Among the most common retrofit methods for some Energy Service Companies (ESCOs) for healthcare facilities, building envelope retrofitting accounts for a relatively small share (about 10%), presumably due to the long payback period compared to other retrofit options such as Heating, ventilation, and air conditioning (HVAC) systems [26]. Both conventional and innovative materials and methods are used in these projects, such as adding spray foam, rigid insulation, aerogel, PCM, improving window systems, and double-layer façades. This section reviews example retrofit projects in residential, commercial, and mixed-use buildings with ECMs that may be adopted in residential building energy retrofit projects.

The main goal in many retrofit projects is to determine retrofit options having the highest impact on reducing energy consumption at the lowest cost, which will then have the combined effect of the shortest payback period. Researchers have shown that, depending on the building type and climate zone, certain ECMs may not be as effective and lead to long payback periods [56]. Conversely, there are examples of successful ECM implementation, such as the Aspinall Courthouse [57], the Empire State Building [58], and a hospital in Alexandria, Egypt [59]. The ECMs used in these projects are summarized in Table 6. Each system is explained in the following paragraphs. It should be noted that such ECMs can also be adopted in residential building energy retrofits.

Table 6.

Summary of the energy retrofit measures (ECMs) in example projects.

Architecture-driven energy retrofit case studies have also been undertaken, such as those of the Stanford Medicine Outpatient Center, the UCLA Center for Health Sciences [60], a 1973-built building in Portland, Oregon [61], and the California Department of Motor Vehicles [60], which was the subject of a façade retrofit, including the addition of a double-layer skin that allowed using a ventilation layer with operable vents within it. During the hot months, natural ventilation helps cool the interior area, whereas trapped air helps keep the interior warm during the cold months. More advanced façade retrofit techniques were used in the 1998 ERGO building, the Italian headquarters of a major insurance company, in Milan, Italy [62], where the DesignBuilder models showed that different ECMs could lead to a 40% decrease in energy consumption. Such ECMs included replacing the glazing system with argon-filled double-pane glass; installing a shading system; installing a ventilated façade consisting of an air gap behind the stone façade; installing a stone façade to work as a thermal mass; using glass wool as insulation; installing a dynamic double-skin façade on the south of the building consisting of computer-controlled blinds and PV panels; and improving roof insulation by adding cellular glass [62] (shown in Table 6).

A “deep energy retrofit,” as opposed to a simple energy retrofit, can reduce the energy consumption by more than 50%; therefore, it typically includes more than a single ECM and requires whole-building energy analysis. Deep energy retrofitting has been of interest in some projects, including Alliance for Sustainable Colorado [63], which achieved energy use that was 55% lower than that of the average office building in the U.S. Other example retrofit projects using ECMs that may be applied to residential buildings include Beardmore in Priest River, Idaho [64], and Home on the Range in Montana [65], as summarized in Table 6. The building envelope ECMs vary between adding exterior wall insulation and insulated low-e glazing systems.

The “cool roof” strategy uses roofing material having high solar radiation reflectance, which is achieved by coating the roofing material with a solar reflective coating. The cool roof strategy can also be compatible with residential buildings, which can be more effective in a hot and arid climate. A one-year study in Abu Dhabi of 10 villas that were retrofitted using windows having a higher shading coefficient, a cool roof, and more efficient electrical and mechanical systems, and in which the airtightness of the buildings was reduced to 5 ACH50, shows that the energy consumption can be reduced by between 14.4% and 47.6%, depending on the behavior of the occupants [23].

The application of precast retrofit insulated panels is also studied in the literature. Bianco and Wiehagen [66] used precast panels in a two-story residential building in Albany, NY, USA. They installed these panels in specific locations, such as the area below doors and the stairs landing, and used 0.4-inch-thick aerogel fabric with a thermal resistance R-value of 4.8. Results showed reductions in gas and electricity use of about 21% and 16%, respectively [66].

Passive House performance criteria have also been of interest as retrofit goals for some projects, including the Glasswood building in Portland, Oregon [67]. The retrofit design was intended to meet an airtightness standard equal to or better than 0.6 ACH50 and reduced the annual energy use to 120 kWh/m2/yr. The 1658 ft2 Sunnyvale residential building is another example of the Passive House approach and the Building America program [68], where the BEopt model showed that the deep energy retrofit led to energy saving of 40% [68].

There are also other target performance criteria in energy retrofitting, such as the net-zero energy house; an example is an old Danish multi-family house built in 1896 that was retrofitted to become a nearly-zero energy building by using more innovative materials and techniques [69], such as the aerogel–stone wool mixture and vacuum-insulated panels. Aerowolle or the Vacupor NT products are made of aerogel and stone wool fibers with thermal conductivity of 0.019 W/(m2·K). Another product used in this project is Vacupor NT, a Vacuum insulated panel (VIP) with a thermal conductivity that varies under different ambient pressures, from 0.005 W/(m2·K) for a thickness of 20 mm under one mbar pressure to 0.019 W/(m2·K) at atmospheric pressure [69]. The “three-liter” BASF house retrofit project, in Germany, also used innovative materials and techniques to keep the indoor temperature in the comfort zone, using only three liters of heating fuel consumption per square meter per year. After the retrofit, this was reduced to 2.6 L of heating oil per square meter. Different ECMs in this project include high R-value exterior foam sheathing, triple-glazed windows, passive solar heating from glazed sunspaces, a controlled ventilation system having 85% thermal recovery, efficient heat and electricity generation from a new miniature power plant in the basement, and PCM-enhanced gypsum boards or internal plasters [70].

The presented review shows various building envelope ECMs in different types of buildings. More common techniques such as adding exterior insulation to walls and roof can be combined with innovative materials and methods such as VIP, aerogel, PCM, and a double-layer skin façade equipped with operable shading systems. Although not all of these projects are residential buildings, the adopted ECMs are still applicable in residential buildings. Table 6 summarizes the features of these example projects and the measures and results of the energy retrofitting. It can be observed that the energy-saving can be up to 40% depending on the methods used; however, it should be noted that some of the reported numbers are energy-saving potential or expected performance, and the actual measurement was not conducted after the energy retrofit.

4. Energy Simulation Software in Energy Retrofit

The effects of different retrofit measures on energy performance can be studied experimentally and numerically by applying energy simulation tools under the three categories of envelope, mechanical, and electrical systems retrofitting. Depending on the retrofit measures, the energy simulation of a building can be complicated, or it may be as simple as changing the thermal properties of materials regardless of the retrofit type [72]. Because multiple options are available for the energy retrofit of a building, it is essential to find and use suitable software to help analyze and evaluate the retrofitted building before actual construction. Crawley et al. [73] compared the capabilities of 20 different energy modeling software packages. In addition to the more well-known packages such as EnergyPlus, BEopt, eQuest, and TRNSYS, other options such as BLAST, DOE-2.1E, and HAP can be used to evaluate retrofit designs. Most energy simulation software packages offer Graphic User Interface (GUI) capability, which interacts with a simulation engine that performs the energy simulation.

In most cases, either EnergyPlus or DOE-2 is used. For example, software packages such as OpenStudio, BEopt, and DesignBuilder use EnergyPlus, whereas eQuest and GBS use DOE-2 or a variation of it. Other software packages, such as DeST, IES-VE, and TAS, work on proprietary or less-common engines such as Apache. A combination of tools can also be used for simulation and optimization purposes. For example, Jankovic [74] used I.E.S., DesignBuilder, and JEPlus to model and optimize the deep energy retrofit of a residential building with precast elements.

These tools create physics-based models, but examples of data-driven modeling approaches use a black-box method to search through pre-populated energy models and simulations. Physics-based models use thermodynamics (i.e., physics laws) to calculate the energy transfer. In contrast, data-driven models rely on the mathematical relationship between energy-related data and do not necessarily consider the physical meaning. Lee et al. [75] reviewed the application of a database that includes 10 million EnergyPlus pre-run simulations using supercomputers for seven building types in different climate zones; the aim was to replace the energy audit process, which can be expensive and time consuming. The project’s name is Database of energy efficiency performance (DEEP), which is a SQL database [75].

Depending on the available building data and the accuracy of the created model, the outputs can be close to the actual energy use. However, some studies show that the difference between the actual energy savings and models’ outputs can be about 42% [76]. The same issue is observed in other studies, which showed energy saving was 10% less after retrofitting than the simulation results [66]. Other weaknesses are listed in the literature for existing energy simulation and retrofit tools, including the need for detailed information for realistic building energy performance outputs, better suitability of simulation tools for evaluation of new buildings rather than refurbishment, and lack of modeling capabilities for innovative retrofit options. However, the existing tools can still help quantify the energy-saving potentials in multiple ECMs, evaluate the impact of simultaneous ECMs, and evaluate long-term building performance and different climate zones.

5. Case Studies Based on Modeling Different Envelope Energy Retrofits

To evaluate the envelope retrofit options and measures presented in the previous sections, a side-by-side comparison of a model house retrofitted using different options is presented in this section. More specifically, the effect of selected energy retrofit measures for building envelope systems was studied by quantifying the impact of each method and comparing their performances in two climate zones, namely, Miami, FL, and Great Falls, MT, representing ASHRAE climate zones 1 A and 6B, respectively. Climate zone 1A is hot and humid, whereas 6B is very cold and dry. A BEopt computer model was created for a residential building retrofitted with different retrofit options, including improved wall R_Value, roof R_Value, windows U_Value and SHGC, and air leakage of the building, and the addition of a cool/warm roof. Most of these ECMs can be modeled in other energy simulation tools with different simulations engines such as IES-VE, as identified by other researchers [77], to model typical building envelope retrofit options, including double-glazed low-e glass, solar control film, shading devices, exterior wall insulation, a cool (i.e., bright) paint layer or green roof, and air infiltration controls.

The benchmark residential building is a DOE detached residential building designed based on IECC 2009 for two climate zones. Using the benchmark buildings based on open-access standards such as IECC makes it easier for other researchers to reproduce these models and replicate the results. A sensitivity analysis shows the percentage of energy use reduction against each ECM range to compare the energy-saving potentials between different ECMs. The case study is meant to guide stakeholders in determining the impact of various measures in building energy retrofitting based on the sensitivity analysis. Regardless of the degree of innovation of the retrofit approach, the retrofit is based on improving the thermal performance of the building envelope and manipulating attributes such as the conductivity and solar heat gain coefficient.

5.1. Development of the Case Study Computer Model for Sensitivity Analysis

The base buildings for the two climate zones were created in BEopt and calibrated based on the DOE prototype building database [78]. Table 7 shows some of the essential characteristics of each prototype building in each climate zone. To study the sensitivity of each ECM, a ±40% range was applied to the baseline values shown in Table 8. The limitation with these ECMs is that they focus on either thermal conductivity or SHGC and do not cover the material’s specific heat. These ranges represent different envelope ECMs. These include adding a continuous wall and roof insulation, replacing windows or adding a transparent layer to the window to improve the U-Value or SHGC, and air sealing the building.

Table 7.

Baseline building characteristics for two climate zones based on IECC 2006.

Table 8.

The range of retrofit measures used in the sensitivity analysis.

5.2. Results of the Computer Modeling

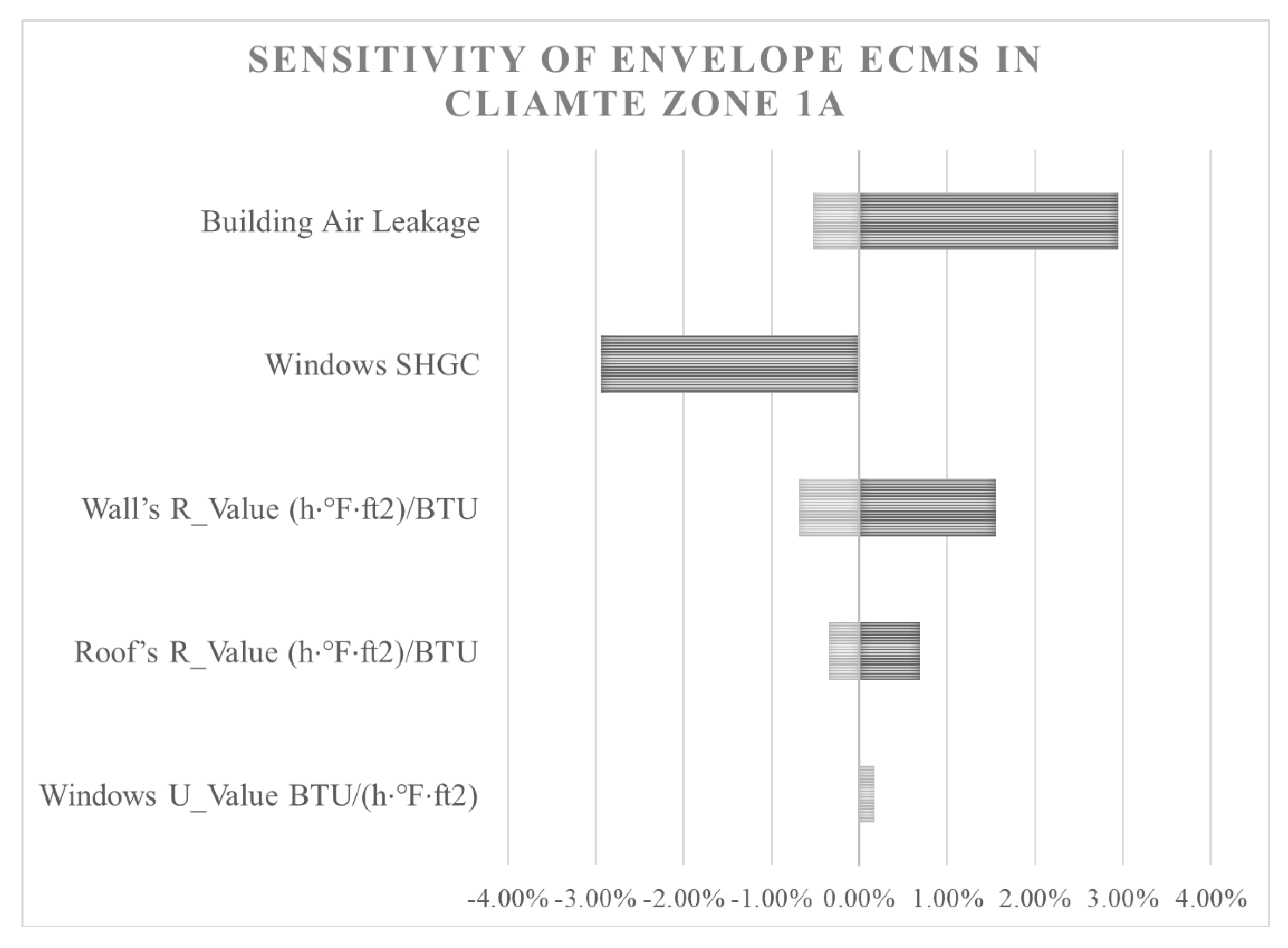

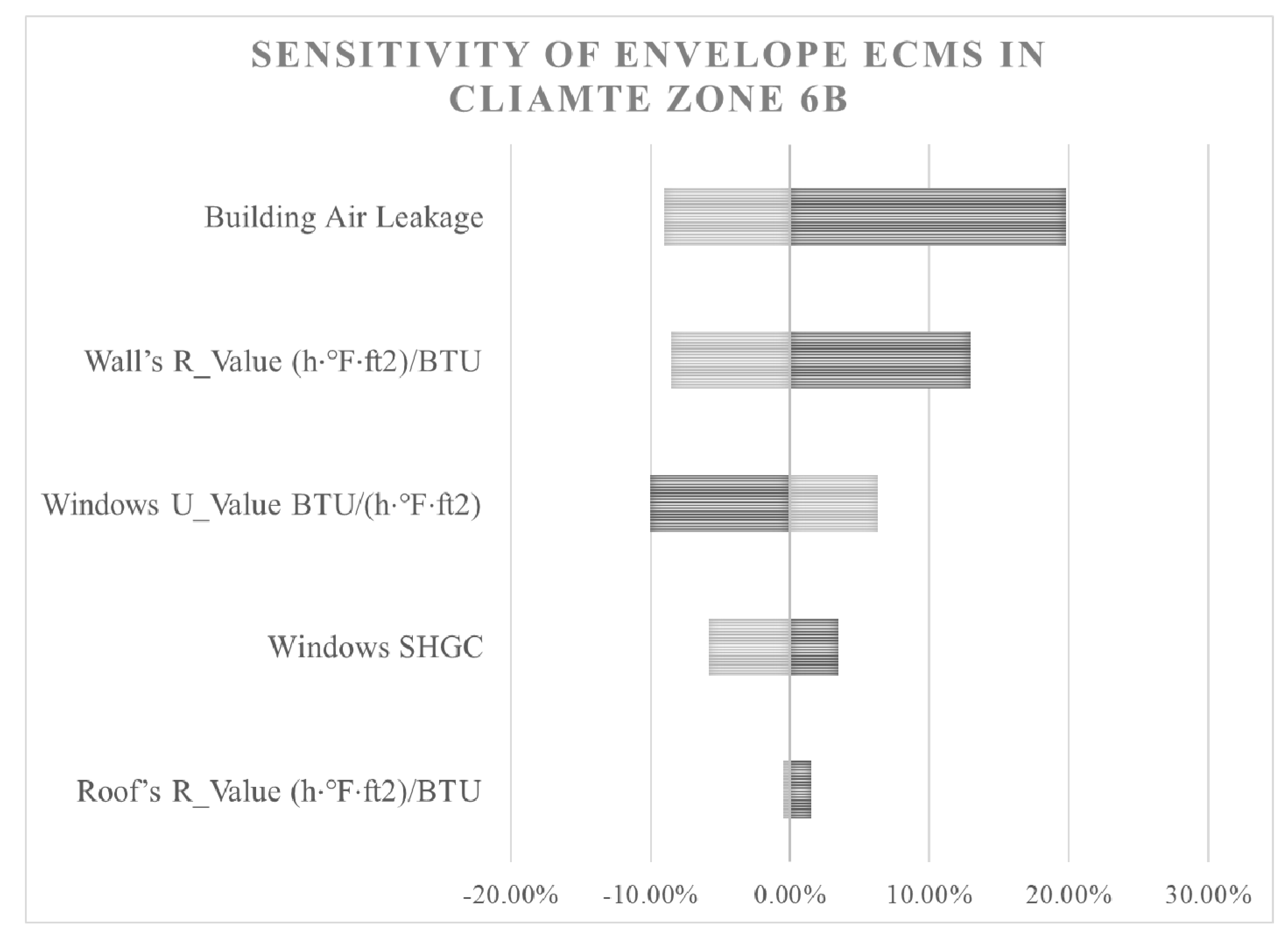

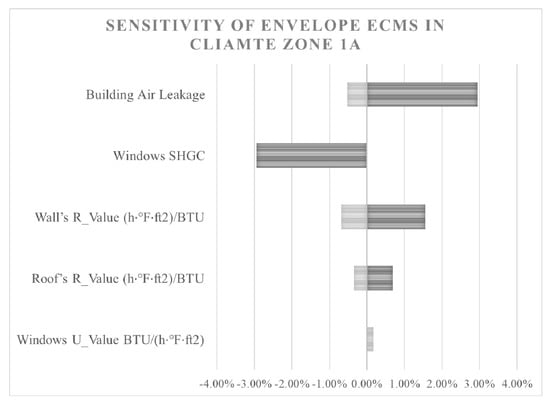

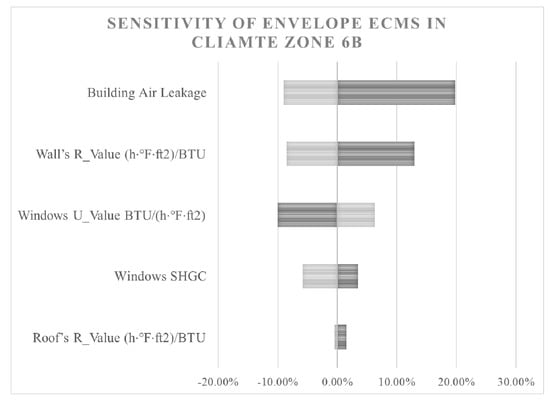

Figure 16 and Figure 17 show the sensitivity analysis results for each ECM based on the ±40% range compared to the baseline as outlined in Table 8. In this sensitivity analysis, each time a parameter changes in the simulation, the remainder of the building’s characteristics are kept the same as those of the baseline building, as explained in Table 7.

Figure 16.

Sensitivity analysis based on energy-saving potentials for different envelope ECMs in climate zone 1A (i.e., hot and humid).

Figure 17.

Sensitivity analysis based on energy-saving potentials for different envelope ECMs in climate zone 6B (i.e., cold and dry).

The impact of these envelope ECMs is higher in the colder climate zone (i.e., 6B). The energy-saving can be about 6% (i.e., from −3% to +3%) in climate zone 1A. By comparison, in climate zone 6B, the energy-saving can be about 30% (−10% to +20%). It can also be observed that the impact of these ECMs varies depending on the initial condition. For example, the windows’ SHGC in climate zone 1A (i.e., hot and humid) has more impact when it ranges between 0.30 and 0.42, and shows a very low impact on SHGC below 0.3. Although these results are for a prototype building, similar results are observed in real case studies conducted by other researchers [79]. However, these results can differ for buildings having different square footage, use, orientation, and climate zones [80].

Air sealing the building has the highest impact on buildings in both climate zones. This can be achieved using conventional methods, such as applying spray foam, or newer methods, such as aerosol-based sealants. In contrast, the roof’s thermal resistance has the most negligible impact on energy saving. Retrofitting the roof may be more effective in buildings having a higher roof-to-wall surface area ratio, and, in small single-family detached houses, it was expected to show minimum impact.

The impact of these ECMs depends on other factors. For example, the impact of windows’ thermal properties depends on the window-to-wall ratio and the climate zone. In the baseline model designed based on IECC requirements, improvements made to windows represent a more effective ECM in cold climate zones, as their impacts can equate to an energy saving of more than 15% (from −10% to about +5%). The U-Value of windows can be improved by replacing them with high-performance products (e.g., double- or triple-pane argon-filled), or with an add-on product installed on top of the existing window.

Similarly, the impact of retrofitting the wall systems depends on other factors, such as their initial thermal performance. Walls can be retrofitted by adding continuous exterior insulation or adding, for example, blown-in cellulose inside the wall cavities. Both climate zones show a relatively high impact on building energy saving. In the warmer region, the energy-saving effect is about 2% (from about −0.5% to +1.5%), and in the colder area, energy savings can be about 20% (from about −10% to +10%).

These results are valid for a building having similar characteristics and properties, such as WWR and building type. Using materials having significantly higher specific heat (i.e., mass wall) can change these results. Moreover, the initial condition of the building determines the maximum energy-saving potential, as less energy-efficient buildings show higher energy-saving potentials.

6. Discussions

Among different sectors that contribute to energy consumption in the US, residential construction contributes 22% of the total annual consumed energy. About 42% of this energy use results from heating and cooling, which can be reduced by improving the building envelopés thermal performance. One of the main contributions of this paper is categorizing the state-of-the-art and conventional building envelope ECMs and materials, and summarizing their energy-saving potentials worldwide. This paper reflects the result of the review of more than 1000 abstracts and a detailed study of about 70 relevant academic and industrial references.

6.1. Findings and Recommendations

Consistent with the main objective of this paper, a thorough review of the literature on commercially available and emerging building envelope energy retrofit materials and methods was presented. The comprehensive literature review (Figure 5) led to the identification of the keywords having the highest level of interest related to building envelope energy retrofitting. The result of reviewing more than 1000 abstracts shows that (1) energy efficiency, (2) energy retrofit, (3) thermal comfort, (4) energy consumption, (5) residential buildings, and (6) energy performance are the main keywords having the highest level of interest. This study focused on building energy consumption before and after the retrofit. Therefore, the authors recommend similar review and simulation studies on thermal comfort as one of the critical factors in evaluating energy-efficient buildings. The authors further recommend performing a literature review on the application of different computer-based techniques (e.g., black box, white box, and grey box) related to building energy retrofitting, specifically, building envelope energy retrofitting. Although the goals of advanced building envelope systems and mechanical systems for energy efficiency in buildings are aligned, it is clear that different simulation techniques need to be employed for these systems.

Over the years, the general research interest in building envelope energy retrofitting or energy conservation has shifted toward topics such as climate change, building performance simulation, and optimization techniques. This indicates the importance of computers and computational methods in designing, evaluating, and decision-making processes related to building energy retrofitting. Therefore, an additional systematic literature review on energy simulation tools was performed in this study, including over 1000 abstracts. This review shows that EnergyPlus, sensitivity analysis, machine learning, optimization, and dynamic simulation are among the topics with the most interest among computer-based processes. The literature review also shows multiple energy simulation GUIs, such as OpenStudio, DesignBuilder, BEopt, and eQuest, using energy simulation engines such as DOE-2, EnergyPlus, and TRNSYS, are widely recognized for facilitating energy simulation and evaluation of energy retrofit measures. These simulation tools can help quantify the impact of different retrofit options, evaluate multiple alternatives, find the optimum retrofit scenarios, and evaluate the retrofit performance under different climates, including future changes in climate.

Under the second main objective, a more in-depth analysis was performed using specific keywords to identify the materials and methods used in conventional and innovative ECMs worldwide to evaluate their impact on EUI. These ECMs may be listed and categorized as follows:

- Use of more energy-efficient windows with different U-Value, SHGC, and emissivity properties (e.g., triple-pane, argon-filled, low-e glass)

- Incorporation of exterior/extra rigid insulation in walls, roof, ceilings, and slabs

- Use of materials having higher reflectance as a roofing material (i.e., cool roof)

- Installation of multi-functional energy-efficient façade and integrated systems (e.g., MEEFS, APSC&VU TU, and ASP&EA TU)

- Incorporation of advanced solar or double-skin façade systems (e.g., ASTF and SGPVTM)

- Use of operable shading systems

- Installation of super-insulated glass units using aerogel

- Use of aerogel/PCM-infused construction materials

Depending on the ECM bundle, climate zone, and the initial state of the building, these methods can reduce the energy consumption by about 50%. The authors recommend performing a parametric study on various ECMs based on different buildings’ initial states, as less energy-efficient buildings show higher energy saving that does not necessarily indicate the corresponding ECM’s superiority.

It is also observed that conventional approaches can be as effective as more innovative systems in energy saving. When ECMs are applied as bundles, the energy saving of ECMs cannot be evaluated separately. Therefore, the authors recommend creating calibrated building energy models to evaluate the energy saving of each ECM based on simulation results. The review of worldwide case studies shows that more innovative methods, such as integrated systems or aerogel/PCM-infused materials, are still under research and have limited applications. Most of the newer practical methods focus on prefabricated products that combine the benefits of multiple materials and systems.

Under the third objective, the authors generated knowledge about the impact of different types of ECM on a typical small residential building in two different climate zones. Regardless of the ECM used in various projects, the physics remains unchanged. Energy-saving is achieved by reducing the heat loss/gain or storing/releasing the heat at different times. Therefore, this study performed a sensitivity analysis using BEopt (i.e., an EnergyPlus-based computer tool) to help stakeholders determine the effectiveness of different building envelope ECMs in a typical residential building in two climate zones. Based on our case study of a two-story single-family building, the observations are summarized as follows:

- The impact of these envelope ECMs is higher in the colder climate zone (i.e., 20% vs. about 6%).

- Air sealing shows the highest impact on buildings in both climate zones. The energy-saving was about 3.5% and 30% in warm and cold climate zones.

- The roof’s thermal resistance shows the most negligible impact in buildings with a small roof-to-wall surface area ratio.

- Improving the U-Value of windows was found to be a more effective ECM in cold climate zones, as its energy-saving impact can be more than 15% (from −10% to about +5%).

- Improving walls’ R-Value in both climate zones shows a relatively high impact. In the warmer region, the energy-saving effect is about 2%, and in the colder region, the energy saving can be 20%.

These energy-saving potentials heavily rely on buildings’ characteristics, initial condition, properties such as WWR, building type, and materials’ specific heat (i.e., mass wall). The authors recommend more comprehensive studies to perform similar sensitivity analyses in a broader range of building characteristics and ECMs in different climate zones.

6.2. Strength and Limitations

Although this paper focuses on residential buildings, additional references relating to commercial buildings that used ECMs are also reviewed and discussed, where the results can be applied to residential buildings. Nonetheless, this paper is limited to evaluating the ECMs’ effectiveness based on their energy-saving impacts and changes in EUI, as opposed to, for example, thermal comfort. Moreover, the references used in this study are limited to the available online resources and do not include all the case studies.

Due to a lack of sufficient data, the initial state of the buildings is not reported for all the case studies, which may significantly affect energy savings. Therefore, the reported energy savings for any specific ECM cannot be generalized.

This paper provides essential data on the effectiveness of different retrofit approaches in typical residential buildings in the U.S. based on computer-based sensitivity analysis. The results are expected to help stakeholders to determine the type of ECM that may be more effective in different climate zones. Finally, the results are limited to the DOE prototype buildings’ settings, which means that a different baseline model may lead to different results.

7. Conclusions

This paper presents a literature review of the conventional and emerging building envelope ECMs worldwide. The authors reviewed over 1000 abstracts to identify the research interests over time, and used more-specific keywords to identify different materials, methods, and case studies relating to building envelope retrofitting that can be adopted in residential buildings’ energy retrofit projects. More innovative approaches are either based on new material or the integration of multiple solutions. The trend in building envelope ECMs seems to be toward precast multi-layer components to combine the benefits of various materials/solutions in a cost-effective approach. The reported energy savings show that the conventional methods can be as effective as innovative and emerging approaches. However, ease of installation, scalability, LCA, and cost benefits are the main drivers/factors in studying and identifying new energy conservation methods. The use of multiple criteria in the decision-making process explains the emergence of computer tools and techniques such as building energy modeling tools, machine learning, and multi-objective optimization.

It seems necessary to evaluate the “true energy savings” of ECMs using simulation tools and a standard benchmark building to ensure they are comparable to those of other ECMs. Finally, the result of the literature review shows that, depending on the climate zone, initial state of the building, building type, and mode of operations, the energy savings can vary significantly.

Author Contributions

Conceptualization, E.K. and A.M.M.; methodology, E.K. and A.M.M.; software, E.K.; validation, E.K. and A.M.M.; investigation, E.K.; writing—original draft preparation, E.K.; writing—review and editing, E.K. and A.M.M.; visualization, E.K.; supervision, A.M.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| AEO | Annual Energy Outlook | HVAC | Heating, ventilation, and air conditioning |

| APSC&VU TU | Advanced Passive Solar Collector & Ventilation Unit Technological Unit | LCA | Life cycle assessment |

| ASP&EA TU | Advanced Solar Protection & Energy Absorption Technological Unit | MDF | Medium-density fiberboard |

| ASTF | Active Solar Thermal Façade | MEEFS | Multi-functional energy-efficient façade system |

| BIPV | Building-integrated PV | OSB | Oriented Strand Board |

| CMU | Concrete masonry unit | PCM | Phase Change Material |

| DEEP | Database of energy efficiency performance | PV | Photovoltaic |

| DOE | Department of Energy | RECS | Residential Energy Consumption Survey |

| ECM | Energy Conservation Measure | SGPVTM | Single-channel glazed photovoltaic thermal module |

| EIFS | Exterior insulating finish system | SHGC | Solar heat gain coefficient |

| EPS | Expanded polystyrene | SRI | Solar Reflectance Index |

| ESCO | Energy service company | TRM | Textile reinforced mortar |

| ETICS | External thermal insulation composite system | VIP | Vacuum insulated panel |

| ETMMS | Exterior thermal & moisture management system | XPS | Extruded polystyrene |

| GUI | Graphic User Interface |

References

- EIA. Annual Energy Outlook 2016; Energy Information Administration (EIA): Washington, DC, USA, 2016.

- Pérez-Lombard, L.; Ortiz, J.; Pout, C. A review on buildings energy consumption information. Energy Build. 2008, 40, 394–398. [Google Scholar] [CrossRef]

- 2009 RECS Survey Data. EIA. 2009. Available online: http://www.eia.gov/consumption/residential/data/2009/ (accessed on 9 September 2016).

- University of Oxford. Our World in Data. Available online: https://ourworldindata.org/energy-production-consumption (accessed on 1 May 2021).

- Kamel, E.; Memari, A. Energy Retrofit Methods for Building Envelope Systems; Pennsylvania Housing Research Center (PHRC): State College, PA, USA, 2016. [Google Scholar]

- National Renewable Energy Laboratory. BEopt: Building Energy Optimization Tool. 2022. Available online: https://www.nrel.gov/buildings/beopt.html (accessed on 1 May 2022).

- Zhang, H.; Hewage, K.; Karunathilake, H.; Feng, H.; Sadig, R. Research on policy strategies for implementing energy retrofits in the residential buildings. Build. Eng. 2021, 43, 103161. [Google Scholar] [CrossRef]

- Hong, Y.; Ezeh, C.; Deng, W.; Hung, S.-H.; Peng, Z. Building Energy Retrofit Measures in Hot-Summer–Cold-Winter Climates: A Case Study in Shanghai. Energies 2019, 12, 3393. [Google Scholar] [CrossRef] [Green Version]

- Li, C.Z.; Zhang, L.; Liang, X.; Xiao, B.; Tam, V.W.; Lai, X.; Chen, Z. Advances in the research of building energy saving. Energy Build. 2022, 254, 111556. [Google Scholar] [CrossRef]

- Al-Homoud, M. Performance characteristics and practical applications of common building thermal insulation materials. Build. Environ. 2005, 40, 353–366. [Google Scholar] [CrossRef]

- Papadopoulos, A. State of the art in thermal insulation materials and aims for future developments. Energy Build. 2005, 37, 77–86. [Google Scholar] [CrossRef]

- Jelle, B.P. Traditional, state-of-the-art and future thermal building insulation materials and solutions—Properties, requirements and possibilities. Energy Build. 2011, 43, 2549–2563. [Google Scholar] [CrossRef] [Green Version]

- Holladay, M. Retrofitting Exterior Foam on Existing Walls. Building Green. 9 May 2009. Available online: https://www.buildinggreen.com/product-review/retrofitting-exterior-foam-existing-walls (accessed on 10 September 2016).

- Ojczyk, C. Cost Analysis of Roof-Only Air Sealing and Insulation Strategies on 1 ½-Story Homes in Cold Climates; U.S. Department of Energy: Washington, DC, USA, 2014. Available online: https://www.nrel.gov/docs/fy15osti/63178.pdf (accessed on 14 September 2016).

- Guattari, C.; Battista, G.; Evangelisti, L.; Fanchiotti, A.; Santarpia, L. Energy Retrofit of Historical Buildings Based on Windowed Elements. Appl. Mech. Mater. 2015, 737, 154–158. [Google Scholar] [CrossRef]

- Beccali, M.; Cellura, M.; Fontana, M.; Longo, S.; Mistretta, M. Energy retrofit of a single-family house: Life cycle net energy saving and environmental benefits. Renew. Sustain. Energy Rev. 2013, 27, 283–293. [Google Scholar] [CrossRef]

- Carbonaro, C.; Tedesco, S.; Thiebat, F.; Fantucci, S.; Serra, V.; Dutto, M. An integrated design approach to the development of a vegetal-basedthermal plaster for the energy retrofit of buildings. Energy Build. 2016, 124, 46–59. [Google Scholar] [CrossRef]

- Pertosa, M.; Pisello, A.L.; Castaldo, V.L.; Cotana, F. Environmental sustainability concept applied to historic buildings: The experience of LEED international protocol in the stable of Sant’Apollinare fortress in Perugia. In Proceedings of the 14th CIRIAF National Congress. Energy, Environment and Sustainable Development, Perugia, Italy, 4–5 April 2014. [Google Scholar]

- Rodrigues, C.; Freire, F. Integrated life-cycle assessment and thermal dynamic simulation of alternative scenarios for the roof retrofit of a house. Build. Environ. 2014, 81, 204–215. [Google Scholar] [CrossRef]

- Mejjaouli, S.; Alzahrani, M. Decision-Making Model for Optimum Energy Retrofitting Strategies in Residential Buildings. Sustain. Prod. Consum. 2020, 24, 211–218. [Google Scholar] [CrossRef]

- Ozarisoy, B.; Altan, H. A novel methodological framework for the optimisation of post-war social housing developments in the South-eastern Mediterranean climate: Policy design and life-cycle cost impact analysis of retrofitting strategies. Sol. Energy 2021, 225, 517–560. [Google Scholar] [CrossRef]

- Levinson, R. Cool Roof Q & A; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2009. Available online: https://heatisland.lbl.gov/sites/all/files/Cool-roof-Q+A.pdf (accessed on 14 September 2016).

- AlFaris, F.; Juaidi, A.; Manzano-Agugliaro, F. Energy retrofit strategies for housing sector in the arid climate. Energy Build. 2016, 131, 158–171. [Google Scholar] [CrossRef]

- Pisello, A.L.; Piselli, C.; Cotana, F. Thermal-physics and energy performance of an innovative green roof system: The Cool-Green Roof. Sol. Energy 2015, 116, 337–356. [Google Scholar] [CrossRef]

- Boarin, P.; Guglielmino, D.; Pisello, A.L.; Cotana, F. Sustainability assessment of historic buildings: Lesson learnt from an Italian case study through LEED® rating system. Energy Procedia 2014, 61, 1029–1032. [Google Scholar] [CrossRef] [Green Version]

- Advanced Energy Retrofit Guide, Practical Ways to Improve Energy Performance, Healthcare Facilities; National Renewable Energy Laboratory for U.S. Department of Energy: Golden, CO, USA, 2013. Available online: https://www.nrel.gov/docs/fy13osti/57864.pdf (accessed on 14 September 2016).

- Advanced Energy Retrofit Guide, Practical Ways to Improve Energy Performance, K-12 Schools; National Renewable Energy Laboratory for U.S. Department of Energy: Golden, CO, USA, 2013. Available online: https://www.nrel.gov/docs/fy14osti/60913.pdf (accessed on 14 September 2016).

- Advanced Energy, Practical Ways to Improve Energy Performance, Retail Buildings; Pacific Northwest National Laboratory for U.S. Department of Energy: Richland, WA, USA, 2011. Available online: https://www.nrel.gov/docs/fy13osti/54243.pdf (accessed on 14 September 2016).

- Advanced Energy Retrofit Guide, Practical Ways to Improve Energy Performance, Office Buildings; Pacific Northwest National Laboratory for U.S. Department of Energy: Richland, WA, USA, 2011. Available online: https://www.pnnl.gov/main/publications/external/technical_reports/PNNL-20761.pdf (accessed on 14 September 2016).

- Casini, M. Smart materials and nanotechnology for energy retrofit of historic buildings. Int. J. Civ. Struct. Eng. 2014, 1, 88–97. [Google Scholar]

- Park, J.H.; Berardi, U.; Chang, S.J.; Wi, S.; Kang, Y.; Kim, S. Energy retrofit of PCM-applied apartment buildings considering building orientation and height. Energy 2021, 222, 119877. [Google Scholar] [CrossRef]

- BASF. Available online: https://www.basf.com/global/en.html (accessed on 1 May 2019).

- Ascione, F.; Bianco, N.; de Masi, R.F.; déRossi, F. Energy retrofit of an educational building in the ancient center of Benevento. Feasibility study of energy savings and respect of the historical value. Energy Build. 2015, 95, 172–183. [Google Scholar] [CrossRef]

- Marin, P.; Saffari, M.; de Gracia, A.; Zhu, X.; Farid, M.M.; Cabeza, L.F.; Ushak, S. Energy savings due to the use of PCM for relocatable lightweight buildings passive heating and cooling in different weather conditions. Energy Build. 2016, 129, 274–293. [Google Scholar] [CrossRef] [Green Version]

- Mujeebu, M.A.; Ashraf, N.; Alsuwayigh, A.H. Effect of nano vacuum insulation panel and nanogel glazing on the energy performance of office building. Appl. Energy 2016, 173, 141–151. [Google Scholar] [CrossRef]

- Aspen. 2016. Available online: http://www.aerogel.com/resources/case-studies/ (accessed on 14 December 2016).

- Harasim, S. Aspen. March 2011. Available online: http://apps1.eere.energy.gov/buildings/publications/pdfs/building_america/ns/eemtg032011_c19_aerogel_insul.pdf (accessed on 14 December 2016).

- Berardi, U. The development of a monolithic aerogel glazed window for an energy retrofitting project. Appl. Energy 2015, 154, 603–615. [Google Scholar] [CrossRef]

- Filate, S.S. Investigation of an Energy Refurbishment Concept for Office Building Using Nanogel/Aerogel Insulation Plaster and Replaced Windows by Building Simulation; Master Programme in Energy Technology; Uppsala Universitet: Uppsala, Sweden, 2014; Available online: https://www.diva-portal.org/smash/get/diva2:772909/ATTACHMENT01.pdf (accessed on 14 September 2016).

- Fenoglio, E.; Fantucci, S.; Perino, M.; Serra, V.; Dutto, M.; Marino, V. Energy retro! t of residential buildings with a novel super-insulating aerogel-based plaster. AiCARR J. 2020, 61, 44–48. [Google Scholar]

- Singh, S.; Agarwal, S.; Tiwari, G.; Chauhan, D. Application of genetic algorithm with multi-objective function to improve the efficiency of glazed photovoltaic thermal system for New Delhi (India) climatic condition. Sol. Energy 2015, 117, 153–166. [Google Scholar] [CrossRef]

- Masera, G.; Iannaccone, G.; Salvalai, G. Retrofitting the Existing Envelope of Residential Buildings: Innovative Technologies, Performance Assessment and Design Methods. In Proceedings of the Advanced Building Skins—9th Energy Forum, Bressanone, Italy, 28–29 October 2014. [Google Scholar]

- Salvalai, G.; Sesana, M.M.; Iannaccone, G. Deep renovation of multi-storey multi-owner existing residential buildings: A pilot case study in Italy. Energy Build. 2017, 148, 23–36. [Google Scholar] [CrossRef]

- ETICS Are Quality Systems, Europian Association for External Thermal Insulation Composite Systems. Available online: http://www.ea-etics.eu/~run/views/etics/about-etics.html (accessed on 11 September 2016).

- Chwieduk, D.A. Towards modern options of energy conservation in buildings. Renew. Energy 2017, 101, 1194–1202. [Google Scholar] [CrossRef]

- Evola, G.; Margani, G. Energy retrofit towards net zeb, Application of BIPV on an Apartment Block in Southern Italy. In Proceedings of the Architectural Research through to Practice: 48th International Conference of the Architectural Science Association, Genoa, Italy, 10–13 December 2014. [Google Scholar]

- Paiho, S.; Seppä, I.P.; Jimenez, C. An energetic analysis of a multifunctional façade system for energy efficient retrofitting of residential buildings in cold climates of Finland and Russia. Sustain. Cities Soc. 2015, 15, 75–85. [Google Scholar] [CrossRef]

- Multifunctional Energy Efficient Facade System for Building Retrofit, European Commission’s 7th Framework Programme for Research. Available online: http://www.meefs-retrofitting.eu/project/retrofitting-facade-concept.html (accessed on 12 September 2016).

- Zhang, X.; Shen, J.; Lu, Y.; He, W.; Xu, P.; Zhao, X.; Qiu, Z.; Zhu, Z.; Zhou, J.; Dong, X. Active Solar Thermal Facades (ASTFs): From concept, application to research questions. Renew. Sustain. Energy Rev. 2015, 50, 32–63. [Google Scholar] [CrossRef]

- Kim, G.; Lim, H.S.; Kim, J.T. Sustainable lighting performance of refurbished glazed walls for oldresidential buildings. Energy Build. 2015, 91, 163–169. [Google Scholar] [CrossRef]

- Kolaitis, D.I.; Malliotakis, E.; Kontogeorgos, D.A.; Mandilaras, I.; Katsourinis, D.I.; Founti, M.A. Comparative assessment of internal and external thermal insulationsystems for energy efficient retrofitting of residential buildings. Energy Build. 2013, 64, 123–131. [Google Scholar] [CrossRef]

- Ascione, F.; Bianco, N.; de Stasio, C.; Mauro, G.M.; Vanoli, G.P. A new methodology for cost-optimal analysis by means of themulti-objective optimization of building energy performance. Energy Build. 2015, 88, 78–90. [Google Scholar] [CrossRef]

- Casquero-Modrego, N.; Goñi-Modrego, M. Energy Retrofit of an Existing Affordable Building Envelope in Spain, Case Study. Sustain. Cities Soc. 2018, 44, 395–405. [Google Scholar] [CrossRef]

- Cho, H.M.; Park, J.H.; Wi, S.; Seong, J.C.; Geon, Y.Y. Energy retrofit analysis of cross-laminated timber residential buildings in Seoul, Korea: Insights from a case study of packages. Energy Build. 2019, 202, 109329. [Google Scholar] [CrossRef]

- Rakhshan, K.; Friess, W.A. Effectiveness and viability of residential building energy retrofits in Dubai. Build. Eng. 2017, 13, 116–126. [Google Scholar] [CrossRef]

- Friedman, C.; Becker, N.; Erell, E. Energy retrofit of residential building envelopes in Israel: A cost-benefit analysis. Energy 2014, 77, 183–193. [Google Scholar] [CrossRef]

- Chang, R.; Hayter, S.; Hotchkiss, E.; Pless, S.; Sielcken, J.; Smith-Larney, C. Aspinall Courthouse: GSA’s Historic Preservation and Net-Zero Renovation; U.S. Department of Energy: Washington, DC, USA, 2014. Available online: https://www.energy.gov/sites/default/files/2014/10/f19/aspinall_courthouse.pdf (accessed on 14 September 2016).

- Case Studies, Empire State Building, New York. Available online: http://www.rmi.org/retrofit_depot_get_connected_true_retrofit_stories##empire (accessed on 14 September 2016).

- Radwan, A.F.; Hanafy, A.A.; Elhelw, M.; El-Sayed, A.E.-H.A. Retrofitting of existing buildings to achieve better energy-efficiency in commercial building case study: Hospital in Egypt. Alex. Eng. J. 2016, in press. [Google Scholar] [CrossRef] [Green Version]

- Deep Energy Retrofits: An Emerging Opportunity; The American Institute of Architects and Rocky Mountain Institute: Basalt, CO, USA, 2013; Available online: https://content.aia.org/sites/default/files/2016-04/Deep-Energy-Retrofits-EmergingOpportunity.pdf (accessed on 14 September 2016).

- 200 Market Building Case Study. 27 April 2012. Available online: http://newbuildings.org/resource/200-market-building-case-study/ (accessed on 14 September 2016).

- Aste, N.; del Pero, C. Energy retrofit of commercial buildings: Case study and applied methodology. Energy Effic. 2013, 6, 407–423. [Google Scholar] [CrossRef]

- Alliance Center Case Study. 27 April 2012. Available online: http://newbuildings.org/resource/alliance-center-case-study/ (accessed on 14 September 2016).

- Beardmore Building Case Study. 27 April 2012. Available online: http://newbuildings.org/resource/beardmore-building-case-study/ (accessed on 14 September 2016).

- Home On The Range Case Study. 27 April 2012. Available online: http://newbuildings.org/resource/home-range-case-study/ (accessed on 14 September 2016).

- Bianco, M.D.; Wiehagen, J. Using Retrofit Nail Base Panels to Expand the Market for Wall Upgrades; U.S. Department of Energy’s Building America Program: Denver, CO, USA, 2016.

- Hagerman, S. Construction Methods and Approach to the Glasswood Commercial Passive House Retrofit. J. Green Build. 2014, 9, 23–36. [Google Scholar] [CrossRef]

- German, A.; Siddiqui, A.; Dakin, B. Sunnyvale Marine Climate Deep Retrofit; U.S. Department of Energy: Davis, CA, USA, 2014.

- Morelli, M.; Rønby, L.; Mikkelsen, S.E.; Minzari, M.G.; Kildemoes, T.; Tommerup, H.M. Energy retrofitting of a typical old Danish multi-family building to a “nearly-zero” energy building based on experiences from a test apartment. Energy Build. 2012, 54, 395–406. [Google Scholar] [CrossRef]

- Kośny, J.; Kossecka, E.; Fallahi, A.; Yarbrough, D. Use of Thermal Inertia for Reduction of HVAC Energy Consumption in Cooling Dominated and Mixed Climates; BEST4 Technical Committee. National Institute of Building Sciences: Washington, DC, USA, 2015. Available online: https://www.brikbase.org/sites/default/files/BEST4_2.2%20kosny.pdf (accessed on 14 September 2016).

- MacDonald, M.; Livengood, S. Benchmarking Residential Energy Use. In Proceedings of the 2000 ACEEE Summer Study on Energy Efficiency in Buildings, Washington, DC, USA, 20–25 August 2000; Department of Energy: Oak Ridge, TN, USA, 2000. [Google Scholar]

- Denis, D. Bottom-Up Modelling of Energy Demand and Technical Energy Savings Potential in the Irish Residential Sector. Ph.D. Thesis, National University of Ireland, Cork, Ireland, 2014. [Google Scholar]

- Crawley, D.B.; Hand, J.W.; Kummert, M.l.; Griffith, B.T. Contrasting the capabilities of building energy performance simulation programs. Build. Environ. 2008, 43, 661–673. [Google Scholar] [CrossRef] [Green Version]

- Jankovic, L. Lessons learnt from design, off-site construction and performance analysis of deep energy retrofit of residential buildings. Energy Build. 2019, 186, 319–338. [Google Scholar] [CrossRef]

- Lee, S.H.; Hong, T.; Piette, M.A.; Sawaya, G.; Chen, Y.; Taylor-Lange, S.C. Accelerating the energy retrofit of commercial buildings using a database of energy efficiency performance. Energy 2015, 90, 738–747. [Google Scholar] [CrossRef] [Green Version]

- Khoury, J.; Pierre, H.; Marie, L.B. Energy performance gap in building retrofit: Characterization and effect on the energy saving potential. In Proceedings of the Building and Renewable Energies Network of Technology, Zürich, Switzerland, 8–9 September 2016. [Google Scholar]

- Lu, Y.; Li, P.; Lee, Y.P.; Song, X. An integrated decision-making framework for existing building retrofits based on energy simulation and cost-benefit analysis. J. Build. Eng. 2021, 43, 103200. [Google Scholar] [CrossRef]

- Office of Energy Efficiency & Renewable Energy, Prototype Building Model, DOE. 2021. Available online: https://www.energycodes.gov/prototype-building-models (accessed on 1 May 2021).

- El-Darwish, I.; Gomaa, M. Retrofitting strategy for building envelopes to achieve energy efficiency. Alex. Eng. J. 2017, 56, 579–589. [Google Scholar] [CrossRef] [Green Version]

- Evangelisti, L.; Guattari, C.; Gori, P. Energy Retrofit Strategies for Residential Building Envelopes: An Italian Case Study of an Early-50s Building. Sustainability 2015, 7, 10445–10460. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).