Estimating the Effect of Vibration Mixing Process on Air Pore Size Distributions in Concrete Using Digital Image Analysis

Abstract

:1. Introduction

- (1)

- The effects of vibration vs. non-vibration mixing process on permeable voids in concrete are examined;

- (2)

- By using digital image analysis, the variations in pore characteristics (including porosity, quantity, size, and specific surface) between vibration and non-vibration mixing processes are studied;

- (3)

- The pore size distribution is examined to determine how the vibration mixing process affects the pore structure of concrete;

- (4)

- The impact of pore structure alterations on concrete’s impermeability and resistance to freeze-thaw is investigated.

2. Methodology

2.1. Materials

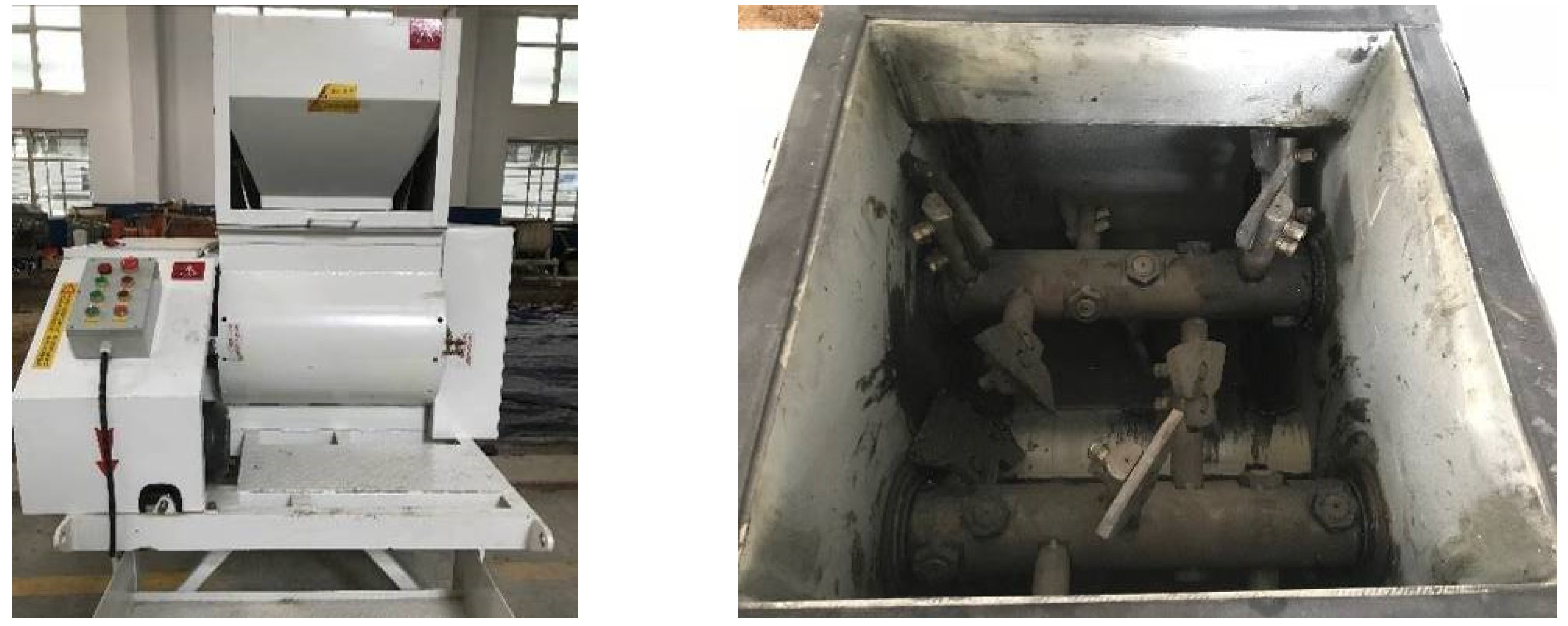

2.2. Vibration Mixing Process

2.3. Mixing Approach

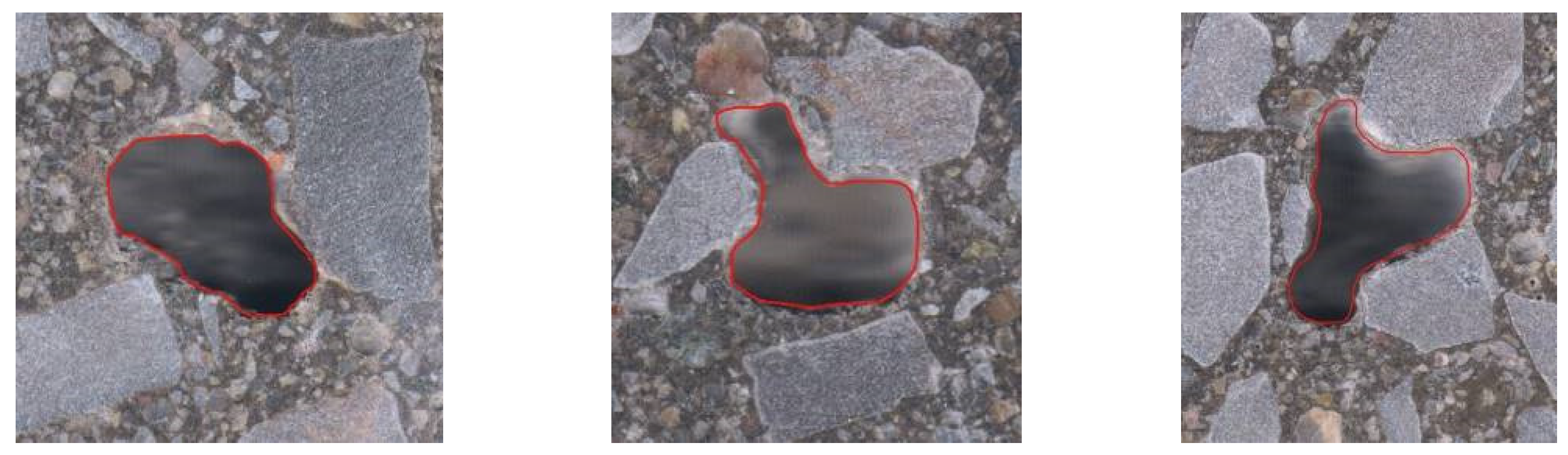

2.4. Digital Image Analysis

2.5. Test Procedure

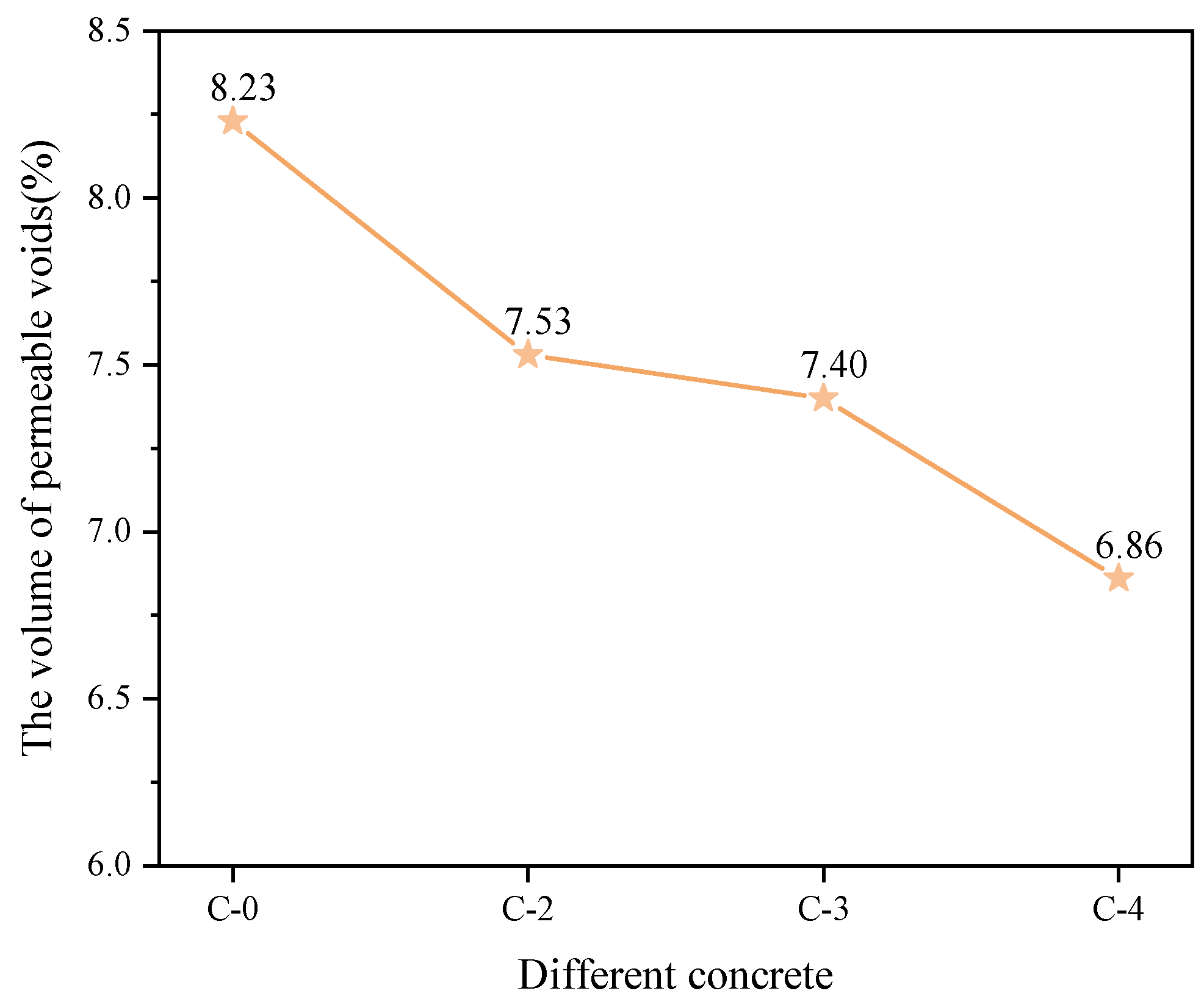

3. The Volume of Permeable Voids

4. Characterization of Air Pores Distribution

4.1. Porosity

4.2. Quantity of Air Pores

4.3. Size of Air Pores

4.4. Specific Surface Area of Air Pores

4.5. Analysis of Variance (ANOVA)

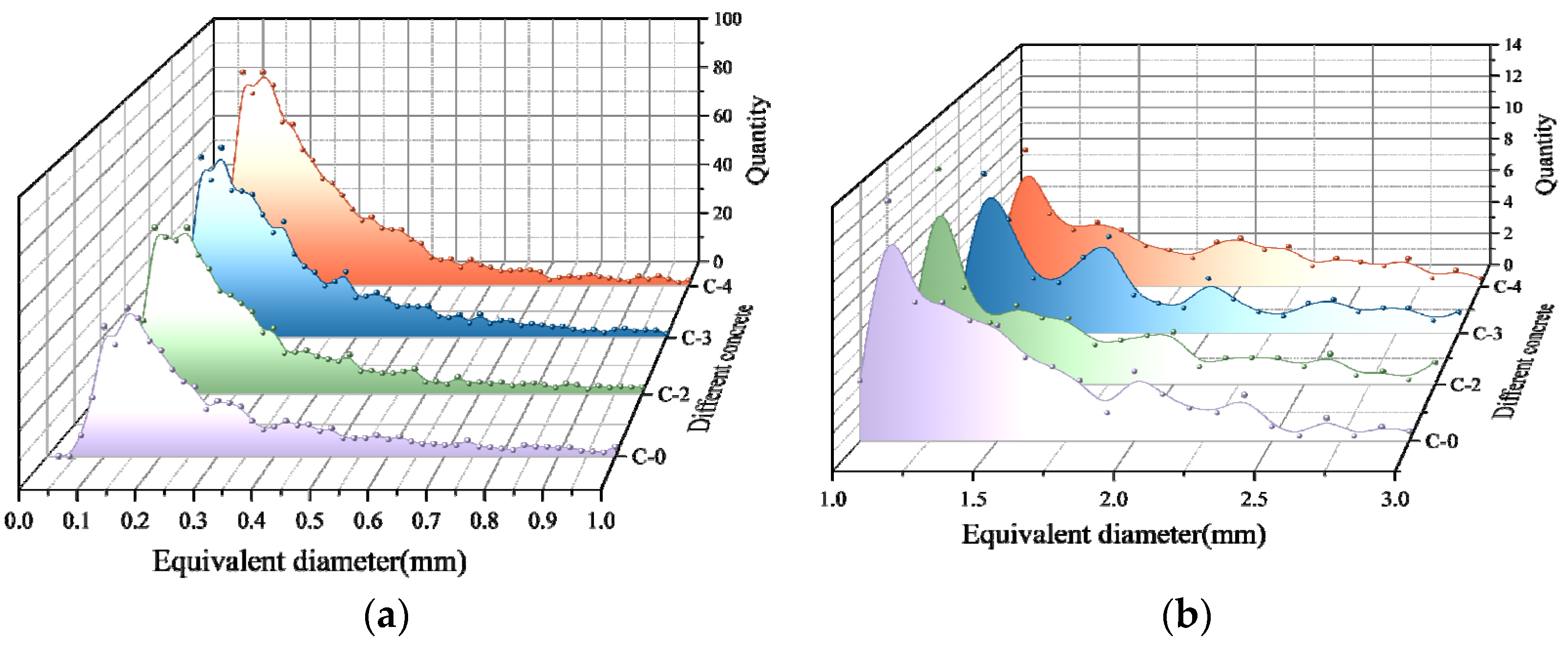

4.6. Pore Size Distribution

5. Freeze-Thaw Resistance

6. Water Penetration Resistance

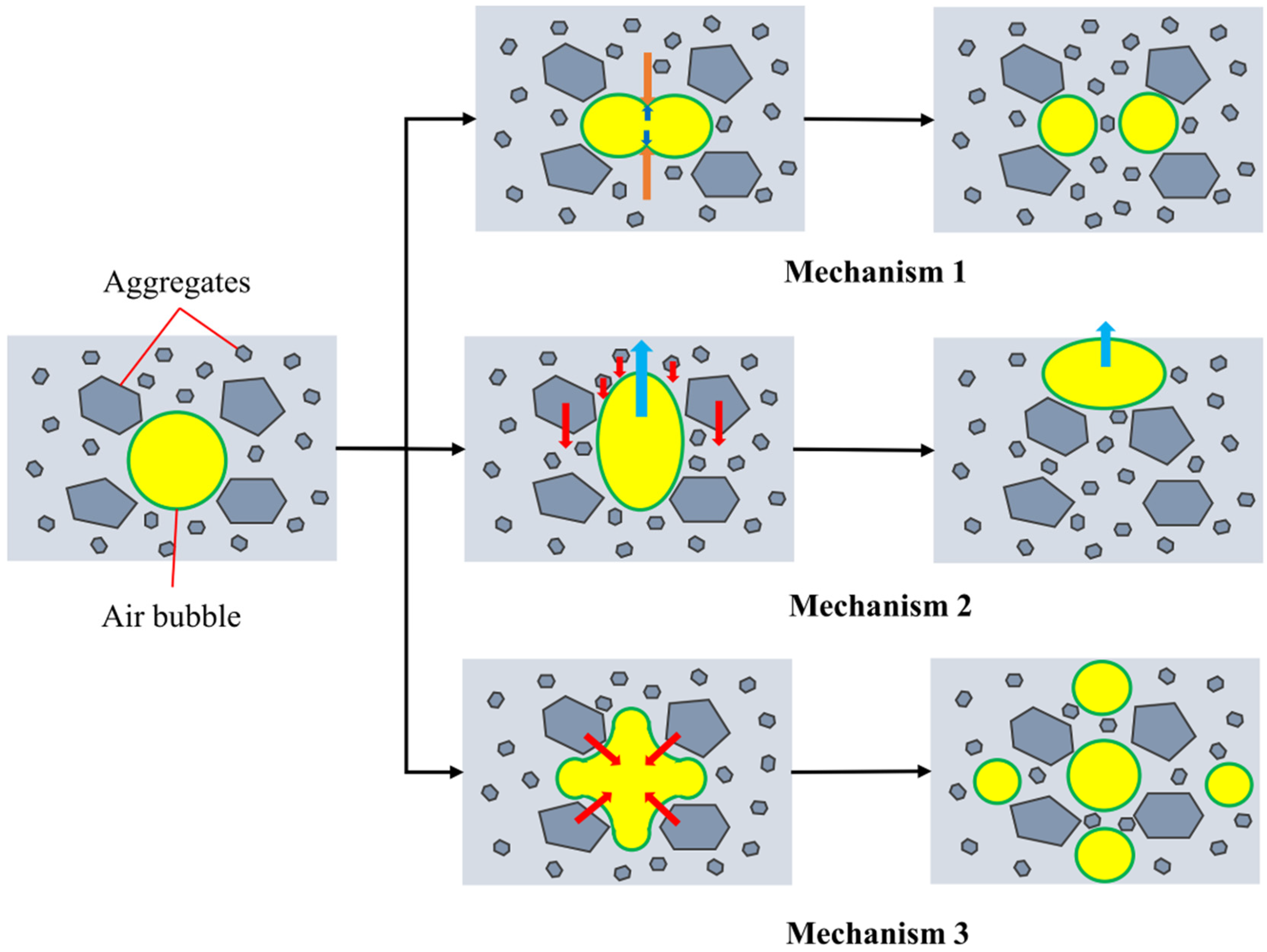

7. Discussion

8. Conclusions

- (1)

- The volume of permeable voids in hardened concrete decreases as vibration acceleration increases. The relative reduction values of C-2, C-3 and C-4 are 8.5%, 10.1% and 16.6%, respectively, as compared to the reference group. This indicates that the concrete produced by the vibration mixing process is denser and has fewer interior open pores.

- (2)

- The digital image analysis has been used to evaluate pore characteristics in hardened concrete. Using this approach, the detailed results show that the porosity of C-2, C-3 and C-4 is relatively reduced by 15.0%, 23.3% and 28.9% compared to the reference concrete. With an increase in vibration acceleration, the average equivalent diameter drops from 413.4 μm to 327.9 μm and the specific surface area rises from 7.94 mm−1 to 9.80 mm−1. The number of pores likewise increases with the alteration in vibration acceleration. The quantity grew to 1122 at 4 g of vibration acceleration, a relative increase of 63.1% compared with the reference group. The ANOVA of the porosity, quantity and pore size also shows that, using the vibration or non-vibration mixing process, the population means are significantly different at the 0.05 level.

- (3)

- The pore gradation for each concrete is also investigated. All concrete has a bimodal pore size distribution, mainly composed of pores with an equivalent diameter between 50 μm and 500 μm, which is a main peak, and a smaller peak of pore diameters between around 1 mm and 2 mm. The pore gradation curves reveal that the vibration mixing process dramatically modified the pore structure by reducing the number of big pores and considerable increasing the amount of tiny pores.

- (4)

- The durability of all concrete has been studied. The findings indicate that, using the vibration mixing process, the positive change of the average size and number of pores improves the freezing-thawing resistance of concrete and the reduction of porosity, and the volume of permeable voids resulted in improved water permeability resistance of concrete.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lo, T.Y.; Tang, W.; Cui, H. The effects of aggregate properties on lightweight concrete. Build. Environ. 2007, 42, 3025–3029. [Google Scholar] [CrossRef]

- Ke, Y.; Ortola, S.; Beaucour, A.-L.; Dumontet, H. Identification of microstructural characteristics in lightweight aggregate concretes by micromechanical modelling including the interfacial transition zone (ITZ). Cem. Concr. Res. 2010, 40, 1590–1600. [Google Scholar] [CrossRef]

- Djerbi, A. Effect of recycled coarse aggregate on the new interfacial transition zone concrete. Constr. Build. Mater. 2018, 190, 1023–1033. [Google Scholar] [CrossRef]

- Wu, K.; Shi, H.; Xu, L.; Ye, G.; De Schutter, G. Microstructural characterization of ITZ in blended cement concretes and its relation to transport properties. Cem. Concr. Res. 2015, 79, 243–256. [Google Scholar] [CrossRef]

- Powers, T.C.; Willis, T. The air requirement of frost resistant concrete. Highw. Res. Board Proc. 1949, 29, 184–211. [Google Scholar]

- Santos, A.R.; Veiga, M.D.R.; Silva, A.S.; de Brito, J.; Álvarez, J.I. Evolution of the microstructure of lime based mortars and influence on the mechanical behaviour: The role of the aggregates. Constr. Build. Mater. 2018, 187, 907–922. [Google Scholar] [CrossRef]

- Kang, S.-H.; Hong, S.-G.; Moon, J. The effect of superabsorbent polymer on various scale of pore structure in ultra-high performance concrete. Constr. Build. Mater. 2018, 172, 29–40. [Google Scholar] [CrossRef]

- Lian, H.; Shi, H. Clarification of a Hypothesis on ‘Centroplasm of Cement-based Composite’ Proposed by Wu Zhongwei. J. Chin. Ceram. Soc. 2020, 48, 167–176. [Google Scholar] [CrossRef]

- Du, L.; Folliard, K.J. Mechanisms of air entrainment in concrete. Cem. Concr. Res. 2005, 35, 1463–1471. [Google Scholar] [CrossRef]

- Shah, H.A.; Yuan, Q.; Zuo, S. Air entrainment in fresh concrete and its effects on hardened concrete—A review. Constr. Build. Mater. 2020, 274, 121835. [Google Scholar] [CrossRef]

- Comite Euro-International du Beton (CEB). Durable Concrete Structures Design Guide; Thomas Telford Services: London, UK, 1989. [Google Scholar]

- Wang, Y.; He, F.; Wang, J.; Wang, C.; Xiong, Z. Effects of calcium bicarbonate on the properties of ordinary Portland cement paste. Constr. Build. Mater. 2019, 225, 591–600. [Google Scholar] [CrossRef]

- Wu, Z.; Lian, H. High Performance Concrete, 1st ed.; China Railway Publishing House: Beijing, China, 1999. [Google Scholar]

- Mehta, P.K.; Monteiro, P. Concrete: Microstructure, Properties, and Materials; McGraw-Hill Education: NewYork, NY, USA, 2013. [Google Scholar]

- Pipilikaki, P.; Beazi-Katsioti, M. The assessment of porosity and pore size distribution of limestone Portland cement pastes. Constr. Build. Mater. 2009, 23, 1966–1970. [Google Scholar] [CrossRef]

- Alvarez, J.; Fernández, J.; Navarro-Blasco, I.; Duran, A.; Sirera, R. Microstructural consequences of nanosilica addition on aerial lime binding materials: Influence of different drying conditions. Mater. Charact. 2013, 80, 36–49. [Google Scholar] [CrossRef] [Green Version]

- Mindess, S.; Young, J.F. Concrete; Prentice Hall: Hoboken, NJ, USA, 2002. [Google Scholar]

- Schober, G. Porosity in autoclaved aerated concrete (AAC): A review on pore structure, types of porosity, measurement methods and effects of porosity on properties. In Proceedings of the 5th International Conference on Autoclaved Aerated Concrete, Bydgoscsz, Poland, 14–17 September 2011; Volume 39–43, pp. 351–359. [Google Scholar]

- Chang, P.-K.; Peng, Y.-N. Influence of mixing techniques on properties of high performance concrete. Cem. Concr. Res. 2001, 31, 87–95. [Google Scholar] [CrossRef]

- Beitzel, H.; Charonnat, Y. Assessment and classification of performance mixers. Mater. Struct. 2003, 36, 250–264. [Google Scholar] [CrossRef]

- Vandanjon, P.-O.; De Larrard, F.; Dehousse, B.; Villain, G.; Maillot, R.; Laplante, P. Homogenisation of concrete in a batch plant: The influence of mixing time and method on the introduction of mineral admixtures. Mag. Concr. Res. 2003, 55, 105–116. [Google Scholar] [CrossRef]

- Feng, Z.; Zhao, L.; Zhao, W.; Wang, W.; Yao, Y. Advanced Theory and Equipment of Production Concrete; China Communications Press: Beijing, China, 2016. [Google Scholar]

- Kovler, K.; Roussel, N. Properties of fresh and hardened concrete. Cem. Concr. Res. 2011, 41, 775–792. [Google Scholar] [CrossRef]

- Zhao, K.; Zhao, L.; Hou, J.; Zhang, X.; Feng, Z.; Yang, S. Effect of vibratory mixing on the slump, compressive strength, and density of concrete with the different mix proportions. J. Mater. Res. Technol. 2021, 15, 4208–4219. [Google Scholar] [CrossRef]

- Zhao, K.; Zhao, L.; Liu, S.; Hou, J. Effect of three-step mixing technology based on vibratory mixing on properties of high-strength concrete. IOP Conf. Series: Mater. Sci. Eng. 2019, 542, 12003. [Google Scholar] [CrossRef] [Green Version]

- Xiong, G.; Wang, C.; Zhou, S.; Jia, X.; Luo, W.; Liu, J.; Peng, X. Preparation of high strength lightweight aggregate concrete with the vibration mixing process. Constr. Build. Mater. 2019, 229, 116936. [Google Scholar] [CrossRef]

- Fu, C. Study on the Effect of Mixing Method on the air Content and Performance of Concrete. Ph.D. Thesis, Chang’an University, Xi’an, China, 2011. [CrossRef]

- Ke, G.; Ke, G.; Zhang, J.; Zhang, J.; Tian, B.; Tian, B.; Wang, J.; Wang, J. Characteristic analysis of concrete air entraining agents in different media. Cem. Concr. Res. 2020, 135, 106142. [Google Scholar] [CrossRef]

- Zhang, J.; Gao, X.; Yu, L. Improvement of viscosity-modifying agents on air-void system of vibrated concrete. Constr. Build. Mater. 2019, 239, 117843. [Google Scholar] [CrossRef]

- Chen, Y.; Al-Neshawy, F.; Punkki, J. Investigation on the effect of entrained air on pore structure in hardened concrete using MIP. Constr. Build. Mater. 2021, 292, 123441. [Google Scholar] [CrossRef]

- Hughes, D.C. Pore structure and permeability of hardened cement paste. Mag. Concr. Res. 1985, 37, 227–233. [Google Scholar] [CrossRef]

- Coletti, C.; Cultrone, G.; Maritan, L.; Mazzoli, C. Combined multi-analytical approach for study of pore system in bricks: How much porosity is there? Mater. Charact. 2016, 121, 82–92. [Google Scholar] [CrossRef]

- Moradian, M.; Hu, Q.; Aboustait, M.; Ley, M.T.; Hanan, J.C.; Xiao, X.; Scherer, G.W.; Zhang, Z. Direct observation of void evolution during cement hydration. Mater. Des. 2017, 136, 137–149. [Google Scholar] [CrossRef]

- Song, Y.; Zhou, J.-W.; Bian, Z.-N.; Dai, G.-Z. Pore Structure Characterization of Hardened Cement Paste by Multiple Methods. Adv. Mater. Sci. Eng. 2019, 2019, 1–18. [Google Scholar] [CrossRef] [Green Version]

- Lyu, K.; She, W.; Miao, C.; Chang, H.; Gu, Y. Quantitative characterization of pore morphology in hardened cement paste via SEM-BSE image analysis. Constr. Build. Mater. 2019, 202, 589–602. [Google Scholar] [CrossRef]

- Gao, L.; Ni, F.; Luo, H.; Charmot, S. Characterization of air voids in cold in-place recycling mixtures using X-ray computed tomography. Constr. Build. Mater. 2015, 84, 429–436. [Google Scholar] [CrossRef]

- Yun, T.S.; Kim, K.Y.; Choo, J.; Kang, D.H. Quantifying the distribution of paste-void spacing of hardened cement paste using X-ray computed tomography. Mater. Charact. 2012, 73, 137–143. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, X.; Jiang, J.; Zhou, L. Characterization of interconnectivity, size distribution and uniformity of air voids in porous asphalt concrete using X-ray CT scanning images. Constr. Build. Mater. 2019, 213, 182–193. [Google Scholar] [CrossRef]

- Tian, W.; Cheng, X.; Liu, Q.; Yu, C.; Gao, F.; Chi, Y. Meso-structure segmentation of concrete CT image based on mask and regional convolution neural network. Mater. Des. 2021, 208, 109919. [Google Scholar] [CrossRef]

- European Standard EN 480-11; Admixtures for Concrete, Mortar and Grout—Test Methods—Part 11: Determination of Air Void Characteristics in Hardened Concrete. European Committee for Standardization (CEN): Brussels, Belgium, 2005.

- ASTM C457/C457M-11; Standard Test Method for Microscopical Determination of Parameters of the Air-Void System in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2011.

- Chung, S.-Y.; Sikora, P.; Rucinska, T.; Stephan, D.; Elrahman, M.A. Comparison of the pore size distributions of concretes with different air-entraining admixture dosages using 2D and 3D imaging approaches. Mater. Charact. 2020, 162, 110182. [Google Scholar] [CrossRef]

- Mayercsik, N.P.; Felice, R.; Ley, M.T.; Kurtis, K. A probabilistic technique for entrained air void analysis in hardened concrete. Cem. Concr. Res. 2014, 59, 16–23. [Google Scholar] [CrossRef]

- Molendowska, A.; Wawrzeńczyk, J.; Kowalczyk, H. Development of the Measuring Techniques for Estimating the Air Void System Parameters in Concrete Using 2D Analysis Method. Materials 2020, 13, 428. [Google Scholar] [CrossRef] [Green Version]

- Song, Y.; Shen, C.; Damiani, R.M.; Lange, D.A. Image-based restoration of the concrete void system using 2D-to-3D unfolding technique. Constr. Build. Mater. 2020, 270, 121476. [Google Scholar] [CrossRef]

- Özcan, F.; Koç, M.E. Influence of ground pumice on compressive strength and air content of both non-air and air entrained concrete in fresh and hardened state. Constr. Build. Mater. 2018, 187, 382–393. [Google Scholar] [CrossRef]

- Song, Y.; Zou, R.; Castaneda, D.I.; Riding, K.A.; Lange, D.A. Advances in Measuring Air-Void Parameters in Hardened Concrete Using a Flatbed Scanner. J. Test. Eval. 2017, 45, 1713–1725. [Google Scholar] [CrossRef]

- Fonseca, P.C.; Scherer, G.W. An image analysis procedure to quantify the air void system of mortar and concrete. Mater. Struct. 2014, 48, 3087–3098. [Google Scholar] [CrossRef] [Green Version]

- Murotani, T.; Igarashi, S.; Koto, H. Distribution analysis and modeling of air voids in concrete as spatial point processes. Cem. Concr. Res. 2018, 115, 124–132. [Google Scholar] [CrossRef]

- Thomas, C.; Setién, J.; Polanco, J.; de Brito, J.; Fiol, F. Micro- and macro-porosity of dry- and saturated-state recycled aggregate concrete. J. Clean. Prod. 2018, 211, 932–940. [Google Scholar] [CrossRef]

- Yao, Y.; Feng, Z.; Chen, S. Strength of concrete reinforced using double-blade mixer. Mag. Concr. Res. 2013, 65, 787–792. [Google Scholar] [CrossRef]

- ASTMC642-13; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2013.

- CNS, GB/T 50082-2009; Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. China National Standard: Beijing, China, 2009.

- Kurata, Y.; Ryosuke, S.; Tomoaki, K.; Takashi, K.; Muto, K.; Ito, Y. Disappearance of Air Bubbles in Concrete Structures (Theoretical Suggestions and Experimental Verification). J. IHI Technol. 2019, 59, 97–106. [Google Scholar]

- Shi, D.; Brown, P.W.; Kurtz, S. A Model for the Distribution of Pore Sizes in Cement Paste. MRS Online Proc. Library 1988, 137, 23–34. [Google Scholar] [CrossRef]

- Payton, E. Revisiting Sphere Unfolding Relationships for the Stereological Analysis of Segmented Digital Microstructure Images. J. Miner. Mater. Charact. Eng. 2012, 11, 221–242. [Google Scholar] [CrossRef]

| w/c Ratio | Cement | Water | Fine Aggregate | Coarse Aggregate | ||

|---|---|---|---|---|---|---|

| 4.75–9.5 mm | 9.5–16 mm | 16–19 mm | ||||

| 0.46 | 467 | 215 | 566 | 460 | 483 | 207 |

| Porosity (%) | Mean | Quantity | Mean | Size (μm) | Mean | Specific Surface Area (mm−1) | Mean | ||

|---|---|---|---|---|---|---|---|---|---|

| C-0 | 1 | 2.35 | 1.80 | 714 | 688 | 457.6 | 413.4 | 7.41 | 7.94 |

| 2 | 1.94 | 825 | 389.6 | 8.22 | |||||

| 3 | 1.33 | 554 | 419.1 | 7.87 | |||||

| 4 | 1.65 | 598 | 425.3 | 7.67 | |||||

| 5 | 1.75 | 748 | 375.2 | 8.51 | |||||

| C-2 | 1 | 1.82 | 1.53 | 857 | 817 | 399.5 | 385.7 | 8.59 | 8.57 |

| 2 | 1.67 | 739 | 406.6 | 7.53 | |||||

| 3 | 1.49 | 892 | 368.2 | 9.22 | |||||

| 4 | 1.40 | 924 | 376.8 | 8.90 | |||||

| 5 | 1.26 | 673 | 377.4 | 8.59 | |||||

| C-3 | 1 | 1.54 | 1.38 | 1127 | 954 | 346.3 | 362.0 | 10.07 | 9.26 |

| 2 | 1.38 | 1005 | 352.0 | 9.19 | |||||

| 3 | 1.61 | 958 | 384.1 | 8.86 | |||||

| 4 | 1.20 | 886 | 364.0 | 8.97 | |||||

| 5 | 1.19 | 793 | 363.7 | 9.23 | |||||

| C-4 | 1 | 1.34 | 1.28 | 1401 | 1122 | 302.2 | 327.9 | 10.87 | 9.80 |

| 2 | 1.22 | 975 | 339.3 | 9.23 | |||||

| 3 | 1.29 | 882 | 358.0 | 9.02 | |||||

| 4 | 1.41 | 1284 | 316.0 | 10.07 | |||||

| 5 | 1.14 | 1067 | 324.2 | 9.82 | |||||

| DF | Sum of Squares | Mean Square | F Value | p Value | ||

|---|---|---|---|---|---|---|

| Porosity | Model | 3 | 0.77526 | 0.25842 | 4.33536 | 0.0204 |

| Error | 16 | 0.95372 | 0.05961 | |||

| Total | 19 | 1.72898 | ||||

| Quantity | Model | 3 | 519,557.4 | 173,185.8 | 8.05505 | 0.0017 |

| Error | 16 | 344,004.4 | 21,500.275 | |||

| Total | 19 | 863,561.8 | ||||

| Size | Model | 3 | 19,694.8175 | 6564.93917 | 13.2482 | 1.32693 × 10−4 |

| Error | 16 | 7928.552 | 495.5345 | |||

| Total | 19 | 27,623.3695 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, F.; Yao, Y.; Wei, J.; Wang, X.; Feng, Z. Estimating the Effect of Vibration Mixing Process on Air Pore Size Distributions in Concrete Using Digital Image Analysis. Buildings 2022, 12, 1142. https://doi.org/10.3390/buildings12081142

Yang F, Yao Y, Wei J, Wang X, Feng Z. Estimating the Effect of Vibration Mixing Process on Air Pore Size Distributions in Concrete Using Digital Image Analysis. Buildings. 2022; 12(8):1142. https://doi.org/10.3390/buildings12081142

Chicago/Turabian StyleYang, Fa, Yunshi Yao, Jin Wei, Xinxin Wang, and Zhongxu Feng. 2022. "Estimating the Effect of Vibration Mixing Process on Air Pore Size Distributions in Concrete Using Digital Image Analysis" Buildings 12, no. 8: 1142. https://doi.org/10.3390/buildings12081142

APA StyleYang, F., Yao, Y., Wei, J., Wang, X., & Feng, Z. (2022). Estimating the Effect of Vibration Mixing Process on Air Pore Size Distributions in Concrete Using Digital Image Analysis. Buildings, 12(8), 1142. https://doi.org/10.3390/buildings12081142