Thermal Insulation Performance and Reliability of the “Structure-Insulation” Integrated Wall Panel (SIW) for Storage Grain Bungalows

Abstract

:1. Introduction

2. Method and Materials

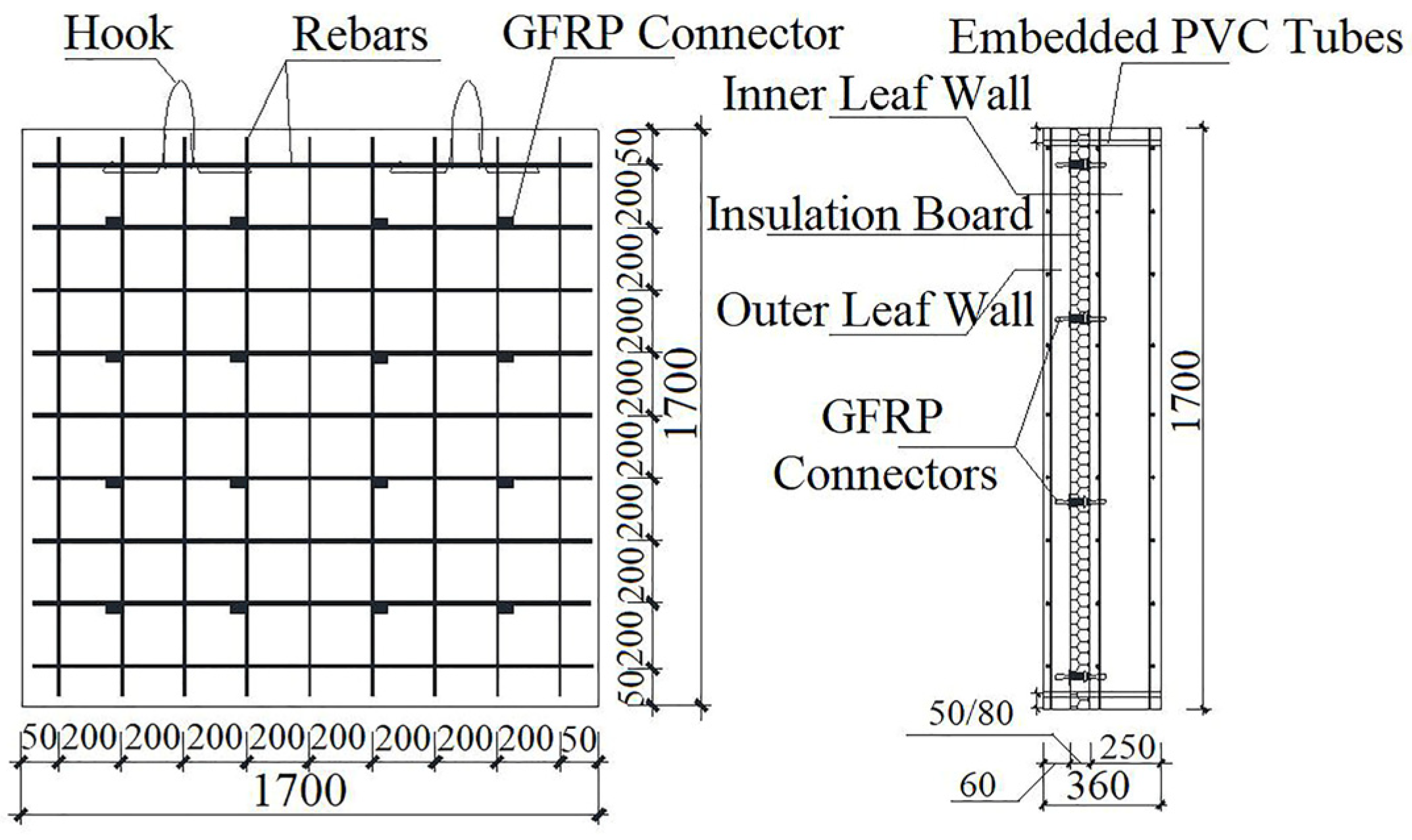

2.1. Design of the SIW Wall Panel Specimen

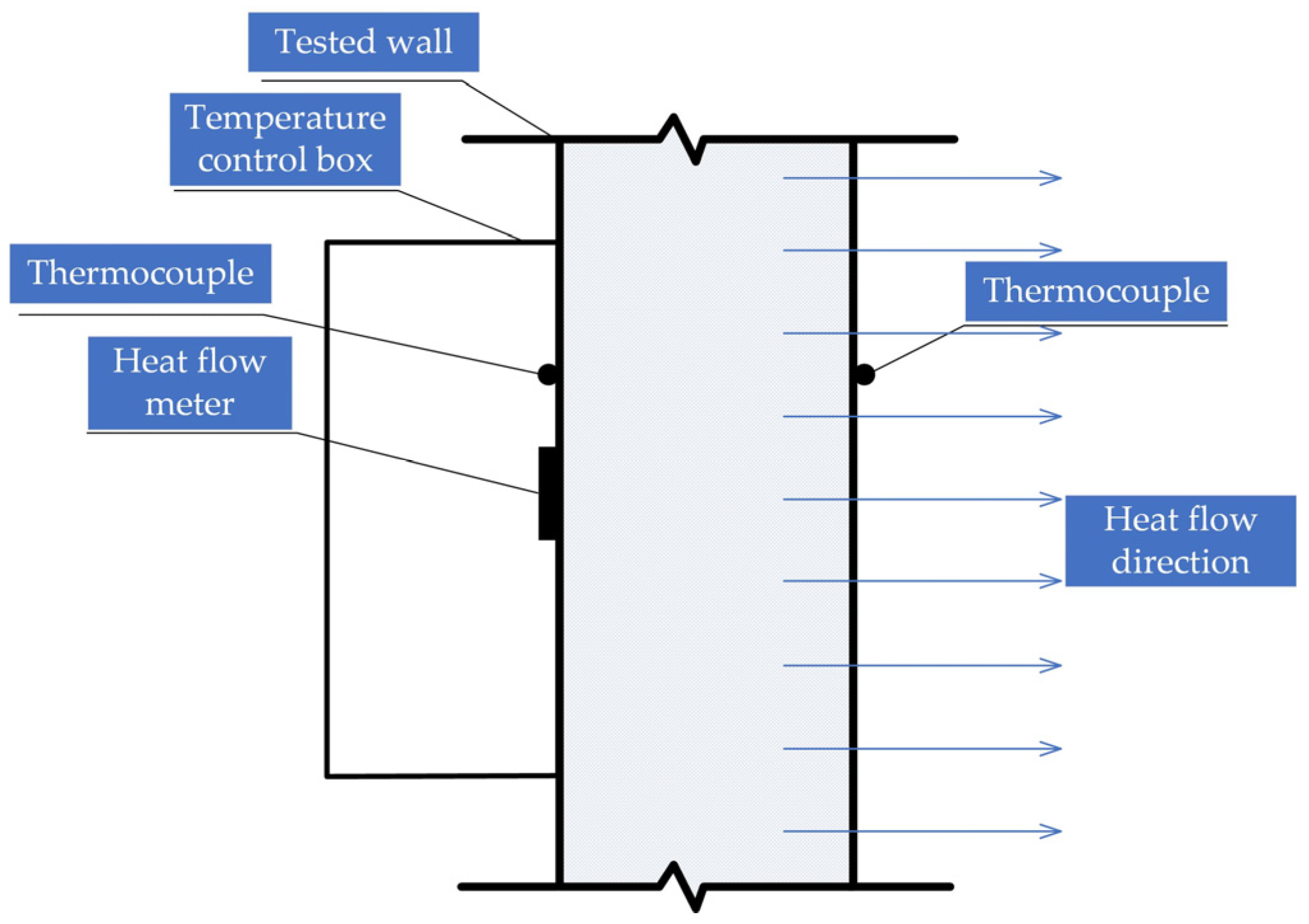

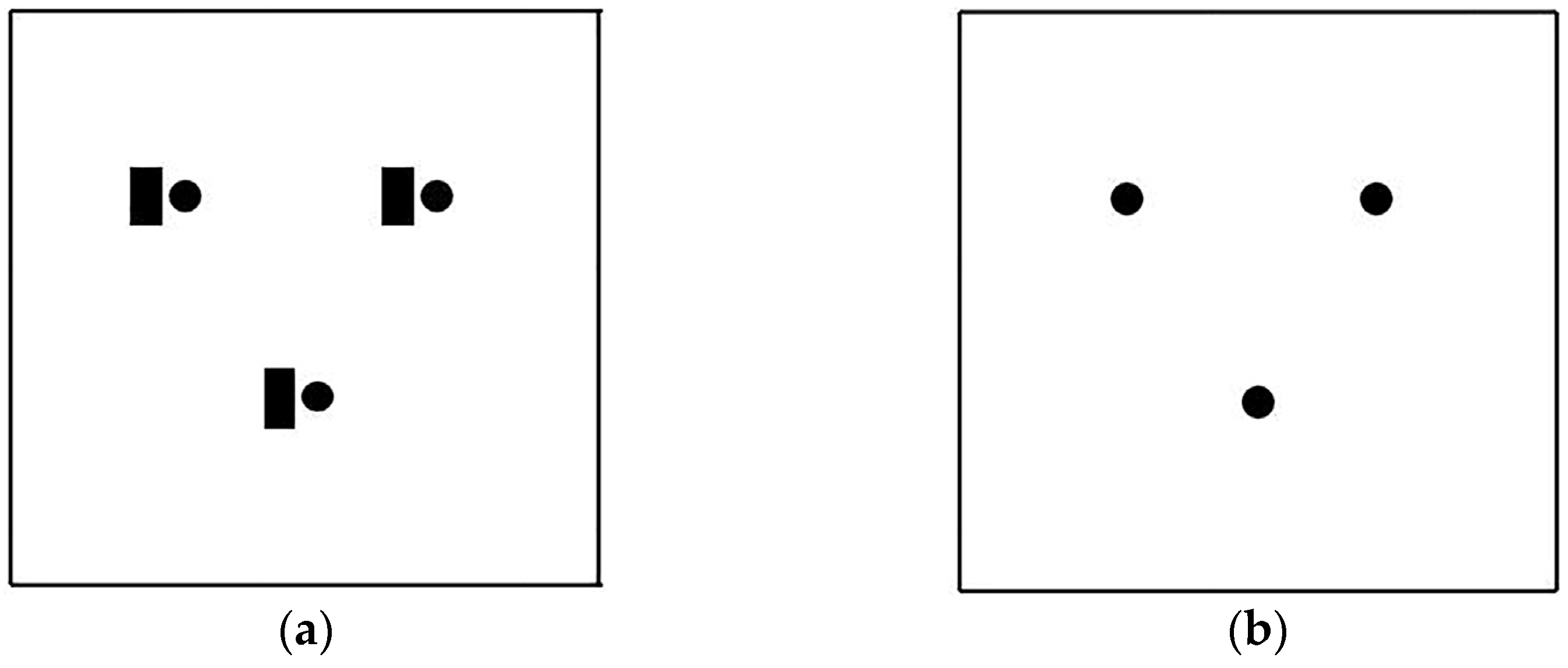

2.2. The Thermal Performance Test and Measuring Point Arrangement

3. Results

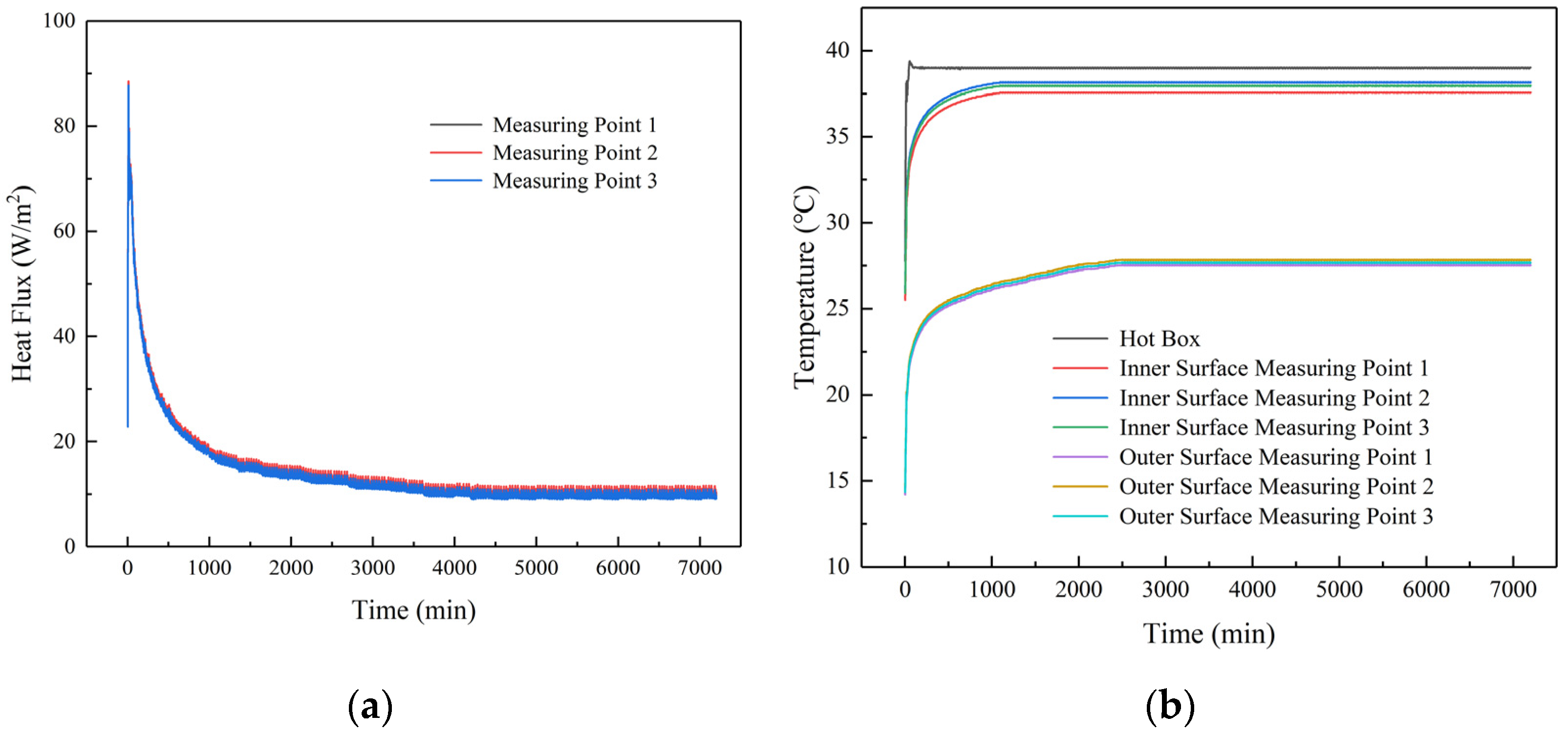

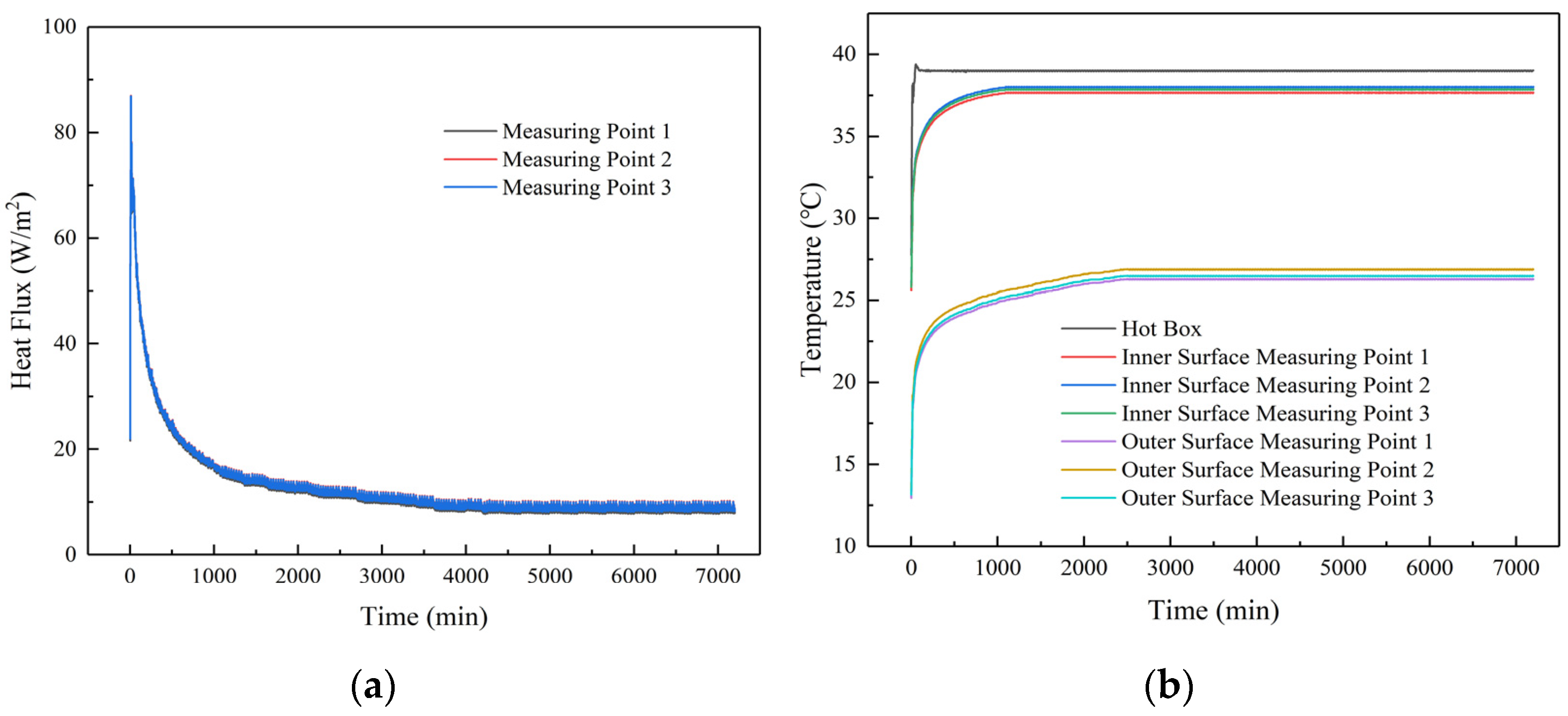

3.1. Analysis of Test Results

3.2. Theoretical Calculation

4. Discussion

4.1. Finite Element Simulation Analysis

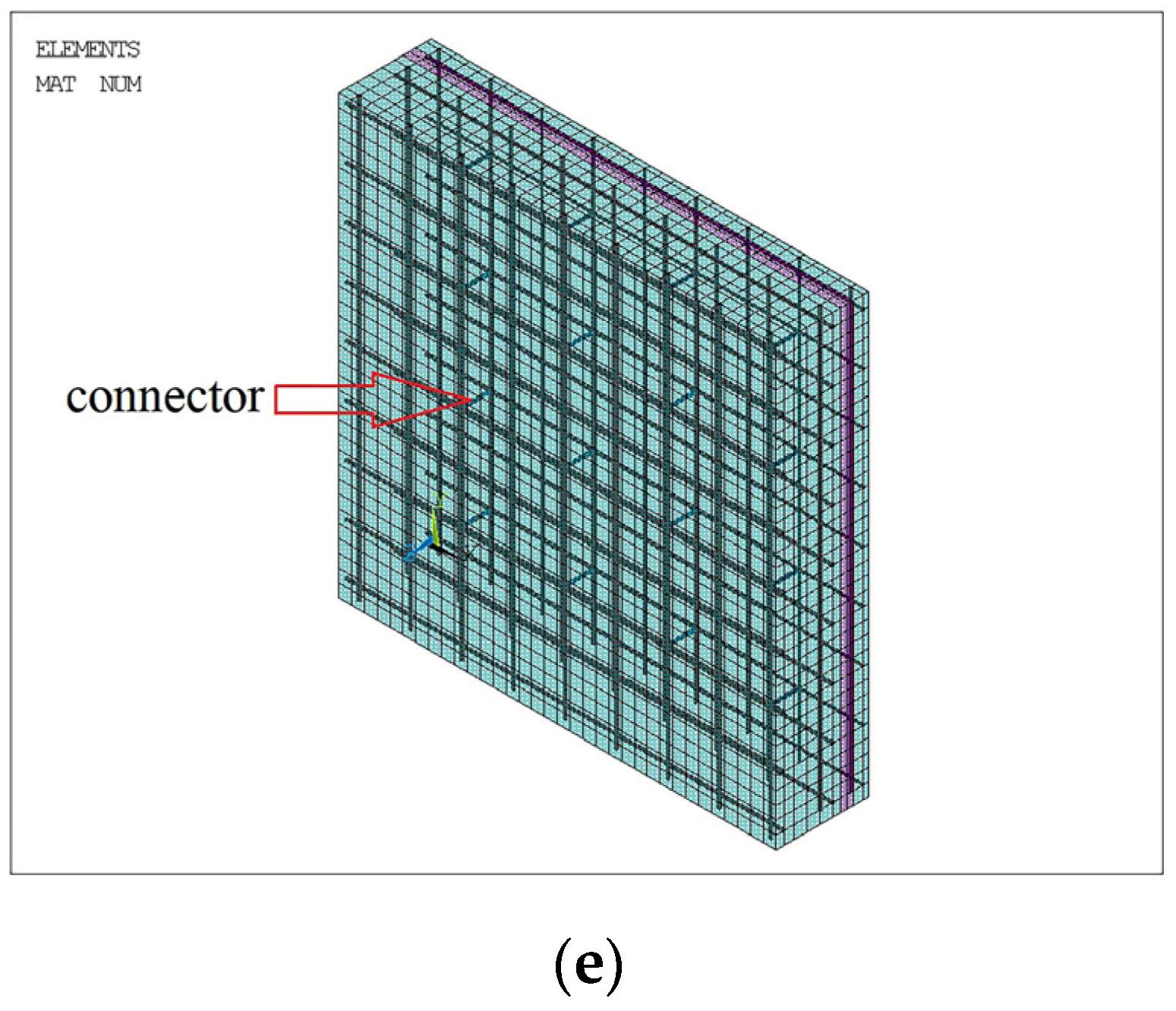

4.1.1. Modeling

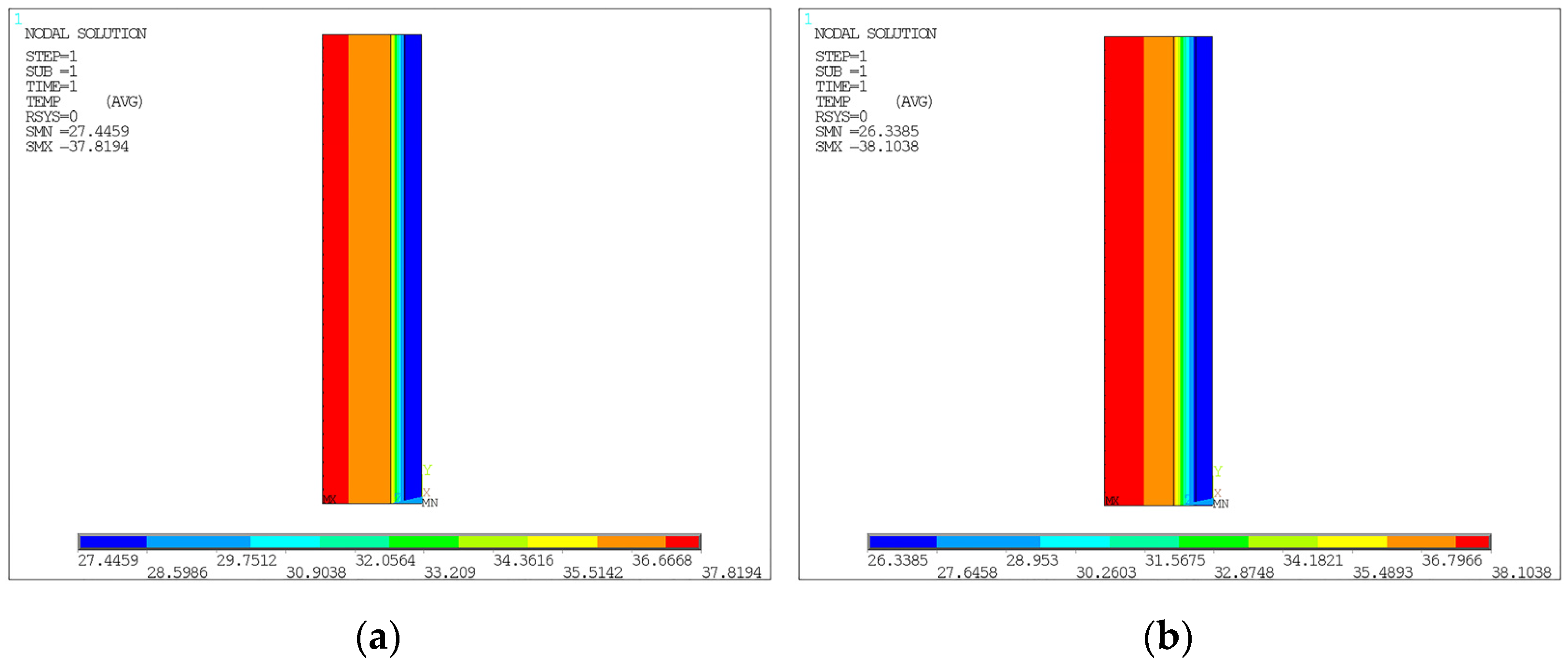

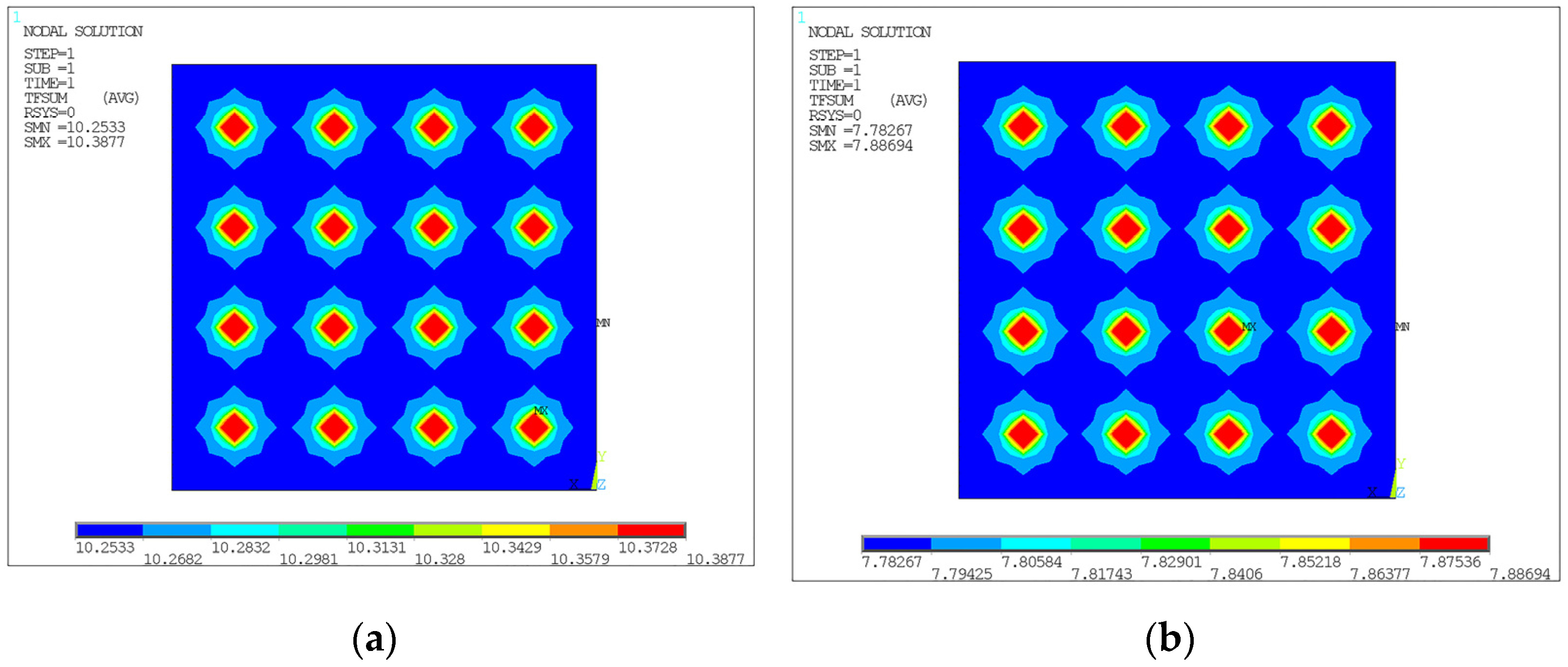

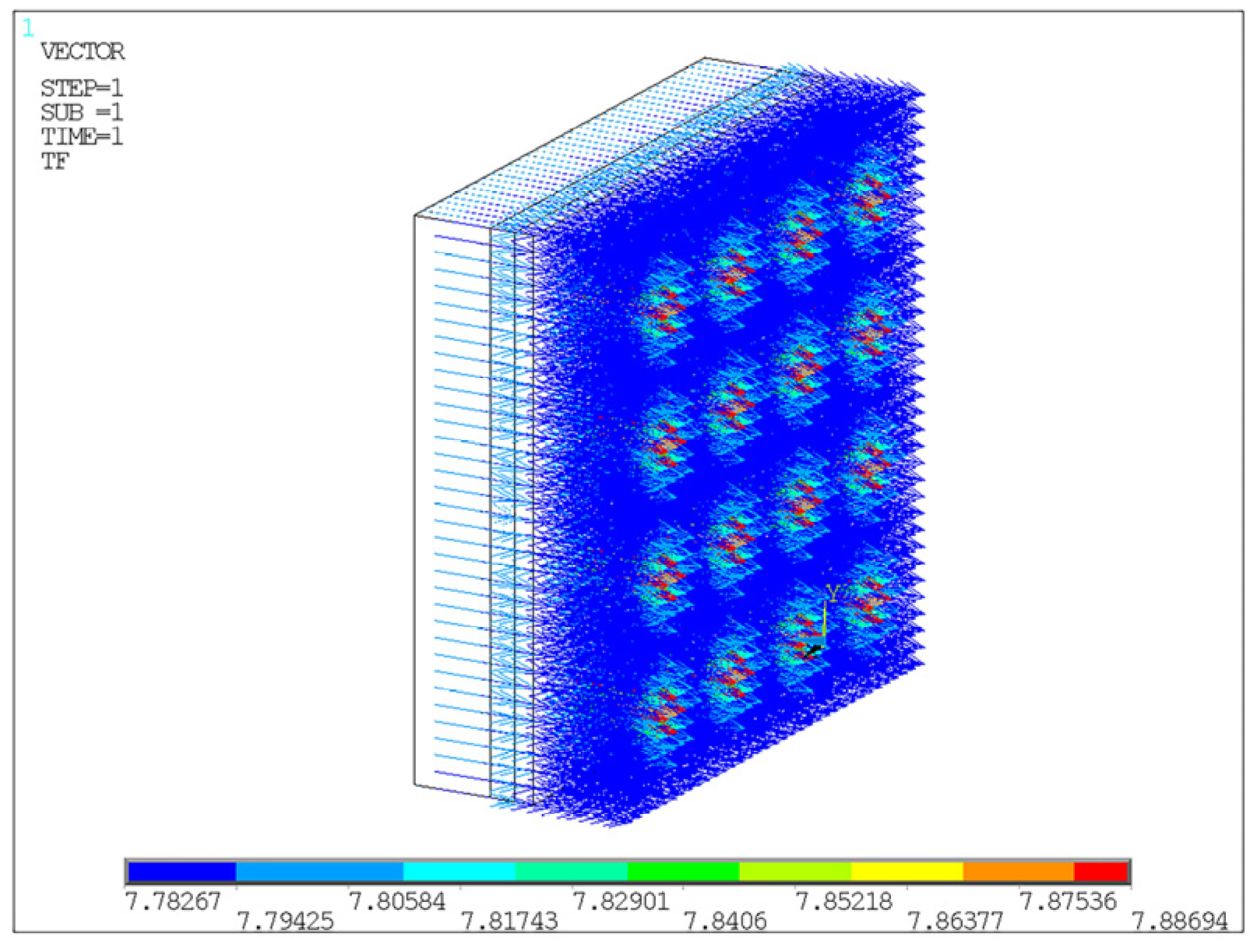

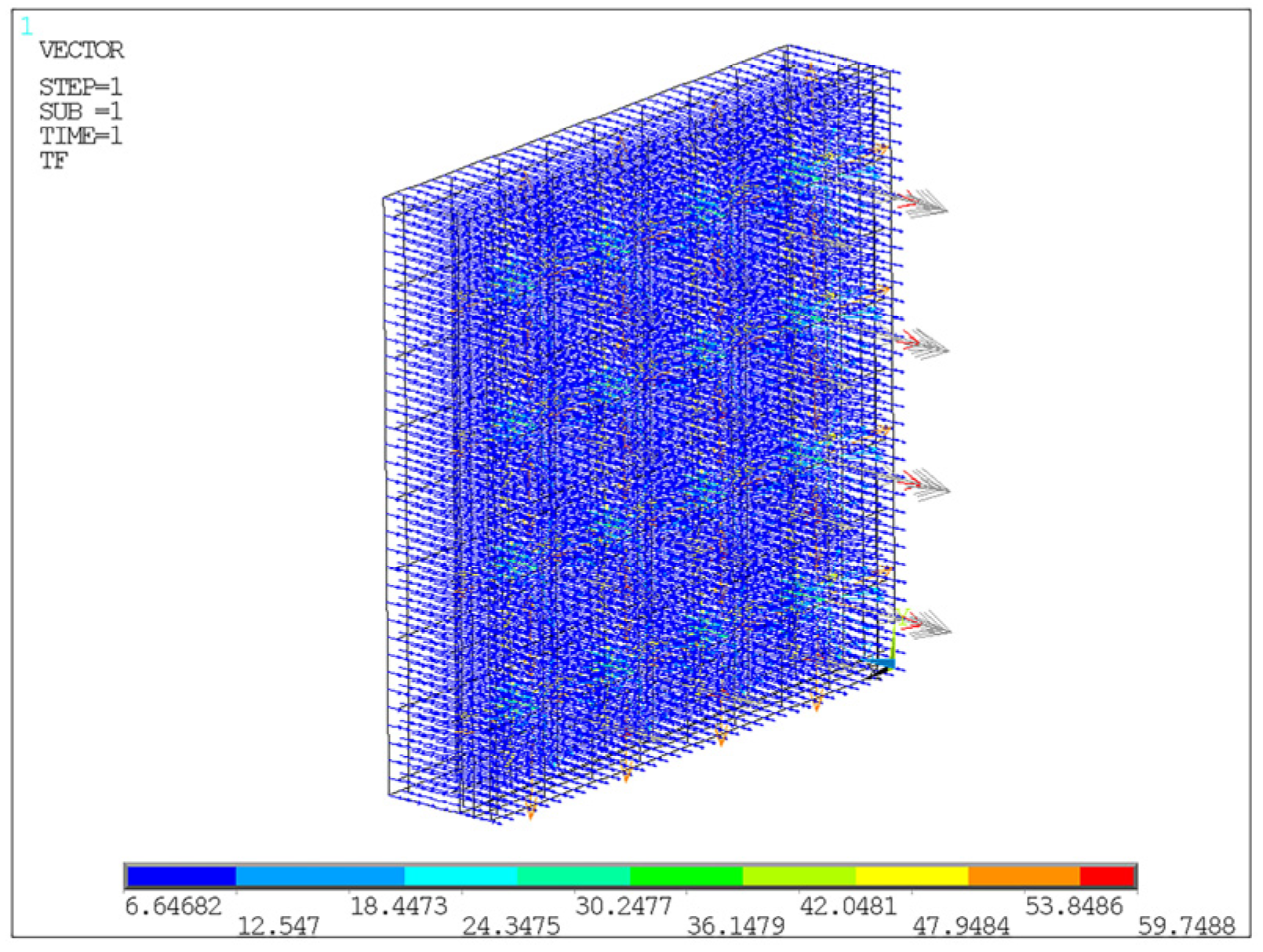

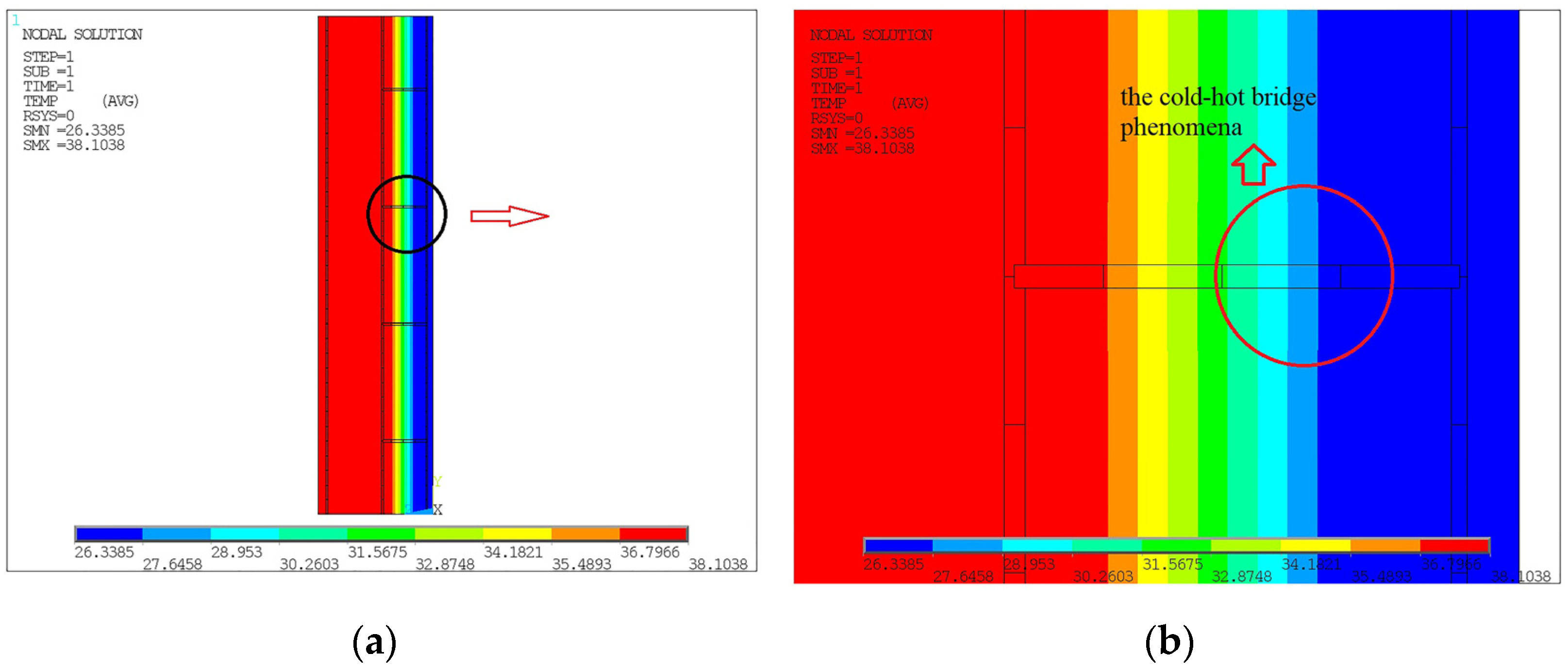

4.1.2. Analysis of Simulation Results

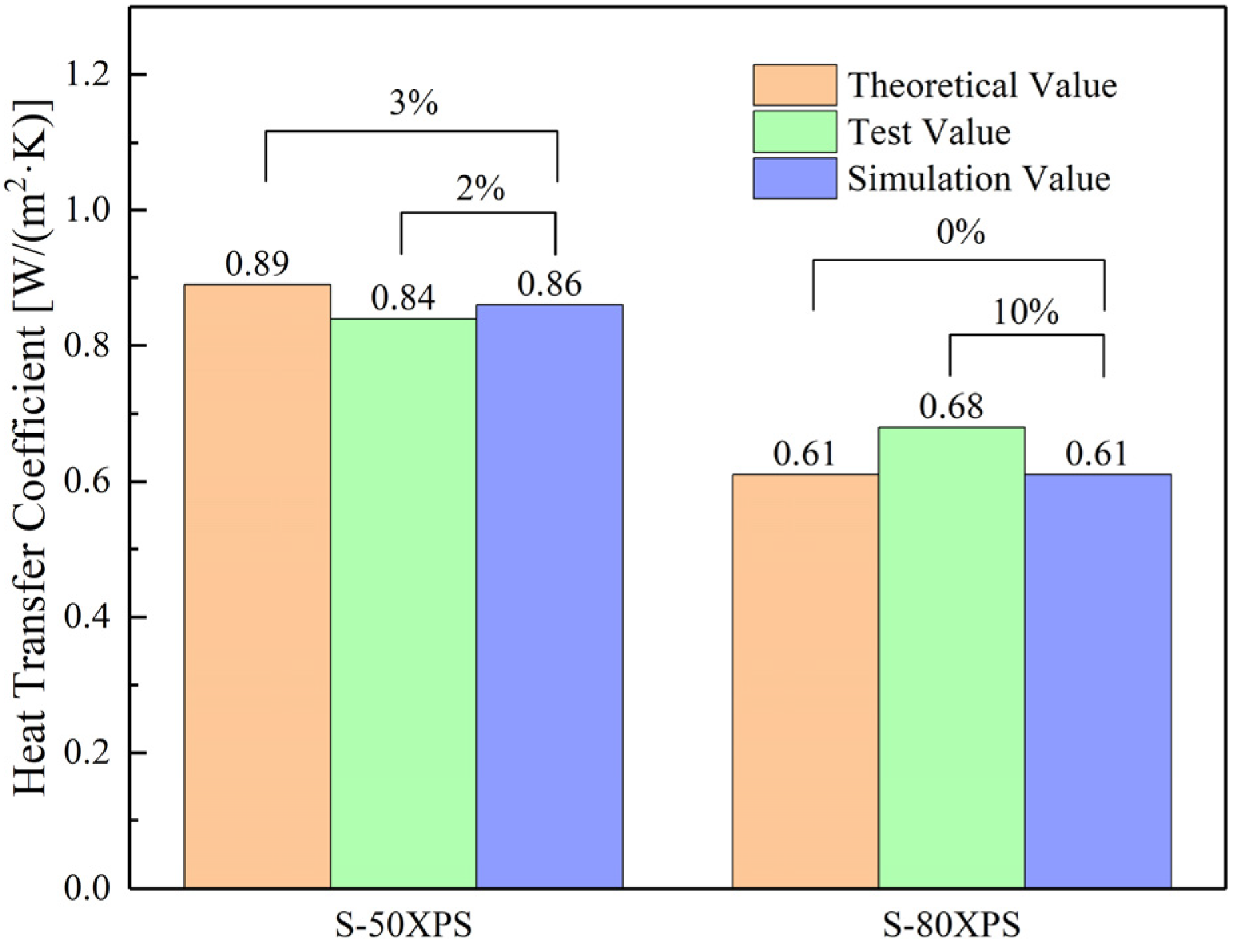

4.1.3. Comparison of Results

4.2. Reliability Analysis

4.2.1. Monte Carlo Method

4.2.2. Establish Functional Function

4.2.3. Random Variables

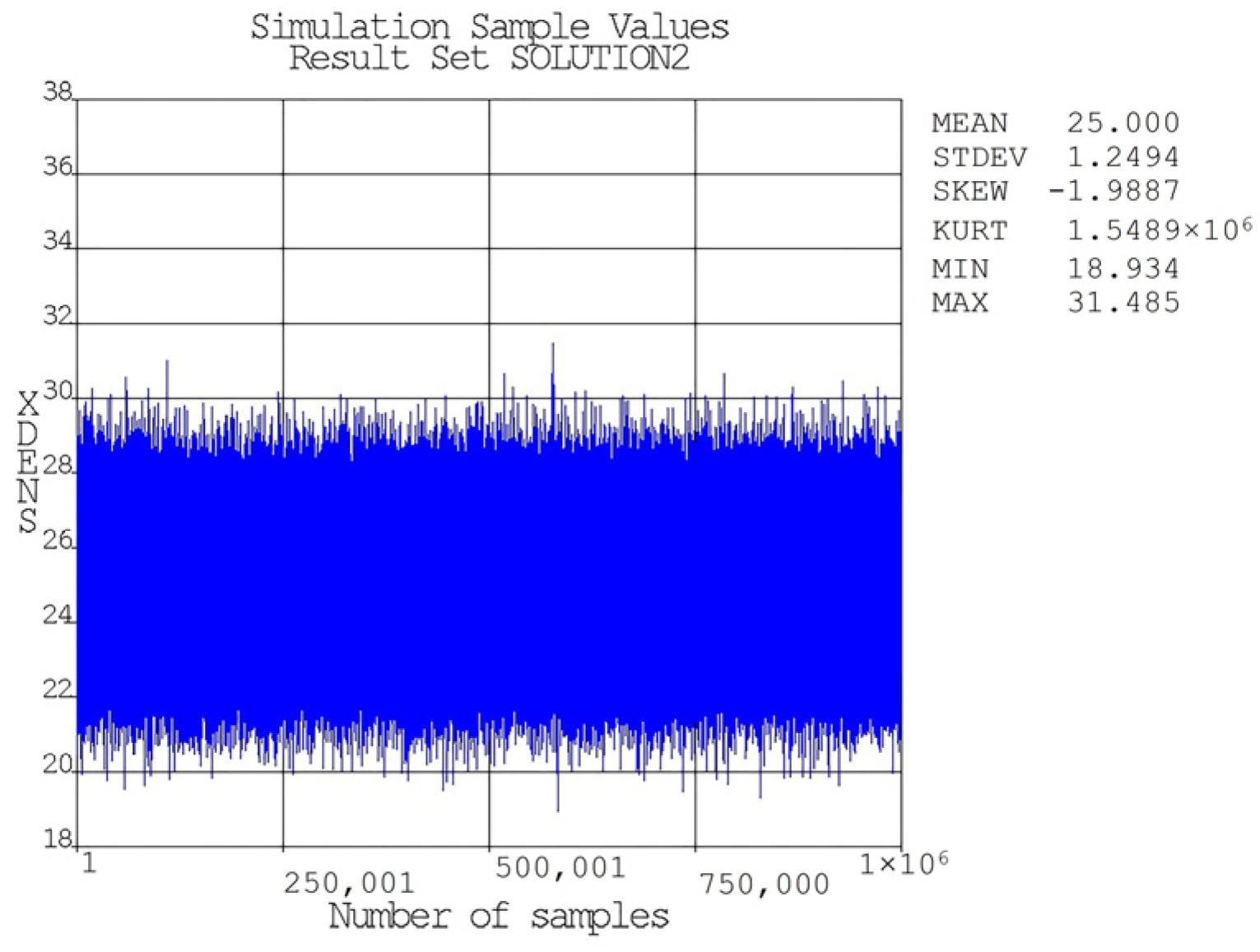

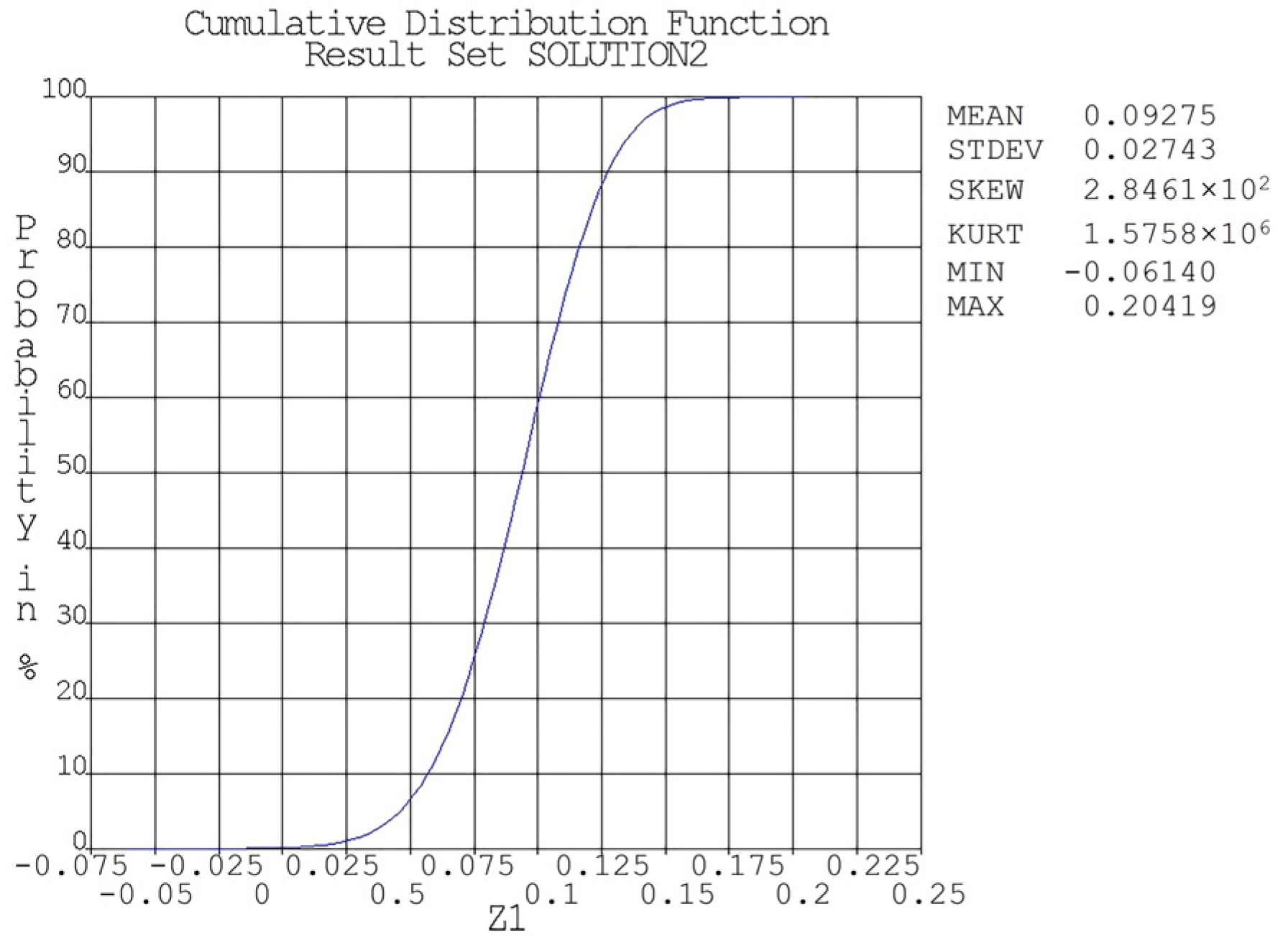

4.2.4. Sampling Calculation

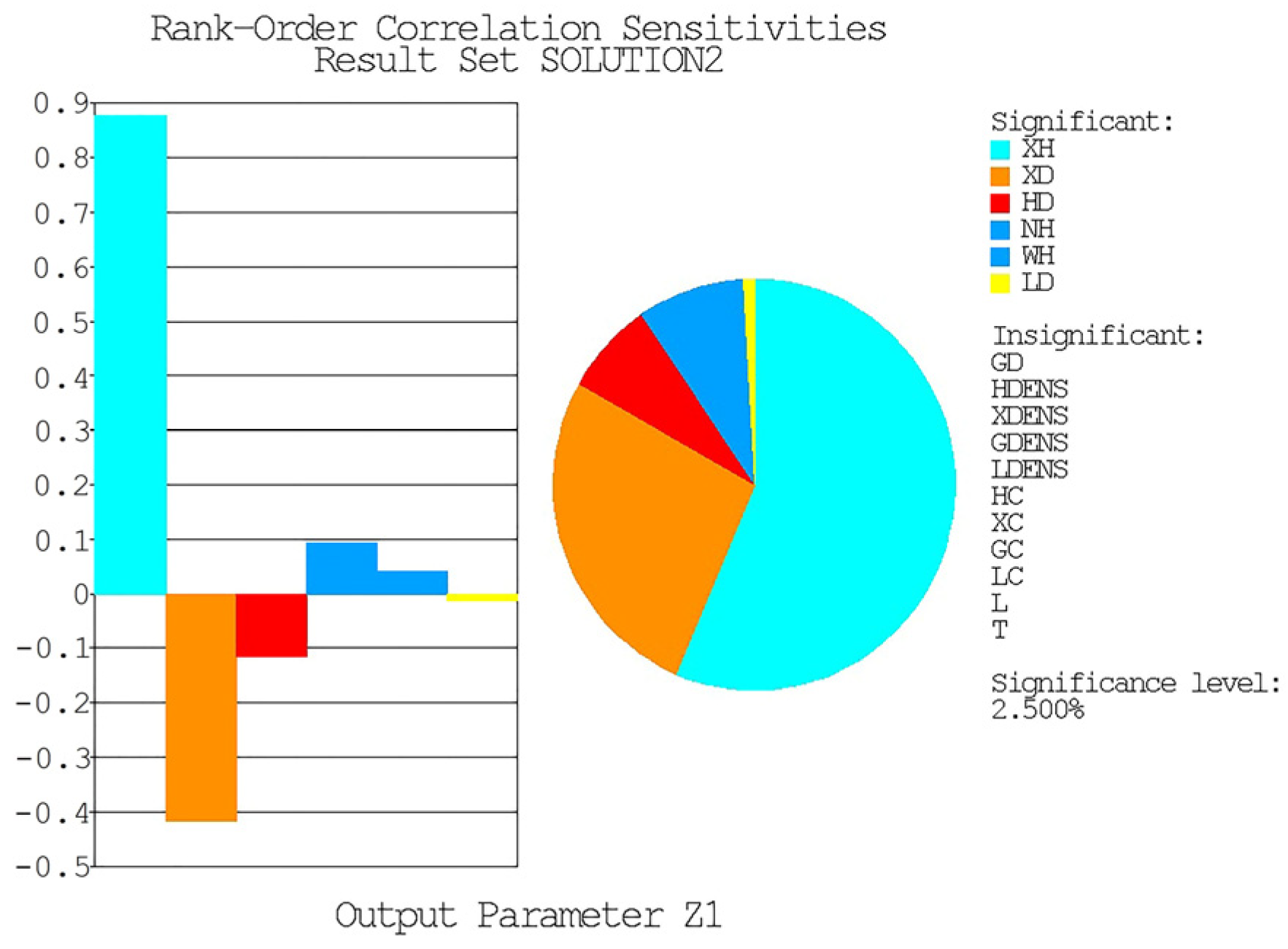

4.2.5. Sensitivity Analysis

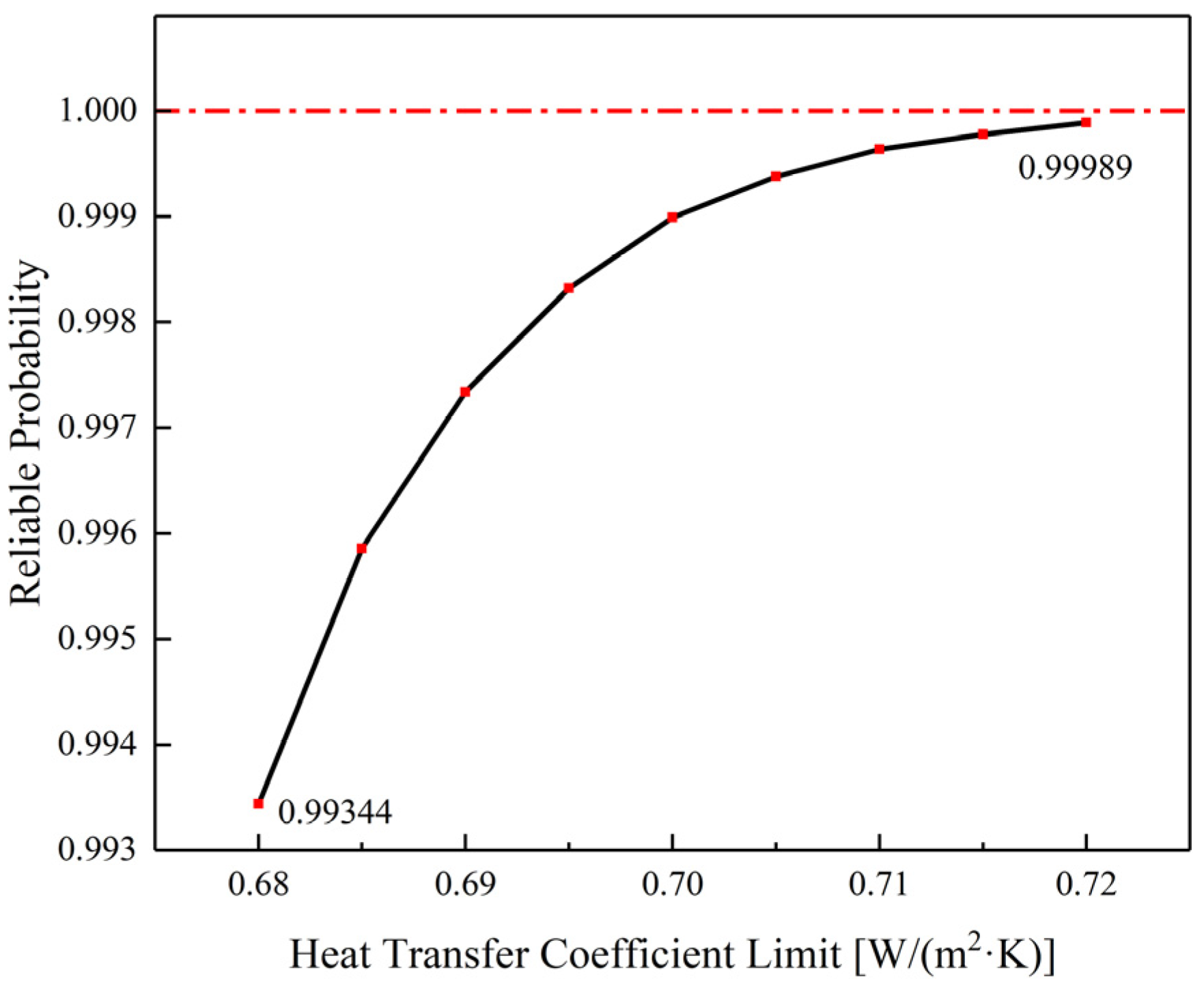

4.2.6. Numerical Analysis

5. Conclusions

- (1)

- The heat transfer coefficients of S-50XPS and S-80XPS are reduced by 45.81% and 56.13%, respectively, compared with the traditional brick bungalow B-490 wall. SIW wall panels have significantly better thermal insulation performance than traditional brick walls.

- (2)

- The SIW wall panel with an insulation panel of 80 mm thickness can meet the requirements of the heat transfer coefficient limit of 0.59 for the granary enclosure structure in the grain storage ecological zone.

- (3)

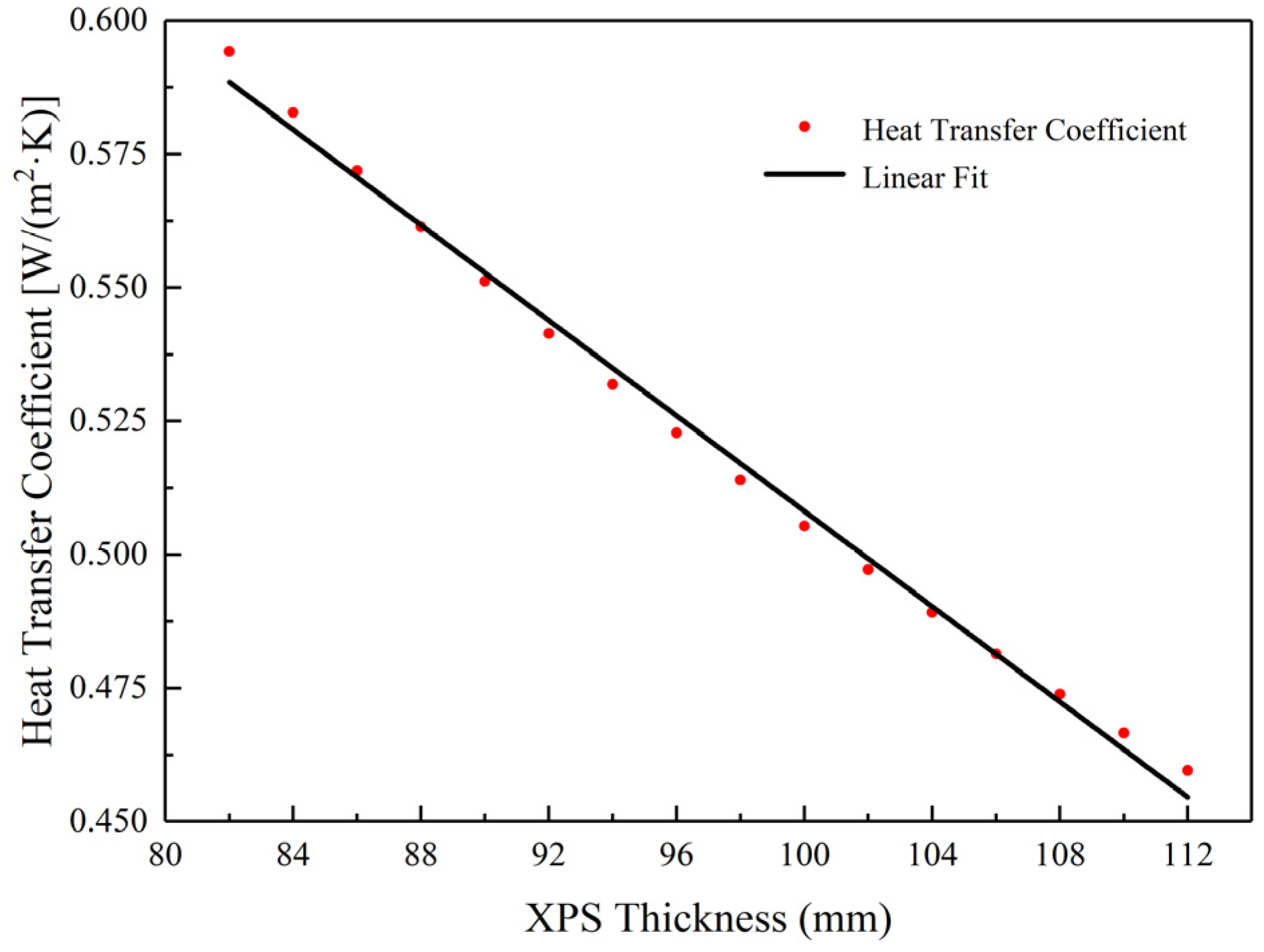

- The thickness of the insulation panel is sensitive mostly to the thermal insulation performance, with a correlation coefficient of 0.877.

- (4)

- The reliability index of S-80XPS meeting the heat transfer coefficient limit for the granary enclosure structure of 0.59 is 3.08. When the thickness of the insulation panel is increased to 94 mm and 107 mm, the wall panel can meet the requirements of the heat transfer coefficient limits of 0.53 and 0.46 with the reliability index of 1.82 and 1.75, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, F.J.; Shi, T.Y.; Cao, Y.; Wu, Y.; Tian, L. The current situation and development of grain storage technologies and facilities for Chinese farmers. J. Food Sci. Eng. 2016, 6, 260–266. [Google Scholar] [CrossRef]

- Lu, J.; Zhu, Q.; Jia, S.; An, X.; Wang, F. Using aeration and insulation to reduce grain temperature in China grain warehouses. Jul. Kühn Archiv. 2010, 425, 729–734. [Google Scholar] [CrossRef]

- Wang, W.; Ma, J. Performance analysis on improvement of the heat insulation of grain storehouse. Appl. Mech. Mater. 2011, 1366, 193–196. [Google Scholar] [CrossRef]

- Cao, W.H.; Ling, Y.Y.; Hua, L.L. The experimental studies on self-heat conserving facade panel with waste fibers. Adv. Mater. Res. 2011, 415–417, 1521–1524. [Google Scholar] [CrossRef]

- Xia, S.; Xia, G.H.; Cui, J.H.; Yin, W.Y. Research on the thermal performance of new sandwich insulation composite wall panel. Adv. Mater. Res. 2012, 1937, 220–223. [Google Scholar] [CrossRef]

- Hamed, E. Modeling, analysis, and behavior of load-carrying precast concrete sandwich panels. J. Struct. Eng. 2016, 142, 041036. [Google Scholar] [CrossRef]

- Giresini, L.; Paone, S.; Sassu, M. Integrated cost-analysis approach for seismic and thermal improvement of masonry building facades. Buildings 2020, 10, 143. [Google Scholar] [CrossRef]

- Jeong, Y.S. Experimental study on the thermal conductivity of thermal insulation materials used in residential buildings. Adv. Mater. Res. 2014, 1025–1026, 535–538. [Google Scholar] [CrossRef]

- Basim, A.; Hyder, A.A.; Amal, M.; Sarah, A.; Asmaa, E.S.; Hend, H.; Asayel, A.; Alia, A. Utilization of polyurethane foam dust in development of thermal insulation composite. Buildings 2022, 12, 126. [Google Scholar] [CrossRef]

- Kirpluks, M.; Cabulis, U.; Zeltins, V.; Stiebra, L.; Avots, A. Rigid polyurethane foam thermal insulation protected with mineral intumescent mat. Autex Res. J. 2014, 14, 259–269. [Google Scholar] [CrossRef] [Green Version]

- Cai, S.S.; Zhang, B.X.; Cremaschi, L. Review of moisture behavior and thermal performance of polystyrene insulation in building applications. Build. Environ. 2017, 123, 50–65. [Google Scholar] [CrossRef]

- Liu, C.Y.; Wang, X.; Shi, J.Z.; Liu, L.L.; Wu, Z.S. Experimental study on the flexural behavior of RC beams strengthened with prestressed BFRP laminates. Eng. Struct. 2021, 233, 111801. [Google Scholar] [CrossRef]

- Jiang, H.Z.; Guo, Z.X.; Liu, J.B. Composite behavior of sandwich panels with W-shaped SGFRP connectors. KSCE J. Civ. Eng. 2018, 22, 1889–1899. [Google Scholar] [CrossRef]

- Hassan, T.K.; Rizkalla, S.H. Analysis and design guidelines of precast, prestressed concrete, composite load-bearing sandwich wall panels reinforced with CFRP grid. PCI J. 2010, 55, 147–162. [Google Scholar] [CrossRef]

- Woltman, G.; Tomlinson, D.; Fam, A. Investigation of various GFRP shear connectors for insulated precast concrete sandwich wall panels. J. Compos. Constr. 2013, 17, 711–721. [Google Scholar] [CrossRef]

- Kim, Y.J.; Allard, A. Thermal response of precast concrete sandwich walls with various steel connectors for architectural buildings in cold regions. Energy Build. 2014, 80, 137–148. [Google Scholar] [CrossRef]

- Zhai, X.M.; Wang, Y.H.; Wang, X.M. Thermal performance of precast concrete sandwich walls with a novel hybrid connector. Energy Build. 2018, 166, 109–121. [Google Scholar] [CrossRef]

- Woltman, G.; Noel, M.; Fam, A. Experimental and numerical investigations of thermal properties of insulated concrete sandwich panels with fiberglass shear connectors. Energy Build. 2017, 145, 22–31. [Google Scholar] [CrossRef]

- Li, R.X.; Wei, X.L.; Li, H.X.; Zhu, J.Y. Experimental study on ventilation and thermal performance of exterior sandwich wall based on hot box method. Procedia Eng. 2017, 205, 2771–2778. [Google Scholar] [CrossRef]

- Souleymane, D.; Won, L.J.; Ho, N.W.; Woo, L.H. Overall heat transfer coefficient measurement of covering materials with thermal screens for greenhouse using the hot box method. J. Korean Soc. Agric. Eng. 2012, 54, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Jack, R.; Loveday, D.; Allinson, D.; Lomas, K. First evidence for the reliability of building co-heating tests. Build. Res. Informat. 2018, 46, 383–401. [Google Scholar] [CrossRef]

- Bruce, E. Structural reliability theory and its applications: By P. Thoft-Christensen and M.J. Baker. Struct. Saf. 1984, 2, 162–163. [Google Scholar] [CrossRef]

- Li, Q.; Jia, H.T.; Qiu, Q.; Lu, Y.Z.; Zhang, J.; Mao, J.H.; Fan, W.J.; Huang, M.F. Typhoon-Induced fragility analysis of transmission tower in Ningbo area considering the effect of long-term corrosion. Appl. Sci. 2022, 12, 4774. [Google Scholar] [CrossRef]

- Zhang, Z.; Jiang, C. Evidence-theory-based structural reliability analysis with epistemic uncertainty: A review. Struct. Multidiscip. Optim. 2021, 63, 2935–2953. [Google Scholar] [CrossRef]

- Melchers, R.E. Structural reliability theory in the context of structural safety. Civ. Eng. Environ. Syst. 2007, 24, 55–69. [Google Scholar] [CrossRef]

- Ding, X.; Jiang, T.F. Spectral distributions of adjacency and laplacian matrices of random graphs. Ann. Appl. Probab. 2010, 20, 2096–2117. [Google Scholar] [CrossRef]

- Wong, F.S. First-order, second-moment methods. Comput. Struct. 1985, 20, 779–791. [Google Scholar] [CrossRef]

- Das, P.K.; Zheng, Y. Cumulative formation of response surface and its use in reliability analysis. Probab. Eng. Eng. Mech. 2000, 15, 309–315. [Google Scholar] [CrossRef]

- Li, H.L.; Huang, X.Z.; Jin, S.J.; Jiang, Z.Y.; Wang, B.X. Reliability and sensitivity analysis of cold-bent curtain wall glass. J. Build. Eng. 2022, 49, 104116. [Google Scholar] [CrossRef]

- Hammersley, J.M. Simulation and the Monte Carlo method. Bull. Lond. Math. Soc. 2005, 14, 174–175. [Google Scholar] [CrossRef]

- Alban, A.; Darji, H.A.; Imamura, A.; Nakayama, M.K. Efficient Monte Carlo methods for estimating failure probabilities. Reliab. Eng. Syst. Saf. 2017, 165, 376–394. [Google Scholar] [CrossRef]

- Broday, E.E.; Ruivo, C.R.; Silva, M.G.d. The use of Monte Carlo method to assess the uncertainty of thermal comfort indices PMV and PPD: Benefits of using a measuring set with an operative temperature probe. J. Build. Eng. 2020, 35, 101961. [Google Scholar] [CrossRef]

- Mattos, L.J.; Marin, R.J. Reliability analysis of bored-pile wall stability considering parameter uncertainties. TecnoLógicas 2020, 23, 163–179. [Google Scholar] [CrossRef]

- Zheng, L.; He, M.; Lam, F.; Zhou, R.; Li, M. Seismic reliability evaluation of steel-timber hybrid shear wall systems. Earthq. Struct. 2017, 13, 289–297. [Google Scholar] [CrossRef]

- Navid, R.; Majid, P.; Nima, R. Reliability-based seismic assessment of controlled rocking steel cores. J. Build. Eng. 2021, 44, 102623. [Google Scholar] [CrossRef]

- Grubisic, M.; Ivosevic, J.; Grubisic, A. Reliability analysis of reinforced concrete frame by finite element method with implicit limit state functions. Buildings 2019, 9, 119. [Google Scholar] [CrossRef]

- Butko, Y. Investigation of random temperature fields in two-layer plates with the use of the Monte Carlo method. Int. Appl. Mech. 1979, 15, 91–98. [Google Scholar] [CrossRef]

- Wang, T.; Zhou, G.Q. Random temperature field of shaft wall based on Monte-Carlo method. J. Min. Saf. Eng. 2014, 31, 612–619. [Google Scholar] [CrossRef]

- Sun, H.; Niu, F.J.; Chen, Z.; Ge, X.R. Stochastic temperature field of frozen soil roadbed based on Monte-Carlo method. Shanghai Jiaotong Daxue Xuebao 2011, 45, 738–742+748. [Google Scholar] [CrossRef]

- Chong, W.; Qiu, Z.; He, Y. Fuzzy stochastic finite element method for the hybrid uncertain temperature field prediction. Int. J. Heat Mass Transf. 2015, 91, 512–519. [Google Scholar] [CrossRef]

- Zhu, L.; Zhang, J.Q.; Gao, Y.Z.; Tian, W.; Yan, Z.X.; Ye, X.S.; Sun, Y.; Wu, C.G. Uncertainty and sensitivity analysis of cooling and heating loads for building energy planning. J. Build. Eng. 2022, 45, 103440. [Google Scholar] [CrossRef]

- Yan, B.; Chen, J.J.; Ma, H.B. Thermal response analysis of stochastic pole structures under random transient temperature field. Dianzi Keji Daxue Xuebao 2012, 41, 631–636. [Google Scholar] [CrossRef]

- Tinti, F.; Bruno, R.; Focaccia, S. Thermal response test for shallow geothermal applications: A probabilistic analysis approach. Geotherm. Energy 2015, 3, 1–20. [Google Scholar] [CrossRef]

- Kaoula, D.; Bouchair, A. The pinpointing of the most prominent parameters on the energy performance for optimal passive strategies in ecological buildings based on bioclimatic, sensitivity and uncertainty analyses. Int. J. Ambient Energy 2022, 43, 685–712. [Google Scholar] [CrossRef]

- Li, X.S.; Ding, Y.G.; Zhao, J.Q.; Xu, Q.K. Experimental study on mechanical properties of integrated wall panels of grain warehouse with “Thermal Insulation”. Adv. Civ. Eng. 2022, 2022, 8636936. [Google Scholar] [CrossRef]

- Sun, L. Experimental Study on the Bearing and Thermal Performance of “Structure-Insulation” Integrated Wall Panel in Grain Warehouse. Master’s Thesis, Henan University of Technology, Zhengzhou, China, 2020. [Google Scholar] [CrossRef]

- GB50176-2016; Code for Thermal Design of Civil Building. Ministry of Housing and Urban-Rural Development: Beijing, China, 2016.

- DG/TJ08-2158-2017; Technical Specification for Precast Concrete Sandwich Wall Panel. Tongji University Press: Shanghai, China, 2018.

- GB50189-2015; Design Standard for Energy Efficiency of Public Buildings. Ministry of Housing and Urban-Rural Development: Beijing, China, 2015.

- Renno, C.; Petito, F.; Accarino, M.L. Thermal model in ANSYS for a comparison between two configurations of a concentrating photovoltaic system. Heat Transf. Eng. 2019, 40, 924–940. [Google Scholar] [CrossRef]

- Carson, J.S. Simulation and the Monte Carlo method. J. Qual. Technol. 1982, 14, 228. [Google Scholar] [CrossRef]

- Grymin, W.; Koniorczyk, M. Stochastic finite element method for modelling heat transfer in the building envelope. E3S Web Conf. 2020, 172, 8007–8013. [Google Scholar] [CrossRef]

- GB/T29890-2013; Technical Criterion for Grain and Oil-Deeds Storage. Standards Press of China: Beijing, China, 2013.

- Onyeneke, C.C. A modified review and proof of central limit theorem in relation with law of large numbers. Data Res. 2018, 2, 111–119. [Google Scholar] [CrossRef]

- Huang, Z.X.; Sun, K.B.; Luan, X.G.; Hu, B. Reliability sensitivity analysis of bolt pre-tightening connection. J. Jilin Univ. 2022, 3, 1–8. [Google Scholar] [CrossRef]

- Lu, C.H.; Wu, Z.Y. Uncertainty quantification of the 1-D SFR thermal stratification model via the Latin Hypercube Sampling Monte Carlo method. Nucl. Technol. 2022, 208, 37–48. [Google Scholar] [CrossRef]

- Sheikholeslami, R.; Razavi, S. Progressive Latin Hypercube Sampling: An efficient approach for robust sampling-based analysis of environmental models. Environ. Modell. Softw. 2017, 93, 109–126. [Google Scholar] [CrossRef]

| Specimens | ||

|---|---|---|

| S-50XPS | 1.03 | 0.84 |

| S-80XPS | 1.31 | 0.68 |

| B-490 | 0.49 | 1.55 |

| Materials | |||

|---|---|---|---|

| Concrete | 2300 | 920 | 1.74 |

| Rebar | 7850 | 480 | 58.2 |

| XPS insulation panel | 25 | 1380 | 0.033 |

| GFRP connectors | 2000 | 1100 | 0.43 |

| Specimens | Inner Surface Temperature °C | Outer Surface Temperature °C | ||

|---|---|---|---|---|

| S-50XPS | 27.45 | 37.82 | 10.25 | 10.39 |

| S-80XPS | 26.34 | 38.10 | 7.78 | 7.89 |

| Regional Division | Ecological Characteristics | |

|---|---|---|

| First Zone | High cold and dry grain storage zone | 0.59–0.70 |

| Second Zone | Low temperature and dry grain storage zone | 0.59–0.70 |

| Third Zone | Low temperature and high humidity grain storage zone | 0.59–0.70 |

| Fourth Zone | Medium temperature and dry grain storage zone | 0.53–0.58 |

| Fifth Zone | Medium temperature and high humidity grain storage zone | 0.46–0.52 |

| Sixth Zone | Medium temperature and low humidity grain storage zone | 0.53–0.58 |

| Seventh Zone | High temperature and high humidity grain storage zone | 0.46–0.52 |

| Random Variables | Distribution Characteristics | Average Value μ | Coefficient of Variation δ | Code Name |

|---|---|---|---|---|

| GUSS | 1.74 | 0.05 | HD | |

| GUSS | 0.033 | 0.05 | XD | |

| GUSS | 58.2 | 0.05 | GD | |

| GUSS | 0.43 | 0.05 | LD | |

| GUSS | 2300 | 0.05 | HDENS | |

| GUSS | 25 | 0.05 | XDENS | |

| GUSS | 7850 | 0.05 | GDENS | |

| GUSS | 2000 | 0.05 | LGENS | |

| GUSS | 920 | 0.05 | HC | |

| GUSS | 1380 | 0.05 | XC | |

| GUSS | 480 | 0.05 | GC | |

| GUSS | 1100 | 0.05 | LC | |

| Thickness of outer leaf wall (m) | GUSS | 0.06 | 0.05 | WH |

| Thickness of XPS (m) | GUSS | 0.08 | 0.05 | XH |

| Thickness of inner leaf wall (m) | GUSS | 0.25 | 0.05 | NH |

| Length and width of wall panel (m) | GUSS | 1.7 | 0.05 | L |

| Temperature load (°C) | GUSS | 39 | 0.05 | T |

| Variables | Correlation Coefficient | Variables | Correlation Coefficient | Variables | Correlation Coefficient |

|---|---|---|---|---|---|

| HD | −0.114 | XD | −0.418 | GD | <0.001> |

| LD | −0.013 | HDENS | <−0.002> | XDENS | <0.001> |

| GDENS | <0.001> | LDENS | <−0.001> | HC | <0.001> |

| XC | <0.001> | GC | <−0.001> | LC | <−0.001> |

| L | <0.001> | XH | 0.877 | WH | 0.042 |

| NH | 0.092 | T | <0.001> |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, Y.; Song, Z.; Chen, K.; Zhang, X. Thermal Insulation Performance and Reliability of the “Structure-Insulation” Integrated Wall Panel (SIW) for Storage Grain Bungalows. Buildings 2022, 12, 1306. https://doi.org/10.3390/buildings12091306

Ding Y, Song Z, Chen K, Zhang X. Thermal Insulation Performance and Reliability of the “Structure-Insulation” Integrated Wall Panel (SIW) for Storage Grain Bungalows. Buildings. 2022; 12(9):1306. https://doi.org/10.3390/buildings12091306

Chicago/Turabian StyleDing, Yonggang, Zhanjiong Song, Kewei Chen, and Xiaohang Zhang. 2022. "Thermal Insulation Performance and Reliability of the “Structure-Insulation” Integrated Wall Panel (SIW) for Storage Grain Bungalows" Buildings 12, no. 9: 1306. https://doi.org/10.3390/buildings12091306

APA StyleDing, Y., Song, Z., Chen, K., & Zhang, X. (2022). Thermal Insulation Performance and Reliability of the “Structure-Insulation” Integrated Wall Panel (SIW) for Storage Grain Bungalows. Buildings, 12(9), 1306. https://doi.org/10.3390/buildings12091306