Push-Out Test and Hysteretic Performance Study of Semi-Rigid Shear Keys with the Triple-Folded Web of Flange

Abstract

1. Introduction

2. Experimental Program

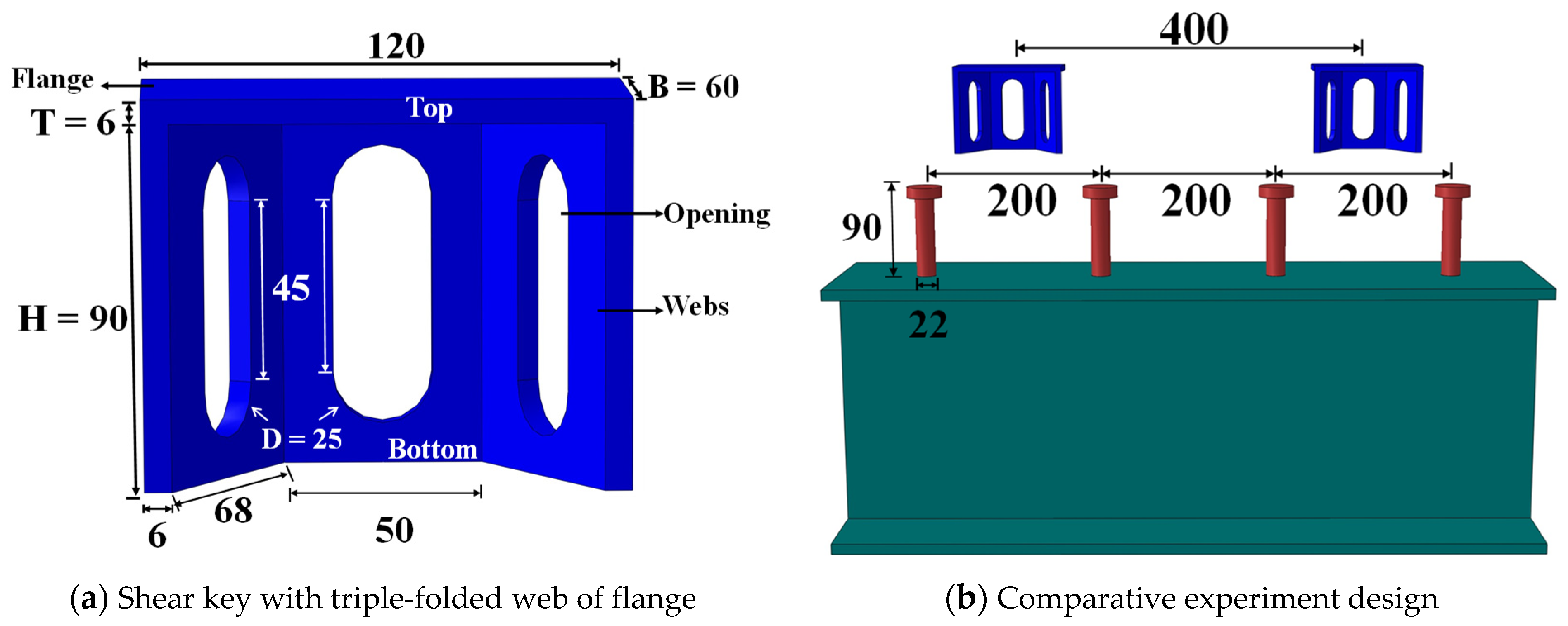

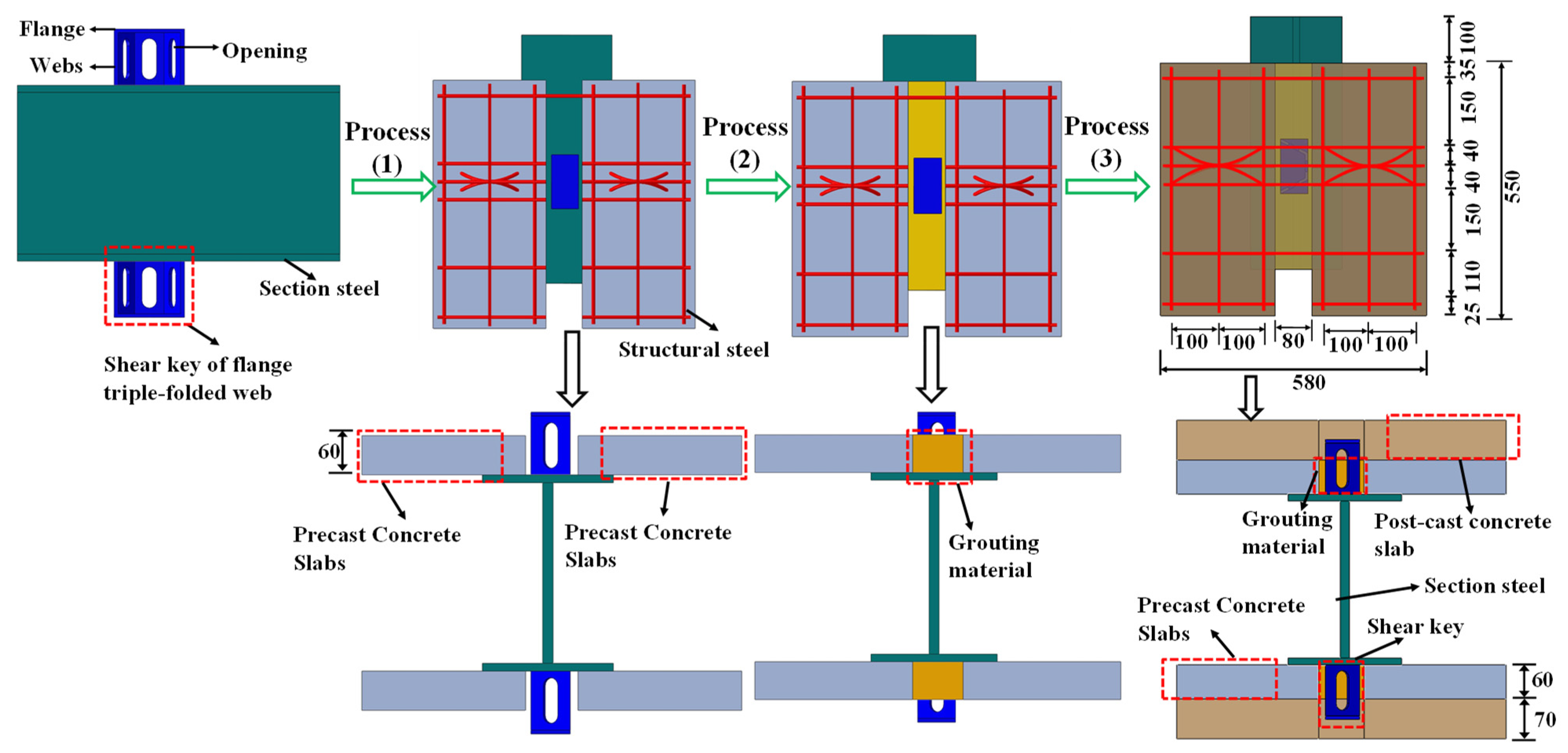

2.1. Test Specimens

2.2. Material Properties

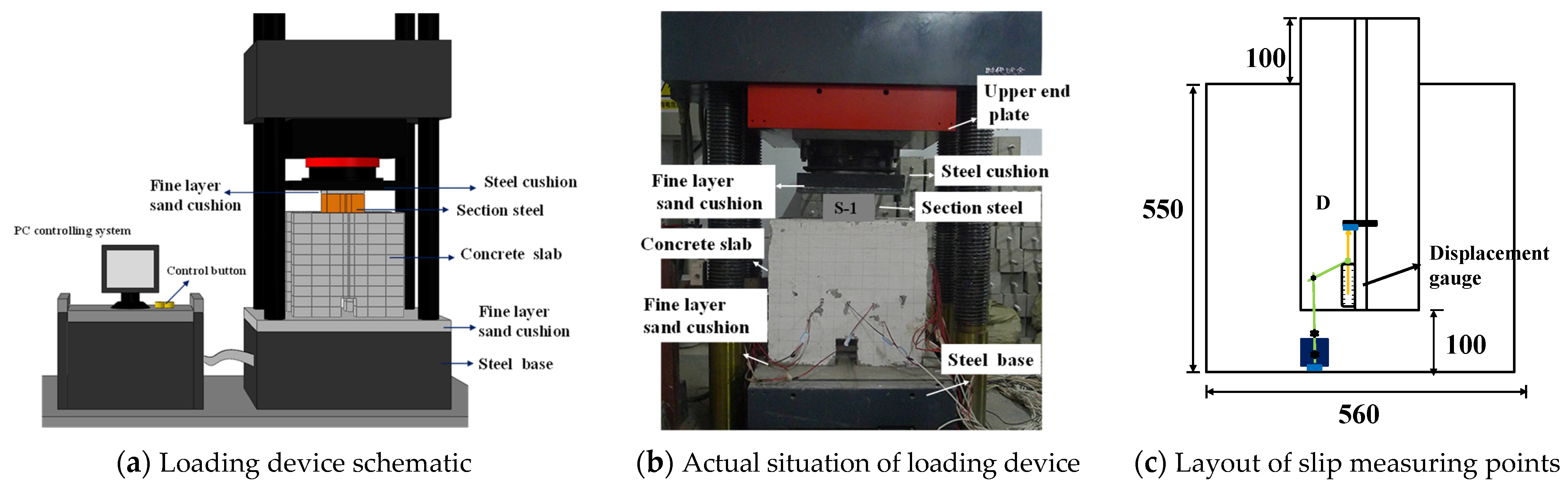

2.3. Test Setup and Loading Procedure

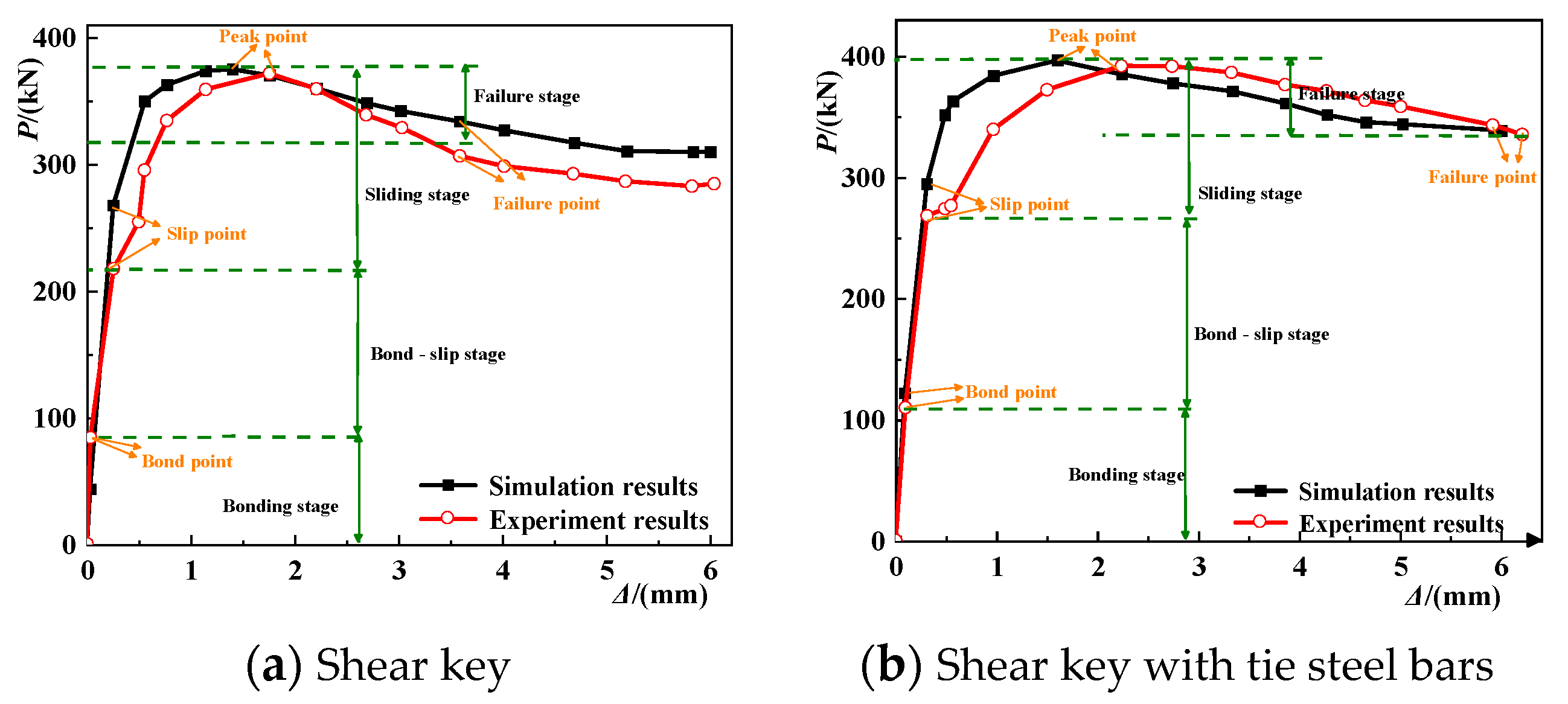

3. Test Results and Discussion

3.1. Failure Modes

3.2. Load-Slippage Curve

4. Finite Element Simulation of Test Specimens

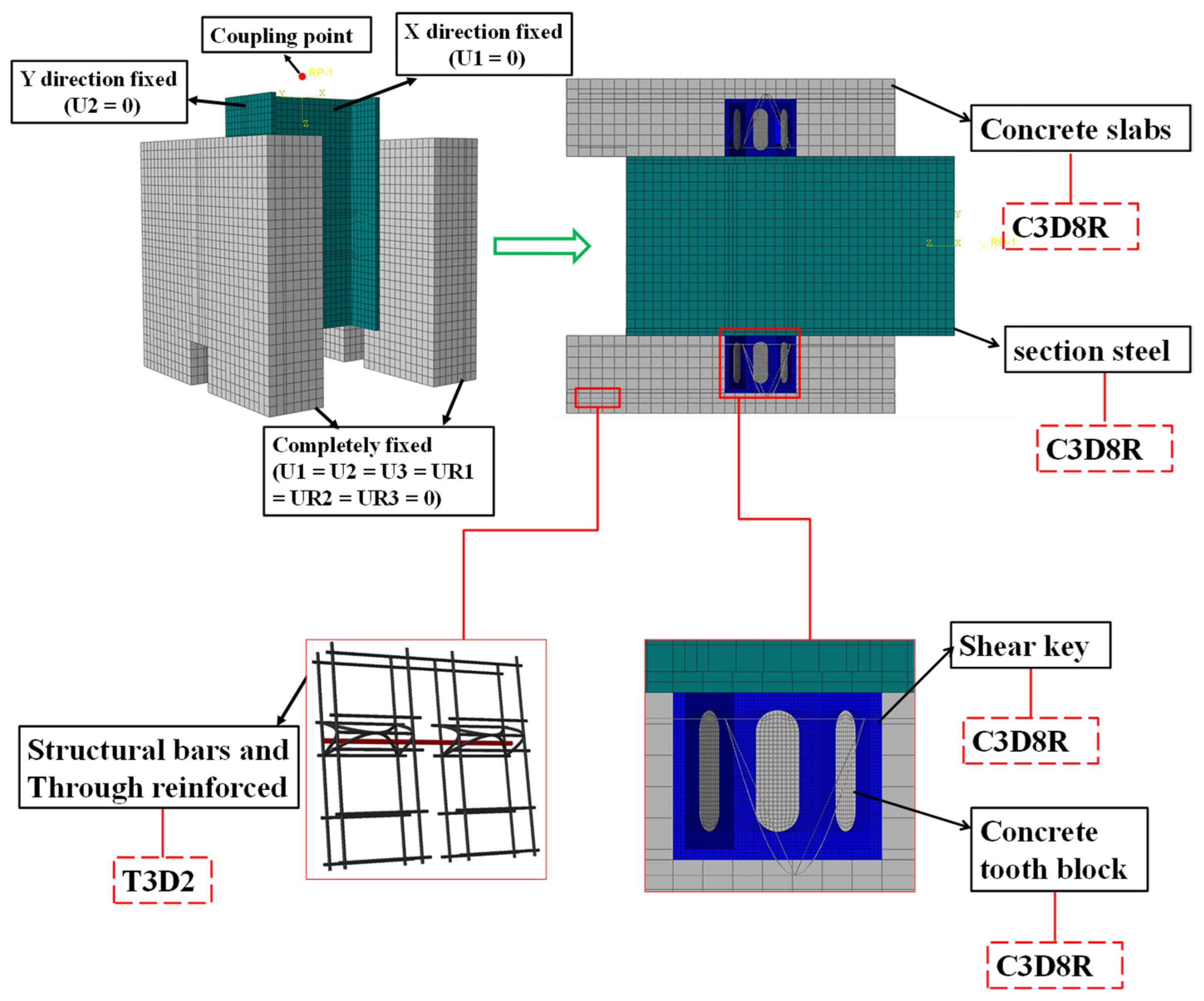

4.1. Finite Element Model

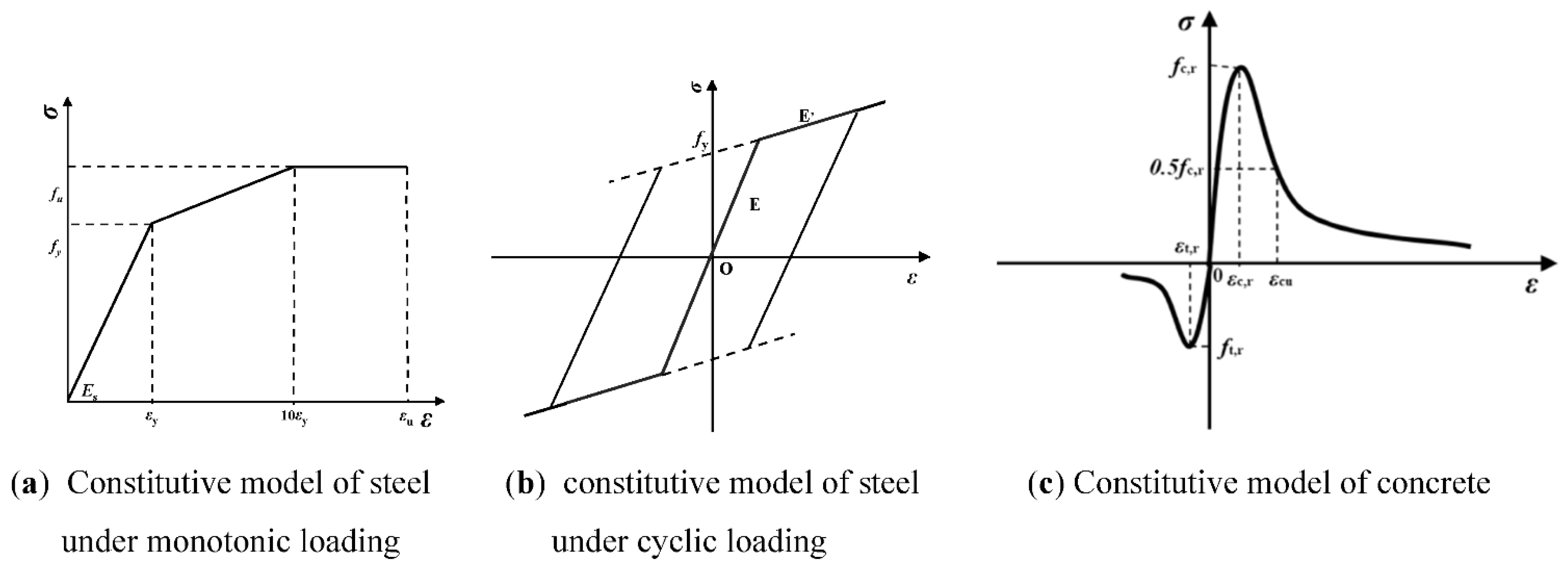

4.2. Material Constitutive Relationship

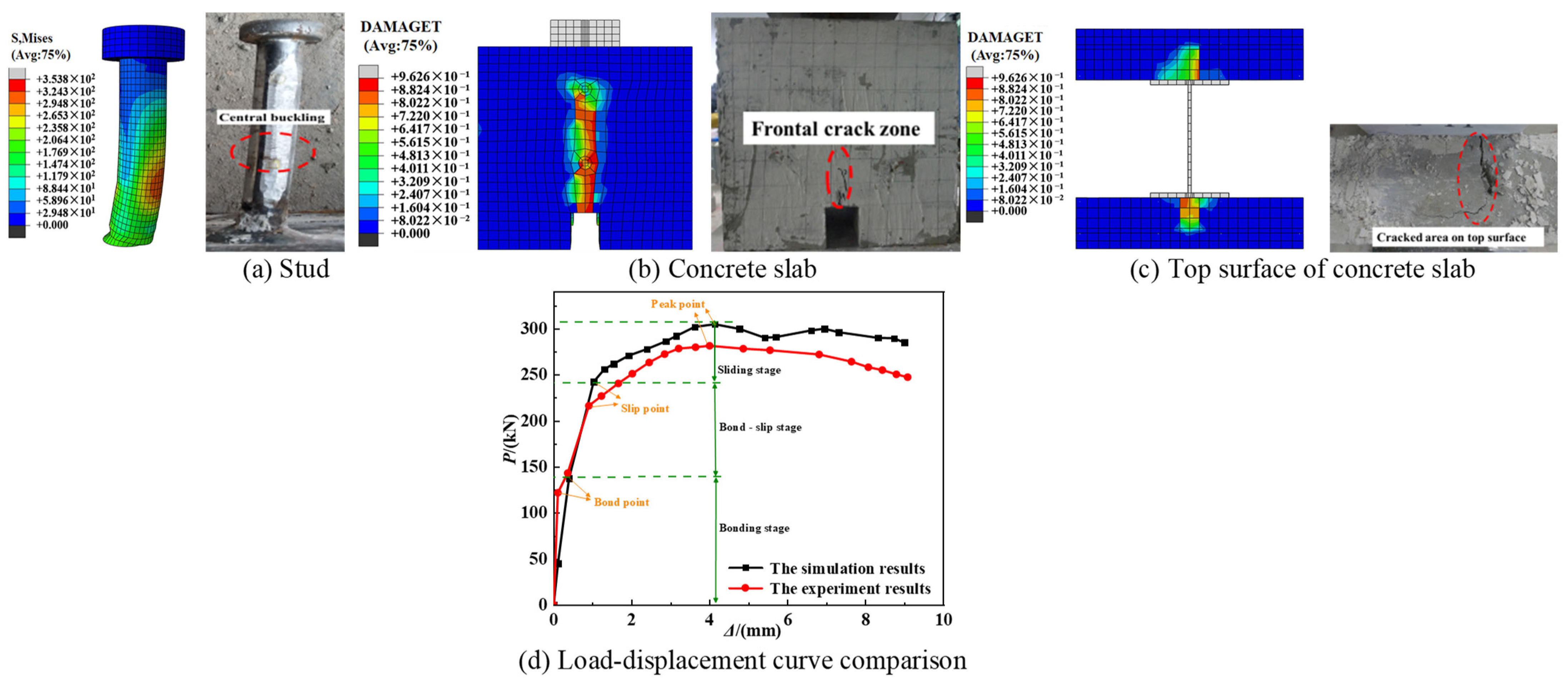

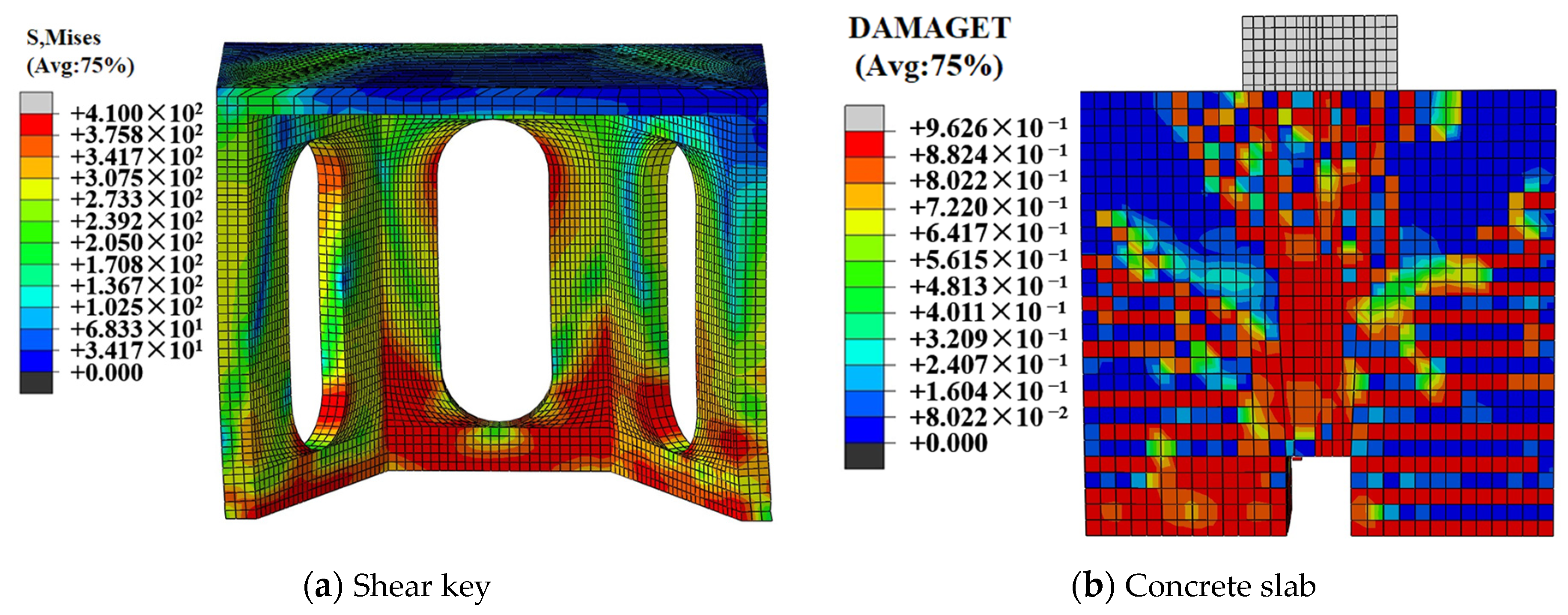

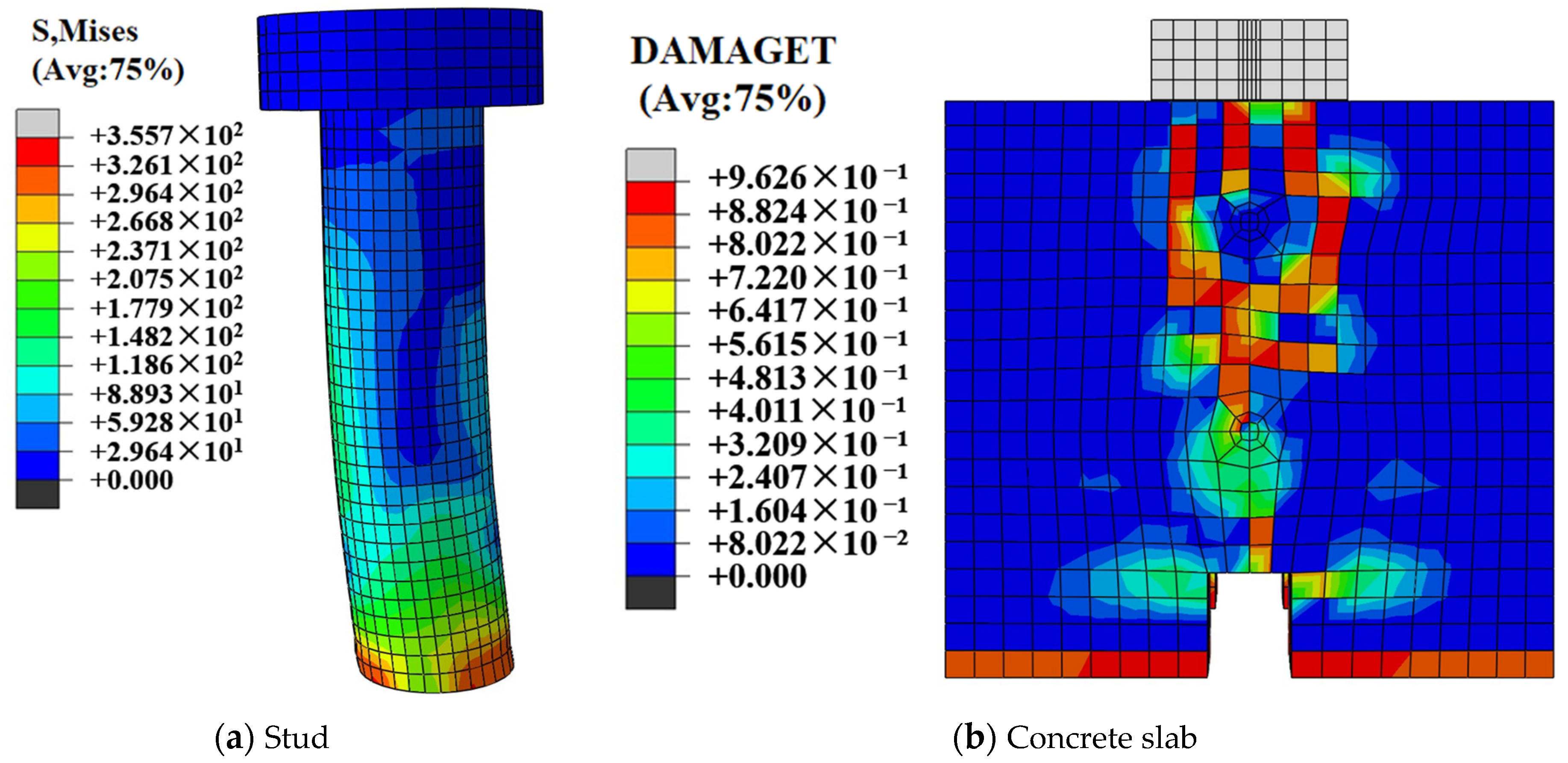

4.3. Finite Element Results

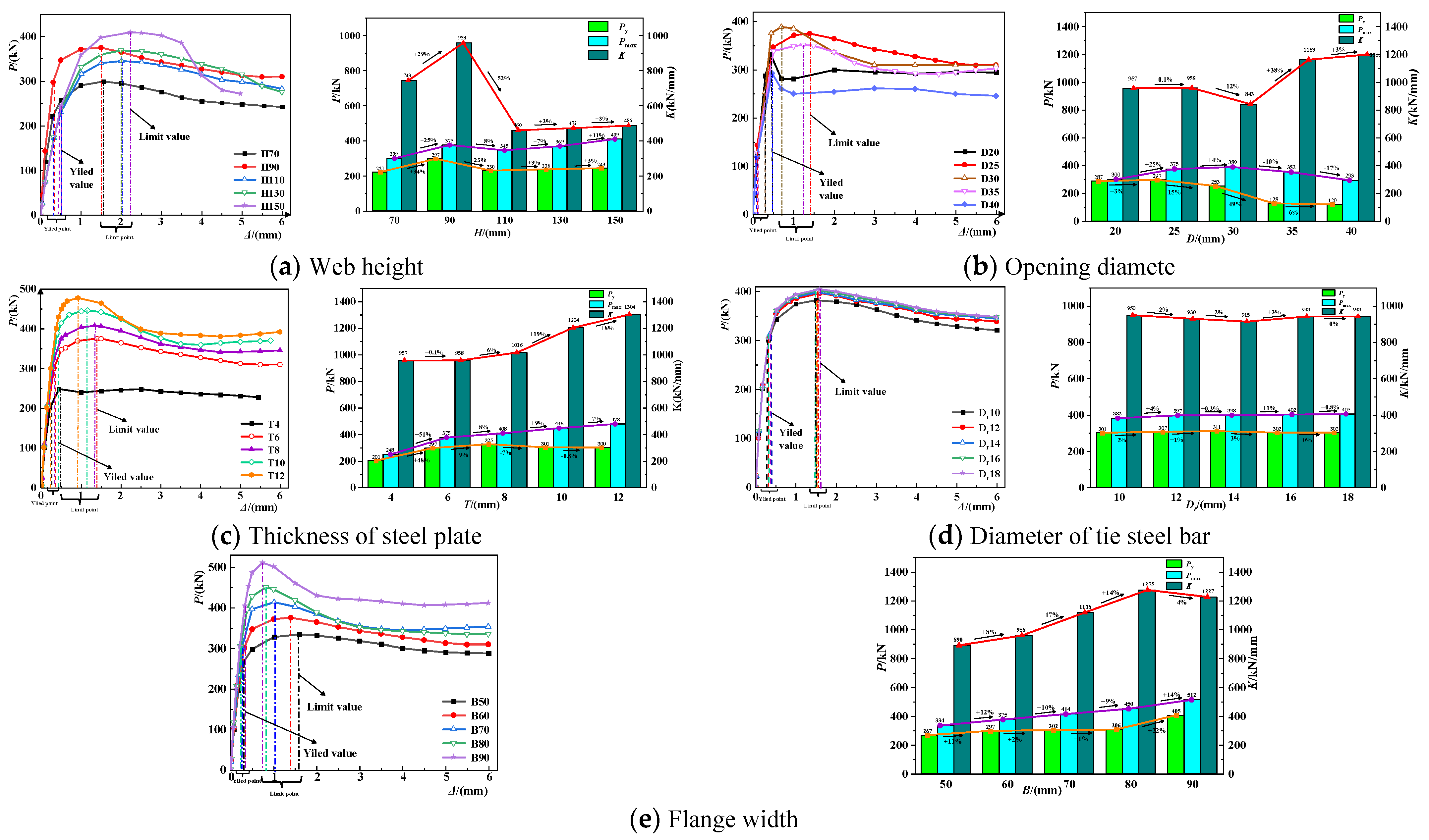

5. Finite Element Parametric Analysis

5.1. Web Height

5.2. Opening Diameter

5.3. Steel Plate Thickness

5.4. Tie Steel Bar Diameter

5.5. Flange Width

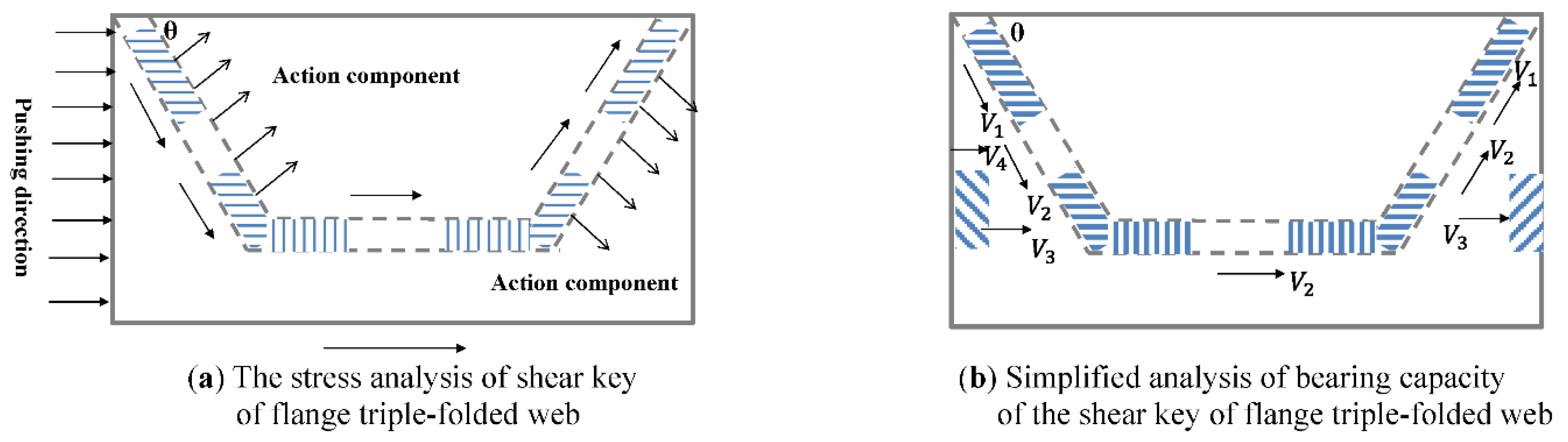

6. Bearing Capacity Calculation

7. Bond-Slip Performance under Seismic Reciprocating Action

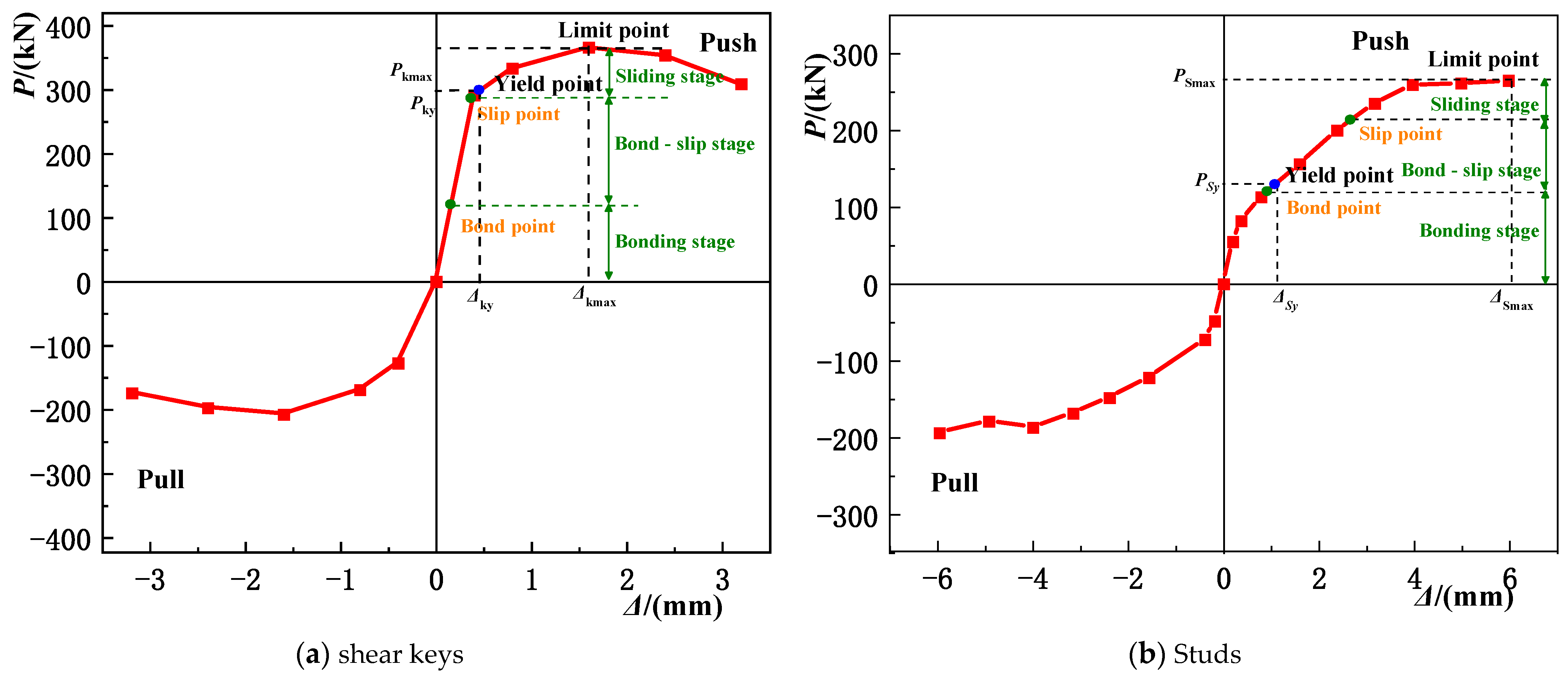

7.1. Load-Displacement Hysteresis Curve

7.2. Stress Distribution and Failure Characteristics

7.3. Bond-Slip Performance under Horizontal Push-Out and Hysteresis Action

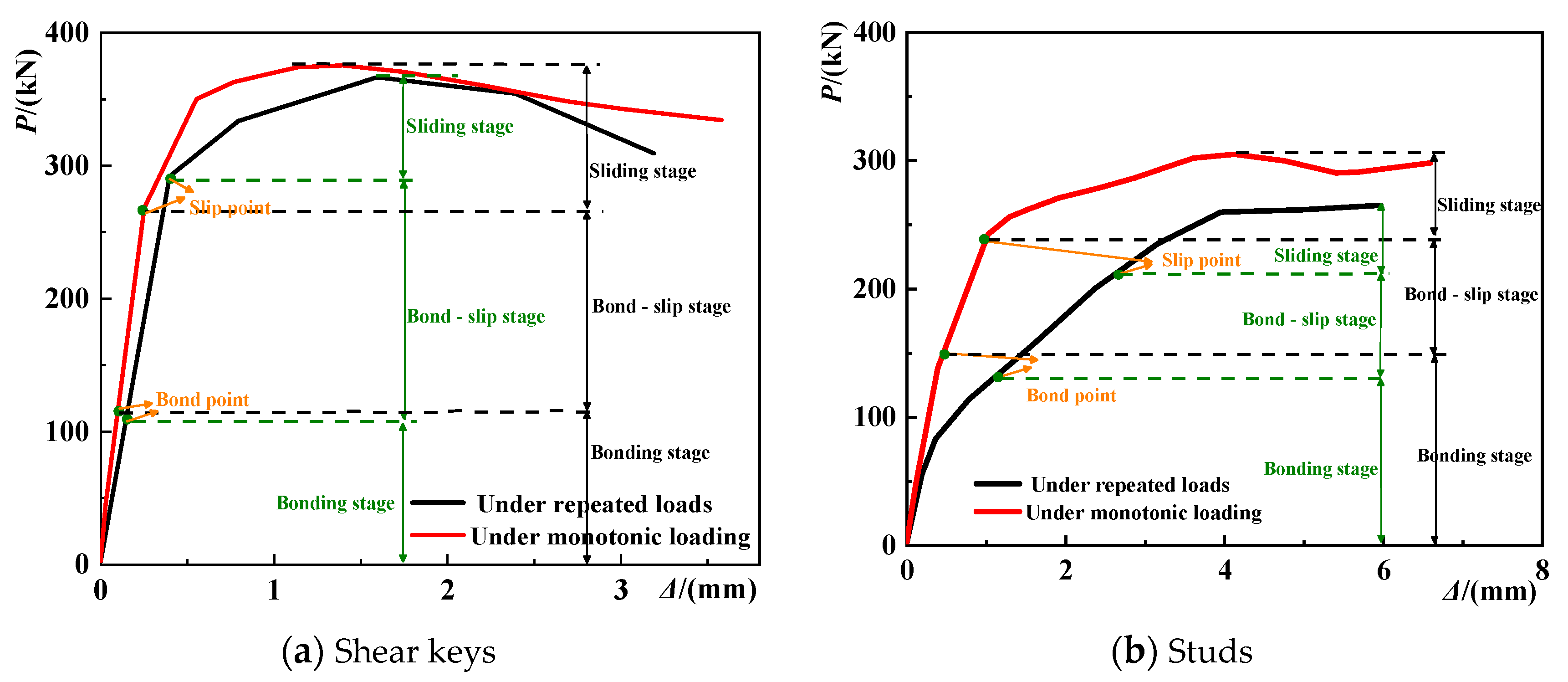

7.4. Skeleton Curves Analysis

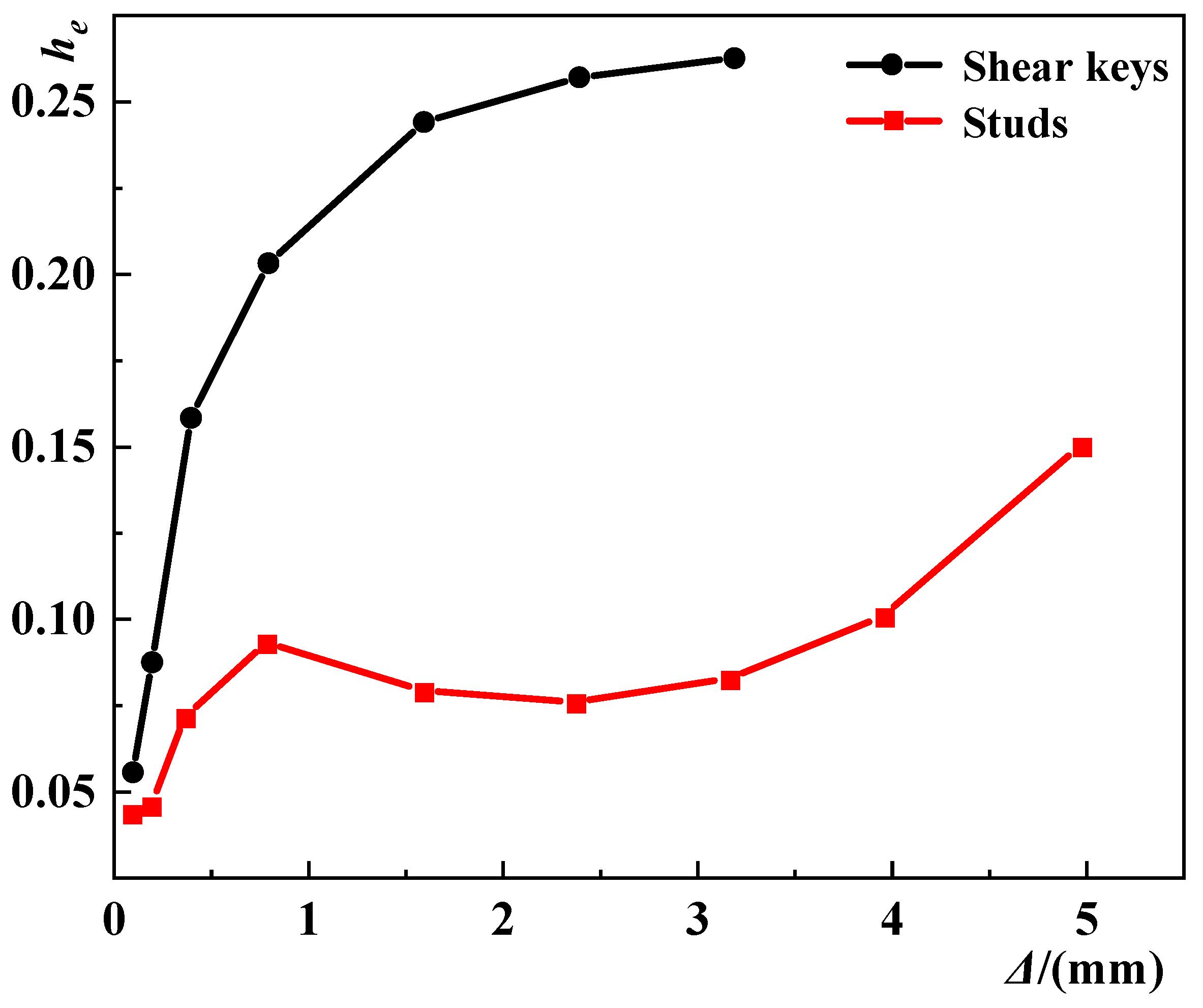

7.5. Stiffness Degradation and Energy Dissipation Capacity Analysis

8. Conclusions

- (1)

- The push-out test shows that the new shear key has high bearing capacity. Compared with the stud connector, the sliding load increases by more than 45%, and the ultimate load increases by more than 32%. The safety margin is slightly small. At the same time, it has good deformation ability and basically realizes the design purpose of “strength” and “deformation” coordination; the failure mode of the shear key is as follows: bending occurs along the push-out direction, and the deformation of both sides of the web and the edge of the opening is serious. The concrete slab forms a trapezoidal cracking area centered on the shear key. Compared with the stud’s point constraint, the shear key’s constraint range is wider, and the integrity is better. In addition, the study on the influence of tie steel bars shows that it has little effect on the bearing capacity of the shear key. However, it can increase the constraint capacity and ductility of the shear key to a certain extent.

- (2)

- Through parameter analysis, it is found that the bearing capacity of triple-folded shear key increases with the increase of web thickness, flange width, and diameter of penetrating steel bar and decreases with the decrease of opening diameter in a certain range; considering the stiffness and ductility performance, the best matching principle of the shear key structure parameters of the flange triple-folded web is obtained: flange width 60 mm–70 mm, plate thickness 6 mm–8 mm, web height 90 mm, and opening diameter 25 mm–30 mm; if the steel bar is inserted at the opening, the steel bar with a diameter of 12 mm should be preferred.

- (3)

- According to the experimental results and numerical simulation, it is found that the width of the flange, the height of the web, the diameter of the opening, and the thickness of the steel plate have a great influence on the bearing capacity of shear keys. Through the fitting analysis of the numerical calculation results, the influence coefficient of web height γH, the embedded influence coefficient γD, the influence coefficient of steel plate thickness γT, and the influence coefficient of flange width γB are obtained, and the calculation formula of ultimate bearing capacity is proposed.

- (4)

- The study of seismic performance found that the load-displacement hysteretic curve of the shear key is full, showing good seismic performance. The ductility coefficient reaches 3.3, and the equivalent viscous damping coefficient is 0.26. The energy dissipation capacity is more than 1.6 times higher than that of the stud, and the stiffness can be more than four times higher than that of the stud. At the same time, the seismic bearing capacity of the shear key is less reduced than that of the unidirectional pushout strength, showing good comprehensive performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Petr, B.; Josef, F.; Alena, K. Behavior of Anchorage Areas in the Steel-concrete Composite Structure Loaded by Longitudinal Shear Forces. Procedia Eng. 2017, 172, 104–110. [Google Scholar] [CrossRef]

- Sirimontree, S.; Thongchom, C.; Keawsawasvong, S.; Nuaklong, P.; Jongvivatsakul, P.; Dokduea, W.; Bui, L.V.H.; Farsangi, E.N. Experimental Study on the Behavior of Steel-Concrete Composite Decks with Different Shear Span-to-Depth Ratios. Buildings 2021, 11, 624. [Google Scholar] [CrossRef]

- Kozma, A.; Odenbreit, C.; Braun, M.; Veljkovic, M.; Nijgh, M. Push-out tests on demountable shear connectors of steel-concrete composite structures. Structures 2019, 21, 45–54. [Google Scholar] [CrossRef]

- Lima, J.M.; Bezerra, L.M.; Bonilla, J.; Barbosa, W.C. Study of the behavior and resistance of right-angle truss shear connector for composite steel concrete beams. Eng. Struct. 2022, 253, 113778. [Google Scholar] [CrossRef]

- Fang, Z.; Fang, S.; Liu, F. Experimental and Numerical Study on the Shear Performance of Short Stud Shear Connectors in Steel-UHPC Composite Beams. Buildings 2022, 12, 418. [Google Scholar] [CrossRef]

- Abdolreza, A.; Mehran, Z.A. Study on structural performance of deconstructable bolted shear connectors in composite beams. Structures 2021, 29, 519–533. [Google Scholar]

- Alsharari, F.; El-Sisi, A.E.-D.; Mutnbak, M.; Salim, H.; El-Zohairy, A. Effect of the Progressive Failure of Shear Connectors on the Behavior of Steel-Reinforced Concrete Composite Girders. Buildings 2022, 12, 596. [Google Scholar] [CrossRef]

- Jun, H.; Ahmed, S.H.S.; George, V. Horizontal pushout tests and parametric analyses of a locking-bolt demountable shear connector. Structures 2022, 35, 667–683. [Google Scholar] [CrossRef]

- Arévalo, D.; Hernández, L.; Gómez, C.; Velasteguí, G.; Guaminga, E.; Baquero, R.; Dibujés, R. Structural performance of steel angle shear connectors with different orientation. Case Stud. Constr. Mat. 2021, 14, e00523. [Google Scholar] [CrossRef]

- Qiu, S.Y.; Fan, J.S.; Nie, J.G.; Tang, L.; Song, S.Y.; Xu, G.P. Experimental and Theoretical Study on Shear Stiffness of Angle Shear Connectors. China J. Highw. Transp. 2021, 34, 136–146. [Google Scholar] [CrossRef]

- Jiang, H.; Fang, H.; Liu, J.; Fang, Z.; Zhang, J. Experimental investigation on shear performance of transverse angle shear connectors. Structures 2021, 33, 2050–2060. [Google Scholar] [CrossRef]

- Vianna, J.D.; Costa-Neves, L.F. Structural behavior of T-Perfobond shear connectors in composite girders: An experimental approach. Eng. Struct. 2008, 30, 2381–2391. [Google Scholar] [CrossRef]

- Isabel, V.; Paulo, J.S.C. Experimental analysis of Perfobond shear connection between steel and lightweight concrete. J. Constr. Steel. Res. 2004, 60, 465–479. [Google Scholar]

- João Paulo, C.R.; Luis, L. Experimental investigation on the structural response of T, T-block and T-Perfobond shear connectors at elevated temperatures. Eng. Struct. 2014, 75, 299–314. [Google Scholar] [CrossRef]

- Vianna, J.; Costa-Neves, L.; Vellasco, P.; de Andrade, S. Experimental assessment of Perfobond and T-Perfobond shear connectors’ structural response. J. Constr. Steel. Res. 2009, 65, 408–421. [Google Scholar] [CrossRef]

- Wang, X.; Zhu, B.; Cui, S.; Lui, E.M. Experimental Research on PBL Connectors Considering the Effects of Concrete Stress State and Other Connection Parameters. J. Bridge Eng. 2018, 23, 04017125. [Google Scholar] [CrossRef]

- Yong, Y.; Yang, C. Experimental Study on Mechanical Behavior of PBL Shear Connectors. J. Bridge Eng. 2018, 23, 04018062. [Google Scholar] [CrossRef]

- Zhang, W.J.; Du, E.X.; Liu, B.Z.; Yang, S.C. Failure Mode Attribution Analysis of PBL Shear Connector. Appl. Mech. Mater. 2013, 351–352, 683–686. [Google Scholar] [CrossRef]

- Zhang, Y.Z.; Li, Q.; Xia, S. Research on the Influence Factors to the Working Performance of PBL Shear Connectors. Appl. Mech. Mater. 2012, 178–181, 2192–2198. [Google Scholar] [CrossRef]

- Yang, Y.; Liang, W.; Yang, Q.; Cheng, Y. Flexural behavior of web embedded steel-concrete composite beam. Eng. Struct. 2021, 240, 112345. [Google Scholar] [CrossRef]

- Zhang, Z.; Shi, J.; Li, G.Q.; Tang, Y.; Li, F.R.; Wang, Y.; Sun, D.S.; Deng, E.F. Experimental study on shear capacity of embedded connector with flange plate. J. Zhengzhou Univ. Eng. Sci. 2020, 41, 86–90. [Google Scholar] [CrossRef]

- Song, R.N.; Zhan, Y.L.; Zhao, R.D.; Mou, T.M.; Fan, B.K.; Shao, J.H. Push-out Test and Numerical Analysis of Embedded Shear Connectors with Corrugated Steel Plates. China J. Highw. Ttansp. 2019, 32, 88–99. [Google Scholar]

- Kim, H.Y.; Jeong, Y.J. Experimental investigation on behaviour of steel-concrete composite bridge decks with perfobond ribs. J. Constr. Steel. Res. 2006, 62, 463–471. [Google Scholar] [CrossRef]

- Ahn, J.-H.; Lee, C.-G.; Won, J.-H.; Kim, S.-H. Shear resistance of the perfobond-rib shear connector depending on concrete strength and rib arrangement. J. Constr. Steel. Res. 2010, 66, 1295–1307. [Google Scholar] [CrossRef]

- Kim, S.H.; Ahn, J.H.; Choi, K.T. Experimental Evaluation of the Shear Resistance of Corrugated Perfobond Rib Shear Connections. Adv. Struct. Eng. 2011, 14, 249–263. [Google Scholar] [CrossRef]

- Zhan, Y.; Yin, C.; Liu, F.; Song, R.; Deng, K.; Sun, J. Pushout Tests on Headed Studs and PBL Shear Connectors Considering External Pressure. J. Bridge Eng. 2020, 25, 04019112. [Google Scholar] [CrossRef]

- Kanchanadevi, A.; Ramanjaneyulu, K.; Gandhi, P. Shear resistance of embedded connection of composite girder with corrugated steel web. J. Constr. Steel. Res. 2021, 187, 106994. [Google Scholar] [CrossRef]

- Nemeth, G.; Jager, B.; Kovacs, N. Experimental study on the shear connections of composite girders with trapezoidally corrugated web. In Proceedings of the International Colloquia on Stability and Ductility of Steel Structures, Czech Tech Univ Prague, Prague, Czech, 11–13 September 2019. [Google Scholar]

- Jáger, B.; Németh, G.; Kovács, N.; Kövesdi, B.; Kachichian, M. Push-out tests on embedded shear connections for hybrid girders with trapezoidal web. In Proceedings of the 12th International Conference on Advances in Steel-Concrete Composite Structures (ASCCS), Univ Politecnica Valencia, Valencia, Spain, 27–29 January 2018. [Google Scholar] [CrossRef][Green Version]

- El-Zohairy, A.; Salim, H.; Saucier, A. Fatigue Tests on Steel-Concrete Composite Beams Subjected to Sagging Moments. J Struct. Eng. 2019, 145, 04019029. [Google Scholar] [CrossRef]

- El-Zohairy, A.; Salim, H.; Shaaban, H. Experimental investigation on fatigue behavior of composite beams with different studs arrangements. Structures 2022, 35, 146–159. [Google Scholar] [CrossRef]

- Elzohairy, A.; AlSharari, F.; Salim, H.; Mustafa, S.; Shabaan, H. Fatigued Composite Beam with Different Shear Connection Arrangement. In Proceedings of the Structures Congress, St Louis, MO, USA, 5–8 April 2020. [Google Scholar]

- Suzuki, A.; Suzuki, K.; Kimura, Y. Ultimate shear strength of perfobond shear connectors subjected to fully reversed cyclic loading. Eng. Struct. 2021, 248, 113240. [Google Scholar] [CrossRef]

- Suzuki, A.; Abe, K.; Suzuki, K. Cyclic Behavior of Perfobond-Shear Connectors Subjected to Fully Reversed Cyclic Loading. J. Struct. Eng. 2021, 147, 04020355. [Google Scholar] [CrossRef]

- Zhang, Q.; Jia, D.; Bao, Y.; Cheng, Z.; Xiao, L.; Bu, Y. Internal force transfer effect-based fatigue damage evaluation for PBL shear connector groups. J. Constr. Steel. Res. 2018, 148, 469–478. [Google Scholar] [CrossRef]

- Xiao, L.; Xiao, X.Z.; Wei, X.; Qiang, S.Z. Experimental study on fatigue performance of PBL shear connectors. China Civ. Eng. J. 2015, 48, 93–101. [Google Scholar] [CrossRef]

- Li, Z.; Wu, B.; Liao, M.; Yang, X.; Deng, K.; Zhao, C. Experimental investigation on the cyclic performance of perfobond rib shear connectors. Adv. Struct. Eng. 2020, 23, 3509–3524. [Google Scholar] [CrossRef]

- Kim, S.-H.; Han, O.; Kim, K.-S.; Park, J.-S. Experimental behavior of double-row Y-type perfobond rib shear connectors. J. Constr. Steel. Res. 2018, 150, 221–229. [Google Scholar] [CrossRef]

- Kim, S.-H.; Kim, K.-S.; Lee, D.-H.; Park, J.-S.; Han, O. Analysis of the Shear Behavior of Stubby Y-Type Perfobond Rib Shear Connectors for a Composite Frame Structure. Eng. Struct. 2017, 10, 1340. [Google Scholar] [CrossRef]

- Kim, K.S.; Han, O.; Choi, J.H. Hysteretic performance of stubby Y-type perfobond rib shear connectors depending on transverse rebar. Constr. Build. Mater. 2019, 3, 64–79. [Google Scholar] [CrossRef]

- Utashev, N.; Wang, Q.Y.; Wang, Z.Y.; Durdyev, S.; Tufail, R.F. Anchorage of Perfobond Leiste shaped shear connector composite dowel with carbon fibre reinforced polymer. J. Build. Eng. 2021, 34, 101711. [Google Scholar] [CrossRef]

- Fan, L.; Zhou, Z.X. New Shear Connectors Based on PBL Shear Connector For Composite Arch Members. Struct. Eng. Int. 2014, 24, 281–284. [Google Scholar] [CrossRef]

- GB50010-2010; Code for Design of Concrete Structures. China Architecture & Building Press: Beijing, China, 2015.

| Specimen Number | Form | Penetrated Steel Bar |

|---|---|---|

| S-1 | Triple-folded plate shear key | No |

| S-2 | Triple-folded plate shear key | No |

| S-3 | Triple-folded plate shear key | Yes |

| S-4 | Stud | — |

| Material Type | fck (MPa) | fcu,k (MPa) | fc (MPa) | Ec (MPa) |

|---|---|---|---|---|

| Commercial concrete | 27.0 | 40.4 | 19.3 | 33,827.1 |

| Specimen Number | fy (MPa) | fu (MPa) | εy (%) | εu (%) | E (GPa) |

|---|---|---|---|---|---|

| Reinforcement (Φ6) | 572.0 | 642.0 | 0.5 | 3.2 | 189.0 |

| Reinforcement (Φ8) | 472.0 | 662.0 | 0.5 | 6.3 | 183.0 |

| Reinforcement (Φ12) | 509.0 | 583.0 | 0.3 | 9.9 | 187.0 |

| Steel plate | 255.0 | 410.0 | 0.8 | 9.5 | 214.0 |

| Specimen | Slip Load Ps/kN | Ultimate Load Pmax/kN | Displacement of Ultimate Load Δmax/mm | Failure Load Pu/kN | Displacement at Failure Load Δu/mm | Bearing Capacity Margin Pmax/Py |

|---|---|---|---|---|---|---|

| S-1 | 250 | 372 | 1.8 | 284 | 3.3 | 1.5 |

| S-2 | 218 | 359 | 1.5 | 304 | 2.4 | 1.6 |

| S-3 | 232 | 392 | 2.2 | 335 | 6.2 | 1.7 |

| S-4 | 150 | 281 | 4.0 | 238 | 9.8 | 1.9 |

| Specimen Number | B | T | H | D | Dr | Specimen Number | B | T | H | D | Dr |

|---|---|---|---|---|---|---|---|---|---|---|---|

| H70 | 60 | 6 | 70 | 25 | - | T10 | 60 | 10 | 90 | 25 | - |

| H90 | 60 | 6 | 90 | 25 | - | T12 | 60 | 12 | 90 | 25 | - |

| H110 | 60 | 6 | 110 | 25 | - | Dr10 | 60 | 6 | 90 | 25 | 10 |

| H130 | 60 | 6 | 130 | 25 | - | Dr12 | 60 | 6 | 90 | 25 | 12 |

| H150 | 60 | 6 | 150 | 25 | - | Dr14 | 60 | 6 | 90 | 25 | 14 |

| D20 | 60 | 6 | 90 | 20 | - | Dr16 | 60 | 6 | 90 | 25 | 16 |

| D25 | 60 | 6 | 90 | 25 | - | Dr18 | 60 | 6 | 90 | 25 | 18 |

| D30 | 60 | 6 | 90 | 30 | - | B50 | 50 | 6 | 90 | 25 | - |

| D35 | 60 | 6 | 90 | 35 | - | B60 | 60 | 6 | 90 | 25 | - |

| D40 | 60 | 6 | 90 | 40 | - | B70 | 70 | 6 | 90 | 25 | - |

| T4 | 60 | 4 | 90 | 25 | - | B80 | 80 | 6 | 90 | 25 | - |

| T6 | 60 | 6 | 90 | 25 | - | B90 | 90 | 6 | 90 | 25 | - |

| Specimen | Vu | Vum | Error Value | Specimen | Vu | Vum | Error Value |

|---|---|---|---|---|---|---|---|

| H70 | 318 | 299 | 6.4% | T4 | 271 | 248 | 9.3% |

| H90 | 364 | 375 | −2.9% | T6 | 363 | 375 | −3.2% |

| H110 | 392 | 361 | 8.6% | T8 | 446 | 408 | 9.3% |

| H130 | 393 | 369 | 6.5% | T10 | 485 | 446 | 8.7% |

| H150 | 355 | 409 | −13.2% | T12 | 447 | 478 | −6.5% |

| D20 | 286 | 300 | −4.7% | B50 | 322 | 334 | −3.6% |

| D25 | 364 | 375 | −2.9% | B60 | 365 | 375 | −2.7% |

| D30 | 380 | 389 | −2.3% | B70 | 398 | 414 | −3.9% |

| D35 | 347 | 352 | −1.4% | B80 | 436 | 450 | −3.1% |

| D40 | 282 | 293 | −3.8% | B90 | 495 | 512 | −3.3% |

| Specimen | Bond-Slip Load PS/(kN) | Displacement of Bond-Slip ΔS/(mm) | Yield Load Py/(kN) | Displacement of Yield Δy/(mm) | Peak Load Pmax/(kN) | Displacement of Peak Δmax/(mm) | Ductility Coefficient μ |

|---|---|---|---|---|---|---|---|

| shear key | 296 | 0.43 | 298 | 0.48 | 366 | 1.59 | 3.30 |

| Stud | 211 | 2.64 | 138 | 1.10 | 264 | 5.98 | 5.40 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Qin, H.; Yang, Y.; Liu, Y.; Guo, H.; Wang, H. Push-Out Test and Hysteretic Performance Study of Semi-Rigid Shear Keys with the Triple-Folded Web of Flange. Buildings 2022, 12, 991. https://doi.org/10.3390/buildings12070991

Wang Z, Qin H, Yang Y, Liu Y, Guo H, Wang H. Push-Out Test and Hysteretic Performance Study of Semi-Rigid Shear Keys with the Triple-Folded Web of Flange. Buildings. 2022; 12(7):991. https://doi.org/10.3390/buildings12070991

Chicago/Turabian StyleWang, Zhenshan, Huaqian Qin, Yong Yang, Yunhe Liu, Hongchao Guo, and Hongchen Wang. 2022. "Push-Out Test and Hysteretic Performance Study of Semi-Rigid Shear Keys with the Triple-Folded Web of Flange" Buildings 12, no. 7: 991. https://doi.org/10.3390/buildings12070991

APA StyleWang, Z., Qin, H., Yang, Y., Liu, Y., Guo, H., & Wang, H. (2022). Push-Out Test and Hysteretic Performance Study of Semi-Rigid Shear Keys with the Triple-Folded Web of Flange. Buildings, 12(7), 991. https://doi.org/10.3390/buildings12070991