Preparation of Recycled and Multi-Recycled Coarse Aggregates Concrete with the Vibration Mixing Process

Abstract

:1. Introduction

1.1. Recycled Concrete

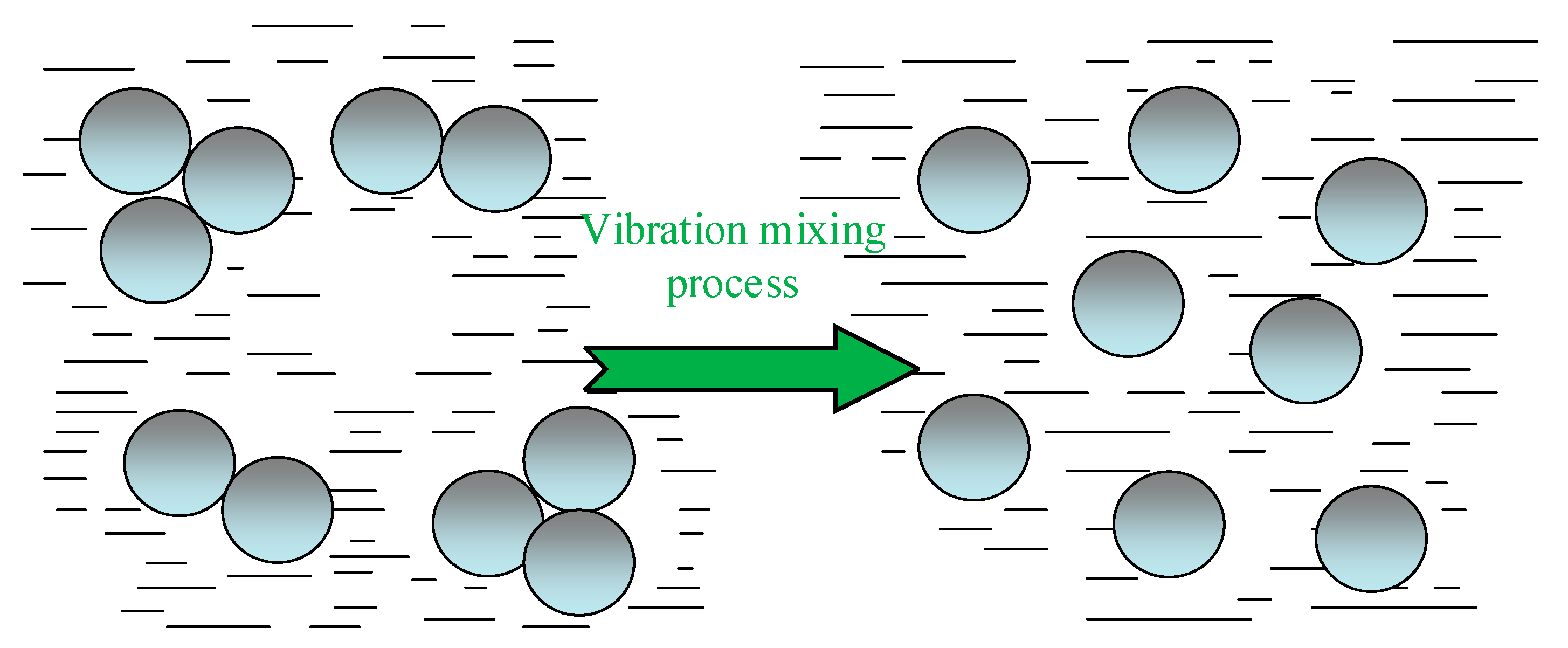

1.2. Vibration Mixing Process

2. Research Objective

3. Materials and Methods

3.1. Materials

3.2. Concrete Composition

3.3. Two-Stage Mixing Approach (TSMA)

3.4. Vibration Mixer

3.5. Tests

4. Properties of Aggregates

4.1. Physical Properties

4.2. The Morphology of Recycled Aggregates

5. Results and Discussion

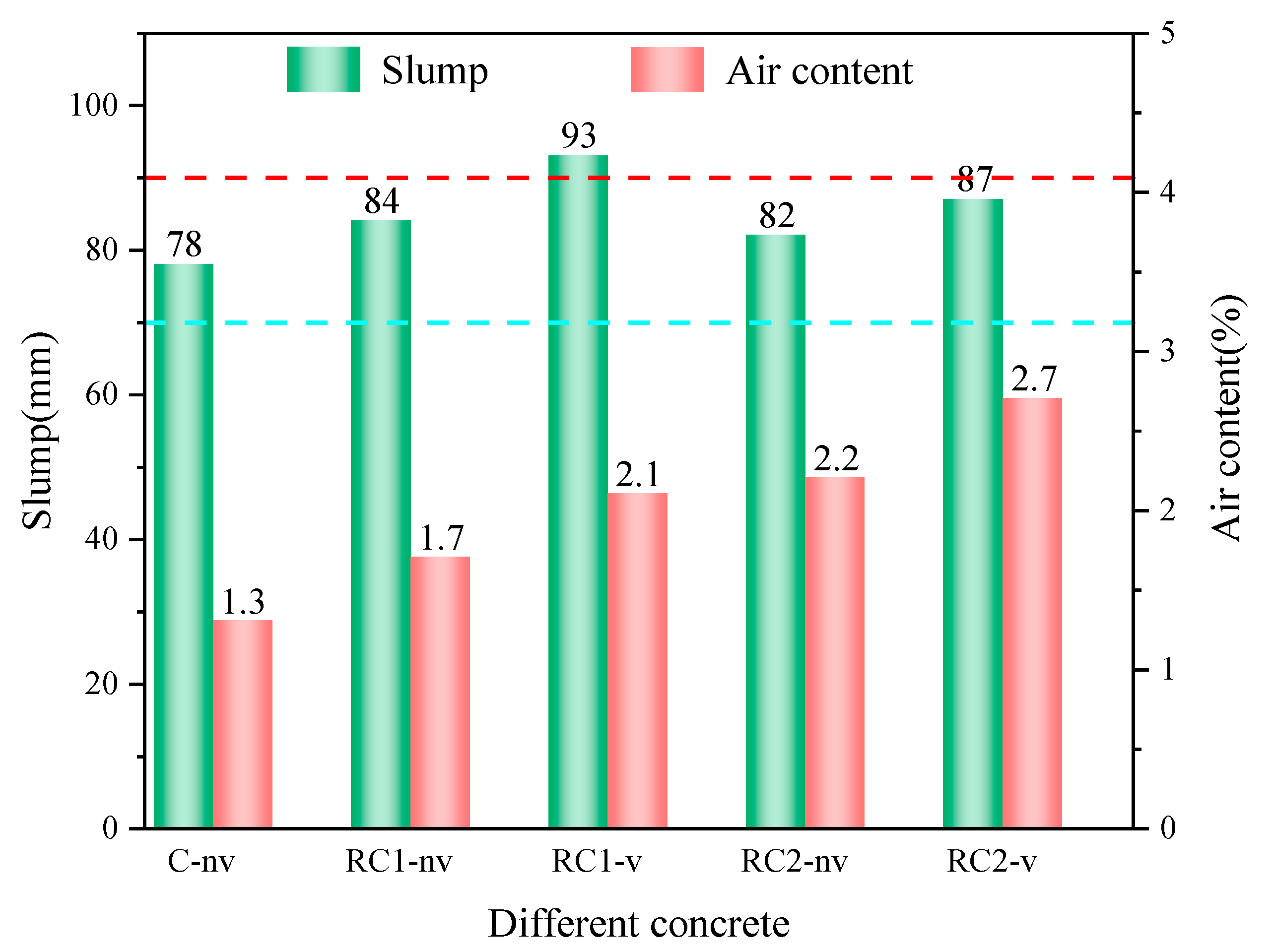

5.1. Fresh Concrete Properties

5.1.1. Slump

5.1.2. Air Content

5.2. Hardened Concrete Mechanical Properties

5.2.1. Compressive Strength

5.2.2. Relative Variation

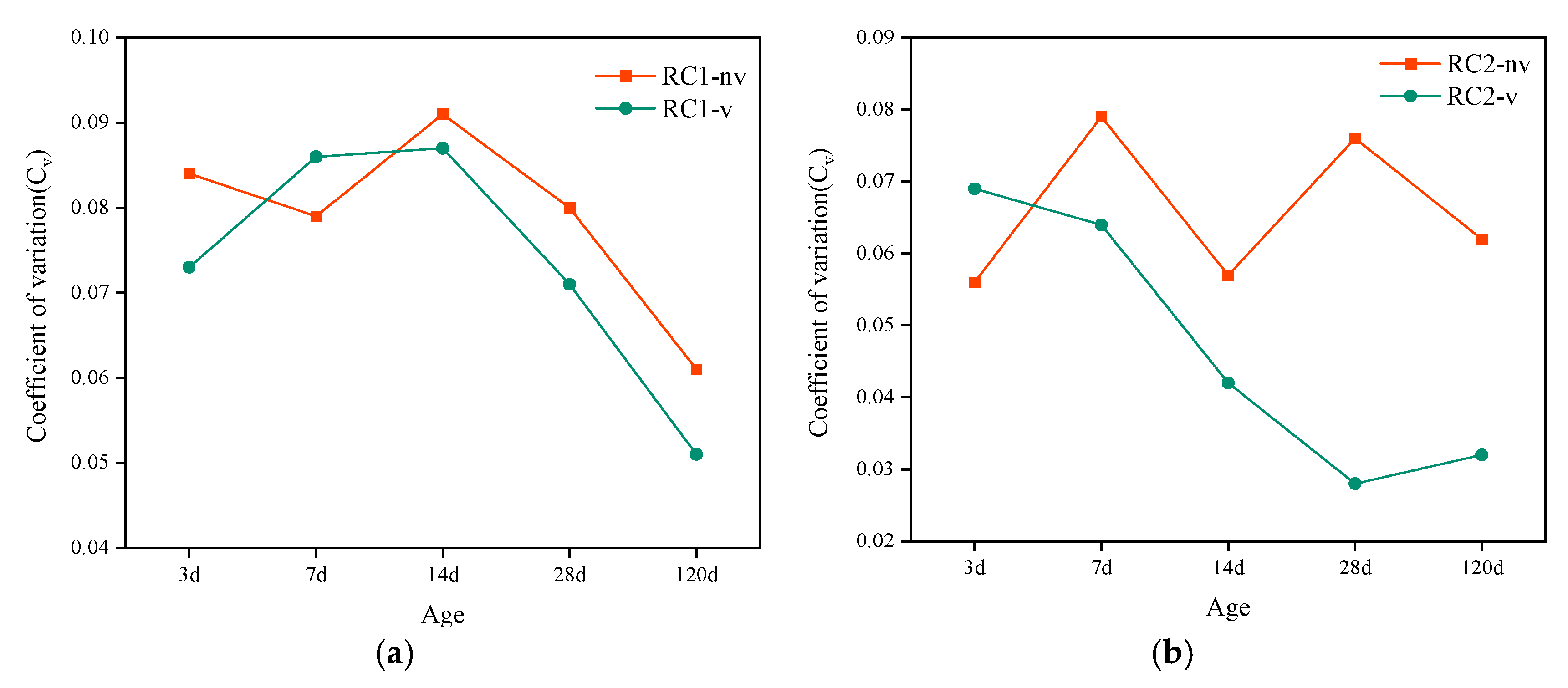

5.2.3. Coefficient of Variation

5.2.4. Splitting Tensile Strength

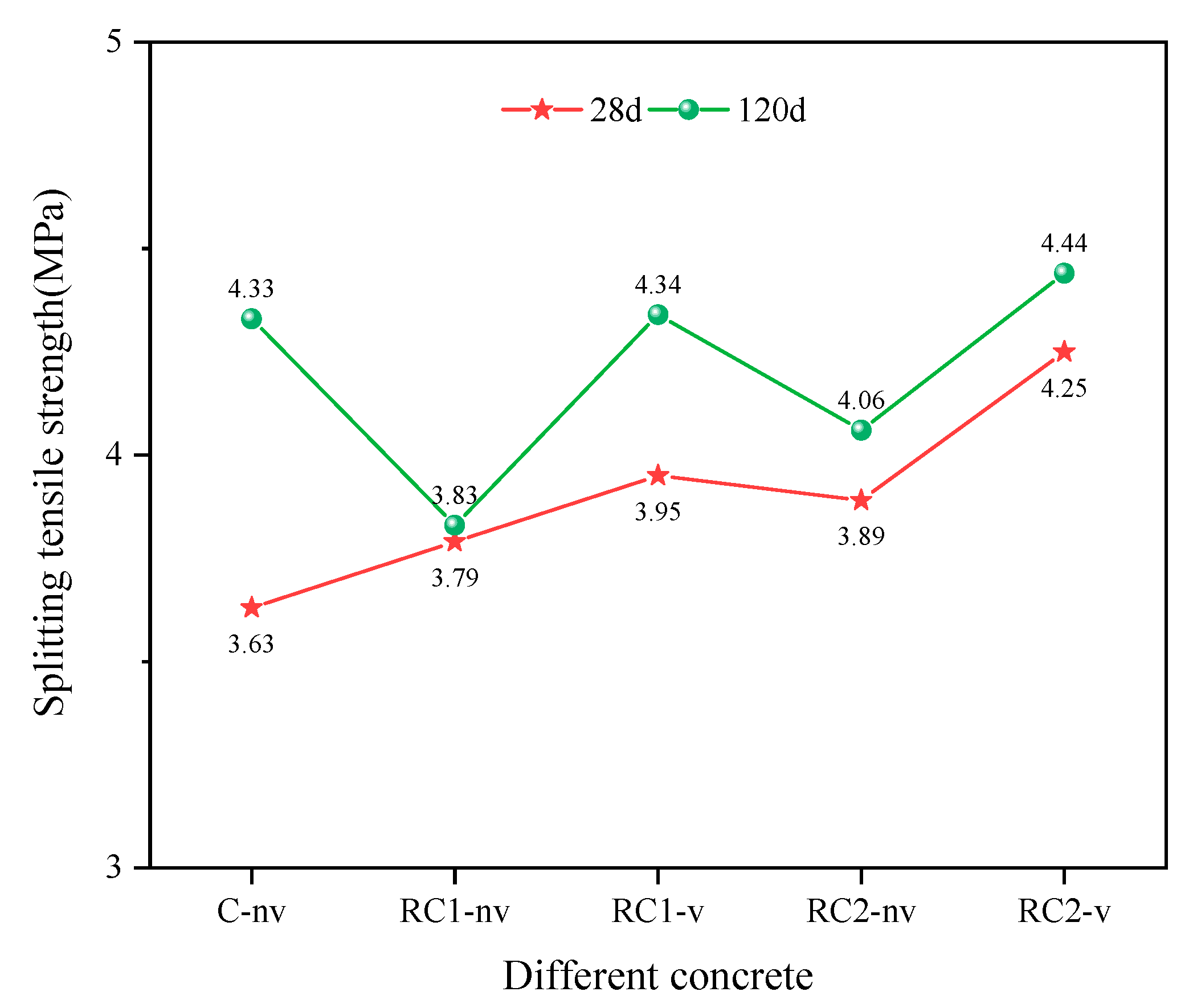

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tam, V.W.; Soomro, M.; Evangelista, A.C.J. A review of recycled aggregate in concrete applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- Tam, V.W.; Tam, L.; Le, K.N. Cross-cultural comparison of concrete recycling decision-making and implementation in construction industry. Waste Manag. 2010, 30, 291–297. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Xia, J.; Thompson, J.R.; Flower, R.J. Urban construction and demolition waste and landfill failure in Shenzhen, China. Waste Manag. 2017, 63, 393–396. [Google Scholar] [CrossRef]

- De Juan, M.S.; Gutiérrez, P.A. Study on the influence of attached mortar content on the properties of recycled concrete aggregate. Constr. Build. Mater. 2009, 23, 872–877. [Google Scholar] [CrossRef]

- McGinnis, M.J.; Davis, M.; de la Rosa, A.; Weldon, B.D.; Kurama, Y.C. Strength and stiffness of concrete with recycled concrete aggregates. Constr. Build. Mater. 2017, 154, 258–269. [Google Scholar] [CrossRef]

- Kovler, K.; Roussel, N. Properties of fresh and hardened concrete. Cem. Concr. Res. 2011, 41, 775–792. [Google Scholar] [CrossRef]

- Manzi, S.; Mazzotti, C.; Bignozzi, M.C. Short and long-term behavior of structural concrete with recycled concrete aggregate. Cem. Concr. Compos. 2013, 37, 312–318. [Google Scholar] [CrossRef]

- Thomas, C.; Setién, J.; Polanco, J. Structural recycled aggregate concrete made with precast wastes. Constr. Build. Mater. 2016, 114, 536–546. [Google Scholar] [CrossRef]

- Kou, S.-C.; Poon, C.-S.; Etxeberria, M. Influence of recycled aggregates on long term mechanical properties and pore size distribution of concrete. Cem. Concr. Compos. 2011, 33, 286–291. [Google Scholar] [CrossRef]

- Thomas, C.; Setién, J.; Polanco, J.; De Brito, J.; Fiol, F. Micro-and macro-porosity of dry-and saturated-state recycled aggregate concrete. J. Clean. Prod. 2019, 211, 932–940. [Google Scholar] [CrossRef]

- Xiao, J.; Li, W.; Fan, Y.; Huang, X. An overview of study on recycled aggregate concrete in China (1996–2011). Constr. Build. Mater. 2012, 31, 364–383. [Google Scholar] [CrossRef]

- Le, H.-B.; Bui, Q.-B. Recycled aggregate concretes—A state-of-the-art from the microstructure to the structural performance. Constr. Build. Mater. 2020, 257, 119522. [Google Scholar] [CrossRef]

- Pradhan, S.; Kumar, S.; Barai, S.V. Multi-scale characterisation of recycled aggregate concrete and prediction of its performance. Cem. Concr. Compos. 2020, 106, 103480. [Google Scholar] [CrossRef]

- Del Bosque, I.S.; Zhu, W.; Howind, T.; Matías, A.; De Rojas, M.S.; Medina, C. Properties of interfacial transition zones (ITZs) in concrete containing recycled mixed aggregate. Cem. Concr. Compos. 2017, 81, 25–34. [Google Scholar] [CrossRef]

- Djerbi, A. Effect of recycled coarse aggregate on the new interfacial transition zone concrete. Constr. Build. Mater. 2018, 190, 1023–1033. [Google Scholar] [CrossRef]

- Liu, Q.; Xiao, J.; Sun, Z. Experimental study on the failure mechanism of recycled concrete. Cem. Concr. Res. 2011, 41, 1050–1057. [Google Scholar] [CrossRef]

- Thomas, C.; Setién, J.; Polanco, J.; Lombillo, I.; Cimentada, A. Fatigue limit of recycled aggregate concrete. Constr. Build. Mater. 2014, 52, 146–154. [Google Scholar] [CrossRef]

- Thomas, C.; Setién, J.; Polanco, J.; Alaejos, P.; De Juan, M.S. Durability of recycled aggregate concrete. Constr. Build. Mater. 2013, 40, 1054–1065. [Google Scholar] [CrossRef]

- Guo, H.; Shi, C.; Guan, X.; Zhu, J.; Ding, Y.; Ling, T.-C.; Zhang, H.; Wang, Y. Durability of recycled aggregate concrete—A review. Cem. Concr. Compos. 2018, 89, 251–259. [Google Scholar] [CrossRef]

- Evangelista, L.; De Brito, J. Durability performance of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2010, 32, 9–14. [Google Scholar] [CrossRef]

- Vymazal, T.; Hrabová, K.; Teplý, B.; Kocáb, D. Sustainability quantification of concrete with recycled aggregate. AIP Conf. Proc. 2020, 2210, 020018. [Google Scholar] [CrossRef]

- Lu, B.; Shi, C.; Cao, Z.; Guo, M.; Zheng, J. Effect of carbonated coarse recycled concrete aggregate on the properties and microstructure of recycled concrete. J. Clean. Prod. 2019, 233, 421–428. [Google Scholar] [CrossRef]

- Liu, K.; Yan, J.; Hu, Q.; Sun, Y.; Zou, C. Effects of parent concrete and mixing method on the resistance to freezing and thawing of air-entrained recycled aggregate concrete. Constr. Build. Mater. 2016, 106, 264–273. [Google Scholar] [CrossRef]

- Tam, V.W.; Tam, C.M.; Wang, Y. Optimization on proportion for recycled aggregate in concrete using two-stage mixing approach. Constr. Build. Mater. 2007, 21, 1928–1939. [Google Scholar] [CrossRef]

- Tam, V.W.; Gao, X.; Tam, C.M. Microstructural analysis of recycled aggregate concrete produced from two-stage mixing approach. Cem. Concr. Res. 2005, 35, 1195–1203. [Google Scholar] [CrossRef]

- Fonseca, N.; De Brito, J.; Evangelista, L. The influence of curing conditions on the mechanical performance of concrete made with recycled concrete waste. Cem. Concr. Compos. 2011, 33, 637–643. [Google Scholar] [CrossRef]

- Thomas, C.; Setién, J.; Polanco, J.; Cimentada, A.; Medina, C. Influence of curing conditions on recycled aggregate concrete. Constr. Build. Mater. 2018, 172, 618–625. [Google Scholar] [CrossRef]

- Horňáková, M.; Lehner, P. Analysis of Measured Parameters in Relation to the Amount of Fibre in Lightweight Red Ceramic Waste Aggregate Concrete. Mathematics 2022, 10, 229. [Google Scholar] [CrossRef]

- Barbudo, A.; De Brito, J.; Evangelista, L.; Bravo, M.; Agrela, F. Influence of water-reducing admixtures on the mechanical performance of recycled concrete. J. Clean. Prod. 2013, 59, 93–98. [Google Scholar] [CrossRef]

- Kou, S.-C.; Poon, C.-S.; Agrela, F. Comparisons of natural and recycled aggregate concretes prepared with the addition of different mineral admixtures. Cem. Concr. Compos. 2011, 33, 788–795. [Google Scholar] [CrossRef]

- Pereira, P.; Evangelista, L.; De Brito, J. The effect of superplasticisers on the workability and compressive strength of concrete made with fine recycled concrete aggregates. Constr. Build. Mater. 2012, 28, 722–729. [Google Scholar] [CrossRef]

- Matias, D.; De Brito, J.; Rosa, A.; Pedro, D. Mechanical properties of concrete produced with recycled coarse aggregates—Influence of the use of superplasticizers. Constr. Build. Mater. 2013, 44, 101–109. [Google Scholar] [CrossRef]

- Pereira, P.; Evangelista, L.; De Brito, J. The effect of superplasticizers on the mechanical performance of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2012, 34, 1044–1052. [Google Scholar] [CrossRef]

- Marie, I.; Quiasrawi, H. Closed-loop recycling of recycled concrete aggregates. J. Clean. Prod. 2012, 37, 243–248. [Google Scholar] [CrossRef]

- Huda, S.B.; Alam, M.S. Mechanical behavior of three generations of 100% repeated recycled coarse aggregate concrete. Constr. Build. Mater. 2014, 65, 574–582. [Google Scholar] [CrossRef]

- Salesa, Á.; Pérez-Benedicto, J.A.; Colorado-Aranguren, D.; López-Julián, P.L.; Esteban, L.M.; Sanz-Baldúz, L.J.; Sáez-Hostaled, J.L.; Ramis, J.; Olivares, D. Physico–mechanical properties of multi-recycled concrete from precast concrete industry. J. Clean. Prod. 2017, 141, 248–255. [Google Scholar] [CrossRef]

- Salesa, Á.; Pérez-Benedicto J, Á.; Esteban, L.M.; Vicente-Vas, R.; Orna-Carmona, M. Physico-mechanical properties of multi-recycled self-compacting concrete prepared with precast concrete rejects. Constr. Build. Mater. 2017, 153, 364–373. [Google Scholar] [CrossRef]

- Thomas, C.; De Brito, J.; Cimentada, A.; Sainz-Aja, J. Macro- and micro-properties of multi-recycled aggregate concrete. J. Clean. Prod. 2020, 245, 118843. [Google Scholar] [CrossRef]

- Thomas, C.; De Brito, J.; Gil, V.; Sainz-Aja, J.; Cimentada, A. Multiple recycled aggregate properties analysed by X-ray microtomography. Constr. Build. Mater. 2018, 166, 171–180. [Google Scholar] [CrossRef]

- Abreu, V.; Evangelista, L.; De Brito, J. The effect of multi-recycling on the mechanical performance of coarse recycled aggregates concrete. Constr. Build. Mater. 2018, 188, 480–489. [Google Scholar] [CrossRef]

- Silva, S.; Evangelista, L.; De Brito, J. Durability and shrinkage performance of concrete made with coarse multi-recycled concrete aggregates. Constr. Build. Mater. 2021, 272, 121645. [Google Scholar] [CrossRef]

- Zhu, P.; Hao, Y.; Liu, H.; Wei, D.; Liu, S.; Gu, L. Durability evaluation of three generations of 100% repeatedly recycled coarse aggregate concrete. Constr. Build. Mater. 2019, 210, 442–450. [Google Scholar] [CrossRef]

- Yao, Y.; Feng, Z.; Chen, S. Strength of concrete reinforced using double-blade mixer. Mag. Concr. Res. 2013, 65, 787–792. [Google Scholar] [CrossRef]

- Feng, Z.; Zhao, L.; Zhao, W.; Wang, W.; Yao, Y. Advanced Theory and Equipment of Production Concrete; China Communications Press: Beijing, China, 2016. [Google Scholar]

- Xiong, G.; Wang, C.; Zhou, S.; Jia, X.; Luo, W.; Liu, J.; Peng, X. Preparation of high strength lightweight aggregate concrete with the vibration mixing process. Constr. Build. Mater. 2019, 229, 116936. [Google Scholar] [CrossRef]

- Zhao, K.; Zhao, L.; Hou, J.; Zhang, X.; Feng, Z.; Yang, S. Effect of vibratory mixing on the slump, compressive strength, and density of concrete with the different mix proportions. J. Mater. Res. Technol. 2021, 15, 4208–4219. [Google Scholar] [CrossRef]

- Zheng, Y.; Wu, X.; He, G.; Shang, Q.; Xu, J.; Sun, Y. Mechanical properties of steel fiber-reinforced concrete by vibratory mixing technology. Adv. Civ. Eng. 2018, 2018, 9025715. [Google Scholar] [CrossRef]

- Zhang, L. Research on Vibratory Mixing Mechanism and Industrial Application of Concrete; Chang’an University: Xi’an, China, 2013. [Google Scholar]

- Montero, J.; Laserna, S. Influence of effective mixing water in recycled concrete. Constr. Build. Mater. 2017, 132, 343–352. [Google Scholar] [CrossRef]

- Tam, V.-Y.; Gao, X.-F.; Tam, C. Comparing performance of modified two-stage mixing approach for producing recycled aggregate concrete. Mag. Concr. Res. 2006, 58, 477–484. [Google Scholar] [CrossRef]

- Kisku, N.; Rajhans, P.; Panda, S.; Nayak, S.; Pandey, V. Development of durable concrete from C&D waste by adopting identical mortar volume method in conjunction with two-stage mixing procedure. Constr. Build. Mater. 2020, 256, 119361. [Google Scholar] [CrossRef]

- Tam, V.W.; Tam, C.M. Diversifying two-stage mixing approach (TSMA) for recycled aggregate concrete: TSMAs and TSMAsc. Constr. Build. Mater. 2008, 22, 2068–2077. [Google Scholar] [CrossRef] [Green Version]

- Kisku, N.; Rajhans, P.; Panda, S.; Pandey, V.; Nayak, S. Microstructural investigation of recycled aggregate concrete produced by adopting equal mortar volume method along with two stage mixing approach. Structures 2020, 24, 742–753. [Google Scholar] [CrossRef]

- Sivamani, J.; Renganathan, N.T. Effect of fine recycled aggregate on the strength and durability properties of concrete modified through two-stage mixing approach. Environ. Sci. Pollut. Res. 2021, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Chinese Standard JGJ 52-2006; Standard for Technical Requirements and Test Method of Sand and Curshed Stone (or Gravel) for Ordinary Concrete. Ministry of Construction of the People’s Republic of China: Beijing, China, 2006.

- Chinese Standard GB/T 25177-2010; Recycled Coarse Aggregate for Concrete. Quality Supervision Inspection and Quarantine of the People’s Republic of China and Standardization Administration of the People’s Republic China: Beijing, China, 2010.

- EN 12390-2:2019; Testing Fresh Concrete-Part 2: Slump Test. BSI: London, UK, 2019.

- EN 12390-7:2009; Testing Hardened Concrete—Part 6: Air Content-Pressure Methods. BSI: London, UK, 2009.

- EN 12390-3:2002; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. BSI: London, UK, 2002.

- EN 12390-6:2009; Testing Hardened Concrete—Part 6: Tensile Splitting Strength of Test Specimens. BSI: London, UK, 2009.

- EN 12390-2:2009; Testing Hardened Concrete—Part 2: Making and Curing Specimens for Strength Tests. BSI: London, UK, 2009.

- Koch, J.A.; Castaneda, D.I.; Ewoldt, R.H.; Lange, D.A. Vibration of fresh concrete understood through the paradigm of granular physics. Cem. Concr. Res. 2019, 115, 31–42. [Google Scholar] [CrossRef]

| Components | Size (mm) | NC | RC1 | RC2 |

|---|---|---|---|---|

| Natural coarse aggregate | 4.75–9.5 | 457.6 | - | - |

| 9.5–16 | 480.9 | - | - | |

| 16–19 | 171.6 | - | - | |

| 19–26.5 | 34.32 | - | - | |

| Recycled coarse aggregate | 4.75–9.5 | - | 428.7 | 405.7 |

| 9.5–16 | - | 450.1 | 425.9 | |

| 16–19 | - | 160.7 | 152.1 | |

| 19–26.5 | - | 32.1 | 30.4 | |

| Fine aggregate | 602 | 602 | 602 | |

| Cement | 439 | 439 | 439 | |

| Water | 215 | 215 | 215 | |

| Compensation water | 0 | 17.6 | 25.6 | |

| w/c | 0.49 | 0.53 | 0.55 | |

| w/ceffective | 0.49 | 0.49 | 0.49 |

| Properties | NCA | RCA1 | RCA2 |

|---|---|---|---|

| Apparent density (kg/m3) | 2739.81 | 2566.51 | 2428.80 |

| Oven-dried density (kg/m3) | 2735.23 | 2424.27 | 2252.74 |

| Saturated surface dry density (kg/m3) | 2759.30 | 2593.94 | 2486.63 |

| Water absorption, 24 h (%) | 0.97 | 7.80 | 11.20 |

| Moisture content (%) | 0.07 | 4.85 | 7.15 |

| Compressive Strength (MPa) | 3 d | Cv | 7 d | Cv | 14 d | Cv | 28 d | Cv | 120 d | Cv |

|---|---|---|---|---|---|---|---|---|---|---|

| C-nv | 20.3 | 0.051 | 29.8 | 0.040 | 34.1 | 0.073 | 41.0 | 0.057 | 44.9 | 0.061 |

| RC1-nv | 15.2 | 0.084 | 26.8 | 0.079 | 31.9 | 0.091 | 34.9 | 0.080 | 40.2 | 0.061 |

| RC1-v | 17.1 | 0.073 | 26.3 | 0.086 | 33.0 | 0.087 | 38.9 | 0.071 | 46.7 | 0.051 |

| RC2-nv | 12.0 | 0.056 | 24.0 | 0.079 | 29.8 | 0.057 | 35.7 | 0.076 | 37.1 | 0.062 |

| RC2-v | 11.8 | 0.069 | 23.5 | 0.064 | 28.9 | 0.042 | 38.8 | 0.028 | 42.9 | 0.032 |

| Age | Concrete | Descriptive Statistics | Test Statistics | ||||||

|---|---|---|---|---|---|---|---|---|---|

| N | Mean | SD | SEM | Median | t Statistic | DF | Prob > |t| | ||

| 28 d | RC1-nv | 6 | 34.852 | 2.791 | 1.139 | 34.844 | −4.617 | 5 | 0.0058 |

| RC1-v | 6 | 38.904 | 2.763 | 1.128 | 38.660 | ||||

| Difference | 6 | −4.052 | 2.150 | 0.878 | −3.593 | ||||

| Overall | 12 | 36.878 | 3.389 | 0.978 | 36.778 | ||||

| RC2-nv | 6 | 35.782 | 2.724 | 1.112 | 35.804 | −2.830 | 5 | 0.0367 | |

| RC2-v | 6 | 38.777 | 1.100 | 0.449 | 38.593 | ||||

| Difference | 6 | −2.995 | 2.592 | 1.058 | −3.810 | ||||

| Overall | 12 | 37.279 | 2.524 | 0.729 | 37.734 | ||||

| 120 d | RC1-nv | 6 | 40.185 | 2.442 | 0.997 | 40.483 | −3.972 | 5 | 0.0106 |

| RC1-v | 6 | 46.774 | 2.375 | 0.970 | 47.265 | ||||

| Difference | 6 | −6.589 | 4.064 | 1.659 | −7.220 | ||||

| Overall | 12 | 43.479 | 4.137 | 1.194 | 43.291 | ||||

| RC2-nv | 6 | 37.121 | 2.318 | 0.946 | 37.354 | −4.673 | 5 | 0.0055 | |

| RC2-v | 6 | 42.904 | 1.386 | 0.566 | 42.858 | ||||

| Difference | 6 | −5.783 | 3.031 | 1.238 | −6.106 | ||||

| Overall | 12 | 40.012 | 3.527 | 1.018 | 40.605 | ||||

| Age | Concrete | Descriptive Statistics | Test Statistics | ||||||

|---|---|---|---|---|---|---|---|---|---|

| N | Mean | SD | SEM | Median | t Statistic | DF | Prob > |t| | ||

| 120 d | RC1-nv | 6 | 3.832 | 0.148 | 0.061 | 3.817 | −5.397 | 5 | 0.0030 |

| RC1-v | 6 | 4.345 | 0.204 | 0.083 | 4.348 | ||||

| Difference | 6 | −0.513 | 0.233 | 0.095 | −0.552 | ||||

| Overall | 12 | 4.088 | 0.317 | 0.092 | 4.035 | ||||

| RC2-nv | 6 | 4.058 | 0.343 | 0.140 | 3.986 | −3.532 | 5 | 0.0167 | |

| RC2-v | 6 | 4.442 | 0.324 | 0.132 | 4.457 | ||||

| Difference | 6 | −0.384 | 0.266 | 0.109 | −0.288 | ||||

| Overall | 12 | 4.250 | 0.376 | 0.109 | 4.327 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, F.; Yao, Y.; Wang, X.; Wei, J.; Feng, Z. Preparation of Recycled and Multi-Recycled Coarse Aggregates Concrete with the Vibration Mixing Process. Buildings 2022, 12, 1369. https://doi.org/10.3390/buildings12091369

Yang F, Yao Y, Wang X, Wei J, Feng Z. Preparation of Recycled and Multi-Recycled Coarse Aggregates Concrete with the Vibration Mixing Process. Buildings. 2022; 12(9):1369. https://doi.org/10.3390/buildings12091369

Chicago/Turabian StyleYang, Fa, Yunshi Yao, Xinxin Wang, Jin Wei, and Zhongxu Feng. 2022. "Preparation of Recycled and Multi-Recycled Coarse Aggregates Concrete with the Vibration Mixing Process" Buildings 12, no. 9: 1369. https://doi.org/10.3390/buildings12091369